Protein-Polymer Matrices with Embedded Carbon Nanotubes for Tissue Engineering: Regularities of Formation and Features of Interaction with Cell Membranes

Abstract

1. Introduction

2. Computational Details

3. Results and Discussion

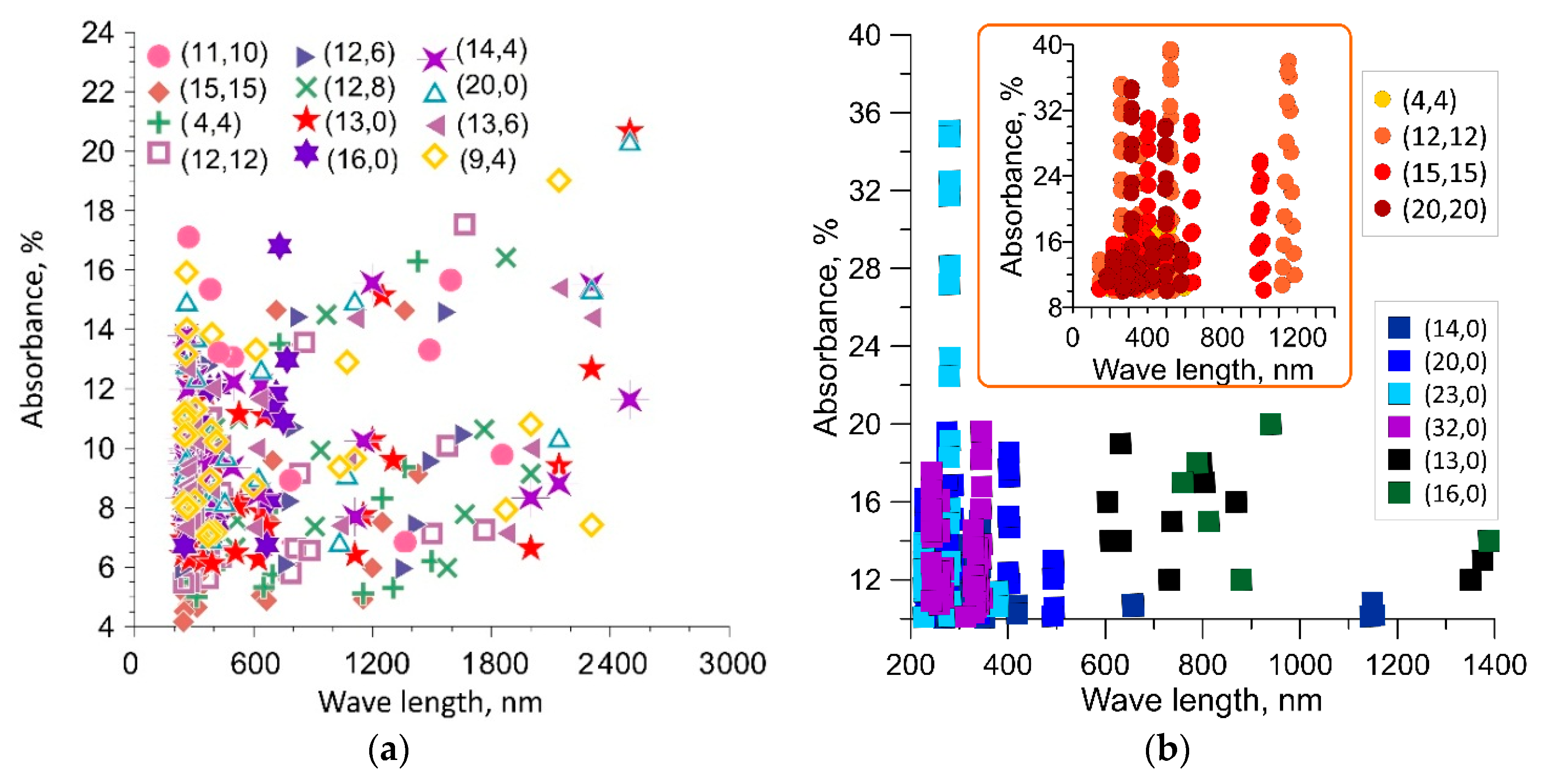

