1. Introduction

Currently, many methods are used to evaluate tool wear in real time. The cutting process monitoring system is a tool used to eliminate catastrophic tool failure (CTF). Assessment of the condition of the tool wear based on physical quantities that are associated with the cutting process is possible on the basis of many different methods. Research has been conducted over the years, which compares the effectiveness of assessing tool wear condition based on diagnostic inference methods. Regression models and pattern recognition are among the basic methods. Monitoring of the manufacturing processes is an issue that still requires improvement, despite the use of many modern systems in industry. One of the newer methods used to monitor the condition of the cutting edge is the empirical method, empirical mode decomposition (EMD), which is based on the decomposition of signals in the time domain. As reported in Olufayo et al. [

1] paper, it was used to detect the cracking of the tool based on the measurement of cutting forces. The researchers presented an online industrial monitoring system that reliably obtained precise information on tool wear. On the basis of the coefficient of friction and average power, two forms of wear, i.e., tool edge chipping and tool edge wear, were detected in real time using the CUSUM algorithm (cumulative sum control chart), which gave satisfactory results as compared to an offline method. Wide usage in machining also has indirect monitoring of cutting wear based on cutting forces, evaluation of chip morphology, mechanical vibrations, and acoustic emission. An internet system for measuring and monitoring tool wear based on machine vision was designed and developed in line with the characteristics of a ball-end cutter. The validation of the experiment showed an error of only 2.5% in relation to the actual tool wear. In Wang et al. [

2] investigations, acoustic emission signals were used to diagnose ceramic inserts during milling at high cutting speeds, where a multisensor system for classifying the used cutting wedge was additionally employed. The research used spectral analysis observation and wavelet feature extraction to evaluate tool wear. On the basis of the data obtained, the researchers developed a feed-forward backpropagation neural network (BPNN) model to predict tool wear. Learning the neural network gave a low error value of 0.00523 to classify the state of the tool. This is a very low average square error relative to actual consumption values, which confirms the effectiveness of the prediction based on acoustic emissions. Very often, cutting forces are used to diagnose the condition of the tool, and neural networks are used for diagnostic inference [

3,

4]. In addition to neural networks, the wavelet transformation and spectral grouping algorithms are also used for diagnostic inference such as in Aghazadeh et al. [

5] paper. This experiment presented a tool conditioning monitoring (TCM) system using deep convolutional neural networks (CNNs) as an effective method of deep learning. Force and vibration signals from the experimental ETS (Emissions Trading System) dataset were used, which were independently selected to develop a monitoring system. In contrast to other learning models, these data-driven models were able to learn discriminative nonlinear feature representations. In this way, they could provide an efficient prediction model for error detection by learning feature representations directly from the input signals. Different methods of machine learning algorithms with force and vibration signals were compared and the smallest root mean square error (RMSE) was obtained for the CNN (0.0709 for force signals and 0.086 for vibration). Another example is the research of Kong et al. [

6] paper that presented an effective model of wear width prediction using the Gaussian model with the radial basis function kernel principal component analysis (KPCA_IRBF). In this technique, the Gaussian noises can be modeled quantitatively in the GPR (Gaussian Process Regression) model. Many studies confirm that cutting forces are the most sensitive to changes in tool wear. However, their industrial application involves interference in the construction of machine tools or causes restrictions in the working space. Vibration sensors do not have such limitations, and therefore they are easy to assemble and do not interfere with the machine’s construction. Therefore, diagnostic methods based on vibration measurements are constantly developed. One of the solutions is the use of multisensors because different sensors correlate better with subsequent stages of tool wear. This solution gives a full view of potential wear. After receiving the raw signal, signal processing and feature extraction methods are used, i.e., time domain analysis using autoregressive models (AR), moving average models (MA) or autoregressive moving average (ARMA) mixed models, and methods based on frequency domain analysis, wavelet transformation or empirical mode decomposition (EMD) method. Methods based on multiple monitoring models such as in Zhou et al. [

7] paper are created based on multisensory systems. In addition, the rapid development of artificial intelligence (AI) and advanced methods of inference enable more and more effective application of these methods to predict tool condition [

8,

9].

Hassan et al. [

10] proposed a monitoring system for online prediction and prevention of tool chipping during intermittent turning. A correlation between the chipping size and cutting parameters was designed to protect the machined surfaces. The work presented an integrated system based on acoustic emission (AE) signal processing in order to detect the tool pre-failure before tool chipping, and focused on cracks due to mechanical loads during an intermittent turning operation. The TKEO-HHT (Teager Kaiser Energy Operator-Hilbert–Huang Transform) technique was used which has the ability to deal with the nonstationary and nonlinearly AE

RMS signal in the pre-failure phase. This method successfully predicted tool chipping before failure with a processing time of 2 ms. The determined parameter, Ψ

BW, showed an exponential relationship with chipping, which made it possible to determine the threshold depending on the allowable chipping. The algorithm was optimized to provide sufficient time to stop the machine from damaging the workpiece. A new method of tool wear modeling is the application of a dedicated tribometer, which is able to simulate tribological conditions between the tool and workpiece. Rech et al. [

11] investigated a contact pressure and sliding velocities (s

n, V

s) during turning. Tribological conditions were used to identify a wear model with a new tool geometry. The modeling method was based on an orthogonal cutting simulation (ALE) developed with Abaqus Implicit. In this work, the researchers reported that using the contact temperature as a parameter in the wear model was not a good idea. Instead, they decided to identify a wear model based on the contact pressure, s

n, and sliding velocity, V

s. Currently, this is in accordance with a trend in the field of tribology. They found that this model was very good to predict crater wear. This wear model has been implemented in numerical cutting model which is able to simulate cutting operations.

