A Novel Preparation Method of Electrically Conductive Adhesives by Powder Spraying Process

Abstract

:1. Introduction

2. Experiment

2.1. Raw Materials and Experimental Equipment

2.1.1. Raw Materials

2.1.2. Experiment Equipment

2.2. Preparation of ECAs

2.2.1. Powder Spraying Process

2.2.2. Conventional Process

2.3. Experiment Tests

2.3.1. Tests on Electrical Conductivity

2.3.2. Tests on Shear Strength

3. Results and Discussion

3.1. Electrical Property of ECAs

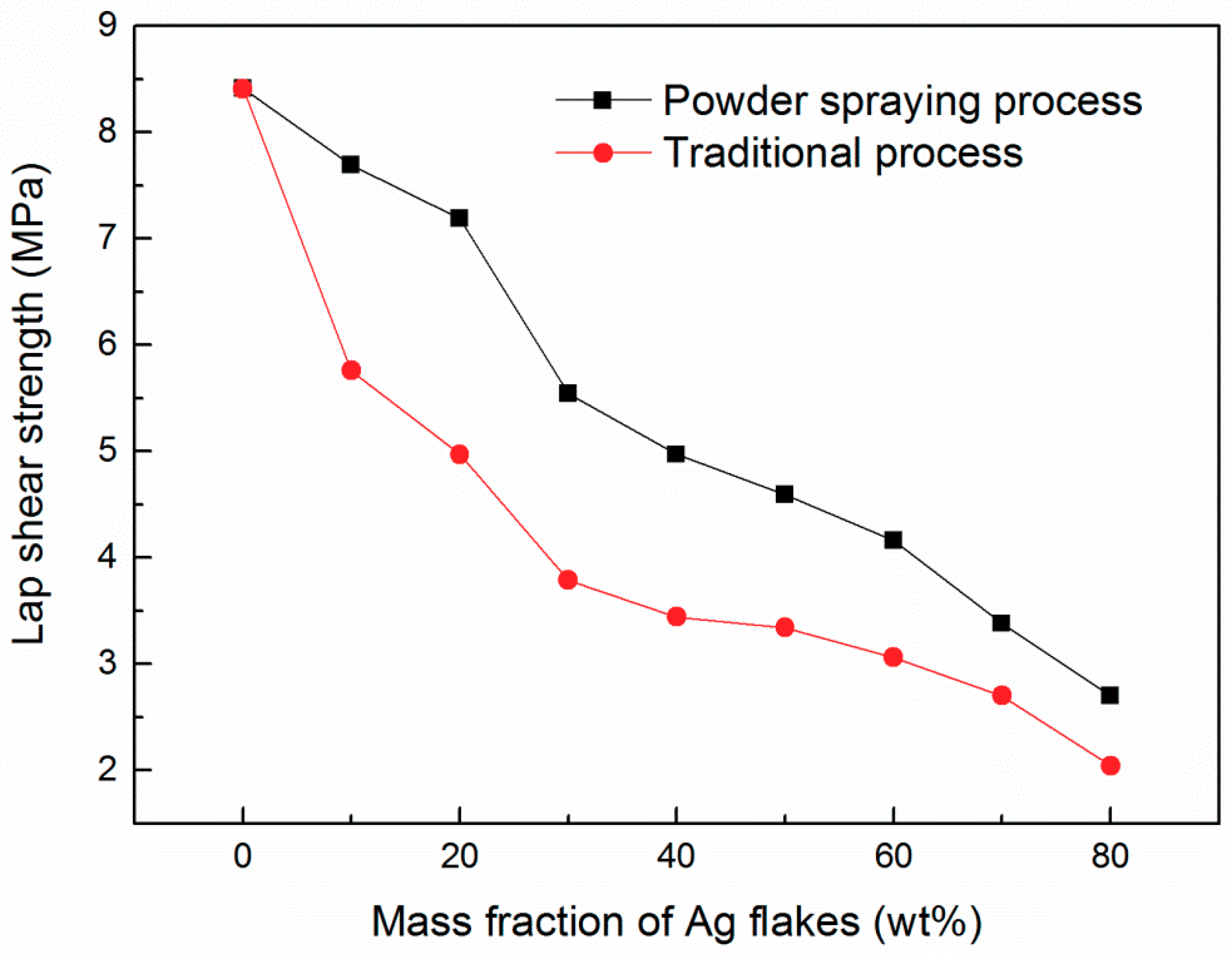

3.2. Mechanical Property

3.3. SEM Analysis

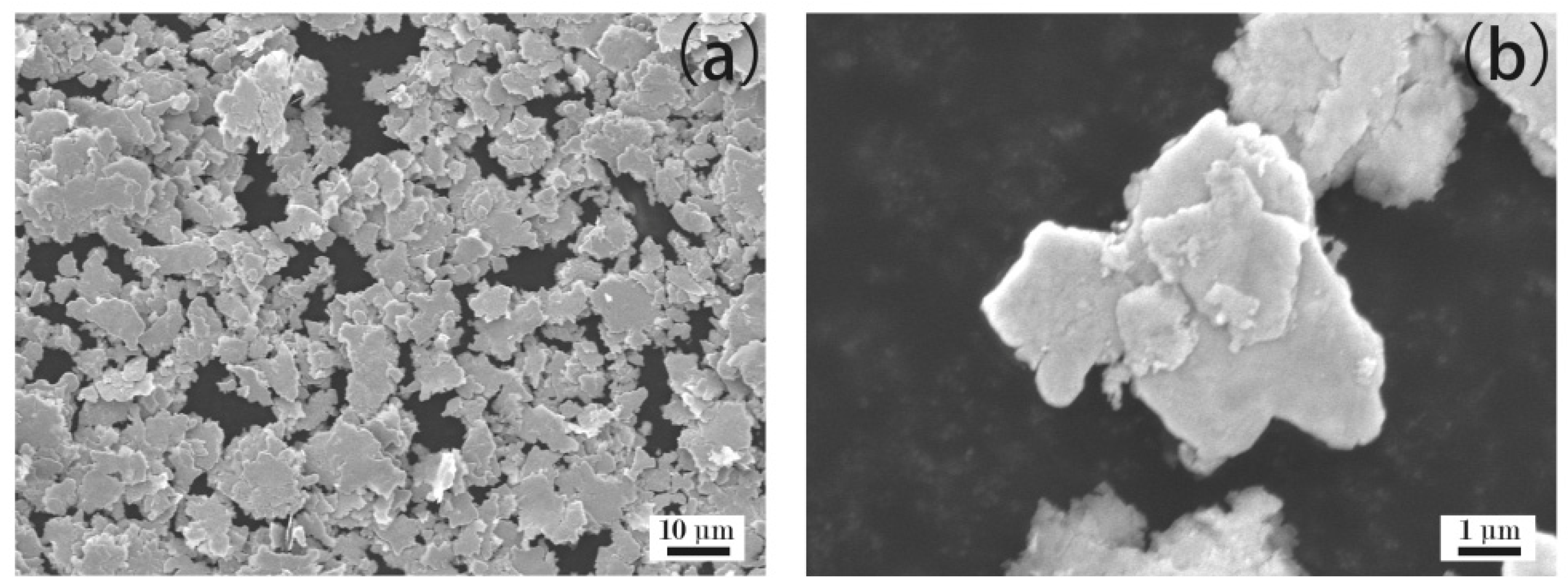

3.3.1. Ag Flakes

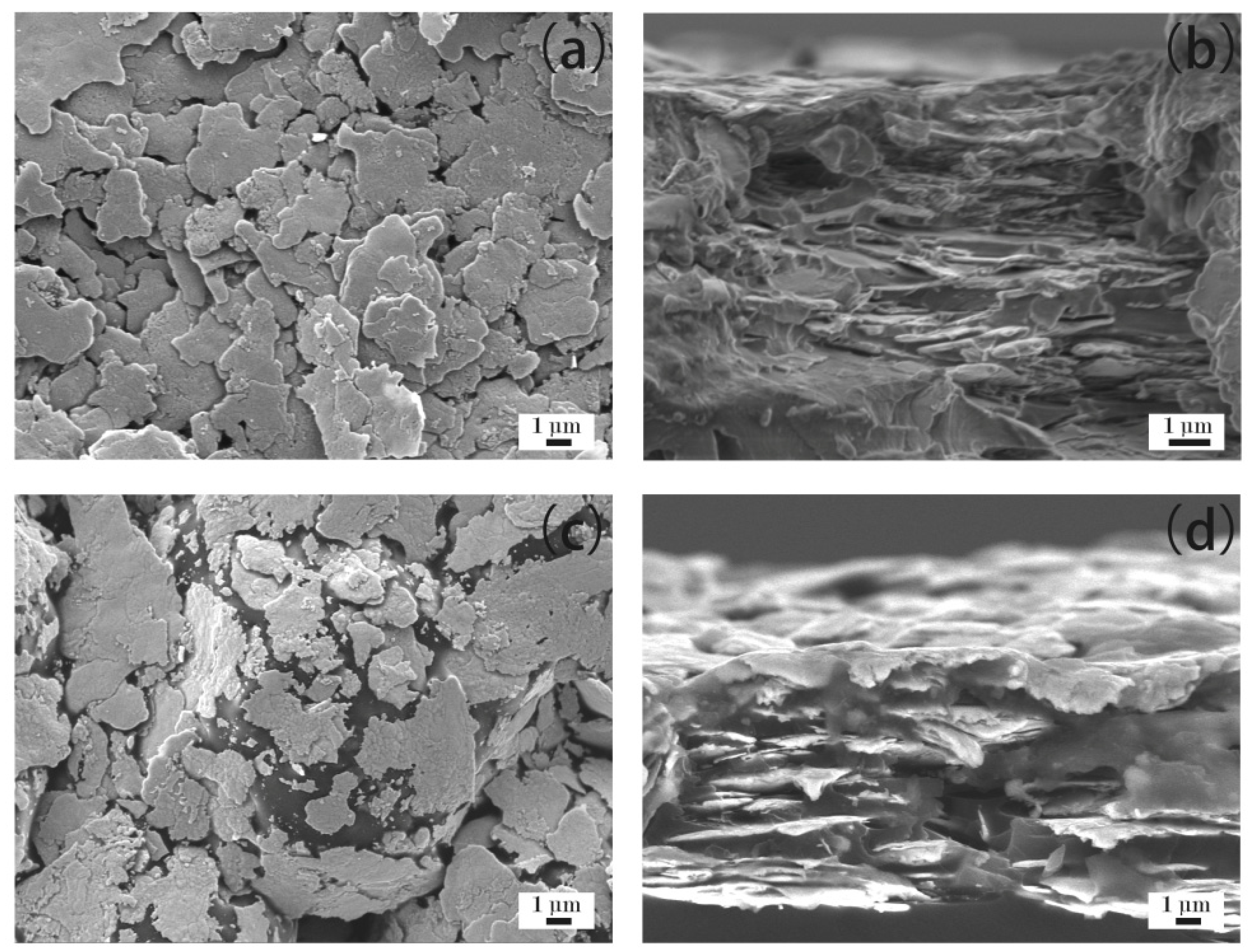

3.3.2. ECAs Filled with 20 wt % Ag Flakes

3.3.3. ECAs Filled with 30 wt % Ag Flakes

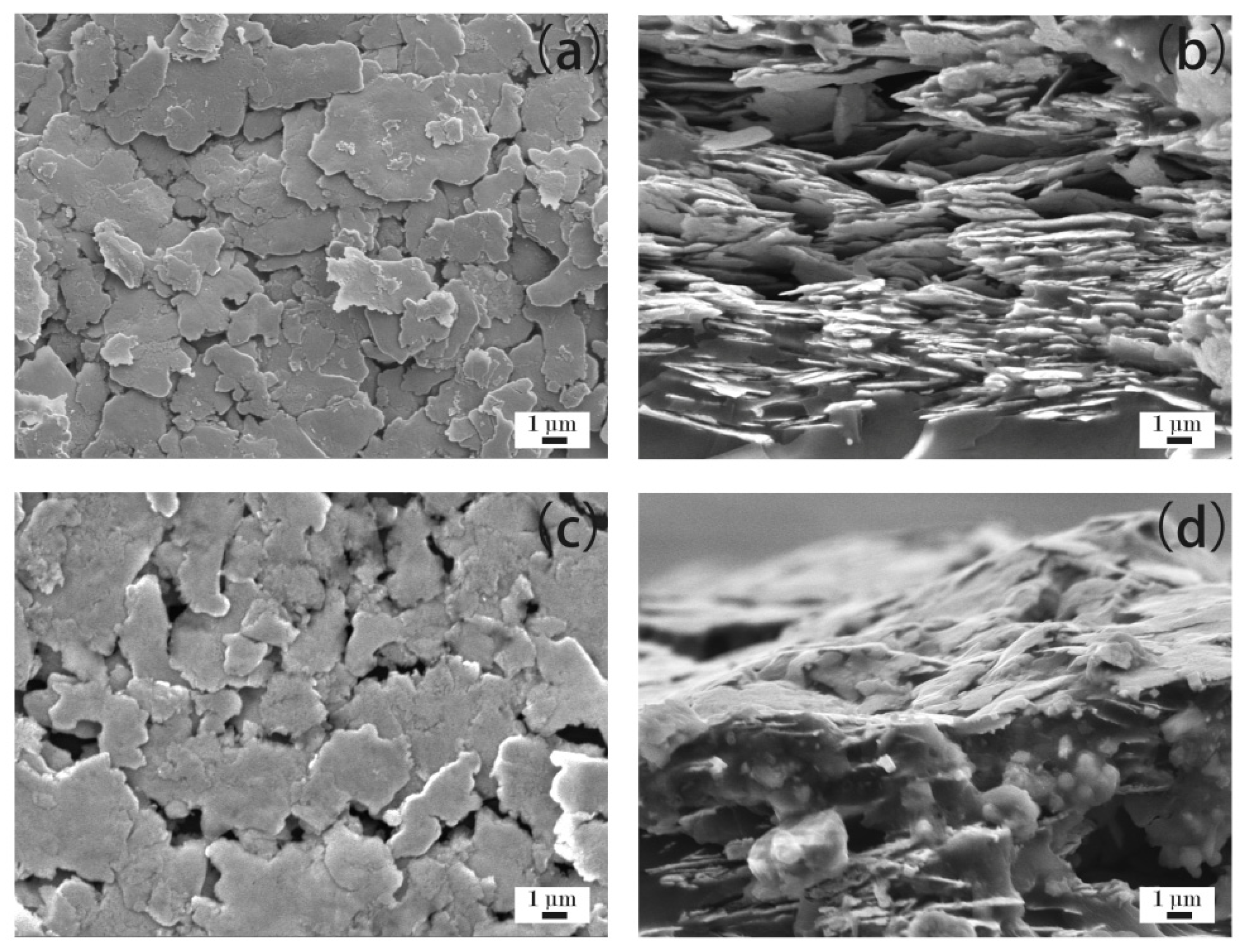

3.3.4. ECAs Filled with 40 wt % Ag Flakes

3.3.5. ECAs Filled with 50 wt % Ag Flakes

3.3.6. ECAs Filled with 60 wt % Ag Flakes

3.3.7. ECAs Filled with 70 wt % Ag Flakes

3.3.8. ECAs Filled with 80 wt % Ag Flakes

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sun, D.; Timmermans, M.Y.; Tian, Y.; Nasibulin, A.G.; Kauppinen, E.I.; Kishimoto, S.; Mizutani, T.; Ohno, Y. Flexible high-performance carbon nanotube integrated circuits. Nat. Nanotechnol. 2011, 6, 156–161. [Google Scholar] [CrossRef]

- Sekitani, T.; Zschieschang, U.; Klauk, H.; Someya, T. Flexible organic transistors and circuits with extreme bending stability. Nat. Mater. 2010, 9, 1015–1022. [Google Scholar] [CrossRef] [PubMed]

- Ahn, J.H.; Kim, H.S.; Lee, K.J.; Jeon, S.; Kang, S.J.; Sun, Y.; Nuzzo, R.G.; Rogers, J.A. Heterogeneous three-dimensional electronics by use of printed semiconductor nanomaterials. Science 2006, 314, 1754–1757. [Google Scholar] [CrossRef] [PubMed]