3.1. Absorption of Electromagnetic Wave Energy by Defect-Free and Defective SWCNTs

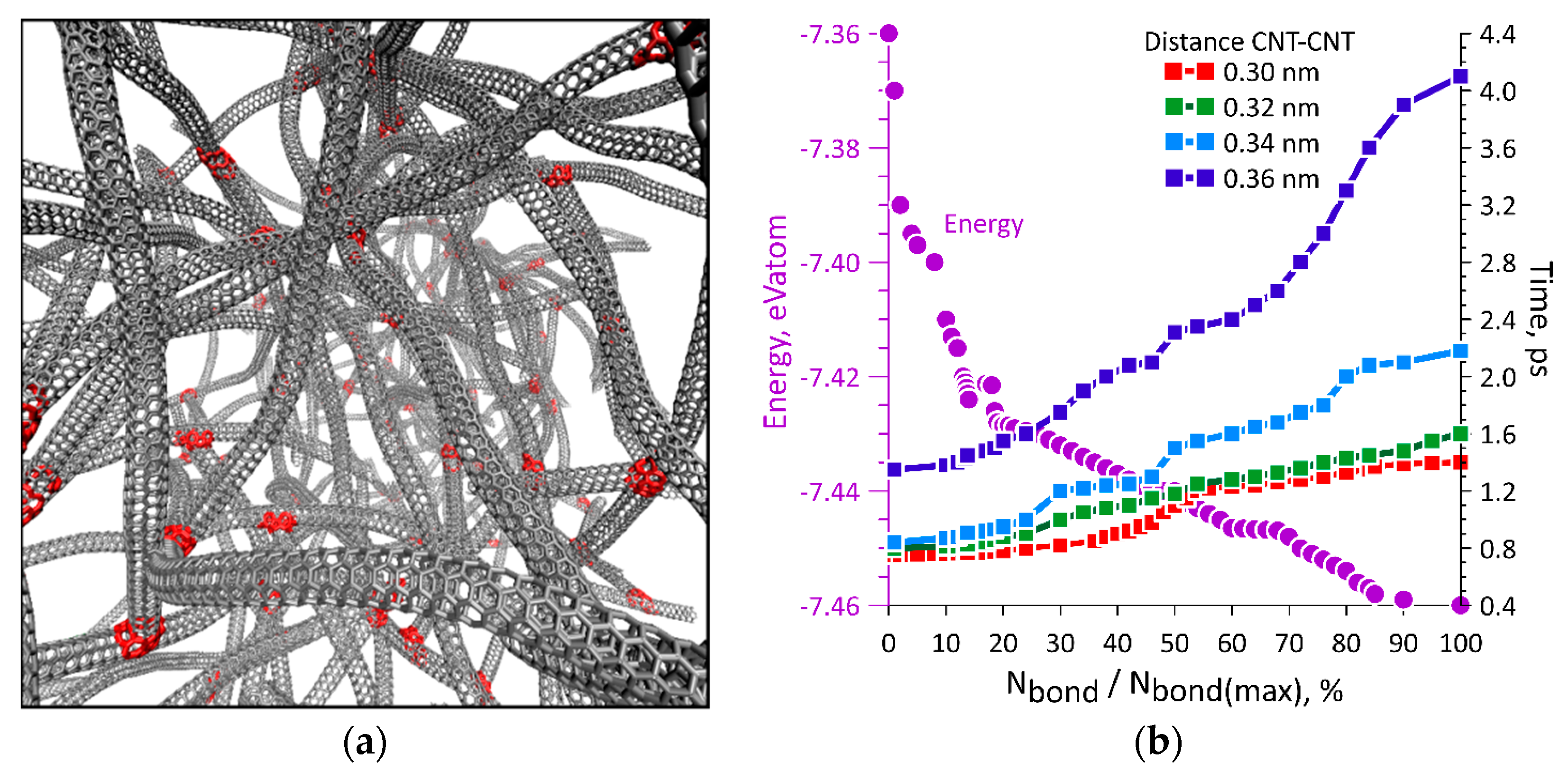

3.2. The formation of A Network of SWCNTs under The Action of Laser Radiation

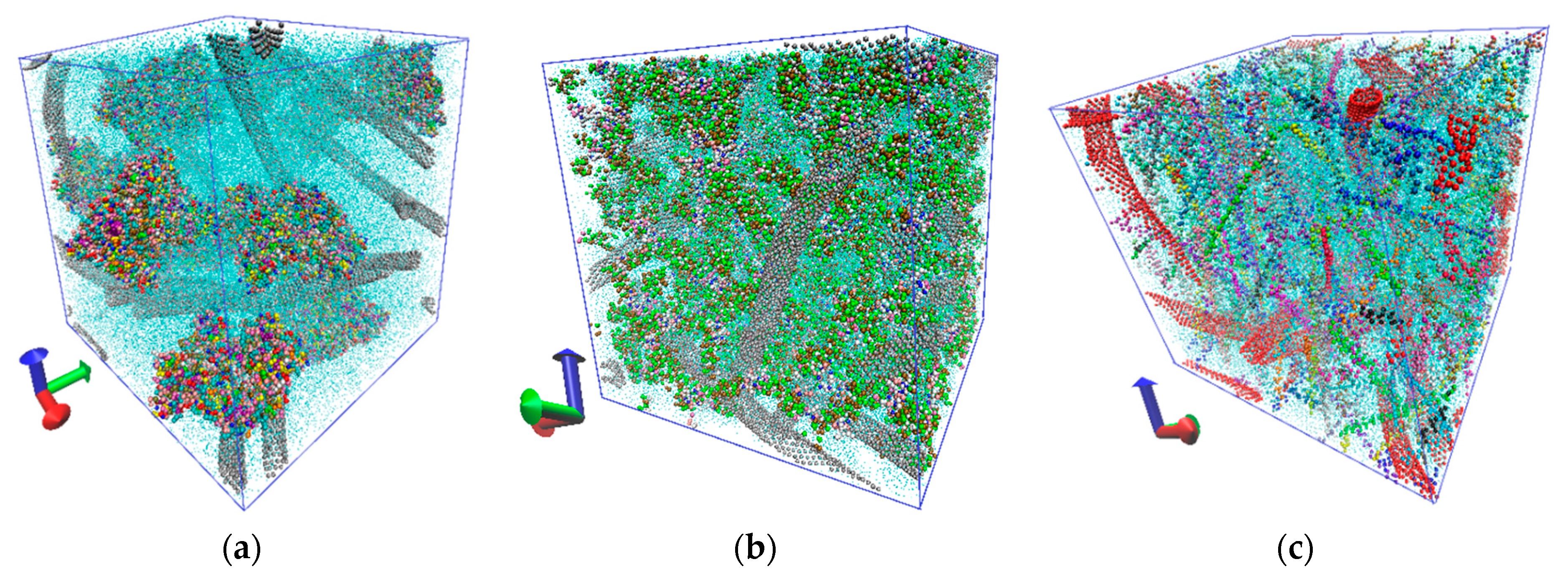

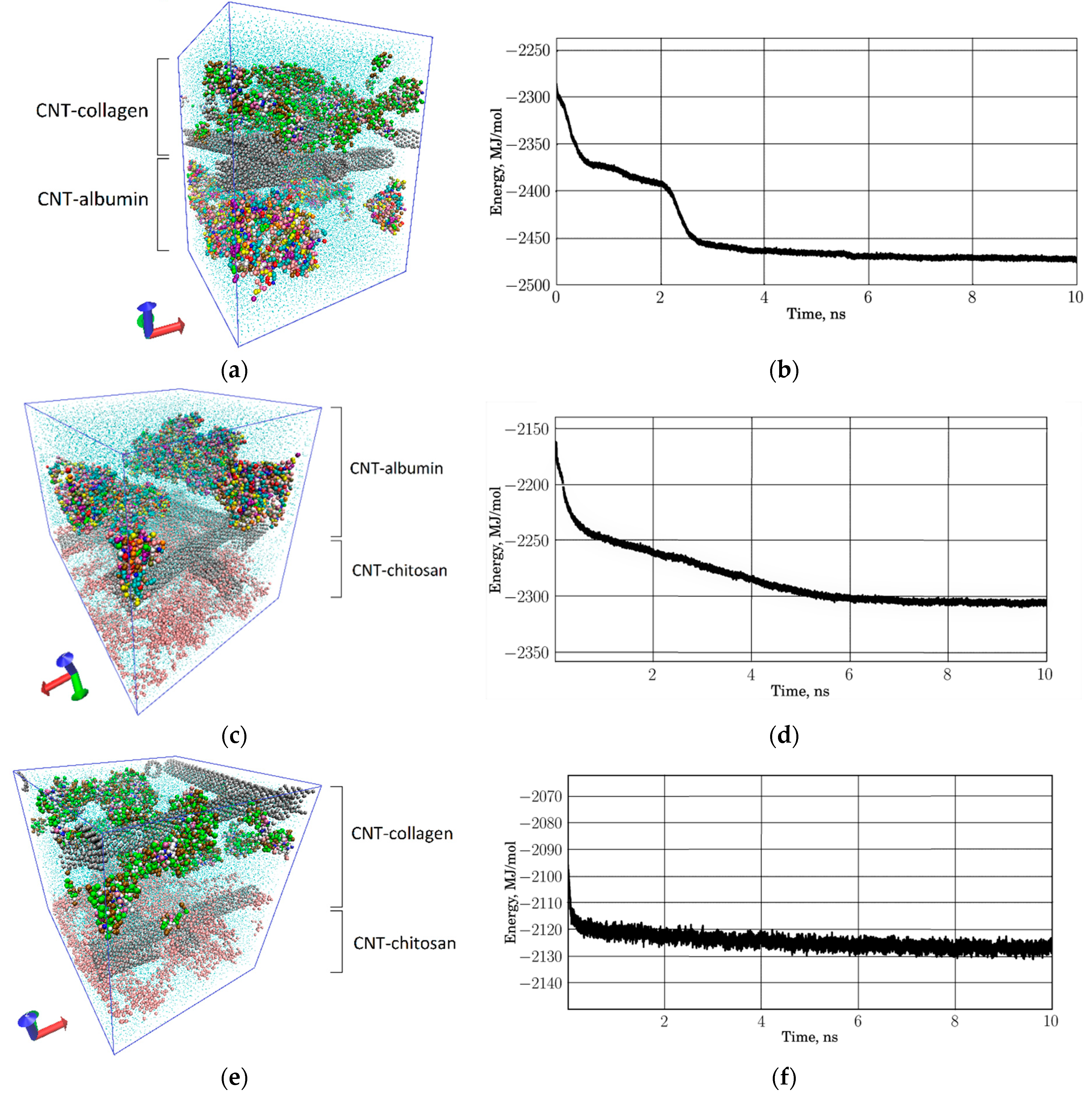

3.3. The Formation of Layered Protein–Polymer Matrices