Currently, there is a lot of work that deals with monitoring wear during hard machining. One such work is Scheffer et al. [

12] paper, where the researchers developed an accurate and flexible system for monitoring tool wear during hard turning. They designed an artificial intelligence (AI) model for monitoring crater and flank wear during hard turning. The purpose of developing the model was to obtain an intelligent and dynamic method. This modern approach to monitoring was based on parameters correlated directly with tool wear such as cutting force, vibration, and AE signals. In connection with this assumption, eight experiments were carried out with simultaneous measurement of cutting force, vibrations, AE, and temperature. An additional advantage of the chosen method was the ability to identify and isolate disturbances generated during the process, which was important because it was difficult to determine if the change in the sensor signal was due to wear or interference from the process. Additionally, they analyzed a self-organizing map (SOM) to identify interference that occurred during the process and they applied the method to achieve more efficient prediction of wear during hard machining. Another example of monitoring tool wear during hard turning is Ozel et al. [

13], in which a neural network model was created for predicting tool wear and surface roughness. It demonstrates that the trend in process monitoring focuses not only on tool wear, but also on the evaluation of the machined surface to allow the best machining efficiency. This study utilized neural network modeling as compared with regression models. A neural network was obtained with the following seven inputs: workpiece hardness in Rockwell-C, cutting speed (m/min), feed rate (mm/rev), axial cutting length (mm), and mean values of three force components Fx, Fy, Fz (N). The small flank wear and surface roughness root mean square (RMS) errors on the test data showed the reliability of the method. The validation using neural networks gave better results than the use of regression models. The developed forecasting system was able to accurately predict surface wear and roughness. The wide range of use of aviation alloys contributed to the development of work in which tool wear is tested during machining of Inconel. One of the works is Capassoa et al. [

14] investigation, in which the characteristics of tool wear during Inconel DA 718 turning with inserts with different coatings were examined. Tool wear was developed using three-dimensional (3D) volumetric wear progression. A predictive model was created based on both 3D and flank wear patterns. The model of tool wear with TiAlCrN/TiCrAl

52Si

8N PVD coating and AlTiN at different cutting speeds reached a value of the fitting factor R of over 93%, which meant that the method produced very good results. In addition to the new predictive models, they found that the tool with a PVD nanocomposite coating exhibited a substantial reduction in chipping, which confirmed superior wear resistance. In summary, the applied methodology proved that the volumetric wear prediction method was reliable.