- Tu, K.N.; Zeng, K.B. Tin–lead (Sn–Pb) solder reaction in flip chip technology. Mater. Sci. Eng. 2001, 34, 1–58. [Google Scholar] [CrossRef]

- Basaran, C.; Jiang, J.B. Measuring intrinsic elastic modulus of Pb/Sn solder alloys. Mech. Mater. 2002, 34, 349–362. [Google Scholar] [CrossRef] [Green Version]

- Frear, D.R. Issues related to the implementation of Pb-free electronic solders in consumer electronics. J. Mater. Sci. 2007, 18, 319–330. [Google Scholar]

- Wu, W.H.; Peng, S.P.; Lin, C.S.; Ho, C.E. Study of DC and AC electromigration behavior in eutectic Pb-Sn solder joints. J. Electron. Mater. 2009, 38, 2184–2193. [Google Scholar] [CrossRef]

- Wei, C.C.; Liu, P.C.; Chen, C.; Tu, K.N. Electromigration-induced Pb and Sn Whisker growth in SnPb solder stripes. J. Mater. Res. 2008, 23, 2017–2022. [Google Scholar] [CrossRef]

- Gomez, J.; Basaran, C. Damage mechanics constitutive model for Pb/Sn solder joints incorporating nonlinear kinematic hardening and rate dependent effects using a return mapping integration algorithm. Mech. Mater. 2006, 38, 585–598. [Google Scholar] [CrossRef]

- Lee, C.F.; Wang, J.J.; Chung, W.K. A steady creep theory of high lead Pb/Sn solder with creep-parameters maps. J. Mech. 2005, 21, 217–225. [Google Scholar] [CrossRef]

- Yang, H.; Wang, H.; Cao, D.Y. Investigation of soldering for crystalline silicon solar cells. Solder. Surf. Mt. Technol. 2016, 28, 222–226. [Google Scholar] [CrossRef]

- Xiong, H.P.; Gan, C.H.; Hu, Z.G.; Niu, H.Y.; Li, J.F.; Si, J.F.; Xing, P.F.; Luo, X.T. Formation and orientational distribution of cracks induced by electromagnetic induction soldering in crystalline silicon solar cells. IEEE J. Photovolt. 2017, 7, 966–973. [Google Scholar] [CrossRef]

- Li, Y.; Moon, K.S.; Wong, C.P. Electronics without lead. Science 2005, 308, 1419–1420. [Google Scholar] [CrossRef] [PubMed]

- Lau, J.H.; Wong, C.P.; Lee, N.-C.; Lee, S.-W.R. Electronics Manufacturing: with Lead-Free, Halogen-Free, and Conductive-Adhesive Materials, 1st ed.; McGraw-Hill: New York, NY, USA, 2003; pp. 11.1–11.8. [Google Scholar]

- Chen, C.; Chiang, J.; Lee, F.Y. De-mystifying materials selection for lead-free soldering. Circuit World 2006, 32, 18–22. [Google Scholar] [CrossRef]

- Heart, S. Green electronics through legislation and lead free soldering. Clean 2008, 36, 145–151. [Google Scholar]

- Nie, L.; Pecht, M.; Ciocci, R. Regulations and market trends in lead-free and halogen-free electronics. Circuit World 2007, 33, 4–9. [Google Scholar] [CrossRef]

- Act for Resource Recycling of Electrical and Electronic Equipment and Vehicles. Available online: http://www.rsjtechnical.com/images/Documents/Korea_RoHS_ELV_April_2007_EcoFrontier.pdf (accessed on 20 August 2019).

