1. Introduction

Structures consisting of sound scatterers periodically arranged in a lattice, known as sonic crystals (SCs), have been the subject of many research studies in the last two decades. Their ability to prevent sound propagation in certain frequency bands, called band gaps, is their most important characteristic. This is possible due to a mechanism called Bragg scattering, which is the destructive interference between the sound reflected from different scatterers in the lattice. A review paper by Kuswaha [

1] reported the “state of the art” regarding the different theoretical approaches employed to predict acoustic band gaps in SCs updated up to 1995. Experimental characterisation of acoustic band gaps was first reported in 1995 within a kinematic sculpture made by Eusebio Sempere, which is exhibited at the Juan March Foundation in Madrid [

2]. A few years later, the results were confirmed in a laboratory environment [

3,

4], where the existence of complete and partial band gaps was associated with the lattice symmetry and its filling fraction. Afterwards, wider and frequency-tuneable band gaps were shown to be feasible by changing the spatial arrangement and the mechanical properties of scatterers [

5,

6]. It should be noted that references already cited and the ones to come are strictly focused on the application of SCs in developing a new type of acoustic barriers and, therefore, the reader is addressed to recently published literature where other applications of photonic crystal and acoustic metamaterial are extensively reported [

7,

8].

Compared to traditional noise barriers, SCs do not necessarily need foundations since they show almost no resistance to air flow. However, a word of caution regarding this property is warranted. When the velocity of air is above a certain cut-off, the generated flow noise can quench the band gaps [

9]. SCs are also lighter compared to traditional noise barriers and have great aesthetic. Nevertheless, there are very few practical implementations of SCs outside laboratory environments [

10,

11], mostly because of fabrication cost. However, the costs could be substantially reduced through mass production.

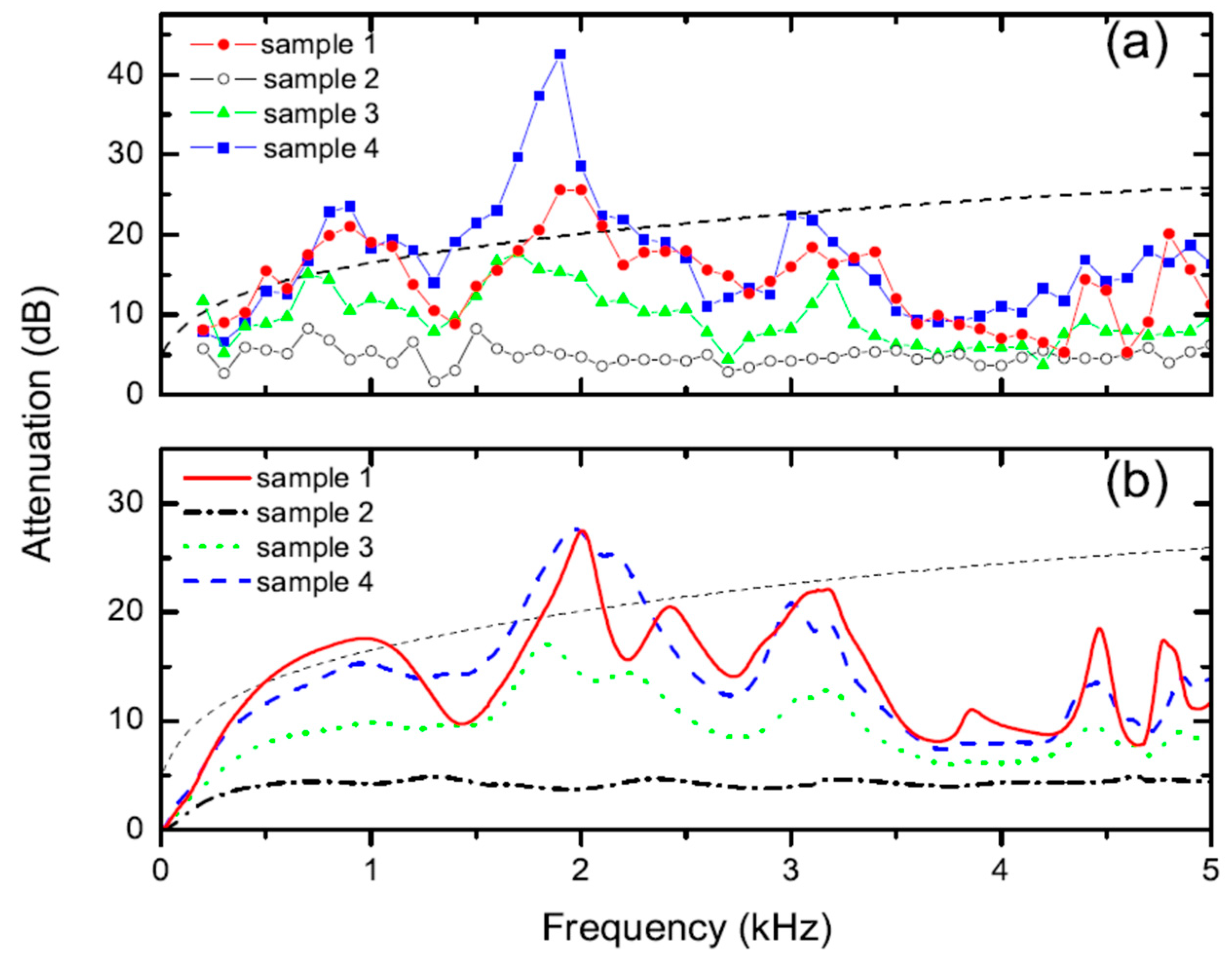

Experimental data show that a periodic arrangement of metallic cylinders in air provides sound attenuation of up to 25 dB [

3,

10,

11,

12,

13,

14], which could compete with traditional noise barriers. At band gap frequencies, simultaneous low transmittance and high reflectance are expected due to Bragg scattering. Unfortunately, the band gaps produced by SCs made of rigid cylinders are confined to a relatively narrow band of frequencies. Outside the band gaps, attenuation is very poor, making the use of SCs infeasible against broadband noise. Hence, additional physical mechanisms should be involved in order to achieve broadband attenuation. In that sense, the use of absorbing material covering the scatterers and local resonant phenomena have been recently proposed [

14,

15,

16,

17,

18,

19]. In this way, it is possible to obtain barriers whose frequency-dependent attenuation is more uniform and, in some cases, to enhance their overall performance.

Most of the reported research on the characterisation of SCs, both in laboratory environments [

4,

5,

12,

13,

14,

15,

16,

17,

18,

19] and in situ [

2,

10], has employed non-standardised measurement techniques, where neither diffraction nor unwanted reflections were excluded. This means that the measured attenuation values should be considered as indicative rather than precise. In this regard, the standardised EN 1793-5 [

20] and EN 1793-6 [

21] methods specify test procedures for assessing the intrinsic reflection and airborne sound insulation performance for noise reducing devices. For example, by applying an appropriate windowing technique, EN 1793-6 accounts for transmitted components only, while dismissing diffracted and sound reflected components from the ground and other objects located nearby. Similarly, the windowing technique in the case of EN 1793-5 excludes components other than those reflected from the barrier itself. Both methods were initially developed and tested by the European Commission funded projects ‘‘Adrienne” [

22] and “QUIESST” [

23]. However, the methods have been tested with traditional noise barriers only, while their applicability in the case of SCs is still uncertain.

Recently, Morandi at al. [

24] characterised an SC noise barrier made of polyvinyl chloride (PVC) rods with a lattice constant of 0.2 m, by implementing standardised EN 1793-5 and EN 1793-6 methods. They showed that the values of the sound insulation index (

SI) and the reflection index (

RI) strongly depend on the measurement configuration, attaining maximum values of about 24 dB for

SI and around 1 (on the decimal scale) for

RI in the Bragg band gap. While the EN 1793-6 method allows calculation of the intrinsic airborne sound insulation, the method itself restricted the applicability to SCs with no more than three rows of cylinders in the lattice. This is due to inability of the temporal window to include all reflections with a significant spectral content. For sound reflection measurements, correlation between the number of rows and the measured data was found to be poor, according to Figure 7 in [

24].

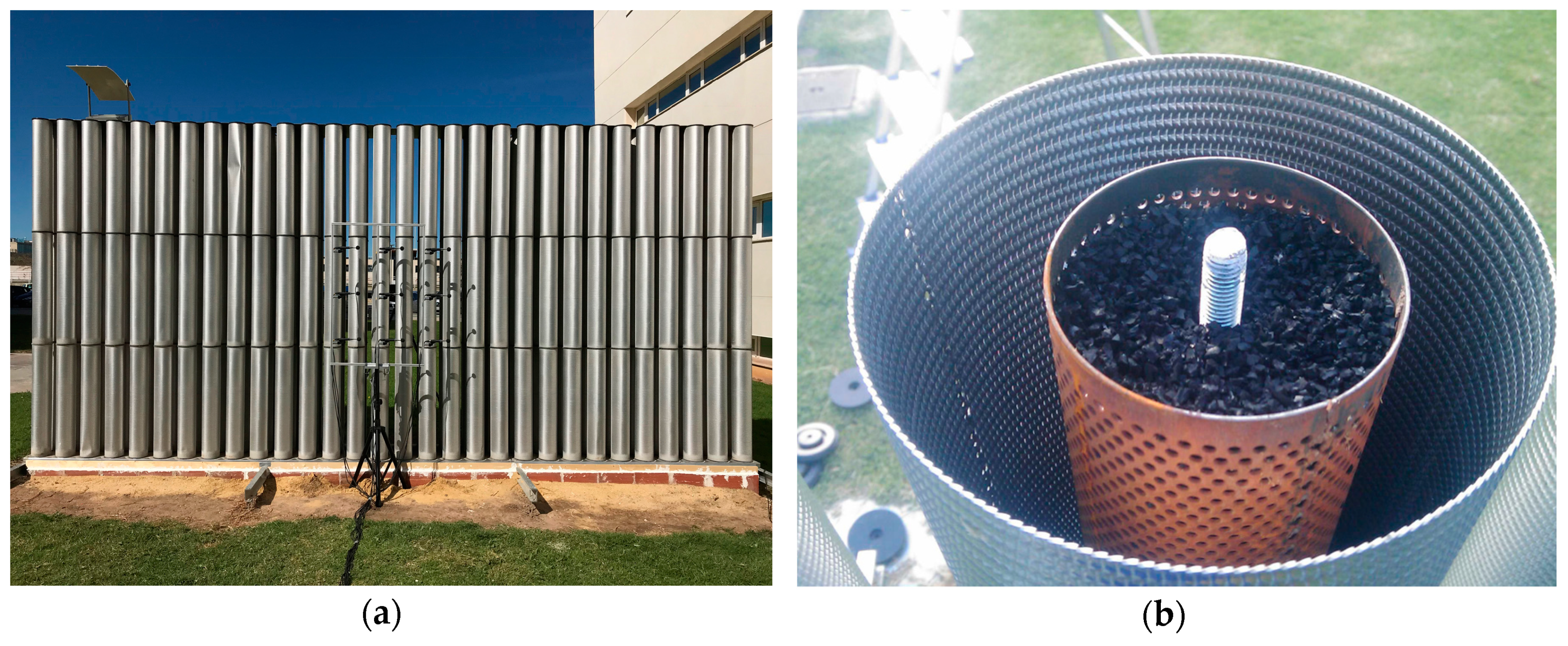

Transmittance, reflectance, and absorption properties of a SC barrier based on three rows of empty micro-perforated (MP) cylindrical shells were previously characterised by using a non-standardised measurement technique [

11]. In the present research, characterisation of the SC barrier consisting of MP cylindrical shells but with an inner core made of rubber crumb, is presented. The purpose of adding the inner core was improving the absorption at high frequencies, where the rubber crumb provides better dissipation of the acoustic energy [

15]. On the one hand, a modelling technique similar to that presented in [

11] was employed in order to compare this barrier with the barrier based on empty MP cylindrical shells used in the previous characterisation. On the other hand, the standardised EN 1793-5 and EN 1793-6 measurement methods were implemented in order to compare data with the barrier based on rigid PVC cylinders, which was characterised in the same manner [

24].

