Effect of Multi-Source Ultrasonic on Segregation of Cu Elements in Large Al–Cu Alloy Cast Ingot

Abstract

1. Introduction

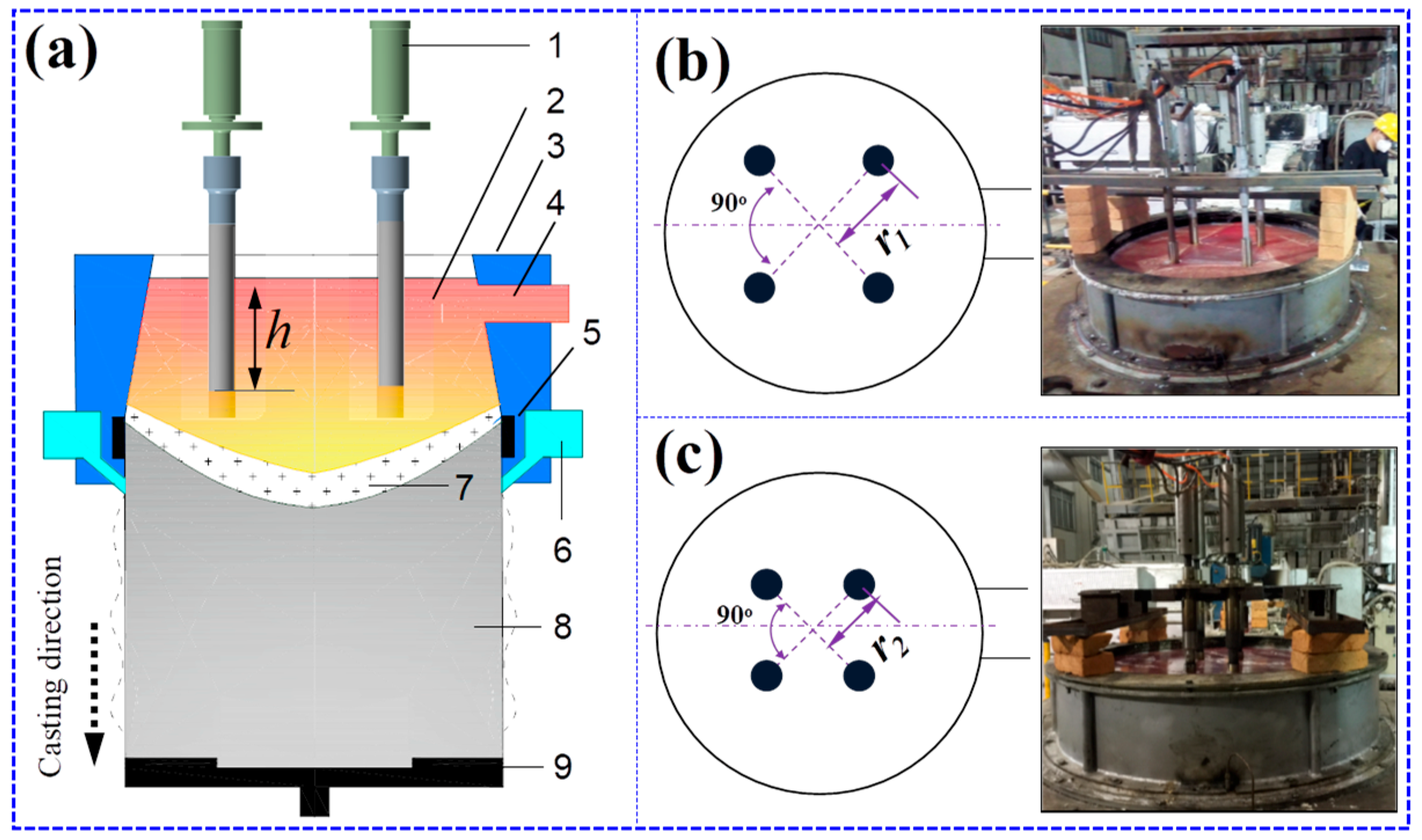

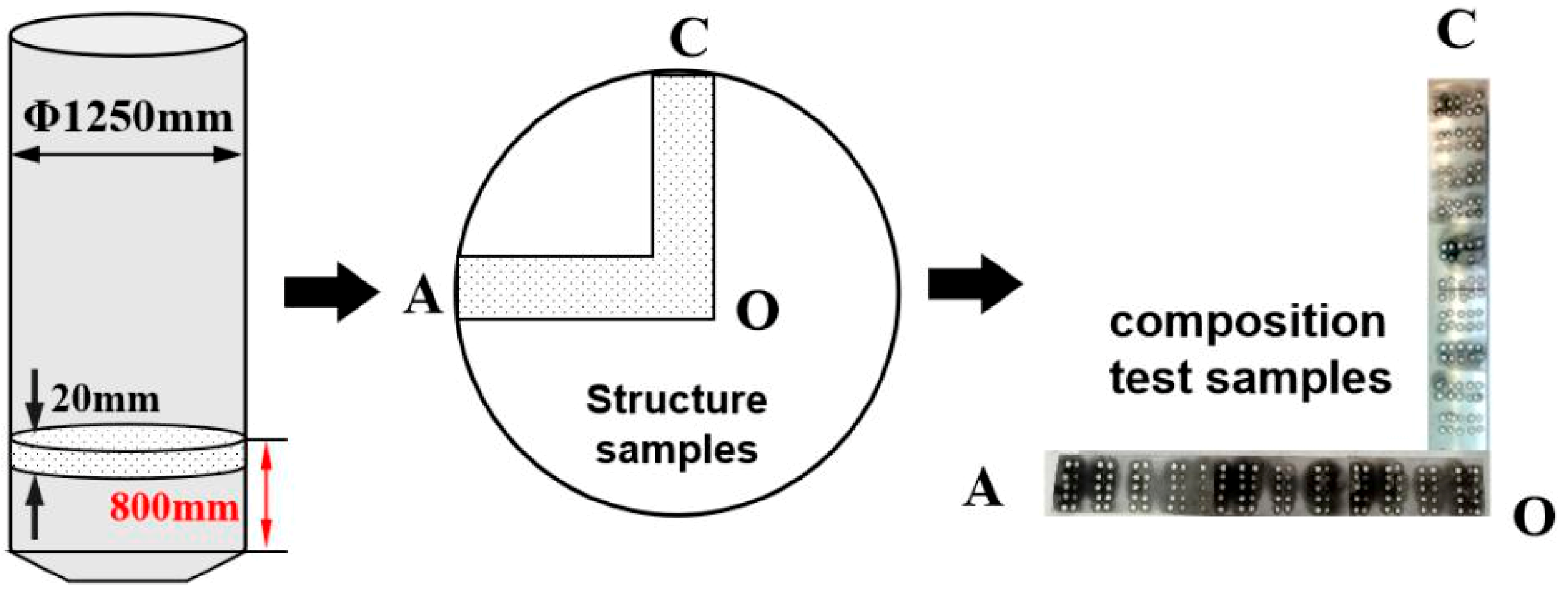

2. Experimental Procedure

2.1. Materials and Process

2.2. Methods

3. Experimental Results