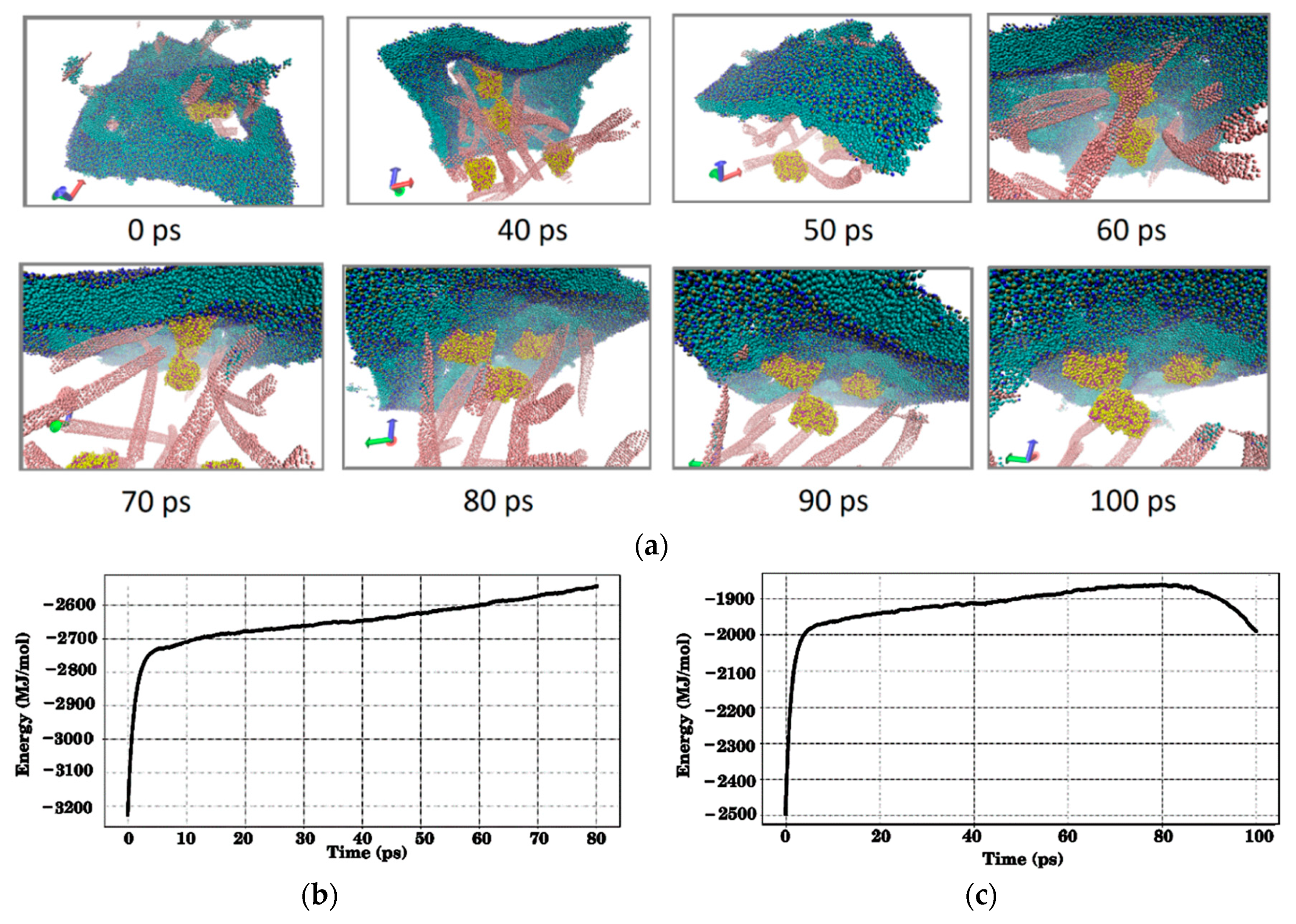

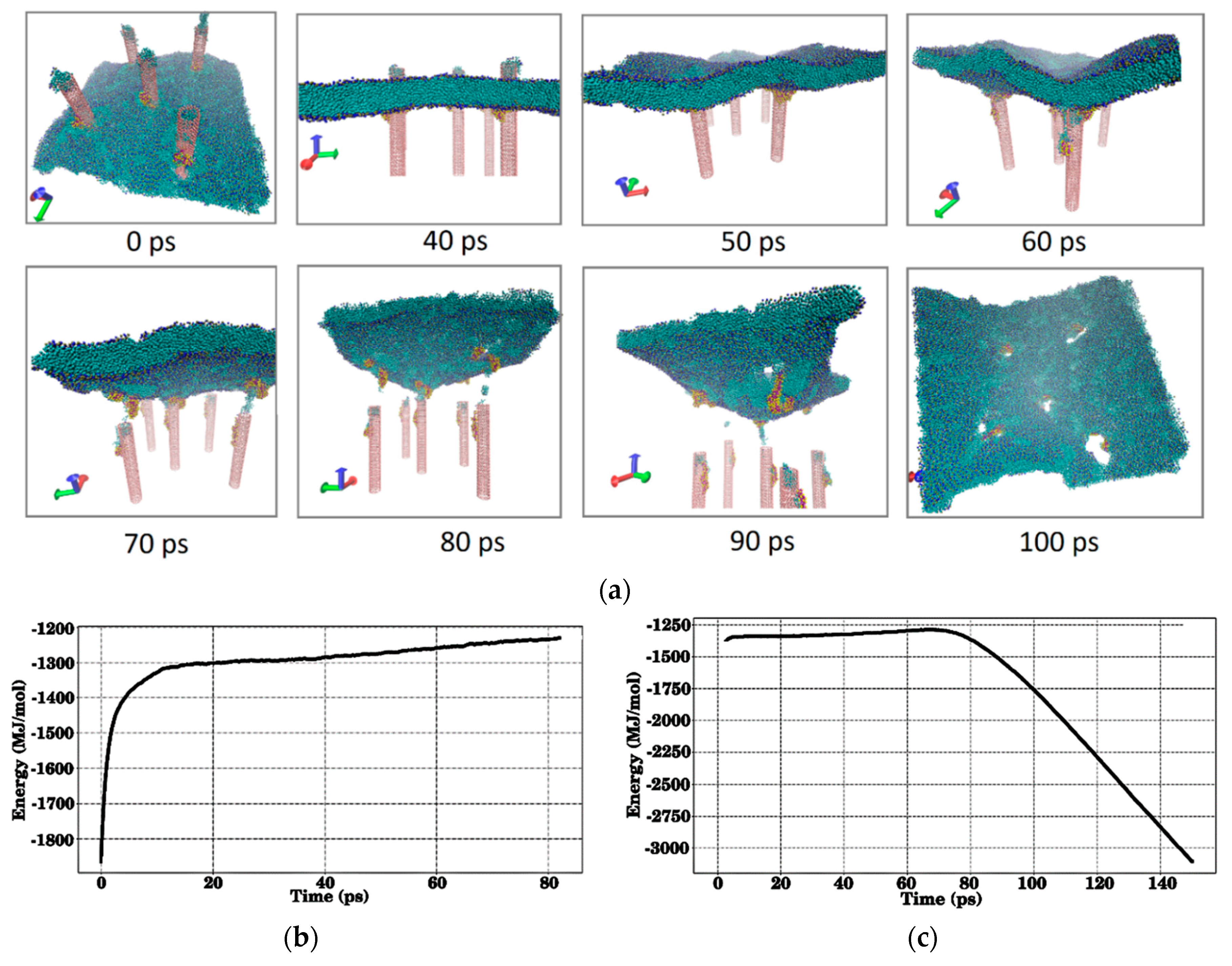

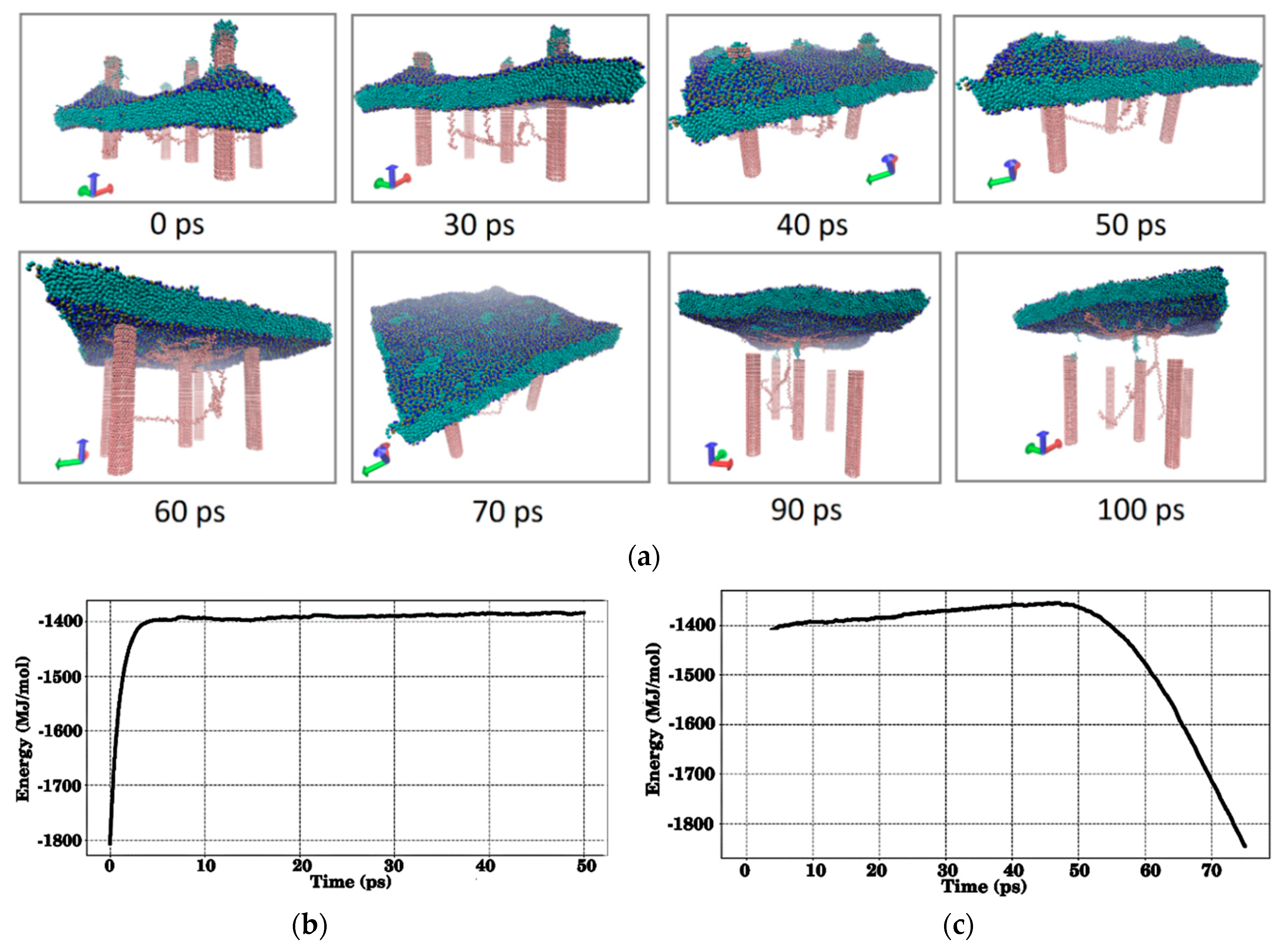

3.4. The Interaction of Layered Protein–Polymer Structures with the Cell Membrane

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Marchesan, S.; Kostarelos, K.; Bianco, A.; Prato, M. The winding road for carbon nanotubes in nanomedicine. Mater. Today 2015, 18, 12–19. [Google Scholar] [CrossRef]

- Gerasimenko, A.Y.; Glukhova, O.E.; Savostyanov, G.V.; Podgaetsky, V.M. Laser structuring of carbon nanotubes in the albumin matrix for the creation of composite biostructures. J. Biomed. Opt. 2017, 22, 065003. [Google Scholar] [CrossRef] [PubMed]

- Scarselli, M.; Castrucci, P.; De Nicola, F.; Cacciotti, I.; Nanni, F.; Gatto, E.; Venanzi, M.; De Crescenzi, M. Applications of three-dimensional carbon nanotube networks. Beilstein J. Nanotechnol. 2015, 6, 792–798. [Google Scholar] [CrossRef] [PubMed]