The paper is described as follows. First,

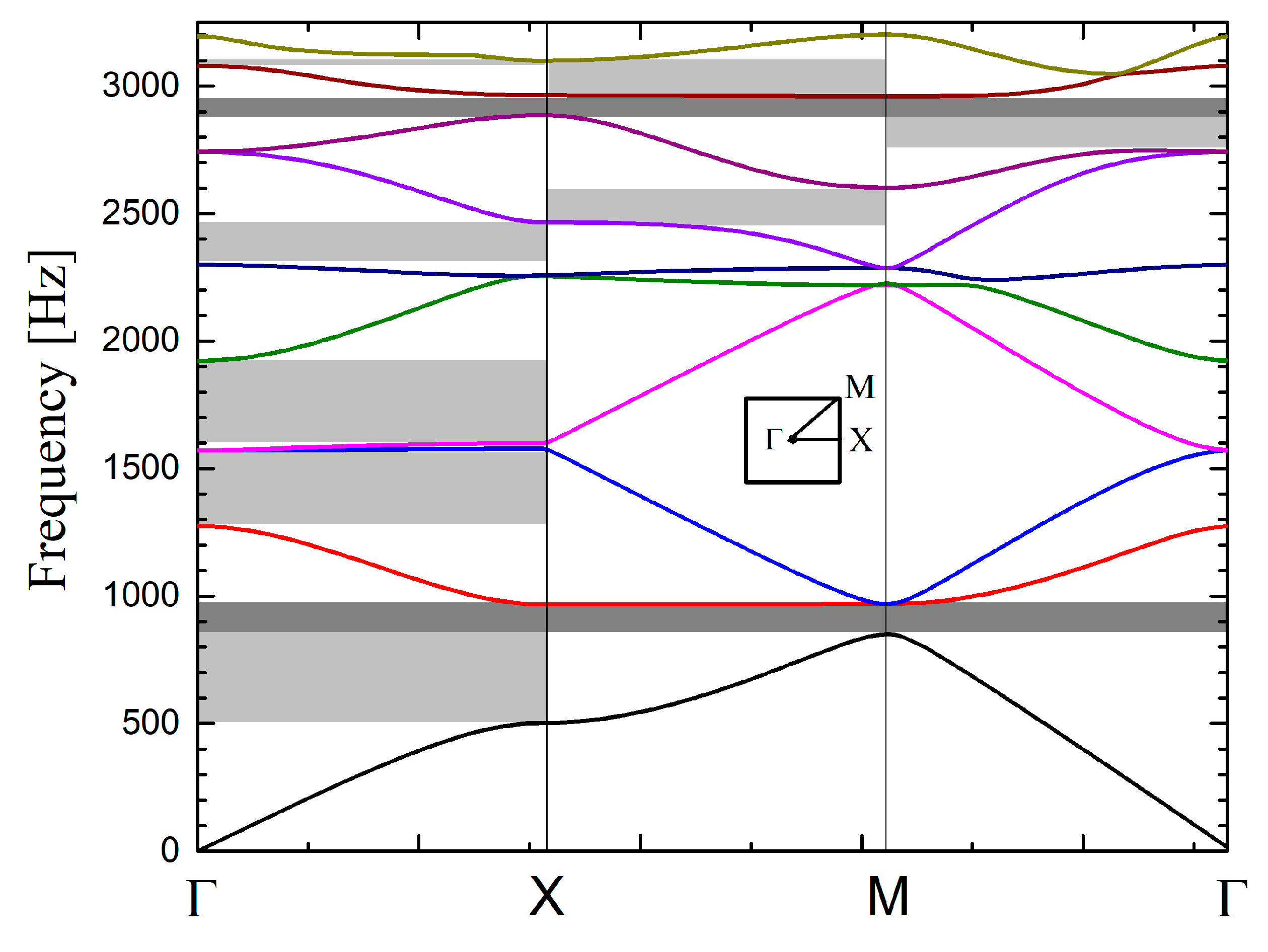

Section 2.1 reports analysis of the physical mechanisms involved in the attenuation properties of the SC barrier with MP cylindrical shells in comparison with the barrier solely based on empty MP shells. Then,

Section 2.2 presents a brief description of the standardised EN 1793-5 and EN 1793-6 measurement methods employed here. Later, in

Section 2.3, theoretical analysis in the framework of finite element method using both plane- and cylindrical-based approaches is reported. A comprehensive report on the experimental data measured by using the standardised measurement methods on the SC barrier with MP cylinders and rubber crumb is presented in

Section 3. To better quantify the effects of micro-perforations on the barrier performance, measured data are compared with those resulting from the standardised characterisation of an SC barrier made of solid PVC cylinders [

24]. Concluding remarks are presented in

Section 4, where superior performance of the barrier based on MP cylinders is understood in terms of the absorptive properties of its building units. The resilience of the constructed MP barrier to deterioration due to ageing is also highlighted. The micro-pores remained open eight years after barrier installation in open air. Finally, the appendices present details of the model employed to describe the absorbing units (

Appendix A), the influence of the width of the temporal window on the sound insulation values (

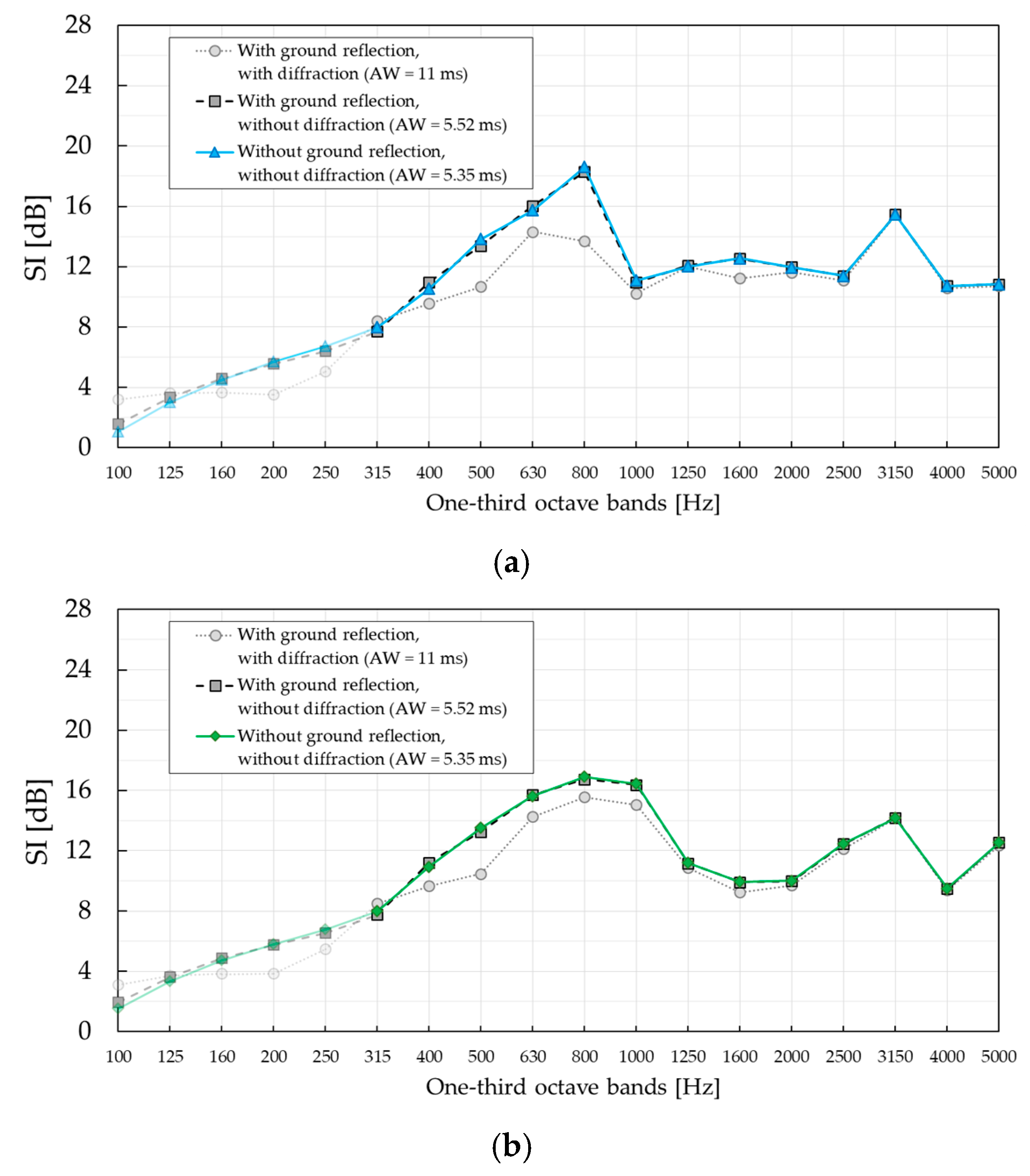

Appendix B), and how the leakage under the barrier affects the sound insulation (