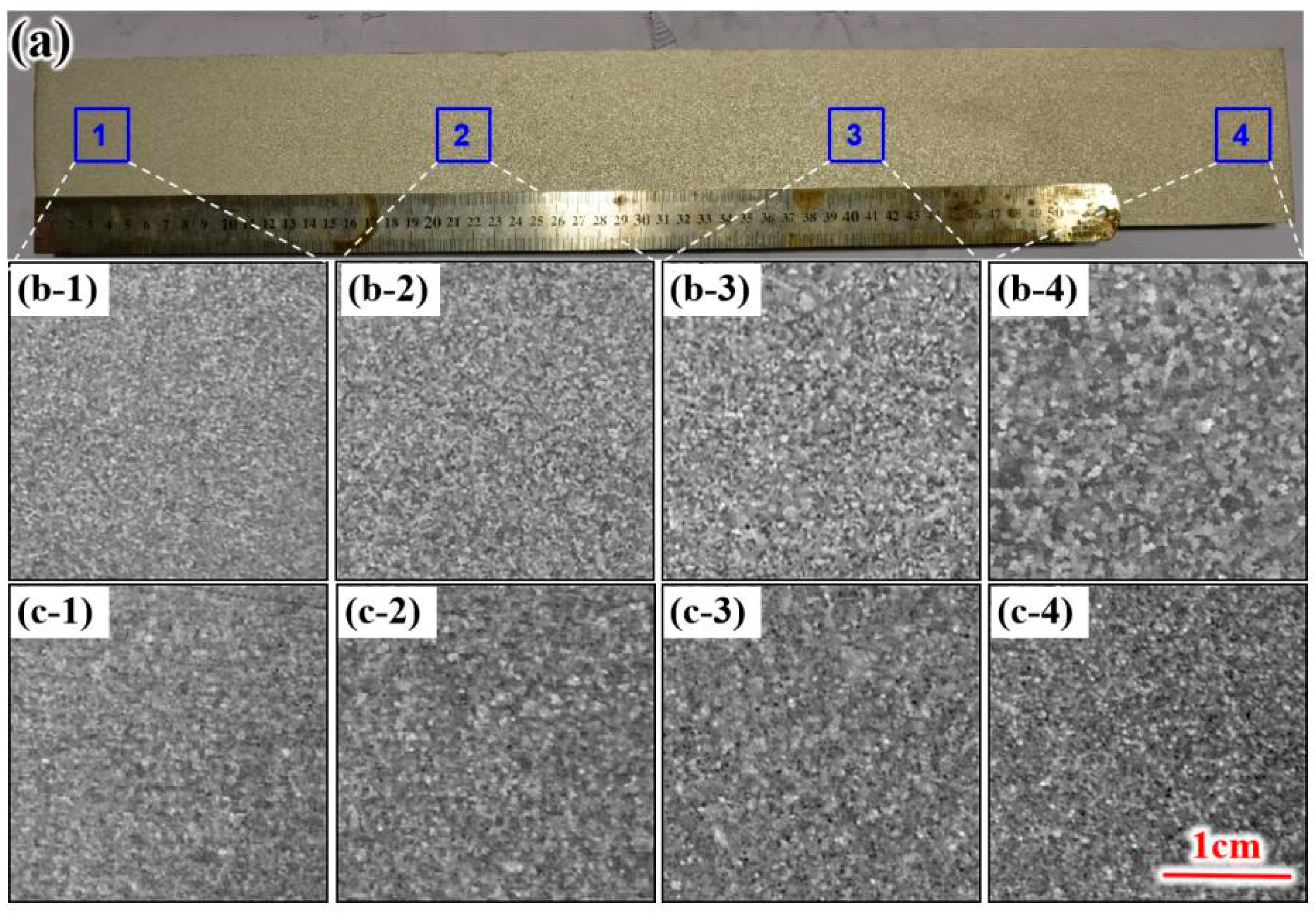

3.1. Macrostructure

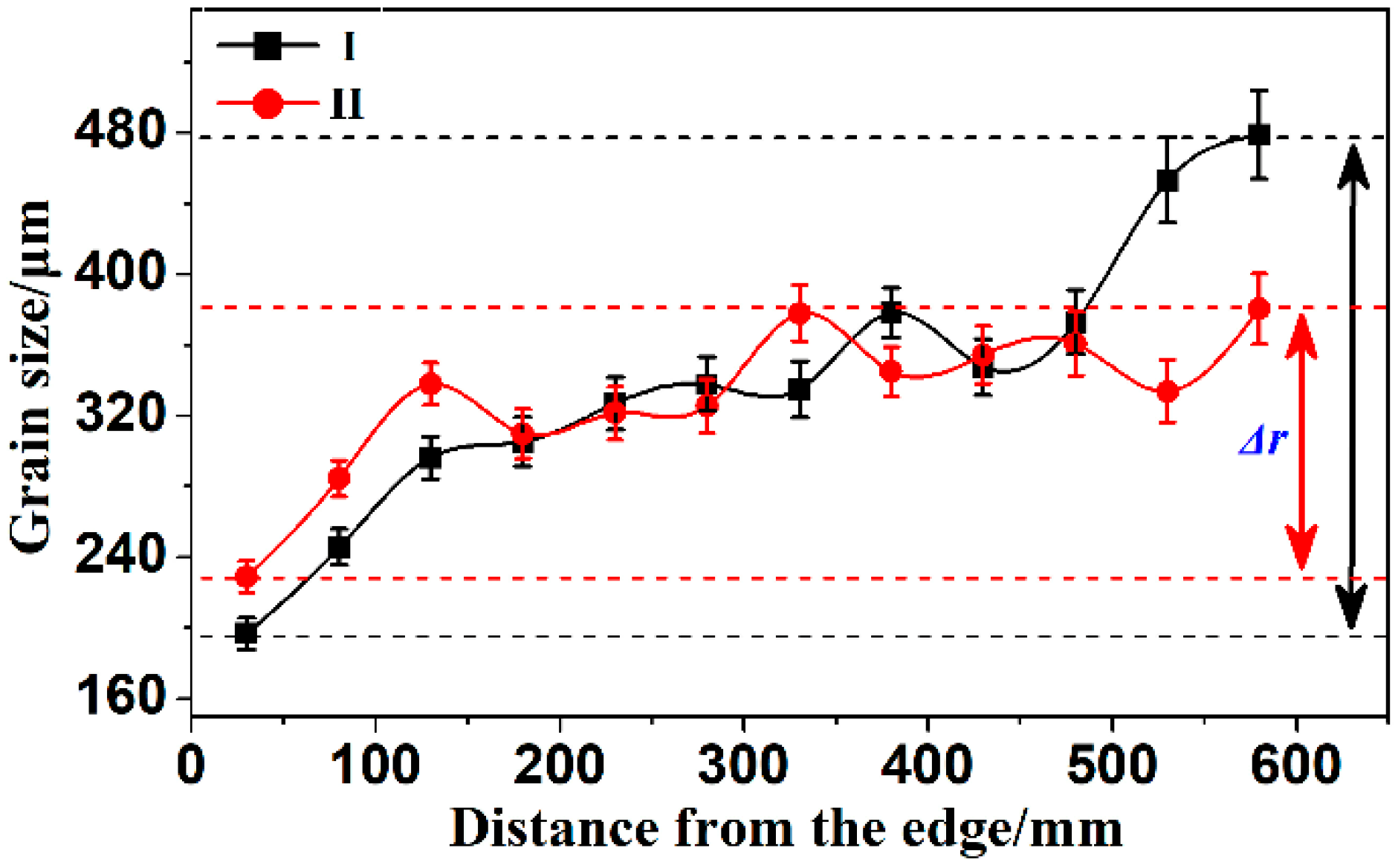

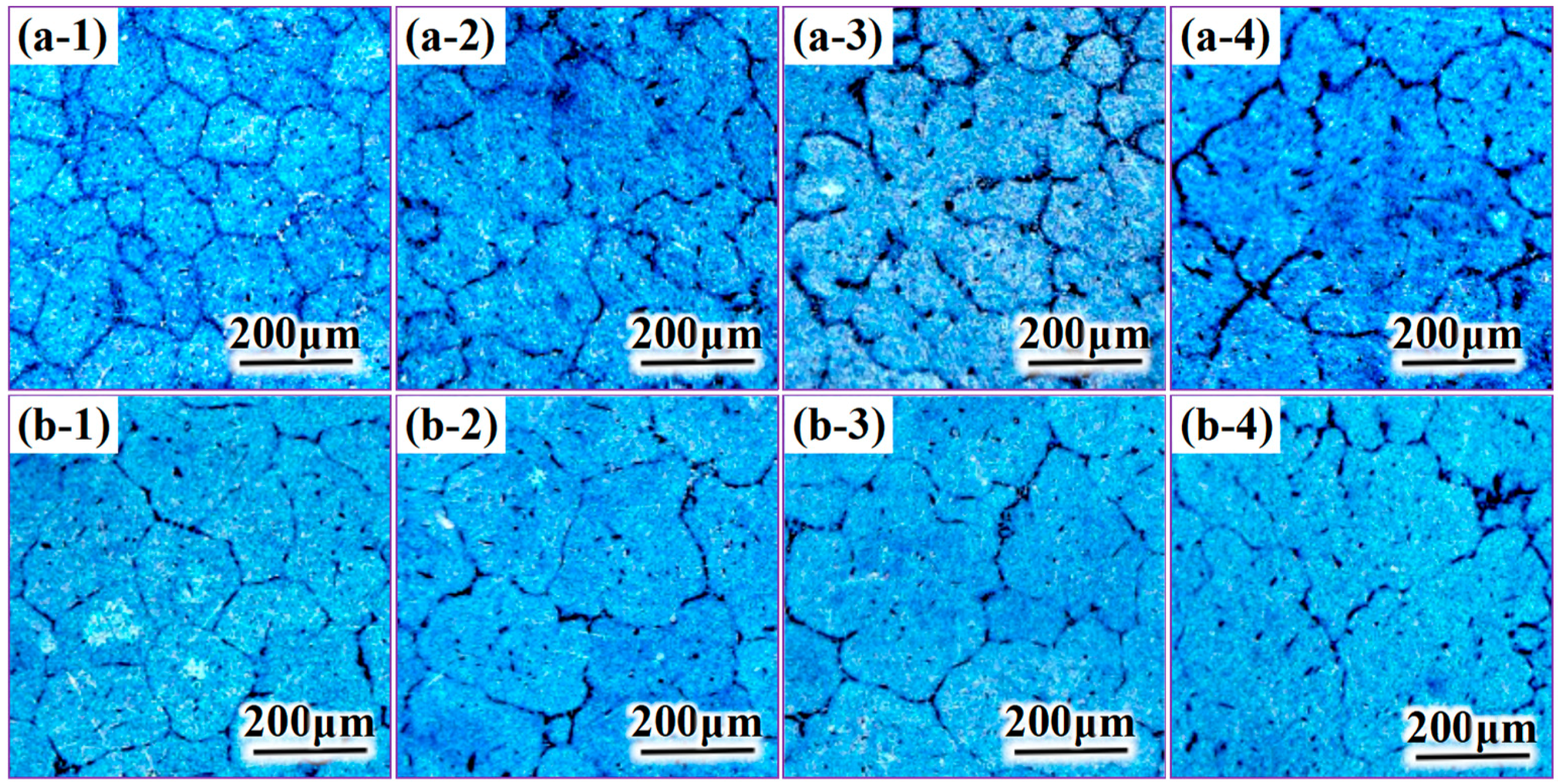

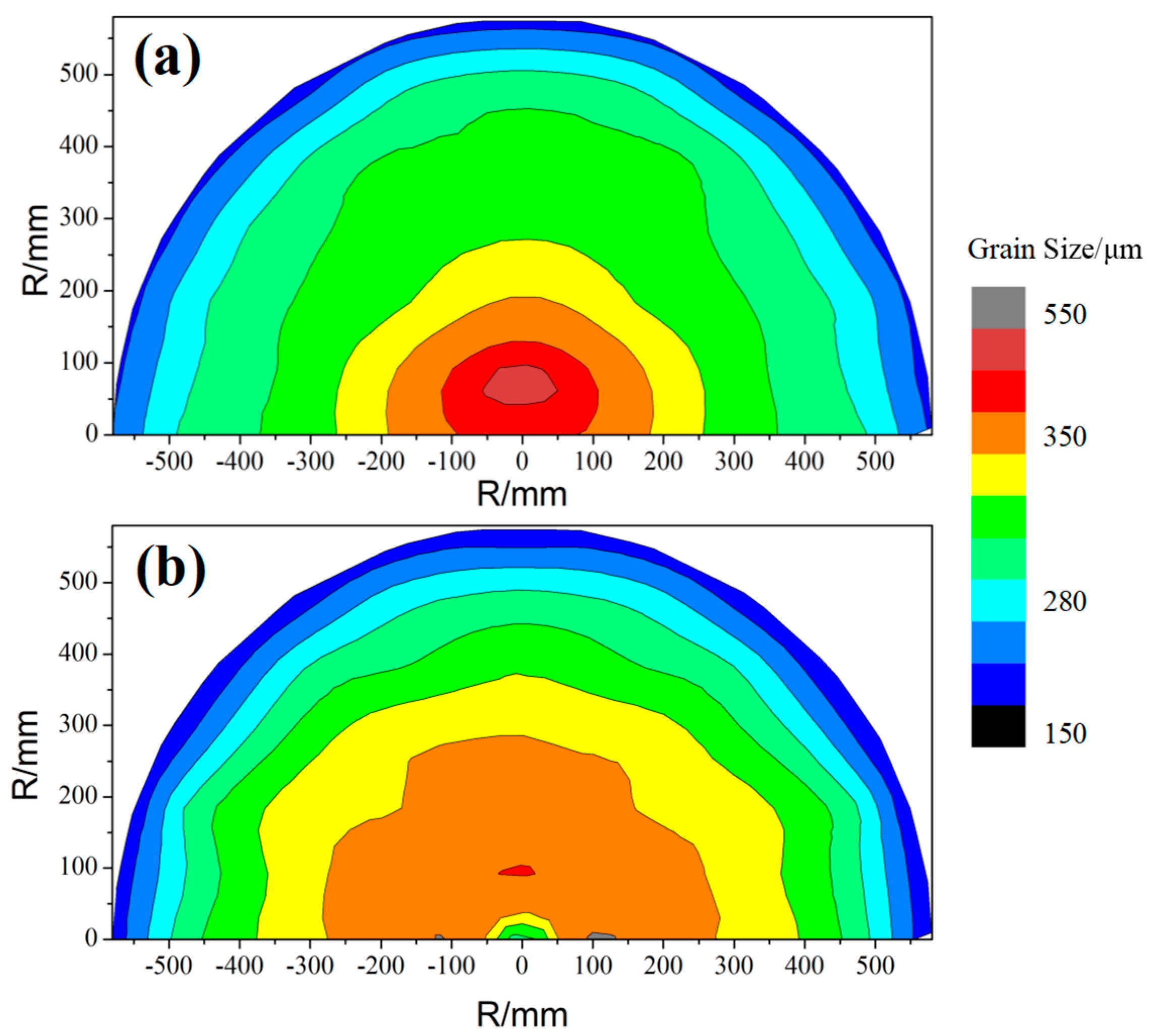

3.2. Microstructure

- (1)

- The grain size gradually increases within 0 to 150 mm from the ingot skin, and the grain size is stable from 150 to 475 mm. Then, the grain size of group I increases sharply from 475 mm to the ingot heart.

- (2)

- The casting grain size of group I was smaller than group II universally, which was in the fine-grained area of the edge. However, the casting ingot in group I was significantly higher than the grain size in group II when in the heart location.

- (3)

- The maximum deviation of the grain size in group I was 282 μm (Δr), which was higher than the same size in group II. The value of the ultrasonically untreated ingot is 300 μm [20].

