Behavior of an Advanced Bolted Shear Connector in Prefabricated Steel-Concrete Composite Beams

Abstract

1. Introduction

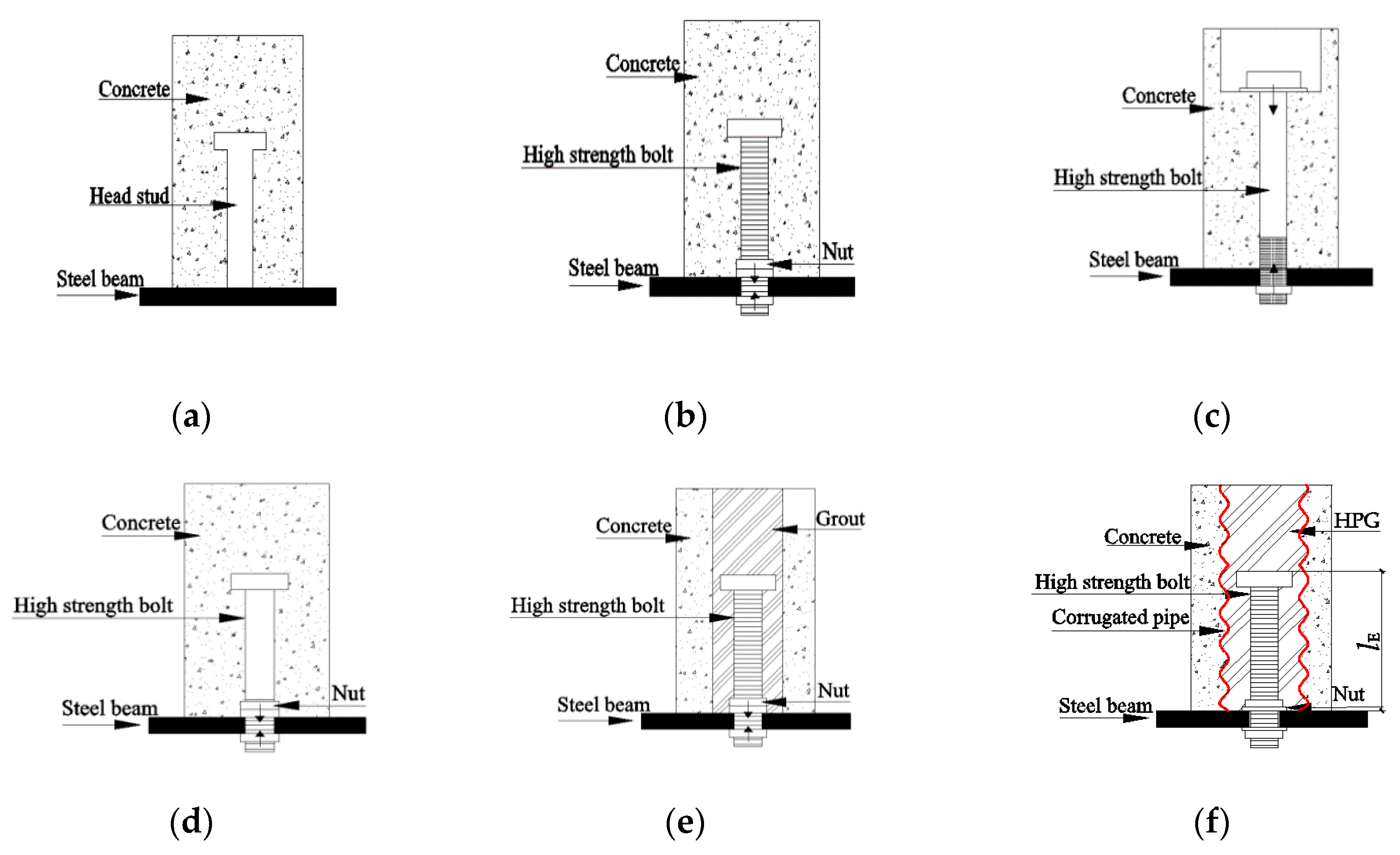

2. Advanced Bolt Shear Connectors

3. Experimental Research

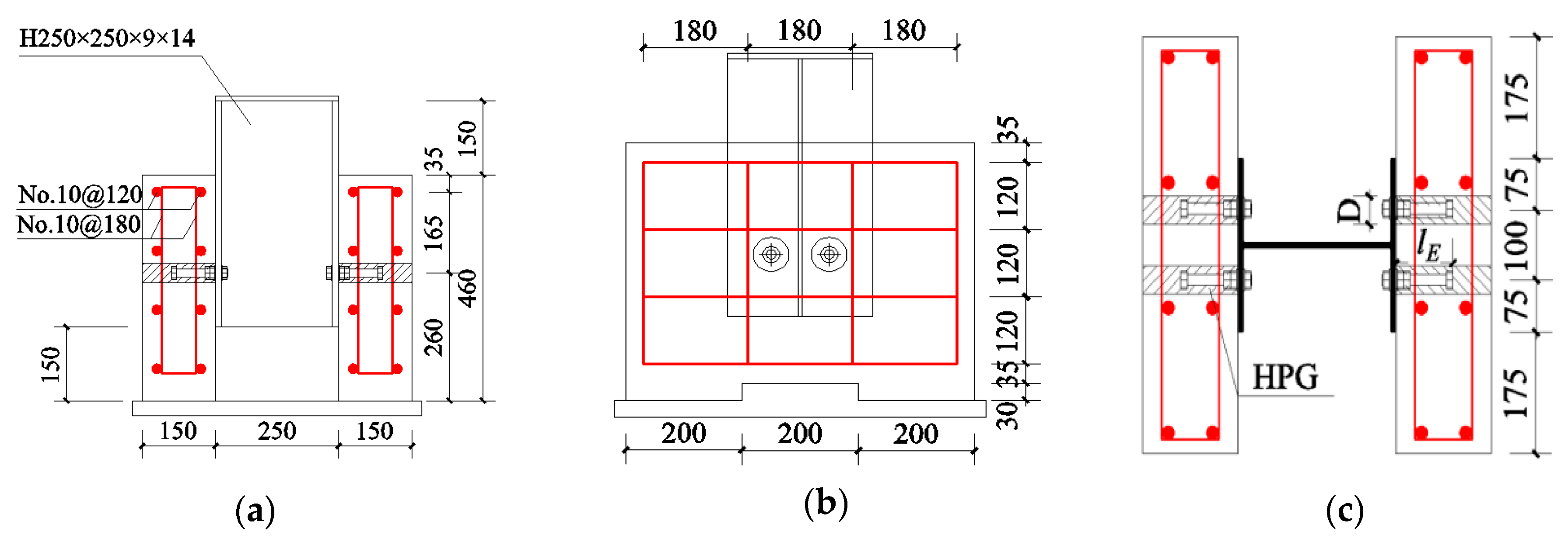

3.1. Test Specimens

3.2. Materials

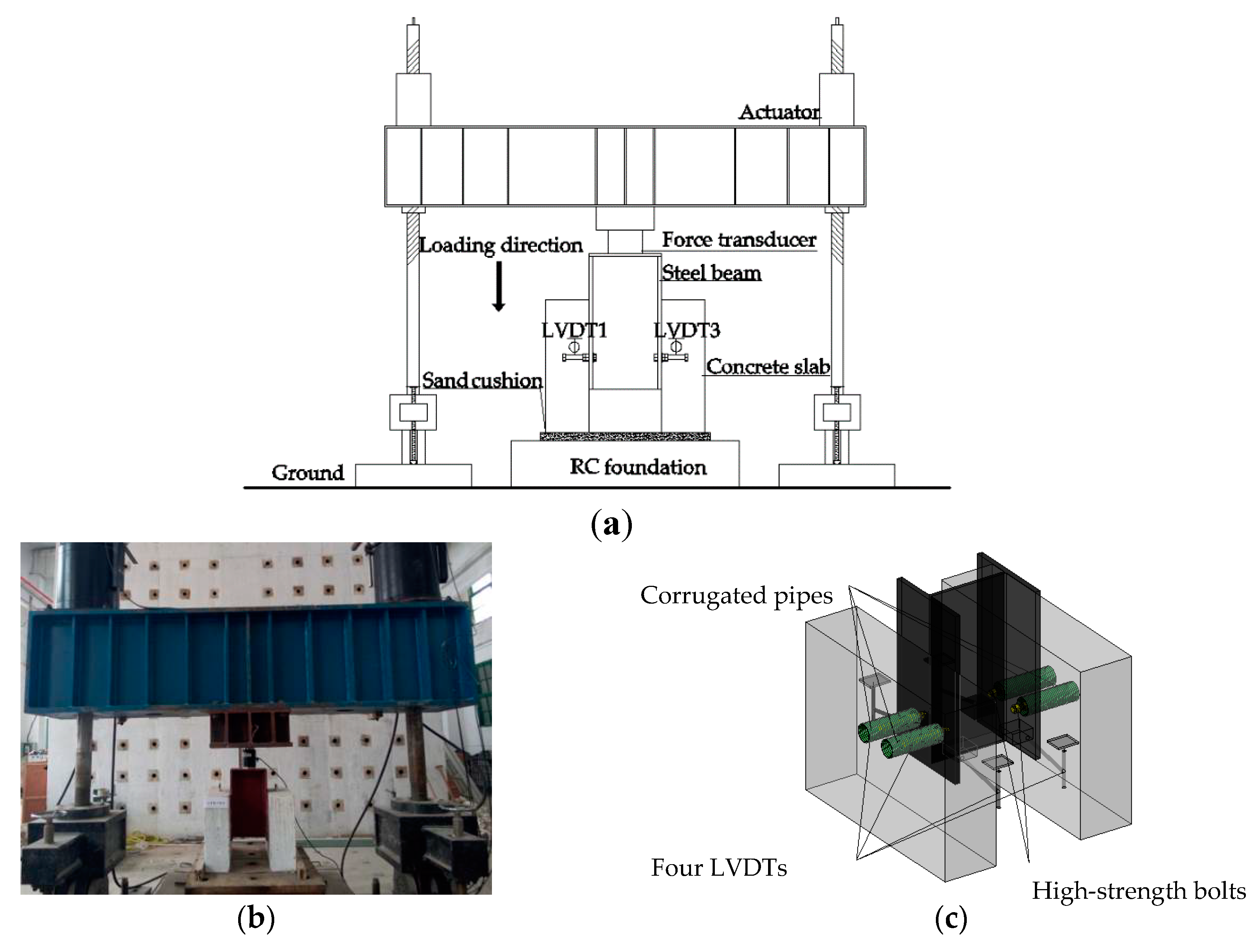

3.3. Experimental Setup and Loading Procedure

4. Results and Discussion

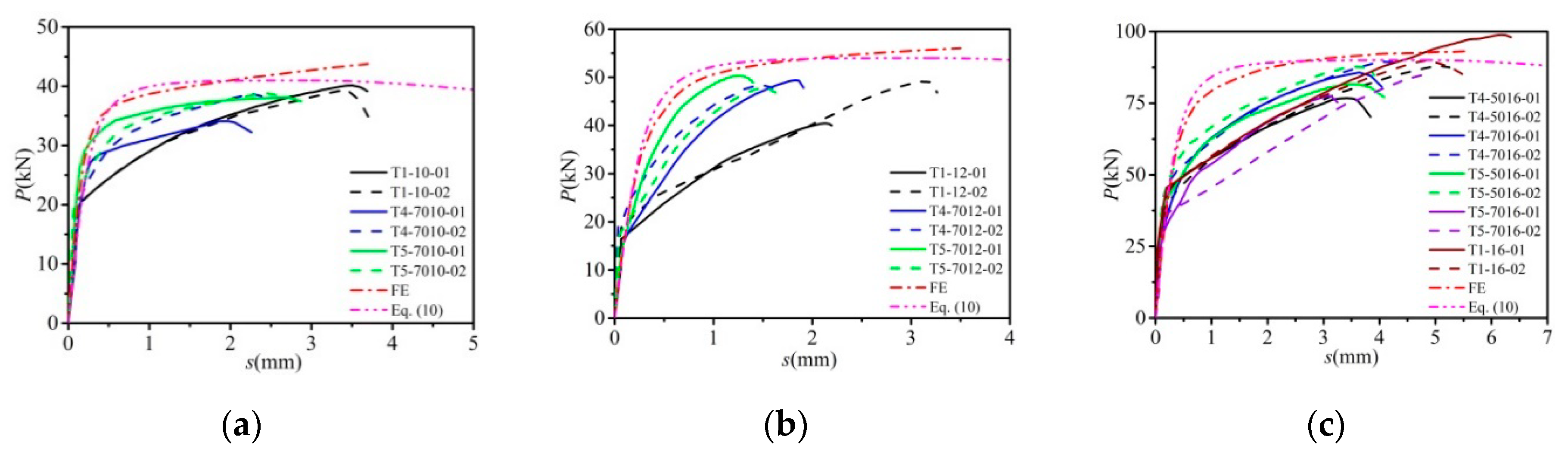

4.1. Load-Displacement Relationship

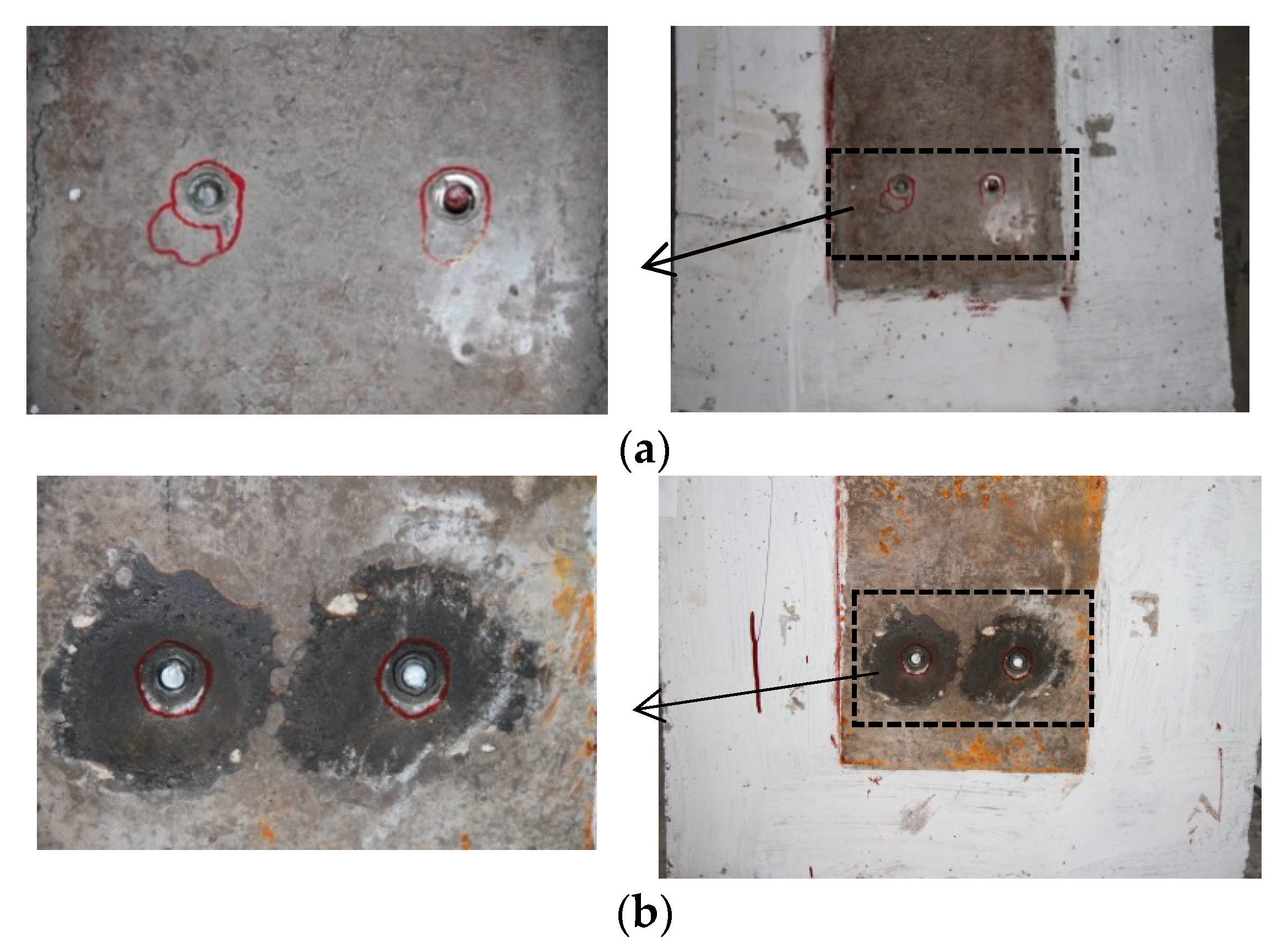

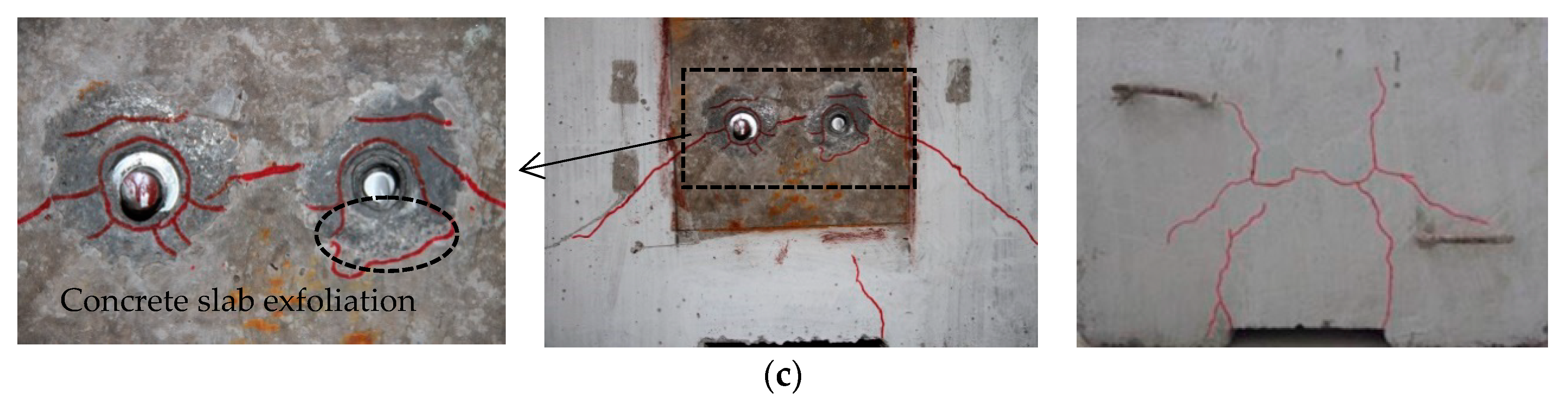

4.2. Failure Modes

4.3. Experimental Results Analysis

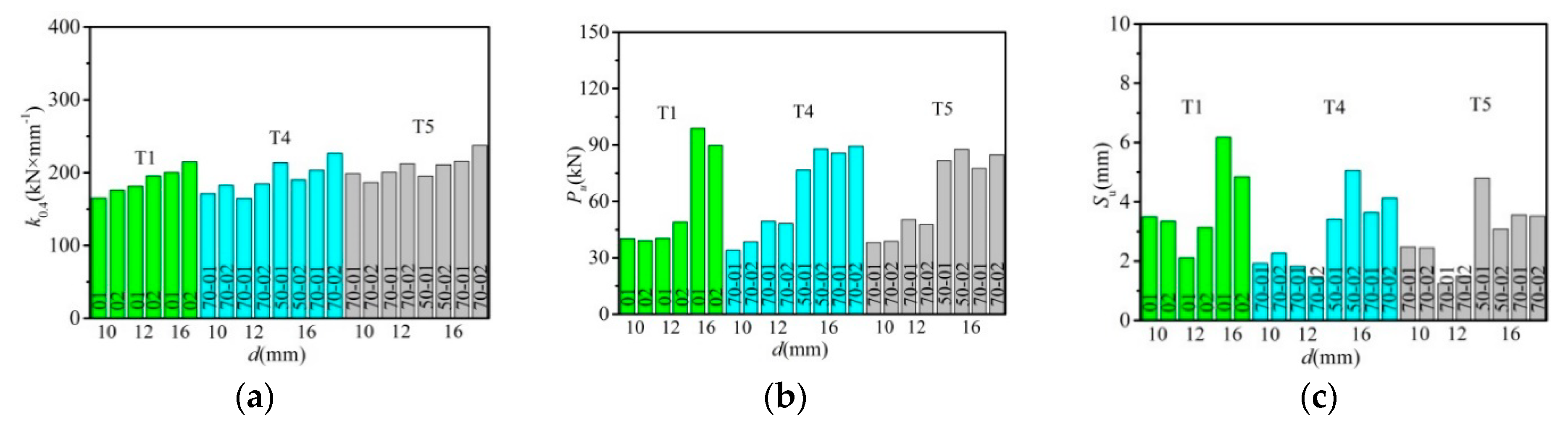

4.3.1. Influence of Bolt Diameter

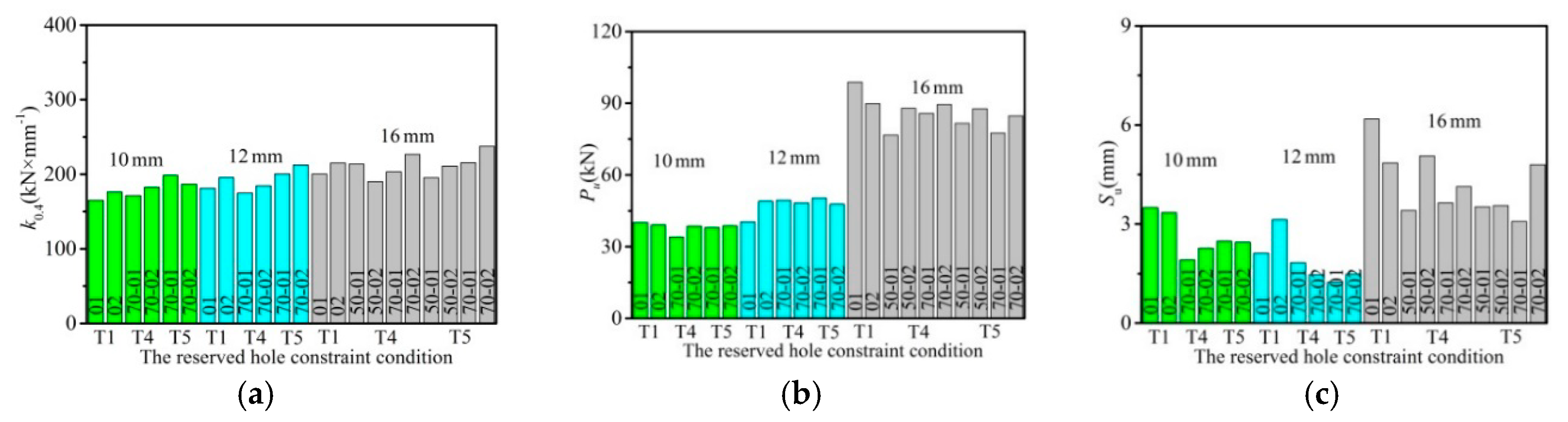

