Polydopamine-Assisted Immobilization of Chitosan Brushes on a Textured CoCrMo Alloy to Improve its Tribology and Biocompatibility

Abstract

1. Introduction

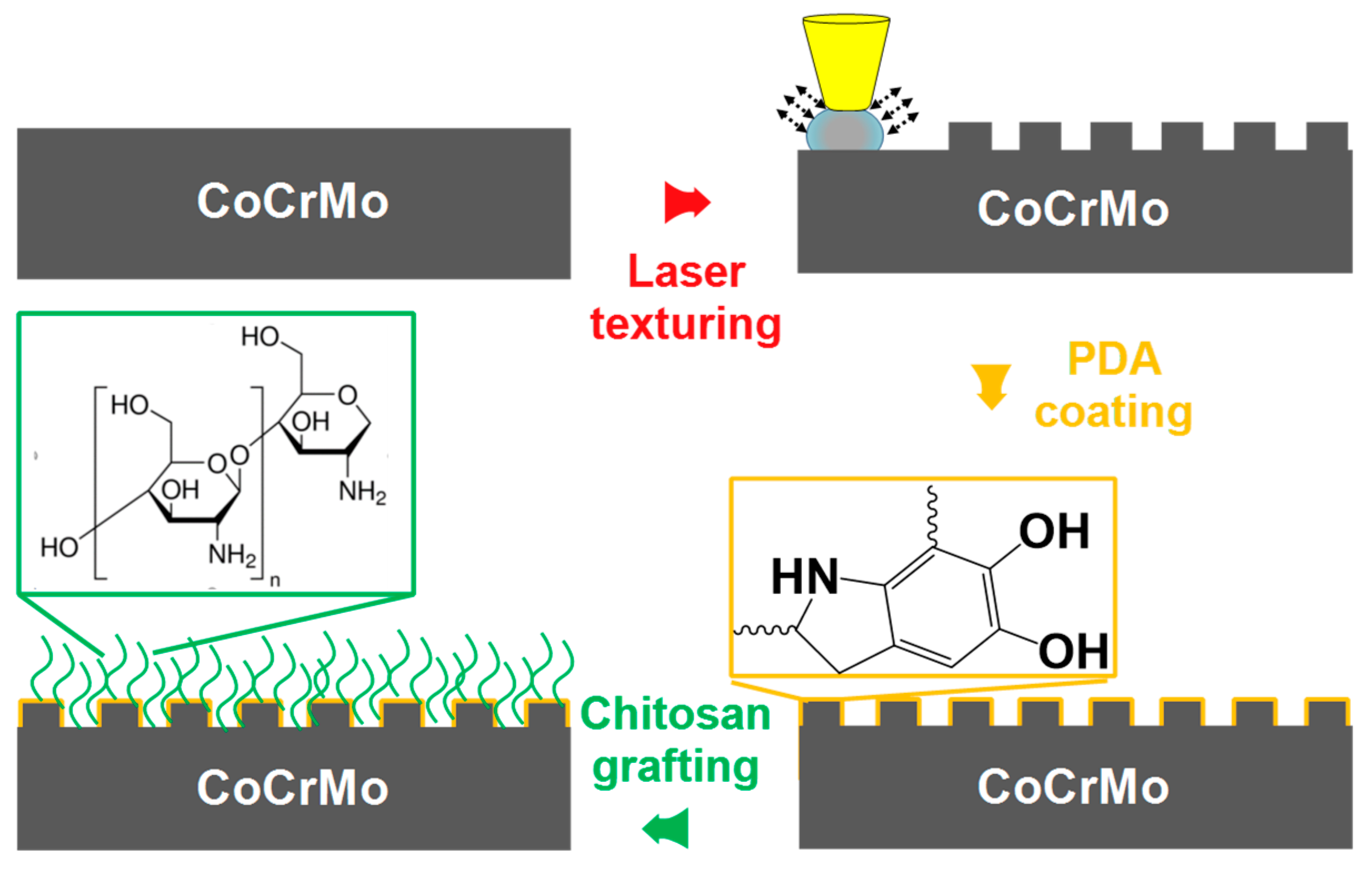

2. Materials and Methods

3. Results

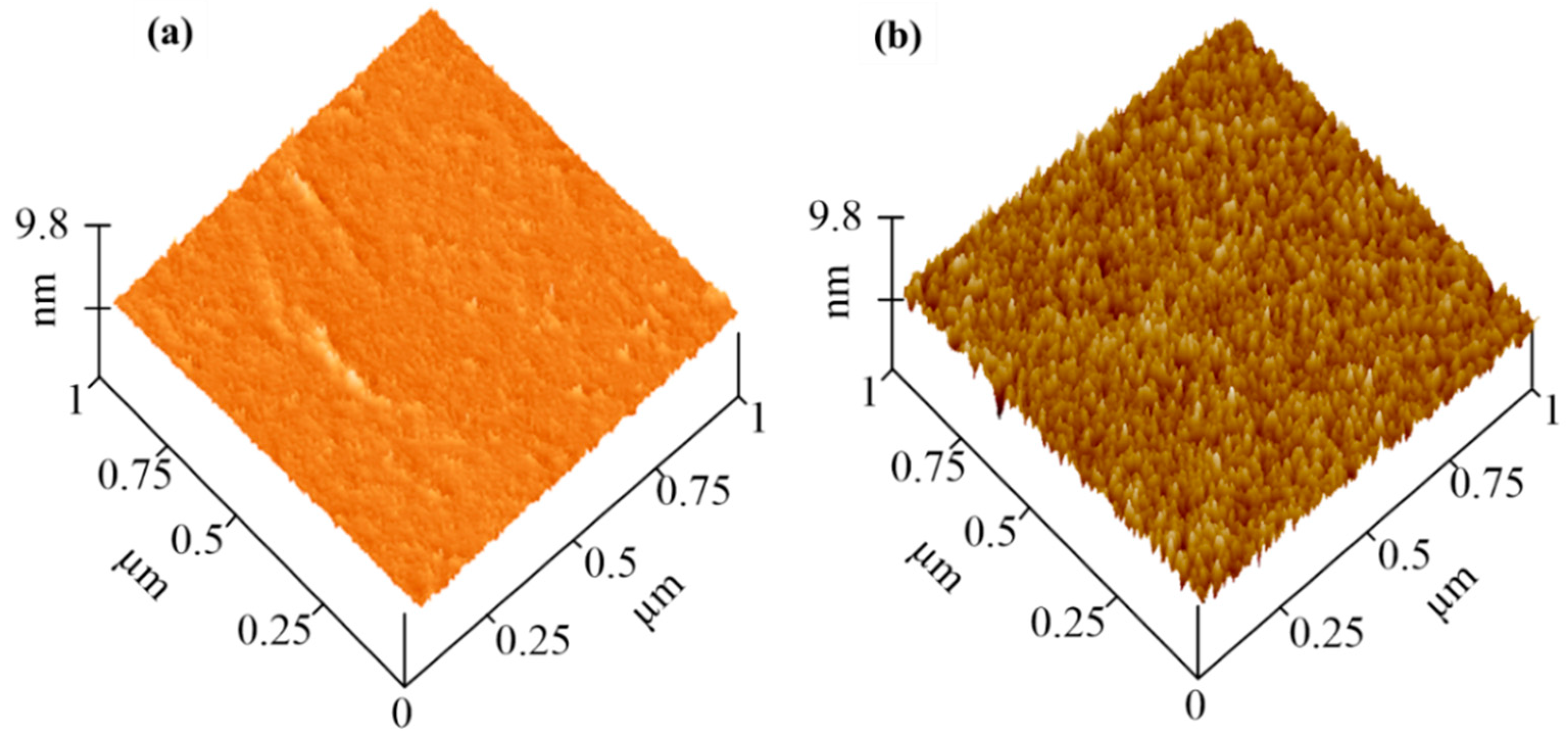

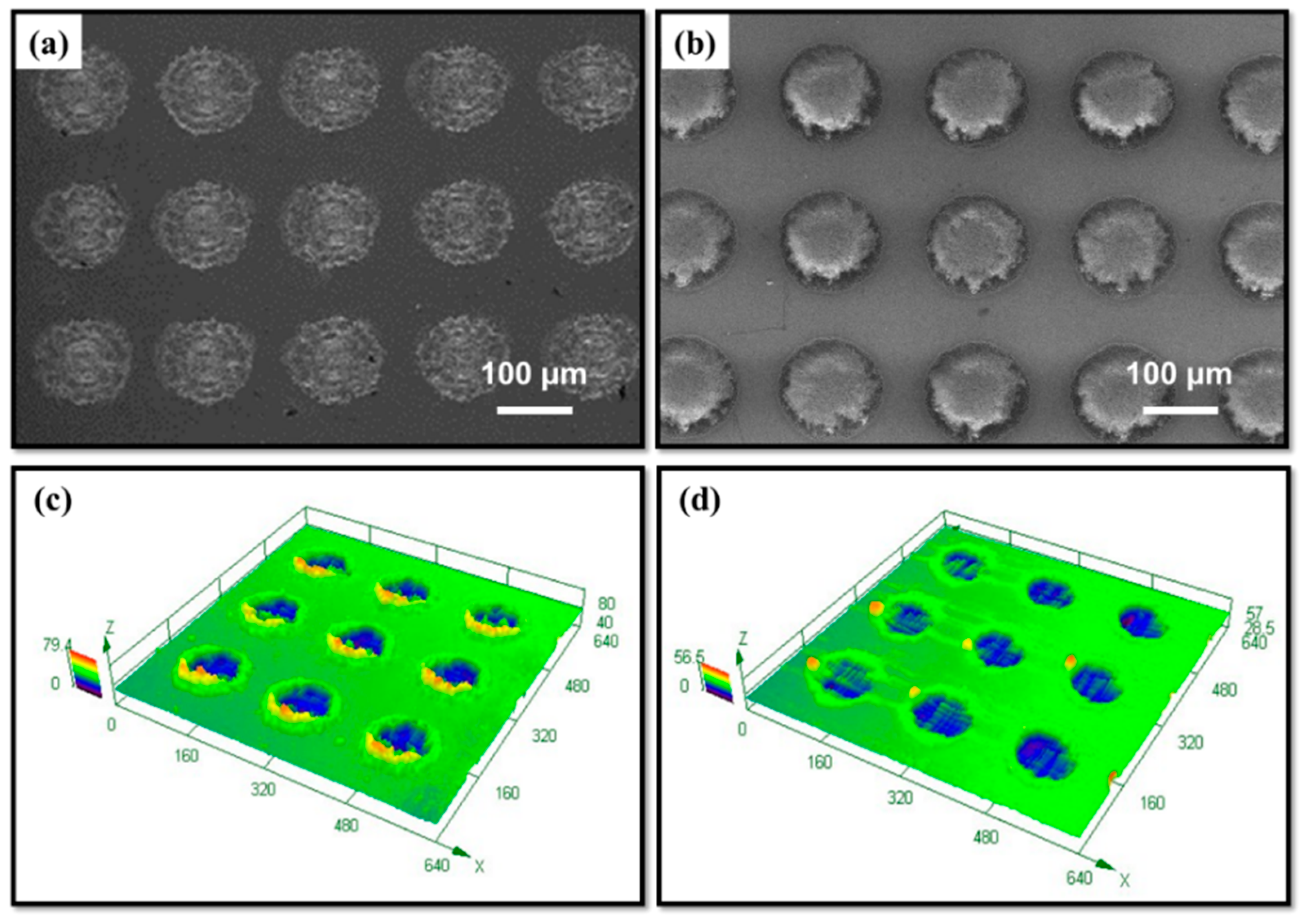

3.1. Surface Characterization

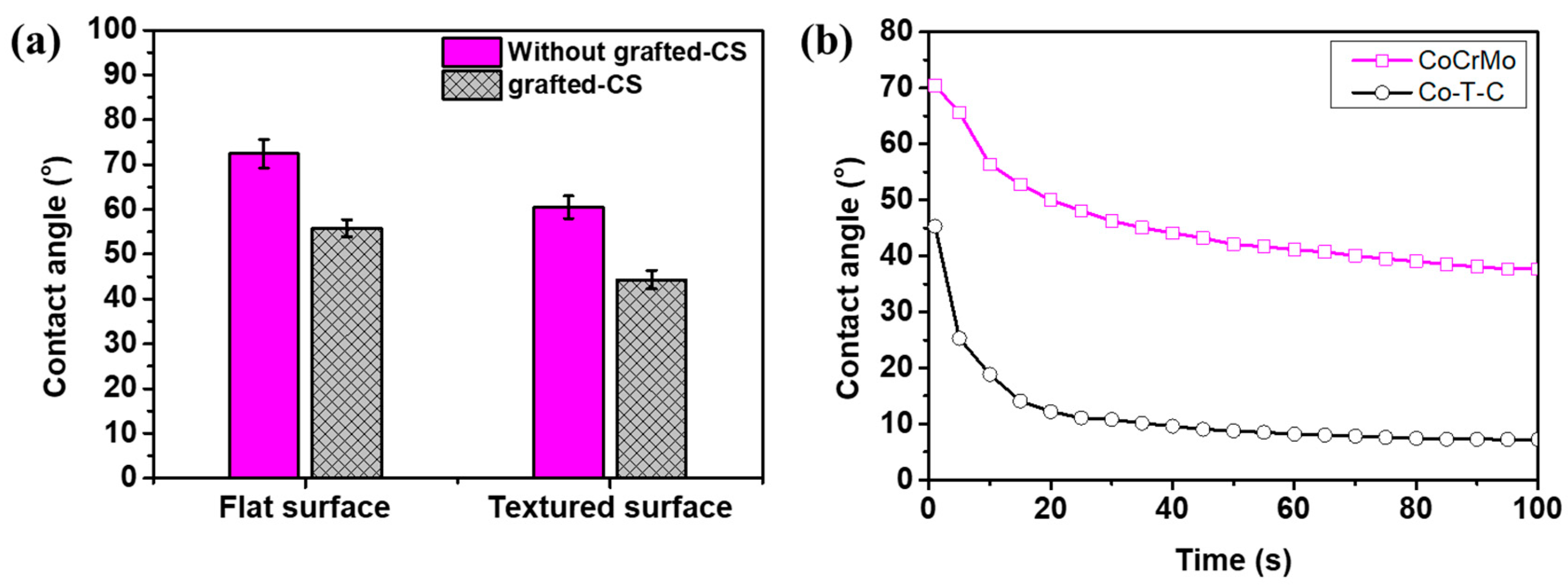

3.2. Surface Wettability

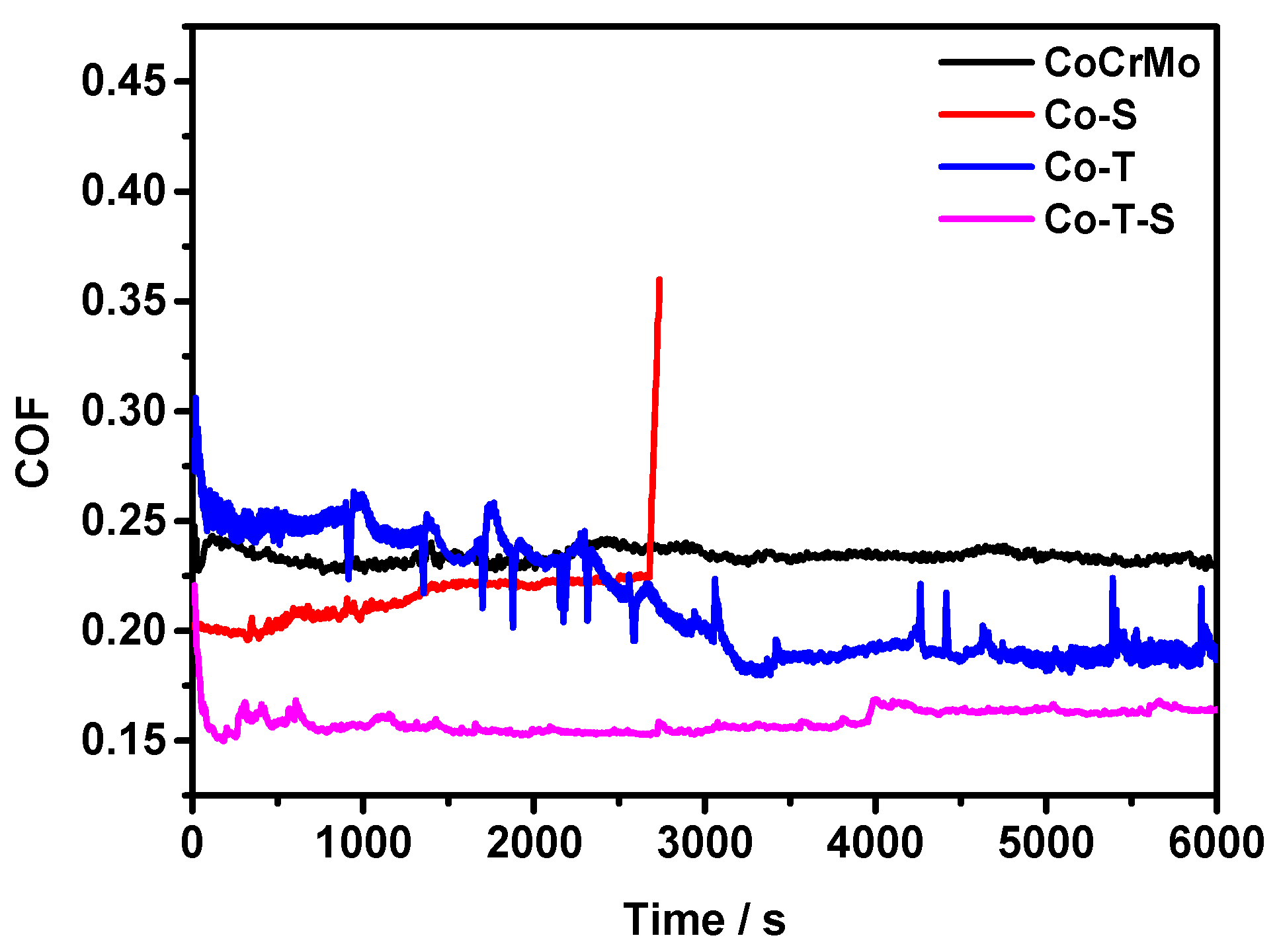

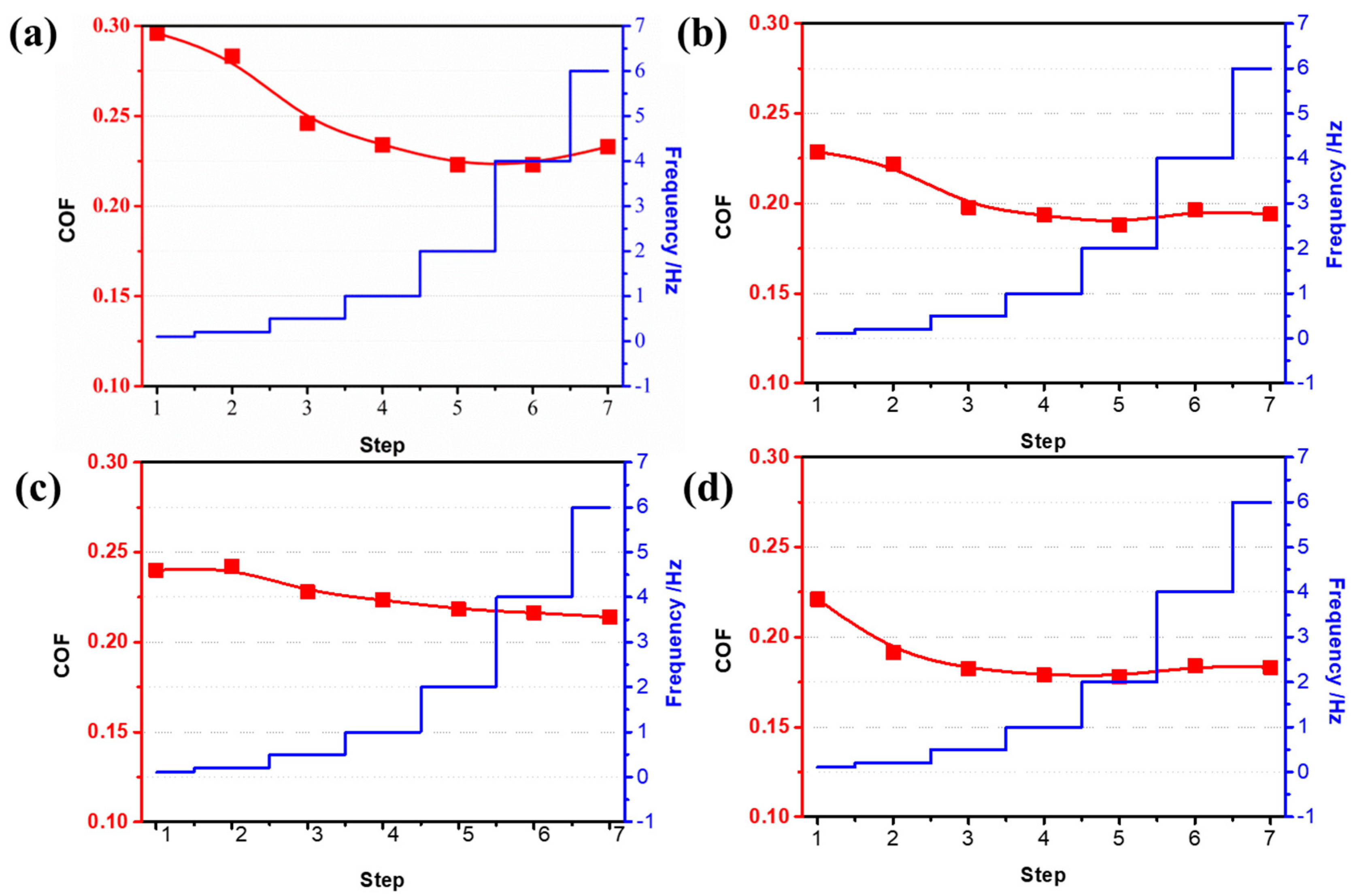

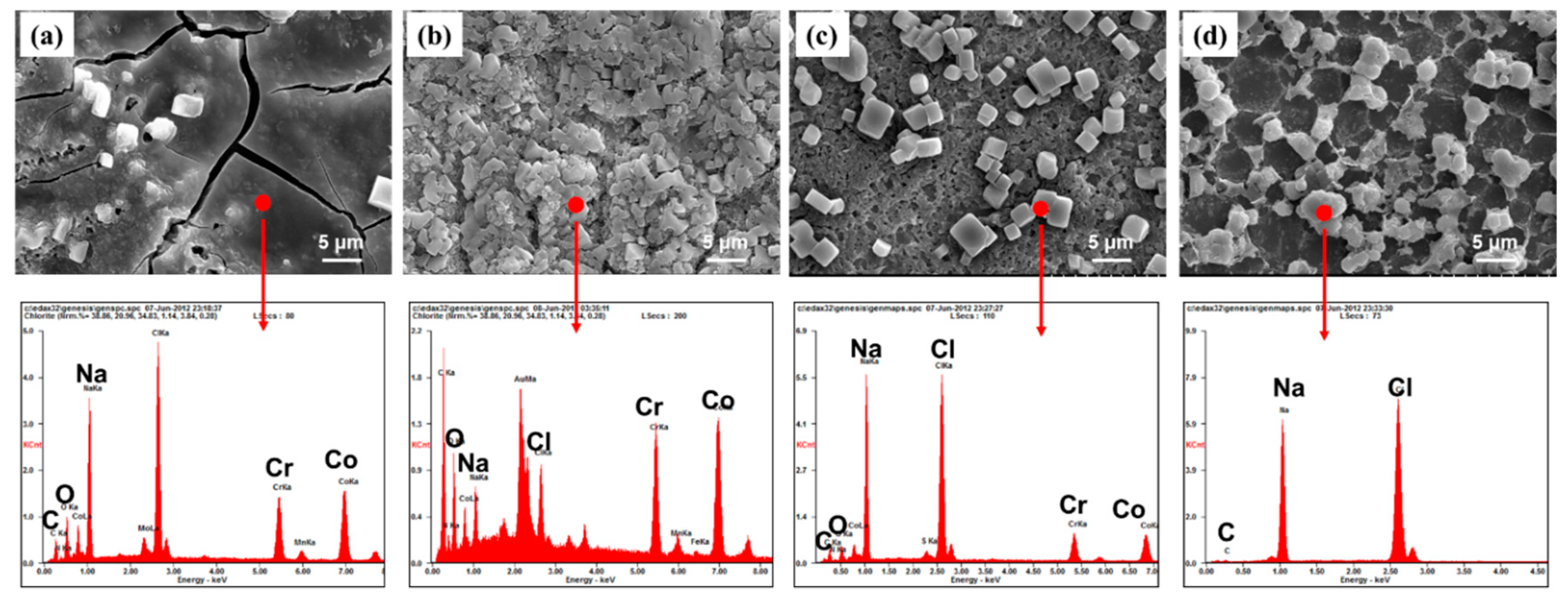

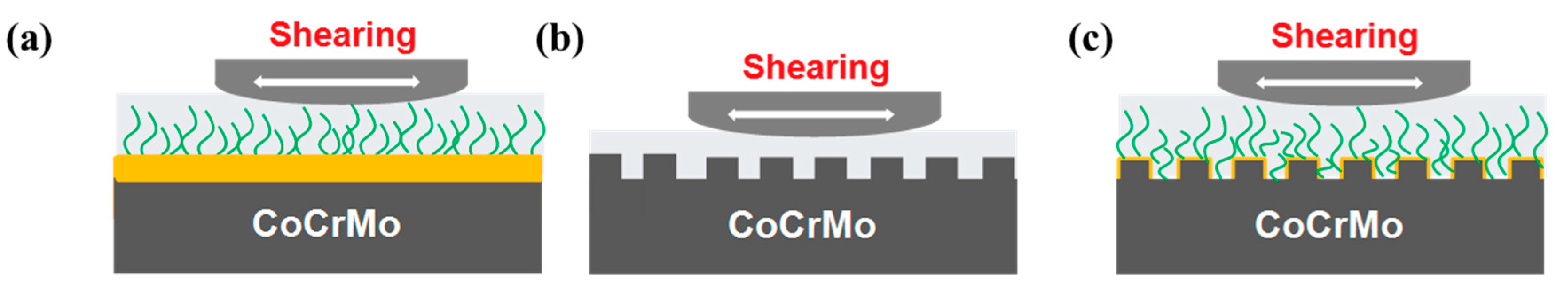

3.3. Tribological Behaviors

3.4. Biocompatibility

