Study on the Fatigue and Durability Behavior of Structural Expanded Polystyrene Concretes

Abstract

1. Introduction

2. Materials and Experiments

2.1. Materials

2.2. Mixture Proportion and Sample Preparation

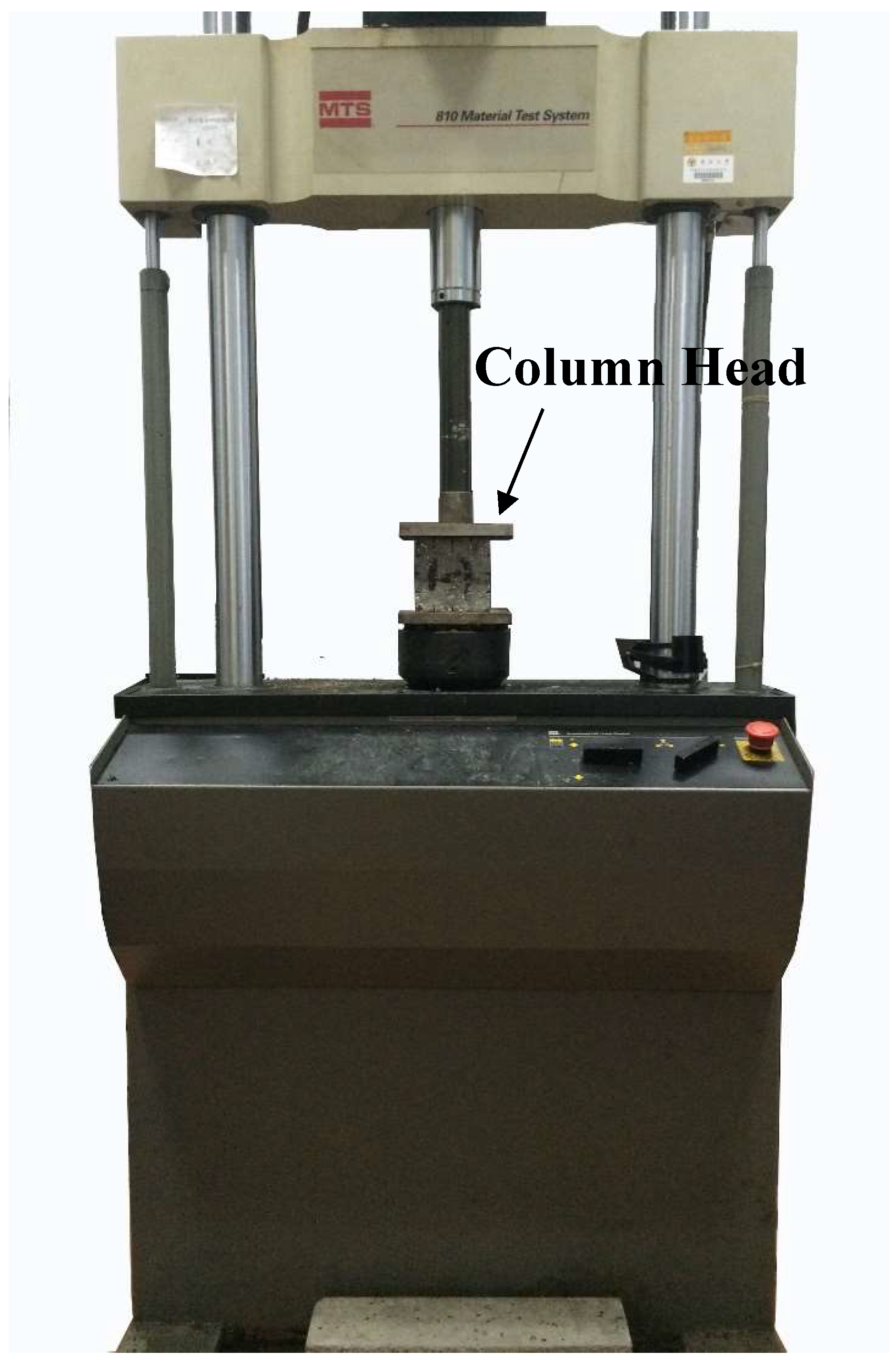

2.3. Long-Term Cyclic Loading Experiment

2.4. Sulfate Attack Experiment

