Mechanochemistry of Metal Hydrides: Recent Advances †

Abstract

1. Introduction

2. High-Energy Mechanochemical Synthesis

2.1. The Planetary Ball Mill

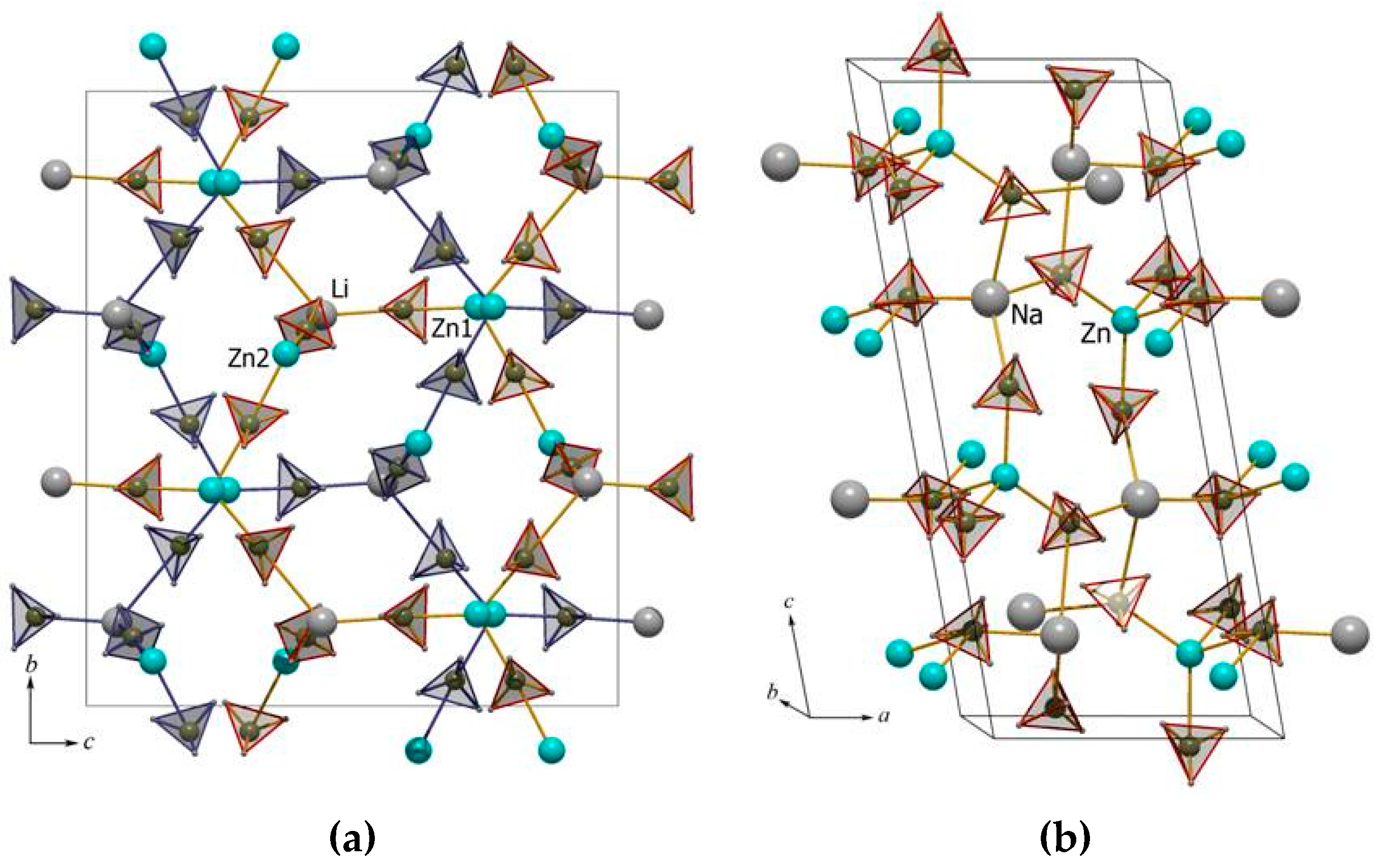

2.2. Solvent Free Synthesis of Metal Borohydrides

2.3. Solvent Free Synthesis of “Reactive Hydride Composites”

2.4. Challenges, Pitfalls and Deliberate Destructive Mechanochemistry

2.4.1. Reaction Byproduct

2.4.2. LiBH4 and the Influence of its Deliberate Destructive Decomposition Product

2.4.3. Conclusions

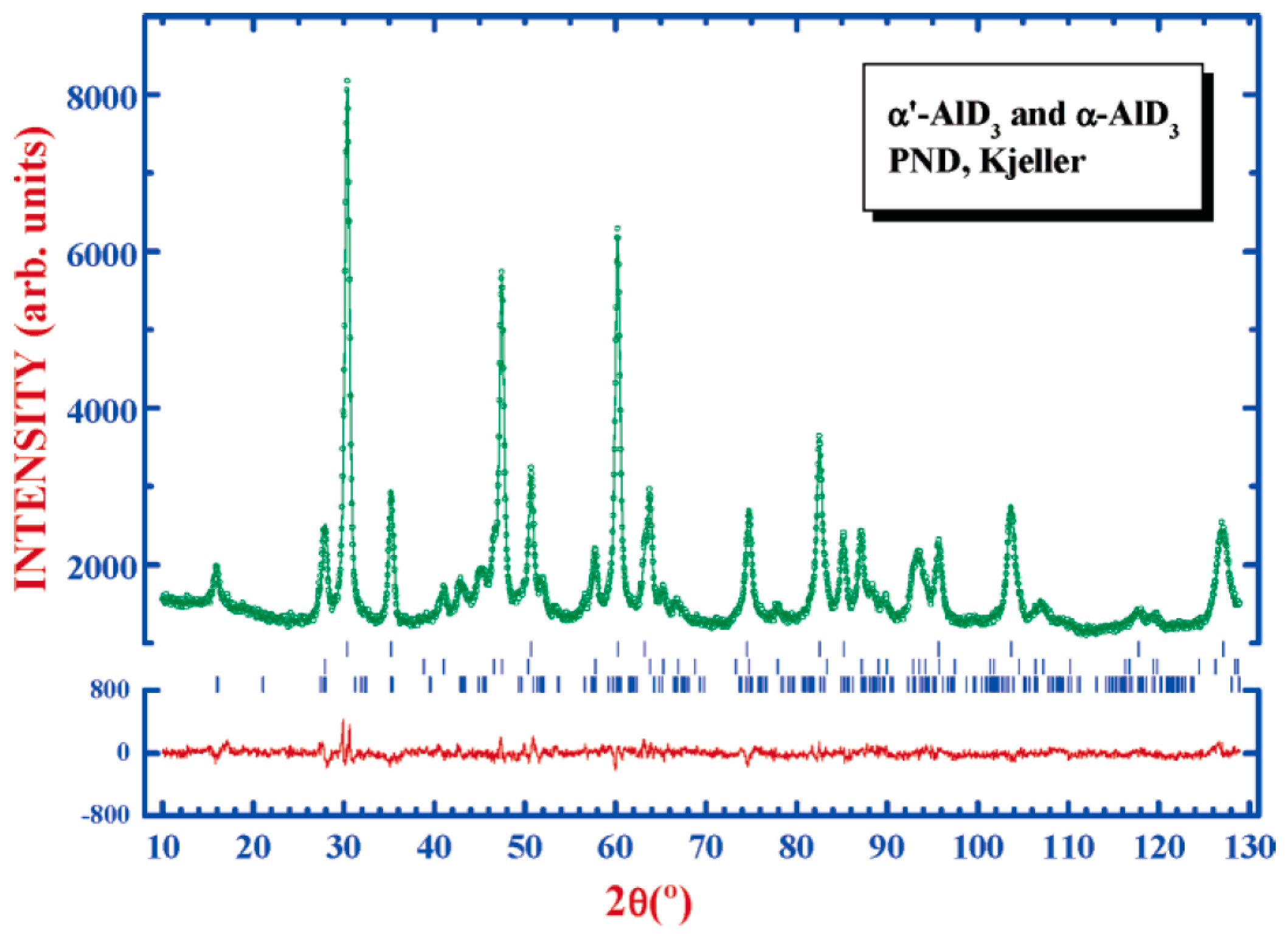

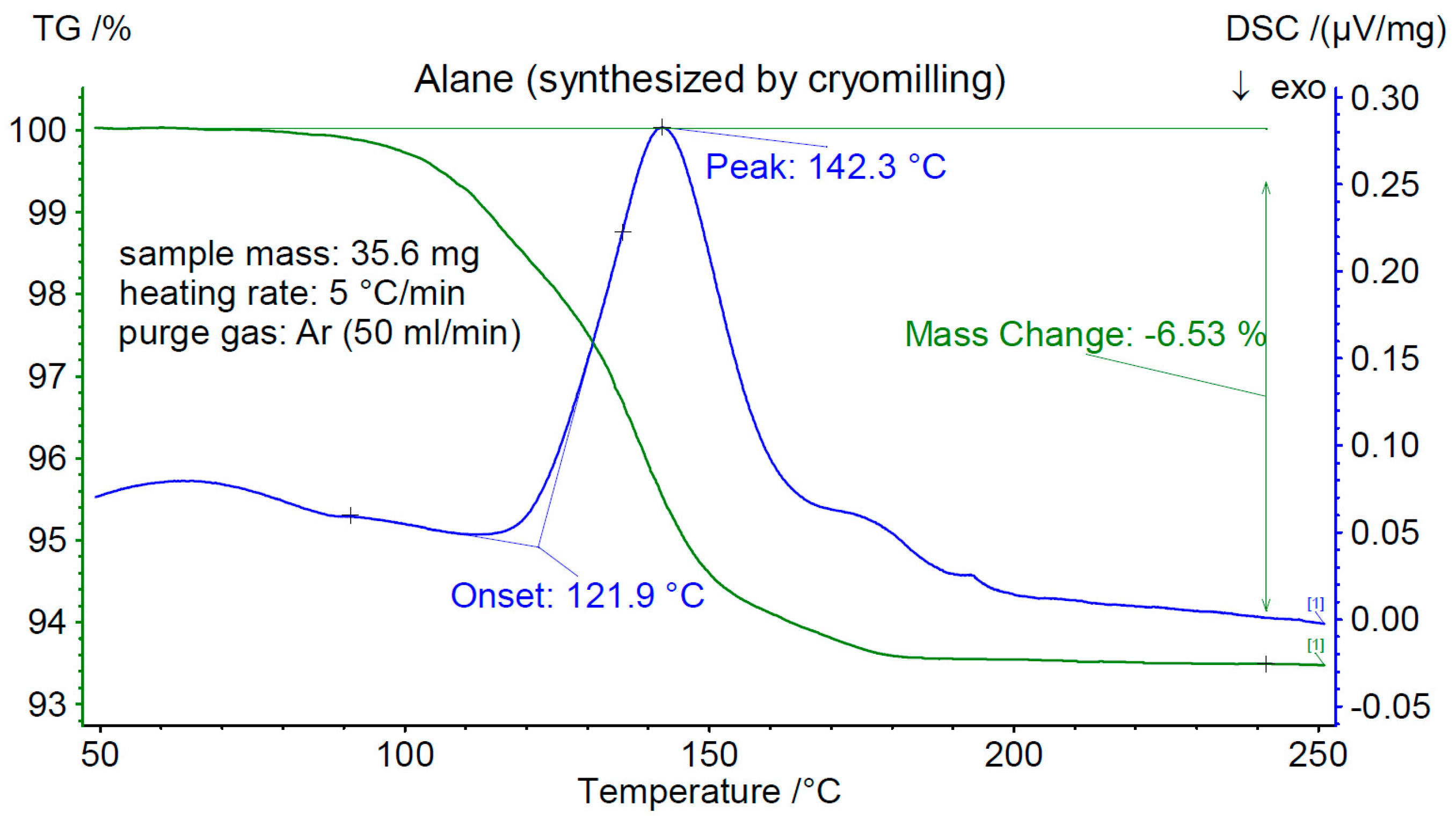

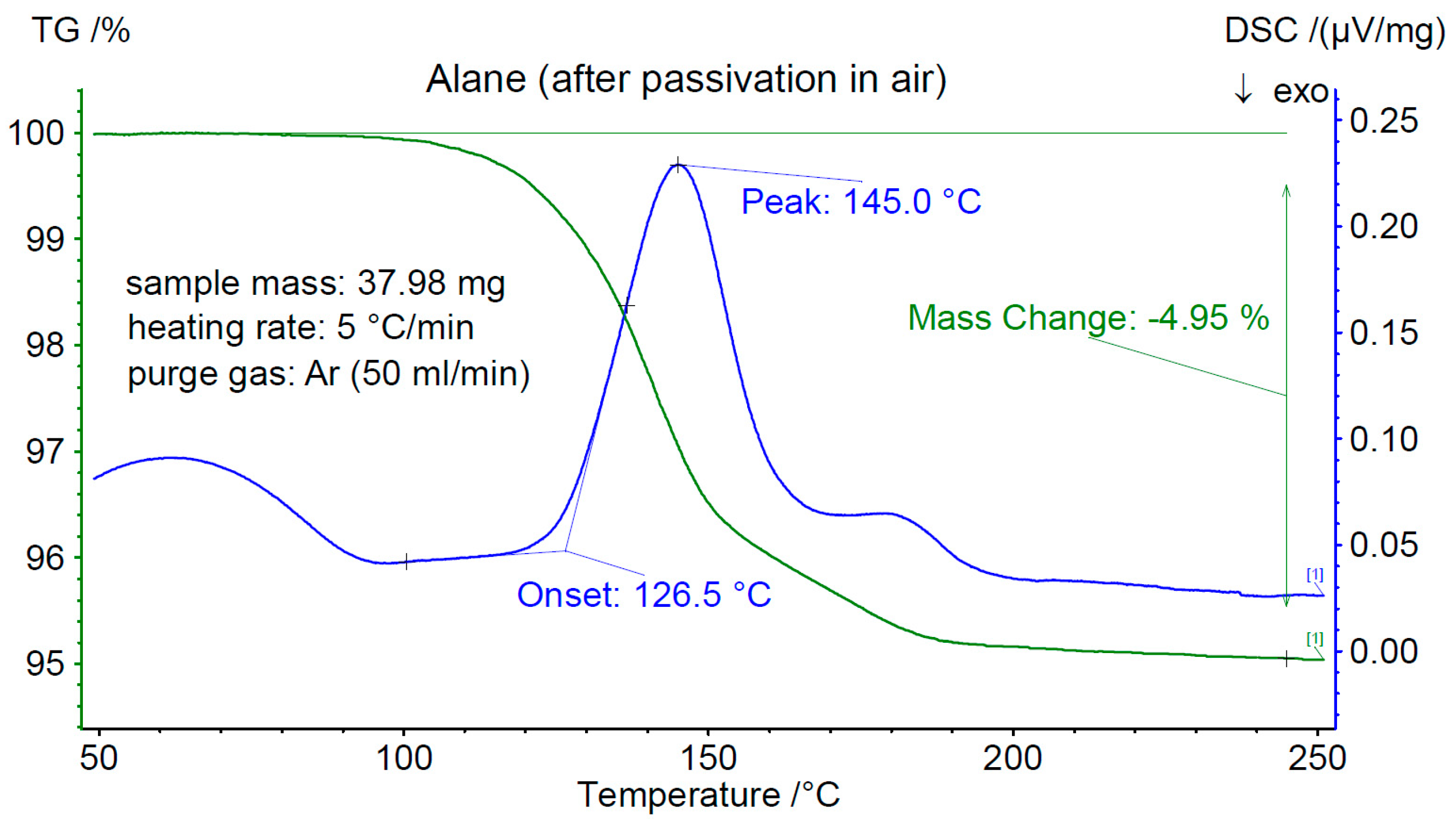

3. Cryomilling—Mechanical Processing and Synthesis at Low Temperatures

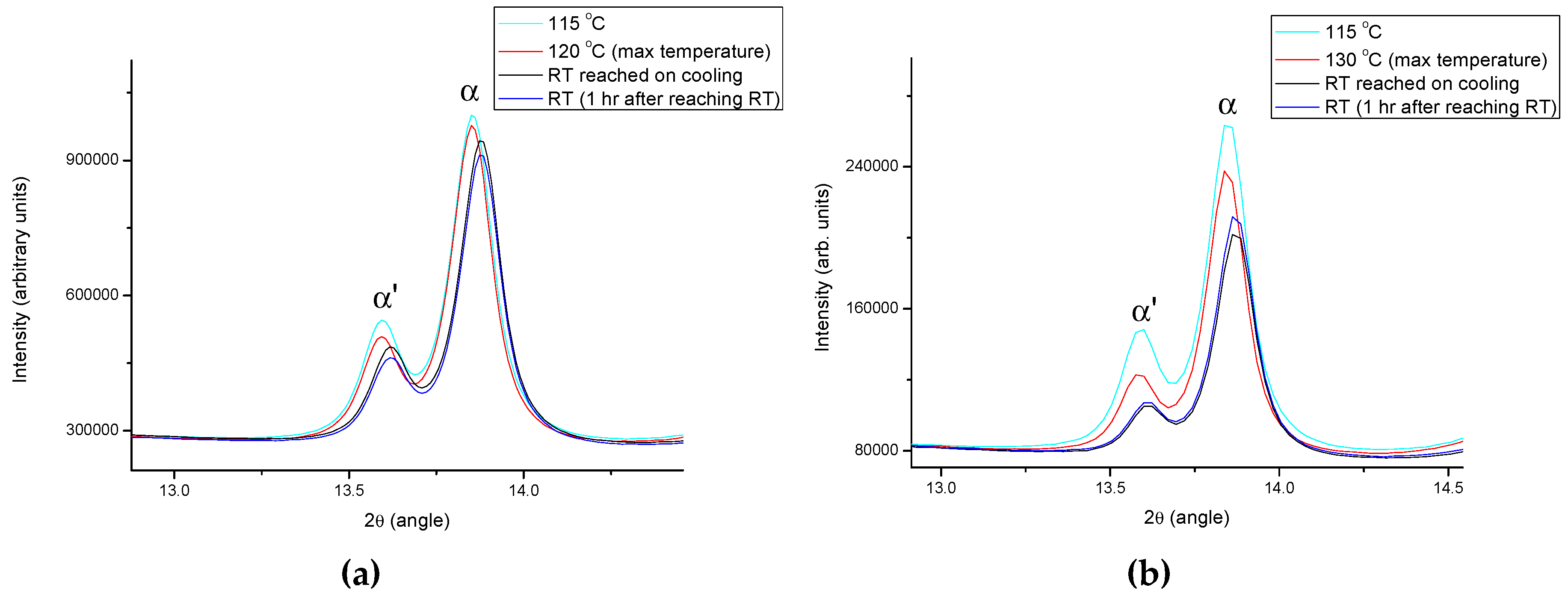

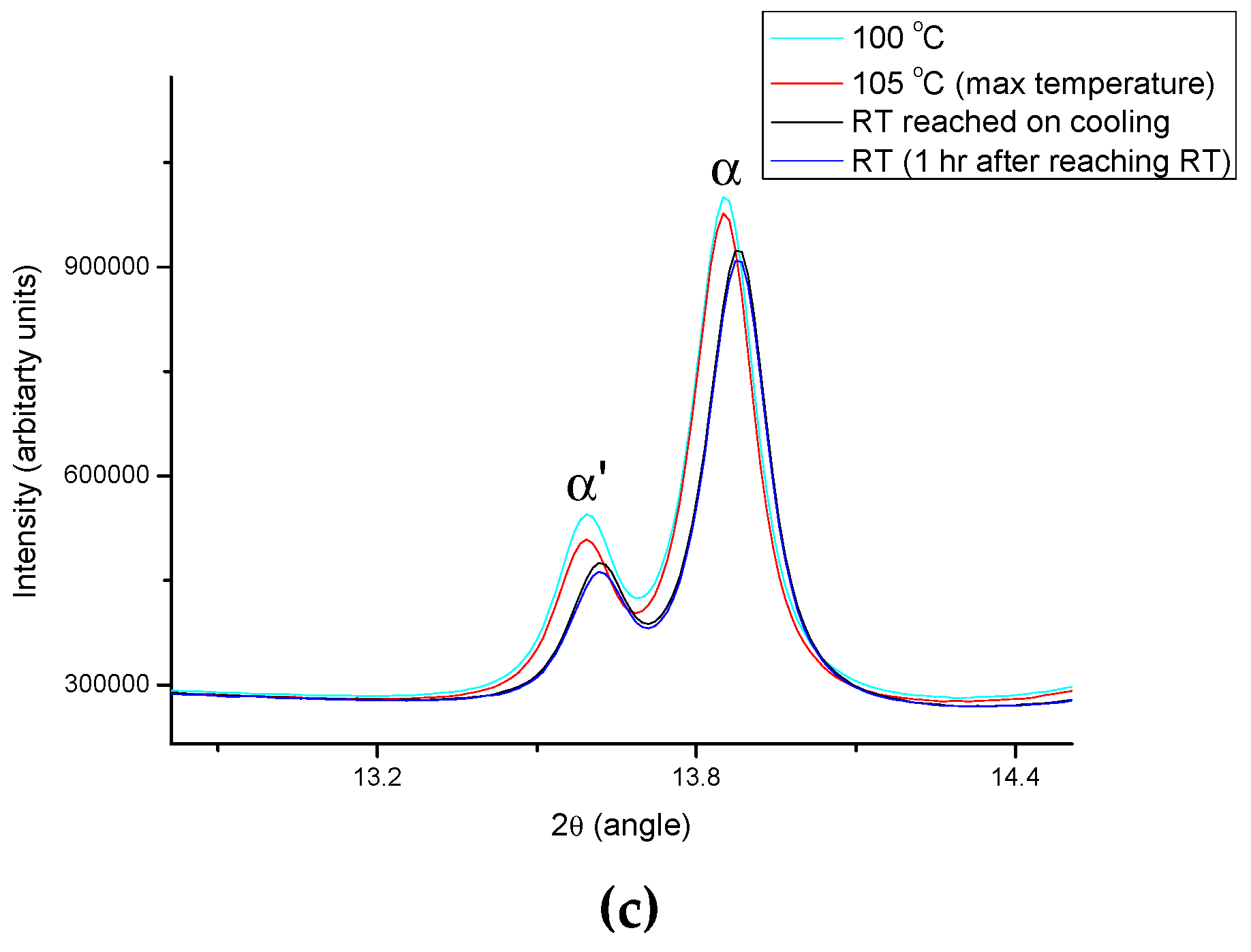

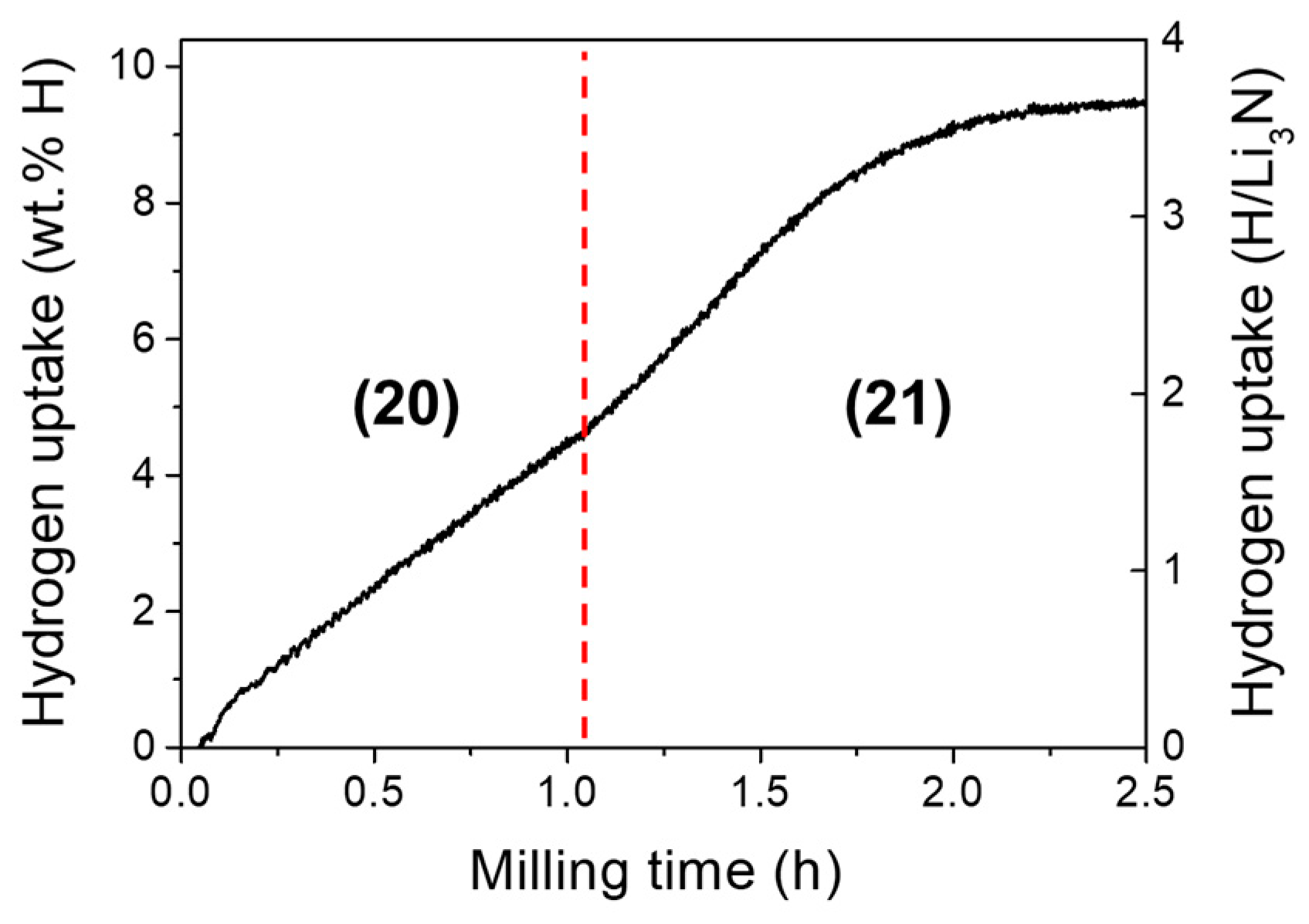

