Numerical Modelling of the Ultrasonic Treatment of Aluminium Melts: An Overview of Recent Advances

Abstract

1. Introduction

2. Existing Models

2.1. Acoustic Cavitation Model

- for infinitely hard boundaries (such as crucible walls);

- at the surface of the sonotrode;

- Setting in the cell layer above the liquid level to approximate the phase shift that occurs upon reflection from the free surface [32].

2.2. Macroscopic Flow Model

3. Numerical Simulations of the Acoustic Field in Crucibles, Moulds and Launders

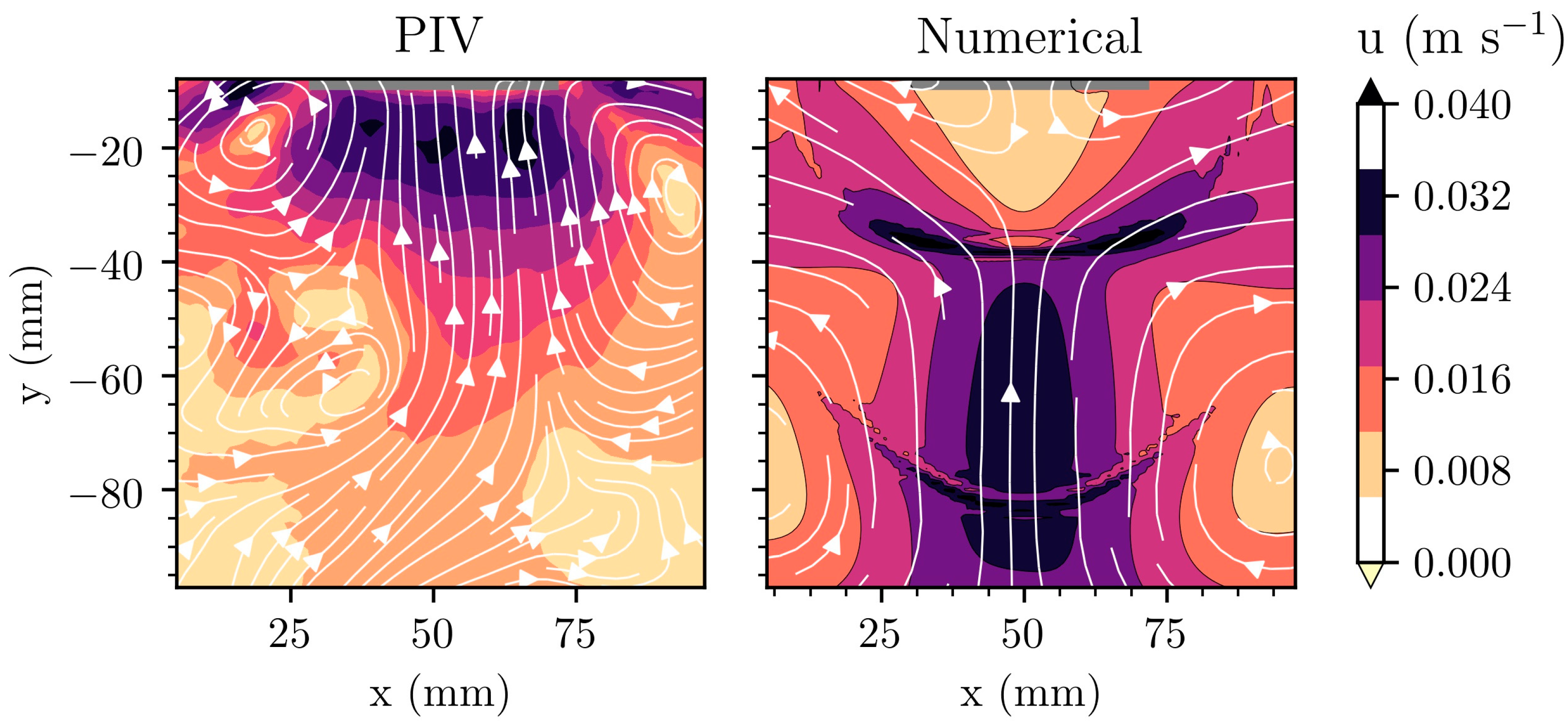

4. Effect of Acoustic Streaming

- Despite simulating the problem in two dimensions, the correct order of magnitude of acoustic streaming is recovered.