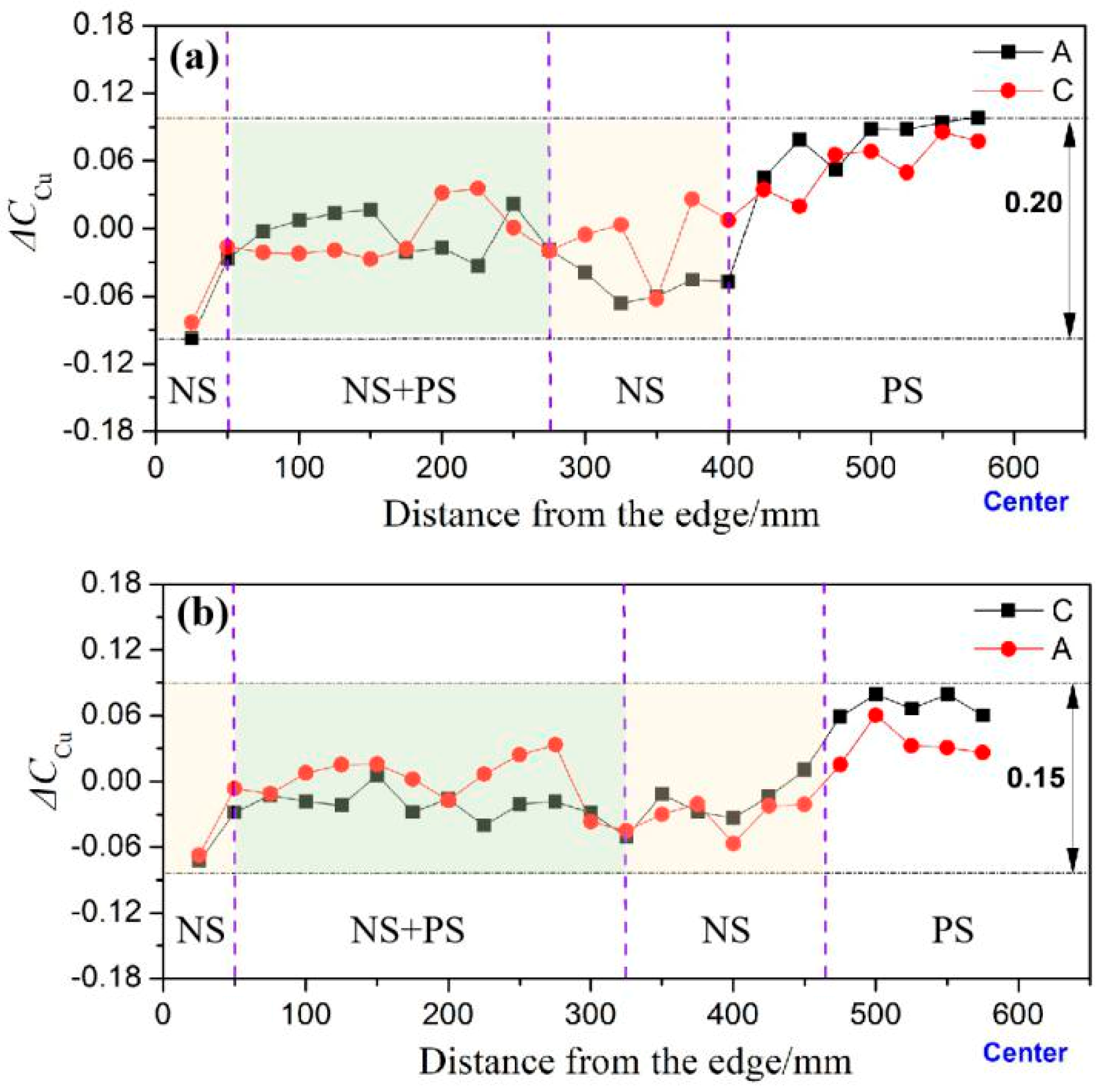

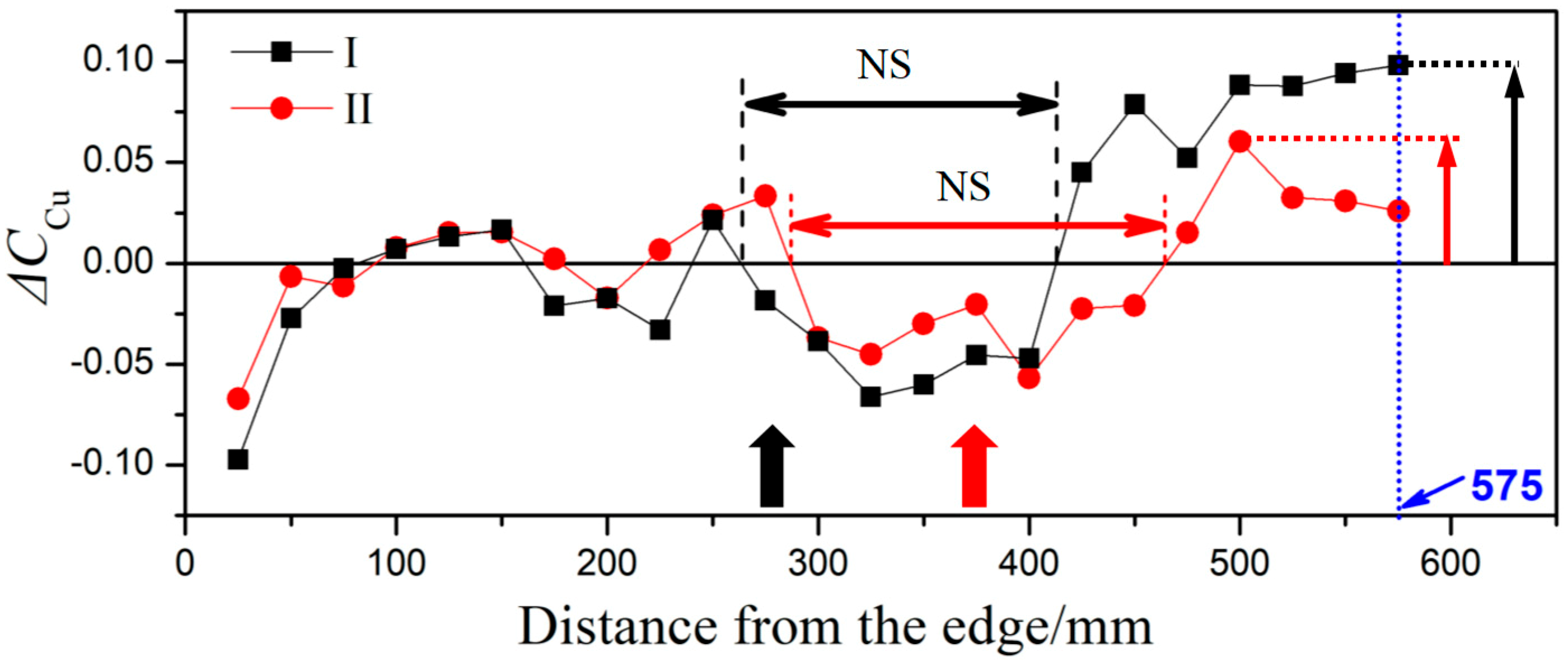

3.3. Macrosegregation of Elemental Cu

- (1)

- The degree and area of positive segregation in the heart of casting ingot II decrease (maximum value of positive segregation is 0.08, range is 150 mm). However, the maximum value and range of positive segregation in the heart of the casting ingot I are 0.1 and 200 mm, respectively.

- (2)

- The range of negative segregation in the middle portion of casting ingot II increases, and the area of negative segregation moves gradually toward the heart integrally. To be specific, the range of negative segregation area of casting ingot I is 125 mm, whereas the corresponding value for group II is 150 mm.

- (3)

- The degree of overall segregation decreases in casting ingot II. Similarly, the segregation index of casting ingot I is 0.2 (S), whereas the segregation index of casting ingot II is 0.15. For the ingot without ultrasonic treatment, the concentration of Cu fluctuated in a large range (S = 0.23), varying from 0.10 at the edge to 0.13 at the central positions [21].

- (4)

- The scope of the stabilization phase of casting group I is 225 mm, and the scope of group II is 275 mm.