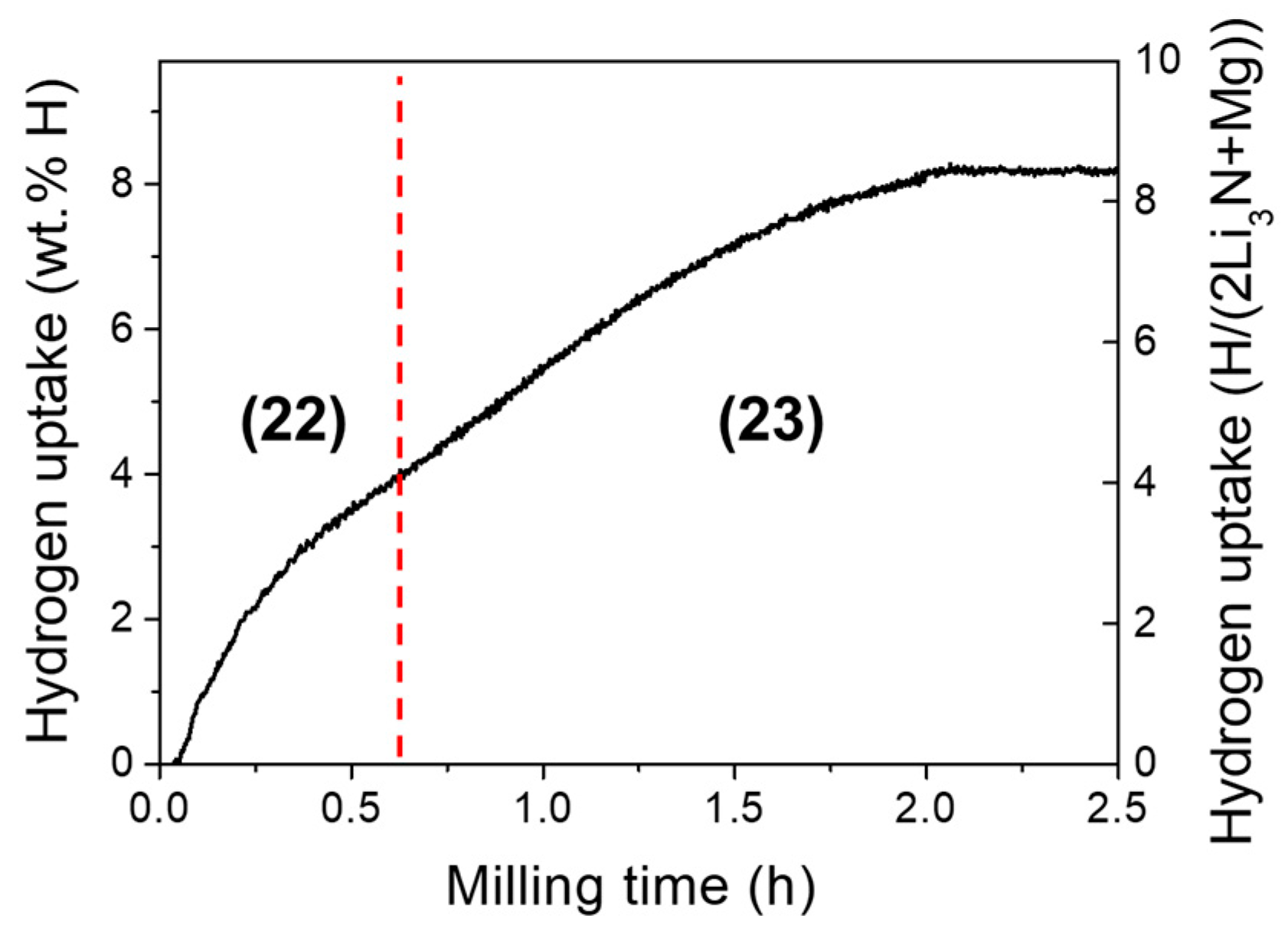

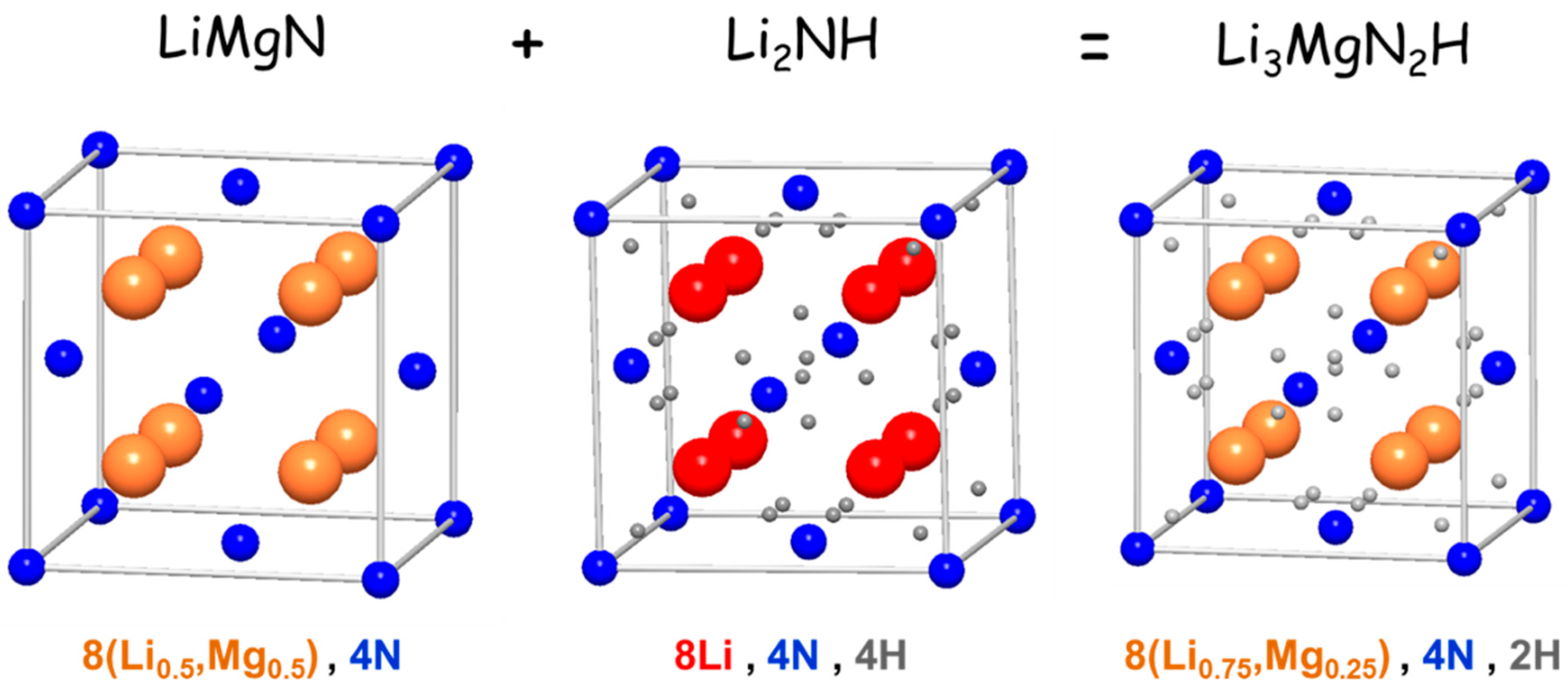

4. Formation and Defect Generation of Lightweight Hydrides by Mechanochemistry under Hydrogen Gas

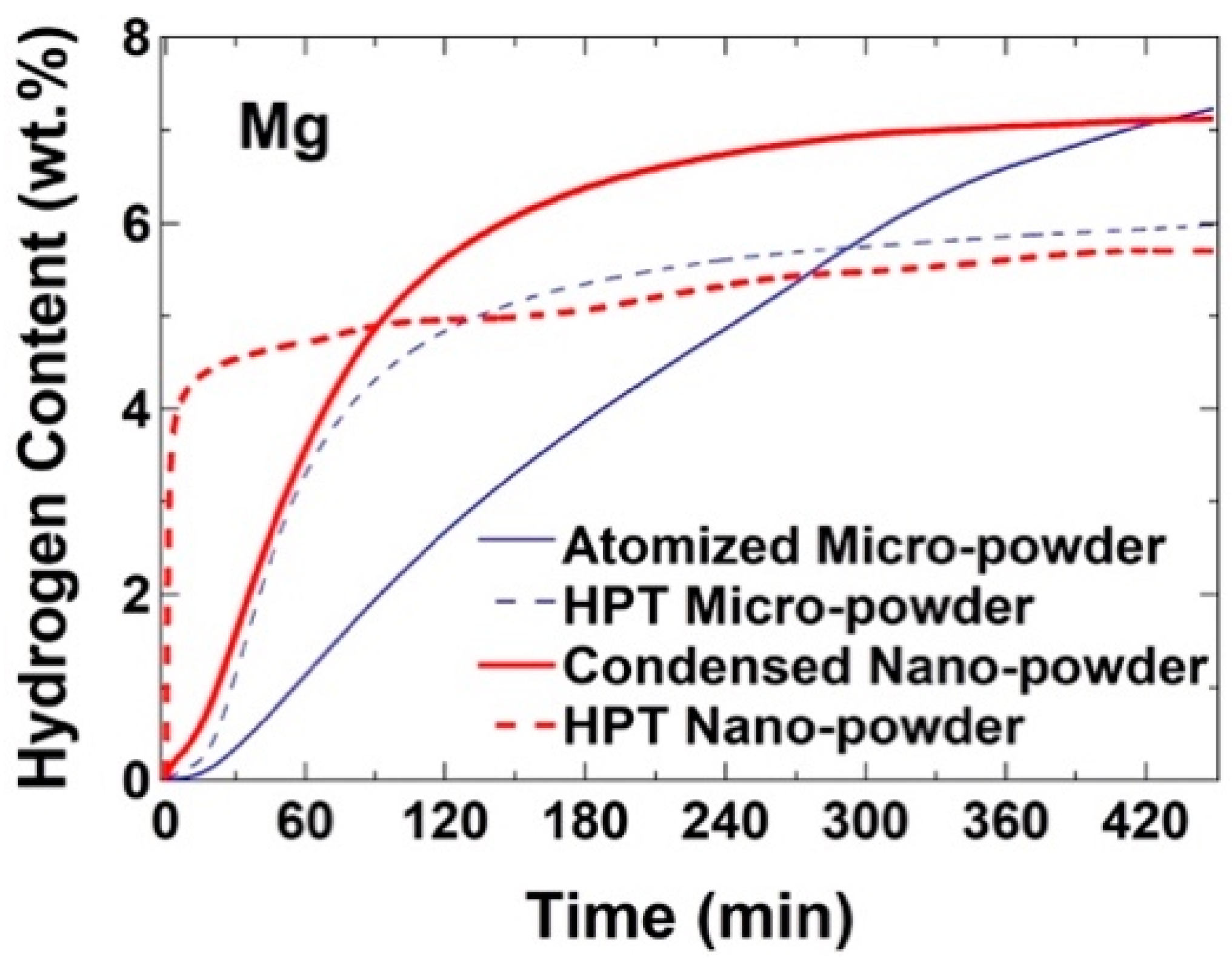

5. High-Pressure Torsion

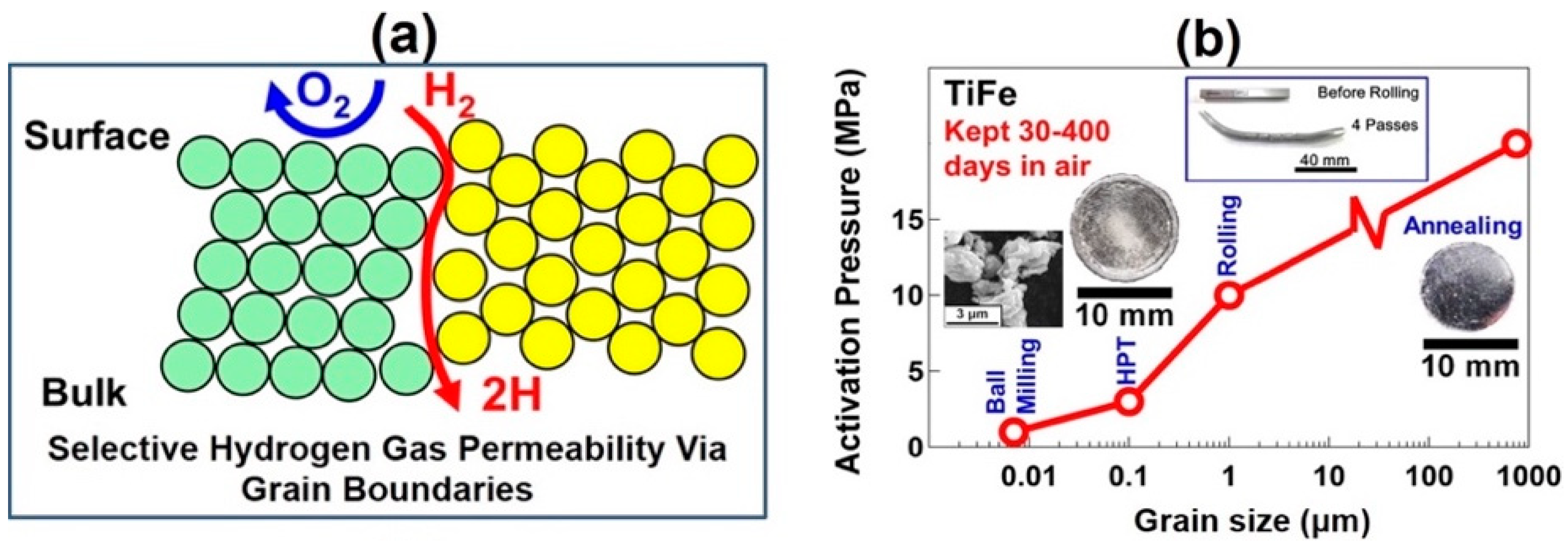

5.1. Significance of Grain Boundaries

5.2. Significance of Dislocations

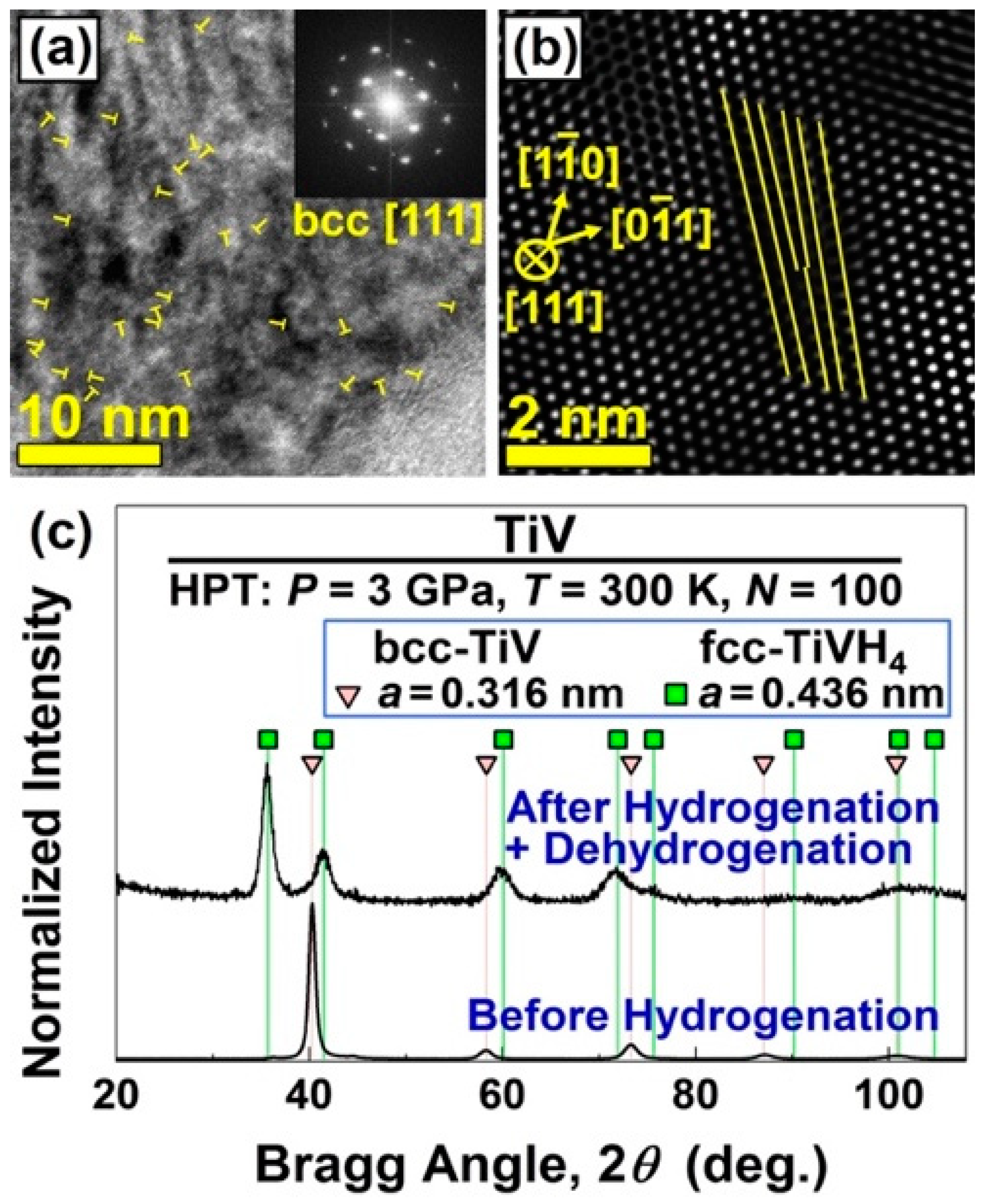

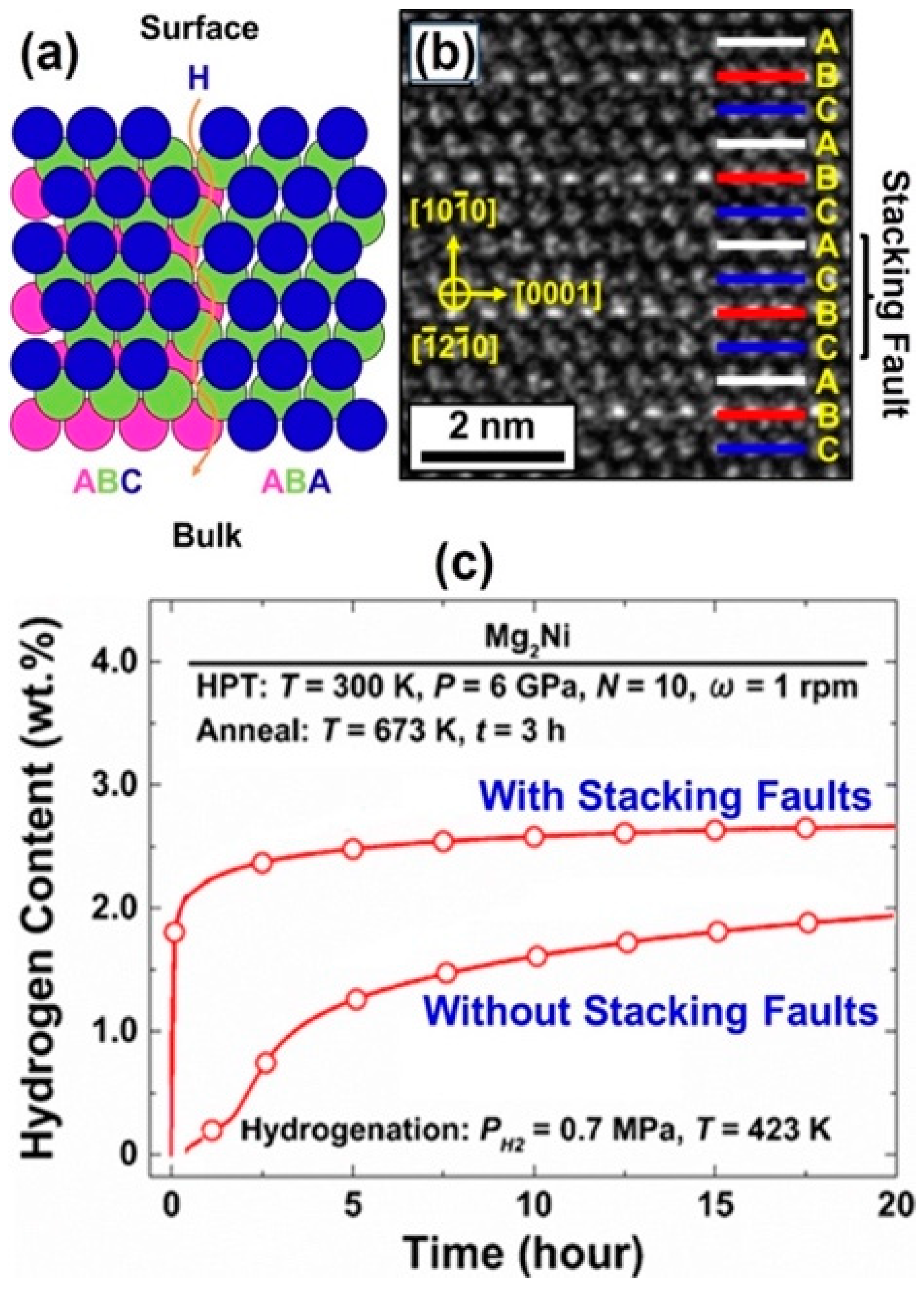

5.3. Significance of Stacking Faults

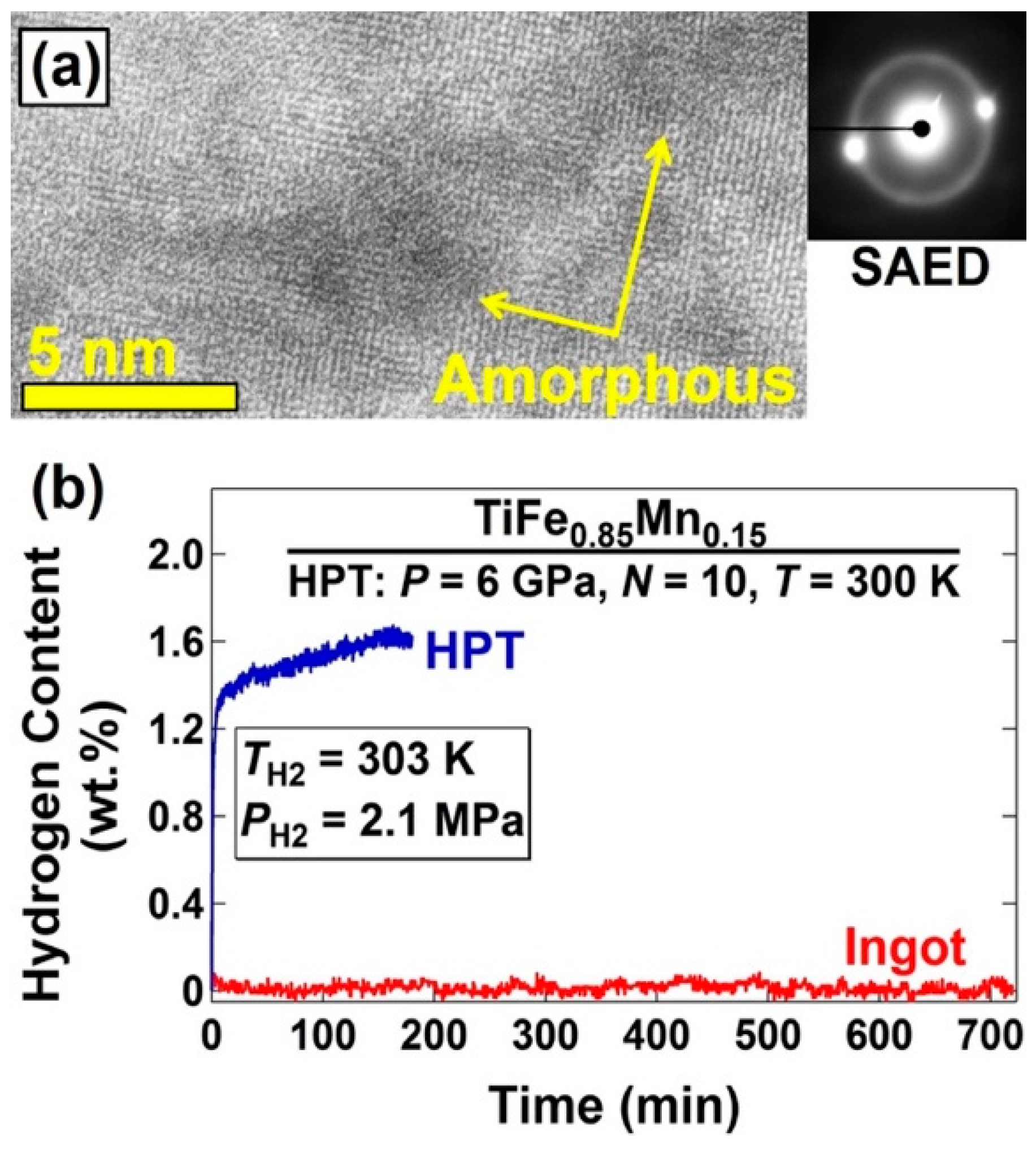

5.4. Significance of Localized Amorphization

5.5. Significance of Phase Transformation

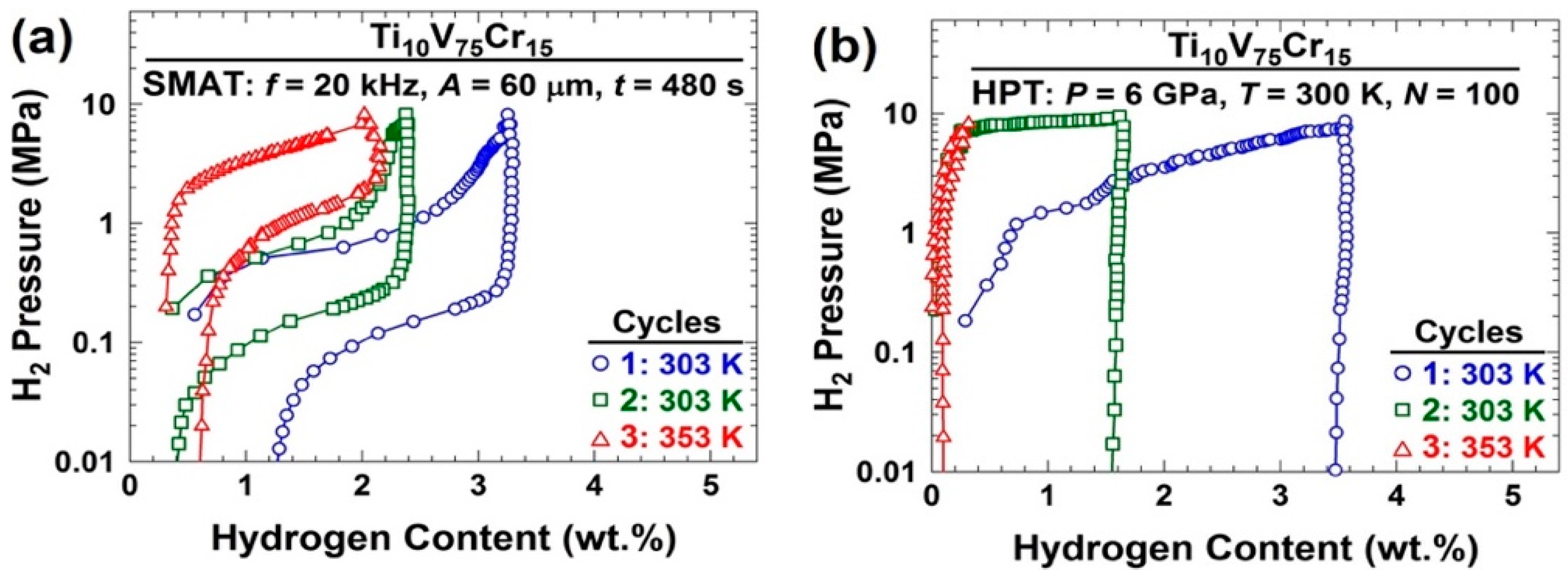

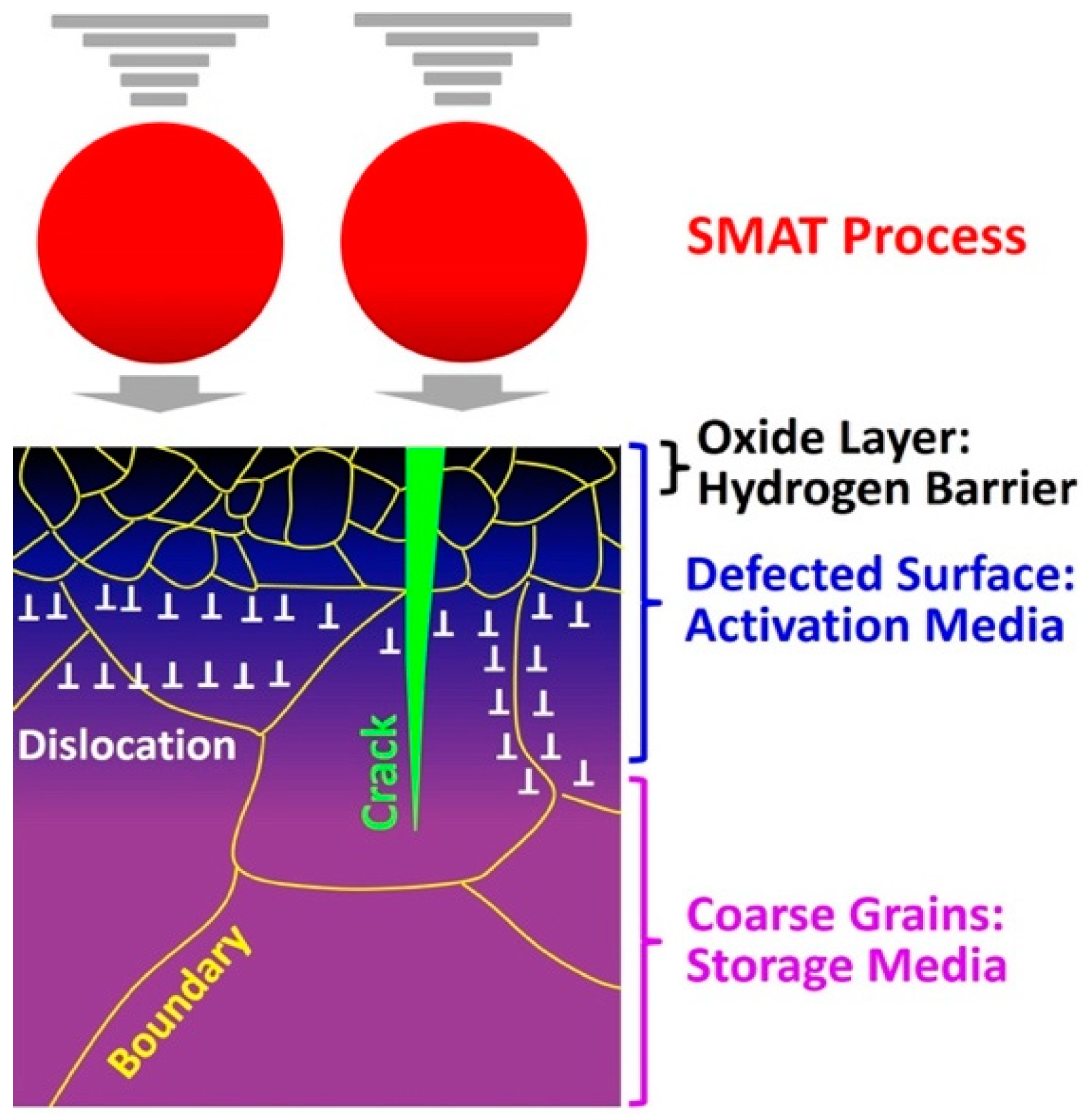

6. Surface Modification by Mechanical Attrition Treatment

Significance of Surface Defects and Gradient-Structure

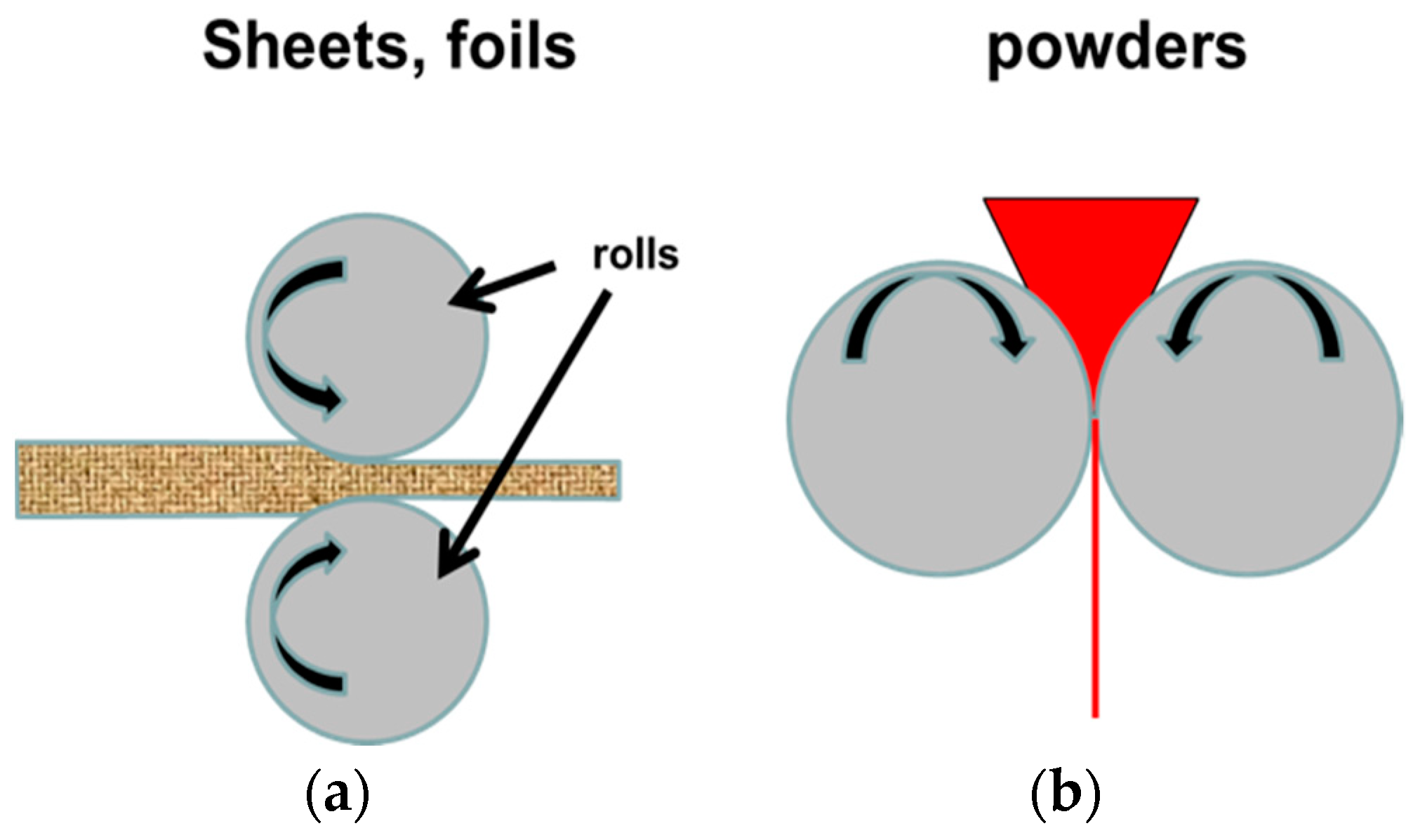

