1. Introduction

Concrete is currently the most commonly used construction and building material. Dynamic resistance is a fundamental basis for the evaluation of structural safety. The responses of concrete to transient dynamic loading (including compressive and tensile loading) are of interest in both academic and engineering fields, such as bridge construction, hydraulic engineering, constructional engineering, and so on [

1,

2,

3]. To better understand the mechanical properties and dynamic behaviors of concrete under dynamic tensile loading is a greatly significant requirement in civil and military protection engineering. Using natural or artificial pozzolans in combination with ordinary Portland cement (OPC) to obtain high-performance concrete is an effective way, which mainly aims to develop the mechanical properties of concrete, such as strength, permeability, sustainability, and durability [

4,

5,

6,

7]. Therefore, it is meaningful to understand the use of silica fume (SF) and other auxiliary cementitious materials. SF is a kind of material that can improve the durability, mechanical properties, and behaviors of concrete [

8,

9]. The average particle size of SF is relatively small, with good filling effect and can be filled between the cement particle gaps. At the same time, the production of gel, water, and alkaline materials, including magnesium oxide, can enhance the strength and durability of concrete. The amount of SF in concrete and mortar can significantly improve its compressive strength, flexural, anti-permeability, corrosion resistance, and abrasion [

10,

11]. Moreover, SF is comprised of amorphous spherical particles which enhance the rheological properties of concrete. Considering the above characteristics, SF is a highly reactive pozzolanic material and has been studied as a partial substitute for cement in concrete. Adding SF into the concrete mixture can reduce the porosity, permeability, and bleeding rate of concrete [

12,

13].

Due to the different mixing methods and amounts, the influence of SF on the mechanical properties and behaviors of concrete is quite different. Recent investigations have tried to improve the mechanical properties and behaviors of concrete by using SF for cement replacement. Pedro et al. [

14] investigated and evaluated the effect of SF on the behaviors of high-performance concrete. They found that the mechanical properties of concrete were improved when SF replaced cement. Shannag [

9] found that the certain natural pozzolan-silica fume combinations can improve the compressive and splitting tensile strengths, workability, and elastic modulus of concrete. Ramezanianpour [

15] studied the effect of combined carbonation and chloride ion ingress by an accelerated test method on the microscopic and mechanical properties of concrete. According to Bingol and Tohumcu [

16], increasing the replacement percentage of SF in concrete can result in increased compressive strength. SF has positive effect on self-settlement properties. Ghahari [

17] investigated the performance of roller compacted concrete (RCC) containing Trass, as a supplementary cementitious material, and an air-entraining agent for salt scaling. Okoye et al. [

18] found that a geopolymer concrete with SF presented higher compressive strength, tensile strength, and flexural strength. These strength values increased with the increasing addition of SF levels. An experimental study carried out by Sarıdemir [

10] indicated that high-strength concrete can be obtained with SF and SF together with ground pumice content. More emphasis has focused on static or quasi-static loading. However, there are few investigations reporting on the mechanical properties and dynamic behaviors of concrete with SF under high strain rates. In addition, the effect of SF is the most qualitative description from previous investigations. In this context, we distinguished the effect of the content of SF in concrete by quantitative description, which is meaningful to understand the influence and effects of SF in concrete under impact loading.

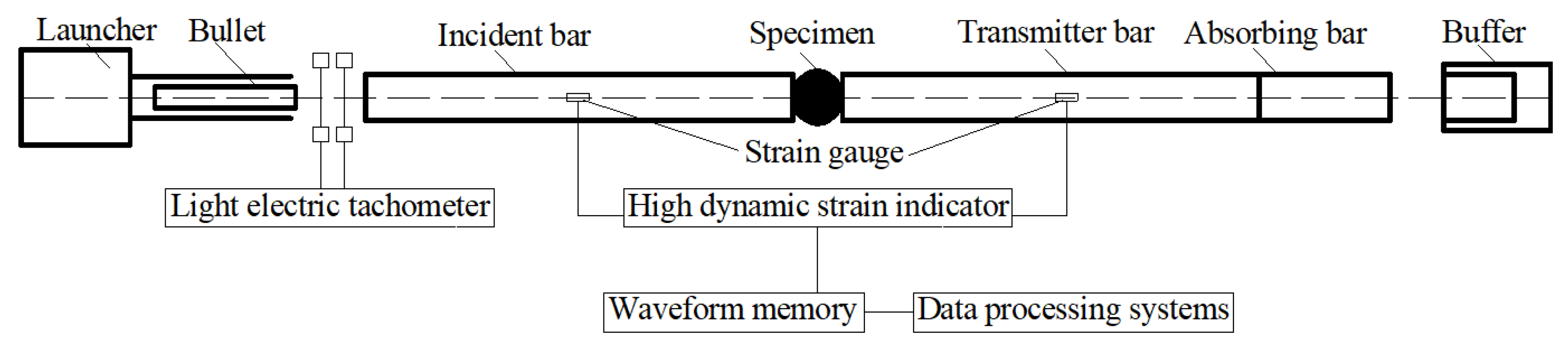

Split Hopkinson pressure bar (SHPB) device is an effective technique to analyze and characterize the mechanical properties and dynamic behaviors of brittle materials at high strain rate. In recent years, researchers studied the dynamic mechanical properties of brittle materials, such as rock or rock-like materials [

19,

20,

21,

22,

23], concrete-like materials [

24,

25,

26,

27,

28], and ceramics materials [

29,

30], by using an SHPB device under strain rates ranging from 10

2 to 10

4 s

−1. Many factors have obvious influences on the strain rate sensitivity of concrete. The strain rate sensitivities are mainly measured by strength or the strains at the maximum stress [

31,

32,

33,

34,

35,

36,

37], and the dynamic compressive strength and impact toughness increase with the strain rate.

