Control of Laves Precipitation in a FeCrAl-based Alloy Through Severe Thermomechanical Processing

Abstract

1. Introduction

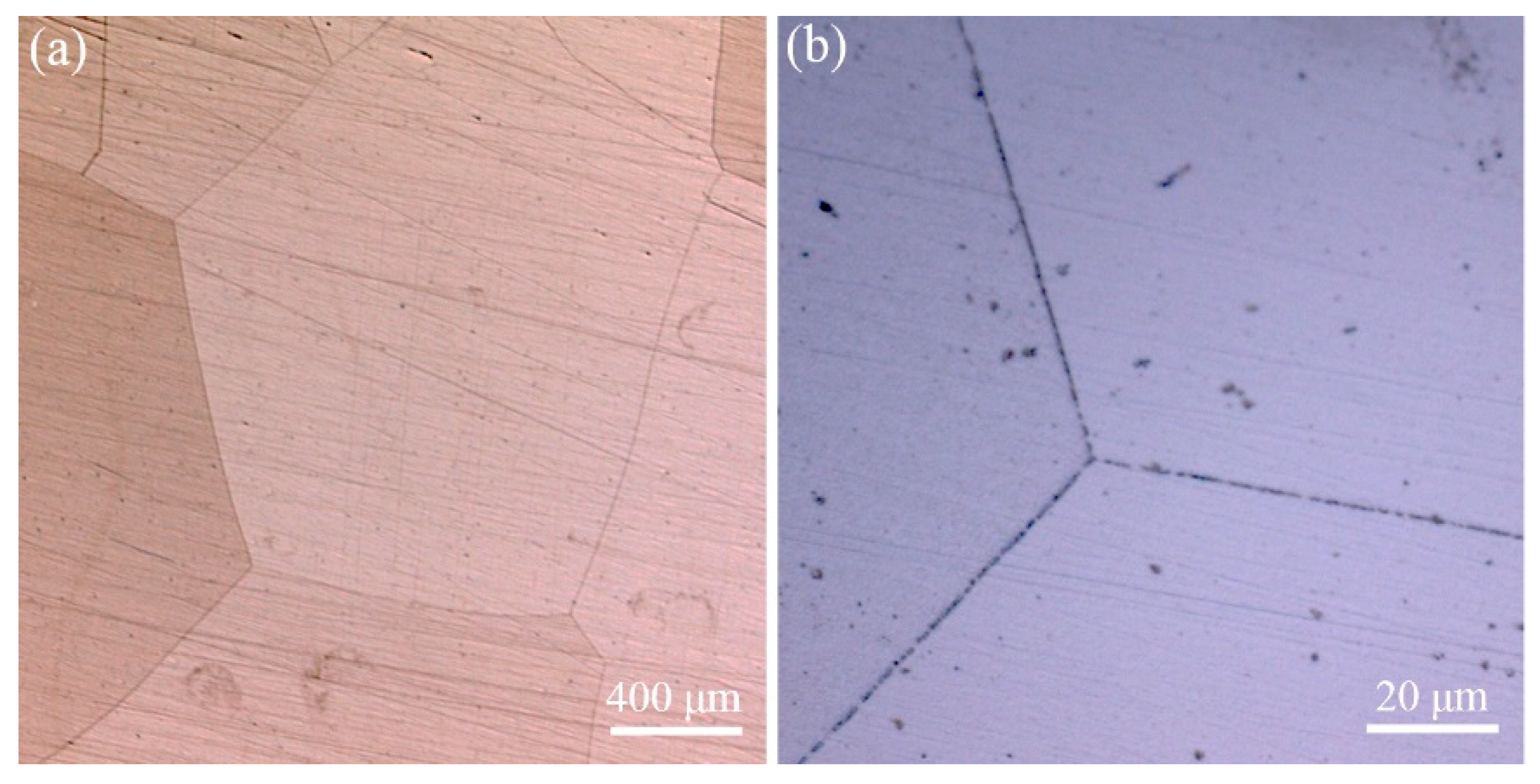

2. Experiment

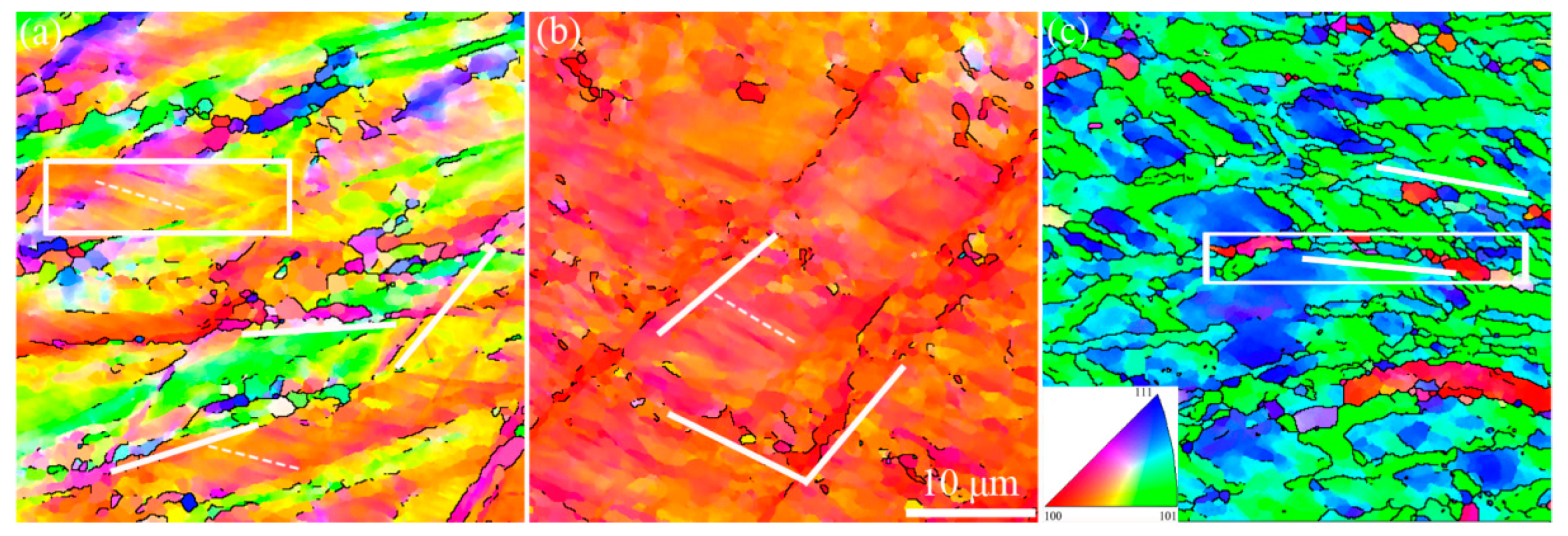

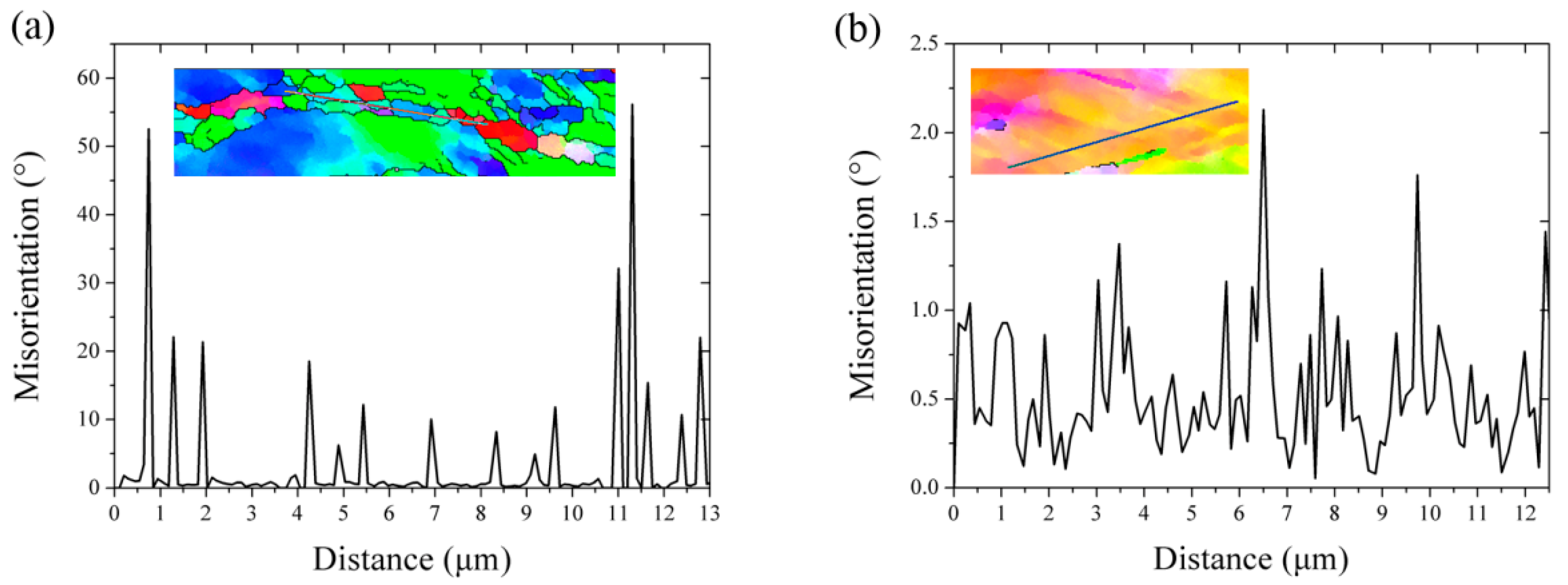