7. Effect of Cold Rolling on Metal Hydrides

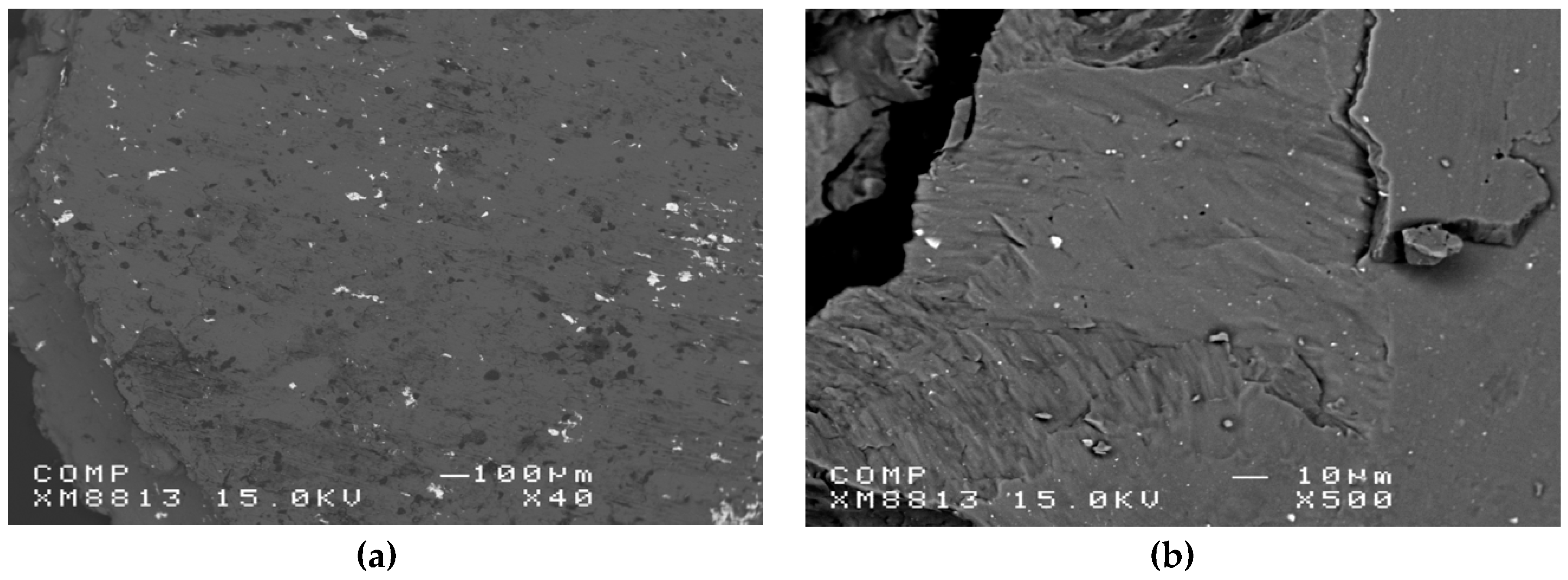

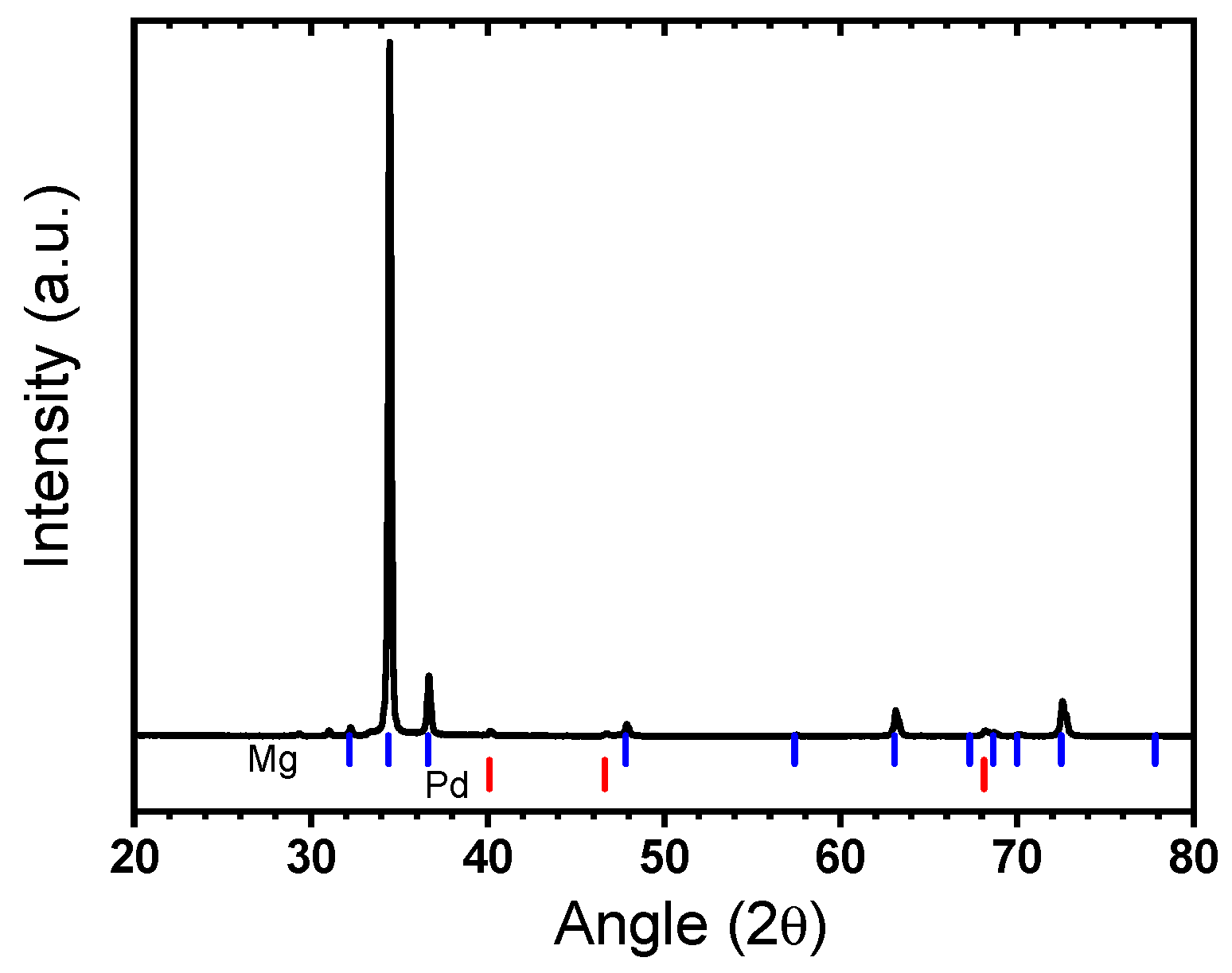

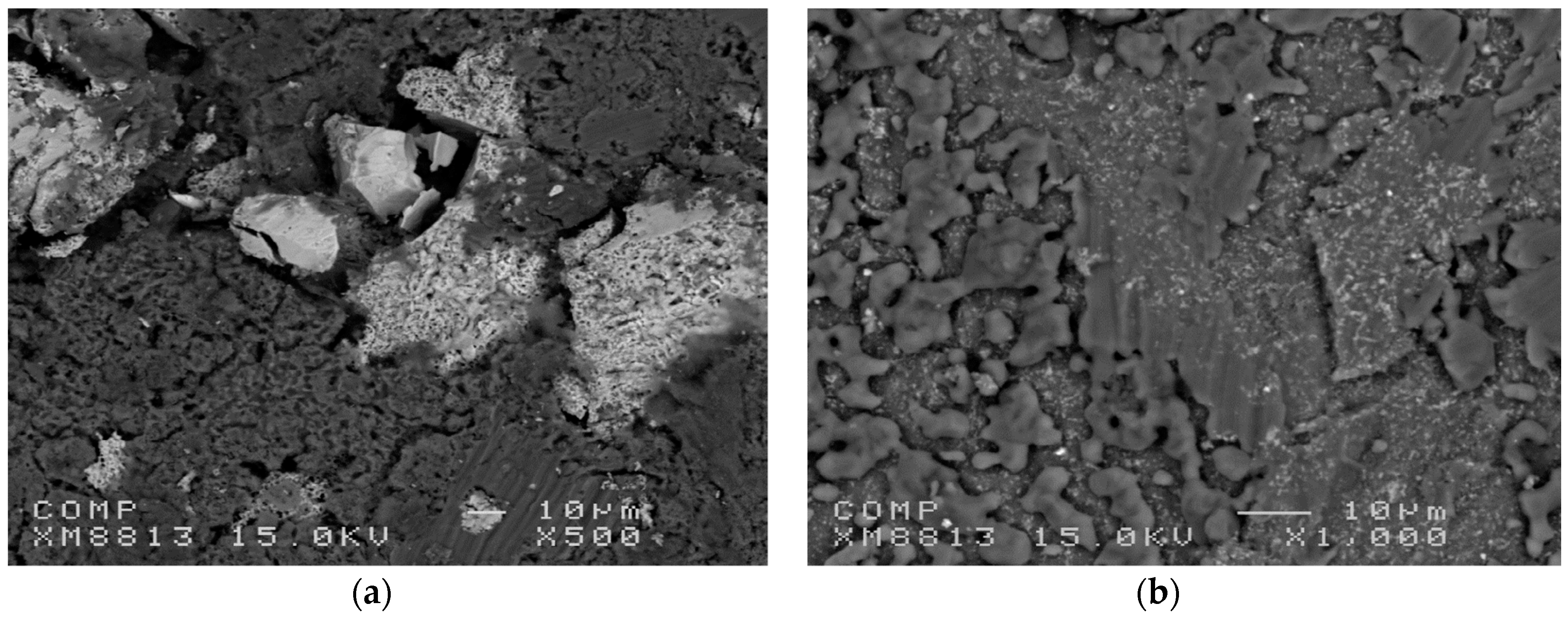

7.1. Cold rolling on Mg-Pd system

7.2. Cold rolling on AB5 system

8. In Situ Characterization of the Mechanochemical Reaction

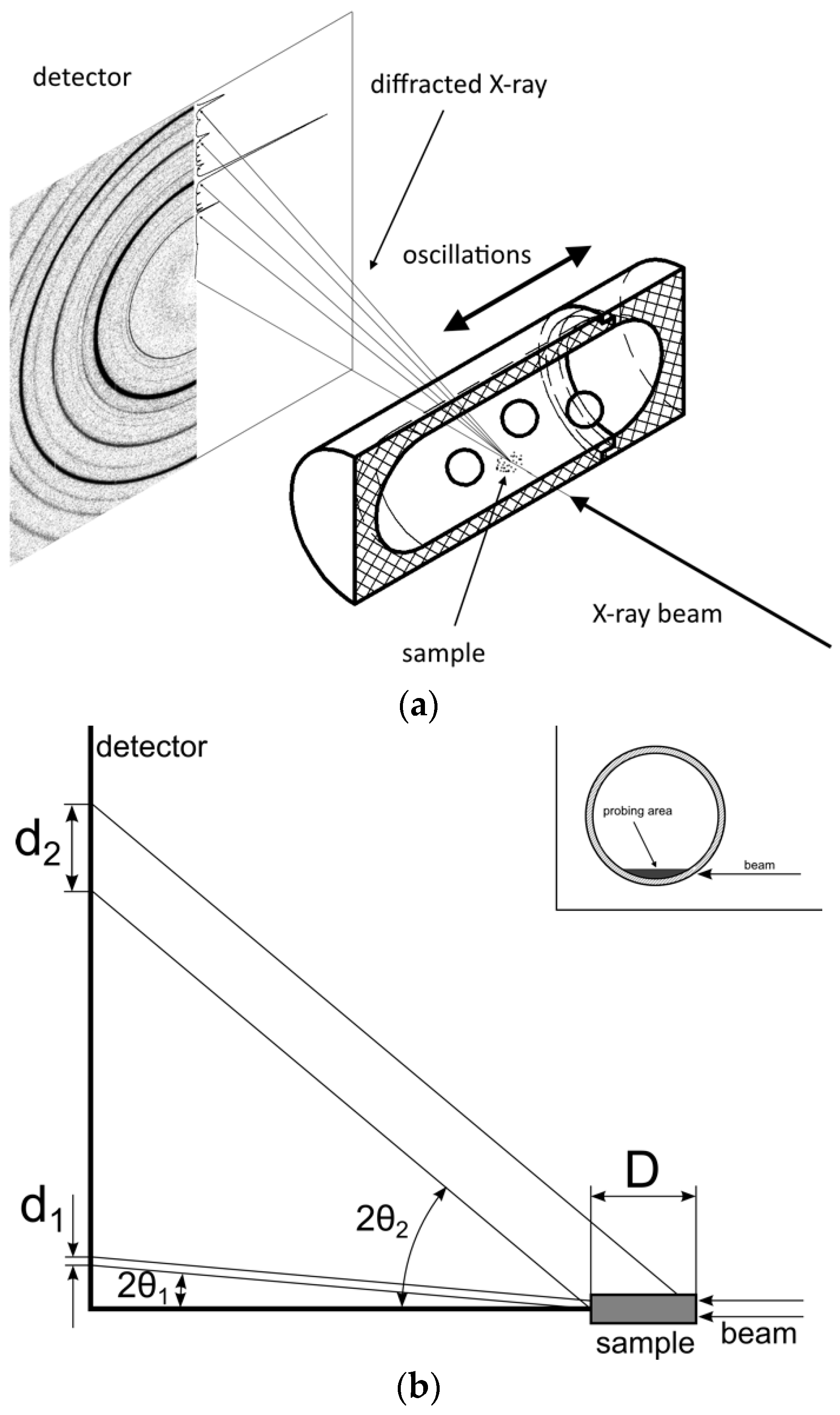

8.1. First In Situ Diffraction Studies

- -

- High energies (short wavelengths) are needed to penetrate the thick-walled plastic jars. This limits the use of the setup only to high-energy synchrotron beamlines with λ or the order of ~0.15 Å.

- -

- The use of high-energy X-rays has another drawback: the powder diffraction data are squeezed in a short 2θ-range, with strongly overlapping Bragg peaks, making it difficult to collect high-resolution data.

- -

- The thick-walled plastic jars produce high amorphous background, which needs to be subtracted for presentation purposes when plotting data for weakly scattering samples, such as hydrides.

- -

- The plastic jars have to be machined in a workshop at relatively high price and they do not stand many milling cycles, being especially prone to degradation when using small amounts of solvents in liquid assisted grinding.

- -

- The large sample volume gives rise to broad or even split diffraction peaks coming from the sample sticking on the opposite sides of the milling jar. In part, this problem can be solved by hitting the milling volume by X-ray beam close to the inner wall edge. Thus, the X-ray beam should not go through the middle of the milling jar but close to its edge. This also reduces the probability of hitting the metal balls with the X-ray beam.