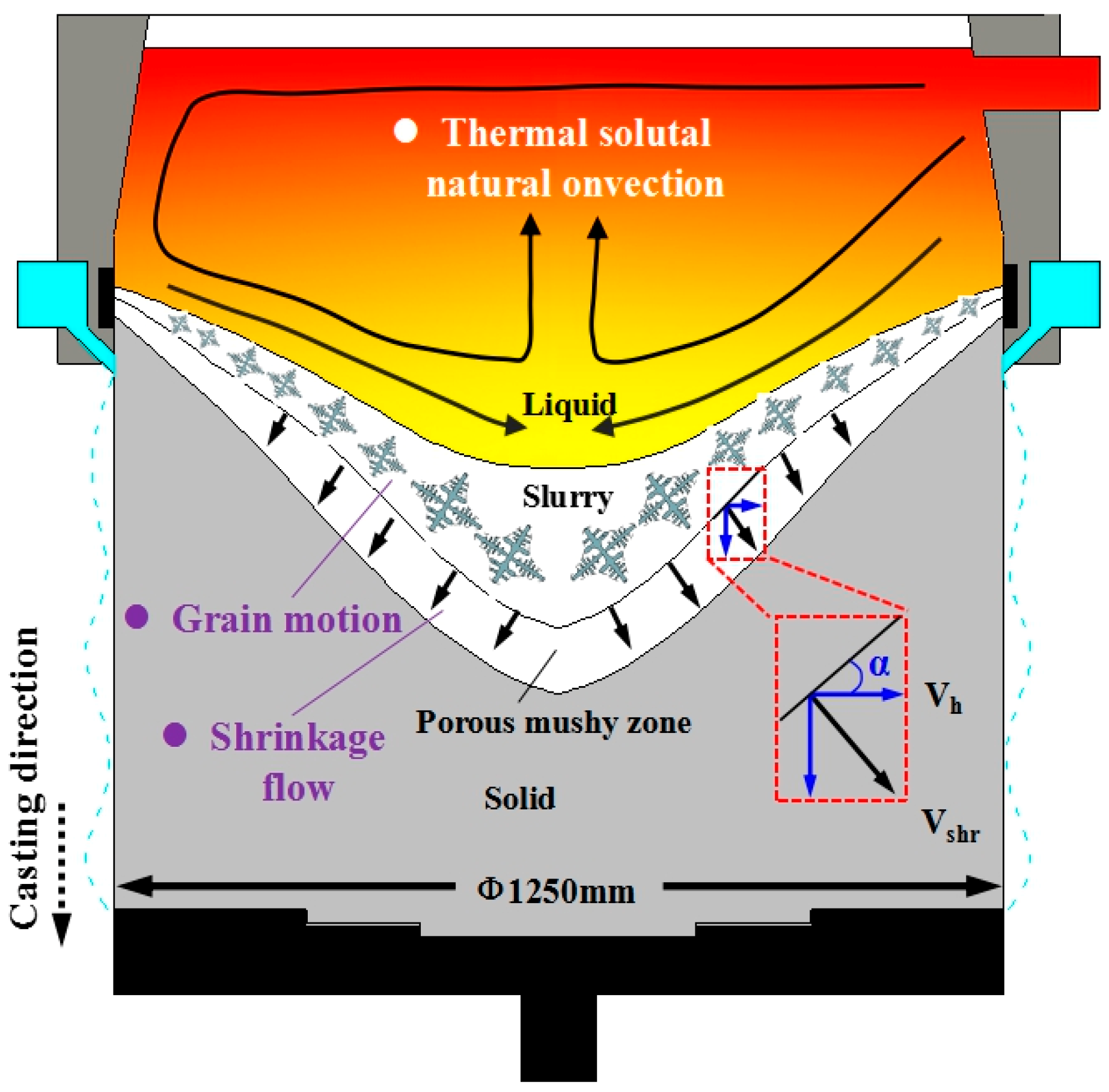

4. Discussion and Analysis

4.1. Influence of Ultrasonic Action on Macrosegregation of Large-Scale Ingot

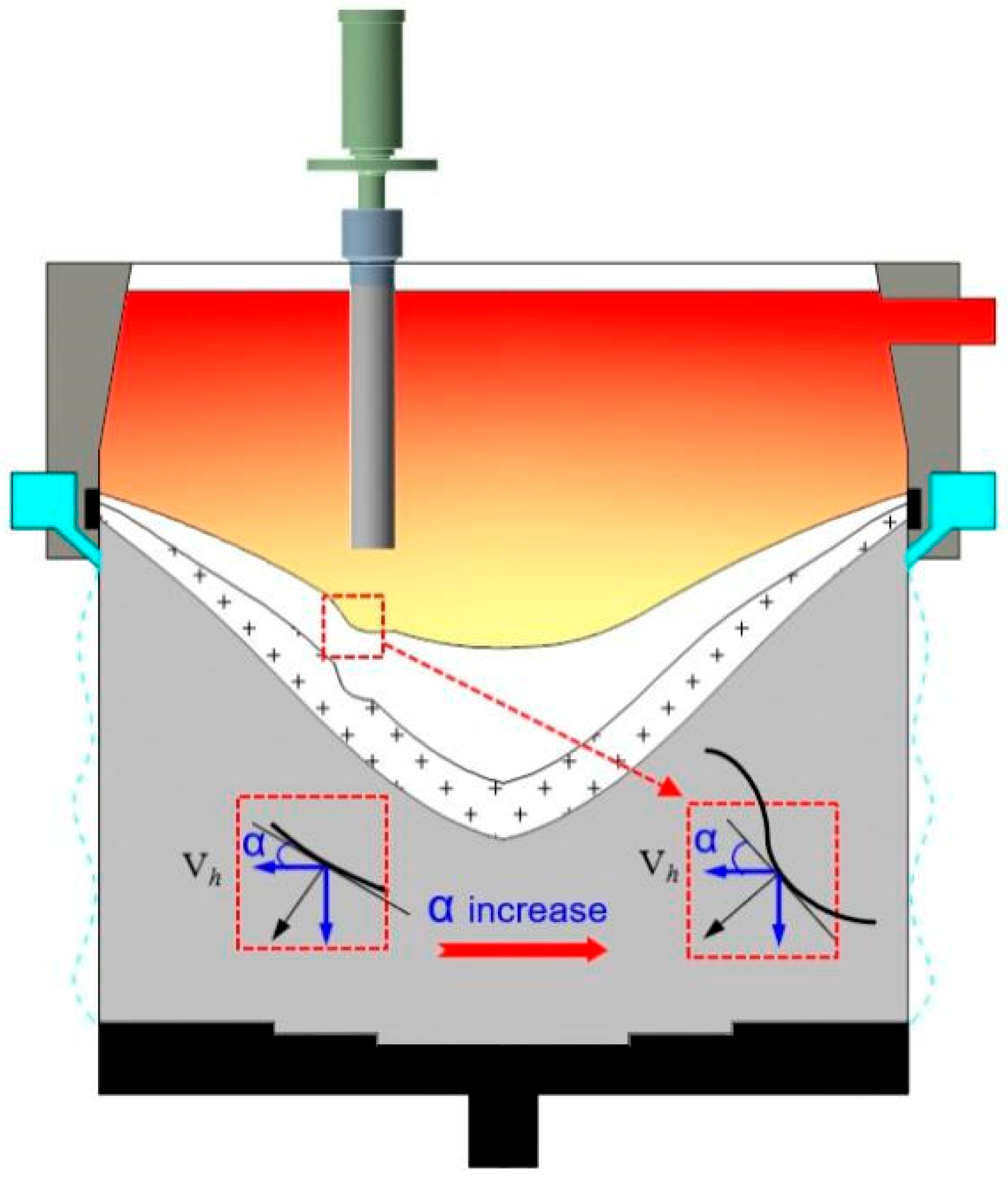

4.1.1. Effect of Ultrasonic Action on Segregation Caused by Thermosolutal Flow

4.1.2. Effect of Ultrasonic Action on Segregation Caused by Grain Movement

4.1.3. Effect of Ultrasonic Action on Segregation Caused by Solidification Shrinkage

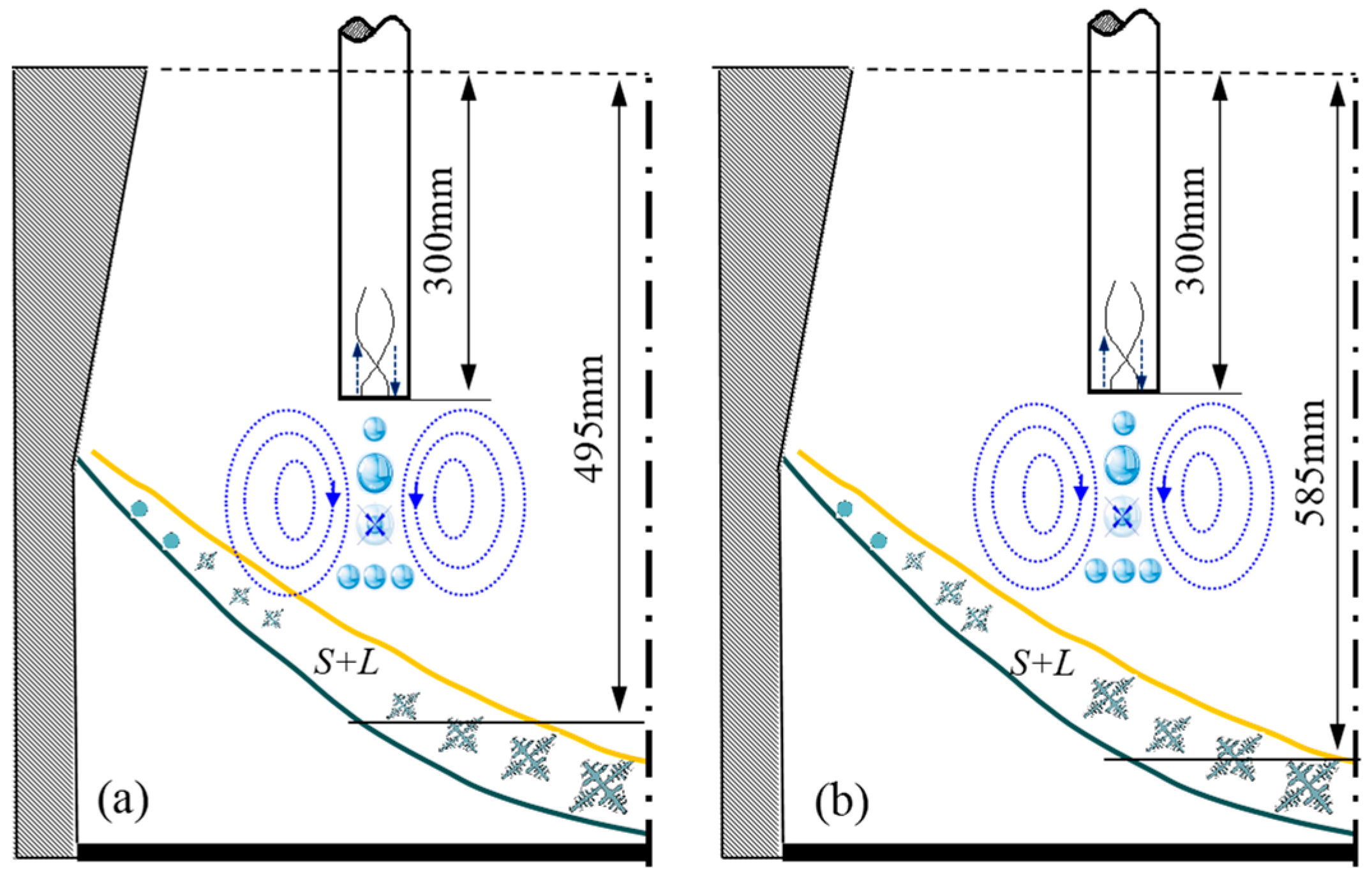

4.2. Effect of Different Ultrasonic Horizontal Position on Segregation in a Large Al–Cu Alloy Ingot

- (1)

- Area of ultrasonic action: When the ultrasound rod is moved from edge to the center, significant negative segregation (see figure) occurs in ultrasound group I (denoted by squares representation), which lies 185 to 330 mm away from the center. The same trend is observed for ultrasound group II (denoted by circles). However, the range of the negative segregation region is 130–310 mm. Additionally, the ultrasonic has a positive effect on the occurrence of negative segregation in the local region.

- (2)