- The net flow reversal below the sonotrode observed at low operating powers is predicted by the model.

- The comparison holds for a time-averaged analysis of transient results, which mimics the way velocities are recorded by PIV.

- The model is tractable since the Helmholtz equation is easier to solve than a system of ODEs representing bubble dynamics.

5. Current Challenges and Future Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Hill, M. Product and process design for structured products. AIChE J. 2004, 50, 1656–1661. [Google Scholar] [CrossRef]

- Kowalski, A.J.; Cooke, M.; Hall, S. Expression for turbulent power draw of an in-line Silverson high shear mixer. Chem. Eng. Sci. 2011, 66, 241–249. [Google Scholar] [CrossRef]

- Håkansson, A. Rotor-Stator Mixers: From Batch to Continuous Mode of Operation—A Review. Processes 2018, 6, 32. [Google Scholar] [CrossRef]

- Eskin, D.G.; Tzanakis, I.; Wang, F.; Lebon, G.S.B.; Subroto, T.; Pericleous, K.; Mi, J. Fundamental studies of ultrasonic melt processing. Ultrason. Sonochem. 2019, 52, 455–467. [Google Scholar] [CrossRef] [PubMed]

- Abramov, O.V. Action of high intensity ultrasound on solidifying metal. Ultrasonics 1987, 25, 73–82. [Google Scholar] [CrossRef]

- Campbell, J. Effects of vibration during solidification. Int. Met. Rev. 1981, 26, 71–108. [Google Scholar] [CrossRef]

- Eskin, G.I.; Eskin, D.G. Ultrasonic Treatment of Light Alloy Melts, 2nd ed.; Taylor & Francis, CRC Press: Boca Raton, FL, USA, 2015; ISBN 978-1-4665-7798-5. [Google Scholar]

- Neppiras, E.A. Acoustic cavitation. Phys. Rep. 1980, 61, 159–251. [Google Scholar] [CrossRef]

- Tzanakis, I.; Eskin, D.G.; Georgoulas, A.; Fytanidis, D.K. Incubation pit analysis and calculation of the hydrodynamic impact pressure from the implosion of an acoustic cavitation bubble. Ultrason. Sonochem. 2014, 21, 866–878. [Google Scholar] [CrossRef]

- Campos-Pozuelo, C.; Granger, C.; Vanhille, C.; Moussatov, A.; Dubus, B. Experimental and theoretical investigation of the mean acoustic pressure in the cavitation field. Ultrason. Sonochem. 2005, 12, 79–84. [Google Scholar] [CrossRef]

- Eskin, D.G. Physical Metallurgy of Direct Chill Casting of Aluminum Alloys; CRC Press: Boca Raton, FL, USA, 2008; ISBN 978-0-429-14523-0. [Google Scholar]

- Wang, G.; Croaker, P.; Dargusch, M.; McGuckin, D.; StJohn, D. Simulation of convective flow and thermal conditions during ultrasonic treatment of an Al-2Cu alloy. Comput. Mater. Sci. 2017, 134, 116–125. [Google Scholar] [CrossRef]

- Shu, D.; Sun, B.; Mi, J.; Grant, P.S. A High-Speed Imaging and Modeling Study of Dendrite Fragmentation Caused by Ultrasonic Cavitation. Metall. Mater. Trans. A 2012, 43, 3755–3766. [Google Scholar] [CrossRef]

- Tzanakis, I.; Xu, W.W.; Eskin, D.G.; Lee, P.D.; Kotsovinos, N. In situ observation and analysis of ultrasonic capillary effect in molten aluminium. Ultrason. Sonochem. 2015, 27, 72–80. [Google Scholar] [CrossRef] [PubMed]

- Tzanakis, I.; Xu, W.W.; Lebon, G.S.B.; Eskin, D.G.; Pericleous, K.; Lee, P.D. In Situ Synchrotron Radiography and Spectrum Analysis of Transient Cavitation Bubbles in Molten Aluminium Alloy. Phys. Procedia 2015, 70, 841–845. [Google Scholar] [CrossRef]