4.3.2. Influence of the Reserved Hole Constraint Condition

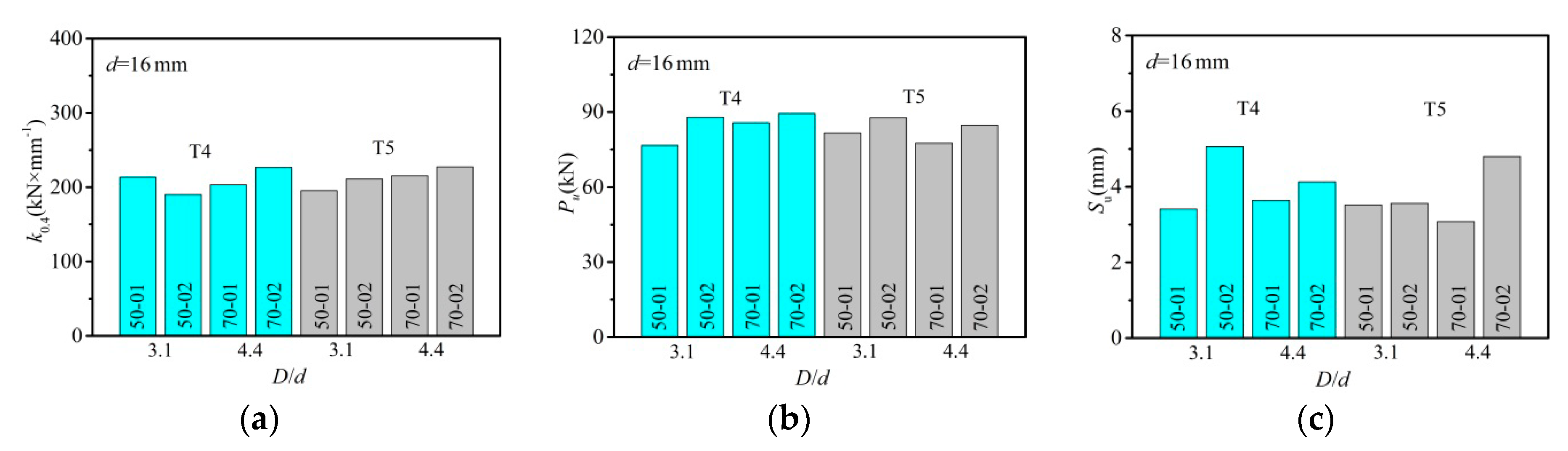

4.3.3. Influence of Hole Diameter Ratio

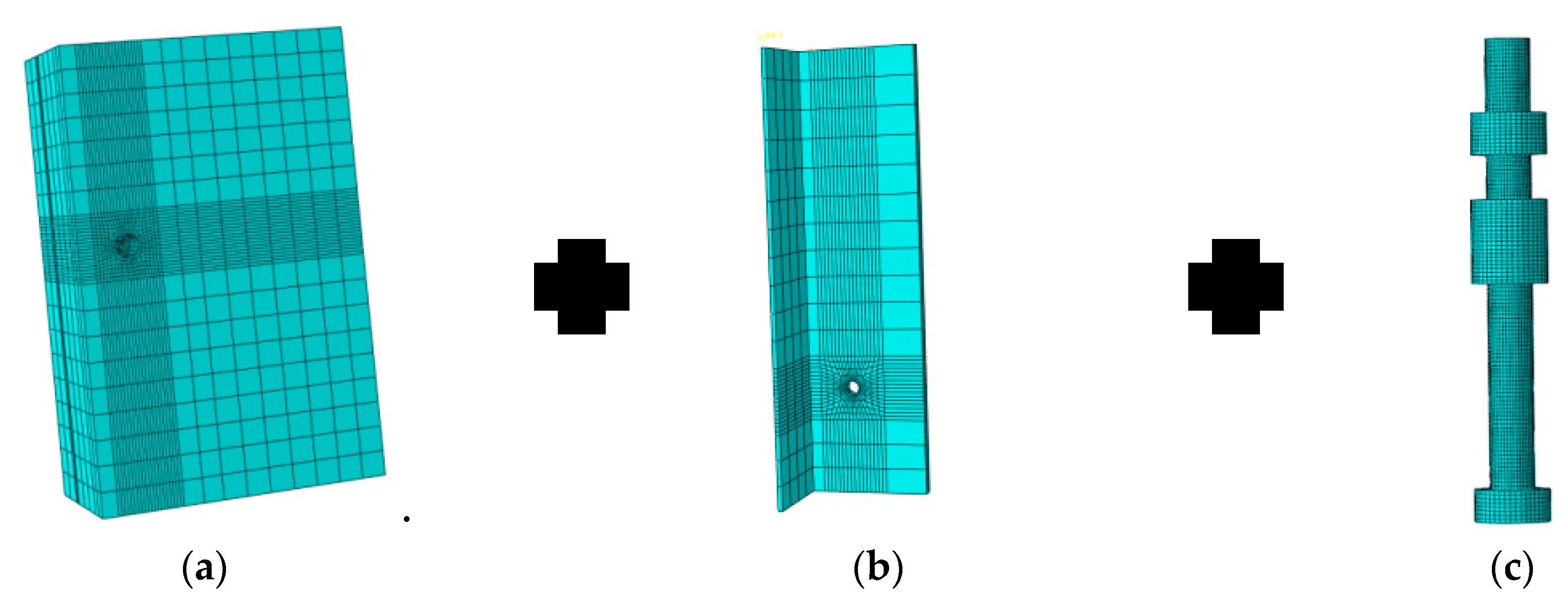

5. Finite Element Model

5.1. General

5.2. Material Models

5.3. Boundary Conditions

5.4. Interaction and Constraint Conditions

5.5. Load Application and Analysis Steps

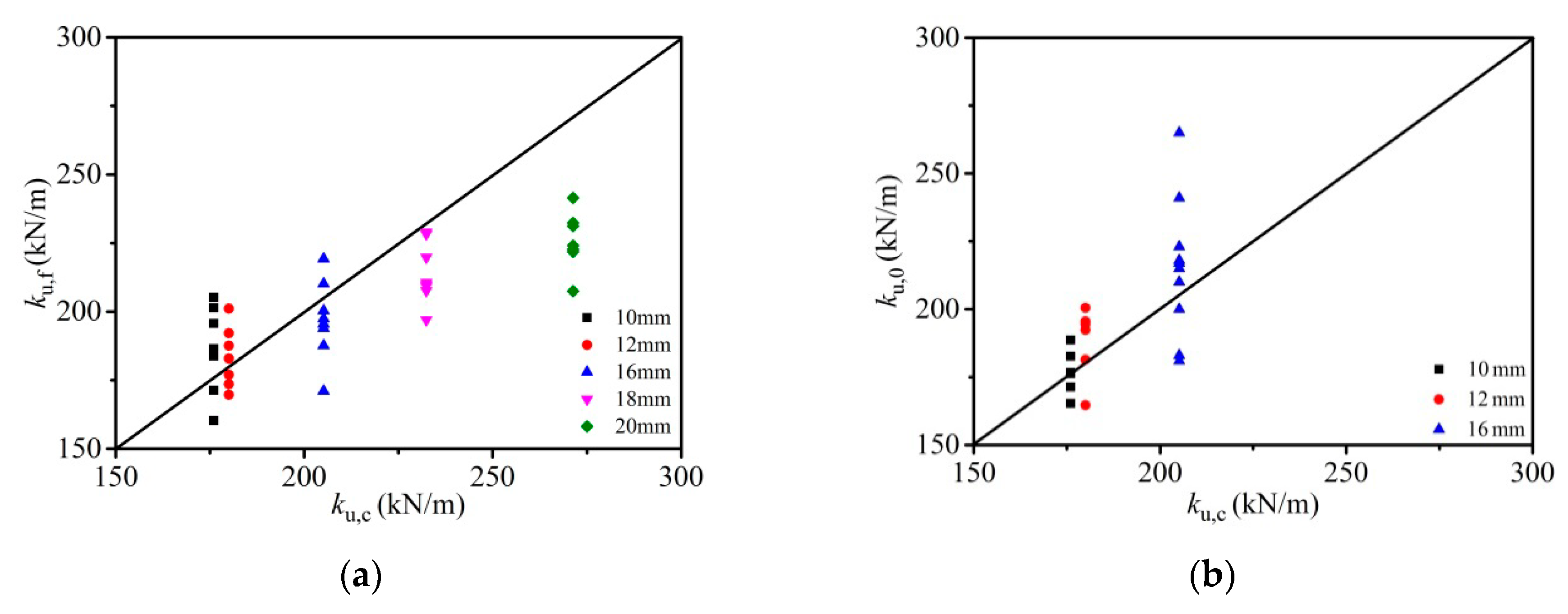

5.6. Comparison and Discussion of Results

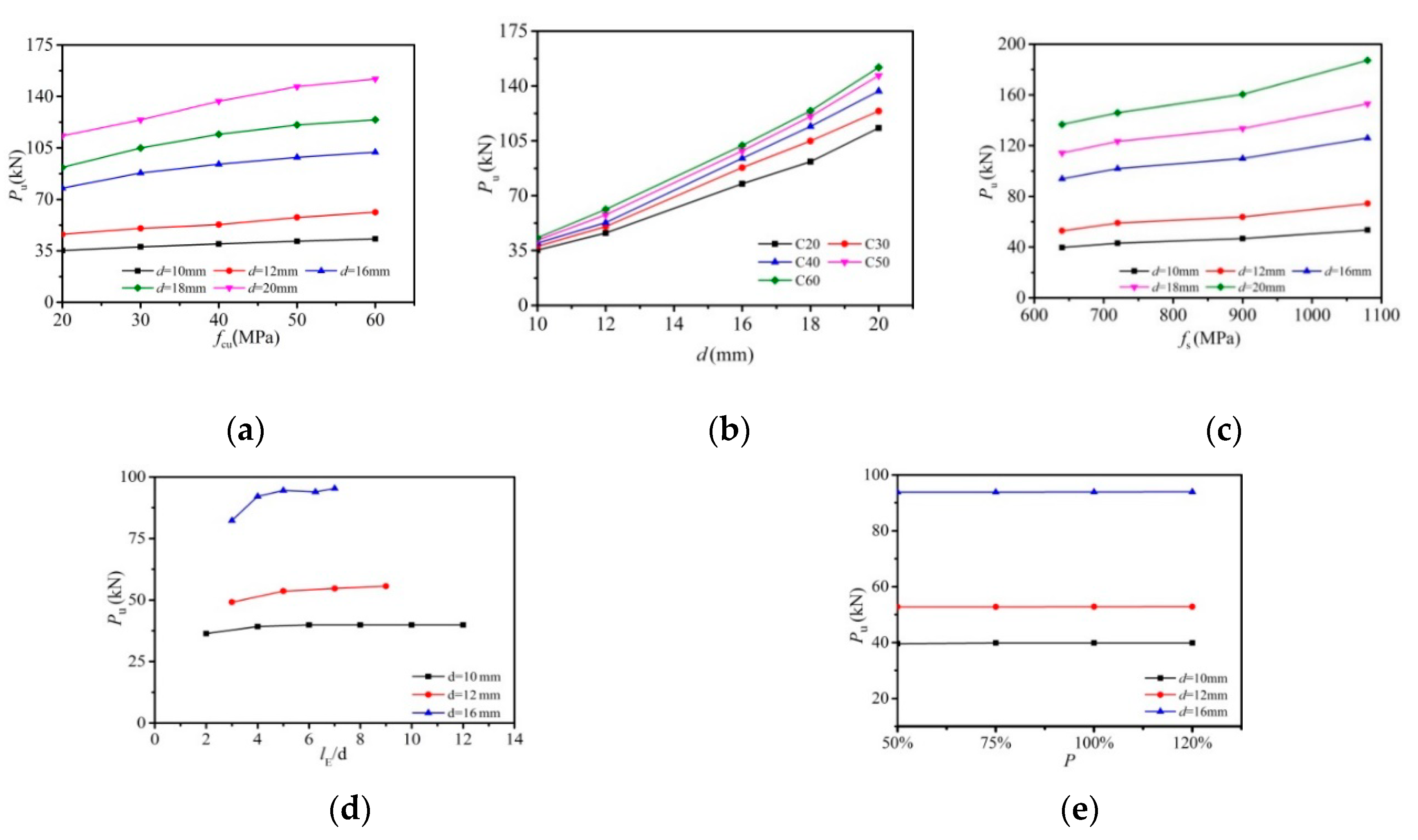

5.7. Parametric Study

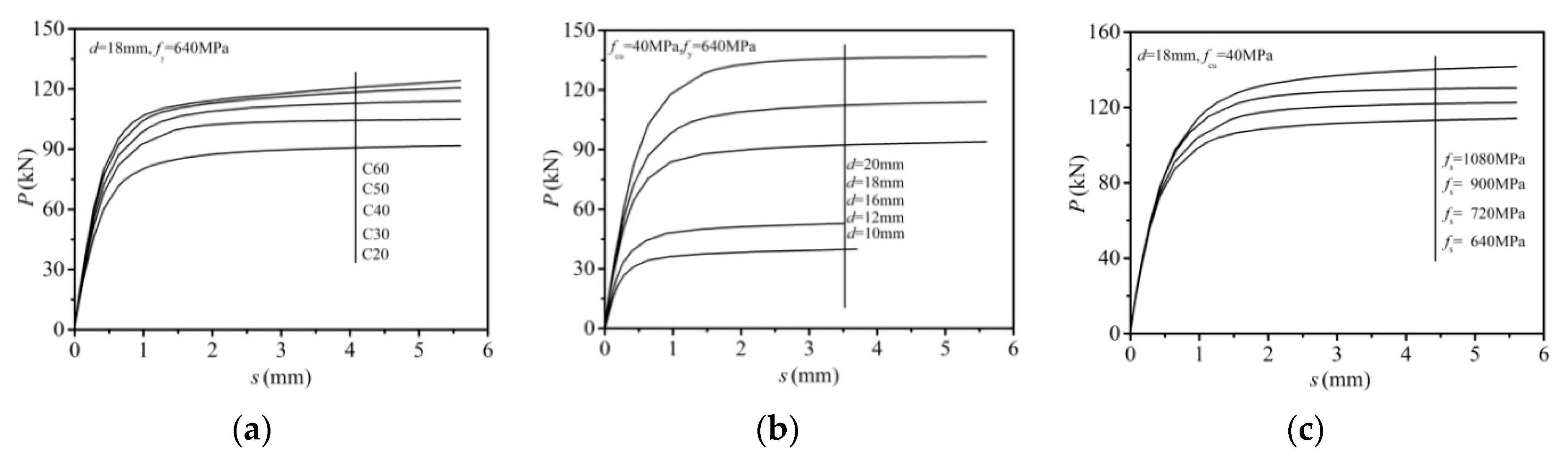

5.7.1. Effect of Bolt Diameter and Concrete Strength

5.7.2. Effect of Bolt Yield Strength

5.7.3. Effect of Length-to-Diameter Ratio of the Bolt

5.7.4. Effect of Bolt Pretension