- Kobashi, K.; Ata, S.; Yamada, T.; Futaba, D.N.; Yumura, M.; Hata, K. A dispersion strategy: Dendritic carbon nanotube network dispersion for advanced composites. Chem. Sci. 2013, 4, 727–733. [Google Scholar] [CrossRef]

- Xue, Y. Carbon nanotubes for biomedical applications. In Industrial Applications of Carbon Nanotubes, 1st ed.; Peng, H., Li, Q., Chen, T., Eds.; Elsevier: Oxford, UK, 2017; pp. 323–346. [Google Scholar]

- Alshehri, R.; Ilyas, A.M.; Hasan, A.; Arnaout, A.; Ahmed, F.; Memic, A. Carbon nanotubes in biomedical applications: Factors, mechanisms, and remedies of toxicity. J. Med. Chem. 2016, 59, 8149–8167. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Vyas, C.; Roberts, I.; Poutrel, Q.A.; Chiang, W.H.; Blaker, J.J.; Huang, Z.; Bártolo, P. Fabrication and characterisation of 3D printed MWCNT composite porous scaffolds for bone regeneration. Mater. Sci. Eng. C-Mater. 2019, 98, 266–278. [Google Scholar] [CrossRef]

- Peña, B.; Bosi, S.; Aguado, B.A.; Borin, D.; Farnsworth, N.L.; Dobrinskikh, E.; Rowland, T.J.; Martinelli, V.; Jeong, M.; Taylor, M.R.G.; et al. Injectable carbon nanotube-functionalized reverse thermal gel promotes cardiomyocytes survival and maturation. ACS Appl. Mater. Interfaces 2017, 9, 31645–31656. [Google Scholar] [CrossRef]

- Nguyen, A.H.; Marsh, P.; Schmiess-Heine, L.; Burke, P.J.; Lee, A.; Lee, J.; Cao, H. Cardiac tissue engineering: State-of-the-art methods and outlook. J. Biol. Eng. 2019, 13, 57. [Google Scholar] [CrossRef]

- Alegret, N.; Dominguez-Alfaro, A.; González-Domínguez, J.M.; Arnaiz, B.; Cossío, U.; Bosi, S.; Vázquez, E.; Ramos-Cabrer, P.; Mecerreyes, D.; Prato, M. Three-dimensional conductive scaffolds as neural prostheses based on carbon nanotubes and polypyrrole. ACS Appl. Mater. Interfaces 2018, 10, 43904–43914. [Google Scholar] [CrossRef]

- Kia, K.K.; Bonabi, F.; Shokrzadeh, M. Electric field-oriented growth of carbon nanotubes and y-branches in a needle-pulsed arc discharge unit: Mechanism of the production. J. Exp. Nanosci. 2015, 10, 1093–1105. [Google Scholar]

- Wei, Q.; Liu, Y.; Zhang, L.; Huang, S. Growth and formation mechanism of branched carbon nanotubes by pyrolysis of Iron(II) phthalocyanine. Nano-Micro Lett. 2013, 5, 124–128. [Google Scholar] [CrossRef]

- Goswami, G.K.; Nandan, R.; Nanda, K.K. Growth of branched carbon nanotubes with doped/un-doped intratubular junctions by one-step co-pyrolysis. Carbon 2013, 56, 97–102. [Google Scholar] [CrossRef]

- Wei, X.L.; Liu, Y.; Chen, Q.; Peng, L.M. Controlling electron-beam-induced carbon deposition on carbon nanotubes by Joule heating. Nanotechnology 2008, 19, 355304. [Google Scholar] [CrossRef] [PubMed]

- Ni, Z.; Li, Q.; Yan, L.; Gong, J.; Zhu, D. Welding of multi-walled carbon nanotubes by ion beam irradiation. Carbon 2008, 46, 376–378. [Google Scholar] [CrossRef]

- Dong, L.; Tao, X.; Zhang, L.; Zhang, X.; Nelson, B.J. Nanorobotic spot welding: Controlled metal deposition with attogram precision from copper-filled carbon nanotubes. Nano Lett. 2007, 7, 58–63. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Fu, K.K.; Zhu, S.; Dai, J.; Wang, Y.; Pastel, G.; Chen, Y.; Li, T.; Wang, C.; Li, T.; et al. Carbon welding by ultrafast joule heating. Nano Lett. 2016, 16, 7282–7289. [Google Scholar] [CrossRef] [PubMed]

- Ozden, S.; Brunetto, G.; Karthiselva, N.S.; Galvão, D.S.; Roy, A.; Bakshi, S.R.; Tiwary, C.S.; Ajayan, P.M. Controlled 3D carbon nanotube structures by plasma welding. Adv. Mater. Interfaces 2016, 3, 1500755. [Google Scholar] [CrossRef]

- Yang, L.; Cui, J.; Wang, Y.; Hou, C.; Xie, H.; Mei, X.; Wang, W.; Wang, K. Nanospot welding of carbon nanotubes using near-field enhancement effect of AFM probe irradiated by optical fiber probe laser. RSC Adv. 2015, 5, 56677–56685. [Google Scholar] [CrossRef]

- Guo, S. The creation of nanojunctions. Nanoscale 2010, 2, 2521–2529. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, Y.; Shang, Y.; Han, W. Structural changes and electrical properties of nanowelded multiwalled carbon nanotube junctions. Appl. Opt. 2018, 57, 7435–7439. [Google Scholar] [CrossRef]