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Park, J.; Bauer, S.; Schlegel, K.A.; Neukam, F.W.; von der Mark, K.; Schmuki, P. TiO2 nanotube surfaces: 15 nm—An optimal length scale of surface topography for cell adhesion and differentiation. Small 2009, 5, 666–671. [Google Scholar] [CrossRef] [PubMed]

- Qin, L.G.; Feng, X.A.; Hafezi, M.; Zhang, Y.L.; Guo, J.D.; Dong, G.N.; Qin, Y.B. Investigating the tribological and biological performance of covalently grafted chitosan coatings on Co–Cr–Mo alloy. Tribol. Int. 2018, 127, 302–312. [Google Scholar] [CrossRef]

- Sato, Y.; Nomura, N.; Chiba, A. Effect of nitrogen content on microstructure of hot-pressed Co–Cr–Mo alloy compacts for biomedical applications. J. Jpn. Inst. Met. 2008, 72, 875–880. [Google Scholar] [CrossRef]

- Gil, R.A.; Munoz, A.I. Influence of the sliding velocity and the applied potential on the corrosion and wear behavior of HC CoCrMo biomedical alloy in simulated body fluids. J. Mech. Behav. Biomed. 2011, 4, 2090–2102. [Google Scholar]

- Zangeneh, S.; Lashgari, H.R.; Roshani, A. Microstructure and tribological characteristics of aged Co–28Cr–5Mo–0.3C alloy. Mater. Des. 2012, 37, 292–303. [Google Scholar] [CrossRef]

