Temperature-Dependent Stiffening and Inelastic Behavior of Newly Synthesized Fiber-Reinforced Super Flexible Silica Aerogels

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| EPS | expanded polystyrene |

| SEM | scanning electron microscopy |

| MTMS | methyltrimethoxysilane |

| DMDS | dimethyldimethoxysilane |

| CTAC | cetyltrimethylammonium chloride |

| HFM | heat flow meter |

References

- Schmidt, M. A review of aircraft turnaround operations and simulations. Prog. Aerosp. Sci. 2017, 92, 25–38. [Google Scholar] [CrossRef]

- Pleasant, T. Rain in the Plane. Aircr. Cabin Manag. 2013, 2, 56–60. [Google Scholar]

- Chen, L.; Wang, S.; Li, G.; Lin, C.H.; Zhang, T.T. CFD modeling of moisture accumulation in the insulation layers of an aircraft. Appl. Therm. Eng. 2016, 102, 1141–1156. [Google Scholar] [CrossRef]

- Fricke, J.; Emmerling, A. Aerogels. J. Am. Ceram. Soc. 1992, 75, 2027–2035. [Google Scholar] [CrossRef]

- Winterling, H.; Sonntag, N. Rigid Polystyrene Foam(EPS, XPS). Kunstst. Int. 2011, 101, 18–21. [Google Scholar]

- Kistler, S.S. Coherent expanded aerogels and jellies. Nature 1931, 127, 741. [Google Scholar] [CrossRef]

- Randall, J.P.; Meador, M.A.B.; Jana, S.C. Tailoring mechanical properties of aerogels for aerospace applications. ACS Appl. Mater. Interfaces 2011, 3, 613–626. [Google Scholar] [CrossRef]

- Bheekhun, N.; Talib, A.; Rahim, A.; Hassan, M.R. Aerogels in aerospace: An overview. Adv. Mater. Sci. Eng. 2013, 2013, 406065. [Google Scholar] [CrossRef]

- Raut, P.; Liang, W.; Chen, Y.M.; Zhu, Y.; Jana, S.C. Syndiotactic Polystyrene-Based Ionogel Membranes for High Temperature Electrochemical Applications. ACS Appl. Mater. Interfaces 2017, 9, 30933–30942. [Google Scholar] [CrossRef]

- Zu, G.; Shimizu, T.; Kanamori, K.; Zhu, Y.; Maeno, A.; Kaji, H.; Shen, J.; Nakanishi, K. Transparent, superflexible doubly cross-linked polyvinylpolymethylsiloxane aerogel superinsulators via ambient pressure drying. ACS Nano 2018, 12, 521–532. [Google Scholar] [CrossRef]

- Zu, G.; Kanamori, K.; Shimizu, T.; Zhu, Y.; Maeno, A.; Kaji, H.; Nakanishi, K.; Shen, J. Versatile double-cross-linking approach to transparent, machinable, supercompressible, highly bendable aerogel thermal superinsulators. Chem. Mater. 2018, 30, 2759–2770. [Google Scholar] [CrossRef]

- He, Y.L.; Xie, T. Advances of thermal conductivity models of nanoscale silica aerogel insulation material. Appl. Therm. Eng. 2015, 81, 28–50. [Google Scholar] [CrossRef]

- He, S.; Huang, Y.; Chen, G.; Feng, M.; Dai, H.; Yuan, B.; Chen, X. Effect of heat treatment on hydrophobic silica aerogel. J. Hazard. Mater. 2019, 362, 294–302. [Google Scholar] [CrossRef] [PubMed]

- Bangi, U.K.; Lee, K.Y.; Maldar, N.M.N.; Park, H.H. Synthesis and Properties of Metal Oxide Aerogels via Ambient Pressure Drying. J. Nanosci. Nanotechnol. 2019, 19, 1217–1227. [Google Scholar] [CrossRef]

- Parmenter, K.E.; Milstein, F. Mechanical properties of silica aerogels. J. Non-Cryst. Solids 1998, 223, 179–189. [Google Scholar] [CrossRef]

- Meador, M.A.B.; Vivod, S.L.; McCorkle, L.; Quade, D.; Sullivan, R.M.; Ghosn, L.J.; Clark, N.; Capadona, L.A. Reinforcing polymer cross-linked aerogels with carbon nanofibers. J. Mater. Chem. 2008, 18, 1843–1852. [Google Scholar] [CrossRef]

- Liao, Y.; Wu, H.; Ding, Y.; Yin, S.; Wang, M.; Cao, A. Engineering thermal and mechanical properties of flexible fiber-reinforced aerogel composites. J. Sol-Gel Sci. Technol. 2012, 63, 445–456. [Google Scholar] [CrossRef]