- Xu, W.W.; Tzanakis, I.; Srirangam, P.; Mirihanage, W.U.; Eskin, D.G.; Bodey, A.J.; Lee, P.D. Synchrotron quantification of ultrasound cavitation and bubble dynamics in Al–10Cu melts. Ultrason. Sonochem. 2016, 31, 355–361. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Eskin, D.; Mi, J.; Wang, C.; Koe, B.; King, A.; Reinhard, C.; Connolley, T. A synchrotron X-radiography study of the fragmentation and refinement of primary intermetallic particles in an Al-35 Cu alloy induced by ultrasonic melt processing. Acta Mater. 2017, 141, 142–153. [Google Scholar] [CrossRef]

- Wang, B.; Tan, D.; Lee, T.L.; Khong, J.C.; Wang, F.; Eskin, D.; Connolley, T.; Fezzaa, K.; Mi, J. Ultrafast synchrotron X-ray imaging studies of microstructure fragmentation in solidification under ultrasound. Acta Mater. 2018, 144, 505–515. [Google Scholar] [CrossRef]

- Tudela, I.; Sáez, V.; Esclapez, M.D.; Díez-García, M.I.; Bonete, P.; González-García, J. Simulation of the spatial distribution of the acoustic pressure in sonochemical reactors with numerical methods: A review. Ultrason. Sonochem. 2014, 21, 909–919. [Google Scholar] [CrossRef]

- Louisnard, O. A viable method to predict acoustic streaming in presence of cavitation. Ultrason. Sonochem. 2017, 35, 518–524. [Google Scholar] [CrossRef]

- Caflisch, R.E.; Miksis, M.J.; Papanicolaou, G.C.; Ting, L. Effective equations for wave propagation in bubbly liquids. J. Fluid Mech. 1985, 153, 259. [Google Scholar] [CrossRef]

- Wijngaarden, L.V. On the equations of motion for mixtures of liquid and gas bubbles. J. Fluid Mech. 1968, 33, 465. [Google Scholar] [CrossRef]

- Foldy, L.L. The Multiple Scattering of Waves. I. General Theory of Isotropic Scattering by Randomly Distributed Scatterers. Phys. Rev. 1945, 67, 107–119. [Google Scholar] [CrossRef]

- Atchley, A.A. The Blake threshold of a cavitation nucleus having a radius-dependent surface tension. J. Acoust. Soc. Am. 1989, 85, 152. [Google Scholar] [CrossRef]

- Louisnard, O. A simple model of ultrasound propagation in a cavitating liquid. Part I: Theory, nonlinear attenuation and traveling wave generation. Ultrason. Sonochem. 2012, 19, 56–65. [Google Scholar] [CrossRef] [PubMed]

- Keller, J.B.; Miksis, M. Bubble oscillations of large amplitude. J. Acoust. Soc. Am. 1980, 68, 628–633. [Google Scholar] [CrossRef]

- Jamshidi, R.; Brenner, G. Dissipation of ultrasonic wave propagation in bubbly liquids considering the effect of compressibility to the first order of acoustical Mach number. Ultrasonics 2013, 53, 842–848. [Google Scholar] [CrossRef] [PubMed]

- Gadi Man, Y.A.; Trujillo, F.J. A new pressure formulation for gas-compressibility dampening in bubble dynamics models. Ultrason. Sonochem. 2016, 32, 247–257. [Google Scholar] [CrossRef] [PubMed]

- Toegel, R.; Gompf, B.; Pecha, R.; Lohse, D. Does Water Vapor Prevent Upscaling Sonoluminescence? Phys. Rev. Lett. 2000, 85, 3165–3168. [Google Scholar] [CrossRef]

- Trujillo, F.J. A strict formulation of a nonlinear Helmholtz equation for the propagation of sound in bubbly liquids. Part I: Theory and validation at low acoustic pressure amplitudes. Ultrason. Sonochem. 2018, 47, 75–98. [Google Scholar] [CrossRef]

- Commander, K.W.; Prosperetti, A. Linear pressure waves in bubbly liquids: Comparison between theory and experiments. J. Acoust. Soc. Am. 1989, 85, 732–746. [Google Scholar] [CrossRef]

- Lebon, G.S.B.; Tzanakis, I.; Pericleous, K.; Eskin, D. Experimental and numerical investigation of acoustic pressures in different liquids. Ultrason. Sonochem. 2018, 42, 411–421. [Google Scholar] [CrossRef]