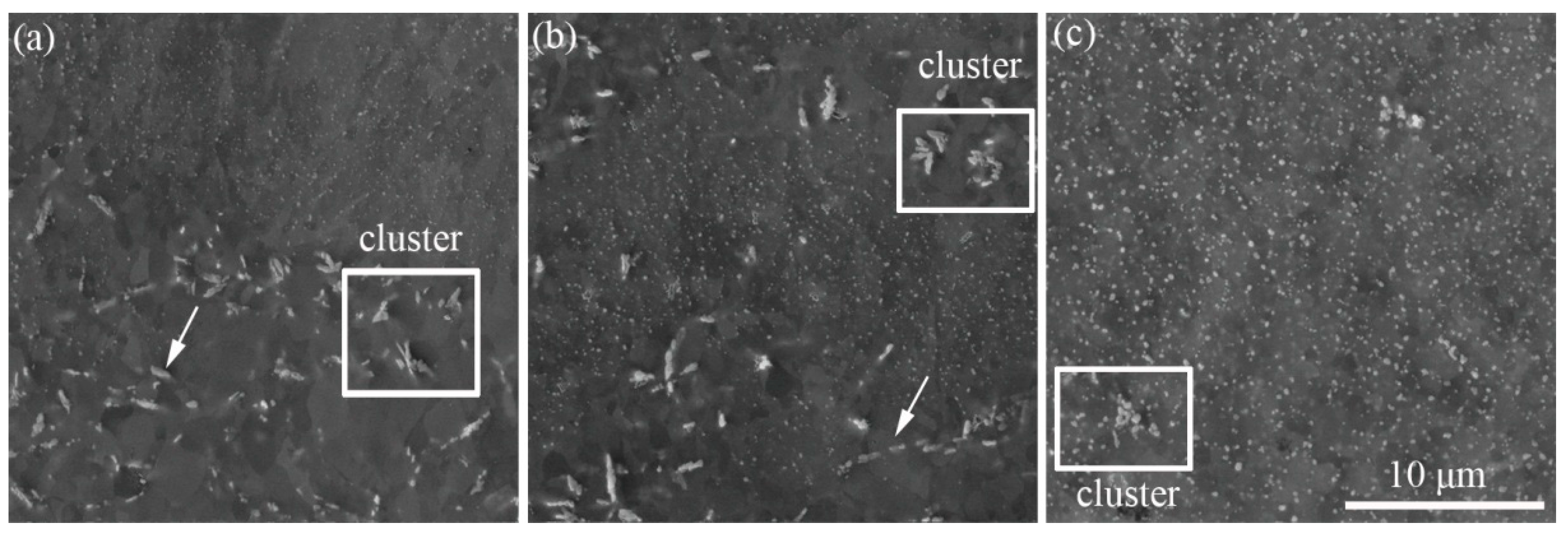

3. Results

4. Discussion

4.1. Deformation Microstructure and Preferential Recrystallization

4.2. Strain-Induced Precipitation

5. Conclusions

- The FeCrAl alloy plate had typical deformation microstructure, with a mix of shear band and cell band structure after hot rolling. The orientation of the matrix gradually rotated from <100>∥RD to <110>∥RD with increasing reduction. The shear band was oriented at ~20°–45°, referring to the processing direction, and acted as preferable nucleation sites for precipitation.