5.7.5. Summary

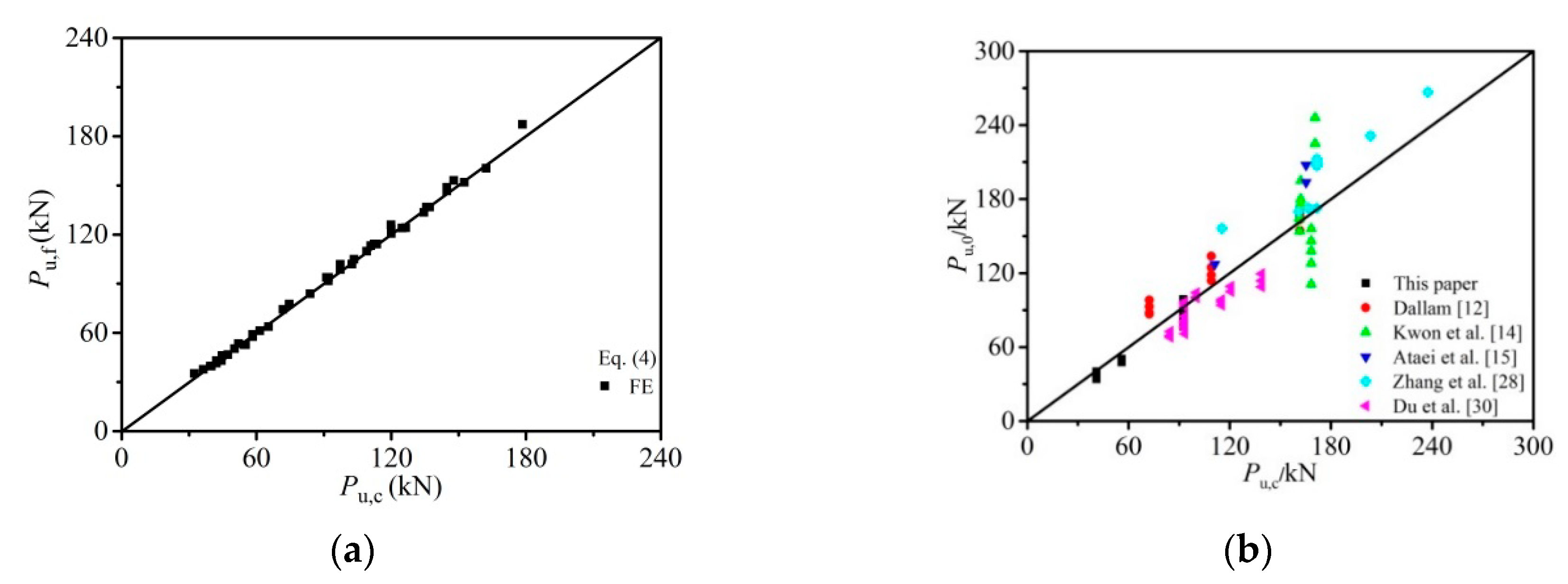

6. Ultimate Shear Bearing Capacity Calculation

6.1. Establish Formula

6.2. Comparison with Different Standard Provisions

7. Load-Slip Relationship Calculation

Formula Development

8. Conclusions

- The primary failure mode of the push-out tests was bolt failure. Additionally, the process of failure and crack developing was affected by the bolt diameter and the reserved hole constraint condition. The inhibition of crack developments in a concrete slab can be achieved by using precast concrete slab with corrugated pipes.

- Experimental results demonstrated that bolt connectors with corrugated pipe had higher shear stiffness than normal reserved hole types and cast-in-place slab specimens. The ultimate shear capacity of the bolt connector was mainly influenced by the bolt diameter.