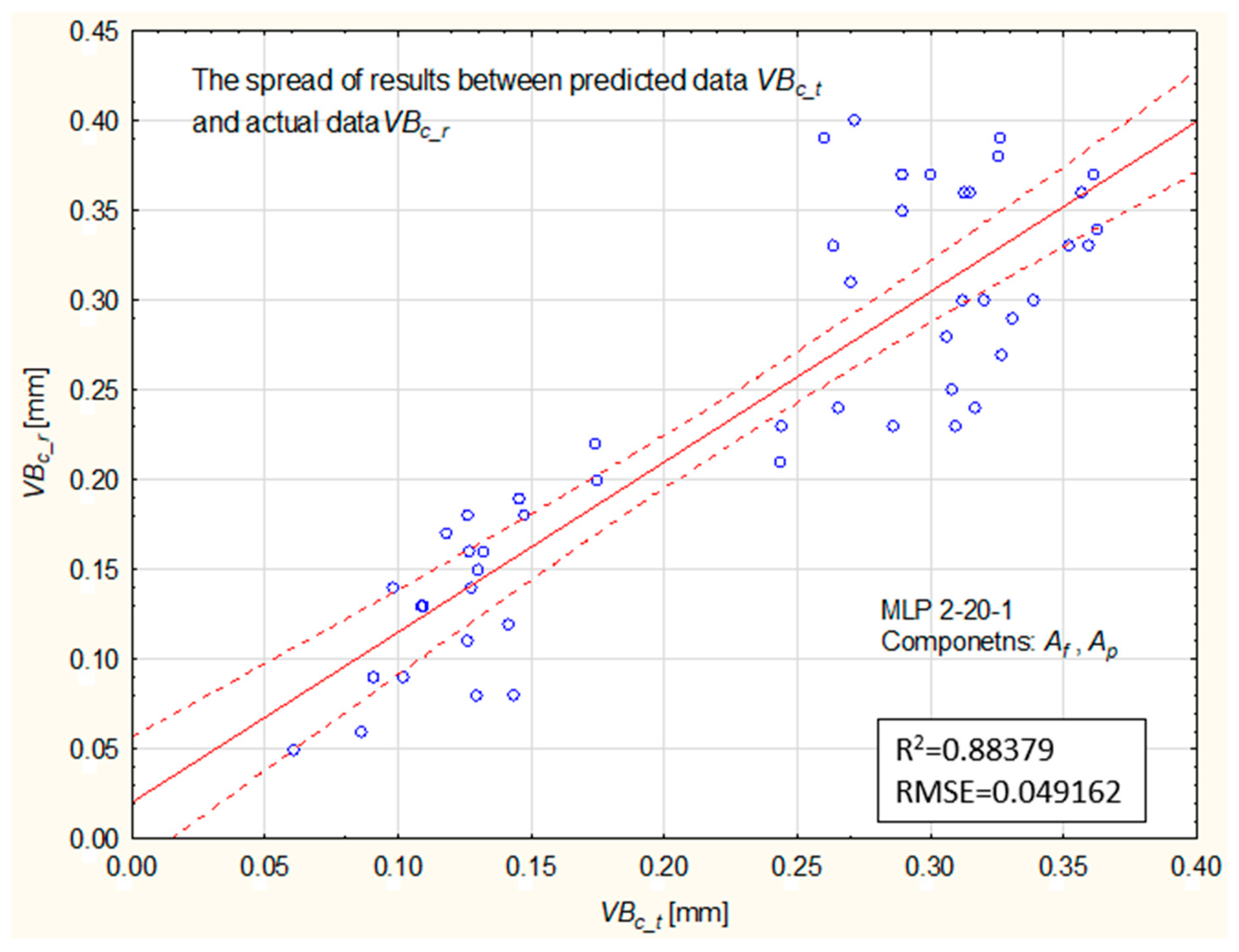

There is a lack of studies comparing the use of different measured quantities as input data during the cutting process. If they already appear, it does not interfere with the network structure such as by changing the activation function or the number of neurons in the layer. In particular little information relates to the processing of hard materials, where the most advantageous information is about predicting tool wear. Therefore, studies have focused on comparing the effectiveness of predicting neural network models with different structures and with different input data.

In this paper, artificial neural networks are presented to predict tool wear based on various input data such as cutting forces and mechanical vibrations. Measurements of selected physical quantities were carried out during turning of hardened steel with constant cutting parameters.

2. Materials and Method

The turning of hardened bearing steel 100Cr6 with a hardness of 61 ± 1 HRC was conducted. The tool material was oxide ceramics (Al2O3 + TiN). Mechanically fixed inserts SNGN120408 MC2 (Kennametal, Latrobe, PA, USA) were used for testing. The research was carried out on a universal lathe TUR560E (FAT, Wroclaw, Poland) with constant cutting parameters:

cutting speed vc = 180 m/min;

rotational speed n = 1400 rev/min;

feed f = 0.08 mm/rev;

depth of cut ap = 0.1 mm.