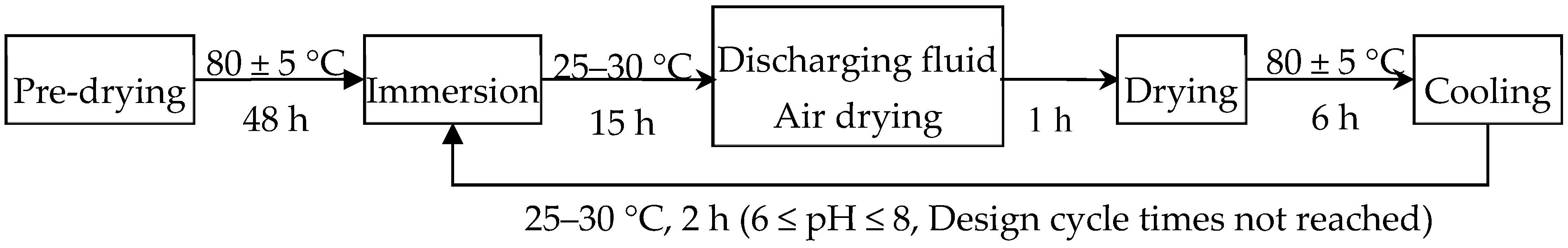

2.4.1. W-D Cyclic Experiment

2.4.2. Compressive Strength Experiment and Mass Measurement

3. Experimental Results and Discussions

3.1. Fatigue Performance of Structural EPS Concrete

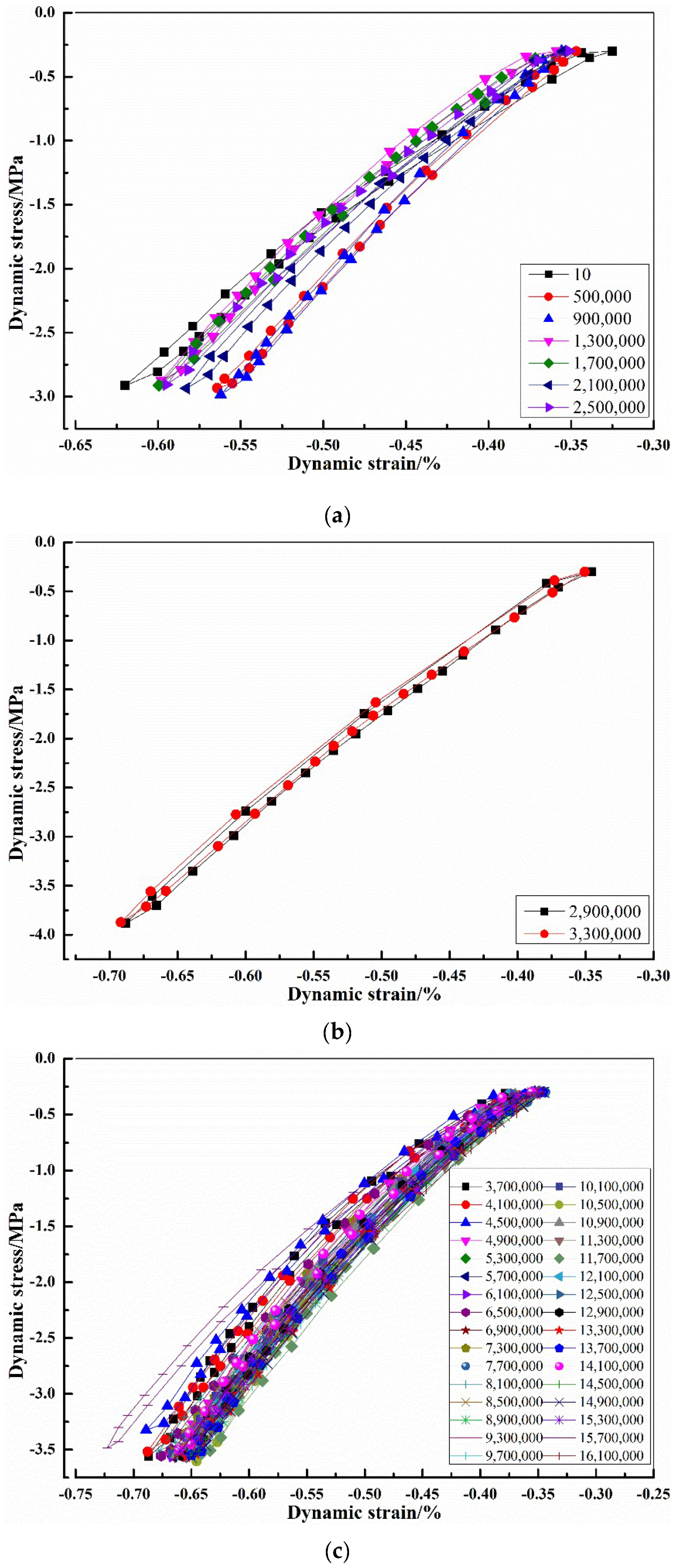

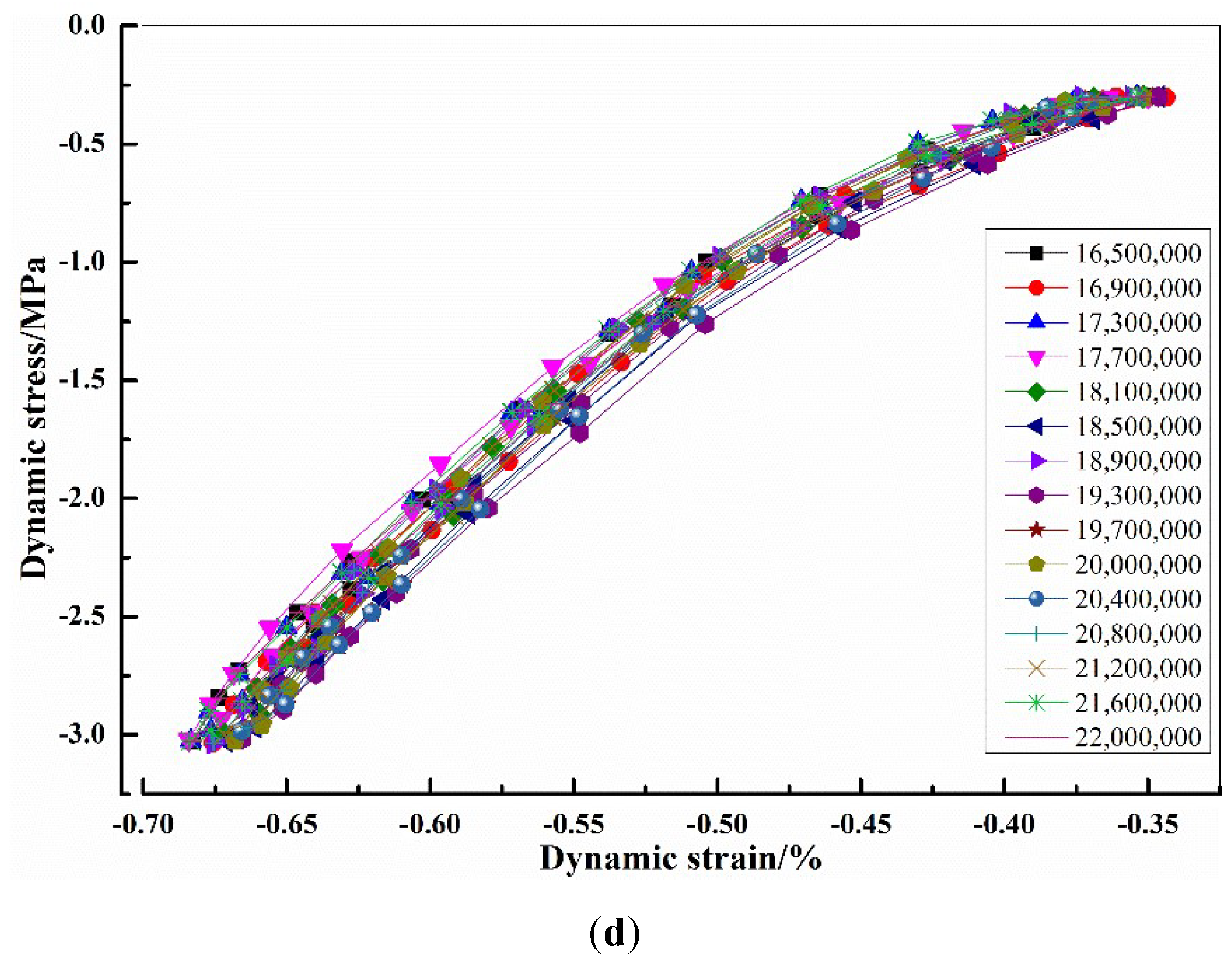

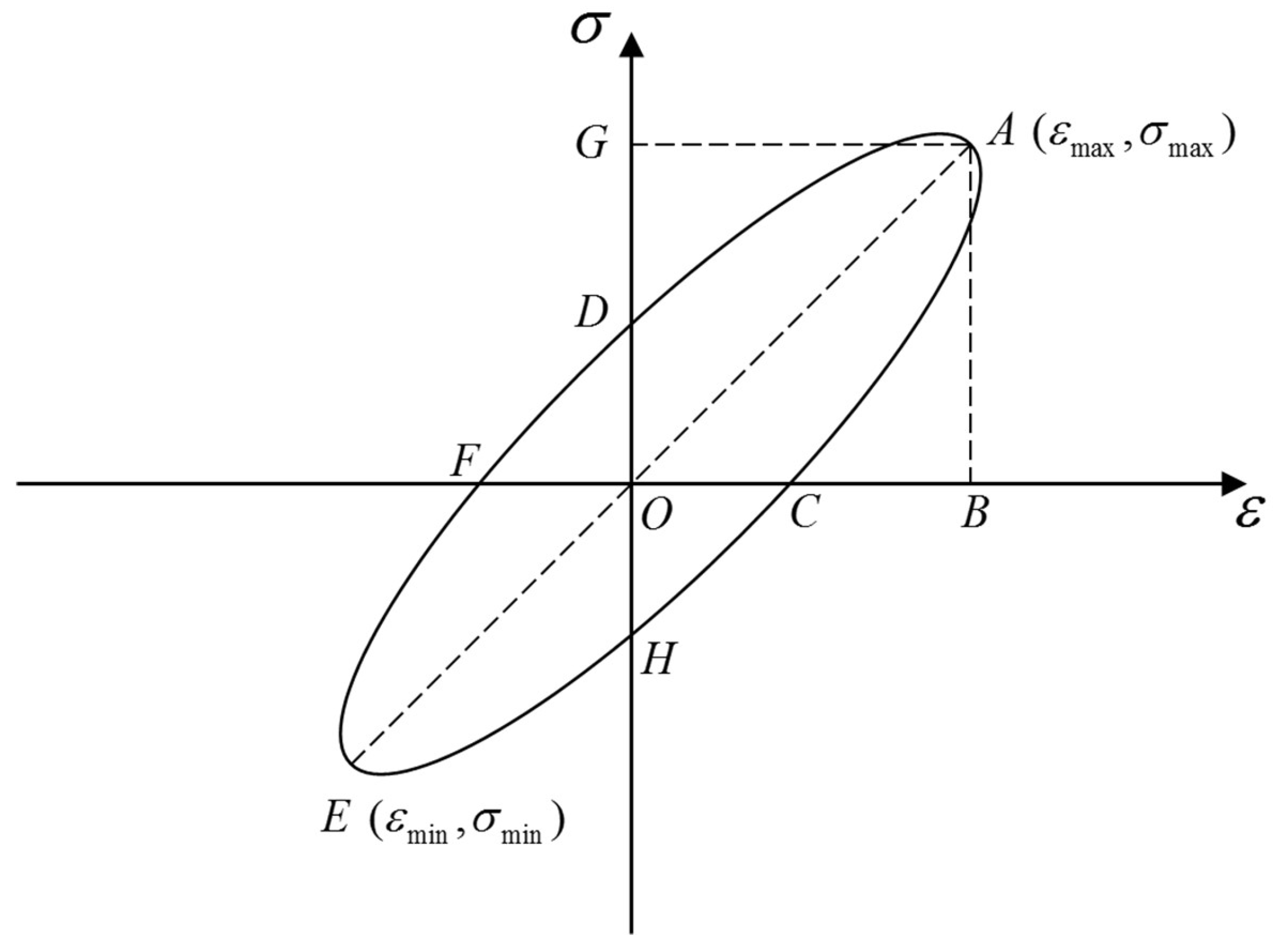