- Zhang, S.Y.; Qi, X.Q.; Yang, M.; Cao, Y.; Lin, T.S.; He, P.; Paik, K.W. A study on the resistivity and mechanical properties of modified nano-Ag coated Cu particles in electrically conductive adhesives. J. Mater. Sci. Mater. Electron. 2019, 30, 9171–9183. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, K.K.; Huo, F.P.; Wang, H.G.; Wang, Y. Microstructures and properties of Sn2.5Ag0.7Cu0.1RE composite solders reinforced with Cu-coated graphene nanosheets synthesized by pyrolysis. Materials 2019, 12, 289. [Google Scholar] [CrossRef]

- Wang, C.H.; Tsai, H.L.; Hwang, W.S. Direct printing of 1-D and 2-D electronically conductive structures by molten lead-free solder. Materials 2017, 10, 1. [Google Scholar] [CrossRef]

- Cheng, S.F.; Huang, C.M.; Pecht, M. Review of lead-free solders for electronics applications. Microelectron. Reliab. 2017, 75, 77–95. [Google Scholar] [CrossRef]

- Fukuda, M.; Imayoshi, K.; Matsumoto, Y. Effect of polyoxyethylenelaurylether on electrodeposition of Pb-free Sn–Bi alloy. Electrochim. Acta 2001, 47, 459–464. [Google Scholar] [CrossRef]

- Firdaus, M.; Nazeri, M. Corrosion characterization of Sn-Zn solder: a review. Solder. Surf. Mt. Technol. 2019, 31, 52–67. [Google Scholar]

- Abtew, M.; Selvaduray, G. Lead-free solders in microelectronics. Mater. Sci. Eng. R 2000, 27, 95–141. [Google Scholar] [CrossRef]

- Suganuma, K. Advances in lead-free electronics soldering. Curr. Opin. Solid State Mater. Sci. 2001, 5, 55–64. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, L.; Liu, Z.Q.; Zhong, S.J.; Ma, J.; Bao, L. Effects of CuZnAl particles on properties and microstructure of Sn-58Bi solder. Materials 2017, 10, 558. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Cheng, Z.J.; Li, C.W.; Wang, L.J.; Yu, C.P.; Zhao, Y.; Chen, M.H.; Li, Q.W.; Yao, Y.G. Electrically conductive adhesives based on thermoplastic polyurethane filled with silver flakes and carbon nanotubes. Compos. Sci. Technol. 2016, 129, 191–197. [Google Scholar] [CrossRef]

- Yan, C.; Liao, Q.W.; Zhou, X.L.; Wang, L.K.; Zhong, C.; Zhang, D. Ultra-low temperature curable nano-silver conductive adhesive for piezoelectric composite material. Phys. B Phys. Condens. Matter. 2018, 529, 9–15. [Google Scholar] [CrossRef]

- Miller, M.S.; O’Kane, J.C.; Niec, A.; Carmichael, R.S.; Carmichael, T.B. Silver nanowire/optical adhesive coatings as transparent electrodes for flexible electronics. Acs Appl. Mater. Interfaces 2013, 5, 10165–10172. [Google Scholar] [CrossRef]

- Ho, L.N.; Wu, T.F.; Nishikawa, H. Properties of phenolic-based Ag-filled conductive adhesive affected by different coupling agents. J. Adhes. 2013, 89, 847–858. [Google Scholar] [CrossRef]

- Suganuma, K.; Sakamoto, S.; Kagami, N.; Wakuda, D.; Kim, K.S.; Nogi, M. Low-temperature low-pressure die attach with hybrid silver particle paste. Microelectron. Reliab. 2012, 52, 375–380. [Google Scholar] [CrossRef]

- Wang, L.; Wan, C.; Fu, Y.G.; Chen, H.T.; Liu, X.J.; Li, M.Y. Study on the effects of adipic acid on properties of dicyandiamide-cured electrically conductive adhesive and the interaction mechanism. J. Electron. Mater. 2014, 43, 132–136. [Google Scholar] [CrossRef]

- Xiong, N.N.; Li, Z.L.; Xie, H.; Zhao, Y.Z.; Wang, Y.H.; Li, J.Z. Influence of curing procedures on the electrical properties of epoxy-based isotropic conductive adhesives. Rare Met. Mater. Eng. 2016, 45, 2524–2528. [Google Scholar]

- Shen, Y.Q.; Chen, Z.X.; Zhou, T.T.; Feng, W.C.; Liu, Y. Green preparation of flaky silver powders with nano-thickness towards electrically conductive adhesives through a nanofilm transition method. J. Mater. Chem. C 2016, 4, 254–258. [Google Scholar] [CrossRef]