- Qin, L.G.; Lin, P.; Zhang, Y.L.; Dong, G.N.; Zeng, Q.F. Influence of surface wettability on the tribological properties of laser textured Co-Cr-Mo alloy in aqueous bovine serum albumin solution. Appl. Surf. Sci. 2013, 268, 79–86. [Google Scholar] [CrossRef]

- Qin, L.G.; Hafezi, M.; Yang, H.; Dong, G.N.; Zhang, Y.L. Constructing a Dual-Function Surface by Microcasting and Nanospraying for Efficient Drag Reduction and Potential Antifouling Capabilities. Micromachines 2019, 10, 490. [Google Scholar] [CrossRef]

- Heneghan, C.; Langton, D.; Thompson, M. Medical devices ongoing problems with metal-on-metal hip implants. Br. Med. J. 2012, 344, e1349. [Google Scholar] [CrossRef]

- Leslie, I.; Williams, S.; Isaac, G.; Hatto, P.; Ingham, E.; Fisher, J. Wear of surface-engineered metal-on-metal bearings for hip prostheses under adverse conditions with the head loading on the rim of the cup. Proc. Inst. Mech. Eng. H 2013, 227, 345–349. [Google Scholar] [CrossRef]

- Ching, H.A.; Choudhury, D.; Nine, M.J.; Abu Osman, N.A. Effects of surface coating on reducing friction and wear of orthopaedic implants. Sci. Technol. Adv. Mater. 2014, 15, 014402. [Google Scholar] [CrossRef]

- Ghosh, S.; Abanteriba, S. Status of surface modification techniques for artificial hip implants. Sci. Technol. Adv. Mater. 2016, 17, 715–735. [Google Scholar] [CrossRef] [PubMed]

- Langhorn, J.; Borjali, A.; Hippensteel, E.; Nelson, W.; Raeymaekers, B. Microtextured CoCrMo alloy for use in metal-on-polyethylene prosthetic joint bearings: Multi-directional wear and corrosion measurements. Tribol. Int. 2018, 124, 178–183. [Google Scholar] [CrossRef] [PubMed]

- Chan, C.W.; Smith, G.C.; Lee, S. A preliminary study to enhance the tribological performance of CoCrMo alloy by fibre laser remelting for articular joint implant applications. Lubricants 2018, 6, 24. [Google Scholar] [CrossRef]

- Voevodin, A.A.; Zabinski, J.S. Laser surface texturing for adaptive solid lubrication. Wear 2006, 261, 1285–1292. [Google Scholar] [CrossRef]