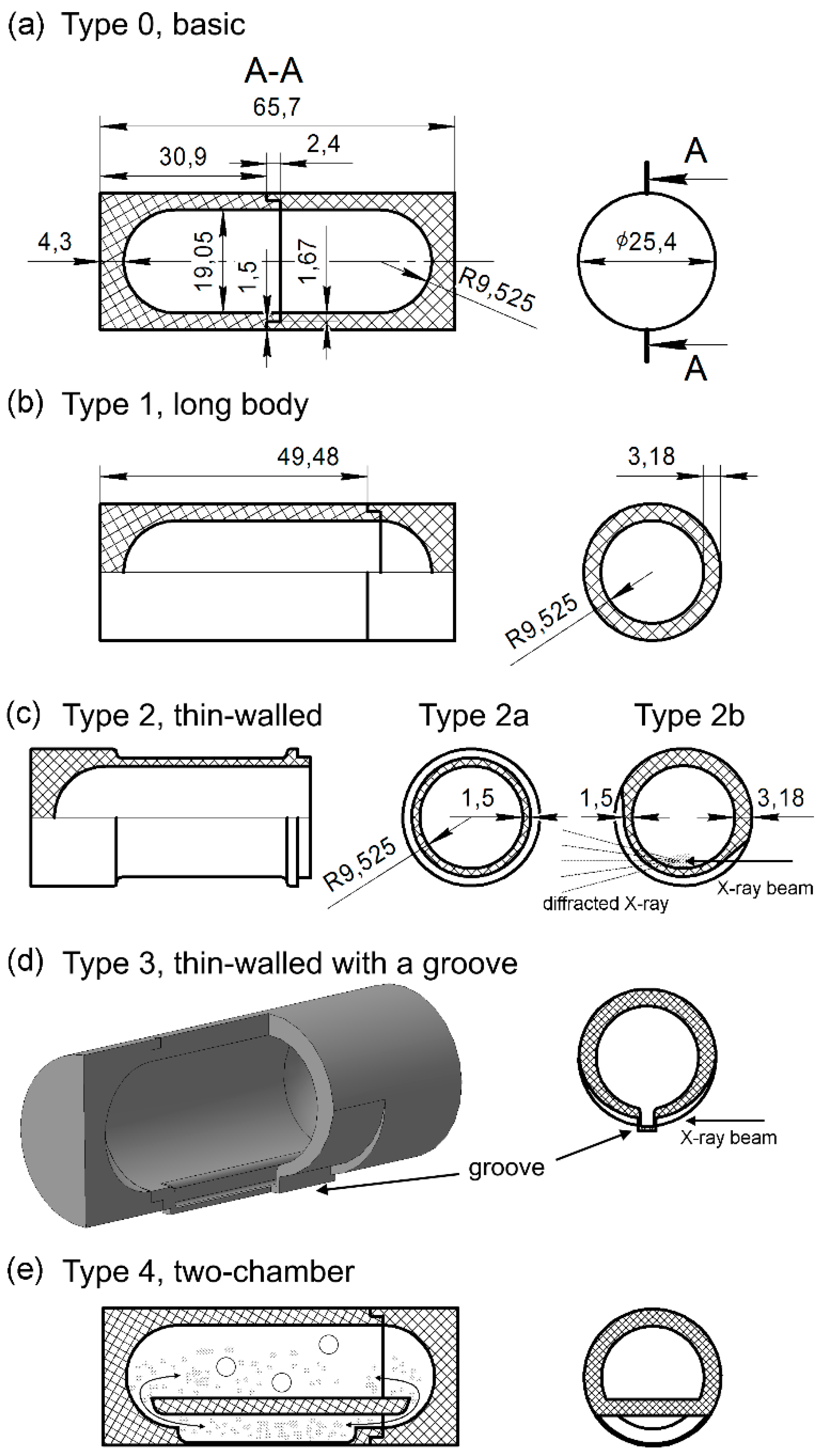

8.2. Improving the Design of the Milling Jars by 3D Printing

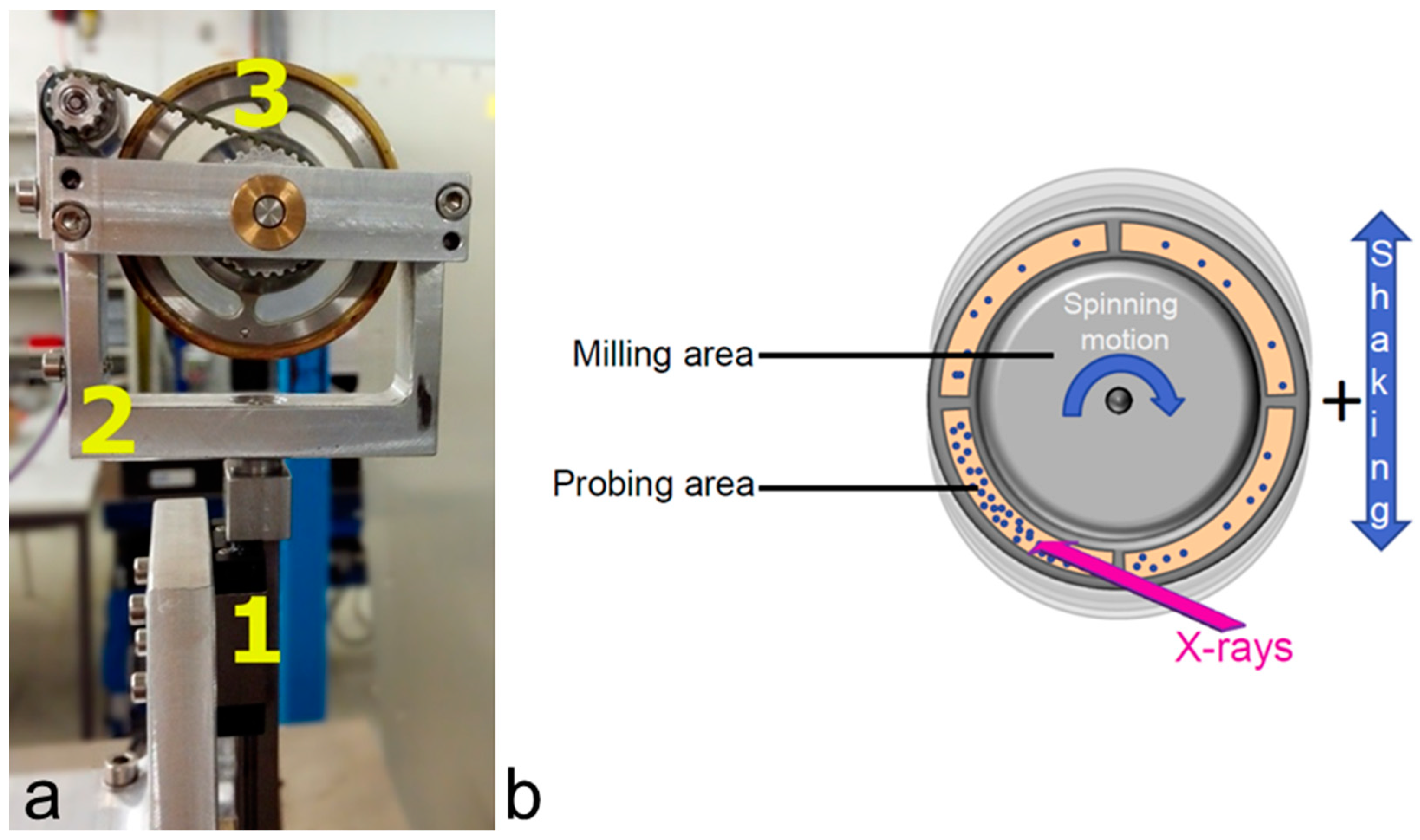

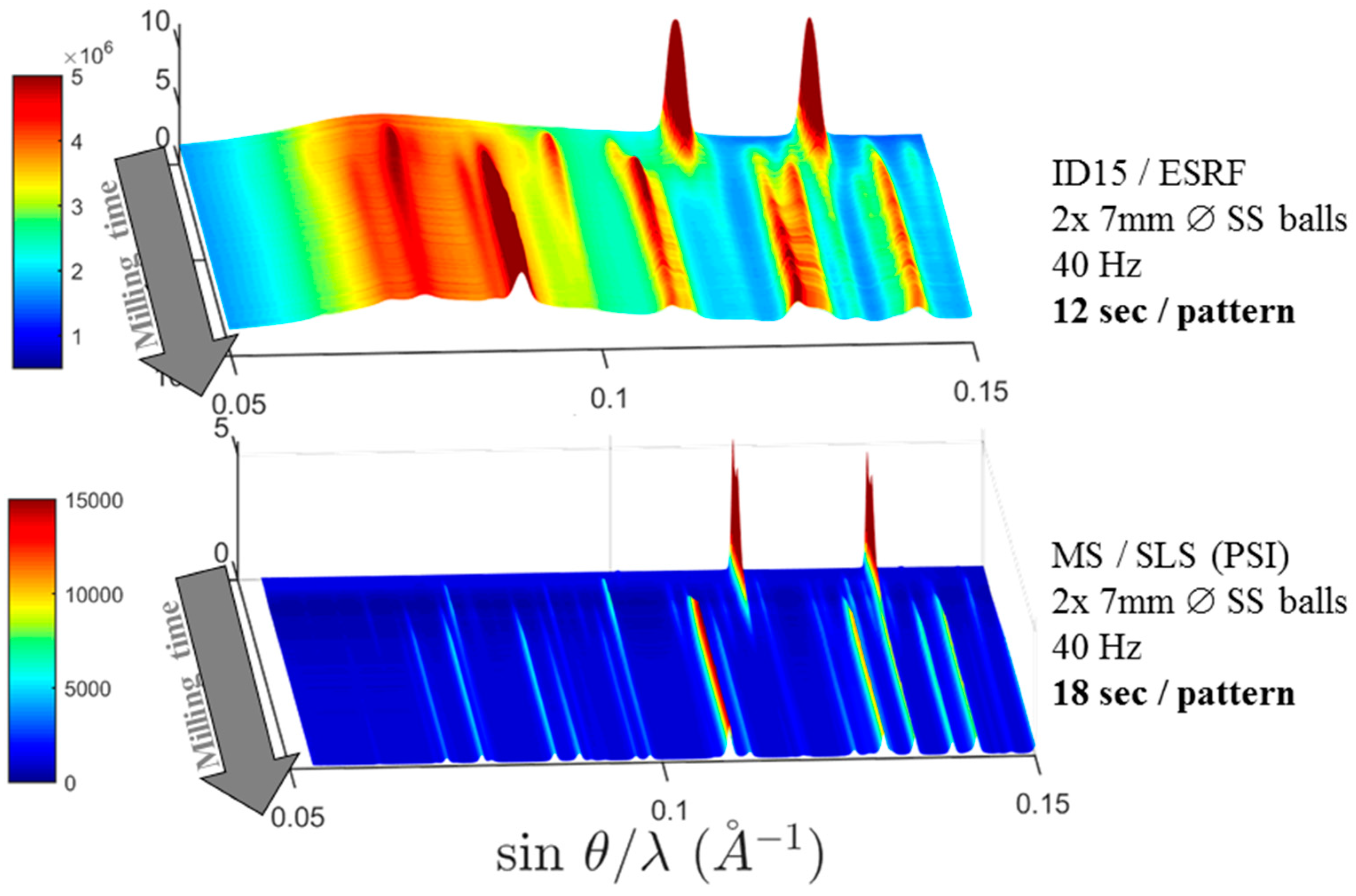

8.3. Going for Ultimate Angular Resolution and an Efficient Sampling

9. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Benjamin, J.S. Mechanical Alloying. Sci. Am. 1976, 235, 40. [Google Scholar] [CrossRef]

- Benjamin, J.S.; Volin, T.E. The mechanism of mechanical alloying. Met. Mater. Trans. A 1974, 5, 1929–1934. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Richter, B.; Grinderslev, J.B.; Møller, K.T.; Paskevicius, M.; Jensen, T.R. From Metal Hydrides to Metal Borohydrides. Inorg. Chem. 2018, 57, 10768–10780. [Google Scholar] [CrossRef] [PubMed]

- Huot, J.; Ravnsbæk, D.; Zhang, J.; Cuevas, F.; Latroche, M.; Jensen, T.R. Mechanochemical synthesis of hydrogen storage materials. Prog. Mater. Sci. 2013, 58, 30–75. [Google Scholar] [CrossRef]

- Balema, V.P.; Wiench, J.W.; Pruski, M.; Pecharsky, V.K. Mechanically Induced Solid-State Generation of Phosphorus Ylides and the Solvent-Free Wittig Reaction. J. Am. Chem. Soc. 2002, 124, 6244–6245. [Google Scholar] [CrossRef] [PubMed]

- Hagemann, H.; Cerny, R. Synthetic approaches to inorganic borohydrides. Dalton Trans. 2010, 39, 6006. [Google Scholar] [CrossRef]

- Beyer, M.K.; Clausen-Schaumann, H. Mechanochemistry: The Mechanical Activation of Covalent Bonds. Chem. Rev. 2005, 105, 2921–2948. [Google Scholar] [CrossRef]

- Bösenberg, U.; Doppiu, S.; Mosegaard, L.; Barkhordarian, G.; Eigen, N.; Borgschulte, A.; Jensen, T.R.; Cerenius, Y.; Gutfleisch, O.; Klassen, T.; et al. Hydrogen sorption properties of MgH2–LiBH4 composites. Acta Mater. 2007, 55, 3951–3958. [Google Scholar] [CrossRef]

- Fichtner, M. Nanotechnological Aspects in Materials for Hydrogen Storage. Adv. Eng. Mater. 2005, 7, 443–455. [Google Scholar] [CrossRef]

- Blanchard, D.; Brinks, H.W.; Hauback, B.C. Isothermal decomposition of LiAlD4. J. Alloys Compd. 2006, 416, 72–79. [Google Scholar] [CrossRef]

- Callini, E.; Atakli, Z.Ö.K.; Hauback, B.C.; Orimo, S.-I.; Jensen, C.; Dornheim, M.; Grant, D.; Cho, Y.W.; Chen, P.; Hjörvarsson, B.; et al. Complex and liquid hydrides for energy storage. Appl. Phys. A 2016, 122, 1–22. [Google Scholar] [CrossRef]

- Møller, K.T.; Jensen, T.R.; Akiba, E.; Li, H.-W. Hydrogen—A sustainable energy carrier. Prog. Nat. Sci. 2017, 27, 34–40. [Google Scholar] [CrossRef]

- Møller, K.T.; Sheppard, D.; Ravnsbæk, D.B.; Buckley, C.E.; Etsuo, A.; Hai-Wen, L.; Jensen, T.R. Complex Metal Hydrides for Hydrogen. Thermal and Electrochemical Energy Storage. Energies 2017, 10, 1645. [Google Scholar] [CrossRef]

- Callini, E.; Aguey-Zinsou, K.-F.; Ahuja, R.; Ares, J.R.; Bals, S.; Biliškov, N.; Chakraborty, S.; Charalambopoulou, G.; Chaudhary, A.-L.; Cuevas, F.; et al. Nanostructured materials for solid-state hydrogen storage: A review of the achievement of COST Action MP1103. Int. J. Hydrog. Energy 2016, 41, 14404–14428. [Google Scholar] [CrossRef]

- Crivello, J.-C.; Dam, B.; Denys, R.V.; Dornheim, M.; Grant, D.M.; Huot, J.; Jensen, T.R.; De Jongh, P.; Latroche, M.; Milanese, C.; et al. Review of magnesium hydride-based materials: Development and optimisation. Appl. Phys. A 2016, 122, 97. [Google Scholar] [CrossRef]

- Crivello, J.-C.; Denys, R.V.; Dornheim, M.; Felderhoff, M.; Grant, D.M.; Huot, J.; Jensen, T.R.; De Jongh, P.; Latroche, M.; Walker, G.S.; et al. Mg-based compounds for hydrogen and energy storage. Appl. Phys. A 2016, 122, 1–17. [Google Scholar] [CrossRef]

- Yartys, V.A.; Lototskyy, M.V.; Akiba, E.; Albert, R.; Antonov, V.E.; Ares, J.R.; Baricco, M.; Bourgeois, N.; Buckley, C.E.; Bellosta von Colbe, J.M.; et al. Magnesium based materials for hydrogen based energy storage: Past, present and future. Int. J. Hydrog. Energy 2019, 44, 7809–7859. [Google Scholar] [CrossRef]

- Milanese, C.; Jensen, T.; Hauback, B.; Pistidda, C.; Dornheim, M.; Yang, H.; Lombardo, L.; Zuettel, A.; Filinchuk, Y.; Ngene, P.; et al. Complex hydrides for energy storage. Int. J. Hydrog. Energy 2019, 44, 7860–7874. [Google Scholar] [CrossRef]

- Von Colbe, J.B.; Ares, J.-R.; Barale, J.; Baricco, M.; Buckley, C.; Capurso, G.; Gallandat, N.; Grant, D.M.; Guzik, M.N.; Jacob, I.; et al. Application of hydrides in hydrogen storage and compression: Achievements, outlook and perspectives. Int. J. Hydrog. Energy 2019, 44, 7780–7808. [Google Scholar] [CrossRef]

- Manickam, K.; Mistry, P.; Walker, G.; Grant, D.; Buckley, C.E.; Humphries, T.D.; Paskevicius, M.; Jensen, T.; Albert, R.; Peinecke, K.; et al. Future perspectives of thermal energy storage with metal hydrides. Int. J. Hydrog. Energy 2019, 44, 7738–7745. [Google Scholar] [CrossRef]

- Latroche, M.; Blanchard, D.; Cuevas, F.; El Kharbachi, A.; Hauback, B.C.; Jensen, T.R.; De Jongh, P.E.; Kim, S.; Nazer, N.S.; Ngene, P.; et al. Full-cell hydride-based solid-state Li batteries for energy storage. Int. J. Hydrog. Energy 2019, 44, 7875–7887. [Google Scholar] [CrossRef]

- Fritsch, Product Information, Planetary Mills Classic Line. Available online: http://www.fritsch.de/uploads/media/e_Planetary_Mills_classic_line.pdf (accessed on 11 March 2019).

- Schilz, J. Internal Kinematics of Tumbler and Planetary Ball Mills: A Mathematical Model for the Parameter Setting. Mater. Trans. JIM 1998, 39, 1152–1157. [Google Scholar] [CrossRef][Green Version]

- Burgio, N.; Iasonna, A.; Magini, M.; Martelli, S.; Padella, F. Mechanical alloying of the Fe−Zr system. Correlation between input energy and end products. Il Nuovo Cim. D 1991, 13, 459–476. [Google Scholar] [CrossRef]

- Murty, B.; Rao, M.M.; Ranganathan, S. Milling maps and amorphization during mechanical alloying. Acta Met. Mater. 1995, 43, 2443–2450. [Google Scholar] [CrossRef]

- Orimo, S.-I.; Nakamori, Y.; Eliseo, J.R.; Zuettel, A.; Jensen, C.M.; Orimo, S. Complex Hydrides for Hydrogen Storage. Chemin 2007, 38, 4111–4132. [Google Scholar] [CrossRef]

- Schlesinger, H.I.; Brown, H.C.; Finholt, A.E. The Preparation of Sodium Borohydride by the High Temperature Reaction of Sodium Hydride with Borate Esters1. J. Am. Chem. Soc. 1953, 75, 205–209. [Google Scholar] [CrossRef]

- Černý, R.; Schouwink, P. The crystal chemistry of inorganic metal boro-hydrides and their relation to metal oxides. Acta Crystallogr. Sect. B Struct. Sci. Cryst. Eng. Mater. 2015, 71, 619–640. [Google Scholar] [CrossRef]

- Paskevicius, M.; Jepsen, L.H.; Schouwink, P.; Černý, R.; Ravnsbæk, D.B.; Filinchuk, Y.; Dornheim, M.; Besenbacher, F.; Jensen, T.R. Metal borohydrides and derivatives—Synthesis, structure and properties. Chem. Soc. Rev. 2017, 46, 1565–1634. [Google Scholar] [CrossRef]

- Frommen, C.; Sørby, M.H.; Heere, M.; Humphries, T.D.; Olsen, J.E.; Hauback, B.C. Rare Earth Borohydrides—Crystal Structures and Thermal Properties. Energies 2017, 10, 2115. [Google Scholar] [CrossRef]

- Sato, T.; Miwa, K.; Nakamori, Y.; Ohoyama, K.; Li, H.-W.; Noritake, T.; Aoki, M.; Towata, S.-I.; Orimo, S.-I. Experimental and computational studies on solvent-free rare-earth metal borohydridesR(BH4)3(R = Y, Dy, and Gd). Phys. Rev. B 2008, 77, 10. [Google Scholar] [CrossRef]

- Olsen, J.E.; Frommen, C.; Sørby, M.; Hauback, B.C. Crystal structures and properties of solvent-free LiYb(BH4)4−xClx, Yb(BH4)3 and Yb(BH4)2−xClx. RSC Adv. 2013, 3, 10764. [Google Scholar] [CrossRef]

- Frommen, C.; Sørby, M.; Ravindran, P.; Vajeeston, P.; Fjellvåg, H.; Hauback, B.; Sørby, M. Synthesis, Crystal Structure, and Thermal Properties of the First Mixed-Metal and Anion-Substituted Rare Earth Borohydride LiCe(BH4)3Cl. J. Phys. Chem. C 2011, 115, 23591–23602. [Google Scholar] [CrossRef]

- Jaron, T.; Grochala, W. Y(BH4)3-an old-new ternary hydrogen store aka learning from a multitude of failures. Dalton Trans. 2010, 39, 160–166. [Google Scholar] [CrossRef]

- Frommen, C.; Aliouane, N.; Deledda, S.; Fonneløp, J.E.; Grove, H.; Lieutenant, K.; Llamas-Jansa, I.; Sartori, S.; Sørby, M.H.; Hauback, B.C. Crystal structure, polymorphism, and thermal properties of yttrium borohydride Y(BH4)3. J. Alloys Compd. 2010, 496, 710–716. [Google Scholar] [CrossRef]

- Ravnsbæk, D.B.; Filinchuk, Y.; Černyý, R.; Ley, M.B.; Haase, D.; Jakobsen, H.J.; Skibsted, J.; Jensen, T.R. Thermal Polymorphism and Decomposition of Y(BH4)3. Inorg. Chem. 2010, 49, 3801–3809. [Google Scholar]

- Ley, M.B.; Jepsen, L.H.; Lee, Y.-S.; Cho, Y.W.; Von Colbe, J.M.B.; Dornheim, M.; Rokni, M.; Jensen, J.O.; Sloth, M.; Filinchuk, Y.; et al. Complex hydrides for hydrogen storage—New perspectives. Mater. Today 2014, 17, 122–128. [Google Scholar] [CrossRef]

- Yan, Y.; Li, H.-W.; Sato, T.; Umeda, N.; Miwa, K.; Towata, S.-I.; Orimo, S.-I. Dehydriding and rehydriding properties of yttrium borohydride Y(BH4)3 prepared by liquid-phase synthesis. Int. J. Hydrog. Energy 2009, 34, 5732–5736. [Google Scholar] [CrossRef]

- Koźmiński, W.; Grochala, W.; Jaroń, T. Phase transition induced improvement in H2 desorption kinetics: The case of the high-temperature form of Y(BH4)3. Phys. Chem. Chem. Phys. 2011, 13, 8847. [Google Scholar]

- Gennari, F.; Esquivel, M. Synthesis and dehydriding process of crystalline Ce(BH4)3. J. Alloys Compd. 2009, 485, L47–L51. [Google Scholar] [CrossRef]

- Li, H.-W.; Yan, Y.; Orimo, S.-I.; Züttel, A.; Jensen, C.M. Recent Progress in Metal Borohydrides for Hydrogen Storage. Energies 2011, 4, 185–214. [Google Scholar] [CrossRef]

- Zhang, B.J.; Liu, B.H.; Li, Z.P. Destabilization of LiBH4 by (Ce, La)(Cl, F)3 for hydrogen storage. J. Alloys Compd. 2011, 509, 751–757. [Google Scholar] [CrossRef]

- Ley, M.B.; Boulineau, S.; Janot, R.; Filinchuk, Y.; Jensen, T.R. New Li Ion Conductors and Solid State Hydrogen Storage Materials: LiM(BH4)3Cl, M = La, Gd. J. Phys. Chem. C 2012, 116, 21267–21276. [Google Scholar] [CrossRef]

- Skripov, A.V.; Soloninin, A.V.; Ley, M.B.; Jensen, T.R.; Filinchuk, Y. Nuclear Magnetic Resonance Studies of BH 4 Reorientations and Li Diffusion in LiLa(BH4)3 Cl. J. Phys. Chem. C 2013, 117, 14965–14972. [Google Scholar] [CrossRef]

- Gennari, F.; Albanesi, L.F.; Puszkiel, J.; Larochette, P.A. Reversible hydrogen storage from 6LiBH4–MCl3 (M = Ce, Gd) composites by in-situ formation of MH2. Int. J. Hydrog. Energy 2011, 36, 563–570. [Google Scholar] [CrossRef]

- Heere, M.; Gharibdoust, S.H.P.; Frommen, C.; Humphries, T.D.; Ley, M.B.; Sørby, M.H.; Jensen, T.R.; Hauback, B.C. The influence of LiH on the rehydrogenation behavior of halide free rare earth (RE) borohydrides (RE = Pr, Er). Phys. Chem. Chem. Phys. 2016, 18, 24387–24395. [Google Scholar] [CrossRef]

- Schouwink, P.; Ley, M.B.; Jensen, T.R.; Černý, R. Borohydrides: From sheet to framework topologies. Dalton Trans. 2014, 43, 7726–7733. [Google Scholar] [CrossRef]

- Grinderslev, J.B.; Møller, K.T.; Bremholm, M.; Jensen, T.R. Trends in Synthesis, Crystal Structure, and Thermal and Magnetic Properties of Rare-Earth Metal Borohydrides. Inorg. Chem. 2019, 58, 5503–5517. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Shim, J.-H.; Cho, Y.W. Polymorphism and Thermodynamics of Y(BH4)3 from First Principles. J. Phys. Chem. C 2010, 114, 12833–12837. [Google Scholar] [CrossRef]

- Ravnsbaek, D.B.; Sørensen, L.H.; Filinchuk, Y.; Reed, D.; Book, D.; Jakobsen, H.J.; Besenbacher, F.; Skibsted, J.; Jensen, T.R.; Ravnsbæk, D.B. Mixed-Anion and Mixed-Cation Borohydride KZn(BH4)Cl2: Synthesis, Structure and Thermal Decomposition. Eur. J. Inorg. Chem. 2010, 2010, 1608–1612. [Google Scholar] [CrossRef]

- Ley, M.B.; Ravnsbæk, D.B.; Filinchuk, Y.; Janot, R.; Cho, Y.W.; Lee, Y.-S.; Skibsted, J.; Jensen, T.R. LiCe(BH4)3Cl, a New Lithium-Ion Conductor and Hydrogen Storage Material with Isolated Tetranuclear Anionic Clusters. Chem. Mater. 2012, 24, 1654–1663. [Google Scholar] [CrossRef]

- Frommen, C.; Heere, M.; Riktor, M.D.; Sørby, M.H.; Hauback, B.C. Hydrogen storage properties of rare earth (RE) borohydrides (RE = La, Er) in composite mixtures with LiBH4 and LiH. J. Alloys Compd. 2015, 645, S155–S159. [Google Scholar] [CrossRef]

- Ravnsbaek, D.; Filinchuk, Y.; Cerenius, Y.; Jakobsen, H.J.; Besenbacher, F.; Skibsted, J.; Jensen, T.R. A Series of Mixed-Metal Borohydrides. Angew. Chem. Int. Ed. 2009, 48, 6659–6663. [Google Scholar] [CrossRef] [PubMed]

- Cerný, R.; Chul Kim, K.; Penin, N.; Da’nna, V.; Hagemann, H.; Sholl, D.S. AZn2(BH4)5(A = Li, Na) and NaZn(BH4)3: Structural studies. J. Phys. Chem. C 2010, 114, 19127–19133. [Google Scholar] [CrossRef]

- Solinas, I.; Lutz, H.D. Nonceramic preparation techniques for ternary halides AB2 × 4 with A = Mg, Mn, Zn B = Li, Na X = Cl, Br-1. J. Solid State Chem. 1995, 117, 34–38. [Google Scholar] [CrossRef]