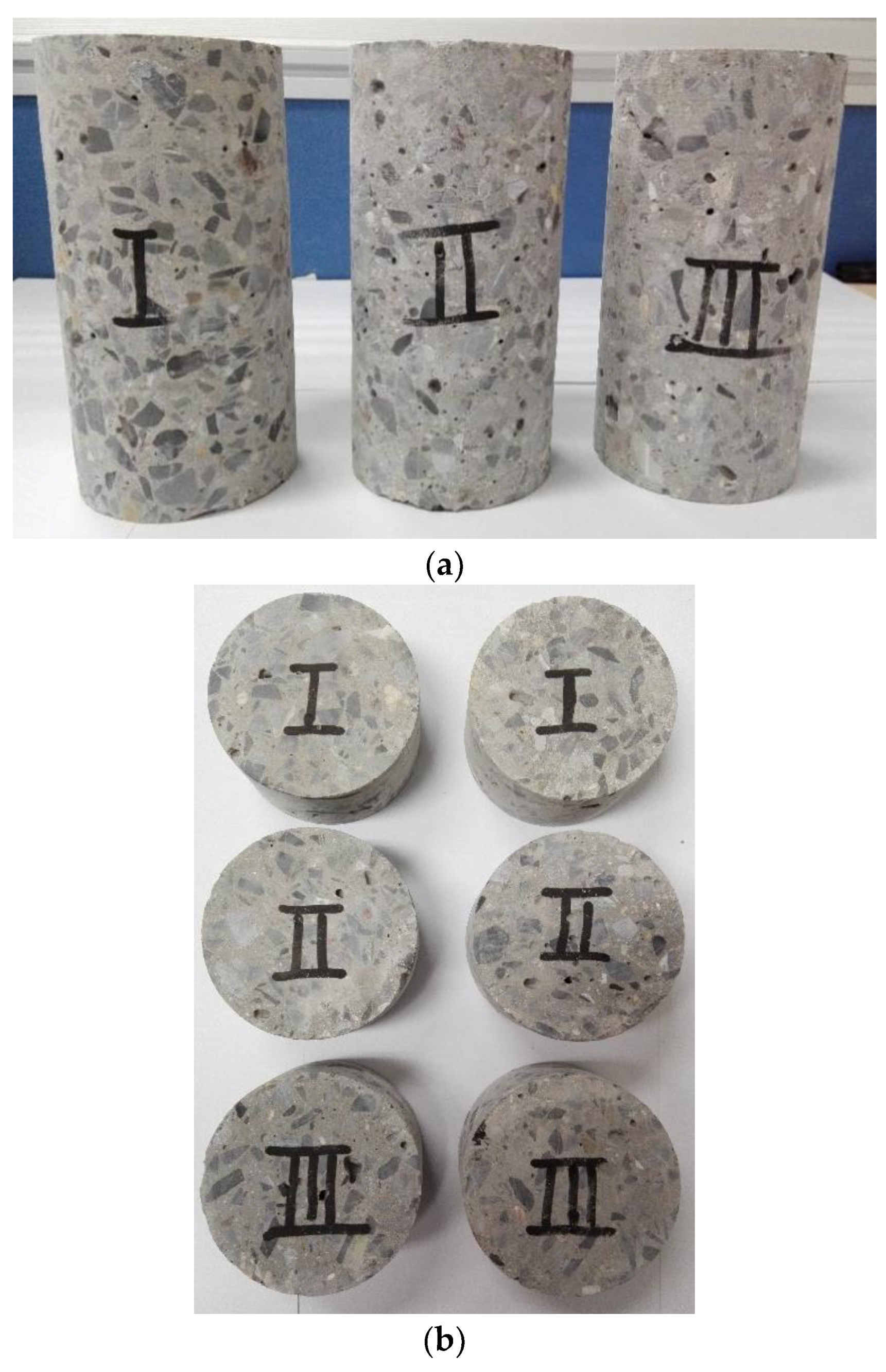

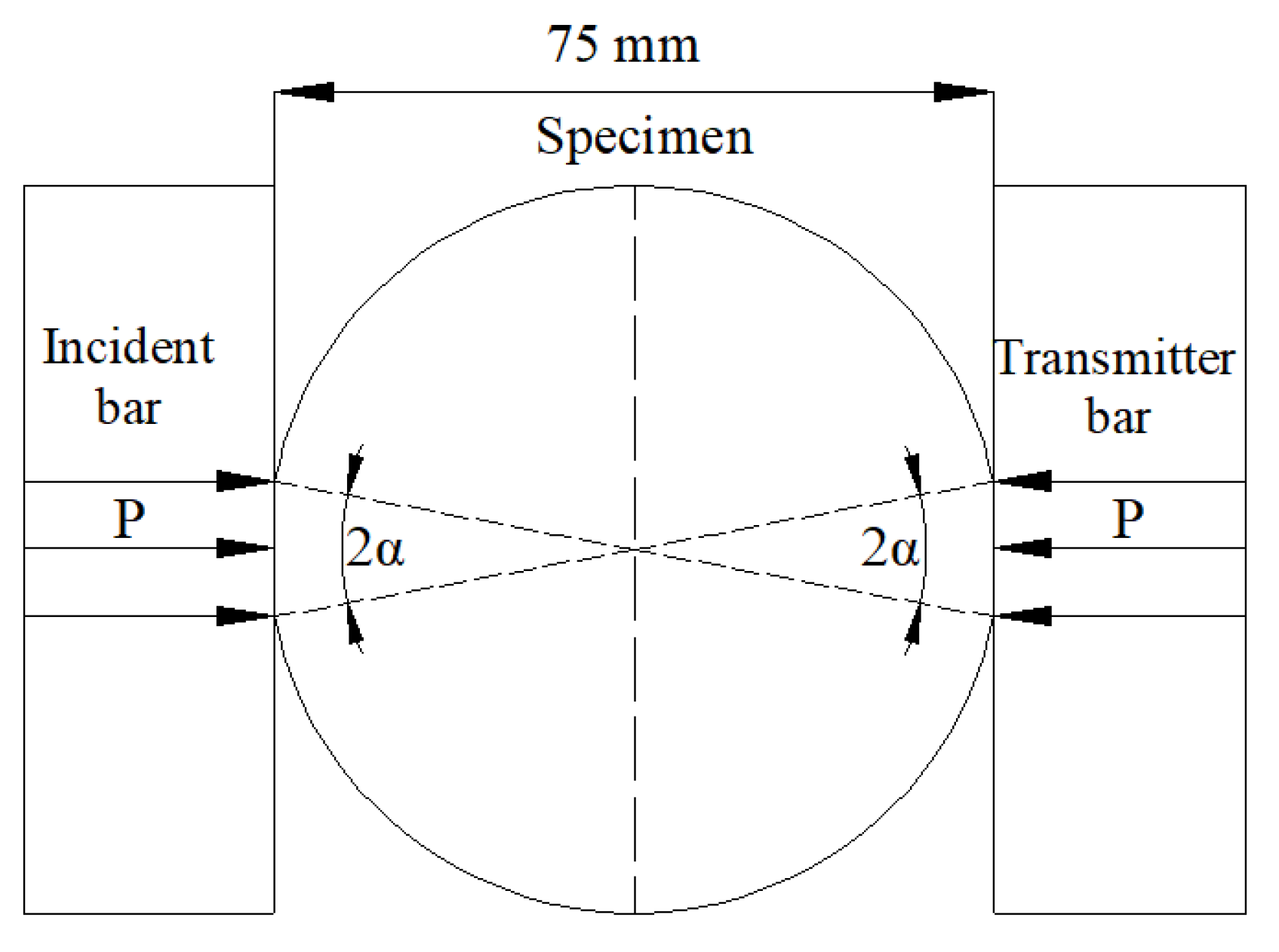

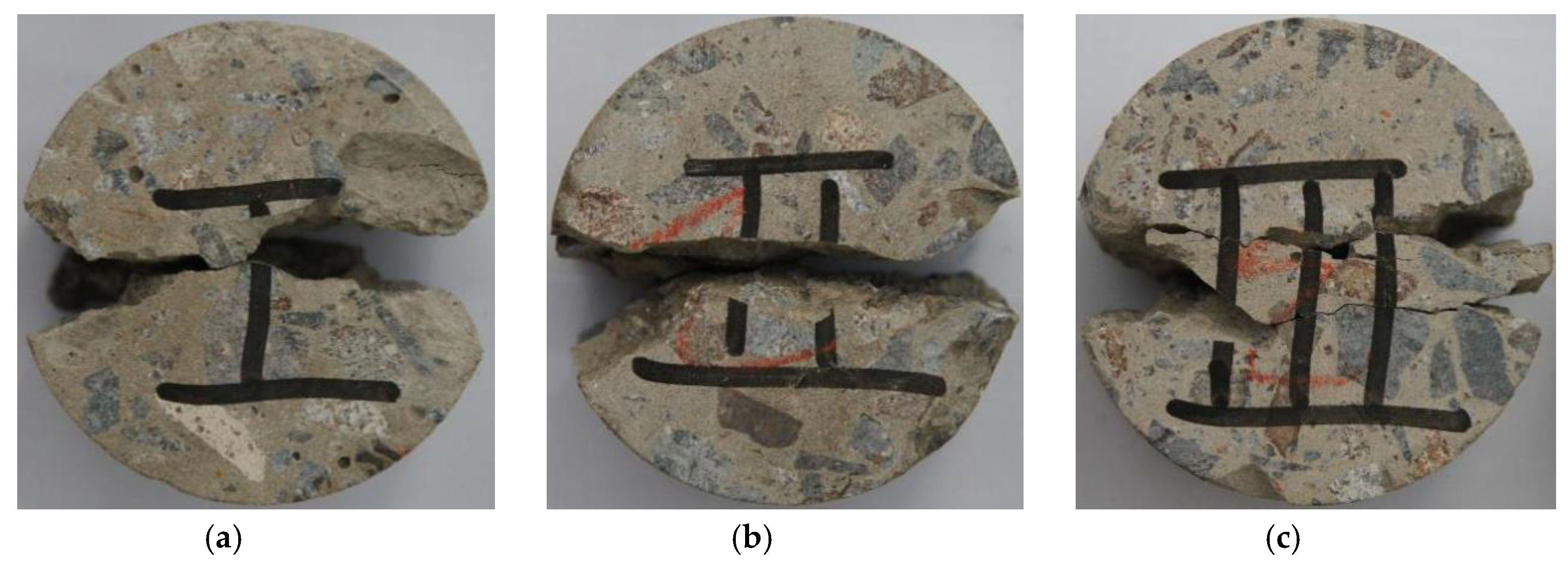

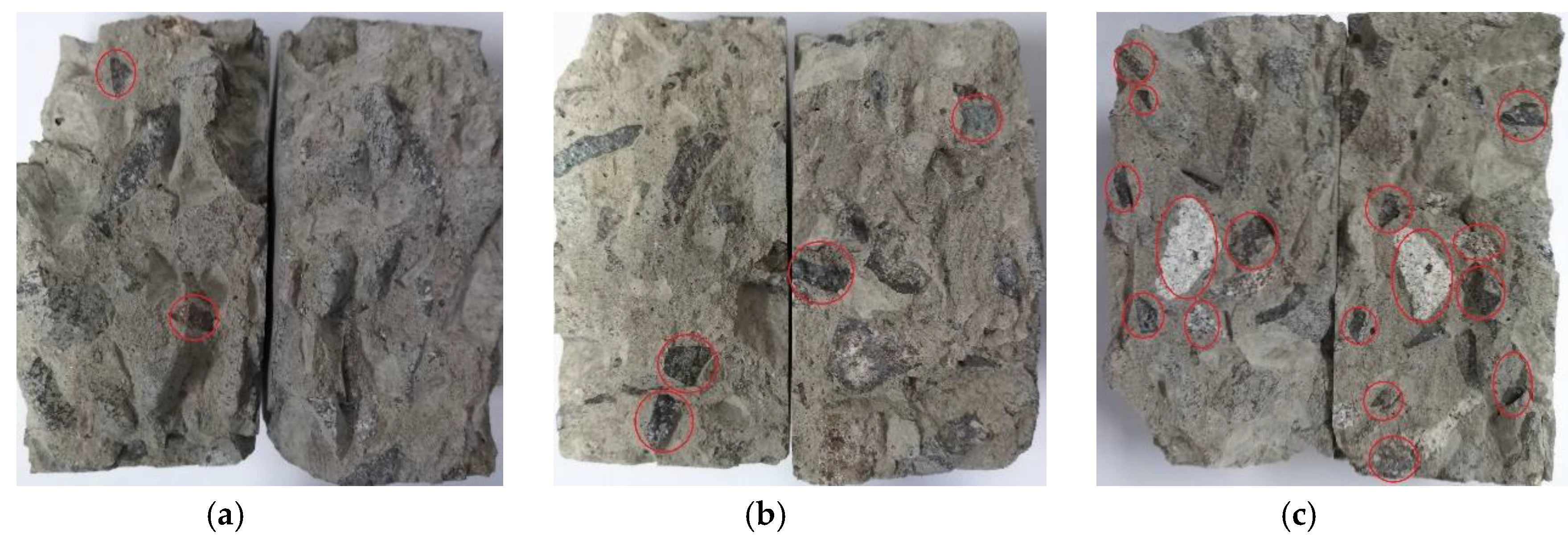

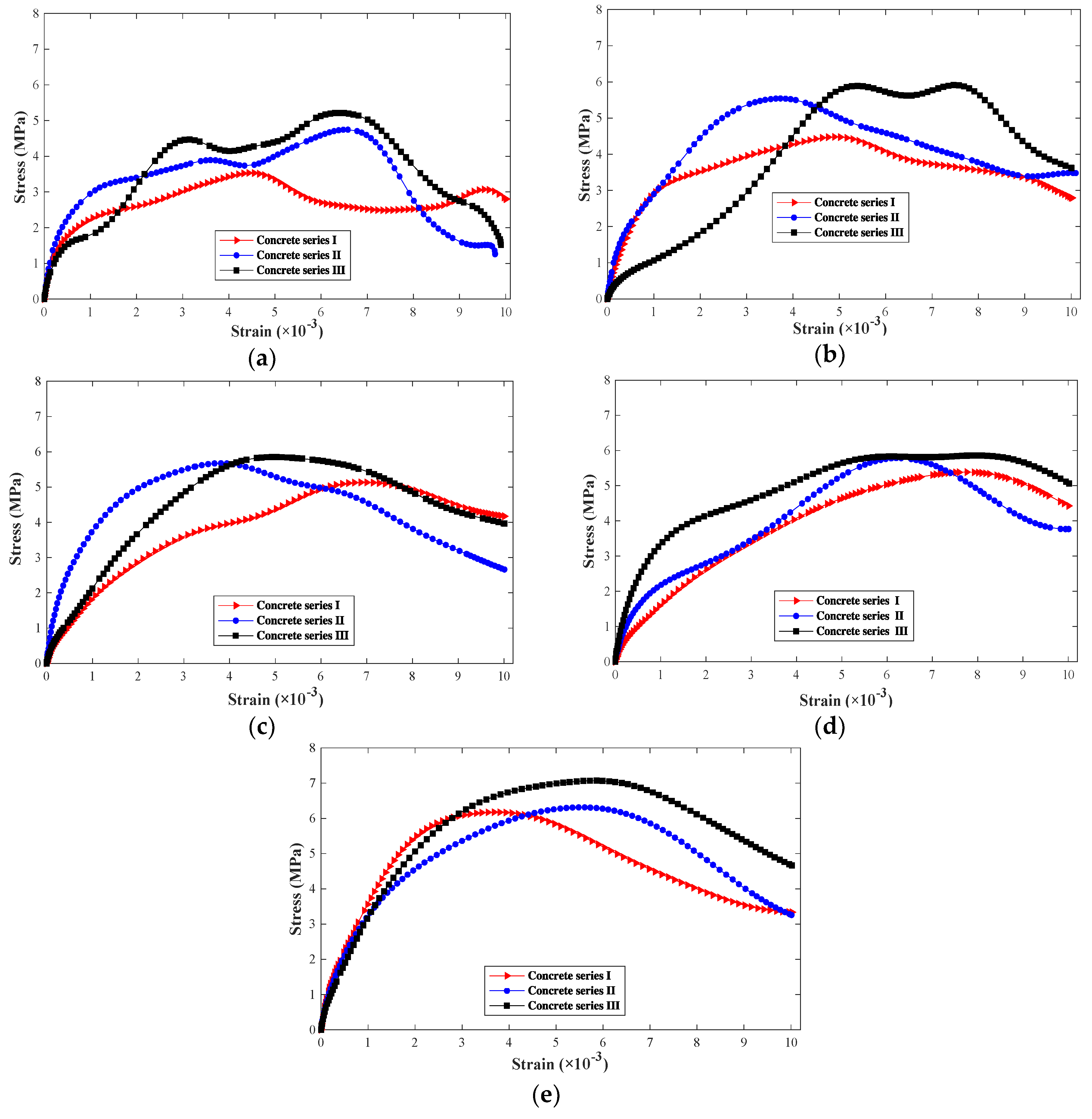

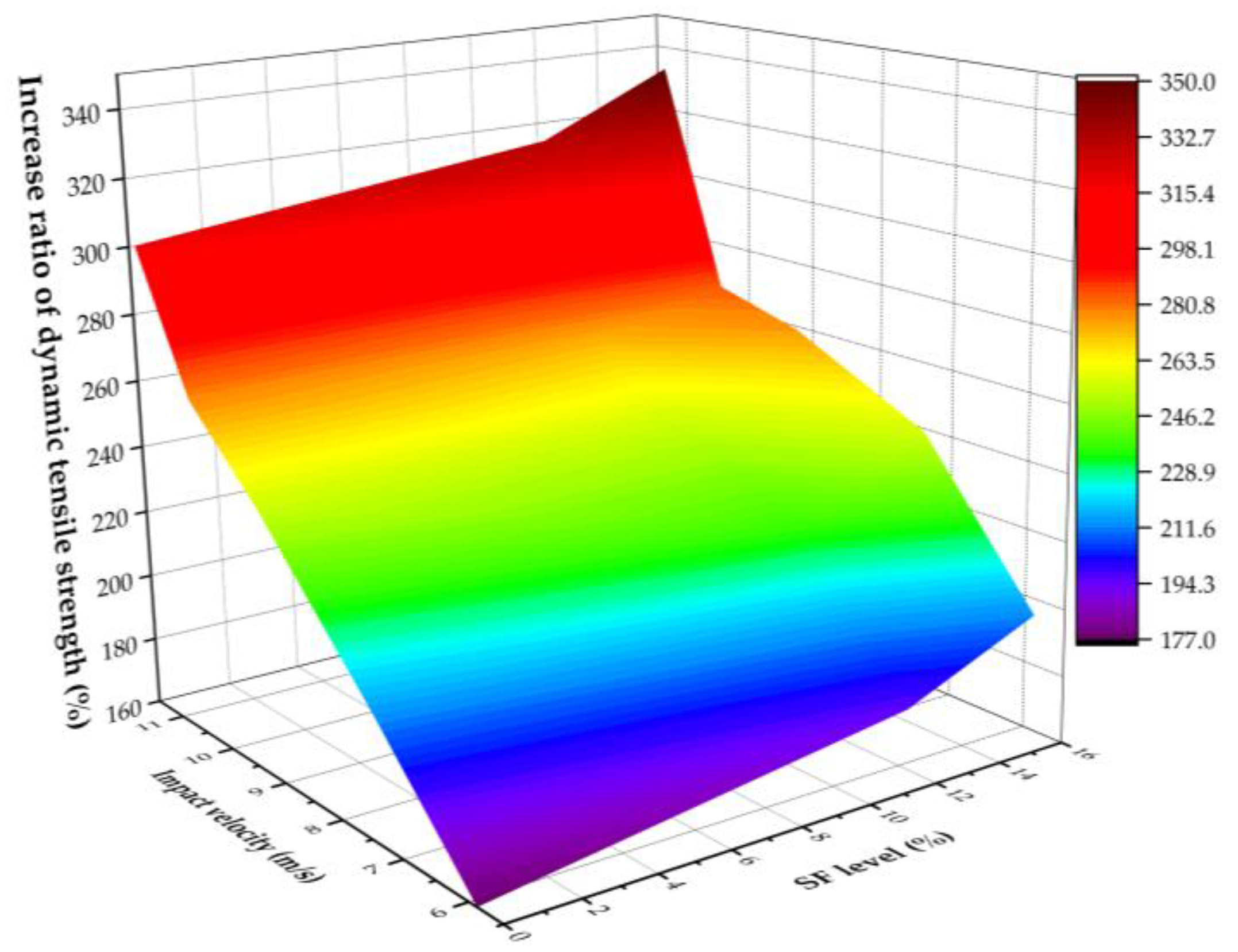

This study uses Brazilian disk (BD) specimens containing different levels of SF, using an SHPB test device, and proposes to enhance the understanding of SF in concrete on the mechanical properties under impact loading. At the same time, it intends to promote and evaluate the use of SF to replace cement in concrete. For those reasons, three series of concrete mixtures with different SF levels were produced and tested. The materials’ strains and derived testing strain rates were recorded by resistance strain gauges which were placed on the surface of elastic bars. The influences of the strain rates on the mechanical properties and dynamic behaviors of the tested specimens with different mixture proportions of SF were studied. This present study is organized as follows:

Section 2 is the tested concrete specimens’ preparation and experimental process. In