- Area of the ingot center: The degree of positive segregation in group II is reduced, as marked by the right-most arrow in the figure, which indicates that the ultrasound rod is approaching the center of the ingot. Therefore, the negative segregation has an increased tendency in the local region and that contrasts the positive segregation.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, H.T.; Wang, Y.; Fan, Z. Mechanisms of enhanced heterogeneous nucleation during solidification in binary Al-Mg alloys. Acta Mater. 2012, 60, 1528–1537. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, Y.; Xia, M.S. Arumuganathar. Enhanced heterogeneous nucleation in AZ91D alloy by intensive melt shearing. Acta Mater. 2009, 57, 4891–4901. [Google Scholar] [CrossRef]

- Zuo, Y.B.; Cui, J.Z.; Mou, D.; Zhu, Q.F.; Wang, X.J.; Li, L. Effect of electromagnetic field on microstructure and macrosegregation of flat ingot of 2524 aluminium alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 2408–2413. [Google Scholar] [CrossRef]

- Wang, F.; Eskin, D.; Connolley, T.; Mi, J.W. Effect of ultrasonic melt treatment on the refinement of primary Al3Ti intermetallic in an Al0.4Ti alloy. J. Cryst. Growth 2016, 435, 24–30. [Google Scholar] [CrossRef]