- Černý, R.; Severa, G.; Ravnsbæk, D.B.; Filinchuk, Y.; D’Anna, V.; Hagemann, H.; Haase, D.; Jensen, C.M.; Jensen, T.R. NaSc(BH4)4: A novel scandium-based borohydride. J. Phys. Chem. C 2010, 114, 1357–1364. [Google Scholar] [CrossRef]

- Černyý, R.; Ravnsbæk, D.B.; Severa, G.; Filinchuk, Y.; Anna, V.D.; Hagemann, H.; Haase, D.; Skibsted, J.; Jensen, C.M.; Jensen, T.R. Structure and Characterization of KSc(BH4)4. J. Phys. Chem. C 2010, 114, 19540–19549. [Google Scholar] [CrossRef]

- Li, Z.; Morigazaki, N.; Liu, B.; Suda, S. Preparation of sodium borohydride by the reaction of MgH2 with dehydrated borax through ball milling at room temperature. J. Alloys Compd. 2003, 349, 232–236. [Google Scholar] [CrossRef]

- Li, Z.P.; Liu, B.H.; Morigazaki, N.; Suda, S. Preparation of potassium borohydride by a mechanico-chemical reaction of saline hydrides with dehydrated borate through ball milling. J. Alloys Compd. 2003, 354, 243–247. [Google Scholar] [CrossRef]

- Ravnsbæk, D.B.; Nickels, E.A.; Cerny, R.; Olesen, C.H.; David, W.I.F.; Edwards, P.P.; Filinchuk, Y.; Jensen, T.R. Novel Alkali Earth Borohydride Sr(BH4)2 and Borohydride-Chloride Sr(BH4)Cl. Inorg. Chem. 2013, 52, 10877–10885. [Google Scholar] [CrossRef]

- Hagemann, H.; Longhini, M.; Kaminski, J.W.; Wesolowski, T.A.; Černyý, R.; Penin, N.; Sørby, M.H.; Hauback, B.C.; Severa, G.; Jensen, C.M. LiSc(BH4)4: A Novel Salt of Li+ and Discrete Sc(BH4)4−Complex Anions. J. Phys. Chem. A 2008, 112, 7551–7555. [Google Scholar] [CrossRef] [PubMed]

- Hwang, S.-J.; Bowman, R.C.; Reiter, J.W.; Rijssenbeek, J.; Soloveichik, G.L.; Zhao, J.-C.; Kabbour, H.; Ahn, C.C.; Rijssenbeek, J. NMR Confirmation for Formation of [B12H12]2− Complexes during Hydrogen Desorption from Metal Borohydrides. J. Phys. Chem. C 2008, 112, 3164–3169. [Google Scholar] [CrossRef]

- Kim, C.; Hwang, S.-J.; Bowman, R.C.; Reiter, J.W.; Zan, J.A.; Kulleck, J.G.; Kabbour, H.; Majzoub, E.H.; Ozolins, V. LiSc(BH4)4 as a Hydrogen Storage Material: Multinuclear High-Resolution Solid-State NMR and First-Principles Density Functional Theory Studies. J. Phys. Chem. C 2009, 113, 9956–9968. [Google Scholar] [CrossRef]

- Ravnsbæk, D.B.; Ley, M.B.; Lee, Y.-S.; Hagemann, H.; D’Anna, V.; Cho, Y.W.; Filinchuk, Y.; Jensen, T.R. A mixed-cation mixed-anion borohydride NaY(BH4)2Cl2. Int. J. Hydrog. Energy 2012, 37, 8428–8438. [Google Scholar] [CrossRef]

- Cerny, R.; Penin, N.; D’Anna, V.; Hagemann, H.; Durand, E.; Růžička, J. MgxMn(1−x)(BH4)2 (x = 0–0.8), a cation solid solution in a bimetallic borohydride. Acta Mater. 2011, 59, 5171–5180. [Google Scholar] [CrossRef]

- Ravnsbaek, D.B.; Sørensen, L.H.; Filinchuk, Y.; Besenbacher, F.; Jensen, T.R.; Ravnsbæk, D.B. Screening of Metal Borohydrides by Mechanochemistry and Diffraction. Angew. Chem. 2012, 124, 3582–3586. [Google Scholar] [CrossRef]

- Lindemann, I.; Ferrer, R.D.; Dunsch, L.; Filinchuk, Y.; Černý, R.; Hagemann, H.; D’Anna, V.; Daku, L.M.L.; Schultz, L.; Gutfleisch, O. Al3Li4(BH4)13: A Complex Double-Cation Borohydride with a New Structure. Chem. A Eur. J. 2010, 16, 8707–8712. [Google Scholar] [CrossRef] [PubMed]

- Mosegaard, L.; Møller, B.; Jørgensen, J.-E.; Filinchuk, Y.; Cerenius, Y.; Hanson, J.C.; DiMasi, E.; Besenbacher, F.; Jensen, T.R. Reactivity of LiBH4: In Situ Synchrotron Radiation Powder X-ray Diffraction Study. J. Phys. Chem. C 2008, 112, 1299–1303. [Google Scholar] [CrossRef]

- Arnbjerg, L.M.; Ravnsbæk, D.B.; Filinchuk, Y.; Vang, R.T.; Cerenius, Y.; Besenbacher, F.; Jørgensen, J.-E.; Jakobsen, H.J.; Jensen, T.R. Structure and Dynamics for LiBH4−LiCl Solid Solutions. Chem. Mater. 2009, 21, 5772–5782. [Google Scholar] [CrossRef]

- Rude, L.; Zavorotynska, O.; Arnbjerg, L.; Ravnsbæk, D.B.; Malmkjær, R.; Grove, H.; Hauback, B.; Baricco, M.; Filinchuk, Y.; Besenbacher, F.; et al. Bromide substitution in lithium borohydride, LiBH4–LiBr. Int. J. Hydrog. Energy 2011, 36, 15664–15672. [Google Scholar] [CrossRef]

- Rude, L.H.; Groppo, E.; Arnbjerg, L.M.; Ravnsbæk, D.B.; Malmkjær, R.A.; Filinchuk, Y.; Baricco, M.; Besenbacher, F.; Jensen, T.R. Iodide substitution in lithium borohydride, LiBH4–LiI. J. Alloys Compd. 2011, 509, 8299–8305. [Google Scholar] [CrossRef]

- Liu, Y.; Reed, D.; Paterakis, C.; Vasquez, L.C.; Baricco, M.; Book, D. Study of the decomposition of a 0.62LiBH4–0.38NaBH4 mixture. Int. J. Hydrog. Energy 2017, 42, 22480–22488. [Google Scholar] [CrossRef]

- Liu, Y.; Heere, M.; Vasquez, L.C.; Paterakis, C.; Sørby, M.H.; Hauback, B.C.; Book, D. Dehydrogenation and rehydrogenation of a 0.62LiBH4-0.38NaBH4 mixture with nano-sized Ni. Int. J. Hydrog. Energy 2018, 43, 16782–16792. [Google Scholar] [CrossRef]

- Ravnsbæk, D.B.; Rude, L.H.; Jensen, T.R. Chloride substitution in sodium borohydride. J. Solid State Chem. 2011, 184, 1858–1866. [Google Scholar] [CrossRef]

- Rude, L.H.; Filinchuk, Y.; Sørby, M.H.; Hauback, B.C.; Besenbacher, F.; Jensen, T.R. Anion Substitution in Ca(BH4)2−CaI2: Synthesis, Structure and Stability of Three New Compounds. J. Phys. Chem. C 2011, 115, 7768–7777. [Google Scholar] [CrossRef]

- GharibDoust, S.; Brighi, M.; Sadikin, Y.; Ravnsbæk, D.B.; Černý, R.; Jensen, T.; Skibsted, J. Synthesis, Structure and Li Ion Conductivity of LiLa(BH4)3X, X = Cl, Br, I. J. Phys. Chem. C 2017, 121, 19010–19021. [Google Scholar] [CrossRef]

- Gharibdoust, S.P.; Ravnsbæk, D.B.; Černý, R.; Jensen, T.R. Synthesis, structure and properties of bimetallic sodium rare-earth (RE) borohydrides, NaRE(BH4)4, RE = Ce, Pr, Er or Gd. Dalton Trans. 2017, 46, 13421–13431. [Google Scholar] [CrossRef]

- Paterakis, C.; Guo, S.; Heere, M.; Liu, Y.; Contreras, L.F.; Sørby, M.H.; Hauback, B.C.; Reed, D.; Book, D. Study of the NaBH4–NaBr system and the behaviour of its low temperature phase transition. Int. J. Hydrog. Energy 2017, 42, 22538–22543. [Google Scholar] [CrossRef]

- Heere, M.; Gharibdoust, S.P.; Sørby, M.H.; Frommen, C.; Jensen, T.R.; Hauback, B.C. In situ investigations of bimetallic potassium erbium borohydride. Int. J. Hydrog. Energy 2017, 42, 22468–22474. [Google Scholar] [CrossRef]

- Reilly, J.J.; Wiswall, R.H. The reaction of hydrogen with alloys of magnesium and copper. Inorg. Chem. 1967, 6, 2220. [Google Scholar] [CrossRef]

- Vajo, J.J.; Skeith, S.L.; Mertens, F. Reversible Storage of Hydrogen in Destabilized LiBH4. J. Phys. Chem. B 2005, 109, 3719–3722. [Google Scholar] [CrossRef] [PubMed]

- Vajo, J.J.; Mertens, F.; Ahn, C.C.; Bowman, R.C.J.; Fultz, B. Altering Hydrogen Storage Properties by Hydride Destabilization Through Alloy Formation: LiH and MgH2 Destabilized with Si. Chemin 2004, 35, 13977–13983. [Google Scholar] [CrossRef]

- Barkhordarian, G.; Klassen, T.; Dornheim, M.; Bormann, R. Unexpected kinetic effect of MgB2 in reactive hydride composites containing complex borohydrides. J. Alloys Compd. 2007, 440, L18–L21. [Google Scholar] [CrossRef]

- Barkhordarian, G.; Klassen, T.; Bormann, R. Fast hydrogen sorption kinetics of nanocrystalline Mg using Nb2O5 as catalyst. Scr. Mater. 2003, 49, 213–217. [Google Scholar] [CrossRef]

- Barkhordarian, G.; Klassen, T.; Bormann, R. Composite Material Storing Hydrogen, and Device for the Reversible Storage of Hydrogen. International Patent Application WO2006063627, 22 June 2006. [Google Scholar]

- Dornheim, M.; Doppiu, S.; Barkhordarian, G.; Boesenberg, U.; Klassen, T.; Gutfleisch, O.; Bormann, R. Hydrogen storage in magnesium-based hydrides and hydride composites. Scr. Mater. 2007, 56, 841–846. [Google Scholar] [CrossRef]

- Garroni, S.; Pistidda, C.; Brunelli, M.; Vaughan, G.B.M.; Surinach, S.; Baro, M.D. Hydrogen desorption mechanism of 2NaBH4 + MgH2 composite prepared by high-energy ball milling. Scr. Mater. 2009, 60, 1129–1132. [Google Scholar] [CrossRef]

- Mao, J.; Yu, X.; Guo, Z.; Liu, H.K.; Wu, Z.; Ni, J. Enhanced hydrogen storage performances of NaBH4–MgH2 system. J. Alloys Compd. 2009, 479, 619–623. [Google Scholar] [CrossRef]

- Pistidda, C.; Napolitano, E.; Pottmaier, D.; Dornheim, M.; Klassen, T.; Baricco, M.; Enzo, S. Structural study of a new B-rich phase obtained by partial hydrogenation of 2NaH+ MgB2. Int. J. Hydrog. Energy 2013, 38, 10479–10484. [Google Scholar] [CrossRef][Green Version]

- Pistidda, C.; Garroni, S.; Minella, C.B.; Dolci, F.; Jensen, T.R.; Nolis, P.; Bösenberg, U.; Cerenius, Y.; Lohstroh, W.; Fichtner, M.; et al. Pressure Effect on the 2NaH + MgB2 Hydrogen Absorption Reaction. J. Phys. Chem. C 2010, 114, 21816–21823. [Google Scholar] [CrossRef]

- Heere, M.; Sørby, M.H.; Pistidda, C.; Dornheim, M.; Hauback, B.C. Milling time effect of Reactive Hydride Composites of NaF NaH MgB2 investigated by in situ powder diffraction. Int. J. Hydrog. Energy 2016, 41, 13101–13108. [Google Scholar] [CrossRef]

- Kim, J.W.; Shim, J.-H.; Ahn, J.-P.; Cho, Y.W.; Kim, J.-H.; Oh, K.H. Mechanochemical synthesis and characterization of TiB2 and VB2 nanopowders. Mater. Lett. 2008, 62, 2461–2464. [Google Scholar] [CrossRef]

- Olsen, J.E.; Sørby, M.H.; Hauback, B.C. Chloride-substitution in sodium borohydride. J. Alloys Compd. 2011, 509, L228–L231. [Google Scholar] [CrossRef]

- Llamas-Jansa, I.; Aliouane, N.; Deledda, S.; Fonneløp, J.E.; Frommen, C.; Humphries, T.; Lieutenant, K.; Sartori, S.; Sørby, M.H.; Hauback, B.C. Chloride substitution induced by mechano-chemical reactions between NaBH4 and transition metal chlorides. J. Alloys Compd. 2012, 530, 186–192. [Google Scholar] [CrossRef]

- Nakamori, Y.; Li, H.; Miwa, K.; Towata, S.-I.; Orimo, S.-I. Syntheses and Hydrogen Desorption Properties of Metal-Borohydrides M(BH4)n (M = Mg, Sc, Zr, Ti, and Zn; n = 2–4) as Advanced Hydrogen Storage Materials. Mater. Trans. 2006, 47, 1898–1901. [Google Scholar] [CrossRef]

- Nakamori, Y.; Li, H.-W.; Kikuchi, K.; Aoki, M.; Miwa, K.; Towata, S.; Orimo, S.-I. Thermodynamical stabilities of metal-borohydrides. J. Alloys Compd. 2007, 446, 296–300. [Google Scholar] [CrossRef]

- Yang, C.-H.; Tsai, W.-T.; Chang, J.-K. Hydrogen desorption behavior of vanadium borohydride synthesized by modified mechano-chemical process. Int. J. Hydrog. Energy 2011, 36, 4993–4999. [Google Scholar] [CrossRef]

- Llamas-Jansa, I.; Aliouane, N.; Deledda, S.; Fonneløp, J.E.; Frommen, C.; Lieutenant, K.; Sartori, S.; Sørby, M.H.; Hauback, B.C. Mechano-chemical reactions in LiBH4 + VCln (n = 2 and 3) mixtures. J. Alloys Compd. 2011, 509, S684–S687. [Google Scholar] [CrossRef]

- Korablov, D.; Ravnsbæk, D.B.; Ban, V.; Filinchuk, Y.; Besenbacher, F.; Jensen, T.R. Investigation of MBH4–VCl2, M = Li, Na or K. Int. J. Hydrog. Energy 2013, 38, 8376–8383. [Google Scholar] [CrossRef]

- Jeon, E.; Cho, Y. Mechanochemical synthesis and thermal decomposition of zinc borohydride. J. Alloys Compd. 2006, 422, 273–275. [Google Scholar] [CrossRef]

- James, B.; Wallbridge, M. Metal tetrahydroborates. Prog. Inorg. Chem. 1970, 11, 99–231. [Google Scholar]

- Ley, M.B.; Paskevicius, M.; Schouwink, P.; Richter, B.; Sheppard, D.A.; Buckley, C.; Jensen, T.R. Novel solvates M(BH4)3S(CH3)2 and properties of halide-free M(BH4)3(M = Y or Gd). Dalton Trans. 2014, 43, 13333–13342. [Google Scholar] [CrossRef] [PubMed]

- Ley, M.B.; Frommen, C.; Munroe, K.T.; Hauback, B.C.; Humphries, T.D.; Jensen, T.R. Crystal structure and in situ decomposition of Eu(BH4)2 and Sm(BH4)2. J. Mater. Chem. A 2015, 3, 691–698. [Google Scholar]

- Visseaux, M.; Bonnet, F. Borohydride complexes of rare earths, and their applications in various organic transformations. Coord. Chem. Rev. 2011, 255, 374–420. [Google Scholar] [CrossRef]

- Ley, M.B.; Jørgensen, M.; Černý, R.; Filinchuk, Y.; Jensen, T.R. From M(BH4)3 (M = La, Ce) Borohydride Frameworks to Controllable Synthesis of Porous Hydrides and Ion Conductors. Inorg. Chem. 2016, 55, 9748–9756. [Google Scholar] [CrossRef] [PubMed]

- Olsen, J.E.; Frommen, C.; Jensen, T.R.; Riktor, M.D.; Sørby, M.H.; Hauback, B.C. Structure and thermal properties of composites with RE-borohydrides (RE = La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Er, Yb or Lu) and LiBH4. RSC Adv. 2014, 4, 1570–1582. [Google Scholar] [CrossRef]

- Gharibdoust, S.P.; Heere, M.; Sørby, M.H.; Ley, M.B.; Ravnsbæk, D.B.; Hauback, B.C.; Černý, R.; Jensen, T.R. Synthesis, structure and properties of new bimetallic sodium and potassium lanthanum borohydrides. Dalton Trans. 2016, 45, 19002–19011. [Google Scholar] [CrossRef] [PubMed]

- Gharibdoust, S.P.; Heere, M.; Nervi, C.; Sørby, M.H.; Hauback, B.C.; Jensen, T.R.R. Synthesis, structure, and polymorphic transitions of praseodymium(iii) and neodymium(iii) borohydride, Pr(BH4)3 and Nd(BH4)3. Dalton Trans. 2018, 47, 8307–8319. [Google Scholar] [CrossRef]

- Gennari, F. Mechanochemical synthesis of erbium borohydride: Polymorphism, thermal decomposition and hydrogen storage. J. Alloys Compd. 2013, 581, 192–195. [Google Scholar] [CrossRef]

- Heere, M.; Gharibdoust, S.H.P.; Brighi, M.; Frommen, C.; Sørby, M.H.; Černý, R.; Jensen, T.R.; Hauback, B.C. Hydrogen Sorption in Erbium Borohydride Composite Mixtures with LiBH4 and/or LiH. Inorganics 2017, 5, 31. [Google Scholar] [CrossRef]

- West, A.R. Solid State Chemistry and Its Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014. [Google Scholar]

- Riktor, M.D.; Deledda, S.; Herrich, M.; Gutfleisch, O.; Fjellvåg, H.; Hauback, B.C. Hydride formation in ball-milled and cryomilled Mg–Fe powder mixtures. Mater. Sci. Eng. B 2009, 158, 19–25. [Google Scholar] [CrossRef]

- Floriano, R.; Deledda, S.; Hauback, B.; Leiva, D.; Botta, W.; Botta, W. Iron and niobium based additives in magnesium hydride: Microstructure and hydrogen storage properties. Int. J. Hydrog. Energy 2017, 42, 6810–6819. [Google Scholar] [CrossRef]

- Ravnsbæk, D.B.; Frommen, C.; Reed, D.; Filinchuk, Y.; Sørby, M.; Hauback, B.C.; Jakobsen, H.J.; Book, D.; Besenbacher, F.; Skibsted, J.; et al. Structural studies of lithium zinc borohydride by neutron powder diffraction, Raman and NMR spectroscopy. J. Alloys Compd. 2011, 509 (Suppl. 2), S698–S704. [Google Scholar] [CrossRef]

- Brower, F.M.; Matzek, N.E.; Reigler, P.F.; Rinn, H.W.; Roberts, C.B.; Schmidt, D.L.; Snover, J.A.; Terada, K. Preparation and properties of aluminum hydride. J. Am. Chem. Soc. 1976, 98, 2450–2453. [Google Scholar] [CrossRef]

- Brinks, H.W.; Istad-Lem, A.; Hauback, B.C. Mechanochemical synthesis and crystal structure of alpha’-AlD3 and alpha-AlD3. J. Phys. Chem. B 2006, 110, 25833–25837. [Google Scholar] [CrossRef] [PubMed]

- Brinks, H.; Langley, W.; Jensen, C.; Graetz, J.; Reilly, J.; Hauback, B. Synthesis and crystal structure of β-AlD3. J. Alloys Compd. 2007, 433, 180–183. [Google Scholar] [CrossRef]

- Brinks, H.W.; Brown, C.; Jensen, C.M.; Graetz, J.; Reilly, J.J.; Hauback, B.C. The crystal structure of γ-AlD3. J. Alloys Compd. 2007, 441, 364–367. [Google Scholar] [CrossRef]

- Yartys, V.A.; Denys, R.V.; Maehlen, J.P.; Frommen, C.; Fichtner, M.; Bulychev, B.M.; Emerich, H. Double-Bridge Bonding of Aluminium and Hydrogen in the Crystal Structure of γ-AlH3. Inorg. Chem. 2007, 46, 1051–1055. [Google Scholar] [CrossRef] [PubMed]

- Hauback, B.C. Structures of aluminium-based light weight hydrides. Z. Krist. 2008, 223, 636–648. [Google Scholar] [CrossRef]

- Graetz, J.; Hauback, B.C. Recent developments in aluminum-based hydrides for hydrogen storage. MRS Bull. 2013, 38, 473–479. [Google Scholar] [CrossRef]