- Bush, J.R.; Nayak, B.K.; Nair, L.S.; Gupta, M.C.; Laurencin, C.T. Improved bio-implant using ultrafast laser induced self-assembled nanotexture in titanium. J. Biomed. Mater. Res. B 2011, 97B, 299–305. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.D.; Liu, X.Y.; Fangteng, J.Z.; Wang, S.L.; Fang, L.P.; Shen, H.Z.; Xiang, S.Y.; Sun, H.C.; Yang, B. Bioinspired polyethylene terephthalate nanocone arrays with underwater superoleophobicity and anti-bioadhesion properties. Nanoscale 2014, 6, 13845–13853. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.S.; Zhang, Q.A.; Li, T.; Li, Z.W. Superoleophobic and superhydrophobic surfaces from microtextured ZnO-based surfaces on si substrate. Key Eng. Mater. 2010, 434–435, 538–541. [Google Scholar] [CrossRef]

- Zhang, R.; Ma, S.H.; Wei, Q.B.; Ye, Q.; Yu, B.; van der Gucht, J.; Zhou, F. The weak interaction of surfactants with polymer brushes and its impact on lubricating behavior. Macromolecules 2015, 48, 6186–6196. [Google Scholar] [CrossRef]

- Yu, J.; Jackson, N.E.; Xu, X.; Morgenstern, Y.; Kaufman, Y.; Ruths, M.; de Pablo, J.J.; Tirrell, M. Multivalent counterions diminish the lubricity of polyelectrolyte brushes. Science 2018, 360, 1434–1438. [Google Scholar] [CrossRef]

- Huang, N.P.; Voros, J.; De Paul, S.M.; Textor, M.; Spencer, N.D. Biotin-derivatized poly(l-lysine)-g-poly(ethylene glycol): A novel polymeric interface for bioaffinity sensing. Langmuir 2002, 18, 220–230. [Google Scholar] [CrossRef]

- Marie, R.; Beech, J.P.; Voros, J.; Tegenfeldt, J.O.; Hook, F. Use of PLL-g-PEG in micro-fluidic devices for localizing selective and specific protein binding. Langmuir 2006, 22, 10103–10108. [Google Scholar] [CrossRef] [PubMed]

- Ramakrishna, S.N.; Morgese, G.; Zenobi-Wong, M.; Benetti, E.M. Comblike polymers with topologically different side chains for surface modification: Assembly process and interfacial physicochemical properties. Macromolecules 2019, 52, 1632–1641. [Google Scholar] [CrossRef]

- Xiao, S.W.; Ren, B.P.; Huang, L.; Shen, M.X.; Zhang, Y.X.; Zhong, M.Q.; Yang, J.T.; Zheng, J. Salt-responsive zwitterionic polymer brushes with anti-polyelectrolyte property. Curr. Opin. Chem. Eng. 2018, 19, 86–93. [Google Scholar] [CrossRef]

- Da Silva, M.C.; da Silva, H.N.; Cruz, R.D.A.L.; Amoah, S.K.S.; Silva, S.M.D.; Fook, M.V.L. N-acetyl-D-glucosamine-loaded chitosan filaments biodegradable and biocompatible for use as absorbable surgical suture materials. Materials 2019, 12, 1807. [Google Scholar] [CrossRef] [PubMed]

- Qin, L.G.; Dong, H.H.; Mu, Z.Q.; Zhang, Y.L.; Dong, G.G. Preparation and bioactive properties of chitosan and casein phosphopeptides composite coatings for orthopedic implants. Carbohydr. Polym. 2015, 133, 236–244. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.C.; Luo, J.Q.; Lv, Y.; Shen, P.; Xu, Z.K. Surface engineering of polymer membranes via mussel-inspired chemistry. J. Membr. Sci. 2015, 483, 42–59. [Google Scholar] [CrossRef]

- Perikamana, S.K.M.; Shin, Y.M.; Lee, J.K.; Lee, Y.B.; Heo, Y.; Ahmad, T.; Park, S.Y.; Shin, J.; Park, K.M.; Jung, H.S.; et al. Graded functionalization of biomaterial surfaces using mussel-inspired adhesive coating of polydopamine. Colloid Surf. B 2017, 159, 546–556. [Google Scholar] [CrossRef] [PubMed]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372, 21–41. [Google Scholar] [CrossRef]

- Qin, L.; Wu, H.; Guo, J.; Feng, X.; Dong, G.; Shao, J.; Zeng, Q.; Zhang, Y.; Qin, Y. Fabricating hierarchical micro and nano structures on implantable Co–Cr–Mo alloy for tissue engineering by one-step laser ablation. Colloids Surf. B Biointerfaces 2018, 161, 628–635. [Google Scholar] [CrossRef]

- Wei, Q.B.; Pei, X.W.; Hao, J.Y.; Cai, M.R.; Zhou, F.; Liu, W.M. Surface modification of diamond-like carbon film with polymer brushes using a bio-inspired catechol anchor for excellent biological lubrication. Adv. Mater. Interfaces 2014, 1, 1400035. [Google Scholar] [CrossRef]

- Murakami, D.; Jinnai, H.; Takahara, A. Wetting transition from the cassie-baxter state to the wenzel state on textured polymer surfaces. Langmuir 2014, 30, 2061–2067. [Google Scholar] [CrossRef] [PubMed]