- The developed numerical model produced satisfactory predictions of the behavior and ultimate shear capacity for the push-out tests on the bolted shear connector. The high strength bolt pretension presented little correlation to the shear capacity on the basis of FE simulations.

- Based on the experimental data and numerical results, a new formula was proposed for calculation of the shear capacity of bolted shear connectors. The accuracy was discussed through the comparison to design code in GB 50017-2017, AISC, EC4, and the experimental and numerical data in this study and extracted from relative references. The proposed calculation method exhibited a better prediction to the experimental results than other formulas. By modifying the parameters, the load-slip curve of welded stud shear connectors proposed by Ding, can describe the load-slip relationship of bolted shear connectors, especially for T5 specimens, reasonably well.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| lE | depth of bolt shank inside concrete | Pu | ultimate shear strength |

| d | high-strength bolt diameter | Pu,m | the mean value of ultimate load |

| D | precast concrete slab hole | Su | maximum slip |

| fcu | compressive cube strength of concrete | Su,m | the mean value of maximum slip |

| fc | compressive strength of concrete | As | gross cross-sectional area of bolt |

| fc’ | compressive cylinder strength of concrete | Asc | effective cross-sectional area of bolt |

| fy | yield strength of steel | α | aspect ratio factor in Eurocode 4 |

| fs | yield strength of bolt | γ | yield ratio of the tensile strength to the yield strength of bolt |

| fu | ultimate strength of steel | γv | partial factor in Eurocode 4 |

| fbtu | ultimate strength of high-strength bolt | Pu,f | ultimate shear strength of finite element result |

| Es | elastic modules of steel | Pu,0 | ultimate shear strength of experiment result |

| Ebs | elastic modules of high-strength bolt | Pu,c | ultimate shear strength of calculate result |

| Ec | elastic modules of concrete | Pu,(4) | ultimate shear strength of the bolt according to Equation (4) |