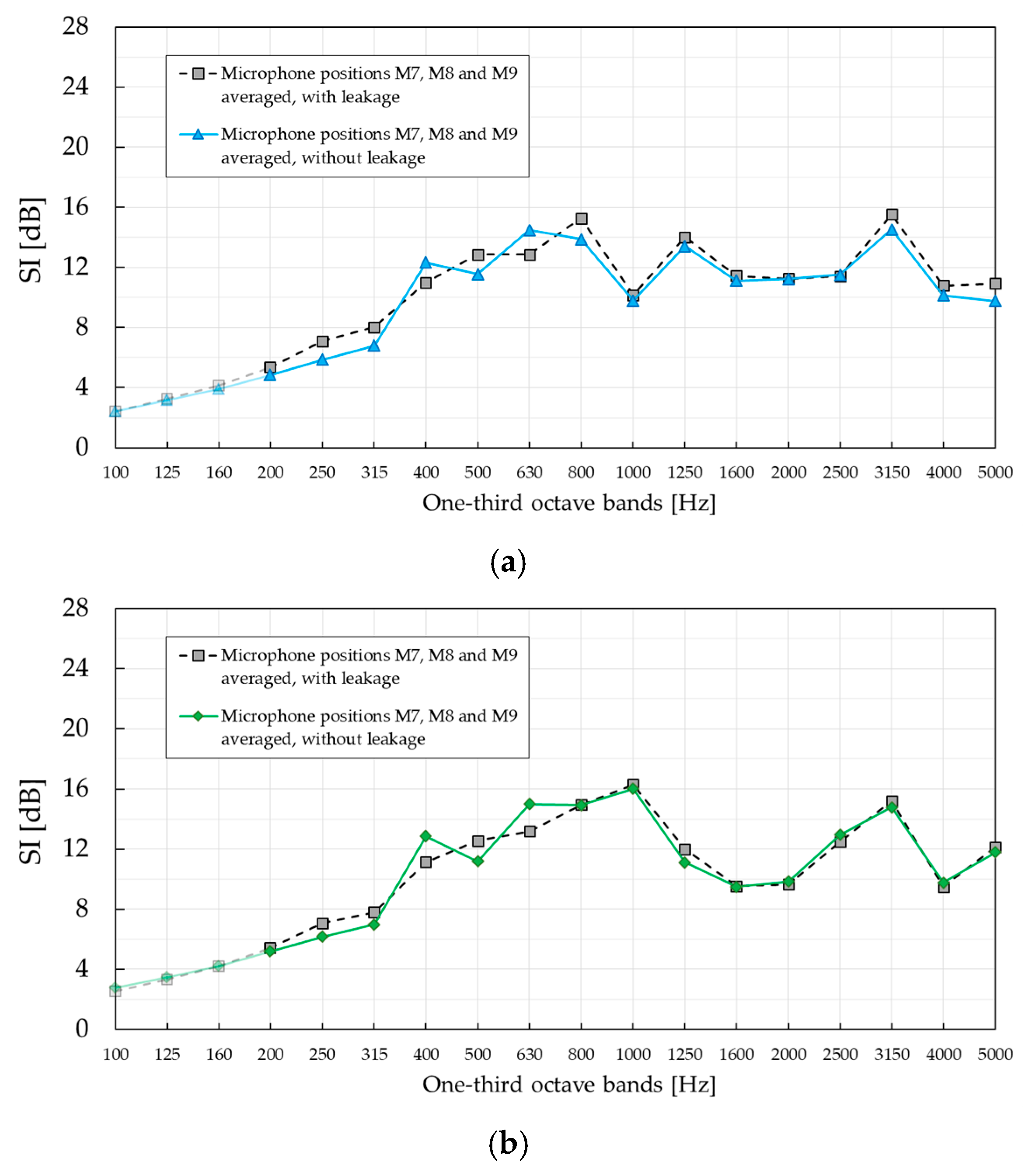

Appendix C).

3. Results and Discussion

For the given size of the SC barrier sample 4 described in

Section 2.1, the calculated low-frequency limit was f

MIN = 259 Hz. Hence, the results of the standardised characterisation are presented in one-third octave bands, starting from a central frequency of 315 Hz. The values in the lower one-third octave bands are retained for presentation purposes, as recommended by EN 1793-5 [

20] and EN 1793-6 [

21] standards. The results for both reflection and airborne sound insulation measurements are reported for the two configurations represented in

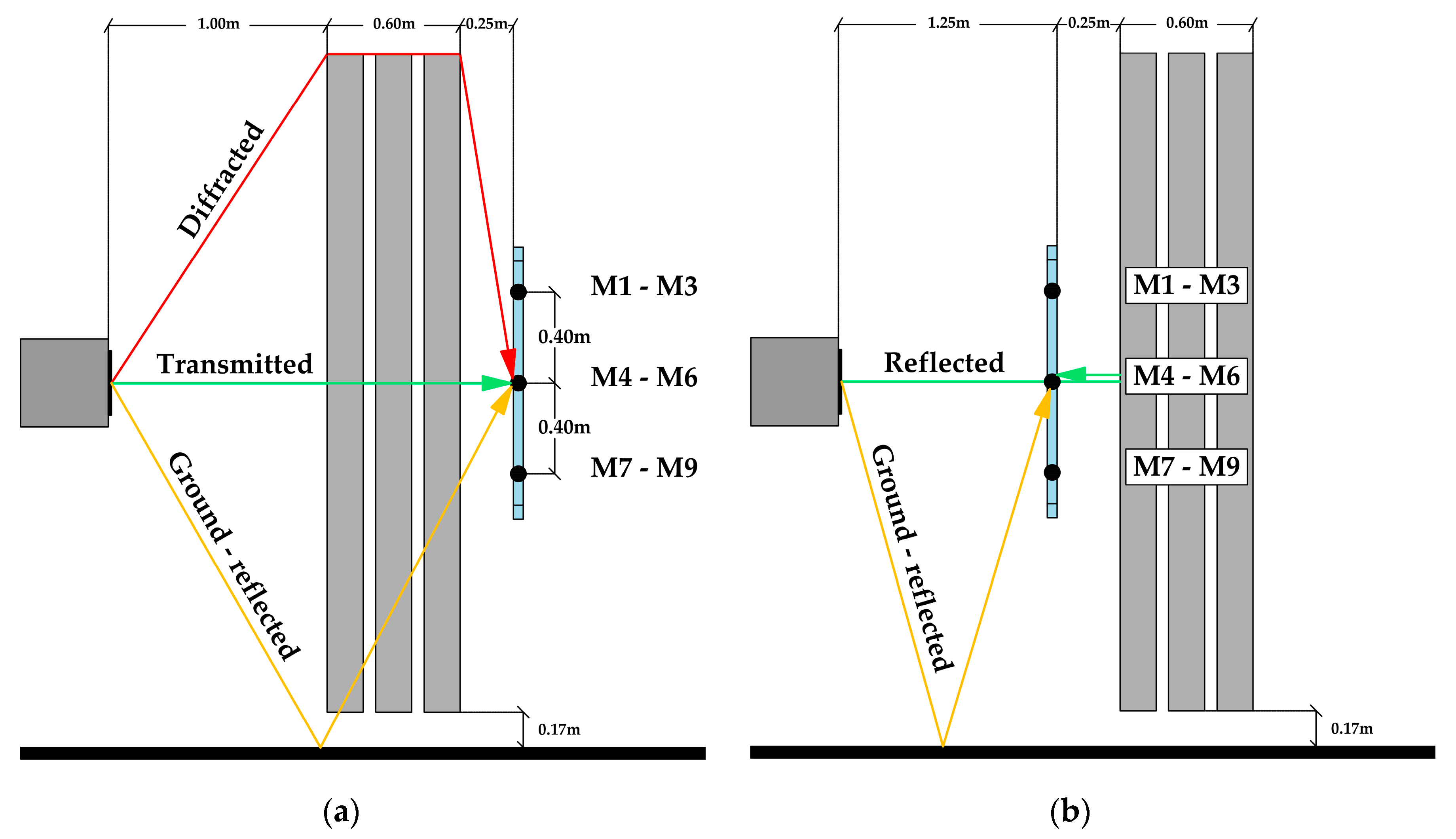

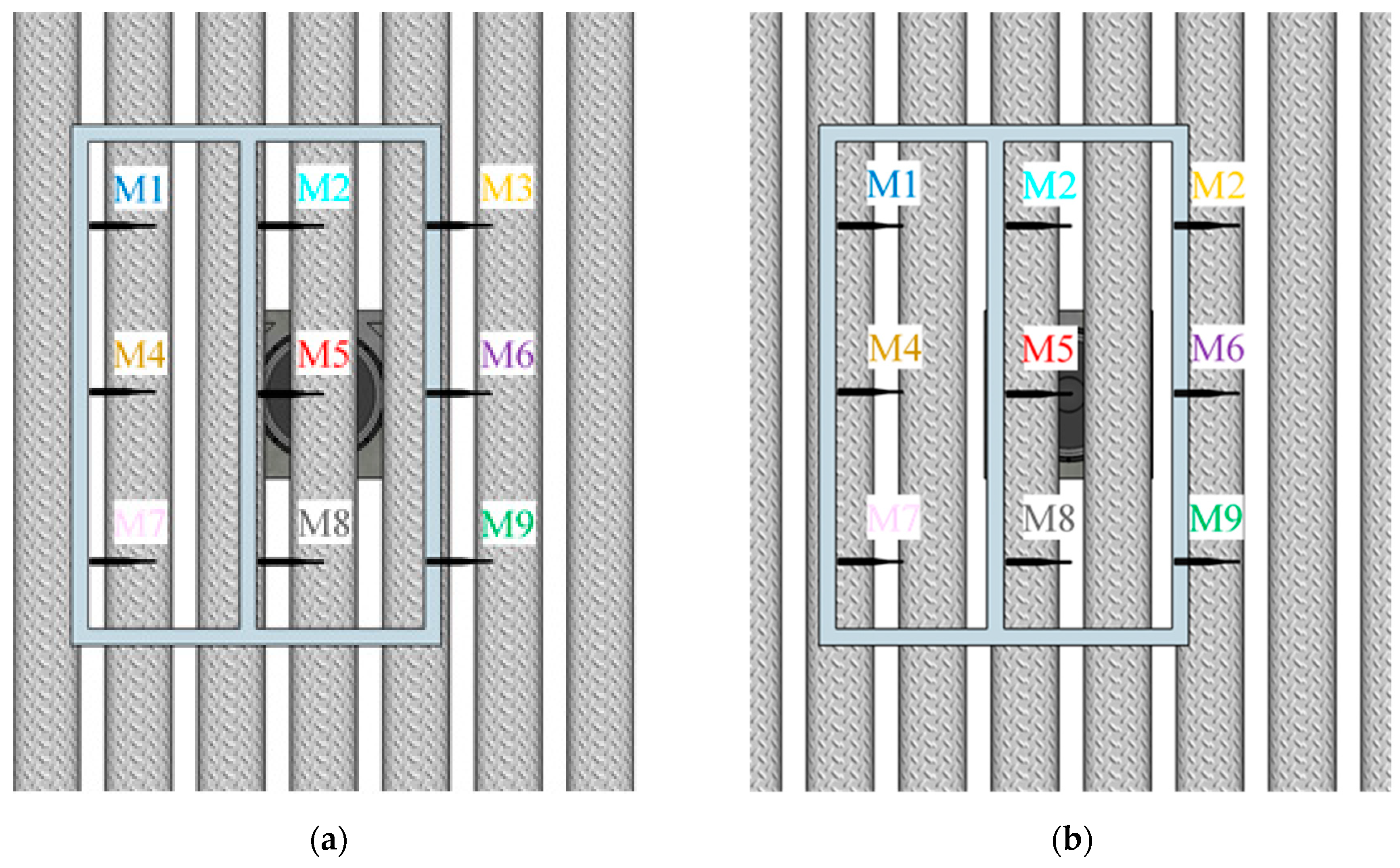

Figure 8. In configuration A, the middle column of microphone grid faced the centre of a cylinder, whereas in configuration B, it faced a space between two adjacent cylinders. Bearing in mind the distance of 0.4 m between micro-phones in the microphone grid and the lattice parameter of 0.22 m, the spacing between the microphones was not a multiple of the lattice constant.