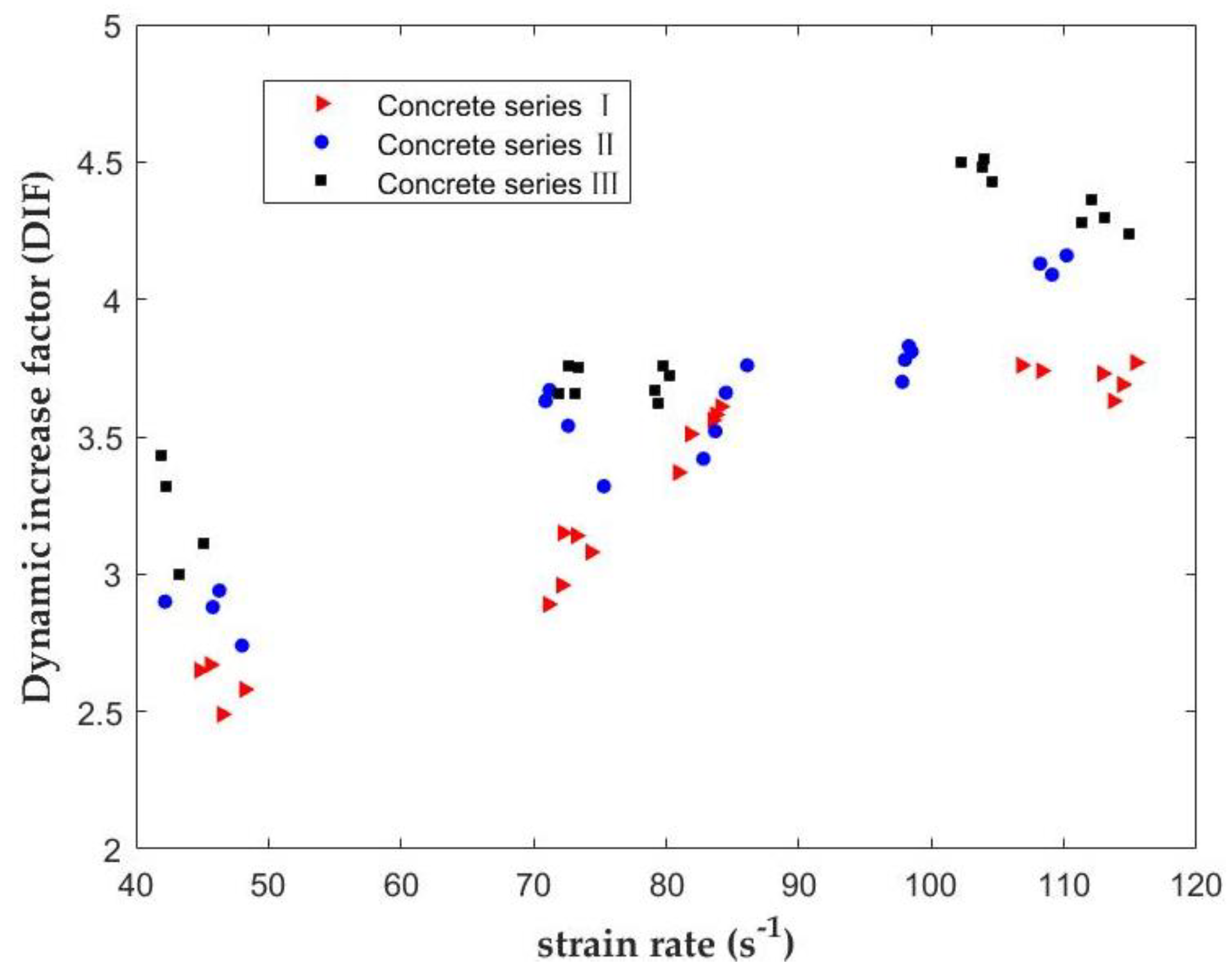

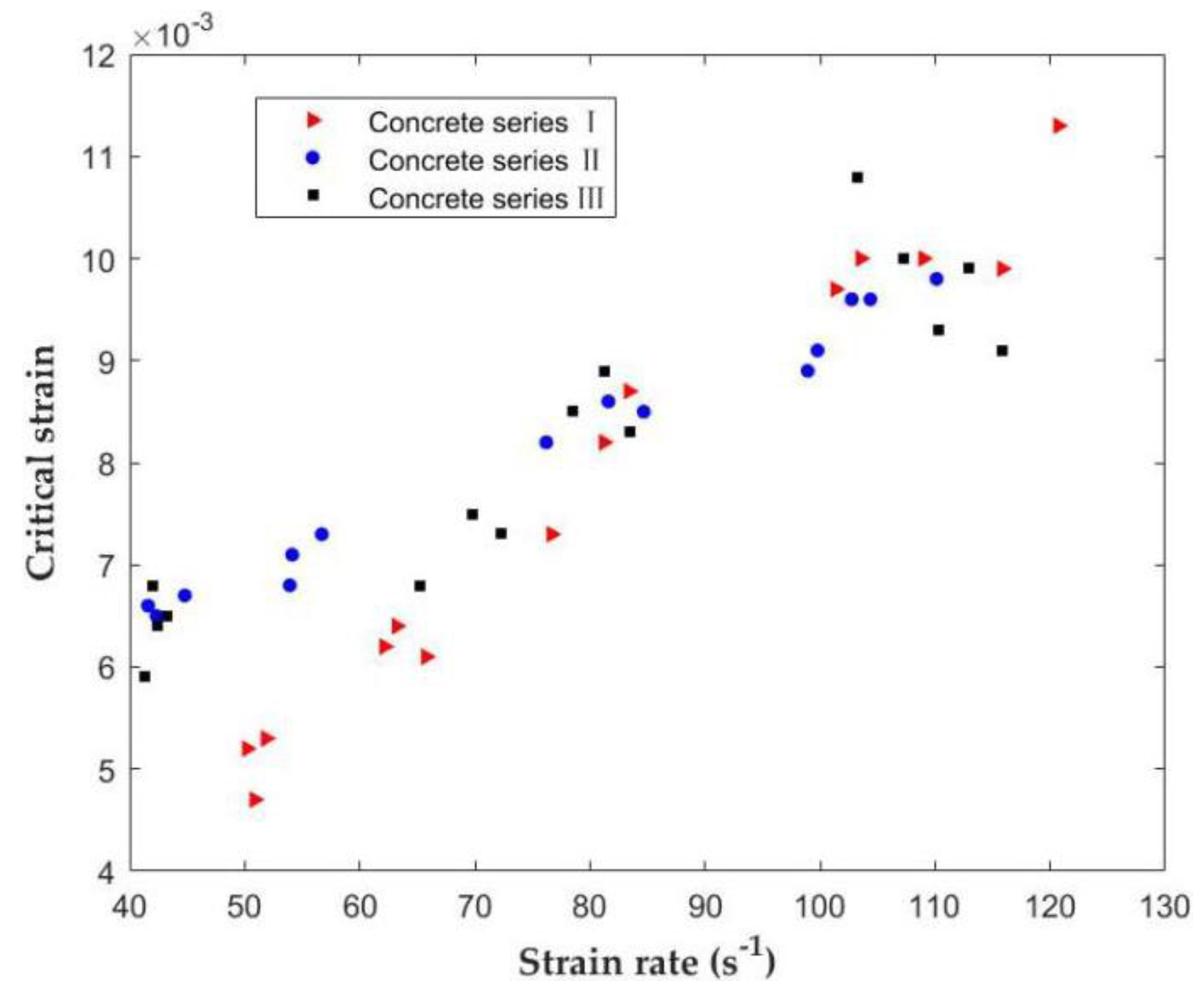

Section 3 we present the testing results (failure patterns of tested specimens, stress-strain curves, strain rate, DIF, and critical strain). The conclusions obtained from this experimental investigation are presented in

Section 4.