3.1.1. Dynamic Stress-Strain Hysteresis Curves

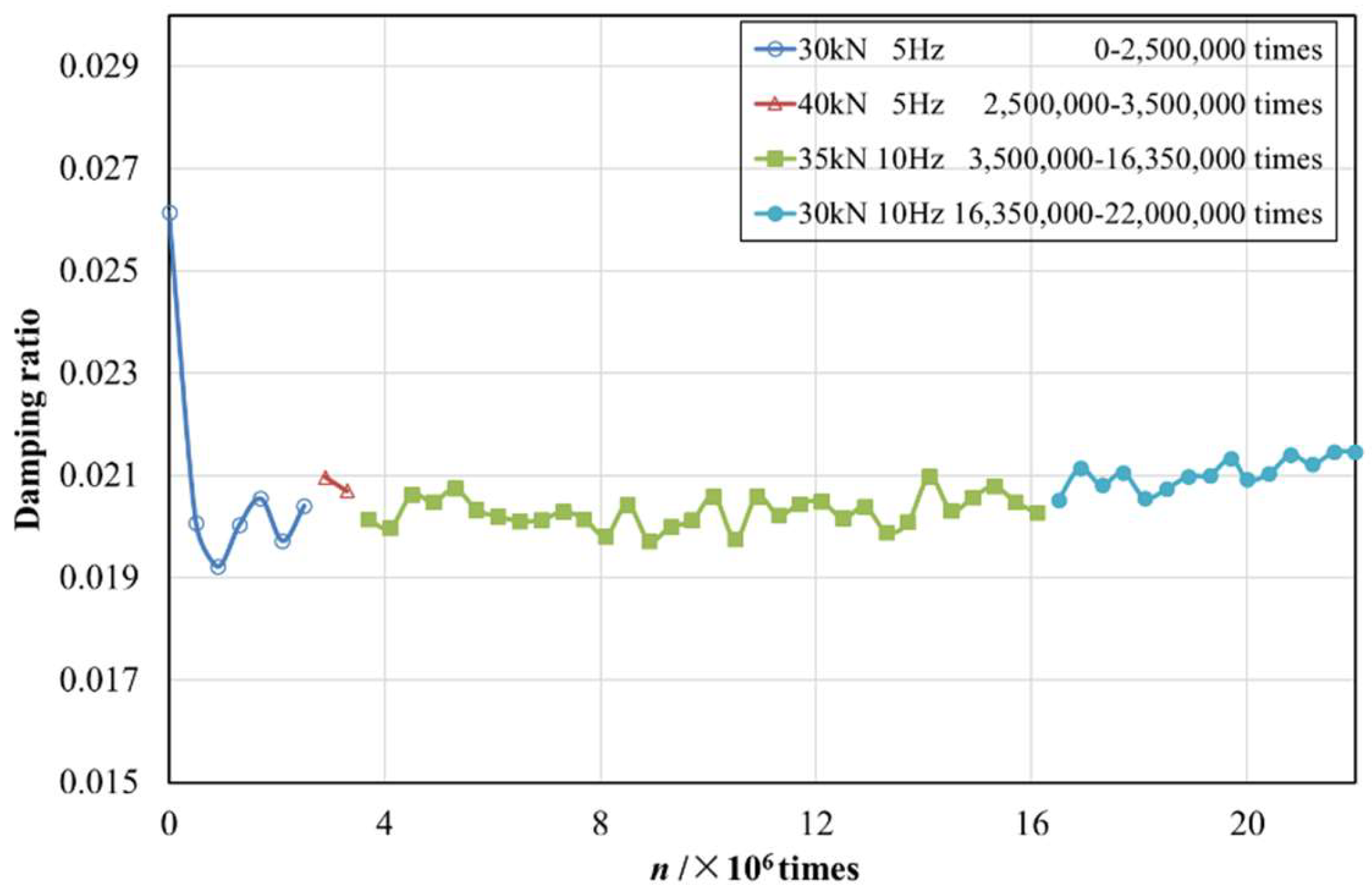

3.1.2. Damping Ratio

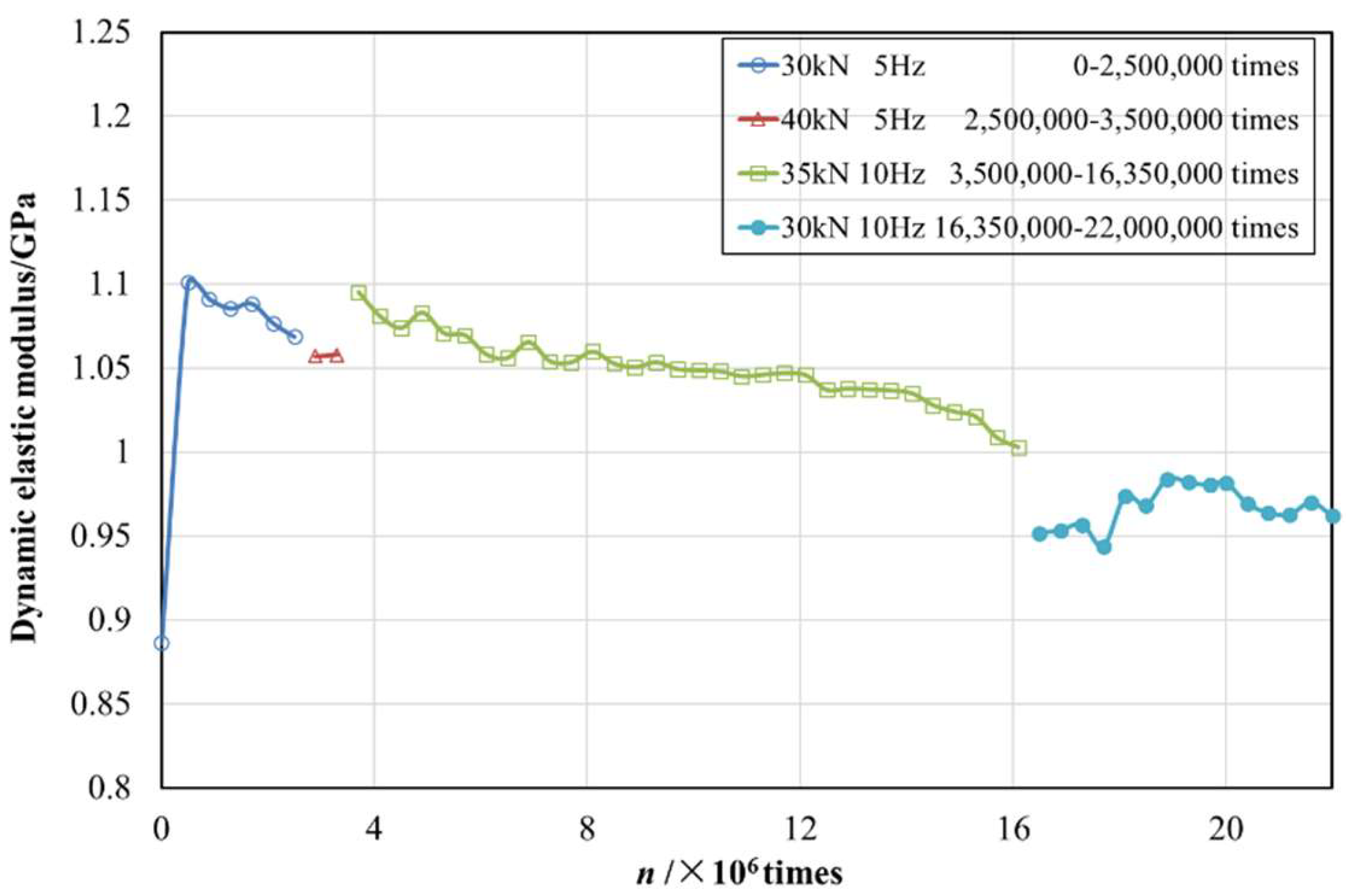

3.1.3. Dynamic Elastic Modulus

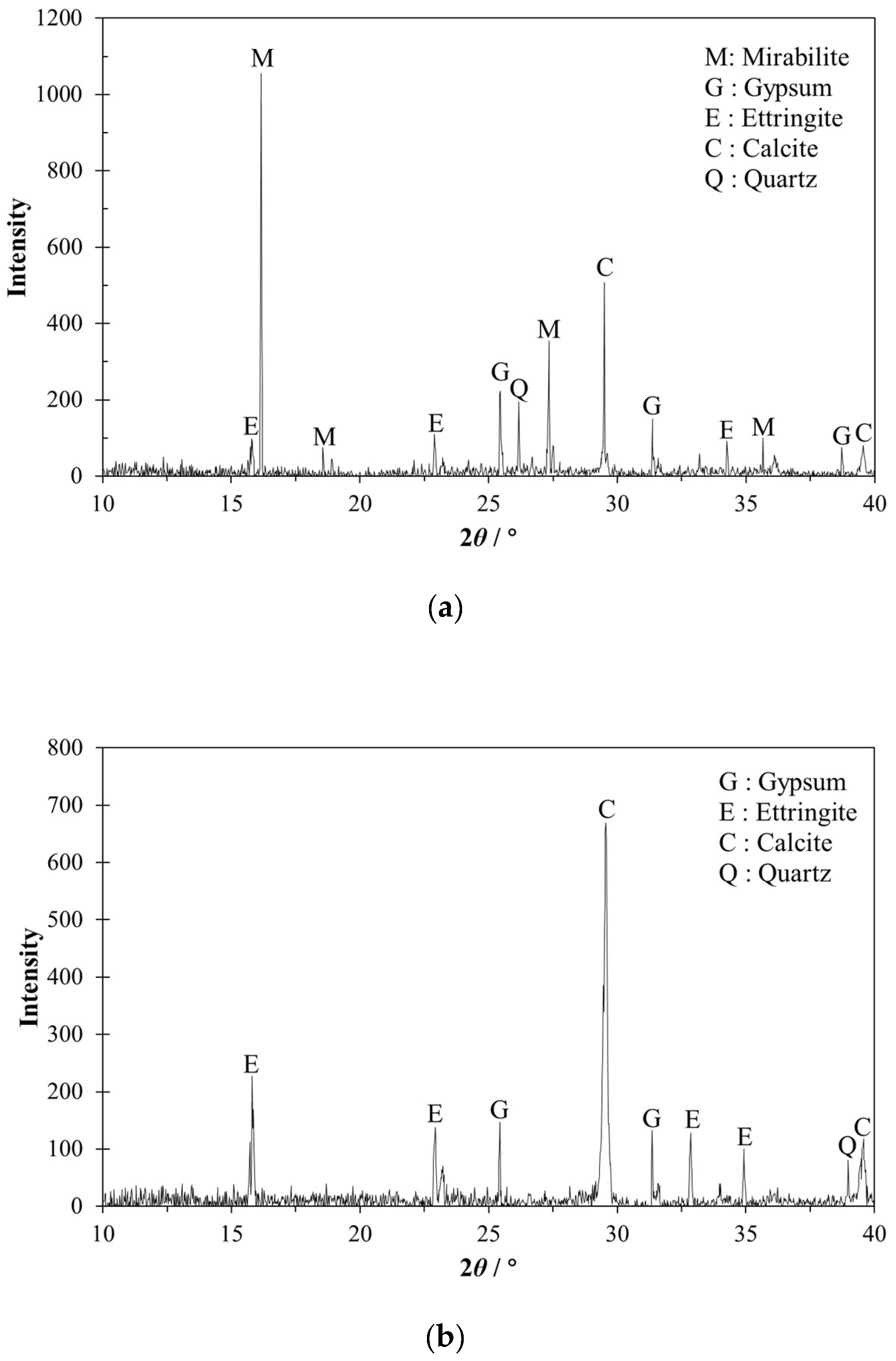

3.2. Sulfate Resistance of Structural EPS Concrete

3.2.1. Sulfate Resistance Level of Structural EPS Concrete