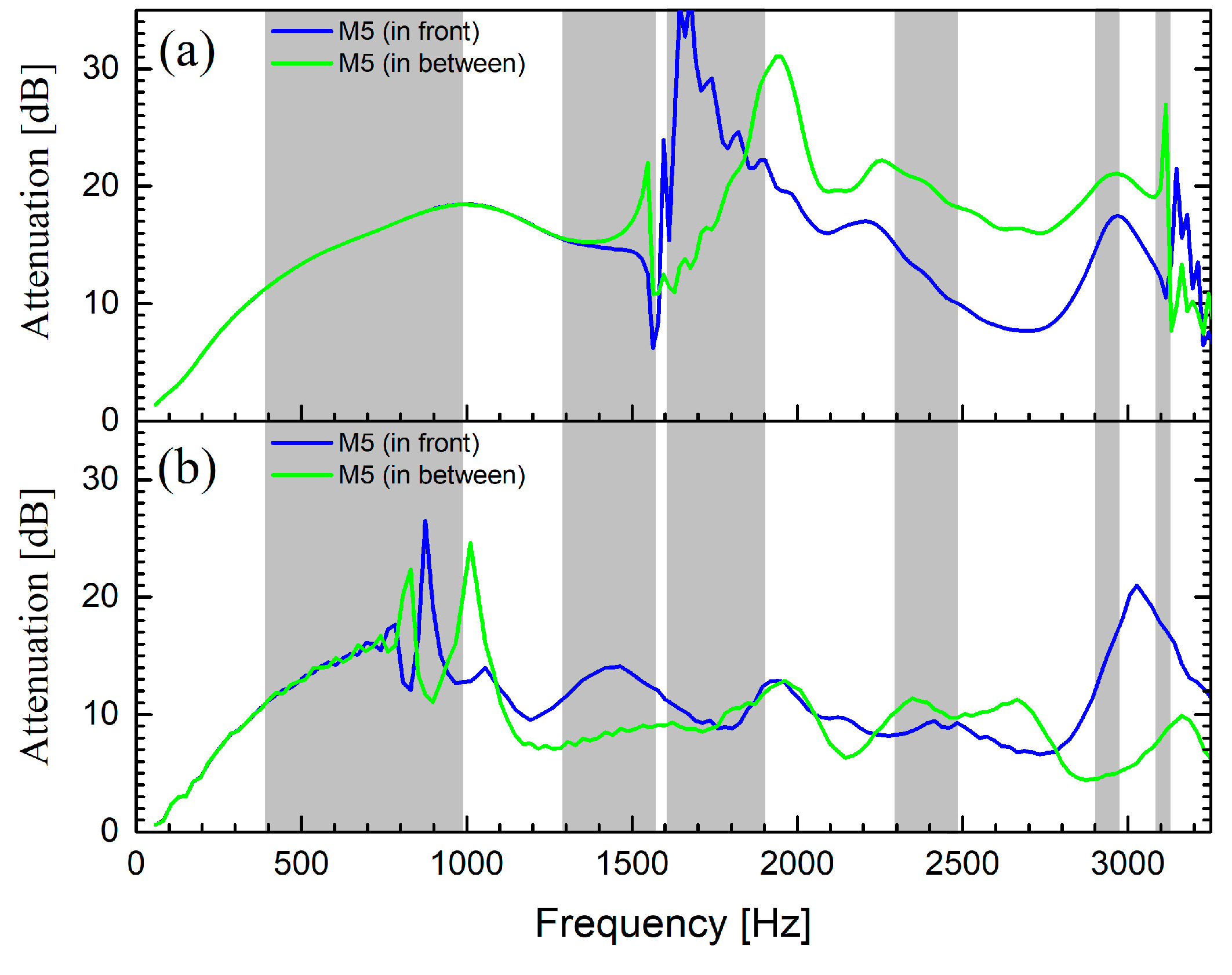

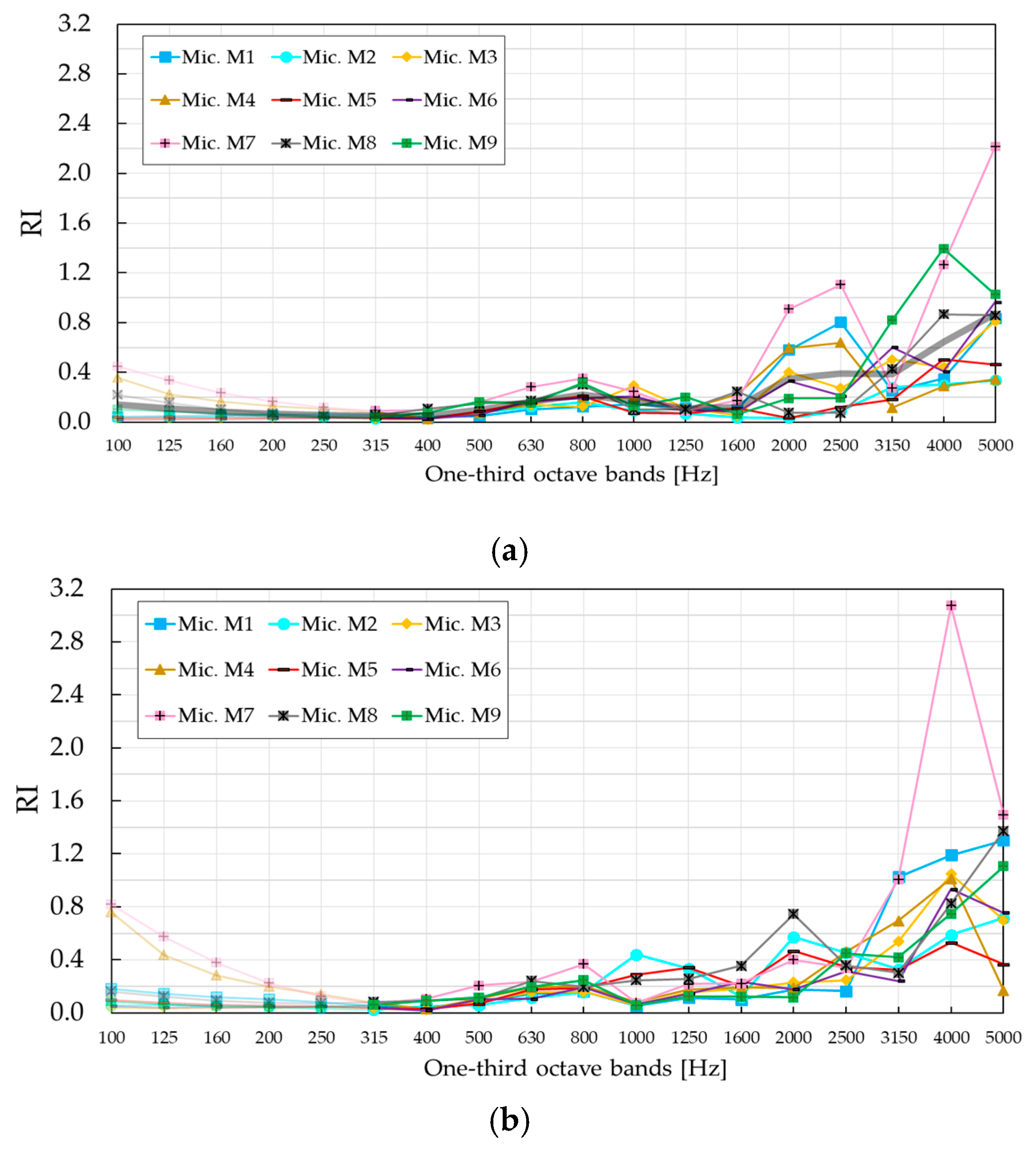

3.1. Experimental Results of Sound Insulation Index SI

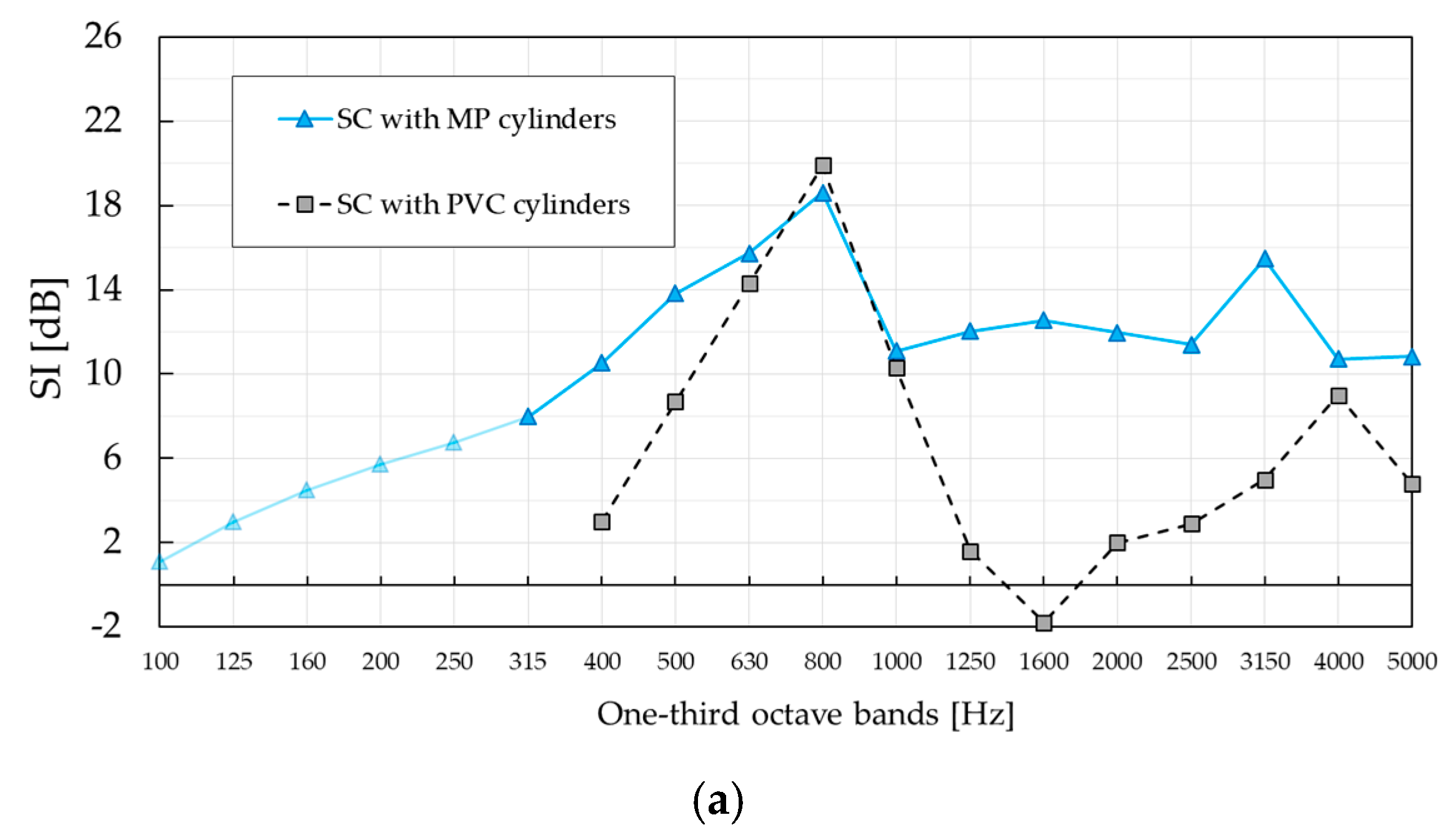

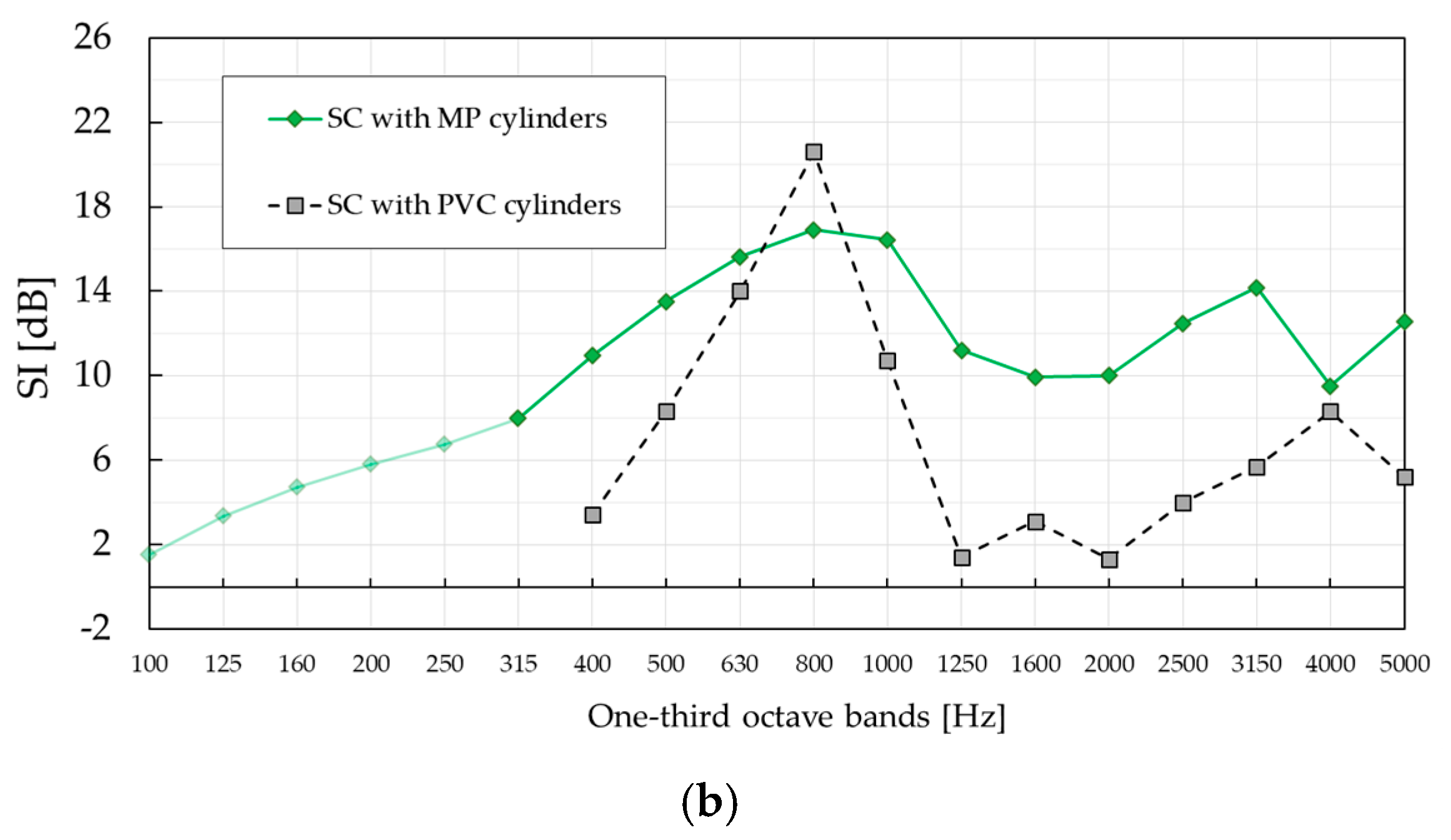

Figure 9 shows the results of the standardised characterisation of the SC barrier with MP cylinders for both configurations, A and B, calculated according to Equation (1). For the sake of comparison,

Figure 9 also shows the results corresponding to the standardised characterisation of the SC barrier with PVC cylinders provided in [

24], calculated in the same manner. Even though the lattice constants are slightly different, 0.22 m in the case of SC with MP and 0.2 m in the case of SC with PVC cylinders, Bragg gaps are expected to be within the same one-third octave band with a centre frequency of 800 Hz.

The SI peak values in both configurations correspond to a complete band gap, as predicted from the lattice constant. Those values were determined to be 18.6 dB and 16.9 dB for configuration A and B, respectively, of SC with MP cylinders. Also, the SI values in the complete band gap are similar to those of SC with PVC cylinders, just slightly lower. This is believed to be due to the absorptive nature of the building units, which slightly dampens the effect of the Bragg scattering. However, SI curves around the complete band gap are wider in case of SC with MP cylinders because of the absorption mechanism introduced by the MP layer, showing a significant difference at low frequencies. Additionally, the SI peak in configuration B is ‘smeared out’ towards the 1000 Hz region, making the difference in the complete band gap between the two SC barriers even more obvious.