- Yang, X.; Sun, Y.; Shi, D. Experimental investigation and modeling of the creep behavior of ceramic fiber-reinforced SiO2 aerogel. J. Non-Cryst. Solids 2012, 358, 519–524. [Google Scholar] [CrossRef]

- Maleki, H.; Durães, L.; Portugal, A. An overview on silica aerogels synthesis and different mechanical reinforcing strategies. J. Non-Cryst. Solids 2014, 385, 55–74. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, X.; He, S.; Shi, X.; Gong, L.; Zhang, H. Aramid fibers reinforced silica aerogel composites with low thermal conductivity and improved mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 84, 316–325. [Google Scholar] [CrossRef]

- Li, C.; Cheng, X.; Li, Z.; Pan, Y.; Huang, Y.; Gong, L. Mechanical, thermal and flammability properties of glass fiber film/silica aerogel composites. J. Non-Cryst. Solids 2017, 457, 52–59. [Google Scholar] [CrossRef]

- Hayase, G.; Kanamori, K.; Kazuki, K.; Hanada, T. Synthesis of new flexible aerogels from MTMS/DMDMS via ambient pressure drying. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2011; Volume 18, p. 032013. [Google Scholar]

- Kanamori, K.; Nakanishi, K.; Hanada, T. Elastic aerogels and xerogels synthesized from methyltrimethoxysilane (MTMS). MRS Online Proc. Libr. Arch. 2008, 1134. [Google Scholar] [CrossRef]

- Hayase, G.; Kanamori, K.; Fukuchi, M.; Kaji, H.; Nakanishi, K. Facile synthesis of marshmallow-like macroporous gels usable under harsh conditions for the separation of oil and water. Angew. Chem. Int. Ed. 2013, 52, 1986–1989. [Google Scholar] [CrossRef] [PubMed]

- Fener, R.; Niemeyer, P. Flexible Komposite auf Basis von Aerogelen; EP 3 042 884 A1 (Pending); Deutsches Zentrum für Luft- und Raumfahrt e.V.: Köln, Germany, 2016. [Google Scholar]

- Hayase, G.; Ohya, Y. Facile fabrication of marshmallow-like gels as flexible thermal insulators and liquid nitrogen retention materials: Application to a cryopreserved embryo container. ChemRxiv 2017. [Google Scholar] [CrossRef]

- Mullins, L. Softening of rubber by deformation. Rubber Chem. Technol. 1969, 42, 339–362. [Google Scholar] [CrossRef]

- Katti, A.; Shimpi, N.; Roy, S.; Lu, H.; Fabrizio, E.F.; Dass, A.; Capadona, L.A.; Leventis, N. Chemical, physical, and mechanical characterization of isocyanate cross-linked amine-modified silica aerogels. Chem. Mater. 2006, 18, 285–296. [Google Scholar] [CrossRef]

- Wong, J.C.; Kaymak, H.; Brunner, S.; Koebel, M.M. Mechanical properties of monolithic silica aerogels made from polyethoxydisiloxanes. Microporous Mesoporous Mater. 2014, 183, 23–29. [Google Scholar] [CrossRef]

- Rege, A.; Schestakow, M.; Karadagli, I.; Ratke, L.; Itskov, M. Micro-mechanical modelling of cellulose aerogels from molten salt hydrates. Soft Matter 2016, 12, 7079–7088. [Google Scholar] [CrossRef]