- Vladescu, S.C.; Olver, A.V.; Pegg, I.G.; Reddyhoff, T. Combined friction and wear reduction in a reciprocating contact through laser surface texturing. Wear 2016, 358–359, 51–61. [Google Scholar] [CrossRef]

- Jahn, S.; Klein, J. Hydration lubrication: The macromolecular domain. Macromolecules 2015, 48, 5059–5075. [Google Scholar] [CrossRef]

- Krupka, I.; Sperka, P.; Hartl, M. Effect of surface roughness on lubricant film breakdown and transition from EHL to mixed lubrication. Tribol. Int. 2016, 100, 116–125. [Google Scholar] [CrossRef]

- Ramakrishna, S.N.; Espinosa-Marzal, R.M.; Naik, V.V.; Nalam, P.C.; Spencer, N.D. Adhesion and friction properties of polymer brushes on rough surfaces: A gradient approach. Langmuir 2013, 29, 15251–15259. [Google Scholar] [CrossRef] [PubMed]

- Ren, S.M.; Huang, J.X.; Cui, M.J.; Pu, J.B.; Wang, L.P. Improved adaptability of polyaryl-ether-ether-ketone with texture pattern and graphite-like carbon film for bio-tribological applications. Appl. Surf. Sci. 2017, 400, 24–37. [Google Scholar] [CrossRef]

- Raviv, U.; Giasson, S.; Kampf, N.; Gohy, J.F.; Jerome, R.; Klein, J. Normal and frictional forces between surfaces bearing polyelectrolyte brushes. Langmuir 2008, 24, 8678–8687. [Google Scholar] [CrossRef] [PubMed]

- Kampf, N.; Raviv, U.; Klein, J. Normal and shear forces between adsorbed and gelled layers of chitosan, a naturally occurring cationic polyelectrolyte. Macromolecules 2004, 37, 1134–1142. [Google Scholar] [CrossRef]

- Iuster, N.; Tairy, O.; Driver, M.J.; Armes, S.P.; Klein, J. Cross-linking highly lubricious phosphocholinated polymer brushes: Effect on surface interactions and frictional behavior. Macromolecules 2017, 50, 7361–7371. [Google Scholar] [CrossRef]

- Dyskova, T.; Gallo, J.; Kriegova, E. The role of the chemokine system in tissue response to prosthetic by-products leading to periprosthetic osteolysis and aseptic loosening. Front. Immunol. 2017, 8, 1026. [Google Scholar] [CrossRef] [PubMed]

- Yiannakou, C.; Simitzi, C.; Manousaki, A.; Fotakis, C.; Ranella, A.; Stratakis, E. Cell patterning via laser micro/nano structured silicon surfaces. Biofabrication 2017, 9, 025024. [Google Scholar] [CrossRef] [PubMed]

- Simitzi, C.; Ranella, A.; Stratakis, E. Controlling the morphology and outgrowth of nerve and neuroglial cells: The effect of surface topography. Acta Biomater. 2017, 51, 21–52. [Google Scholar] [CrossRef] [PubMed]

- Luhmann, T.; Hall, H. Cell guidance by 3d-gradients in hydrogel matrices: Importance for biomedical applications. Materials 2009, 2, 1058–1083. [Google Scholar] [CrossRef]

- Ghosh, K.; Ingber, D.E. Micromechanical control of cell and tissue development: Implications for tissue engineering. Adv. Drug Deliv. Rev. 2007, 59, 1306–1318. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.N.; Xie, Z.; Gan, T.S.; Wang, Y.; Zhang, G.Z.; Mirkin, C.A.; Zheng, Z.J. Biomimicking nano-micro binary polymer brushes for smart cell orientation and adhesion control. Small 2016, 12, 3400–3406. [Google Scholar] [CrossRef]

- Lotz, E.M.; Olivares-Navarrete, R.; Hyzy, S.L.; Berner, S.; Schwartz, Z.; Boyan, B.D. Comparable responses of osteoblast lineage cells to microstructured hydrophilic titanium-zirconium and microstructured hydrophilic titanium. Clin. Oral Implant Res. 2017, 28, e51–e59. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, L.; Sun, H.; Hafezi, M.; Zhang, Y. Polydopamine-Assisted Immobilization of Chitosan Brushes on a Textured CoCrMo Alloy to Improve its Tribology and Biocompatibility. Materials 2019, 12, 3014. https://doi.org/10.3390/ma12183014

Qin L, Sun H, Hafezi M, Zhang Y. Polydopamine-Assisted Immobilization of Chitosan Brushes on a Textured CoCrMo Alloy to Improve its Tribology and Biocompatibility. Materials. 2019; 12(18):3014. https://doi.org/10.3390/ma12183014

Chicago/Turabian StyleQin, Liguo, Hongjiang Sun, Mahshid Hafezi, and Yali Zhang. 2019. "Polydopamine-Assisted Immobilization of Chitosan Brushes on a Textured CoCrMo Alloy to Improve its Tribology and Biocompatibility" Materials 12, no. 18: 3014. https://doi.org/10.3390/ma12183014

APA StyleQin, L., Sun, H., Hafezi, M., & Zhang, Y. (2019). Polydopamine-Assisted Immobilization of Chitosan Brushes on a Textured CoCrMo Alloy to Improve its Tribology and Biocompatibility. Materials, 12(18), 3014. https://doi.org/10.3390/ma12183014