The presence of the absorbing MP layer was even more noticeable in the frequency region 1250–5000 Hz, showing a maximum difference of 14.4 dB in the one-third octave band with a central frequency of 1600 Hz, in the case of configuration A. Low

SI values at twice the Bragg frequency measured for the SC barrier with PVC cylinders, negative in configuration A and around zero in configuration B, significantly differ from those measured for the SC barrier with MP cylinders. Around this frequency, the first diffracted mode become propagative, according to the band diagram in

Figure 4. However, this was barely visible only in configuration A. The reason is that the

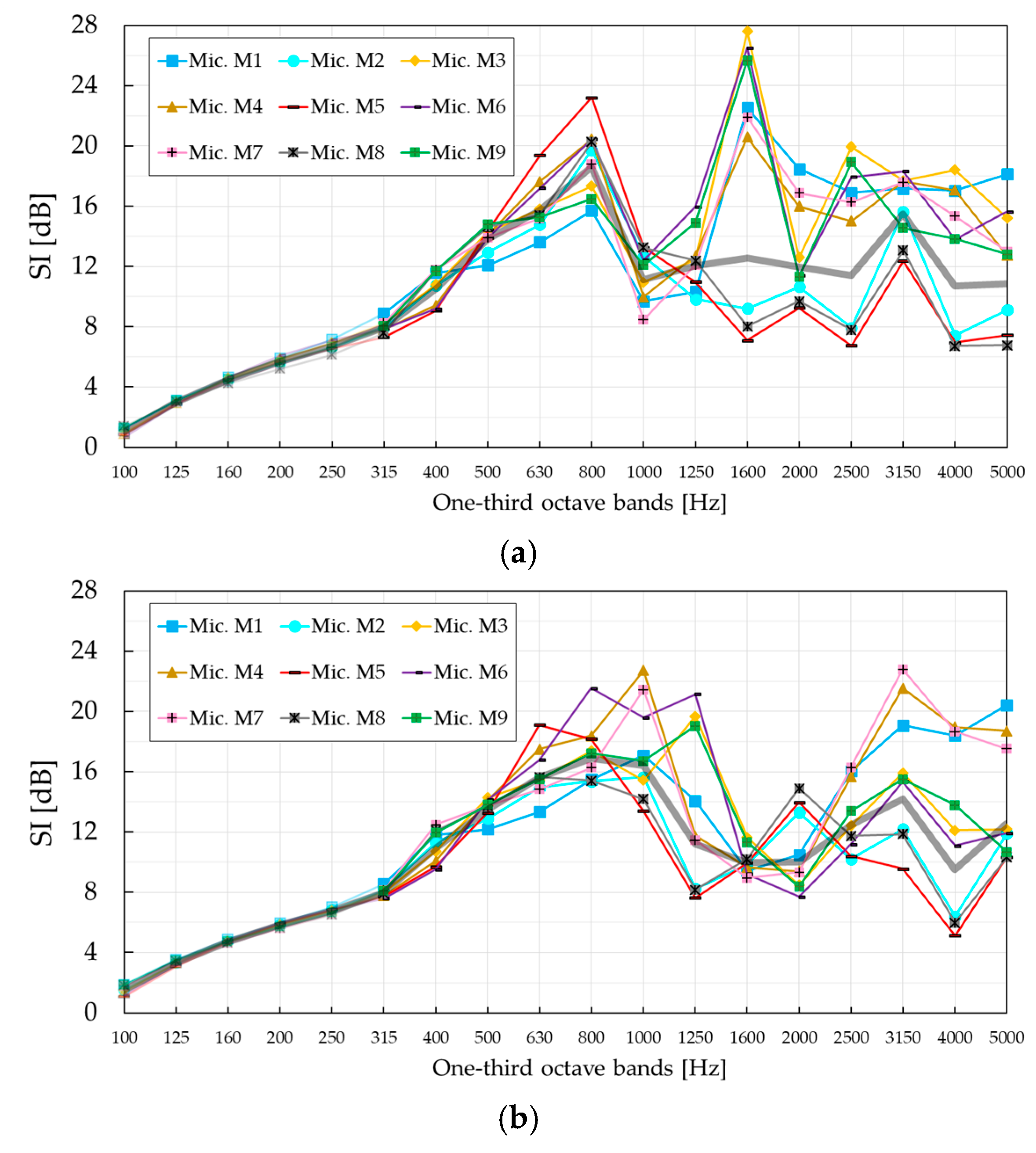

SI curve is the result of averaging over nine microphones. This is most evident when

SI values are investigated at individual microphone positions, as shown in

Figure 10. Despite the fact that high

SI values were measured at as many as six microphones at 1600 Hz in configuration A, the contribution of low

SI values at the same frequency to the overall

SI values was disregarded after averaging. A similar effect is noticeable at 3150 Hz in configuration B, where a new diffracted mode starts propagating but this time it was more apparent in the averaged

SI curve.