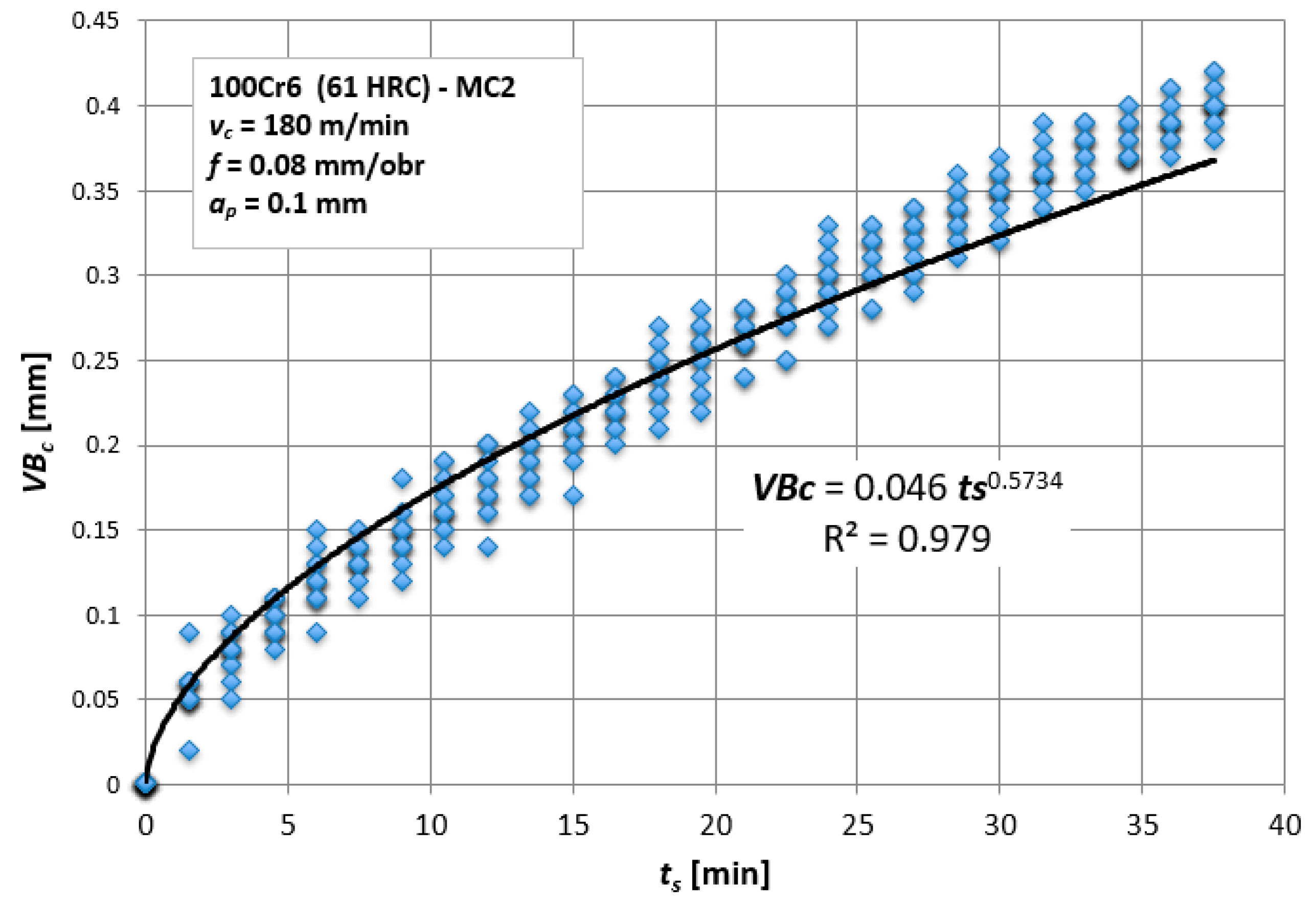

After each pass (length of the shaft L = 150 mm and cutting time of a single pass ts = 1.34 min) the value of flank wear, VBc, was measured (VBc, flank wear of the tool corner), by means of a workshop microscope with a resolution of 0.01 mm.