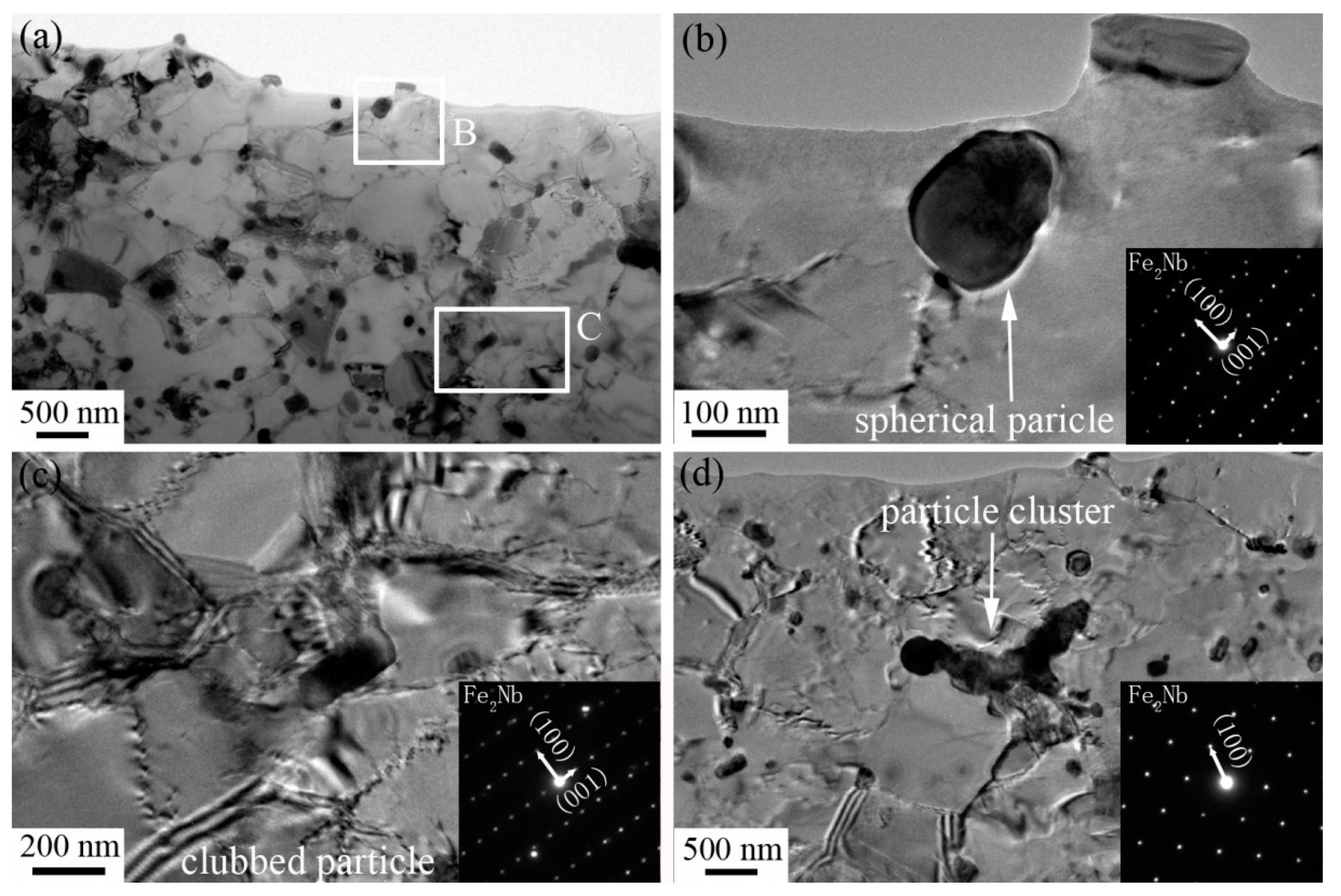

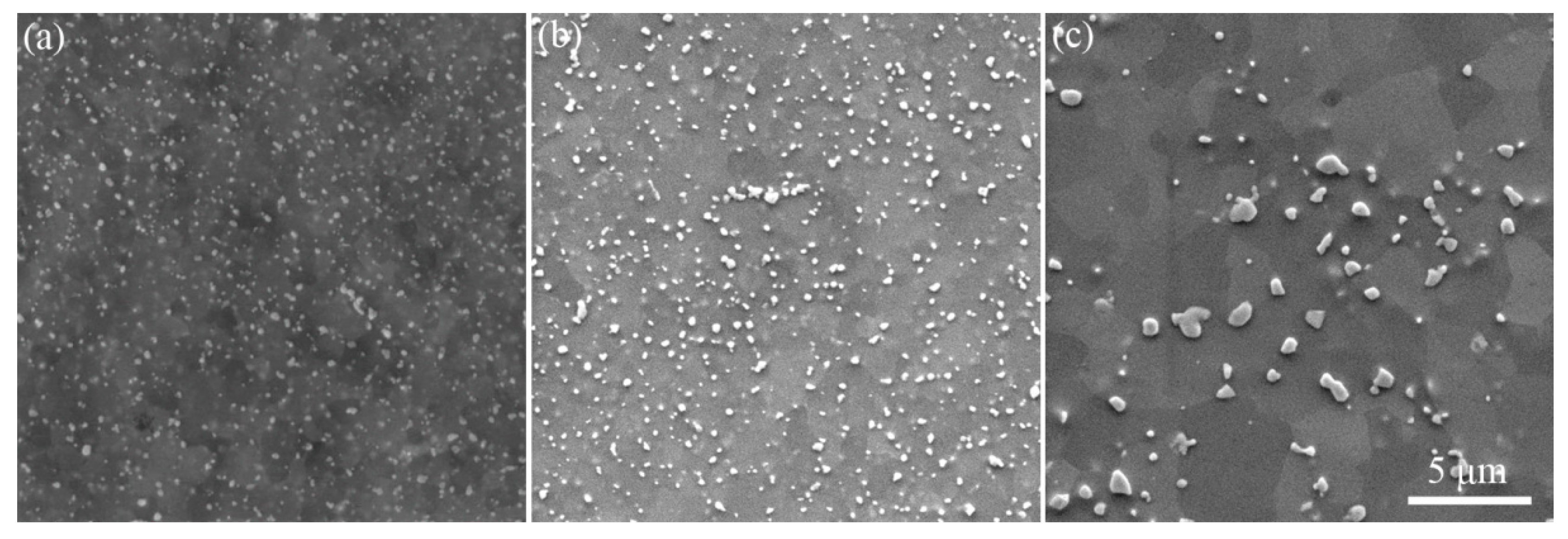

- Improved deformation contributed to causing strain-induced precipitation. The FeCrAl alloy plate with 83% reduction had the most homogeneous precipitation particles. The identification results by TEM indicated that the Laves phase precipitate was Fe2Nb-type crystal structure with impurities including Mo, Cr, and Si atoms.

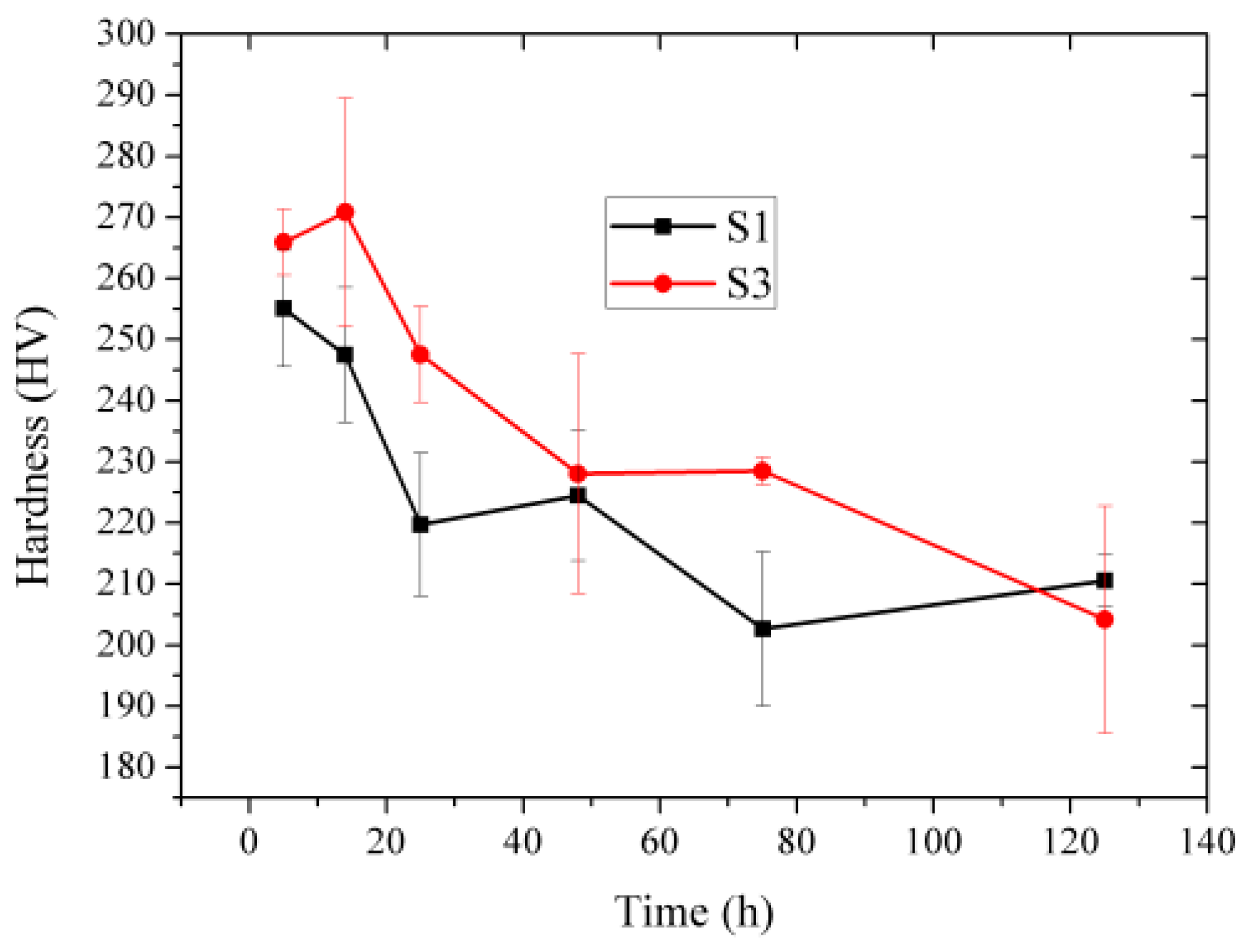

- The FeCrAl alloy plate with uniform Laves particles displayed favorable heat stability after a long period of aging at 800 °C. However, the aging effect of Laves particles was obvious up to 125 h of holding. The microstructure stability of FeCrAl alloy was closely related to the distribution of fine Laves precipitates. The strain-induced precipitation mechanism could be taken use of for the preparation of FeCrAl alloy cladding with fine and uniform precipitation.