The maximum SI value of 23.2 dB at the Bragg frequency in configuration A was measured for microphone position M5. In configuration B, the maximum SI value of 21.5 dB at the Bragg frequency was measured for microphone position M6. However, these values were not the maximum values for all microphone positions and frequencies. The maximum SI value of 27.6 dB in configuration A was measured for microphone position M3 at 1600 Hz. In configuration B, the maximum SI value of 22.8 dB was measured for microphone position M7 at 3150 Hz, which was also near the cut-off frequency of the diffracted mode. The diverse SI curves between individual microphone positions in both configurations were a consequence of the occurrence of different modes above the diffraction limit. Asymmetry of absorption properties of different cylinders, but also inherently imperfect positioning of the microphone grid, might have been additional reasons. Despite the differences in the SI values between different microphone positions, characteristic frequency phenomena like the Bragg gap and diffracted modes were still easily noticeable. The method itself will average out all large deviations between the SI values in the same frequency range, providing overall information about the effectiveness of the SC barrier. It is still very important to be aware of the strong position-dependent insulation behaviour of SCs.

As explained in

Section 2.2.1, a single-number rating,

DLSI, is introduced by EN 1793-6 standard in order to categorise the airborne sound insulation performance of noise barriers. Single-number rating values were calculated for different low frequency limits, f

MIN = 315 Hz in the case of SC with MP and f

MIN = 400 Hz in the case of SC with PVC cylinders. Low-frequency limits influenced calculated single-number values, since they were obtained for different frequency ranges. The calculated single-number values of SC with MP cylinders are

DLSI, Conf-A = 12.3 dB and

DLSI, Conf-B = 12.2 dB, while the values of SC with PVC cylinders were

DLSI, Conf-A = 3.7 dB and

DLSI, Conf-B = 5 dB.

Requirements for sound attenuation and frequency span of the SC barrier needed in practice are a matter of type of noise as well as sound levels for which the barrier is used for. According to categorisation of airborne sound insulation presented in EN 1793-6, there are five possible categories (see

Table 1). For given single-number values of SC with MP cylinders,

DLSI, Conf-A = 12.3 dB and

DLSI, Conf-B = 12.2 dB, the SC barrier is categorised as D1 against traffic noise. To rate the SC barrier against other types of noise, appropriate spectrum should be used for calculation of single-number values.

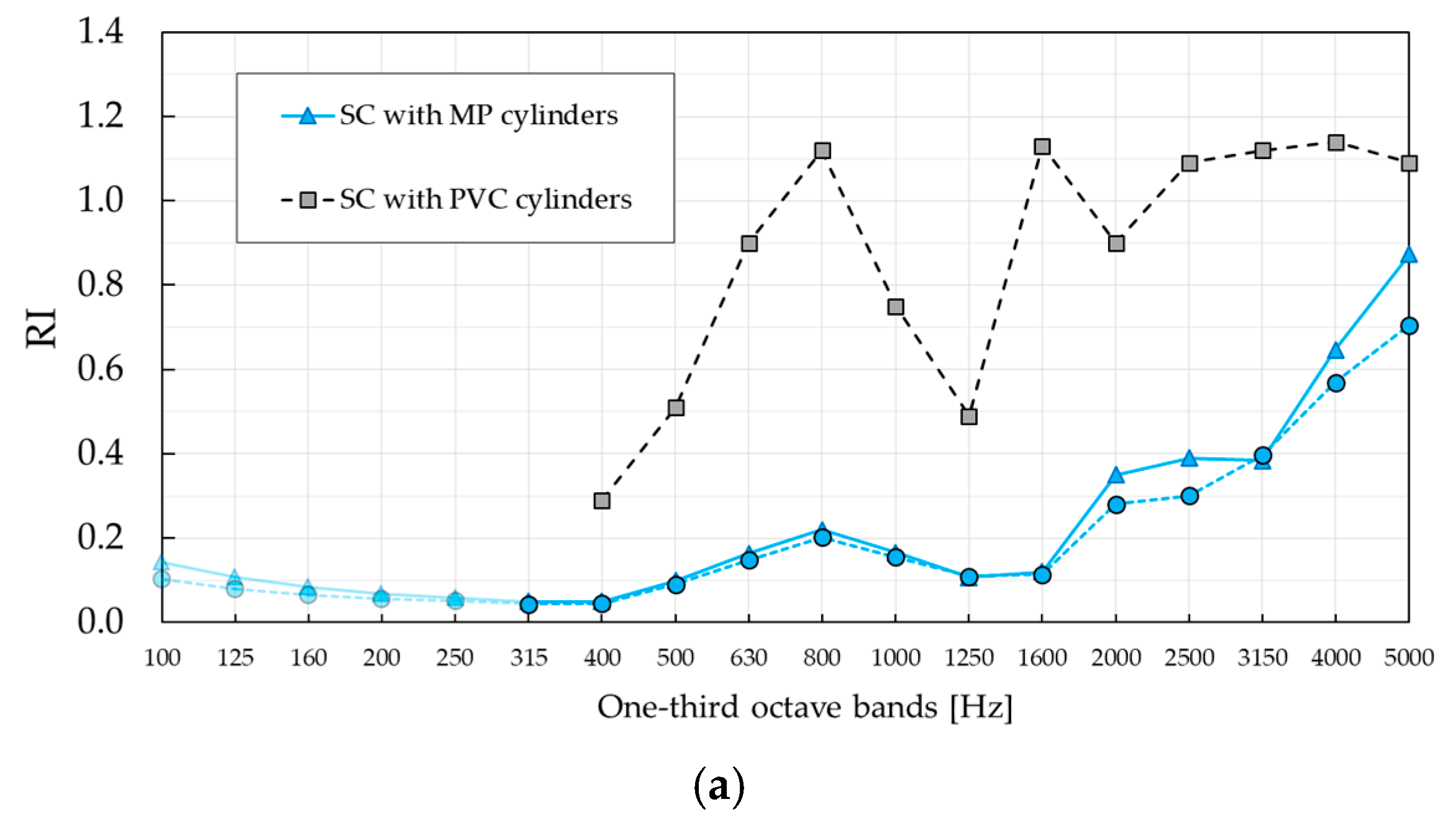

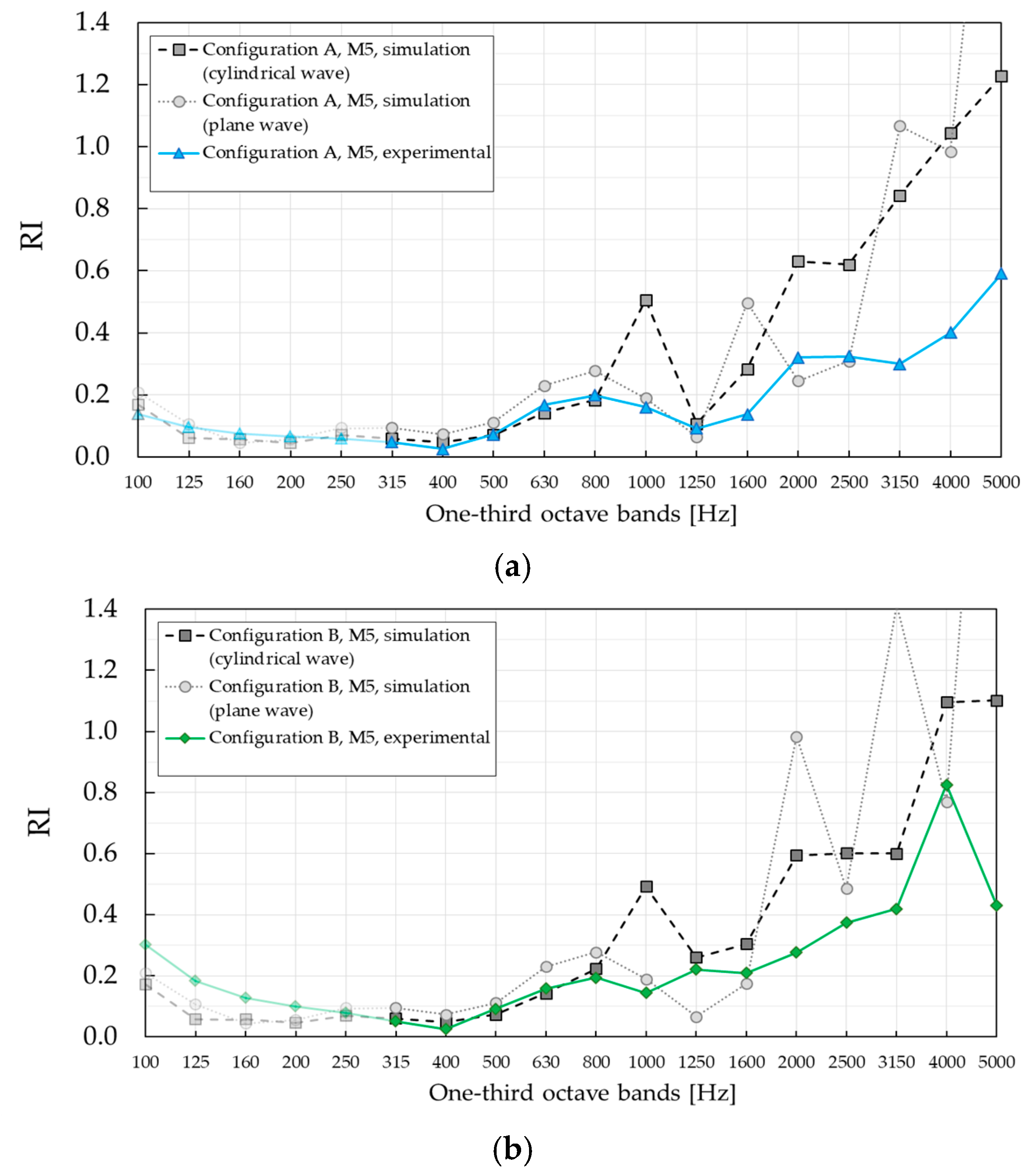

3.2. Experimental Results of Sound Reflection Index RI

The results of standardised measurements of reflection index

RI, computed according to Equation (2), are shown in

Figure 11. As in the case of

SI measurement, the results are also compared with those of standardized measurement of reflection index

RI applied to the SC barrier with PVC cylinders [

24]. The maximum

RI values in

Figure 11, in the Bragg gap, were well defined in both configurations of SC with PVC cylinders, with values approximately 0.9 higher than of SC with absorptive MP cylinders.