- Yuan, Y.; Liu, Z.; Zhang, K.; Han, W.; Chen, J. Nanoscale welding of multi-walled carbon nanotubes by 1064 nm fiber laser. Opt. Laser Technol. 2018, 103, 327–329. [Google Scholar] [CrossRef]

- Yuan, Y.; Chen, J. Nano-welding of multi-walled carbon nanotubes on silicon and silica surface by laser irradiation. Nanomaterials 2016, 6, 36. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Chen, J. Morphology adjustments of multi-walled carbon nanotubes by laser irradiation. Laser Phys. Lett. 2016, 13, 066001. [Google Scholar] [CrossRef]

- Krasheninnikov, A.V.; Nordlund, K.; Keinonen, J.; Banhart, F. Ion-irradiation-induced welding of carbon nanotubes. Phys. Rev. B 2002, 66, 245403. [Google Scholar] [CrossRef]

- Terrones, M.; Banhart, F.; Grobert, N.; Charlier, J.C.; Terrones, H.; Ajayan, P.M. Molecular junctions by joining single-walled carbon nanotubes. Phys. Rev. Lett. 2002, 89, 075505. [Google Scholar] [CrossRef] [PubMed]

- Bullard, Z.; Meunier, V. Dynamical properties of carbon nanotube welding into X junctions. Phys. Rev. B 2013, 88, 035422. [Google Scholar] [CrossRef]

- Cui, J.; Yang, L.; Wang, Y. Molecular dynamics study of the positioned single-walled carbon nanotubes with T-, X-, Y- junction during nanoscale soldering. Appl. Surf. Sci. 2013, 284, 392–396. [Google Scholar] [CrossRef]

- Cui, J.; Yang, L.; Wang, Y. Nanowelding configuration between carbon nanotubes in axial direction. Appl. Surf. Sci. 2013, 264, 713–717. [Google Scholar] [CrossRef]

- Cui, J.; Yang, L.; Zhou, L.; Wang, Y. Nanoscale soldering of axially positioned single-walled carbon nanotubes: A molecular dynamics simulation study. ACS Appl. Mater. Interfaces 2014, 6, 2044–2050. [Google Scholar] [CrossRef]

- Kirca, M.; Yang, X.; To, A.C. A stochastic algorithm for modeling heat welded random carbon nanotube network. Comput. Methods Appl. Mech. Eng. 2013, 259, 1–9. [Google Scholar] [CrossRef]

- Zhang, Y.; Gong, T.; Jia, Y.; Liu, W.; Wei, J.; Ma, M.; Wang, K.; Zhong, M.; Wu, D.; Cao, A. Tailoring the intrinsic metallic states of double-walled nanotube films by self-soldered laser welding. Appl. Phys. Lett. 2007, 91, 233109. [Google Scholar] [CrossRef]

- Kroustalli, A.; Zisimopoulou, A.E.; Koch, S.; Rongen, L.; Deligianni, D.; Diamantouros, S.; Athanassiou, G.; Kokozidou, M.; Mavrilas, D.; Jockenhoevel, S. Carbon nanotubes reinforced chitosan films: Mechanical properties and cell response of a novel biomaterial for cardiovascular tissue engineering. J. Mater. Sci. Mater. Med. 2013, 24, 2889–2896. [Google Scholar] [CrossRef] [PubMed]

- Savostyanov, G.V.; Slepchenkov, M.M.; Shmygin, D.S.; Glukhova, O.E. Specific features of structure, electrical conductivity and interlayer adhesion of the natural polymer matrix from the layers of branched carbon nanotube networks filled with albumin, collagen and chitosan. Coatings 2018, 8, 378. [Google Scholar] [CrossRef]

- Hsu, C.C.; Serio, A.; Amdursky, N.; Besnard, C.; Stevens, M.M. Fabrication of hemin-doped serum albumin-based fibrous scaffolds for neural tissue engineering applications. ACS Appl. Mater. Interfaces 2018, 10, 5305–5317. [Google Scholar] [CrossRef] [PubMed]

- Aiyelabegan, H.T.; Zaidi, S.S.Z.; Fanuel, S.; Eatemadi, A.; Ebadi, M.T.K.; Sadroddiny, E. Albumin-based biomaterial for lung tissue engineering applications. Int. J. Polym. Mater. Po. 2016, 65, 853–861. [Google Scholar] [CrossRef]

- Fleischer, S.; Shapira, A.; Regev, O.; Nseir, N.; Zussman, E.; Dvir, T. Albumin fiber scaffolds for engineering functional cardiac tissues. Biotechnol. Bioeng. 2014, 111, 1246–1257. [Google Scholar] [CrossRef] [PubMed]

- Overby, R.J.; Feldman, D.S. Influence of Poly(Ethylene Glycol) End groups on Poly(Ethylene Glycol)-albumin system properties as a potential degradable tissue scaffold. J. Funct. Biomater. 2019, 10, 1. [Google Scholar] [CrossRef] [PubMed]

- Cen, L.; Liu, W.; Cui, L.; Zhang, W.; Cao, Y. Collagen tissue engineering: Development of novel biomaterials and applications. Pediatr. Res. 2008, 63, 492–496. [Google Scholar] [CrossRef]

- Dong, C.; Lv, Y. Application of collagen scaffold in tissue engineering: Recent advances and new perspectives. Polymers (Basel) 2016, 8, 42. [Google Scholar] [CrossRef]

- Irawan, V.; Sung, T.C.; Higuchi, A.; Ikoma, T. Collagen scaffolds in cartilage tissue engineering and relevant approaches for future development. Tissue Eng. Regen Med. 2018, 15, 673–697. [Google Scholar] [CrossRef]