- Eckart, C. Vortices and Streams Caused by Sound Waves. Phys. Rev. 1948, 73, 68–76. [Google Scholar] [CrossRef]

- Zarembo, L.K. Acoustic Streaming. In High-Intensity Ultrasonic Fields; Rozenberg, L.D., Ed.; Springer US: Boston, MA, USA, 1971; pp. 135–199. ISBN 978-1-4757-5410-0. [Google Scholar]

- Lebon, G.S.B.; Tzanakis, I.; Pericleous, K.; Eskin, D.; Grant, P.S. Ultrasonic liquid metal processing: The essential role of cavitation bubbles in controlling acoustic streaming. Ultrason. Sonochem. 2019, 55, 243–255. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Yamamoto, T.; Komarov, S. Cavitation and acoustic streaming generated by different sonotrode tips. Ultrason. Sonochem. 2018, 48, 79–87. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, T.; Komarov, S. Investigation on Acoustic Streaming During Ultrasonic Irradiation in Aluminum Melts. In Light Metals 2019; Chesonis, C., Ed.; Springer International Publishing: New York, NY, USA, 2019; pp. 1527–1531. ISBN 978-3-030-05863-0. [Google Scholar]

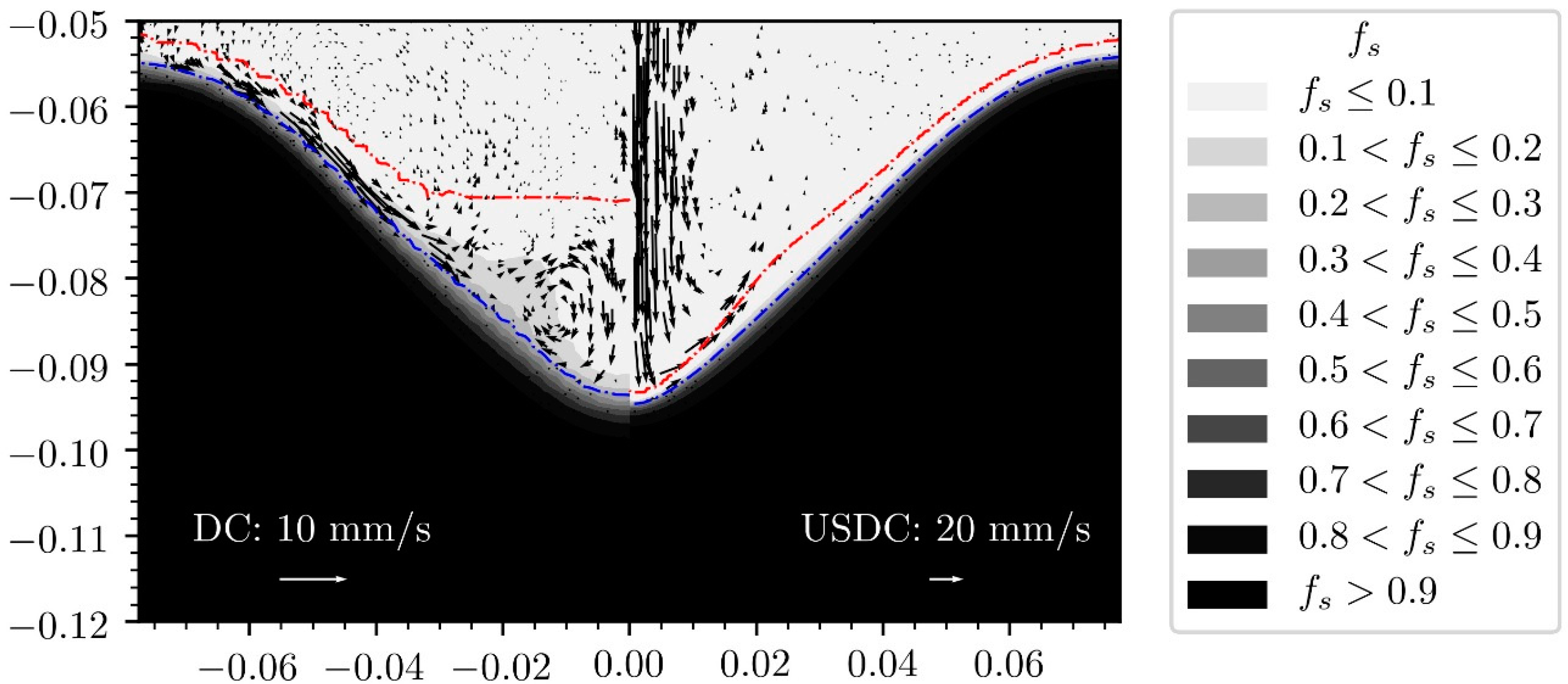

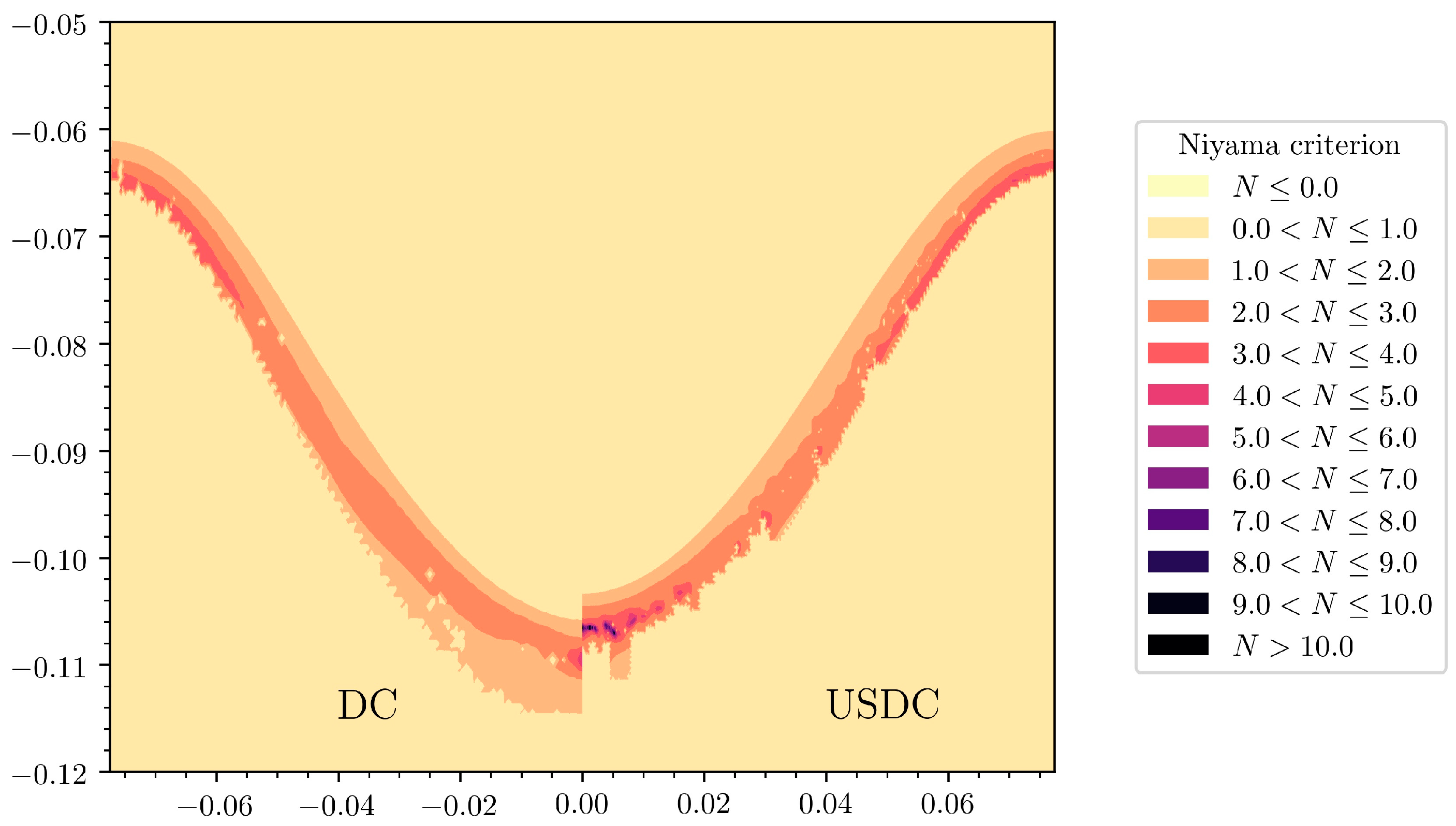

- Lebon, G.S.B.; Salloum-Abou-Jaoude, G.; Eskin, D.; Tzanakis, I.; Pericleous, K.; Jarry, P. Numerical modelling of acoustic streaming during the ultrasonic melt treatment of direct-chill (DC) casting. Ultrason. Sonochem. 2019, 54, 171–182. [Google Scholar] [CrossRef] [PubMed]