- Guan, Y.L.; Chen, X.; Li, F.Q.; Gao, H. Study on the curing process and shearing tests of die attachment by Ag-epoxy electrically conductive adhesive. Int. J. Adhes. Adhes. 2010, 30, 80–88. [Google Scholar] [CrossRef]

- Zhang, Y.; Qi, S.H.; Wu, X.M.; Duan, G.C. Electrically conductive adhesive based on acrylate resin filled with silver plating graphite nanosheet. Synth. Met. 2011, 161, 516–522. [Google Scholar] [CrossRef]

- Chen, D.P.; Qiao, X.L.; Qiu, X.L.; Tan, F.T.; Chen, J.G.; Jiang, R.Z. Effect of silver nanostructures on the resistivity of electrically conductive adhesives composed of silver flakes. J. Mater. Sci. Mater. Electron. 2010, 21, 486–490. [Google Scholar] [CrossRef]

- Eitner, U.; Geipel, T.; Holtschke, S.N.; Tranitz, M. Characterization of electrically conductive adhesives. Energy Procedia 2012, 27, 676–679. [Google Scholar] [CrossRef]

- Cui, H.W.; Jiu, J.T.; Sugahara, T.; Nagao, S.; Suganuma, K.; Uchid, H. High performance heat curing copper-silver powders filled electrically conductive adhesives. Electron. Mater. Lett. 2015, 11, 315–322. [Google Scholar] [CrossRef]

- Wen, J.Y.; Tian, Y.H.; Hang, C.J.; Zheng, Z.; Zhang, H.; Mei, Z.P.; Hu, X.Y.; Tian, Y.Q. Fabrication of novel printable electrically conductive adhesives (ECAs) with excellent conductivity and stability enhanced by the addition of polyaniline nanoparticles. Nanomaterials 2019, 9, 960. [Google Scholar] [CrossRef]

- Meng, M.; Cheng, L.J.; Yang, K.; Sun, M.Y.; Luo, Y. A novel seedless TSV process based on room temperature curing silver nanowires ECAs for MEMS packaging. Micromachines 2019, 10, 351. [Google Scholar] [CrossRef]

- Liao, G.F.; Li, Q.; Zhao, W.Z.; Pang, Q.H.; Gao, H.Y.; Xu, Z.S. In-situ construction of novel silver nanoparticle decorated polymeric spheres as highly active and stable catalysts for reduction of methylene blue dye. Appl. Catal. AGen. 2018, 549, 102–111. [Google Scholar] [CrossRef]

- Xu, S.Y.; Dillard, D.A.; Dillard, J.G. Environmental aging effects on the durability of electrically conductive adhesive joints. Int. J. Adhes. Adhes. 2003, 23, 235–250. [Google Scholar] [CrossRef]

- Kuang, J.H.; Hsu, C.M.; Lin, A.D. A study on the conductivity variation of au coated conductive particles in ACF packaging process. J. Nanomater. 2015, 2015, 1–8. [Google Scholar] [CrossRef]

- Li, Y.; Moon, K.S.; Wong, C.P. Adherence of self-assembled monolayers on gold and their effects for high-performance anisotropic conductive adhesives. J. Electron. Mater. 2005, 34, 266–271. [Google Scholar] [CrossRef]

- Zhou, J.G.; Sancaktar, E. Geometric effects on multilayer generic circuits fabricated using conductive epoxy/nickel adhesives. J. Adhes. Sci. Technol. 2008, 22, 947–956. [Google Scholar] [CrossRef]

- Sancaktar, E.; Dilsiz, N. Thickness-dependent conduction behavior of various particles for conductive adhesive applications. J. Adhes. Sci. Technol. 1999, 13, 763–771. [Google Scholar] [CrossRef]

- Hansen, N.; Adams, D.O.; DeVries, K.L.; Goff, A.; Hansen, G. Investigation of electrically conductive structural adhesives using nickel nanostrands. J. Adhes. Sci. Technol. 2011, 25, 2659–2670. [Google Scholar] [CrossRef]

- Li, Y.; Moon, K.S.; Wong, C.P. High performance anisotropic conductive adhesives using copper particles with an anti-oxidant coating layer. J. Electron. Packag. 2010, 132, 011007-1–011007-5. [Google Scholar]