Author Contributions

Funding

Conflicts of Interest

References

- Moalem, M.; Olander, D.R. Oxidation of Zircaloy by steam. J. Nucl. Mater. 1991, 182, 170–194. [Google Scholar] [CrossRef]

- Pint, B.A.; Terrani, K.A.; Brady, M.P.; Cheng, T.; Keiser, J.R. High temperature oxidation of fuel cladding candidate materials in steam–hydrogen environments. J. Nucl. Mater. 2013, 440, 420–427. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Pint, B.A.; Terrani, K.A.; Field, K.G.; Yang, Y.; Snead, L.L. Development and property evaluation of nuclear grade wrought FeCrAl fuel cladding for light water reactors. J. Nucl. Mater. 2015, 467, 703–716. [Google Scholar] [CrossRef]

- Gamble, K.A.; Barani, T.; Pizzocri, D.; Hales, J.D.; Terrani, K.A.; Pastore, G. An investigation of FeCrAl cladding behavior under normal operating and loss of coolant conditions. J. Nucl. Mater. 2017, 491, 55–56.

- Ott, L.J.; Robb, K.R.; Wang, D. Preliminary assessment of accident-tolerant fuels on LWR performance during normal operation and under DB and BDB accident conditions. J. Nucl. Mater. 2014, 448, 520–533. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Terrani, K.A.; Gehin, J.C.; Ott, L.J.; Snead, L.L. Accident tolerant fuels for LWRs: A perspective. J. Nucl. Mater. 2014, 448, 374–379. [Google Scholar] [CrossRef]

- Terrani, K.A.; Zinkle, S.J.; Snead, L.L. Advanced oxidation-resistant iron-based alloys for LWR fuel cladding. J. Nucl. Mater. 2014, 448, 420–435. [Google Scholar] [CrossRef]

- Sun, Z.; Yamamoto, Y. Processability evaluation of a Mo-containing FeCrAl alloy for seamless thinwall tube fabrication. Mater. Sci. Eng. A 2017, 700, 554–561. [Google Scholar] [CrossRef]

- Cheng, T.; Keiser, J.R.; Brady, M.P.; Terrani, K.A.; Pint, B.A. Oxidation of fuel cladding candidate materials in steam environments at high temperature and pressure. J. Nucl. Mater. 2012, 427, 396–400. [Google Scholar] [CrossRef]

- Sun, Z.; Edmondson, P.D.; Yamamoto, Y. Effects of Laves phase particles on recovery and recrystallization behaviors of Nb-containing FeCrAl alloys. Acta Mater. 2018, 144, 716–727. [Google Scholar] [CrossRef]

- Sun, Z.; Bei, H.; Yamamoto, Y. Microstructural control of FeCrAl alloys using Mo and Nb additions. Mater. Charact. 2017, 132, 126–131. [Google Scholar] [CrossRef]

- Zinklea, S.J. Materials challenges in nuclear energy. Acta Mater. 2013, 61, 735–758. [Google Scholar] [CrossRef]

- Murty, K.L.; Charit, I. Texture development and anisotropic deformation of zircaloys. Prog. Nucl. Energ. 2006, 48, 325–359. [Google Scholar] [CrossRef]

- Suh, D.W.; Kim, N.J. Low-density steels. Scripta Mater. 2013, 68, 337–338. [Google Scholar] [CrossRef]

- Rana, R.; Liu, C.; Ray, R.K. Low-density low-carbon Fe–Al ferritic steels. Scripta Mater. 2013, 68, 354–359. [Google Scholar] [CrossRef]

- Voß, S.; Palm, M.; Stein, F.; Raabe, D. Phase Equilibria in the Fe-Nb System. J. Phase Equilib. Diff. 2011, 32, 97–104. [Google Scholar] [CrossRef]

- Hurley, P.J.; Humphreys, F.J. The application of EBSD to the study of substructural development in a cold rolled single-phase aluminium alloy. Acta Mater. 2003, 51, 1087–1102. [Google Scholar] [CrossRef]

- Chen, L.Y.; Xu, J.Q.; Choi, H.; Pozuelo, M.; Ma, X.; Bhowmick, S.; Yang, J.M.; Mathaudhu, S.; Li, X.C. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 2015, 528, 539. [Google Scholar] [CrossRef] [PubMed]

- Medina, S.F. From heterogeneous to homogeneous nucleation for precipitation in austenite of microalloyed steels. Acta Mater. 2015, 84, 202–207. [Google Scholar] [CrossRef]