- Grove, H.; Sørby, M.H.; Brinks, H.W.; Hauback, B.C. In situ synchrotron powder X-ray diffraction studies of the thermal decomposition of β- and γ-AlD3. J. Phys. Chem. C 2007, 111, 16693–16699. [Google Scholar] [CrossRef]

- Maehlen, J.; Yartys, V.; Denys, R.; Fichtner, M.; Frommen, C.; Bulychev, B.; Pattison, P.; Emerich, H.; Filinchuk, Y.; Chernyshov, D.; et al. Thermal decomposition of AlH3 studied by in situ synchrotron X-ray diffraction and thermal desorption spectroscopy. J. Alloys Compd. 2007, 446, 280–289. [Google Scholar] [CrossRef]

- Sartori, S.; Opalka, S.M.; Løvvik, O.M.; Guzik, M.N.; Tang, X.; Hauback, B.C. Experimental studies of α-AlD3 and α’-AlD3 versus first-principles modelling of the alane isomorphs. J. Mater. Chem. 2008, 18, 2361–2370. [Google Scholar] [CrossRef]

- Sartori, S.; Istad-Lem, A.; Brinks, H.W.; Hauback, B.C. Mechanochemical synthesis of alane. International J. Hydrog. Energy 2009, 34, 6350–6356. [Google Scholar] [CrossRef]

- Fonneløp, J.E.; Sartori, S.; Sørby, M.H.; Hauback, B.C. Polymorphic composition of alane after cryomilling with fluorides. J. Alloys Compd. 2012, 540, 241–247. [Google Scholar] [CrossRef]

- Fonneløp, J.E.; Corno, M.; Grove, H.; Pinatel, E.; Sørby, M.H.; Ugliengo, P.; Baricco, M.; Hauback, B.C. Experimental and computational investigations on the AlH3/AlF3 system. J. Alloys Compd. 2011, 509, 10–14. [Google Scholar] [CrossRef]

- Brinks, H.W.; Fossdal, A.; Hauback, B.C. Adjustment of the stability of complex hydrides through anion substitution. J. Phys. Chem. C 2008, 112, 5658–5661. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z.; Cuevas, F.; Latroche, M. Phase Stabilities in the Mg–Si–H System Tuned by Mechanochemistry. J. Phys. Chem. C 2014, 118, 21889–21895. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Latroche, M.; Wang, S.M.; Jiang, L.J.; Du, J.; Cuevas, F. Mechanochemical synthesis under deuterium gas in the Li-Mg-N-D system: A neutron diffraction study. Phys. Chem. Chem. Phys 2016, 18, 23944. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Wang, S.; Jiang, L.; Latroche, M.; Du, J.; Cuevas, F. Mechanochemistry of lithium nitride under hydrogen gas. Phys. Chem. Chem. Phys. 2015, 17, 21927–21934. [Google Scholar] [CrossRef]

- Chen, P.; Xiong, Z.; Luo, J.; Lin, J.; Tan, K.L. Interaction of hydrogen with metal nitrides and imides. Nature 2002, 420, 302–304. [Google Scholar] [CrossRef]

- Luo, W. (LiNH2–MgH2): A viable hydrogen storage system. J. Alloys Compd. 2004, 381, 284–287. [Google Scholar] [CrossRef]

- Matsuo, M.; Orimo, S.-I. Lithium Fast-Ionic Conduction in Complex Hydrides: Review and Prospects. Adv. Energy Mater. 2011, 1, 161–172. [Google Scholar] [CrossRef]

- Li, B.; Liu, Y.; Li, C.; Gao, M.; Pan, H. In situ formation of lithium fast-ion conductors and improved hydrogen desorption properties of the LiNH2–MgH2 system with the addition of lithium halides. J. Mater. Chem. A 2014, 2, 3155. [Google Scholar] [CrossRef]

- Li, W.; Wu, G.; Xiong, Z.; Feng, Y.-P.; Chen, P. Li+ ionic conductivities and diffusion mechanisms in Li-based imides and lithium amide. Phys. Chem. Chem. Phys 2012, 14, 1596–1606. [Google Scholar] [CrossRef] [PubMed]

- Beister, H.J.; Haag, S.; Kniep, R.; Strössner, K.; Syassen, K. Phase Transformations of Lithium Nitride under Pressure. Angew. Chem. Int. Ed. 1988, 27, 1101–1103. [Google Scholar] [CrossRef]

- Bortz, M.; Bertheville, B.; Böttger, G.; Yvon, K. Structure of the high pressure phase g-MgH2 by neutron powder diffraction. J. Alloys Compd. 1999, 287, L4–L6. [Google Scholar] [CrossRef]

- Huot, J.; Swainson, I.; Schulz, R. Phase transformation in magnesium hydride induced by ball milling. Eur. J. Control 2006, 31, 135–144. [Google Scholar] [CrossRef]

- Cuevas, F.; Korablov, D.; Latroche, M. Synthesis, structural and hydrogenation properties of Mg-rich MgH2–TiH2 nanocomposites prepared by reactive ball milling under hydrogen gas. Phys. Chem. Chem. Phys. 2012, 14, 1200–1211. [Google Scholar] [CrossRef]

- Khawam, A.; Flanagan, D.R. Solid-State Kinetic Models: Basics and Mathematical Fundamentals. J. Phys. Chem. B 2006, 110, 17315–17328. [Google Scholar] [CrossRef]

- Weidner, E.; Bull, D.; Shabalin, I.; Keens, S.; Telling, M.; Ross, D.; Ross, K. Observation of novel phases during deuteration of lithium nitride from in situ neutron diffraction. Chem. Phys. Lett. 2007, 444, 76–79. [Google Scholar] [CrossRef]

- Behrendt, G.; Reichert, C.; Kohlmann, H. Hydrogenation Reaction Pathways in the Systems Li3N–H2, Li3N–Mg–H2, and Li3N–MgH2–H2 by in Situ X-ray Diffraction, in Situ Neutron Diffraction, and in Situ Thermal Analysis. J. Phys. Chem. C 2016, 120, 13450–13455. [Google Scholar] [CrossRef]

- Bull, D.J.; Sorbie, N.; Baldissin, G.; Moser, D.; Telling, M.T.F.; Smith, R.I.; Gregory, D.H.; Ross, D.K. In situ powder neutron diffraction study of non-stoichiometric phase formation during the hydrogenation of Li3N. Faraday Discuss. 2011, 151, 263–270. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Li, Z.; Qiu, H.C.; Wang, S.M.; Jiang, L.J.; Du, J.; Zhang, J.; Latroche, M.; Cuevas, F. Mechanochemistry and hydrogen storage properties of 2Li3N + Mg mixture. Rare Met. 2015. [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zechetbauer, M.J.; Zhu, Y.T. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Kusadome, Y.; Ikeda, K.; Nakamori, Y.; Orimo, S.-I.; Horita, Z. Hydrogen storage capability of MgNi2 processed by high pressure torsion. Scr. Mater. 2007, 57, 751–753. [Google Scholar] [CrossRef]

- Leiva, D.R.; Jorge, A.M.; Ishikawa, T.T.; Huot, J.; Fruchart, D.; Miraglia, S.; Kiminami, C.S.; Botta, W.J. Nanoscale Grain Refinement and H-Sorption Properties of MgH2 Processed by High-Pressure Torsion and Other Mechanical Routes. Adv. Eng. Mater. 2010, 12, 786–792. [Google Scholar] [CrossRef]

- Revesz, A.; Kánya, Z.; Verebélyi, T.; Szabó, P.; Zhilyaev, A.; Spassov, T.; Zhilyaev, A. The effect of high-pressure torsion on the microstructure and hydrogen absorption kinetics of ball-milled Mg70Ni30. J. Alloys Compd. 2010, 504, 83–88. [Google Scholar] [CrossRef]

- Edalati, K.; Yamamoto, A.; Horita, Z.; Ishihara, T. High-pressure torsion of pure magnesium: Evolution of mechanical properties, microstructures and hydrogen storage capacity with equivalent strain. Scr. Mater. 2011, 64, 880–883. [Google Scholar] [CrossRef]

- 1De Lima, G.F.; Leiva, D.R.; Ishikawa, T.T.; Bolfarini, C.; Kiminami, C.S.; Botta, W.J.; Jorge, A.M. Hydrogen sorption properties of the complex hydride Mg2FeH6 consolidated by HPT. Mater. Sci. Forum 2011, 2011, 1053–1058. [Google Scholar]

- Révész, Á.; Kis-Tóth, Á.; Varga, L.; Schafler, E.; Bakonyi, I.; Spassov, T. Hydrogen storage of melt-spun amorphous Mg65Ni20Cu5Y10 alloy deformed by high-pressure torsion. Int. J. Hydrog. Energy 2012, 37, 5769–5776. [Google Scholar] [CrossRef]

- Botta, W.J.; Jorge Jr, A.M.; Veron, M.; Rauch, E.F.; Ferrie, E.; Yavari, A.R.; Huot, J.; Leiva, D.R. H-sorption properties and structural evolution of Mg processed by severe plastic deformation. J. Alloys Compd. 2013, 580, S187–S191. [Google Scholar] [CrossRef]

- Zou, J.X.; Pérez-Brokate, C.F.; Arruffat, R.; Bolle, B.; Fundenberger, J.J.; Zeng, X.Q.; Grosdidier, T.; Ding, W.J. Nanostructured bulk Mg + MgO composite synthesized through arc plasma evaporation and high pressure torsion for H-storage application. Mater. Sci. Eng. B 2014, 183, 1–5. [Google Scholar] [CrossRef]

- Hongo, T.; Edalati, K.; Arita, M.; Matsuda, J.; Akiba, E.; Horita, Z. Significance of grain boundaries and stacking faults on hydrogen storage properties of Mg2Ni intermetallics processed by high-pressure torsion. Acta Mater. 2015, 92, 46–54. [Google Scholar] [CrossRef]

- Grosdidier, T.; Fundenberger, J.; Zou, J.; Pan, Y.; Zeng, X. Nanostructured Mg based hydrogen storage bulk materials prepared by high pressure torsion consolidation of arc plasma evaporated ultrafine powders. Int. J. Hydrog. Energy 2015, 40, 16985–16991. [Google Scholar] [CrossRef]

- Xu, C.; Lin, H.; Edalati, K.; Li, W.; Li, L.; Zhu, Y. Superior hydrogenation properties in a Mg65Ce20Ni10Cu5 nanoglass processed by melt-spinning followed by high-pressure torsion. Scr. Mater. 2018, 152, 137–140. [Google Scholar] [CrossRef]

- Panda, S.; Fundenberger, J.-J.; Zhao, Y.; Zou, J.; Toth, L.S.; Grosdidier, T. Effect of initial powder type on the hydrogen storage properties of high-pressure torsion consolidated Mg. Int. J. Hydrog. Energy 2017, 42, 22438–22448. [Google Scholar] [CrossRef]

- Grill, A.; Horky, J.; Panigrahi, A.; Krexner, G.; Zehetbauer, M. Long-term hydrogen storage in Mg and ZK60 after Severe Plastic Deformation. Int. J. Hydrog. Energy 2015, 40, 17144–17152. [Google Scholar] [CrossRef]

- Edalati, K.; Matsuda, J.; Iwaoka, H.; Toh, S.; Akiba, E.; Horita, Z. High-pressure torsion of TiFe intermetallics for activation of hydrogen storage at room temperature with heterogeneous nanostructure. Int. J. Hydrog. Energy 2013, 38, 4622–4627. [Google Scholar] [CrossRef]

- Edalati, K.; Matsuda, J.; Arita, M.; Daio, T.; Akiba, E.; Horita, Z. Mechanism of activation of TiFe intermetallics for hydrogen storage by severe plastic deformation using high-pressure torsion. Appl. Phys. Lett. 2013, 103, 143902. [Google Scholar] [CrossRef]

- Edalati, K.; Matsuda, J.; Yanagida, A.; Akiba, E.; Horita, Z. Activation of TiFe for hydrogen storage by plastic deformation using groove rolling and high-pressure torsion: Similarities and differences. Int. J. Hydrog. Energy 2014, 39, 15589–15594. [Google Scholar] [CrossRef]

- Edalati, K.; Matsuo, M.; Emami, H.; Itano, S.; Alhamidi, A.; Staykov, A.; Smith, D.J.; Orimo, S.-I.; Akiba, E.; Horita, Z. Impact of severe plastic deformation on microstructure and hydrogen storage of titanium-iron-manganese intermetallics. Scr. Mater. 2016, 124, 108–111. [Google Scholar] [CrossRef]

- Edalati, K.; Shao, H.; Emami, H.; Iwaoka, H.; Akiba, E.; Horita, Z. Activation of titanium-vanadium alloy for hydrogen storage by introduction of nanograins and edge dislocations using high-pressure torsion. Int. J. Hydrog. Energy 2016, 41, 8917–8924. [Google Scholar] [CrossRef]

- Edalati, K.; Novelli, M.; Itano, S.; Li, H.-W.; Akiba, E.; Horita, Z.; Grosdidier, T. Effect of gradient-structure versus uniform nanostructure on hydrogen storage of Ti-V-Cr alloys: Investigation using ultrasonic SMAT and HPT processes. J. Alloys Compd. 2018, 737, 337–346. [Google Scholar] [CrossRef]

- Edalati, K.; Uehiro, R.; Ikeda, Y.; Li, H.-W.; Emami, H.; Filinchuk, Y.; Arita, M.; Sauvage, X.; Tanaka, I.; Akiba, E.; et al. Design and synthesis of a magnesium alloy for room temperature hydrogen storage. Acta Mater. 2018, 149, 88–96. [Google Scholar] [CrossRef]

- Fujiwara, K.; Uehiro, R.; Edalati, K.; Li, H.-W.; Floriano, R.; Akiba, E.; Horita, Z. New Mg–V–Cr BCC Alloys Synthesized by High-Pressure Torsion and Ball Milling. Mater. Trans. 2018, 59, 741–746. [Google Scholar] [CrossRef]

- Edalati, K.; Uehiro, R.; Fujiwara, K.; Ikeda, Y.; Li, H.-W.; Sauvage, X.; Valiev, R.Z.; Akiba, E.; Tanaka, I.; Horita, Z. Ultra-severe plastic deformation: Evolution of microstructure, phase transformation and hardness in immiscible magnesium-based systems. Mater. Sci. Eng. A 2017, 701, 158–166. [Google Scholar] [CrossRef]

- Edalati, K.; Akiba, E.; Horita, Z. High-pressure torsion for new hydrogen storage materials. Sci. Technol. Adv. Mater. 2018, 19, 185–193. [Google Scholar] [CrossRef]

- Edalati, K.; Daio, T.; Lee, S.; Horita, Z.; Nishizaki, T.; Akune, T.; Nojima, T.; Sasaki, T. High strength and superconductivity in nanostructured niobium-titanium alloy by high-pressure torsion and annealing: Significance of elemental decomposition and supersaturation. Acta Mater. 2014, 80, 149–158. [Google Scholar] [CrossRef]

- Edalati, K.; Emami, H.; Staykov, A.; Smith, D.J.; Akiba, E.; Horita, Z. Formation of metastable phases in magnesium–titanium system by high-pressure torsion and their hydrogen storage performance. Acta Mater. 2015, 99, 150–156. [Google Scholar] [CrossRef]

- Emami, H.; Edalati, K.; Staykov, A.; Hongo, T.; Iwaoka, H.; Horita, Z.; Akiba, E. Solid-state reactions and hydrogen storage in magnesium mixed with various elements by high-pressure torsion: Experiments and first-principles calculations. RSC Adv. 2016, 6, 11665–11674. [Google Scholar] [CrossRef]

- Edalati, K.; Emami, H.; Ikeda, Y.; Iwaoka, H.; Tanaka, I.; Akiba, E.; Horita, Z. New nanostructured phases with reversible hydrogen storage capability in immiscible magnesium–zirconium system produced by high-pressure torsion. Acta Mater. 2016, 108, 293–303. [Google Scholar] [CrossRef]

- Reilly, J.J.; Wiswall, R.H. Formation and properties of iron titanium hydride. Inorg. Chem. 1974, 13, 218–222. [Google Scholar] [CrossRef]

- Emami, H.; Edalati, K.; Matsuda, J.; Akiba, E.; Horita, Z. Hydrogen storage performance of TiFe after processing by ball milling. Acta Mater. 2015, 88, 190–195. [Google Scholar] [CrossRef]

- Nomura, K.; Uruno, H.; Ono, S.; Shinozuka, H.; Suda, S. Effects of lattice strain on the hysteresis of pressure-composition isotherms for the LaNi5 H2 system. J. Less Common Met. 1985, 107, 221–230. [Google Scholar] [CrossRef]

- Inui, H.; Yamamoto, T.; Hirota, M.; Yamaguchi, M. Lattice defects introduced during hydrogen absorption–desorption cycles and their effects on P–C characteristics in some intermetallic compounds. J. Alloys Compd. 2002, 330, 117–124. [Google Scholar] [CrossRef]

- Nagel, H.; Perkins, R.S. Crystallographic Investigation of Ternary Titanium Vanadium Hydrides. Z. Met. 1975, 66, 362–366. [Google Scholar]

- Ono, S.; Nomura, K.; Ikeda, Y. The raction of hydrogen with alloys of vanadium and titanium. J. Less Common Met. 1980, 72, 159–165. [Google Scholar] [CrossRef]

- Hara, S.; Sakaki, K.; Itoh, N.; Kimura, H.-M.; Asami, K.; Inoue, A. An amorphous alloy membrane without noble metals for gaseous hydrogen separation. J. Membr. Sci. 2000, 164, 289–294. [Google Scholar] [CrossRef]

- Nagai, H.; Kitagaki, K.; Shoji, K. Microstructure and hydriding characteristics of FeTi alloys containing manganese. J. Less Common Met. 1987, 134, 275–286. [Google Scholar] [CrossRef]

- Lee, S.M.; Perng, T.P. Effect of the 2nd phase on the initiation of hydrogenation of TiFe1-xMx (M = Cr, Mn) alloys. Int. J. Hydrog. Energy 1994, 19, 259–263. [Google Scholar] [CrossRef]

- Rigney, D.; Naylor, M.; Divakar, R.; Ives, L. Low energy dislocation structures caused by sliding and by particle impact. Mater. Sci. Eng. 1986, 81, 409–425. [Google Scholar] [CrossRef]

- Samih, Y.; Marcos, G.; Stein, N.; Allain, N.; Fleury, E.; Dong, C.; Grosdidier, T. Microstructure modifications and associated hardness and corrosion improvements in the AISI 420 martensitic stainless steel treated by high current pulsed electron beam (HCPEB). Surf. Coat. Technol. 2014, 259, 737–745. [Google Scholar] [CrossRef]

- Lu, K.; Lu, J. Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment. Mater. Sci. Eng. A 2004, 375, 38–45. [Google Scholar] [CrossRef]

- Liu, G.; Lü, J.; Lu, K. Surface nanocrystallization of 316L stainless steel induced by ultrasonic shot peening. Mater. Sci. Eng. A 2000, 286, 91–95. [Google Scholar] [CrossRef]

- Bagherifard, S.; Guagliano, M. Fatigue behavior of a low-alloy steel with nanostructured surface obtained by severe shot peening. Eng. Fract. Mech. 2012, 81, 56–68. [Google Scholar] [CrossRef]

- Novelli, M.; Fundenberger, J.-J.; Bocher, P.; Grosdidier, T. On the effectiveness of surface severe plastic deformation by shot peening at cryogenic temperature. Appl. Surf. Sci. 2016, 389, 1169–1174. [Google Scholar] [CrossRef]

- Novelli, M.; Bocher, P.; Grosdidier, T. Effect of cryogenic temperatures and processing parameters on gradient-structure of a stainless steel treated by ultrasonic surface mechanical attrition treatment. Mater. Charact. 2018, 139, 197–207. [Google Scholar] [CrossRef]

- Badreddine, J.; Rouhaud, E.; Micoulaut, M.; Remy, S. Simulation of shot dynamics for ultrasonic shot peening: Effects of process parameters. Int. J. Mech. Sci. 2014, 82, 179–190. [Google Scholar] [CrossRef]

- Akiba, E.; Iba, H. Hydrogen absorption by Laves phase related BCC solid solution. Intermetallics 1998, 6, 461–470. [Google Scholar] [CrossRef]

- Yu, X.; Wu, Z.; Xia, B.; Xu, N. The activation mechanism of Ti–V-based hydrogen storage alloys. J. Alloys Compd. 2004, 375, 221–223. [Google Scholar] [CrossRef]

- Miraglia, S.; De Rango, P.; Rivoirard, S.; Fruchart, D.; Charbonnier, J.; Skryabina, N. Hydrogen sorption properties of compounds based on BCC Ti1- xV1-yCr1 + x +y alloys. J. Alloys Compd. 2012, 536, 1–6. [Google Scholar] [CrossRef]

- Huot, J.; Enoki, H.; Akiba, E. Synthesis, phase transformation, and hydrogen storage properties of ball-milled TiV0.9Mn1.1. J. Alloys Compd. 2008, 453, 203–209. [Google Scholar] [CrossRef]