References

- Zheng, S.; Liu, Y.; Liu, Y.; Zhao, C. Experimental and numerical study on shear resistance of notched perfobond shear connector. Materials 2019, 12, 341. [Google Scholar] [CrossRef] [PubMed]

- Ollgaard, J.; Slutter, R.; Fisher, J. Shear strength of stud connectors in lightweight and normal-weight concrete. AISC Eng. J. 1971, 8, 55–64. [Google Scholar]

- Lam, D.; Ellobody, E. Behavior of headed stud shear connectors in composite beam. J. Struct. Eng. 2005, 1, 96–107. [Google Scholar] [CrossRef]

- Ding, F.; Yin, G.; Wang, H.; Wang, L.; Guo, Q. Static behavior of stud connectors in bi-direction push-off tests. Thin-Walled Struct. 2017, 120, 307–318. [Google Scholar] [CrossRef]

- Ling, Y.; Zheng, Z.; Yang, T.; Ma, H. Behavior and modeling of the bearing capacity of shear stud connectors. Int. J. Steel Struct. 2019, 19, 650–659. [Google Scholar] [CrossRef]

- Lam, D. Capacities of headed stud shear connectors in composite steel beams with precast hollowcore slabs. Steel Constr. 2008, 63, 1160–1174. [Google Scholar] [CrossRef]

- Dai, X.; Lam, D.; Saveri, E. Effect of concrete strength and stud collar size to shear capacity of demountable shear connectors. J. Struct. Eng. 2015, 141, 4015025. [Google Scholar] [CrossRef]

- Rehman, N.; Lam, D.; Dai, X. Experimental study on demountable shear connectors in composite slabs with profiled decking. J. Constr. Steel Res. 2016, 122, 178–189. [Google Scholar] [CrossRef]

- Ling, J.; Rahman, A.; Ibrahim, I.; Hamid, Z. Behavior of grouted pipe splice under incremental tensile load. Constr. Build. Mater. 2012, 33, 90–98. [Google Scholar] [CrossRef]

- Henin, E.; Morcous, G. Non-proprietary bar splice sleeve for precast concrete construction. Eng. Struct. 2015, 83, 154–162. [Google Scholar] [CrossRef]

- Alias, A.; Zubir, M.; Shahid, K.; Ahman, A. Structural performance of grouted sleeve connectors with and without transverse reinforcement for precast concrete structure. Procedia Eng. 2013, 53, 116–123. [Google Scholar] [CrossRef]

- Dallam, L. High strength bolt shear connectors-pushout tests. J. Proc. 1968, 65, 767–769. [Google Scholar]

- Dedic, D.; Klaiber, F. High-strength bolts as shear connectors in rehabilitation work. Concr. Int. 1984, 6, 41–46. [Google Scholar]

- Kwon, G.; Engelhardt, M.; Klingner, R. Behavior of post-installed shear connectors under static and fatigue loading. J. Constr. Steel Res. 2010, 66, 532–541. [Google Scholar] [CrossRef]

- Ataei, A.; Bradford, M.; Liu, X. Sustainable composite beams and joints with deconstructable bolted shear connectors. In Proceedings of the 23rd Australasian Conference on the Mechanics of Structures and Materials (ACMSM23), Byron Bay, Australia, 9–12 December 2014; Volume Ⅱ. [Google Scholar]

- Liu, X.; Bradford, M.; Michael, S. Behavior of high-strength friction-grip bolted shear connectors in sustainable composite beams. J. Struct. Eng. 2015, 141, 04014149-1–04014149-12. [Google Scholar] [CrossRef]

- Liu, X.; Bradford, M.; Chen, Q.; Ban, H. Finite element modelling of steel–concrete composite beams with high-strength friction-grip bolt shear connectors. Finite Elem. Anal. Des. 2016, 108, 54–65. [Google Scholar] [CrossRef]

- Moynihan, M.; Allwood, J. Viability and performance of demountable composite connectors. J. Constr. Steel Res. 2014, 99, 47–56. [Google Scholar] [CrossRef]

- EN 1994-1-1:2004. Eurocode 4: Design of Composite Steel and Concrete Structures, Part 1-1: General Rules and Rules for Buildings; European Committee for Standardization (CEN): Brussels, Belgium, 2004. [Google Scholar]

- Pavlović, M.; Marković, Z.; Veljković, M.; Budevac, D. Bolted shear connectors vs. headed studs behaviour in push-out tests. J. Constr. Steel Res. 2013, 88, 134–149. [Google Scholar]

- Suwaed, A.; Karavasilis, T. Novel demountable shear connector for accelerated disassembly, repair, or replacement of precast steel-concrete composite bridges. J. Bridge Eng. 2017, 22, 04017052-1–04017052-18. [Google Scholar] [CrossRef]

- GB 50017-2017. Code for Design of Steel Structures; China Architecture and Building Press: Beijing, China, 2017. [Google Scholar]

- Metallic Materials-Tensile Testing at Ambient Temperature; GB/T 228-2010; China Architecture and Building Press: Beijing, China, 2010.

- Standard for Test Method of Mechanical Properties on Ordinary Concrete; GB/T 50081-2002; China Architecture and Building Press: Beijing, China, 2002.

- Ding, F.; Ying, X.; Zhou, L.; Yu, Z. Unified calculation method and its application in determining the uniaxial mechanical properties of concrete. Front. Archit. Civ. Eng. China 2011, 5, 381–393. [Google Scholar] [CrossRef]

- Ding, F.; Yu, Z. Strength criterion for plain concrete under multiaxial stress based on damage Poisson’s ratio. Acta Mech. Solida Sin. 2006, 19, 307–316. [Google Scholar] [CrossRef]

- Loh, H.; Uy, B.; Bradford, M. The effects of partial shear connection in composite flush end plate joints Part II—Analytical study and design appraisal. J. Constr. Steel Res. 2006, 62, 391–412. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, L.; Xiang, P. Improving the durability of the optical fiber sensor based on strain transfer analysis. Opt. Fiber Technol. 2018, 42, 97–104. [Google Scholar] [CrossRef]

- Specification for Structural Steel Buildings; ANSI/AISC 360-16; American Institute of Steel Construction: Chicago, IL, USA, 2016.

- Du, H.; Zhang, B.; Hu, X.; Kou, L.; Xia, Y. Experimental study on shear behavior of bolt connectors in steel-concrete composite beams. J. Build. Struct. (S1) 2017, 38, 308–314. [Google Scholar]

| Specimen | d (mm) | lE (mm) | D (mm) | D/d | Reserved Hole Constraint Condition |

|---|---|---|---|---|---|

| T1-10-01,02 | 10 | 100 | - | - | Type 1 |

| T1-12-01,02 | 12 | 100 | - | - | Type 1 |

| T1-16-01,02 | 16 | 100 | - | - | Type 1 |

| T4-5016-01,02 | 16 | 100 | 50 | 3.1 | Type 4 |

| T4-7016-01,02 | 16 | 100 | 70 | 4.4 | Type 4 |

| T4-7012-01,02 | 12 | 100 | 70 | 5.8 | Type 4 |

| T4-7010-01,02 | 10 | 100 | 70 | 7.0 | Type 4 |

| T5-5016-01,02 | 16 | 100 | 50 | 3.1 | Type 5 |

| T5-7016-01,02 | 16 | 100 | 70 | 4.4 | Type 5 |

| T5-7012-01,02 | 12 | 100 | 70 | 5.8 | Type 5 |

| T5-7010-01,02 | 10 | 100 | 70 | 7.0 | Type 5 |

| Material | fcu or fy (MPa) | fu (MPa) | Es or Ec (MPa) |

|---|---|---|---|

| Concrete | 33.7 | NA | 3.1 × 104 |

| HPG | 67.0 | NA | 3.7 × 104 |

| Steel | 256.4 | 457.1 | 2.03 × 105 |

| No. 10 bars | 456 | 606 | 1.76 × 105 |

| 10 mm bolt | 696 | 877 | 2.08 × 105 |

| 12 mm bolt | 676 | 852 | 2.08 × 105 |

| 16 mm bolt | 663 | 835 | 2.08 × 105 |

| Specimens | Concrete Slab Type | D/d | Pu (kN) | Pu,m (kN) | Su (mm) | Su,m (mm) | k0.4 (kN × mm−1) | k0.4,m (kN × mm−1) |