- Tzanakis, I.; Hodnett, M.; Lebon, G.S.B.; Dezhkunov, N.; Eskin, D.G. Calibration and performance assessment of an innovative high-temperature cavitometer. Sens. Actuators A Phys. 2016, 240, 57–69. [Google Scholar] [CrossRef]

- Tzanakis, I.; Lebon, G.S.B.; Eskin, D.G.; Pericleous, K.A. Characterisation of the ultrasonic acoustic spectrum and pressure field in aluminium melt with an advanced cavitometer. J. Mater. Process. Technol. 2016, 229, 582–586. [Google Scholar] [CrossRef]

- Nastac, L. Mathematical Modeling of the Solidification Structure Evolution in the Presence of Ultrasonic Stirring. Metall. Mater. Trans. B 2011, 42, 1297–1305. [Google Scholar] [CrossRef]

- Nastac, L. Multiscale Modeling of Ingot Solidification Structure Controlled by Electromagnetic and Ultrasonic Stirring Technologies. In CFD Modeling and Simulation in Materials Processing; Nastac, L., Zhang, L., Thomas, B.G., Sabau, A., El-Kaddah, N., Powell, A.C., Combeau, H., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 261–268. ISBN 978-1-118-36469-7. [Google Scholar]

- Nastac, L. Numerical Modeling of Fluid Flow and Solidification Characteristics of Ultrasonically Processed A356 Alloys. ISIJ Int. 2014, 54, 1830–1835. [Google Scholar] [CrossRef]

- Song, S.; Zhou, X.; Li, L.; Ma, W. Numerical simulation and experimental validation of SiC nanoparticle distribution in magnesium melts during ultrasonic cavitation based processing of magnesium matrix nanocomposites. Ultrason. Sonochem. 2015, 24, 43–54. [Google Scholar] [CrossRef]

- Lebon, G.S.B.; Pericleous, K.; Tzanakis, I.; Eskin, D. A model of cavitation for the treatment of a moving liquid metal volume. Int. J. Cast Met. Res. 2016, 29, 324–330. [Google Scholar] [CrossRef]

- Singhal, A.K.; Athavale, M.M.; Li, H.; Jiang, Y. Mathematical Basis and Validation of the Full Cavitation Model. J. Fluid. Eng. 2002, 124, 617. [Google Scholar] [CrossRef]

- Plesset, M.S. The dynamics of cavitation bubbles. J. Appl. Mech. 1949, 16, 277–282. [Google Scholar] [CrossRef]

- Neppiras, E.A.; Noltingk, B.E. Cavitation Produced by Ultrasonics: Theoretical Conditions for the Onset of Cavitation. Proc. Phys. Soc. Sect. B 1951, 64, 1032–1038. [Google Scholar] [CrossRef]

- Jasper, J.J. The Surface Tension of Pure Liquid Compounds. J. Phys. Chem. Ref. Data 1972, 1, 841–1010. [Google Scholar] [CrossRef]

- Chen, Y.-J.; Hsu, W.-N.; Shih, J.-R. The Effect of Ultrasonic Treatment on Microstructural and Mechanical Properties of Cast Magnesium Alloys. Mater. Trans. 2009, 50, 401–408. [Google Scholar] [CrossRef]

- Puga, H.; Barbosa, J.; Carneiro, V.H. The Role of Acoustic Pressure during Solidification of AlSi7Mg Alloy in Sand Mold Casting. Metals 2019, 9, 490. [Google Scholar] [CrossRef]

- Wang, S.; Kang, J.; Guo, Z.; Lee, T.L.; Zhang, X.; Wang, Q.; Deng, C.; Mi, J. In situ high speed imaging study and modelling of the fatigue fragmentation of dendritic structures in ultrasonic fields. Acta Mater. 2019, 165, 388–397. [Google Scholar] [CrossRef]