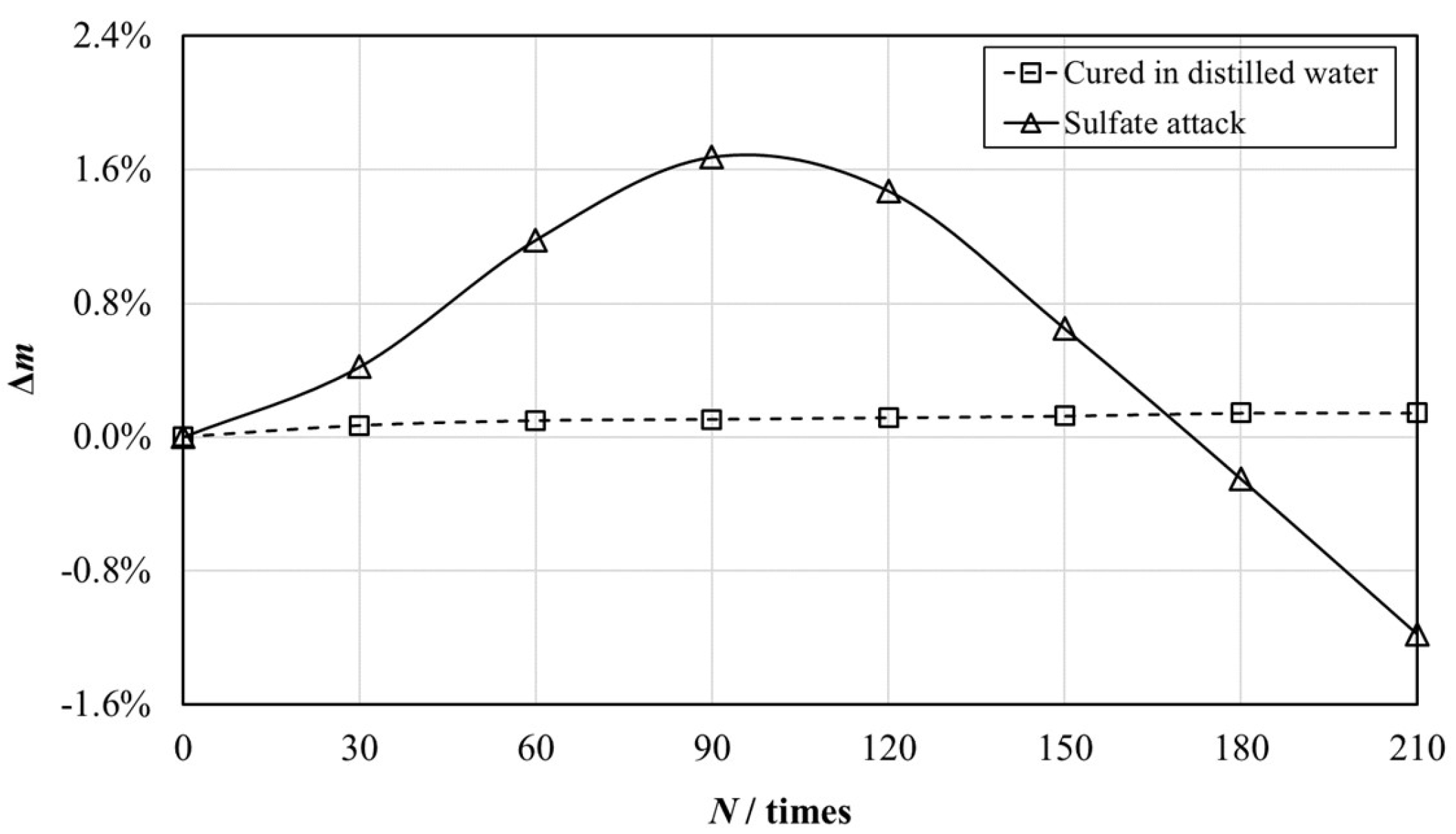

3.2.2. Variation of the Mass of Structural EPS Concrete

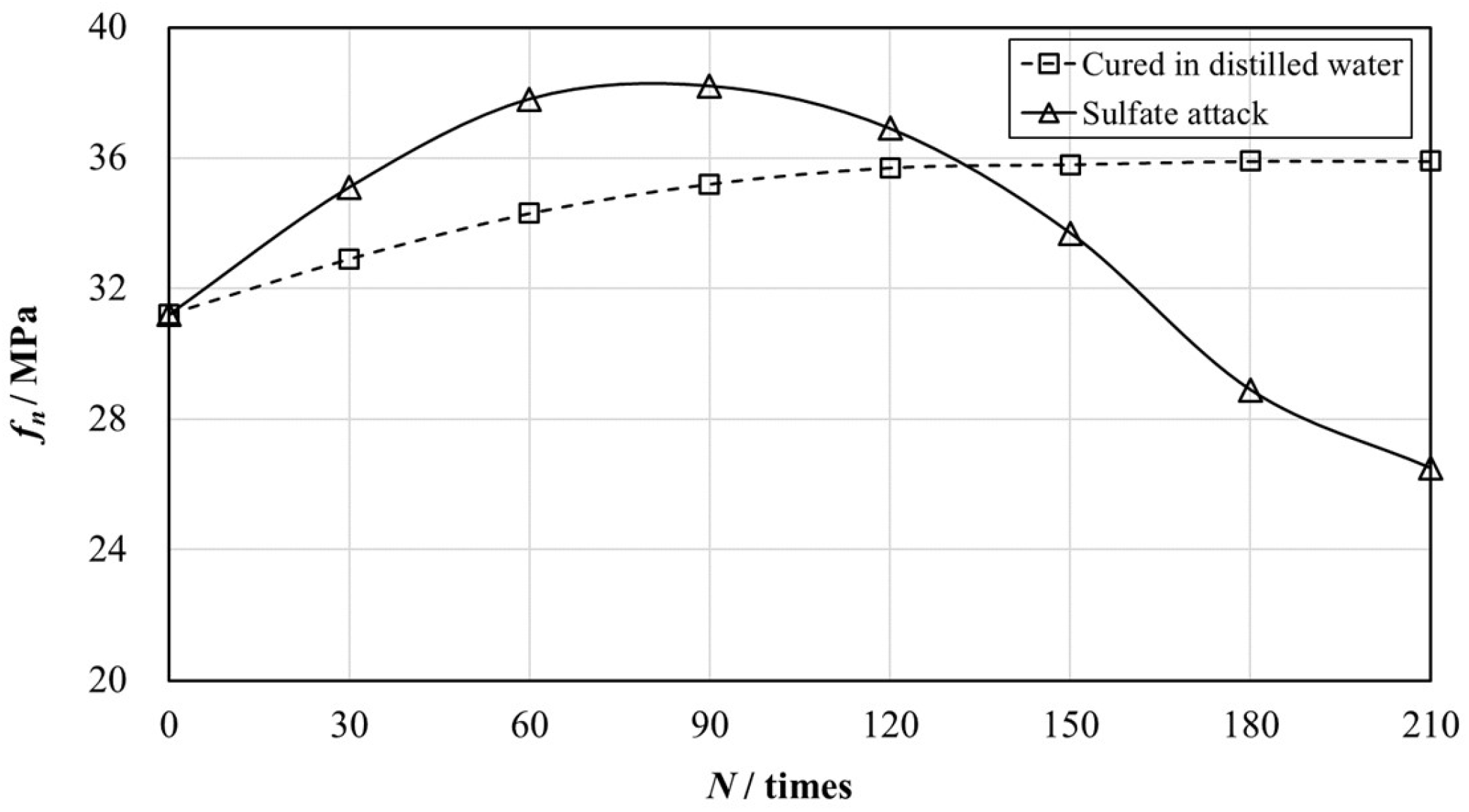

3.2.3. Evolution of Compressive Strength of Structural EPS Concrete

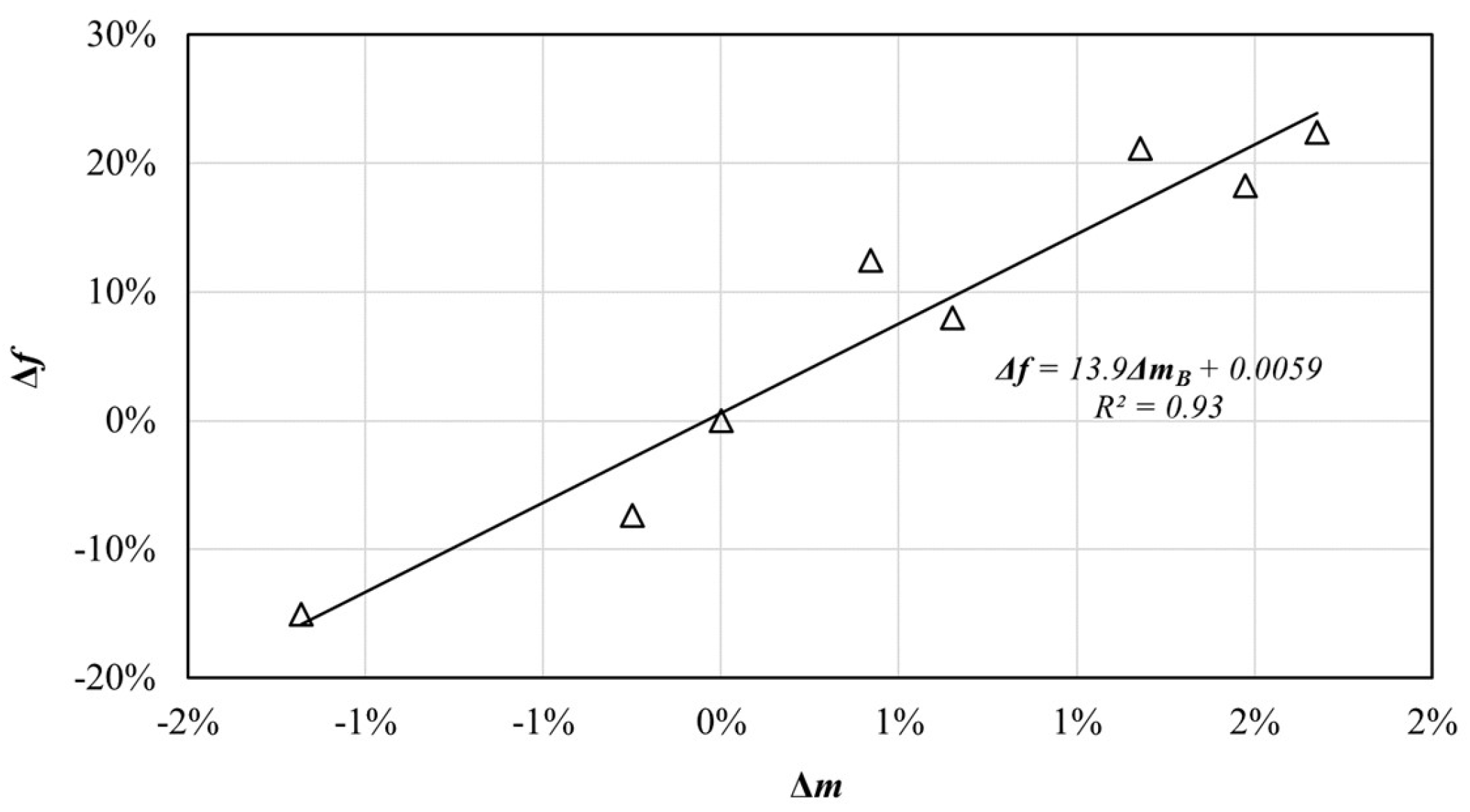

3.2.4. Relationship between the Evolution of Compressive Strength and Variation of Mass

4. Conclusions

- (1)

- Based on the dynamic stress–strain hysteresis curve of structural EPS concrete under long-term cyclic loading, the dynamic stress–strain curve of structural EPS concrete basically overlapped with each other under the same load and frequency, which indicated that the structural EPS concrete had good stability under a dynamic load.

- (2)

- Compared with plain concretes of the same strength level, the damping ratio of structural EPS concrete was larger, and the dynamic elastic modulus was smaller, which indicated that structural EPS concrete had a superior performance of vibration attenuation, toughness.

- (3)