|---|---|---|---|---|---|---|---|---|

| T1-16-01 | In situ | - | 98.8 | 94.3 | 6.18 | 5.52 | 200.21 | 207.61 |

| T1-16-02 | - | 89.8 | - | 4.85 | - | 215.00 | - | |

| T1-12-01 | - | 45.4 | 47.3 | 2.12 | 2.63 | 181.37 | 188.44 | |

| T1-12-02 | - | 49.1 | - | 3.14 | - | 195.50 | - | |

| T1-10-01 | - | 45.1 | 42.2 | 3.50 | 3.43 | 165.30 | 170.78 | |

| T1-10-02 | - | 39.2 | - | 3.35 | - | 176.62 | - | |

| T4-5016-01 | Precast | 3.1 | 76.7 | 82.3 | 3.41 | 4.24 | 213.63 | 201.92 |

| T4-5016-02 | 3.1 | 87.9 | - | 5.06 | - | 190.20 | - | |

| T4-7016-01 | 4.4 | 85.7 | 87.6 | 3.64 | 3.89 | 203.34 | 214.97 | |

| T4-7016-02 | 4.4 | 89.4 | - | 4.13 | - | 226.60 | - | |

| T4-7012-01 | 5.8 | 49.4 | 48.9 | 1.83 | 1.65 | 174.67 | 179.59 | |

| T4-7012-02 | 5.8 | 48.3 | - | 1.47 | - | 184.50 | - | |

| T4-7010-01 | 7.0 | 34.1 | 36.4 | 1.92 | 2.10 | 171.35 | 177.04 | |

| T4-7010-02 | 7.0 | 38.6 | - | 2.27 | - | 182.72 | - | |

| T5-5016-01 | Precast with corrugated pipe | 3.1 | 81.6 | 84.7 | 3.52 | 3.54 | 195.38 | 203.17 |

| T5-5016-02 | 3.1 | 87.7 | - | 3.56 | - | 210.96 | - | |

| T5-7016-01 | 4.4 | 77.5 | 81.1 | 3.08 | 3.94 | 215.51 | 226.39 | |

| T5-7016-02 | 4.4 | 84.7 | - | 4.80 | - | 237.26 | - | |

| T5-7012-01 | 5.8 | 50.3 | 49.1 | 1.24 | 1.37 | 200.54 | 206.50 | |

| T5-7012-02 | 5.8 | 47.8 | - | 1.49 | - | 212.45 | - | |

| T5-7010-01 | 7.0 | 38.1 | 38.5 | 2.48 | 2.47 | 198.67 | 192.70 | |

| T5-7010-02 | 7.0 | 38.8 | - | 2.45 | - | 186.72 | - |

| Pu,f/Pu,(4) | Pu,f/Pu,(5) | Pu,f/Pu,(6) | Pu,f/Pu,(7) | Pu,f/Pu,(8) | Pu,f/Pu,(9) | |

|---|---|---|---|---|---|---|

| Mean (µ) | 1.010 | 1.387 | 1.316 | 1.778 | 1.595 | 1.208 |

| Coefficient of variation (η) | 0.025 | 0.157 | 0.174 | 0.177 | 0.439 | 0.439 |

| Reference | Number | Pu,0/Pu,f | Pu,0/Pu,(4) | Pu,0/Pu,(5) | Pu,0/Pu,(6) | Pu,0/Pu,(7) | Pu,0/Pu,(8) | Pu,0/Pu,(9) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| µ | η | µ | η | µ | η | µ | η | µ | η | µ | η | µ | η | ||

| This paper | 22 | 0.908 | 0.077 | 0.908 | 0.076 | 1.231 | 0.097 | 1.191 | 0.097 | 1.611 | 0.097 | 1.378 | 0.081 | 1.044 | 0.081 |

| [12] | 12 | 1.017 | 0.059 | 1.133 | 0.104 | 1.386 | 0.177 | 1.324 | 0.186 | 1.400 | 0.186 | 1.718 | 0.109 | 1.302 | 0.109 |

| [14] | 14 | - | - | 1.004 | 0.207 | 1.434 | 0.200 | 1.379 | 0.200 | 1.459 | 0.199 | 1.085 | 0.208 | 0.822 | 0.208 |

| [15] | 3 | 1.115 | 0.027 | 1.158 | 0.012 | 1.377 | 0.013 | 1.079 | 0.013 | 1.205 | 0.013 | 1.715 | 0.111 | 1.299 | 0.111 |

| [28] | 11 | - | - | 1.163 | 0.084 | 2.624 | 0.134 | 1.389 | 0.091 | 1.470 | 0.090 | 1.614 | 0.109 | 1.223 | 0.109 |

| [30] | 24 | - | - | 0.886 | 0.094 | 1.239 | 0.091 | 1.209 | 0.092 | 1.083 | 0.096 | 1.237 | 0.127 | 0.937 | 0.127 |

| All | 86 | - | - | 0.988 | 0.161 | 1.470 | 0.501 | 1.215 | 0.224 | 1.376 | 0.275 | 1.374 | 0.274 | 1.041 | 0.207 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Wang, W.; Ding, F.-X.; Xiang, P.; Yu, Y.-J.; Liu, X.-M.; Xu, F.; Yang, C.-Q.; Long, S.-G. Behavior of an Advanced Bolted Shear Connector in Prefabricated Steel-Concrete Composite Beams. Materials 2019, 12, 2958. https://doi.org/10.3390/ma12182958

Chen J, Wang W, Ding F-X, Xiang P, Yu Y-J, Liu X-M, Xu F, Yang C-Q, Long S-G. Behavior of an Advanced Bolted Shear Connector in Prefabricated Steel-Concrete Composite Beams. Materials. 2019; 12(18):2958. https://doi.org/10.3390/ma12182958

Chicago/Turabian StyleChen, Jun, Wei Wang, Fa-Xing Ding, Ping Xiang, Yu-Jie Yu, Xue-Mei Liu, Fu Xu, Cai-Qian Yang, and Shi-Guo Long. 2019. "Behavior of an Advanced Bolted Shear Connector in Prefabricated Steel-Concrete Composite Beams" Materials 12, no. 18: 2958. https://doi.org/10.3390/ma12182958

APA StyleChen, J., Wang, W., Ding, F.-X., Xiang, P., Yu, Y.-J., Liu, X.-M., Xu, F., Yang, C.-Q., & Long, S.-G. (2019). Behavior of an Advanced Bolted Shear Connector in Prefabricated Steel-Concrete Composite Beams. Materials, 12(18), 2958. https://doi.org/10.3390/ma12182958