- Pandey, A.R.; Singh, U.S.; Momin, M.; Bhavsar, C. Chitosan: Application in tissue engineering and skin grafting. J. Polym. Res. 2017, 24, 125. [Google Scholar] [CrossRef]

- Ahsan, S.M.; Thomas, M.; Reddy, K.K.; Sooraparaju, S.G.; Asthana, A.; Bhatnagar, I. Chitosan as biomaterial in drug delivery and tissue engineering. Int. J. Biol. Macromol. 2018, 110, 97–109. [Google Scholar] [CrossRef] [PubMed]

- Glukhova, O.E.; Nefedov, I.S.; Shalin, A.S.; Slepchenkov, М.М. New 2D graphene hybrid composites as an effective base element of optical nanodevices. Beilstein J. Nanotechnol. 2018, 9, 1321–1327. [Google Scholar] [CrossRef] [PubMed]

- Marder, M.P. Condensed Matter Physics, 2nd ed.; Wiley-VCH: Berlin, Germany, 2011; pp. 623–631. [Google Scholar]

- Le, H.A.; Ho, S.T.; Nguyen, D.C.; Do, V.N. Optical Properties of Graphene Superlattices. J. Phys. Condens. Matter 2014, 26, 405304. [Google Scholar] [CrossRef]

- Glukhova, O.E. Molecular dynamics as the tool for investigation of carbon nanostructures properties. In Thermal Transport in Carbon-Based Nanomaterials, 1st ed.; Zhang, G., Ed.; Elsevier: Oxford, UK, 2017; pp. 267–289. [Google Scholar]

- Aradi, B.; Hourahine, B.; Frauenheim, T. DFTB+, a sparse matrix-based implementation of the DFTB method. J. Phys. Chem. A 2007, 111, 5678–5684. [Google Scholar] [CrossRef] [PubMed]

- Nikitin, A.; Ogasawara, H.; Mann, D.; Denecke, R.; Zhang, Z.; Dai, H.; Cho, K.; Nilsson, A. Hydrogenation of Single-Walled Carbon Nanotubes. Phys. Rev. Lett. 2005, 95, 225507. [Google Scholar] [CrossRef] [PubMed]

- de Jong, D.H.; Singh, G.; Bennett, W.F.D.; Arnarez, C.; Wassenaar, T.A.; Schäfer, L.V.; Periole, X.; Tieleman, D.P.; Marrink, S.J. Improved parameters for the martini coarse-grained protein force Field. J. Chem. Th. Comp. 2013, 9, 687–697. [Google Scholar] [CrossRef]

- GROMACS. Available online: http://www.gromacs.org (accessed on 15 April 2019).

- Park, J.; Bifano, M.F.P.; Prakash, V. Sensitivity of thermal conductivity of carbon nanotubes to defect concentrations and heat-treatment. J. Appl. Phys. 2013, 113, 034312. [Google Scholar] [CrossRef]

- Kumanek, B.; Janas, D. Thermal conductivity of carbon nanotube networks: A review. J. Mater. Sci. 2019, 54, 7397–7427. [Google Scholar] [CrossRef]

- Che, J.; Cagın, T.; Goddard, W.A., III. Thermal conductivity of carbon nanotubes. Nanotechnology 2000, 11, 65–69. [Google Scholar] [CrossRef]

- Chang, M.; Fan, H.D.E.; Chowdhury, M.M.; Sawatzky, G.A.; Nojeh, A. Heat localization through reduced dimensionality. Phys. Rev. B 2018, 98, 155422. [Google Scholar] [CrossRef]

- Bakan, G.; Khan, N.; Cywar, A.; Cil, K.; Akbulut, M.; Gokirmak, A.; Silva, H. Self-heating of silicon microwires: Crystallization and thermoelectric effects. J. Mat. Res. 2011, 26, 1061. [Google Scholar] [CrossRef]

- Mecklenburg, M.; Hubbard, W.A.; White, E.R.; Dhall, R.; Cronin, S.B.; Aloni, S.; Regan, B.C. Nanoscale temperature mapping in operating microelectronic devices. Science 2015, 347, 629. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slepchenkov, M.M.; Gerasimenko, A.Y.; Telyshev, D.V.; Glukhova, O.E. Protein-Polymer Matrices with Embedded Carbon Nanotubes for Tissue Engineering: Regularities of Formation and Features of Interaction with Cell Membranes. Materials 2019, 12, 3083. https://doi.org/10.3390/ma12193083

Slepchenkov MM, Gerasimenko AY, Telyshev DV, Glukhova OE. Protein-Polymer Matrices with Embedded Carbon Nanotubes for Tissue Engineering: Regularities of Formation and Features of Interaction with Cell Membranes. Materials. 2019; 12(19):3083. https://doi.org/10.3390/ma12193083

Chicago/Turabian StyleSlepchenkov, Michael M., Alexander Yu. Gerasimenko, Dmitry V. Telyshev, and Olga E. Glukhova. 2019. "Protein-Polymer Matrices with Embedded Carbon Nanotubes for Tissue Engineering: Regularities of Formation and Features of Interaction with Cell Membranes" Materials 12, no. 19: 3083. https://doi.org/10.3390/ma12193083

APA StyleSlepchenkov, M. M., Gerasimenko, A. Y., Telyshev, D. V., & Glukhova, O. E. (2019). Protein-Polymer Matrices with Embedded Carbon Nanotubes for Tissue Engineering: Regularities of Formation and Features of Interaction with Cell Membranes. Materials, 12(19), 3083. https://doi.org/10.3390/ma12193083