- Ho, L.N.; Nishikawa, H. Influence of post-curing and coupling agents on polyurethane based copper filled electrically conductive adhesives. J. Mater. Sci. Mater. Electron. 2013, 24, 2077–2081. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Liu, Y.L.; Long, J.M.; Liu, X.L. Electrochemical migration behavior of Ag-plated Cu-filled electrically conductive adhesives. Rare Met. 2012, 31, 64–70. [Google Scholar] [CrossRef]

- Pu, N.W.; Peng, Y.Y.; Wang, P.C.; Chen, C.Y.; Shi, J.N.; Liu, Y.M.; Ger, M.D.; Chang, C.L. Application of nitrogen-doped graphene nanosheets in electrically conductive adhesives. Carbon 2014, 67, 449–456. [Google Scholar] [CrossRef]

- Amoli, B.M.; Trinidad, J.; Hu, A.M.; Zhou, Y.N.; Zhao, B.X. Highly electrically conductive adhesives using silver nanoparticle (Ag NP)-decorated graphene: The effect of NPs sintering on the electrical conductivity improvement. J. Mater. Sci. Mater. Electron. 2015, 26, 590–600. [Google Scholar] [CrossRef]

- Ma, H.R.; Ma, M.Z.; Zeng, J.F.; Guo, X.H.; Ma, Y.Q. Hydrothermal synthesis of graphene nanosheets and its application in electrically conductive adhesives. Mater. Lett. 2016, 178, 181–184. [Google Scholar] [CrossRef]

- Masaebi, N.; Peighambardoust, S.J.; Ahadzadeh, I. Electrically conductive nanocomposite adhesives based on epoxy resin filled with silver coated nanocarbon black. J. Mater. Sci. Mater. Electron. 2018, 29, 11840–11851. [Google Scholar] [CrossRef]

- Wu, J.Y.; Lai, Y.C.; Chang, C.L.; Hung, W.C.; Wu, H.M.; Liao, Y.C.; Huang, C.H.; Liu, W.R. Facile and green synthesis of graphene-rased conductive adhesives via liquid exfoliation process. Nanomaterials 2019, 9, 38. [Google Scholar] [CrossRef] [PubMed]

- Ji, Y.H.; Liu, Y.; Huang, G.W.; Shen, X.J.; Xiao, H.M.; Fu, S.Y. Ternary Ag/epoxy adhesive with excellent overall performance. Acs Appl. Mater. Interfaces 2015, 7, 8041–8052. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Chen, J.Y.; Yuan, W.H.; Liu, Y.H.; Sun, Y.J.; Wu, H.J.; Zhou, X.Q. Self-assembly synthesis of silver nanowires/graphene nanocomposite and its effects on the performance of electrically conductive adhesive. Materials 2018, 11, 2028. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.G. The preparation of high conductivity of silver conductive adhesive and low-cost research. Master’s Thesis, Hunan University of Technology, Zhuzhou, China, 28 May 2012. [Google Scholar]

- Koury, A.J.; Conte, A.A., Jr.; Devine, M.J. Powder coating technology. Aircr. Eng. Aerosp. Technol. 1972, 44, 18–23. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, H.; Li, X.; Dong, Y.; Guo, S.; Zhao, L. A Novel Preparation Method of Electrically Conductive Adhesives by Powder Spraying Process. Materials 2019, 12, 2793. https://doi.org/10.3390/ma12172793

Dong H, Li X, Dong Y, Guo S, Zhao L. A Novel Preparation Method of Electrically Conductive Adhesives by Powder Spraying Process. Materials. 2019; 12(17):2793. https://doi.org/10.3390/ma12172793

Chicago/Turabian StyleDong, Hongyu, Xin Li, Yi Dong, Shaoqing Guo, and Liangfu Zhao. 2019. "A Novel Preparation Method of Electrically Conductive Adhesives by Powder Spraying Process" Materials 12, no. 17: 2793. https://doi.org/10.3390/ma12172793

APA StyleDong, H., Li, X., Dong, Y., Guo, S., & Zhao, L. (2019). A Novel Preparation Method of Electrically Conductive Adhesives by Powder Spraying Process. Materials, 12(17), 2793. https://doi.org/10.3390/ma12172793