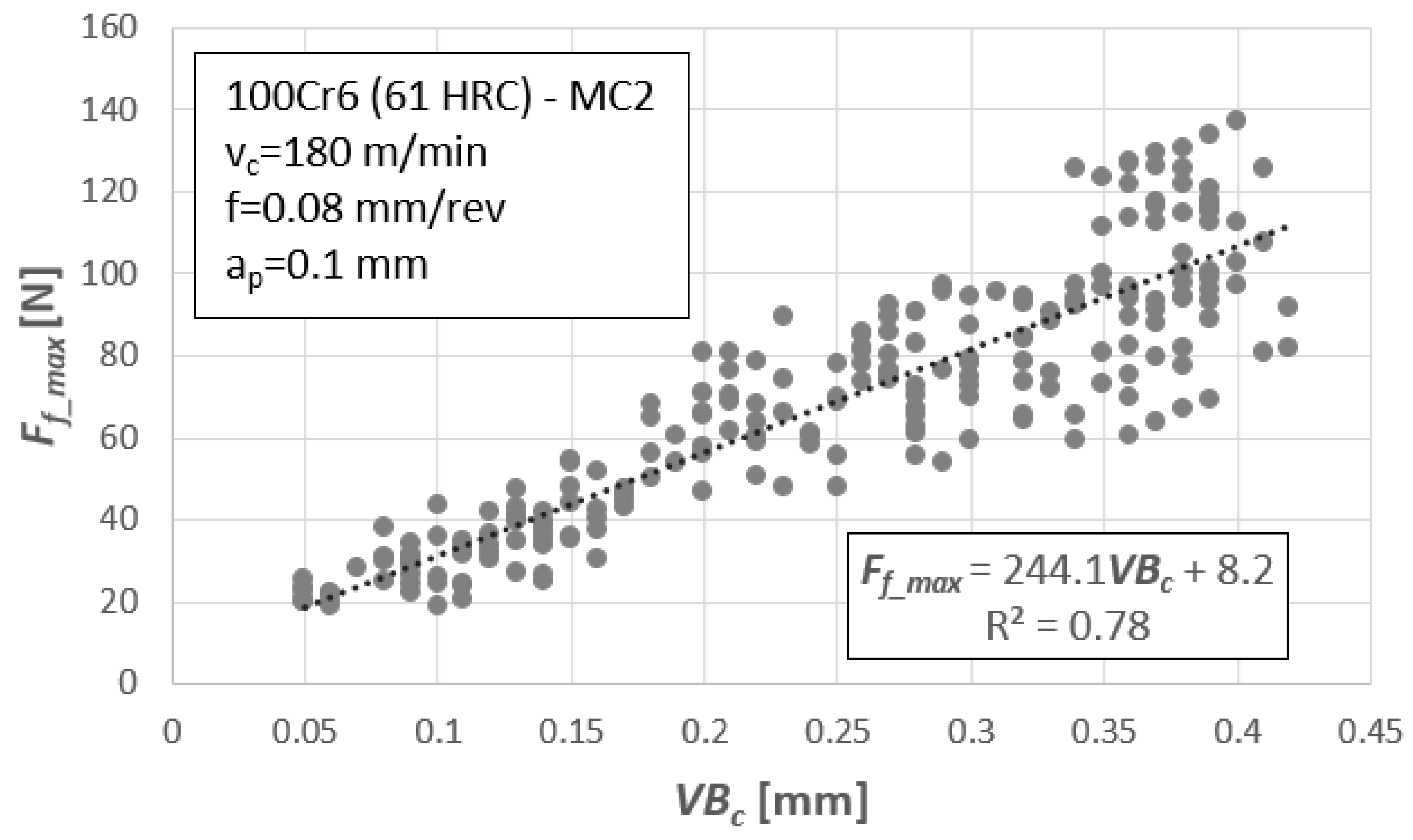

During the turning operation, the following cutting force components were measured:

Fx, Ff for feed direction;

Fy, Fp for radial direction;

Fz, Fc for main direction,

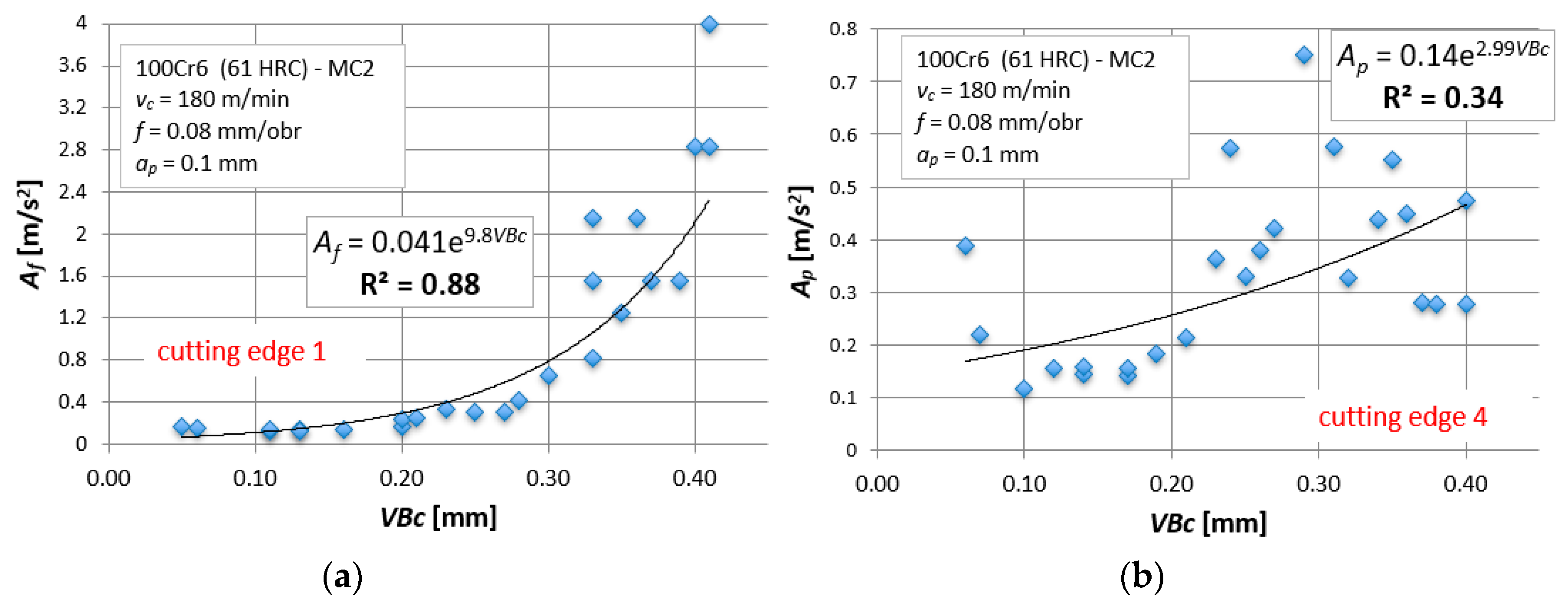

In addition, the acceleration of vibration was measured in the following different directions:

Ax, Af for feed direction;

Ay, Ap for radial direction;

Az, Ac for main direction.