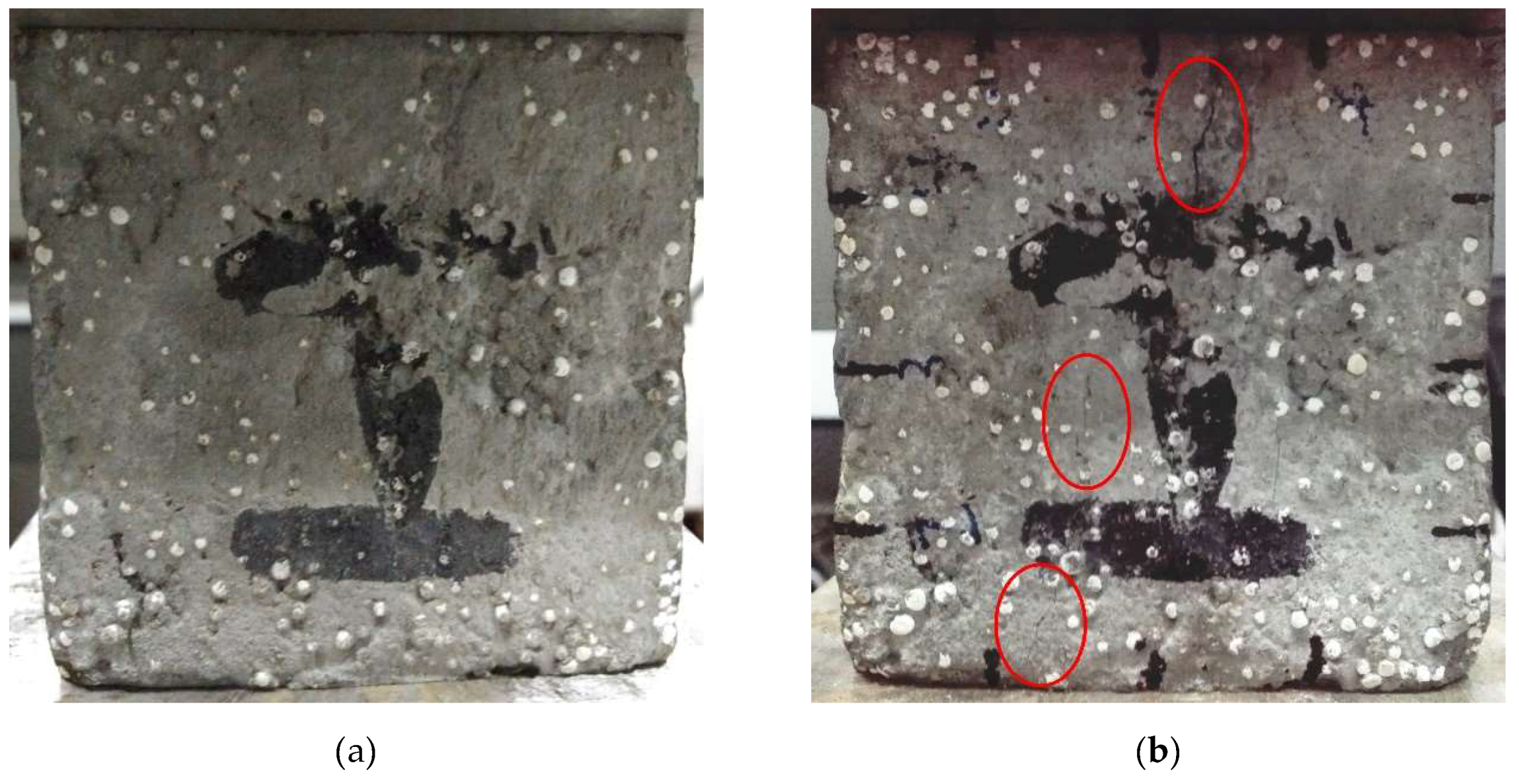

- A slight crack occurred on the surface of the concrete specimen at about the cyclic number of 15.7 million. However, the relevant dynamic properties could remain stable, which proved the fatigue stability of the structural EPS concrete.

- (4)

- The sulfate resistance of structural EPS concrete was evaluated as the highest level regulated by GB/T 50082 [30] owing to the addition of fly ash, low water:binder ratio, and the incorporation of EPS beads. The structural EPS concrete exhibited a much higher sulfate resistance than plain concrete on the basis of the previous literature.

- (5)

- The indices Δf and ΔmB were presented to evaluate the variation of compressive strength and mass of structural EPS concretes, which could be used to describe the damage extent of structural EPS concrete under sulfate attack. XRD analysis illustrated that the products generated in the specimens were the reasons for the evolution of the compressive strength and mass. There was an approximately linear relationship between these two indices, which indicated that ΔmB could be substituted for Δf to evaluate the degree of structural EPS concrete damage under sulfate attack for a more convenient acquiring method and no damage when measuring.

Author Contributions

Funding

Conflicts of Interest

References

- Xu, Y.; Jiang, L.; Xu, J.; Li, Y. Mechanical properties of expanded polystyrene lightweight aggregate concrete and brick. Constr. Build. Mater. 2012, 27, 32–38. [Google Scholar] [CrossRef]

- Babu, D.S.; Babu, K.G.; Tiong-Huan, W. Effect of polystyrene aggregate size on strength and moisture migration characteristics of lightweight concrete. Cem. Concr. Compos. 2006, 28, 520–527. [Google Scholar] [CrossRef]

- Miled, K.; Le Roy, R.; Sab, K.; Boulay, C. Compressive behavior of an idealized EPS lightweight concrete: Size effects and failure mode. Mech. Mater. 2004, 36, 1031–1046. [Google Scholar] [CrossRef]

- Mohammed, H.J.; Zain, M.F.M. Experimental application of EPS concrete in the new prototype design of the concrete barrier. Constr. Build. Mater. 2016, 124, 312–342. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, D.; Jiang, Z.; Xiao, F.; Huang, X.; Liu, Z.; Tang, L. Dynamic response of expanded polystyrene concrete during low speed impact. Constr. Build. Mater. 2016, 122, 72–80. [Google Scholar] [CrossRef]

- American Concrete Institute Committee. Guide for Structural Lightweight Aggregate Concrete; ACI 213R-14; American Concrete Institute: Farmington Hills, MI, USA, 2014; p. 4. [Google Scholar]

- Dima, S.O.; Sarbit, A.; Dobre, T.; Radu, A.L.; Nicolescu, T.V.; Lungu, A. The rheological behaviour of lightweight concrete with embedded EPS beads. Mater. Plast. 2009, 46, 224–229. [Google Scholar]

- Chen, B.; Liu, N. A novel lightweight concrete-fabrication and its thermal and mechanical properties. Constr. Build. Mater. 2013, 44, 691–698. [Google Scholar] [CrossRef]

- Ferrándiz-Mas, V.; Sarabia, L.A.; Ortiz, M.C.; Cheeseman, C.R.; García-Alcocel, E. Design of bespoke lightweight cement mortars containing waste expanded polystyrene by experimental statistical methods. Mater. Design 2016, 89, 901–912. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Wang, L.M.; Liang, X.P. Steady State Dynamic Performance of the Slab with EPS-Blocks. In Proceedings of the International Conference on Structures and Building Materials, Guangzhou, China, 7–9 January 2011. [Google Scholar]

- Gao, H.; Bu, C.; Wang, Z.; Shen, Y.; Chen, G. Dynamic characteristics of expanded polystyrene composite soil under traffic loadings considering initial consolidation state. Soil Dyn. Earthq. Eng. 2017, 102, 86–98. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, M.; He, Q.; Wen, K. Deformation and Damping Characteristics of Lightweight Clay-EPS Soil under Cyclic Loading. Adv. Civ. Eng. 2018, 2018, 8093719. [Google Scholar] [CrossRef]

- Shi, W.; Miao, L.; Luo, J.; Wang, J.; Chen, Y. Durability of modified expanded polystyrene concrete after dynamic cyclic loading. Shock. Vib. 2016, 2016, 2391476. [Google Scholar] [CrossRef][Green Version]

- Haque, M.N.; Al-Khaiat, H.; Kayali, O. Strength and durability of lightweight concrete. Cem. Concr. Compos. 2004, 26, 307–314. [Google Scholar] [CrossRef]

- Babu, K.G.; Babu, D.S. Performance of fly ash concretes containing lightweight EPS aggregates. Cem. Concr. Compos. 2004, 26, 605–611. [Google Scholar] [CrossRef]

- Ravindrarajah, R.S.; Tuck, A.J. Properties of hardened concrete containing treated expanded polystyrene beads. Cem. Concr. Compos. 1994, 16, 273–277. [Google Scholar] [CrossRef]

- Ghafoori, N.; Najimi, M.; Diawara, H.; Islam, M.S. Effects of class F fly ash on sulfate resistance of Type V Portland cement concretes under continuous and interrupted sulfate exposures. Constr. Build. Mater. 2015, 78, 85–91. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Hooton, R.D. Experimental study on physical sulfate salt attack. Mater. Struct. 2017, 50, 54. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Kurtis, K.E. Time to failure for concrete exposed to severe sulfate attack. Cem. Concr. Res. 2003, 33, 987–993. [Google Scholar] [CrossRef]

- Babu, K.G.; Babu, D.S. Behaviour of lightweight expanded polystyrene concrete containing silica fume. Cem. Concr. Res. 2003, 33, 755–762. [Google Scholar] [CrossRef]

- Diab, A.M.; Awad, A.M.; Elyamany, H.E.; Abd Elmoaty, A.E.M. Guidelines in compressive strength assessment of concrete modified with silica fume due to magnesium sulfate attack. Constr. Build. Mater. 2012, 36, 311–318. [Google Scholar] [CrossRef]

- Sawicz, Z.; Heng, S.S. Durability of concrete with addition of limestone powder. Mag. Concr. Res. 1996, 175, 131–137. [Google Scholar] [CrossRef]

- ASTM C150/C150M–Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C618–Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2015.