The reason is that absorptive units played a significant role in damping the effect of Bragg scattering. Compared to PVC-rigid cylinders, which provided only reflection mechanism, absorptive cylinders highlighted absorption mechanism combined with Bragg scattering, leading to a pronounced reduction of the barrier reflective properties.

While SC barrier with PVC cylinders showed a remarkable difference between

RI values evaluated in the two configurations, SC barrier with MP cylinders showed a similar trend. Namely, both configurations displayed a local maximum in the one-third octave band centred at 800 Hz and increased at higher frequencies. Small differences were visible in two frequency ranges: (i) In the one-third octave bands with the central frequency of 1250 Hz and 1600 Hz, and (ii) in the one-third octave bands, higher than the one centred at 2500 Hz. In both cases, the values were higher in configuration B. Compared to the barrier based on rigid PVC cylinders,

RI values in the case of SC made of absorptive MP cylinders were significantly lower in nearly all one-third octave bands. The only exception was the one-third octave band centred at 4000 Hz in configuration B, where a higher

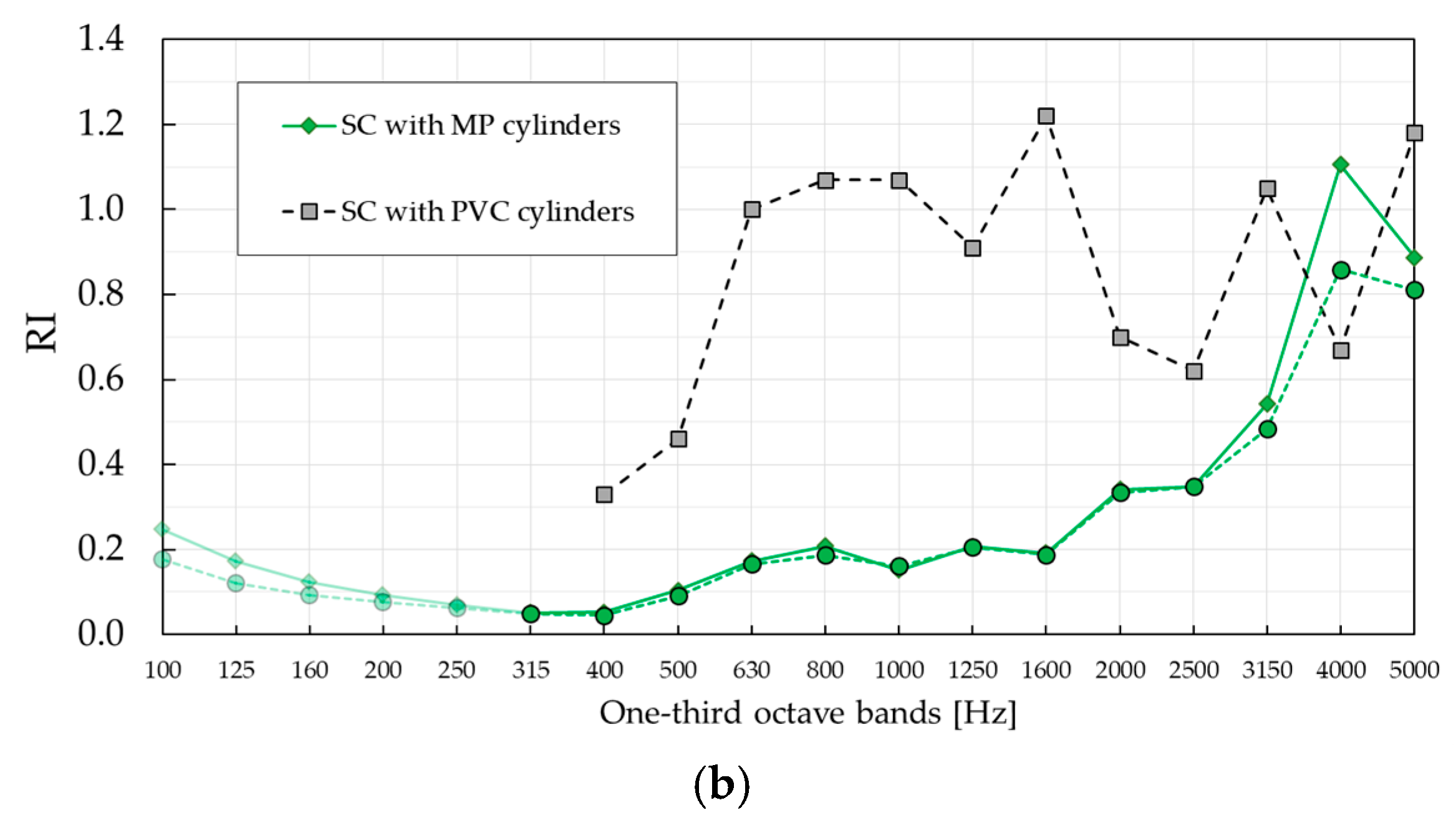

RI was obtained for the barrier with absorptive cylinders. To investigate possible differences between different microphones,

RI values were calculated at individual microphone positions, as shown in

Figure 12. It was observed that microphone M7 exhibited an extraordinarily high value in the one-third octave band centred at 4000 Hz in configuration B, probably due to a wrong data acquisition. For that reason, results in

Figure 11 were recalculated without microphone M7 and presented with blue and green curves for configurations A and B, respectively. The higher

RI value found in SCs with MP cylinders at 4 kHz still prevailed, although after removing the effect of microphone M7, the difference was lower. The slightly higher reflectance was due to the reflectance of the barrier with PVC cylinders, which abruptly decreases at this specific third-octave band as a consequence of an interference phenomenon. An additional factor behind this behaviour might be given by the fact that the temporal window in the case of SC with PVC cylinders was centred on the arrival of the direct sound, not on the arrival of the first reflection as it is suggested by [

20]. In that way, multiple scattering components coming from the surrounding cylinders were most likely windowed out. Also, two barriers are completely different, one being absorptive and the other one being completely reflective. This means that multiple scattering components did not contribute to the overall energy of reflections in the same way for two barriers. While authors in [

20] highlighted the importance of the first reflection in

RI measurements, it was the scattered energy that made a significant contribution to the overall energy of the reflections in case of the SC with MP cylinders. The reader is encouraged to observe the amplitude of the reflection components in

Figure S1 in the Supporting material, where impulse responses at individual microphone positions M1–M9 in configuration A are presented.

As explained in

Section 2.2.2, a single-number rating,

DLRI, was introduced by EN 1793-5 standard in order to indicate the performance of the product. The calculated values were

DLRI = 6.9 dB and

DLRI = 6.3 dB for configuration A and B, respectively. The corresponding values in the case of SC with

PVC barrier were DLRI = 0.8 dB and DLRI = 0.5 dB for configuration A and B, respectively.