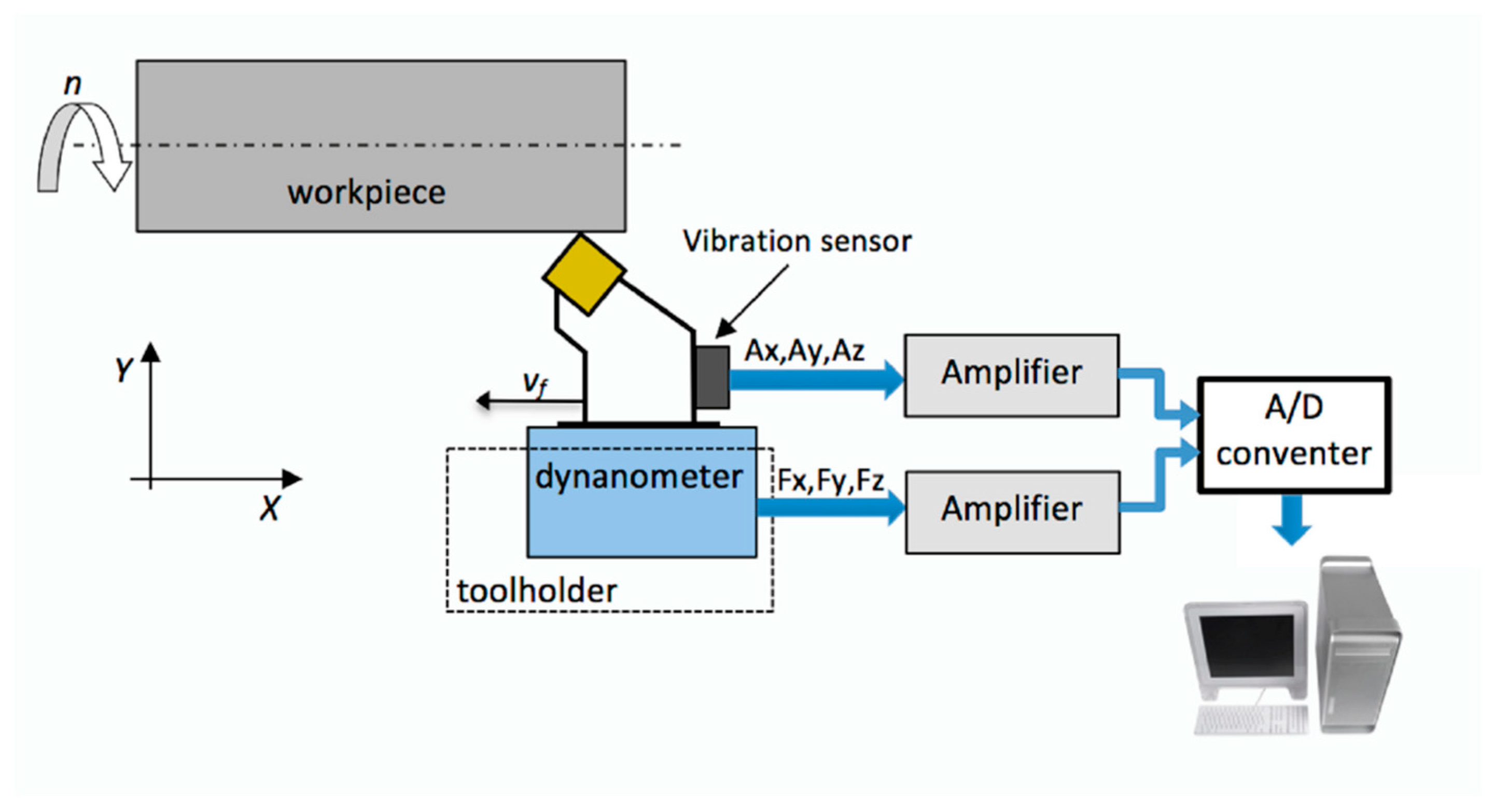

Figure 1 presents a simplified diagram of the measurement setup, which considers the location of sensors and additional components necessary for signal processing and analysis. Piezoelectric sensors were used to measure cutting forces and mechanical vibrations.