- Bonakdar, A.; Mobasher, B. Multi-parameter study of external sulfate attack in blended cement materials. Constr. Build. Mater. 2010, 24, 61–70. [Google Scholar] [CrossRef]

- You, Q.; Miao, L.; Li, C.; Hu, S.; Fang, H. Experimental study on preventing expanded polystyrene concrete segregation. Adv. Cem. Res. 2019, 31, 448–462. [Google Scholar] [CrossRef]

- Li, C.; Miao, L.; You, Q.; Hu, S.; Fang, H. Effects of viscosity modifying admixture (VMA) on workability and compressive strength of structural EPS concrete. Constr. Build. Mater. 2018, 175, 342–350. [Google Scholar] [CrossRef]

- ASTM C192–Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C 511–Standard Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of Hydraulic Cements and Concretes; ASTM International: West Conshohocken, PA, USA, 2013.

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete; GB/T 50082-2009; China Architecture & Building Press: Beijing, China, 2009; pp. 69–72. (In Chinese)

- Rahman, M.M.; Bassuoni, M.T. Thaumasite sulfate attack on concrete: Mechanisms, influential factors and mitigation. Constr. Build. Mater. 2014, 73, 652–662. [Google Scholar] [CrossRef]

- Gao, H.; Shen, Y.; Wang, Z. Dynamic modulus and damping ratio characteristics of EPS composite soil. Chin. J. Geotech. Eng. 2017, 39, 279–286. (In Chinese) [Google Scholar]

- Ke, G.; Guo, C.; Hu, S.; Chen, Z. Study on the damping ratio of concrete. J. Build. Mater. 2004, 7, 35–40. (In Chinese) [Google Scholar]

- Jin, Z.; Cui, Z. Investigation on strain dependence of dynamic recrystallization behavior using an inverse analysis method. Mater. Sci. Eng. A Struct. 2010, 527, 3111–3119. [Google Scholar] [CrossRef]

- Lydon, F.D.; Balendran, R.V. Some observations on elastic properties of plain concrete. Cem. Concr. Res. 1986, 16, 314–324. [Google Scholar] [CrossRef]

- Al-Amawee, A.H.; Salman, M.M. The Ratio between Static and Dynamic Modulusof Elasticity in Normal and High Strength Concrete. J. Eng. Sustain. Dev. 2006, 10, 163–174. [Google Scholar]

- Flatt, R.J. Salt damage in porous materials: How high supersaturations are generated. J. Cryst. Growth 2002, 242, 435–454. [Google Scholar] [CrossRef]

- Aye, T.; Oguchi, C.T. Resistance of plain and blended cement mortars exposed to severe sulfate attacks. Constr. Build. Mater. 2011, 25, 2988–2996. [Google Scholar] [CrossRef]

- Haynes, H.; O’Neill, R.; Neff, M.; Mehta, P.K. Salt weathering distress on concrete exposed to sodium sulfate environment. ACI Mater. J. 2008, 105, 35. [Google Scholar]

- Liao, Y.D.; Yang, Y.C.; Jiang, C.H.; Feng, X.G.; Chen, D. Degradation of mechanical properties of cementitious materials exposed to wet–dry cycles of sulphate solution. Mater. Res. Innov. 2015, 19, S5-173–S5-177. [Google Scholar] [CrossRef]

| Class F Fly Ash | |

|---|---|

| Chemical Composition (%) | |

| Silicon dioxide (SiO2) | 58.27 |

| Aluminum oxide (Al2O3) | 23.65 |

| Ferric oxide (Fe2O3) | 6.28 |

| Calcium oxide (CaO) | 4.18 |

| Magnesium oxide (MgO) | 1.52 |

| Sulfur trioxide (SO3) | 0.33 |

| Potassium oxide (K2O) | 1.95 |

| sodium oxide (Na2O) | 1.06 |

| Loss on ignition (LOI), % | 0.27 |

| Physical properties | |

| Specific gravity | 2.20 |

| Blaine (cm2/g) | 3340 |

| Cement | Fly Ash | Water | Coarse Aggregate (Type A) | Coarse Aggregate (Type B) | Sand | SP | VMA | PE | EPS Volume |

|---|---|---|---|---|---|---|---|---|---|

| (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (m3) a |

| 413 | 22 | 126 | 181 | 423 | 534 | 6.52 | 0.35 | 4.35 | 0.30 |

| Stage | Amplitudes of the Bias Force | Frequencies | Accumulated Cyclic Numbers, n |

|---|---|---|---|

| Ⅰ | 30 kN | 5 Hz | 0–2,500,000 |

| Ⅱ | 40 kN | 5 Hz | 2,500,000–3,500,000 |

| Ⅲ | 40 kN | 10 Hz | 3,500,000–16,350,000 |

| Ⅳ | 30 kN | 10 Hz | 16,350,000–22,000,000 |

| Cyclic Numbers, n | fBn/MPa | fCn/MPa | Kf |

|---|---|---|---|

| 30 | 35.1 | 32.9 | 106.7% |

| 60 | 37.8 | 34.3 | 110.2% |

| 90 | 38.2 | 35.2 | 108.5% |

| 120 | 36.9 | 35.7 | 103.4% |

| 150 | 33.7 | 35.8 | 94.1% |

| 180 | 28.9 | 35.9 | 80.5% |

| 210 | 26.5 | 35.9 | 73.8% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, Q.; Miao, L.; Li, C.; Fang, H.; Liang, X. Study on the Fatigue and Durability Behavior of Structural Expanded Polystyrene Concretes. Materials 2019, 12, 2882. https://doi.org/10.3390/ma12182882

You Q, Miao L, Li C, Fang H, Liang X. Study on the Fatigue and Durability Behavior of Structural Expanded Polystyrene Concretes. Materials. 2019; 12(18):2882. https://doi.org/10.3390/ma12182882

Chicago/Turabian StyleYou, Quan, Linchang Miao, Chao Li, Huanglei Fang, and Xiaodong Liang. 2019. "Study on the Fatigue and Durability Behavior of Structural Expanded Polystyrene Concretes" Materials 12, no. 18: 2882. https://doi.org/10.3390/ma12182882

APA StyleYou, Q., Miao, L., Li, C., Fang, H., & Liang, X. (2019). Study on the Fatigue and Durability Behavior of Structural Expanded Polystyrene Concretes. Materials, 12(18), 2882. https://doi.org/10.3390/ma12182882