- Hutchinson, B.; Hansen, N.; Houtte, P.V.; Jensen, D.J. Deformation microstructures and textures in steels [and discussion]. Philo. Trans. Math. Phy. Eng. Sci. 1999, 357, 1471–1485. [Google Scholar] [CrossRef]

- Hansen, N.; Hughes, D.A. Analysis of large dislocation populations in deformed metals. Phys. Status Solidi 2010, 149, 155–172. [Google Scholar] [CrossRef]

- Hatherly, M.; Malin, A.S. Shear bands in deformed metals. Scripta Metall. 1984, 18, 449–454. [Google Scholar] [CrossRef]

- Barnett, M.R. Role of in-grain shear bands in the nucleation of //ND recrystallization textures in warm rolled steel. Trans. Iron Steel Inst. Jap. 1998, 38, 78–85. [Google Scholar] [CrossRef]

- Martı́Nez-De-Guerenu, A.; Arizti, F.; Dı́Az-Fuentes, M.; Gutiérrez, I. Recovery during annealing in a cold rolled low carbon steel. Part I: Kinetics and microstructural characterization. Acta Mater. 2004, 52, 3657–3664. [Google Scholar] [CrossRef]

- Cheng, L.; Chen, Y.; Cai, Q.; Yu, W.; Han, G.; Dong, E.; Li, X. Precipitation enhanced ultragrain refinement of Ti-Mo microalloyed ferritic steel during warm rolling. Mater. Sci. Eng. A 2017, 698, 117–125. [Google Scholar] [CrossRef]

- Oyarzábal, M.; Martínez-De-Guerenu, A.; Gutiérrez, I. Effect of stored energy and recovery on the overall recrystallization kinetics of a cold rolled low carbon steel. Mater. Sci. Eng. A 2008, 485, 200–209. [Google Scholar] [CrossRef]

- Zuo, J.; Hou, L.; Shi, J.; Cui, H.; Zhuang, L.; Zhang, J. Effect of deformation induced precipitation on dynamic aging process and improvement of mechanical/corrosion properties AA7055 aluminum alloy. Mater. Charact. 2017, 130, 123–134. [Google Scholar] [CrossRef]

- Dutta, B.; Palmiere, E.J.; Sellars, C.M. Modelling the kinetics of strain induced precipitation in Nb microalloyed steels. Acta Mater. 2001, 49, 785–794. [Google Scholar] [CrossRef]

- Wang, Z.; Mao, X.; Yang, Z.; Sun, X.; Yong, Q.; Li, Z.; Weng, Y. Strain-induced precipitation in a Ti micro-alloyed HSLA steel. Mater. Sci. Eng. A 2011, 529, 459–467. [Google Scholar] [CrossRef]

- Atake, M.; Barnett, M.; Hutchinson, B.; Ushioda, K. Warm deformation and annealing behaviour of iron–silicon–(carbon) steel sheets. Acta Mater. 2015, 96, 410–419. [Google Scholar] [CrossRef]

| Fe | Cr | Al | Mo | Nb | Ti | V | Y |

|---|---|---|---|---|---|---|---|

| bal. | 13 | 4.5 | 2 | 3 | 0.1 | 0.1 | 0.05 |

| Nominal Deformation | Thickness after Hot Rolling | Actual Deformation | Symbol |