4. Conclusions

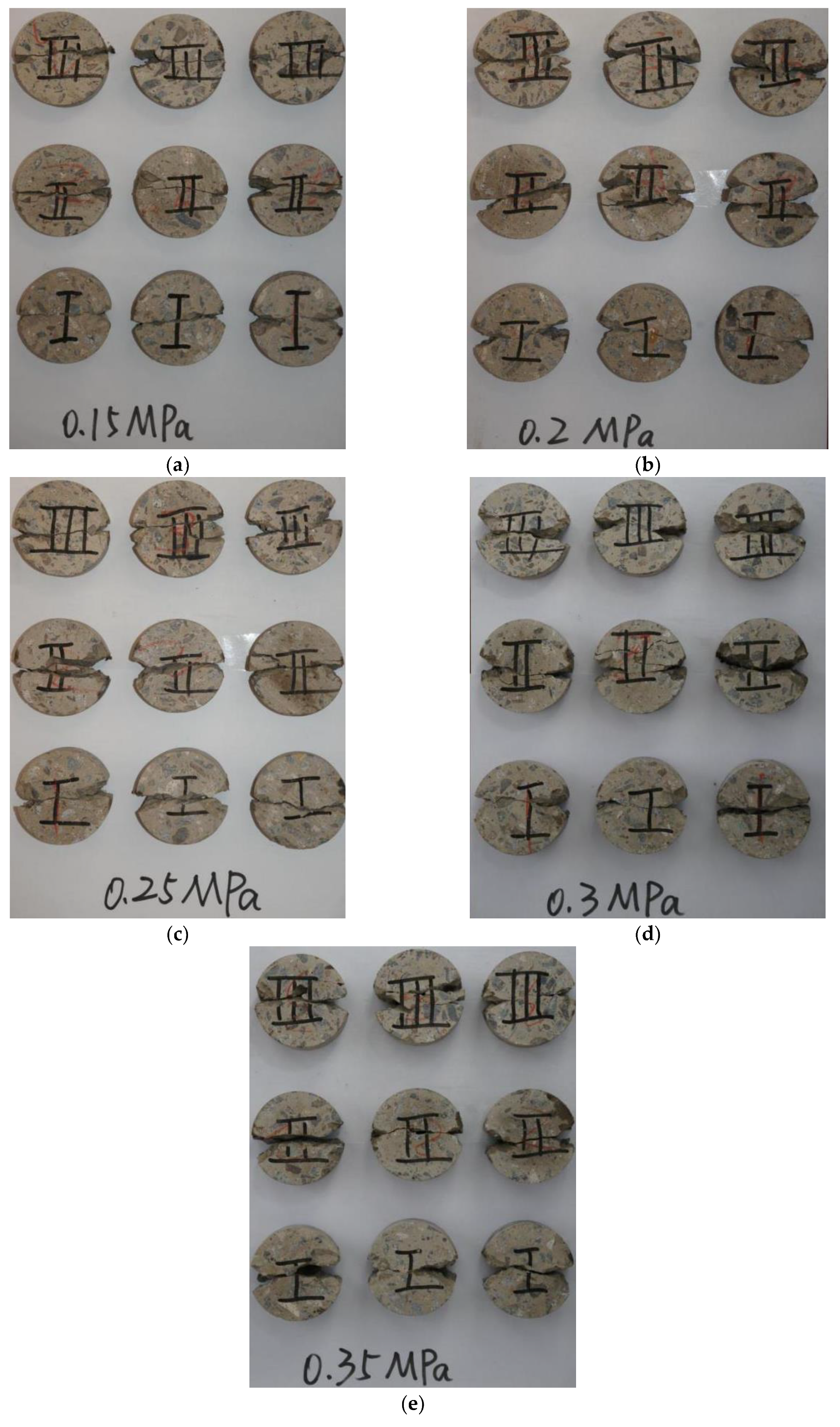

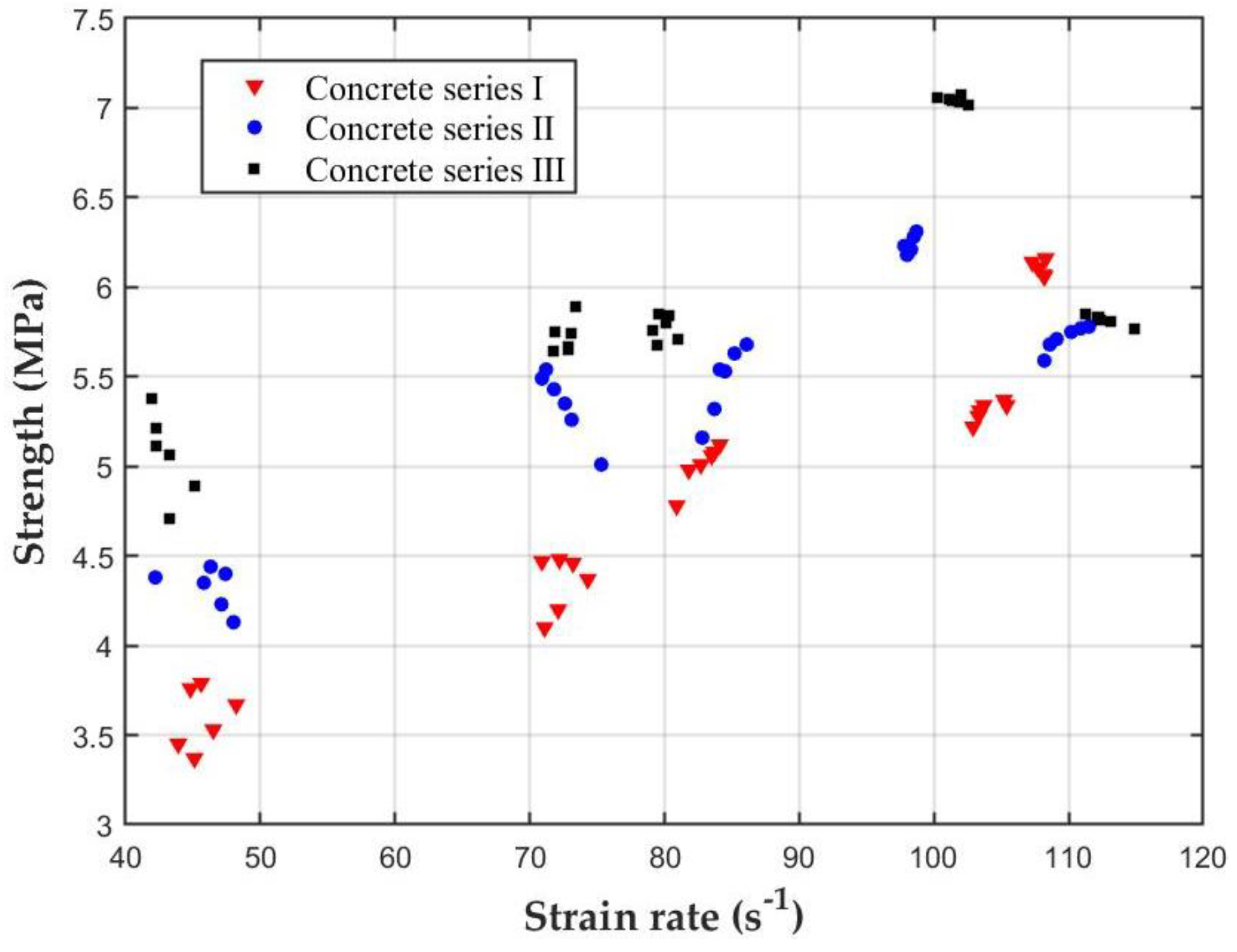

In this study, the effect of SF in concrete on the mechanical properties and dynamic behaviors of concrete under impact loading were investigated. With SF replacing cement, a series of changes have taken place in the physical structure and chemical composition of concrete. SF is particularly recommended as an alternative to moderate amounts of cement to obtain high-performance concrete with better mechanical properties. The SF in concrete gives better results and performance on mechanical properties under dynamic tensile loading. The dynamic tensile strength of specimens increases with the increase of the strain rate due to the excellent physical and mechanical properties of SF, and the stress-strain behaviors of concrete have a significant sensitivity to the strain rate.

From the above results, it is observed that strain rate sensitivity is one of the important factors affecting the performance of concrete under impact loading. The failure mode of specimens will change with the increase of the strain rate. However, the strain rate sensitivity of the critical strain has little relationship with concrete series. In addition, the impact stress with respect to the cracking of concrete is a major issue under dynamic loading, but difficult to attain. Using more advanced instruments to obtain the impact stress, and proposing the most plausible explanation, are the important targets for the next research step.