- Lebon, G.S.B.; Tzanakis, I.; Pericleous, K.A.; Eskin, D.G. Comparison between low-order and high-order acoustic pressure solvers for bubbly media computations. J. Phys. Conf. Ser. 2015, 656, 012134. [Google Scholar] [CrossRef]

- Lebon, G.S.B.; Tzanakis, I.; Djambazov, G.; Pericleous, K.; Eskin, D.G. Numerical modelling of ultrasonic waves in a bubbly Newtonian liquid using a high-order acoustic cavitation model. Ultrason. Sonochem. 2017, 37, 660–668. [Google Scholar] [CrossRef]

- Manoylov, A.; Lebon, B.; Djambazov, G.; Pericleous, K. Coupling of Acoustic Cavitation with DEM-Based Particle Solvers for Modeling De-agglomeration of Particle Clusters in Liquid Metals. Met. Mater. Trans. A 2017, 48, 5616–5627. [Google Scholar] [CrossRef]

- Lebon, G.S.B.; Kao, A.; Pericleous, K. The uncertain effect of cavitating bubbles on dendrites. In Proceedings of the 6th Decennial International Conference on Solidification Processing, Old Windsor, UK, 25–28 July 2017; pp. 554–557. [Google Scholar]

- Wang, Y.; Lebon, B.; Tzanakis, I.; Zhao, Y.; Wang, K.; Stella, J.; Poirier, T.; Darut, G.; Liao, H.; Planche, M.-P. Experimental and numerical investigation of cavitation-induced erosion in thermal sprayed single splats. Ultrason. Sonochem. 2019, 52, 336–343. [Google Scholar] [CrossRef] [PubMed]

- Tonry, C.E.H.; Djambazov, G.; Dybalska, A.; Bojarevics, V.; Griffiths, W.D.; Pericleous, K.A. Resonance from Contactless Ultrasound in Alloy Melts. In Light Metals 2019; Chesonis, C., Ed.; Springer International Publishing: New York, NY, USA, 2019; pp. 1551–1559. ISBN 978-3-030-05863-0. [Google Scholar]

- Djambazov, G.S.; Lai, C.-H.; Pericleous, K.A. Staggered-Mesh Computation for Aerodynamic Sound. AIAA J. 2000, 38, 16–21. [Google Scholar] [CrossRef]

- Huang, H.; Shu, D.; Fu, Y.; Zhu, G.; Wang, D.; Dong, A.; Sun, B. Prediction of Cavitation Depth in an Al-Cu Alloy Melt with Bubble Characteristics Based on Synchrotron X-ray Radiography. Met. Mater. Trans. A 2018, 49, 2193–2201. [Google Scholar] [CrossRef]

- Jamshidi, R.; Pohl, B.; Peuker, U.A.; Brenner, G. Numerical investigation of sonochemical reactors considering the effect of inhomogeneous bubble clouds on ultrasonic wave propagation. Chem. Eng. J. 2012, 189–190, 364–375. [Google Scholar] [CrossRef]

- Chopra, K.; Prasada Rao, A.K. Ultrasonicated Direct Chill Clad Casting of Magnesium Alloy: A Computational Approach. Trans. Indian Inst. Met. 2019, 1–7. [Google Scholar] [CrossRef]

- Tzanakis, I.; Lebon, G.S.B.; Eskin, D.; Hyde, M.; Grant, P.S. Investigation of acoustic streaming and cavitation intensity in water as an analogue for liquid metal. In Proceedings of the 10th International Symposium on Cavitation (CAV2018), Baltimore, MD, USA, 14–16 May 2018. [Google Scholar]

- Wang, G.; Croaker, P.; Dargusch, M.; McGuckin, D.; StJohn, D. Evolution of the As-Cast Grain Microstructure of an Ultrasonically Treated Al-2Cu Alloy. Adv. Eng. Mater. 2018, 20, 1800521. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Q.; Balasubramani, N.; Qian, M.; Eskin, D.G.; Dargusch, M.S.; StJohn, D.H. The Role of Ultrasonically Induced Acoustic Streaming in Developing Fine Equiaxed Grains During the Solidification of an Al-2 Pct Cu Alloy. Met. Mater. Trans. A 2019. [Google Scholar] [CrossRef]