|---|---|---|---|

| 50% | 2.4 | 52% | S1 |

| 70% | 1.65 | 67% | S2 |

| 90% | 0.85 | 83% | S3 |

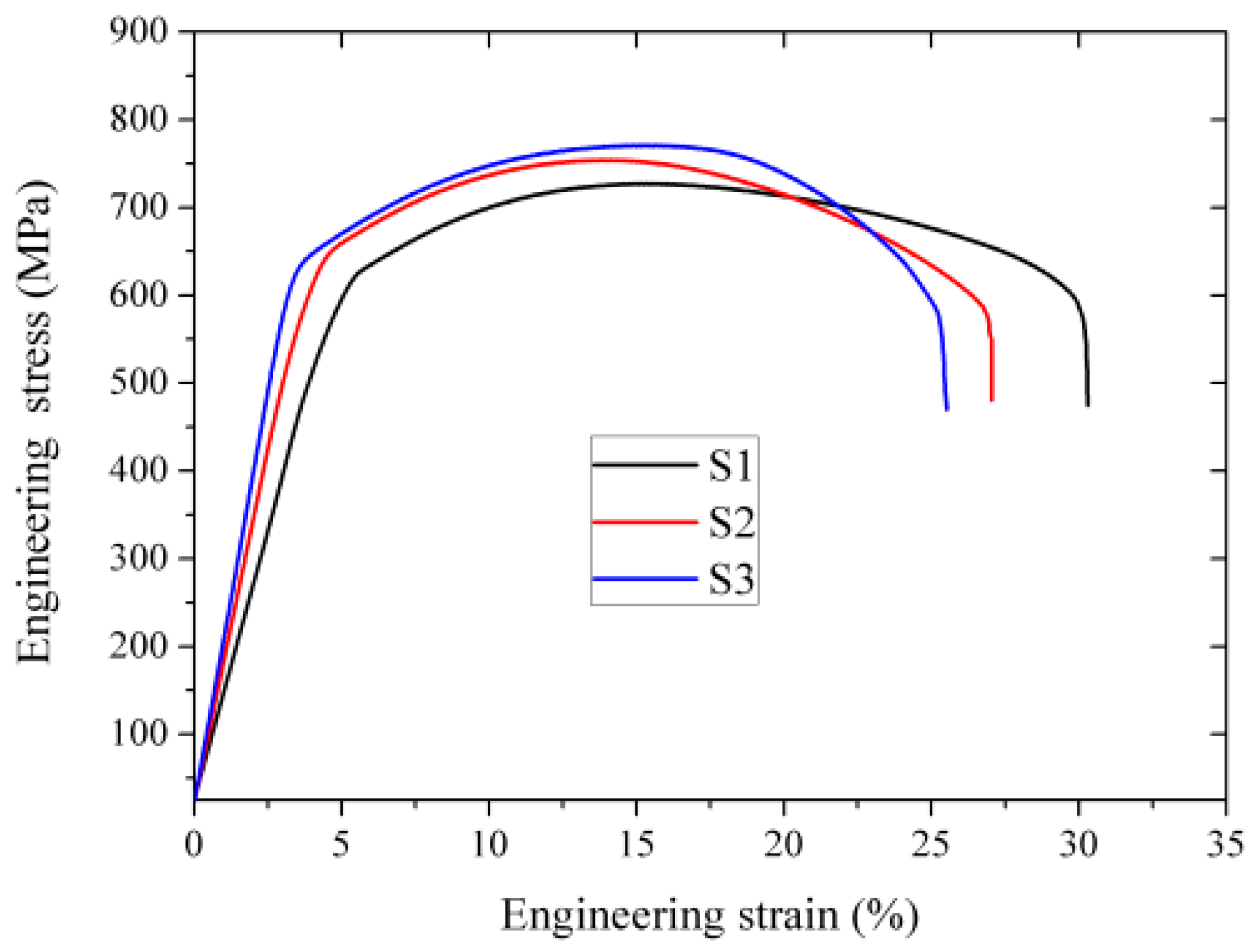

| Samples | YTS a/MPa | UTS b/MPa | Elongation/% |

|---|---|---|---|

| S1 | 560.8 ± 10 | 733.4 ± 18.2 | 34.2 ± 5 |

| S2 | 589.9 ± 11.8 | 738 ± 22.9 | 26.9 ± 0.8 |

| S3 | 593.9 ± 18.9 | 747.3 ± 20.9 | 20.6 ± 3.6 |

| Particle Type | Fe | Nb | Mo | Si | Cr | Al | Atom Ratio (Fe: Nb + Mo) |

|---|---|---|---|---|---|---|---|

| Spherical | 48.78 | 13.19 | 15.06 | 9.63 | 7.95 | 2.16 | 1.68 |

| Clubbed | 51.5 | 14.2 | 13.12 | 8.04 | 8.30 | 2.37 | 1.88 |

| Cluster | 49.73 | 14.4 | 13.82 | 11.44 | 8.07 | 2.52 | 1.76 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, J.; Jia, Y.; Du, P.; Wang, H.; Pan, Q.; Zhang, Y.; Liu, C.; Zhang, R.; Qiu, S. Control of Laves Precipitation in a FeCrAl-based Alloy Through Severe Thermomechanical Processing. Materials 2019, 12, 2939. https://doi.org/10.3390/ma12182939

Zheng J, Jia Y, Du P, Wang H, Pan Q, Zhang Y, Liu C, Zhang R, Qiu S. Control of Laves Precipitation in a FeCrAl-based Alloy Through Severe Thermomechanical Processing. Materials. 2019; 12(18):2939. https://doi.org/10.3390/ma12182939

Chicago/Turabian StyleZheng, Jiyun, Yuzhen Jia, Peinan Du, Hui Wang, Qianfu Pan, Yiyong Zhang, Chaohong Liu, Ruiqian Zhang, and Shaoyu Qiu. 2019. "Control of Laves Precipitation in a FeCrAl-based Alloy Through Severe Thermomechanical Processing" Materials 12, no. 18: 2939. https://doi.org/10.3390/ma12182939

APA StyleZheng, J., Jia, Y., Du, P., Wang, H., Pan, Q., Zhang, Y., Liu, C., Zhang, R., & Qiu, S. (2019). Control of Laves Precipitation in a FeCrAl-based Alloy Through Severe Thermomechanical Processing. Materials, 12(18), 2939. https://doi.org/10.3390/ma12182939