- Eskin, G.I.; Eskin, D.G. Ultrasonic Treatment of Light Alloy Melts; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Wannasin, J.; Martinez, R.A.; Flemings, M.C. Grain refinement of an aluminum alloy by introducing gas bubbles during solidification. Scr. Mater. 2006, 55, 115–118. [Google Scholar] [CrossRef]

- Eskin, D.G.; Jafari, A.; Katgerman, L. Contribution of forced centreline convection during direct chill casting of round billets to macrosegregation and structure of binary Al-Cu aluminum alloy. Mater. Sci. Technol. 2011, 27, 890–896. [Google Scholar] [CrossRef]

- Vreeman, C.J.; Schloz, J.D.; Krane, M.J.M. Direct Chill Casting of Aluminum Alloys: Modeling and Experiments on Industrial Scale Ingots. Int. J. Heat Mass Transf. 2002, 124, 947–953. [Google Scholar] [CrossRef]

- Založnik, M.; Kumar, A.; Combeau, H.; Bedel, M.; Jarry, P.; Waz, E. Influence of transport mechanisms on macrosegregation formation in direct chill cast industrial scale aluminum alloy ingots. Adv. Eng. Mater. 2011, 13, 570–580. [Google Scholar] [CrossRef]

- Venneker, B.C.H.; Katgerman, L. Modelling issues in macrosegregation predictions in direct chill castings. J. Light Met. 2002, 2, 149–159. [Google Scholar] [CrossRef]

- Eskin, D.G.; Dua, Q.; Katgerman, L. Relationship between shrinkage-induced macrosegregation and the sump profile upon direct-chill casting. Scr. Mater. 2006, 55, 715–718. [Google Scholar] [CrossRef]

- Chu, M.G.; Jacoby, J.E. Light Metals; TMS: Warrendale, PA, USA, 1990; pp. 925–930. [Google Scholar]

- Glenn, A.M.; Russo, S.P.; Paterson, P.J.K. The effect of grain refining on macrosegregation and dendrite arm spacing of direct chill cast AA5182. Metall. Mater. Trans. A 2003, 34, 1513–1523. [Google Scholar] [CrossRef]

- Suyitno Eskin, D.G.; Savran, V.I.; Katgerman, L. Effects of alloy composition and casting speed on structure formation and hot tearing during direct-chill casting of Al-Cu alloys. Metall. Mater. Trans. A 2004, 35, 3551–3561. [Google Scholar] [CrossRef]

- Eskin, D.G.; Dua, Q.; Katgerman, L. Scale Rules for Macrosegregation during Direct-Chill Casting of Aluminum Alloys. Metall. Mater. Trans. A 2008, 5, 1206–1211. [Google Scholar] [CrossRef]

- Zaloznik, M.; Sarler, B. Modeling of macrosegregation in direct-chill casting of aluminum alloys: Estimating the influence of casting parameters. Mater. Sci. Eng. A 2005, 413–414, 85–91. [Google Scholar] [CrossRef]

- Eskin, D.G.; Zuidema, J., Jr.; Savran, V.I.; Katgerman, L. Structure formation and macrosegregation under different process conditions during DC casting. Mater. Sci. Eng. A 2005, 384, 232–244. [Google Scholar] [CrossRef]

- Nadella, R.; Eskin, D.G.; Du, Q.; Katgerman, L. Macrosegregation in direct-chill casting of aluminium alloys. Prog. Mater. Sci. 2008, 53, 421–480. [Google Scholar] [CrossRef]

- Eskin, D.G. Physical Metallurgy of Direct Chill Casting of Aluminum Alloys, 1st ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Li, R.; Liu, Z.; Chen, P.; Zhong, Z.; Li, X. Investigation on the Manufacture of a Large-Scale Aluminum Alloy Ingot: Microstructure and Macrosegregation. Adv. Eng. Mater. 2017, 2, 19. [Google Scholar] [CrossRef]

- Liu, Z.; Li, R.; Jiang, R.; Zhang, L.; Li, X. Scalable Ultrasound-Assisted Casting of Ultra-large 2219 Al Alloy Ingots. Metal. Mater. Trans. A 2019, 50, 1146–1152. [Google Scholar] [CrossRef]

- Ni, J.; Incropera, F.P. Extension of the continuum model for transport phenomena occurring during metal metal alloy solidification-II. Microscopic considerations. Int. J. Heat Mass Transf. 1995, 38, 1285–1296. [Google Scholar] [CrossRef]

- Drezet, J.-M.; Gremaud, M.; Rappaz, M. Continuous Casting; Wiley-VCH: Weinheim, Germany, 2005; pp. 151–161. [Google Scholar]

- Du, Q.; Eskin, D.; Katgerman, L. Modeling of Casting, Welding and Advanced Solidification Processes XI; TMS: Warrendale, PA, USA, 2006; pp. 235–242. [Google Scholar]

- Li, R.; Liu, Z.; Dong, F.; Li, X.; Chen, P. Grain refinement of a large-scale Al alloy casting by introducing the multiple ultrasonic generators during solidification. Metall. Mater. Trans. A 2016, 47, 3790. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, H.; Li, R.; Li, X.; Ding, S.; Chang, M.; Liao, L.; Zhang, Y.; Chen, P. Effect of Multi-Source Ultrasonic on Segregation of Cu Elements in Large Al–Cu Alloy Cast Ingot. Materials 2019, 12, 2828. https://doi.org/10.3390/ma12172828

Peng H, Li R, Li X, Ding S, Chang M, Liao L, Zhang Y, Chen P. Effect of Multi-Source Ultrasonic on Segregation of Cu Elements in Large Al–Cu Alloy Cast Ingot. Materials. 2019; 12(17):2828. https://doi.org/10.3390/ma12172828

Chicago/Turabian StylePeng, Hao, Ruiqing Li, Xiaoqian Li, Shan Ding, Mengjun Chang, Liqing Liao, Yun Zhang, and Pinghu Chen. 2019. "Effect of Multi-Source Ultrasonic on Segregation of Cu Elements in Large Al–Cu Alloy Cast Ingot" Materials 12, no. 17: 2828. https://doi.org/10.3390/ma12172828

APA StylePeng, H., Li, R., Li, X., Ding, S., Chang, M., Liao, L., Zhang, Y., & Chen, P. (2019). Effect of Multi-Source Ultrasonic on Segregation of Cu Elements in Large Al–Cu Alloy Cast Ingot. Materials, 12(17), 2828. https://doi.org/10.3390/ma12172828