- Lee, Y.K.; Youn, J.I.; Kim, Y.J. Modeling of the Effect of Ultrasonic Frequency and Amplitude on Acoustic Streaming. In Light Metals 2019; Chesonis, C., Ed.; Springer International Publishing: New York, NY, USA, 2019; pp. 1573–1578. ISBN 978-3-030-05863-0. [Google Scholar]

- Lee, Y.K.; Youn, J.I.; Hwang, J.H.; Kim, J.H.; Kim, Y.J.; Lee, T.Y. Modeling of the effect of ultrasonic amplitude and frequency on acoustic streaming. Jpn. J. Appl. Phys. 2019, 58, SGGD07. [Google Scholar] [CrossRef]

- Riedel, E.; Horn, I.; Stein, N.; Stein, H.; Bähr, R.; Scharf, S. Ultrasonic treatment: A clean technology that supports sustainability in casting processes. Procedia CIRP 2019, 80, 101–107. [Google Scholar] [CrossRef]

- Lebon, B.; Tzanakis, I.; Pericleous, K.; Eskin, D.; Grant, P.S. Ultrasonic Liquid Metal Processing: The Essential Role of Cavitation Bubbles in Controlling Acoustic Streaming Dataset. Available online: https://brunel.figshare.com/articles/Ultrasonic_liquid_metal_processing_The_essential_role_of_cavitation_bubbles_in_controlling_acoustic_streaming_dataset/7435457 (accessed on 1 October 2019).

- Vanhille, C.; Campos-Pozuelo, C. Nonlinear Ultrasonic Propagation in Bubbly Liquids: A Numerical Model. Ultrasound Med. Biol. 2008, 34, 792–808. [Google Scholar] [CrossRef]

- Vanhille, C.; Campos-Pozuelo, C. Nonlinear ultrasonic waves in bubbly liquids with nonhomogeneous bubble distribution: Numerical experiments. Ultrason. Sonochem. 2009, 16, 669–685. [Google Scholar] [CrossRef] [PubMed]

- Vanhille, C.; Campos-Pozuelo, C. Nonlinear ultrasonic standing waves: Two-dimensional simulations in bubbly liquids. Ultrason. Sonochem. 2011, 18, 679–682. [Google Scholar] [CrossRef] [PubMed]

- Lebon, B.; Salloum-Abou-Jaoude, G.; Eskin, D.; Tzanakis, I.; Pericleous, K.; Jarry, P. Numerical Modelling of Acoustic Streaming during the Ultrasonic Melt Treatment of Direct-Chill (DC) Casting Dataset. Available online: https://brunel.figshare.com/articles/Numerical_modelling_of_acoustic_streaming_during_the_ultrasonic_melt_treatment_of_direct-chill_DC_casting_dataset/7610924/1 (accessed on 1 October 2019).

- Pericleous, K.A.; Bojarevics, V.; Djambazov, G.; Dybalska, A.; Griffiths, W.; Tonry, C. The Contactless Electromagnetic Sonotrode. In Shape Casting; Tiryakioğlu, M., Griffiths, W., Jolly, M., Eds.; Springer International Publishing: New York, NY, USA, 2019; pp. 239–252. ISBN 978-3-030-06033-6. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lebon, B.; Tzanakis, I.; Pericleous, K.; Eskin, D. Numerical Modelling of the Ultrasonic Treatment of Aluminium Melts: An Overview of Recent Advances. Materials 2019, 12, 3262. https://doi.org/10.3390/ma12193262

Lebon B, Tzanakis I, Pericleous K, Eskin D. Numerical Modelling of the Ultrasonic Treatment of Aluminium Melts: An Overview of Recent Advances. Materials. 2019; 12(19):3262. https://doi.org/10.3390/ma12193262

Chicago/Turabian StyleLebon, Bruno, Iakovos Tzanakis, Koulis Pericleous, and Dmitry Eskin. 2019. "Numerical Modelling of the Ultrasonic Treatment of Aluminium Melts: An Overview of Recent Advances" Materials 12, no. 19: 3262. https://doi.org/10.3390/ma12193262

APA StyleLebon, B., Tzanakis, I., Pericleous, K., & Eskin, D. (2019). Numerical Modelling of the Ultrasonic Treatment of Aluminium Melts: An Overview of Recent Advances. Materials, 12(19), 3262. https://doi.org/10.3390/ma12193262