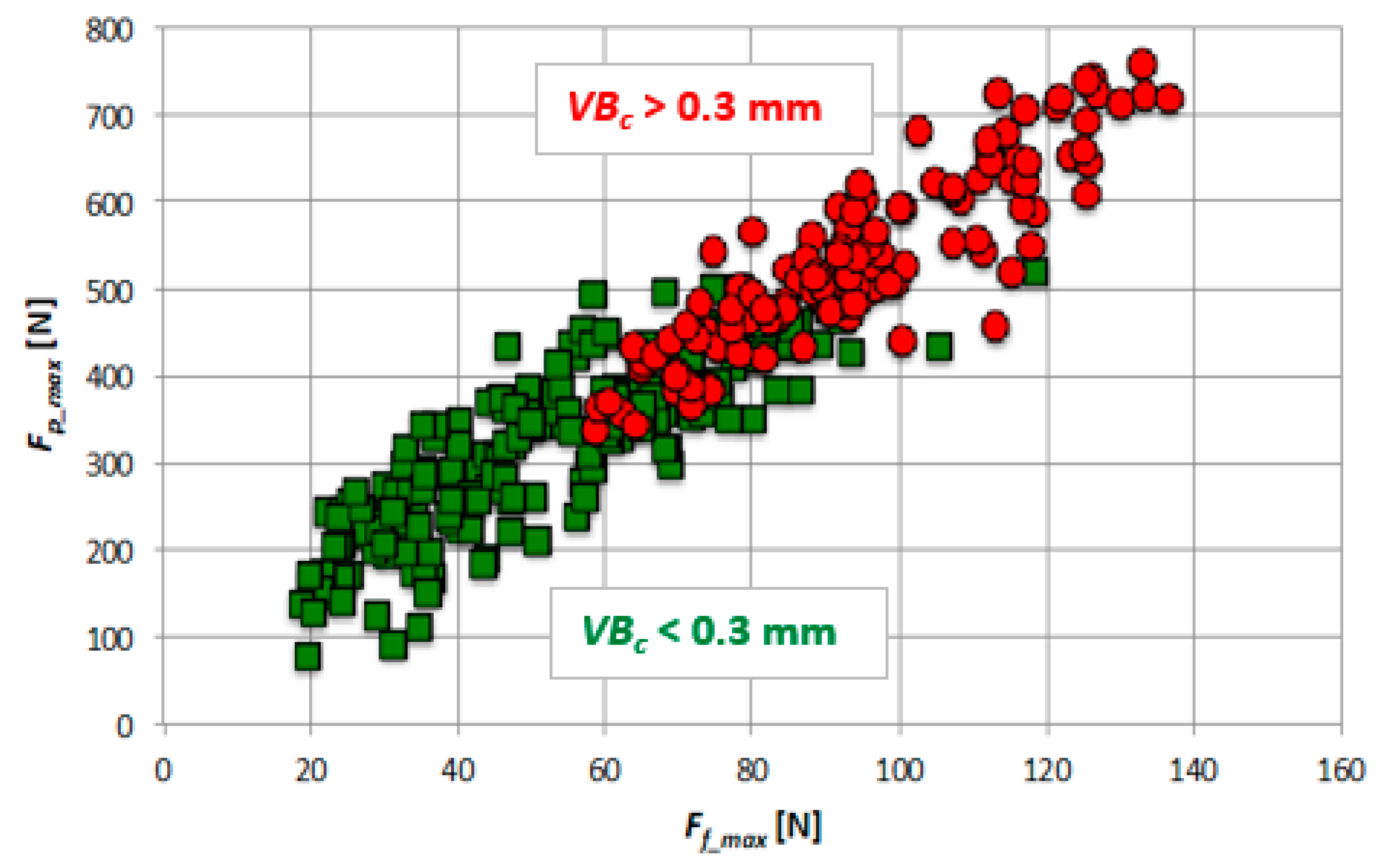

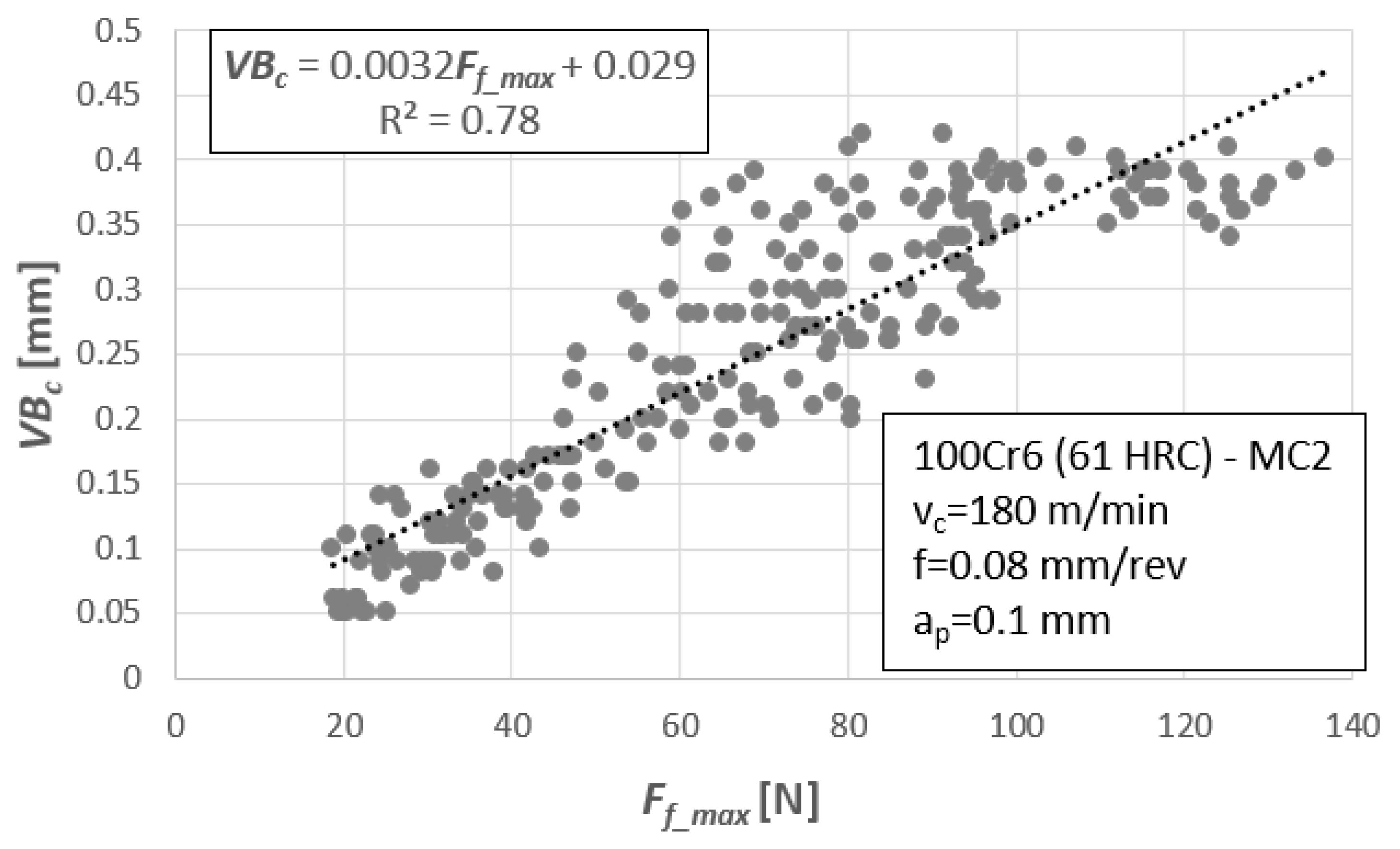

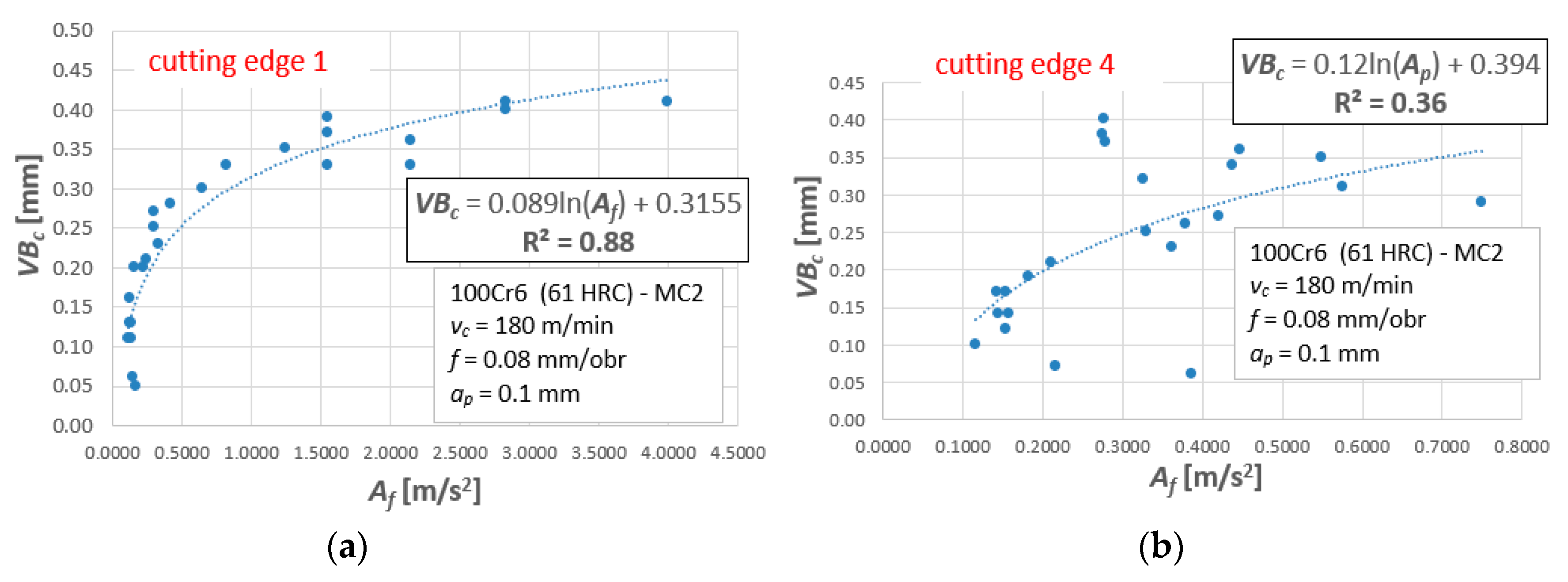

The maximum, minimum, and mean square values of cutting forces and vibration accelerations were selected as diagnostic measures. The mechanical vibrations were measured by a piezoelectric three-axis acceleration sensor fixed to the toolholder using a thread, while the cutting forces were measured using a piezoelectric measuring platform.

On the basis of digital signals sent to the computer, the mean square RMS values (Equation (1)) were evaluated:

where

MRMS is the mean square value for arbitrary diagnostic measure.

The time interval for determining the maximum, minimum, and RMS value was 4 s and the obtained measures were correlated with the corresponding tool wear values.

Under the same conditions, the wear process was carried out for 15 tool tips (15 tests). For each corner, the test was continued until the wear value VBc ≈ 0.4 mm was reached. The conventional tool life criterium that was adopted was VBc = 0.3 mm.