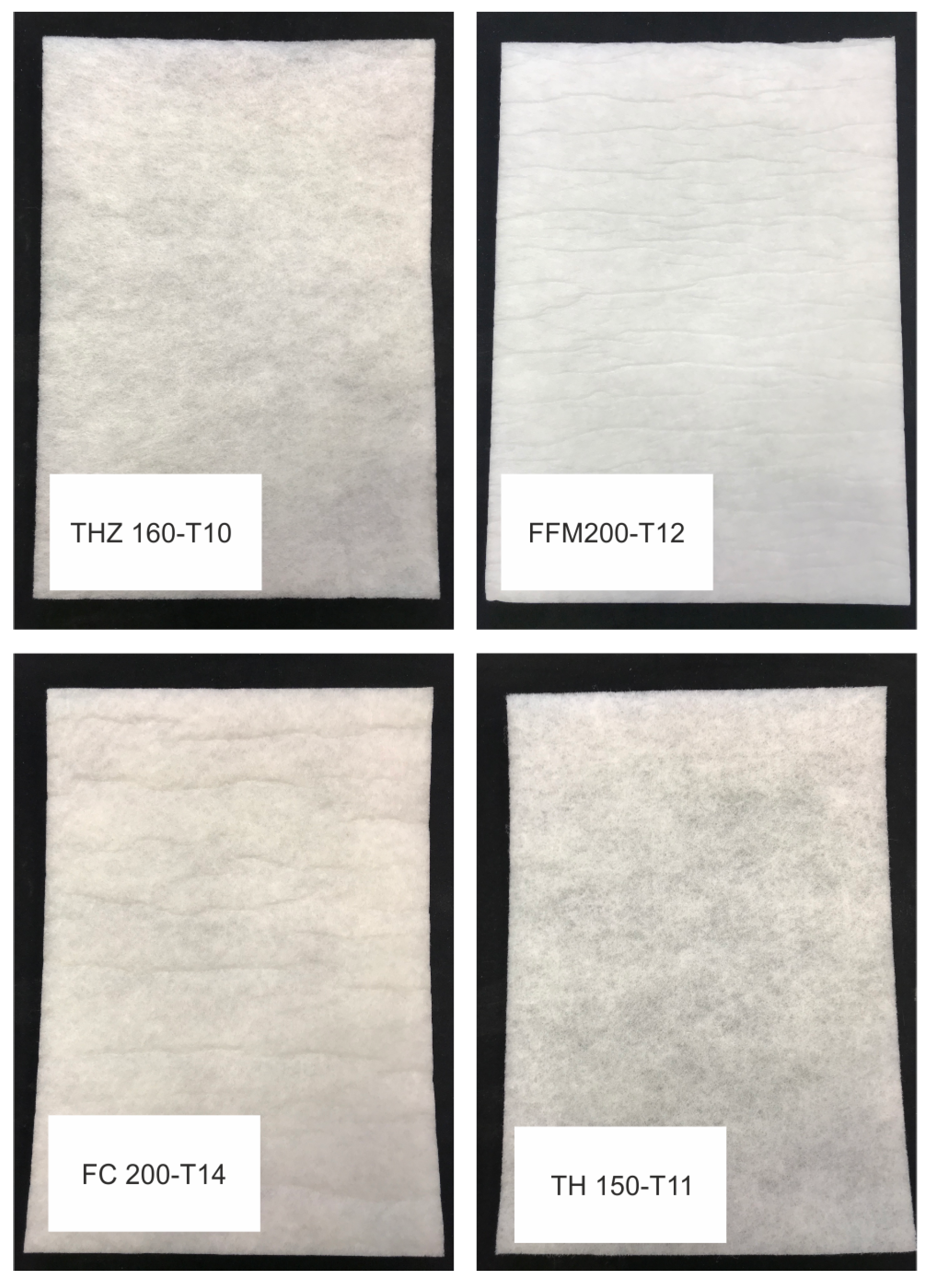

| Fiber Type | Fiber Volume (cm−3) | Sol Volume (cm−3) |

|---|---|---|

| FFM | 20.5 × 27 × 1.2 | 665 |

| TH | 20.5 × 27 × 1.1 | 610 |

| THZ | 20.5 × 27 × 1.0 | 555 |

| FC | 20.5 × 27 × 1.4 | 775 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rege, A.; Voepel, P.; Okumus, E.; Hillgärtner, M.; Itskov, M.; Milow, B. Temperature-Dependent Stiffening and Inelastic Behavior of Newly Synthesized Fiber-Reinforced Super Flexible Silica Aerogels. Materials 2019, 12, 2878. https://doi.org/10.3390/ma12182878

Rege A, Voepel P, Okumus E, Hillgärtner M, Itskov M, Milow B. Temperature-Dependent Stiffening and Inelastic Behavior of Newly Synthesized Fiber-Reinforced Super Flexible Silica Aerogels. Materials. 2019; 12(18):2878. https://doi.org/10.3390/ma12182878

Chicago/Turabian StyleRege, Ameya, Pascal Voepel, Emrah Okumus, Markus Hillgärtner, Mikhail Itskov, and Barbara Milow. 2019. "Temperature-Dependent Stiffening and Inelastic Behavior of Newly Synthesized Fiber-Reinforced Super Flexible Silica Aerogels" Materials 12, no. 18: 2878. https://doi.org/10.3390/ma12182878

APA StyleRege, A., Voepel, P., Okumus, E., Hillgärtner, M., Itskov, M., & Milow, B. (2019). Temperature-Dependent Stiffening and Inelastic Behavior of Newly Synthesized Fiber-Reinforced Super Flexible Silica Aerogels. Materials, 12(18), 2878. https://doi.org/10.3390/ma12182878