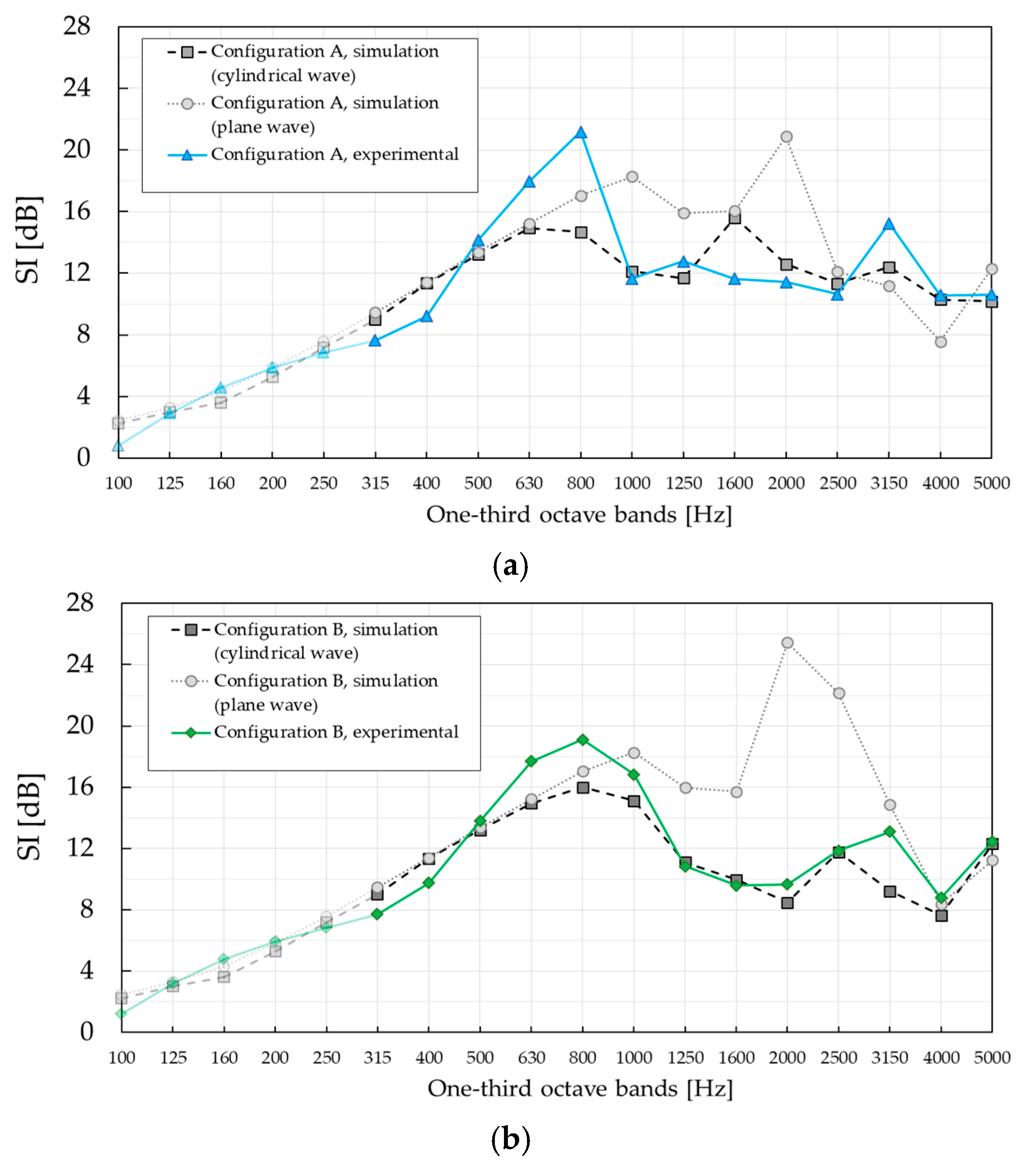

3.3. Three Microphone Measurements: Experimental Vs. FE Simulations

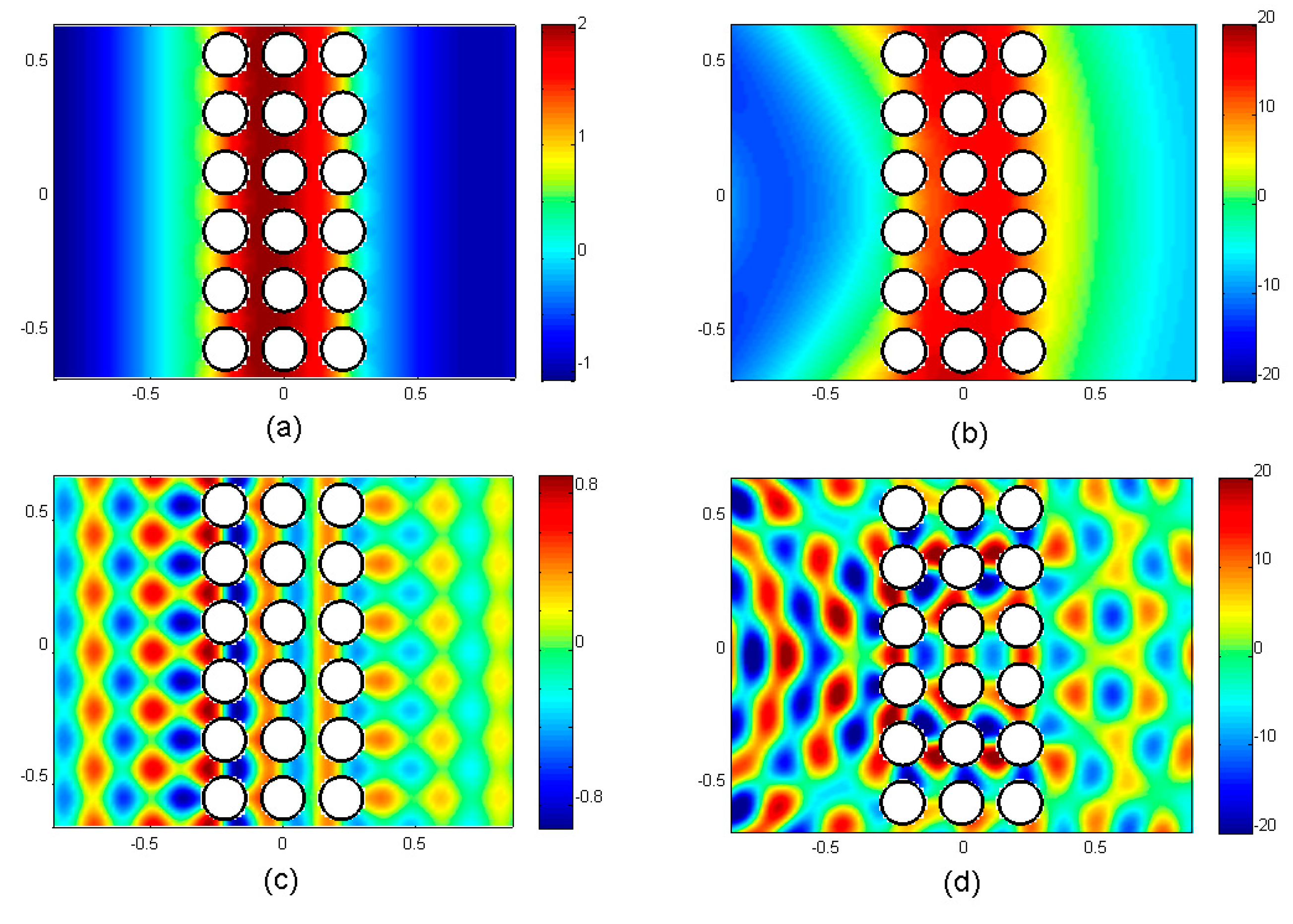

In order to describe the experimental data, particularly the presence of the Bragg gap and diffraction effects, numerical simulations were performed in the framework of the finite element (FE) method, using

COMSOL. Both plane and cylindrical wave-based investigations were performed using FE simulations. The former corresponded to data that one would obtain if the sample was measured in an impedance tube or at long distances from the excitation source and it was directly related to the dimensions and properties of the used materials. The latter is expected to be more realistic since the excitation source was closer to the barrier. The simulations were performed by assuming infinitely long and infinitely wide barrier for plane wave-based investigations, and infinitely long cylinders with the real width for cylindrical wave-based investigations. Results were obtained by using a mesh size small enough to guarantee both convergence and accuracy.

Figure 13 and

Figure 14 show a comparison of the FE simulations and experimental

SI and

RI results, respectively. The results were averaged over three microphone positions in the two different configurations, as shown in

Figure 8. The results are presented in one–third octave bands, for consistency with the previous figures.

Regarding the results for SI, a better agreement between experimental data and FE simulations was obtained for the cylindrical wave condition in both configurations, except around the Bragg frequency where the simulations underestimated the measured SI values. For the barrier under study, based on absorptive MP cylinders, the FE simulations exhibited a quantitative agreement for most frequencies above the Bragg peak when the simulations employed cylindrical incident waves. Even though the SI peak values derived from the FE simulations at the Bragg frequency was lower than those derived from experimental data, the Bragg gap was still well predicted. However, the differences between the plane wave–based FE simulation results and experimental results were found to be large. In fact, the distance between the loudspeaker and the SC barrier was only 1 m, making the impinging wave at the SC barrier more cylindrical– than plane–like.

It should be pointed out that FE simulation results for

RI, presented in

Figure 14, were obtained by calculating the difference between the pressure in case with and without the SC barrier. As in case of

SI results,

RI values were averaged over microphones M4, M5 and M6. A good agreement between the simulated and the experimental data was observed in the frequency region up to one–third octave band with the central frequency of 800 Hz, including the Bragg gap. In higher one–third octave bands starting with one with the central frequency of 1000 Hz, a large disagreement was obtained. This issue might be related to the fact that loudspeakers at high frequencies manifest high directivity, whose radiation is significantly different from the cylindrical wave radiation. Additionally, lateral diffractions included in FE simulations with cylindrical wave–based approach were efficiently windowed out in the experimental results. As in case of

SI measurements, plane wave–based simulations were not the appropriate approach for the given measurement setup. This is precisely why those simulations showed strong oscillations, which did not appear in the experimental results. However, both simulations and experiments show the same trend of increment of

RI values as the frequency increased.

4. Conclusions

Experimental results of a standardised characterisation of a new type of sonic crystal barrier consisting of micro-perforated cylindrical shells with rubber crump, according to EN 1793-5 and EN 1793-6, were presented and discussed. Attenuation was analysed as a function of the number of layers in the barrier. The results for the barrier made of three layers were compared with reported data from a similar standardised characterisation of a sonic crystal barrier made of three layers of solid PVC cylinders. Additionally, numerical simulations were performed in the framework of multiple scattering method and the finite element method to support the measurements.

Theoretical simulations, based on finite element methods, showed a better agreement with the experimental data when a cylindrical source was employed (as opposed to a plane wave), which was attributable to the short distance between the source and the microphones in the experimental setup.

Compared to standardised characterisation of the barrier made of rigid PVC cylinders, the sonic crystal barrier consisting of absorbing micro-perforated cylindrical shells showed improved broadband sound insulation and reflection properties. Sound insulation values SI of 18.6 dB and 16.9 dB were obtained for two different configurations at the Bragg frequency, with single-number rating values DLSI of 12.3 dB and 12.2 dB. As opposed to the sonic crystal with rigid PVC cylinders, no pronounced constructive interference at twice the Bragg frequency was observed in the case of sonic crystal with micro-perforated shells. At individual microphone positions, SI values of up to 23.2 dB were obtained at Bragg frequency, as well as up to 27.6 dB in the one-third octave band centred at 1600 Hz. However, the contribution of the lower SI values at individual microphone positions to the averaged SI value in the same one-third octave band was more significant than of the higher SI values.

The SC barrier with micro-perforated shells exhibited significantly lower reflection values

RI than that made of PVC cylinders, which was attributed to the energy dissipation by its absorptive building units. Reflection indices

RI of approximately 0.2 were obtained for both configurations at the Bragg frequency, with single-number values

DLRI of 6.9 dB and 6.3 dB. While reflection measurements in the case of the sonic crystal barrier with PVC cylinders were strongly affected by the position of the microphone grid, the same trend was not apparent in the barrier made of MP shells with rubber crump. Energy of multiple scattering components was found to be significant when calculating the total energy of the reflections. This was in contrary to

RI measurements implemented in the case of the reflective sonic crystal barrier [

24], where the significance of first reflections in measured impulse responses was emphasised.

The influence of leakage under the barrier and the width of the Adrienne temporal window was also investigated. On the one hand, leakage under the barrier had no major impact on sound insulation measurement results. Differences of 0.4 dB and 0.1 dB were obtained for single-number values with and without leakage, at the lowest three microphone positions. On the other hand, the width of the Adrienne temporal window would not have affected the sound insulation measurement results if ground-reflected sound transmitted through the barrier was included. When diffracted sound over the top of the barrier was included in all microphone positions, the single-number values decreased by about 2 dB in both configurations. More precisely, the diffracted sound mostly influenced the sound insulation values around the Bragg frequency.

Even though standardised EN 1793-5 and EN 1793-6 methods were not implemented on the sonic crystal barrier made with empty micro-perforated cylindrical shells in 2011, when the barrier was constructed, the absorption capability of the micro-perforated shells combined here with an inner core of rubber crumb, was preserved in both sound insulation and reflection properties. Concern that the pores of the micro-perforated shell might be clogged was unjustified.

As in the previous research by Morandi et al. [

24], the

SI measurements exhibited a strong dependency on microphone positions. The diverse sound insulation values at individual microphone positions was mainly a consequence of complex pressure patterns above the diffraction limit. Because of this strong position-dependable behaviour, but also keeping in mind the fixed distance between adjacent microphones suggested by the standardised EN 1793-5 and EN 1793-6 procedures, adjustment of their applicability to barriers based on sonic crystals requires further investigation.