- Matsuda, J.; Akiba, E. Lattice defects in V–Ti BCC alloys before and after hydrogenation. J. Alloys Compd. 2013, 581, 369–372. [Google Scholar] [CrossRef]

- Kim, H.; Sakaki, K.; Ogawa, H.; Nakamura, Y.; Nakamura, J.; Akiba, E.; Machida, A.; Watanuki, T.; Proffen, T. Origin of Degradation in the Reversible Hydrogen Storage Capacity of V1–xTixAlloys from the Atomic Pair Distribution Function Analysis. J. Phys. Chem. C 2013, 117, 26543–26550. [Google Scholar] [CrossRef]

- Huot, J. Enhancing Hydrogen Storage Properties of Metal Hydrides; Springer: Berlin, Germany, 2016; p. 39. [Google Scholar]

- Ueda, T.T.; Tsukahara, M.; Kamiya, Y.; Kikuchi, S. Preparation and hydrogen storage properties of Mg–Ni–Mg2Ni laminate composites. J. Alloys Compd. 2005, 386, 253–257. [Google Scholar] [CrossRef]

- Dufour, J.; Huot, J. Rapid activation, enhanced hydrogen sorption kinetics and air resistance in laminated Mg–Pd 2.5at.%. J. Alloys Compd. 2007, 439, L5–L7. [Google Scholar] [CrossRef]

- Dufour, J.; Huot, J. Study of Mg6Pd alloy synthesized by cold rolling. J. Alloys Compd. 2007, 446, 147–151. [Google Scholar] [CrossRef]

- Løken, S.; Solberg, J.; Maehlen, J.; Denys, R.; Lototsky, M.; Tarasov, B.; Yartys, V.; Denys, R. Nanostructured Mg–Mm–Ni hydrogen storage alloy: Structure–properties relationship. J. Alloys Compd. 2007, 446, 114–120. [Google Scholar] [CrossRef]

- Mori, R.; Miyamura, H.; Kikuchi, S.; Tanaka, K.; Takeichi, N.; Tanaka, H.; Kuriyama, N.; Ueda, T.T.; Tsukahara, M. Hydrogenation Characteristics of Mg Based Alloy Prepared by Super Lamination Technique. Mater. Sci. Forum 2007, 561, 1609–1612. [Google Scholar] [CrossRef]

- Suganuma, K.; Miyamura, H.; Kikuchi, S.; Takeichi, N.; Tanaka, K.; Tanaka, H.; Kuriyama, N.; Ueda, T.T.; Tsukahara, M. Hydrogen Storage Properties of Mg-Al Alloy Prepared by Super Lamination Technique. Adv. Mater. Res. 2007, 26, 857–860. [Google Scholar] [CrossRef]

- Takeichi, N.; Tanaka, K.; Tanaka, H.; Ueda, T.T.; Kamiya, Y.; Tsukahara, M.; Miyamura, H.; Kikuchi, S. The hydrogen storage properties of Mg/Cu and Mg/Pd laminate composites and metallographic structure. J. Alloys Compd. 2007, 446–447, 543–548. [Google Scholar] [CrossRef]

- Takeichi, N.; Tanaka, K.; Tanaka, H.; Ueda, T.T.; Tsukahara, M.; Miyamura, H.; Kikuchi, S. Hydrogen Storage Properties and Corresponding Phase Transformations of Mg/Pd Laminate Composites Prepared by a Repetitive-Rolling Method. Mater. Trans. 2007, 48, 2395–2398. [Google Scholar] [CrossRef]

- Ebrahimi-Purkani, A.; Kashani-Bozorg, S. Nanocrystalline Mg2Ni-based powders produced by high-energy ball milling and subsequent annealing. J. Alloys Compd. 2008, 456, 211–215. [Google Scholar] [CrossRef]

- Pedneault, S.; Huot, J.; Roué, L. Nanostructured Mg2Ni materials prepared by cold rolling and used as negative electrode for Ni–MH batteries. J. Power Sources 2008, 185, 566–569. [Google Scholar] [CrossRef]

- Pedneault, S.; Roué, L.; Huot, J. Synthesis of Metal Hydrides by Cold Rolling. Mater. Sci. Forum 2008, 570, 33–38. [Google Scholar] [CrossRef]

- Danaie, M.; Mauer, C.; Mitlin, D.; Huot, J. Hydrogen storage in bulk Mg–Ti and Mg–stainless steel multilayer composites synthesized via accumulative roll-bonding (ARB). Int. J. Hydrog. Energy 2011, 36, 3022–3036. [Google Scholar] [CrossRef]

- Lang, J.; Huot, J. A new approach to the processing of metal hydrides. J. Alloys Compd. 2011, 509, L18–L22. [Google Scholar] [CrossRef]

- Leiva, D.; Floriano, R.; Huot, J.; Jorge, A.; Bolfarini, C.; Kiminami, C.; Ishikawa, T.; Botta, W.; Leiva, D.; Kiminami, C.; et al. Nanostructured MgH2 prepared by cold rolling and cold forging. J. Alloys Compd. 2011, 509, S444–S448. [Google Scholar] [CrossRef]

- Amira, S.; Huot, J. Effect of cold rolling on hydrogen sorption properties of die-cast and as-cast magnesium alloys. J. Alloys Compd. 2012, 520, 287–294. [Google Scholar] [CrossRef]

- Bellemare, J.; Huot, J. Hydrogen storage properties of cold rolled magnesium hydrides with oxides catalysts. J. Alloys Compd. 2012, 512, 33–38. [Google Scholar] [CrossRef]

- Floriano, R.; Leiva, D.R.; Deledda, S.; Hauback, B.C.; Botta, W.J. Nanostructured MgH2 Obtained by Cold Rolling Combined with Short-time High-energy Ball Milling. Mater. Res. Ibero am. J. Mater. 2013, 16, 158–163. [Google Scholar] [CrossRef]

- Floriano, R.; Leiva, D.; Deledda, S.; Hauback, B.; Botta, W.; Leiva, D.; Botta, W. Cold rolling of MgH2 powders containing different additives. Int. J. Hydrog. Energy 2013, 38, 16193–16198. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, G.; Wang, L.; Roven, H.J.; Pan, F. Enhanced mechanical properties of AZ31 magnesium alloy sheets processed by three-directional rolling. J. Alloys Compd. 2013, 575, 408–413. [Google Scholar] [CrossRef]

- Floriano, R.; Leiva, D.; Deledda, S.; Hauback, B.; Botta, W.; Botta, W. MgH2-based nanocomposites prepared by short-time high energy ball milling followed by cold rolling: A new processing route. Int. J. Hydrog. Energy 2014, 39, 4404–4413. [Google Scholar] [CrossRef]

- Asselli, A.; Leiva, D.; Huot, J.; Kawasaki, M.; Langdon, T.; Botta, W. Effects of equal-channel angular pressing and accumulative roll-bonding on hydrogen storage properties of a commercial ZK60 magnesium alloy. Int. J. Hydrog. Energy 2015, 40, 16971–16976. [Google Scholar] [CrossRef]

- Faisal, M.; Gupta, A.; Shervani, S.; Balani, K.; Subramaniam, A. Enhanced hydrogen storage in accumulative roll bonded Mg-based hybrid. Int. J. Hydrog. Energy 2015, 40, 11498–11505. [Google Scholar] [CrossRef]

- Li, Q.; Lin, Q.; Chou, K.-C.; Jiang, L.-J.; Zhan, F. Hydrogen storage properties of mechanically alloyed Mg–8 mol% LaNi0.5 composite. J. Mater. Res. 2004, 19, 2871–2876. [Google Scholar] [CrossRef]

- Liu, D.; Liu, X.; Zhu, Y.; Li, L. Hydriding combustion synthesis of Mg–CaNi5 composites. J. Alloys Compd. 2008, 458, 394–397. [Google Scholar] [CrossRef]

- Soyama, J.; Floriano, R.; Leiva, D.R.; Guo, Y.; Jorge Junior, A.M.; Pereira da Silva, E.; Pinto, H.C.; Bolfarini, C.; Kiminami, C.S.; Botta, W.J. Severely deformed ZK60 + 2.5% Mm alloy for hydrogen storage produced by two different processing routes. Int. J. Hydrog. Energy 2016, 41, 11284–11292. [Google Scholar] [CrossRef]

- Floriano, R.; Leiva, D.; Melo, G.; Ishikawa, T.; Huot, J.; Kaufman, M.; Figueroa, S.; Mendoza-Zélis, L.; Damonte, L.; Botta, W. Low temperature rolling of AZ91 alloy for hydrogen storage. Int. J. Hydrog. Energy 2017, 42, 29394–29405. [Google Scholar] [CrossRef]

- Jung, J.Y.; Fadonougbo, J.O.; Suh, J.-Y.; Lee, Y.-S.; Huh, J.-Y.; Cho, Y.W. Synthesis of Mg2FeH6 by hydrogenation of Mg/Fe powder mixture prepared by cold roll milling in air: Effects of microstructure and oxygen distribution. Int. J. Hydrog. Energy 2018, 43, 16758–16765. [Google Scholar] [CrossRef]

- Márquez, J.J.; Leiva, D.R.; Floriano, R.; Soyama, J.; Silva, W.B.; Ishikawa, T.T.; Kiminami, C.S.; Botta, W.J. Hydrogen storage in MgH 2 LaNi 5 composites prepared by cold rolling under inert atmosphere. Int. J. Hydrog. Energy 2018, 43, 13348–13355. [Google Scholar] [CrossRef]

- Yoo, M.H. Slip, twinning, and fracture in hexagonal close-packed metals. Met. Mater. Trans. A 1981, 12, 409–418. [Google Scholar] [CrossRef]

- Tonda, H.; Ando, S. Effect of temperature and shear direction on yield stress by {1122}<1123> slip in HCP metals. Met. Mat Trans A 2002, 33, 831–836. [Google Scholar] [CrossRef]

- Broom, D.P. Hydrogen Storage Materials: The Characterisation of Their Storage Properties; Springer: Berlin, Germany, 2011; p. 258. [Google Scholar]

- Vucht, J.H.N.V.; Kuijpers, F.A.; Bruning, H.C.A.M. Reversible room-temperature absorption of large quantities of hydrogen by intermetallic compounds. Philips Res. Rep. 1970, 25, 133. [Google Scholar]

- Hanada, N.; Nakagawa, T.; Asada, H.; Ishida, M.; Takahashi, K.; Isobe, S.; Saita, I.; Asano, K.; Nakamura, Y.; Fujisawa, A.; et al. Dependence of constituent elements of AB 5 type metal hydrides on hydrogenation degradation by CO2 poisoning. J. Alloys Compd. 2015, 647, 198–203. [Google Scholar] [CrossRef]

- Seta, S.; Uchida, H. Hydrogen solubility in LaNi5. J. Alloys Compd. 1995, 231, 448–453. [Google Scholar] [CrossRef]

- Termsuksawad, P.; Niyomsoan, S.; Mishra, B.; Olson, D.; Gavra, Z.; Kaydanov, V. Prediction of hydrogen absorption behavior in AB5 hydrogen storage alloys by electronic techniques. Mater. Sci. Eng. B 2005, 117, 45–51. [Google Scholar] [CrossRef]

- Uchida, H.; Sato, M.; Moriwaki, O. Hydrogen absorption and desorption isotherms in the solid solution regions of the LaNi5–H system. J. Alloys Compd. 1997, 253–254, 235–237. [Google Scholar] [CrossRef]

- Tousignant, M.; Huot, J. Hydrogen sorption enhancement in cold rolled LaNi5. J. Alloys Compd. 2014, 595, 22–27. [Google Scholar] [CrossRef]

- Huot, J.; Tousignant, M. Hydrogen sorption enhancement in cold-rolled and ball-milled CaNi5. J. Mater. Sci. 2017, 52, 11911–11918. [Google Scholar] [CrossRef]

- Yoshikawa, A.; Uyenishi, Y.; Iizumi, H.; Matsumoto, T.; Takano, N.; Terasaki, F. Determination of the positionand occupancy of deuterium in CaNi5 deuterides by neutron diffraction. J. Alloys Compd. 1998, 280, 204–208. [Google Scholar] [CrossRef]

- Couillaud, S.; Enoki, H.; Amira, S.; Bobet, J.; Akiba, E.; Huot, J. Effect of ball milling and cold rolling on hydrogen storage properties of nanocrystalline TiV1.6Mn0.4 alloy. J. Alloys Compd. 2009, 484, 154–158. [Google Scholar] [CrossRef]

- Dupim, I.; Moreira, J.; Huot, J.; Santos, S. Effect of cold rolling on the hydrogen absorption and desorption kinetics of Zircaloy-4. Mater. Chem. Phys. 2015, 155, 241–245. [Google Scholar] [CrossRef]

- Khajavi, S.; Rajabi, M.; Huot, J. Effect of cold rolling and ball milling on first hydrogenation of Ti0.5Zr0.5 (Mn1-xFex) Cr1, x = 0, 0.2, 0.4. J. Alloys Compd. 2019, 775, 912–920. [Google Scholar] [CrossRef]

- Leiva, D.R.; Costa, H.C.D.A.; Huot, J.; Pinheiro, T.S.; Junior, A.M.J.; Ishikawa, T.T.; Filho, W.J.B. Magnesium-Nickel alloy for hydrogen storage produced by melt spinning followed by cold rolling. Mater. Res. 2012, 15, 813–817. [Google Scholar] [CrossRef][Green Version]

- Lima, G.F.; Triques, M.R.M.; Kiminami, C.S.; Botta, W.J.; Jorge Jr, A.M. Hydrogen storage properties of 2Mg–Fe after the combined processes of hot extrusion and cold rolling. J. Alloys Compd. 2014, 586 (Suppl. 1), S409–S412. [Google Scholar] [CrossRef]

- Friščić, T.; Halasz, I.; Beldon, P.J.; Belenguer, A.M.; Adams, F.; Kimber, S.A.J.; Honkimäki, V.; Dinnebier, R.E. Real-time and in situ monitoring of mechanochemical milling reactions. Nat. Chem. 2013, 5, 66–73. [Google Scholar] [CrossRef]

- Halasz, I.; Kimber, S.A.J.; Beldon, P.J.; Belenguer, A.M.; Adams, F.; Honkimäki, V.; Nightingale, R.C.; E Dinnebier, R.; Friščić, T. In situ and real-time monitoring of mechanochemical milling reactions using synchrotron X-ray diffraction. Nat. Protoc. 2013, 8, 1718–1729. [Google Scholar] [CrossRef]

- Katsenis, A.D.; Puškarić, A.; Strukil, V.; Mottillo, C.; Julien, P.A.; Uzarevic, K.; Pham, M.-H.; Do, T.-O.; Kimber, S.A.J.; Lazić, P.; et al. In situ X-ray diffraction monitoring of a mechanochemical reaction reveals a unique topology metal-organic framework. Nat. Commun. 2015, 6, 6662. [Google Scholar] [CrossRef] [PubMed]

- Filinchuk, Y.; Ban, V.; Morelle, F.; Tumanov, N.; Dovgaliuk, I.; Cerny, R.; Sadikin, Y.; Schouwink, P. Mechanochemical synthesis of hydrides followed in situ by X-ray diffraction. In Proceedings of the 14th International Symposium on Metal-Hydrogen Systems: Fundamentals and Applications (MH2014), Manchwiester, UK, 17 February 2014. [Google Scholar]

- Batzdorf, L.; Fischer, F.; Wilke, M.; Wenzel, K.-J.; Emmerling, F. Direct in situ investigation of milling reactions using combined x-ray diffraction and raman spectroscopy. Angew. Chem. Int. Ed. 2015, 54, 1799–1802. [Google Scholar] [CrossRef] [PubMed]

- Halasz, I.; Užarević, K.; Friščić, T. Real-Time and in Situ Monitoring of Mechanochemical Reactions: A New Playground for All Chemists. J. Phys. Chem. Lett. 2015, 6, 4129–4140. [Google Scholar]

- Halasz, I.; Puškarić, A.; Kimber, S.A.J.; Beldon, P.J.; Belenguer, A.M.; Adams, F.; Honkimäki, V.; Dinnebier, R.E.; Patel, B.; Jones, W.; et al. Real-Time in Situ Powder X-ray Diffraction Monitoring of Mechanochemical Synthesis of Pharmaceutical Cocrystals. Angew. Chem. 2013, 125, 11752–11755. [Google Scholar] [CrossRef]

- Fischer, F.; Heidrich, A.; Greiser, S.; Benemann, S.; Rademann, K.; Emmerling, F. Polymorphism of Mechanochemically Synthesized Cocrystals: A Case Study. Cryst. Growth Des. 2016, 16, 1701–1707. [Google Scholar] [CrossRef]

- Fischer, F.; Lubjuhn, D.; Greiser, S.; Rademann, K.; Emmerling, F. Supply and Demand in the Ball Mill: Competitive Cocrystal Reactions. Cryst. Growth Des. 2016, 16, 5843–5851. [Google Scholar] [CrossRef]

- Gracin, D.; Štrukil, V.; Friščić, T.; Halasz, I.; Užarević, K. Laboratory Real-Time and in Situ Monitoring of Mechanochemical Milling Reactions by Raman Spectroscopy. Angew. Chem. 2014, 126, 6307–6311. [Google Scholar] [CrossRef]

- Kulla, H.; Haferkamp, S.; Akhmetova, I.; Röllig, M.; Maierhofer, C.; Rademann, K.; Emmerling, F.L. In Situ Investigations of Mechanochemical One-Pot Syntheses. Angew. Chem. Int. Ed. 2018, 57, 5930–5933. [Google Scholar] [CrossRef]

- Tumanov, N.; Ban, V.; Poulain, A.; Filinchuk, Y. 3D-printed jars for ball-milling experiments monitored in situ by X-ray powder diffraction. J. Appl. Crystallogr. 2017, 50, 994–999. [Google Scholar] [CrossRef]

- Ban, V.; Sadikin, Y.; Lange, M.; Tumanov, N.; Filinchuk, Y.; Černý, R.; Casati, N. Innovative in Situ Ball Mill for X-ray Diffraction. Anal. Chem. 2017, 89, 13176–13181. [Google Scholar] [CrossRef]

| Compound | Reactants Opt. | Ratio | Side Products | tmt | rpm | Ref. |

|---|---|---|---|---|---|---|

| NaBH4 | MgH2 + Na2B4O7 | 4:1 | MgO, B2O3 | 60 | 2750 | [28,59] |

| KBH4 | MgH2 + KBO2 | 2:1 | MgO | 120 | 490 | [60] |

| Sr(BH4)Cl | LiBH4 + SrCl2 | 1:1 | LiCl, Sr(BH4)2 | 120 | 400 | [61] |

| Sr(BH4)2 | LiBH4 + SrCl2 | 1:1 | LiCl, Sr(BH4)Cl | 120 | 400 | [61] |

| LiSc(BH4)4 | LiBH4 + ScCl3 | 4:1 | LiCl | 180 | 500 | [62,63,64] |

| NaSc(BH4)4 | NaBH4 + ScCl3 | 2:1 | Na3ScCl6 | 120 | 400 | [57] |

| KSc(BH4)4 | KBH4 + ScCl3 | 2:1 | K3ScCl6 | 120 | 400 | [58] |

| Y(BH4)3 | LiBH4 + YCl3 | 3:1 | LiCl | 120 | 200 | [36,37] |

| NaY(BH4)2Cl2 | NaBH4 + YCl3 | 2:1 | Na3YCl6, Na(BH4)1–xClx | 120 | 200 | [65] |

| Mn(BH4)2 | LiBH4 + MnCl2 | 2:1 | LiCl | 350 | 600 | [66] |

| Mn(BH4)2 | NaBH4 + MnCl2 | 2:1 | NaCl | 350 | 600 | [66] |

| LiZn2(BH4)5 | LiBH4 + ZnCl2 | 5:2 | LiCl | 120 | 200 | [54] |

| NaZn2(BH4)5 | NaBH4 + ZnCl2 | 5:2 | Na2ZnCl4, NaCl | 120 | 200 | [54] |

| NaZn(BH4)3 | NaBH4 + ZnCl2 | 3:1 | Na2ZnCl4, NaCl | 120 | 200 | [54] |

| KZn(BH4)Cl2 | KBH4 + ZnCl2 | 1:1 | - | 120 | 200 | [51] |

| Cd(BH4)2 | LiBH4 + CdCl2 | 2:1 | LiCl | 30 | 200 | [67] |

| Cd(BH4)2 | NaBH4 + CdCl2 | 14:9 | NaCl, Na6CdCl8 | 30 | 200 | [67] |

| KCd(BH4)3 | KBH4 + CdCl2 | 1:1 | KCdCl3, K2Cd(BH4)4, Cd(BH4)2 | 20 | 200 | [67] |

| K2Cd(BH4)4 | KBH4 + CdCl2 | 4:3 | KCdCl3 | 20 | 200 | [67] |

| Li4Al3(BH4)13 | LiBH4 + AlCl3 | 13:3 | LiCl | 300 | 500 | [68] |

| Li(BH4)0.9Cl0.1 | LiBH4 + LiCl | - | - | 120 | 200 | [69,70] |

| Li(BH4)0.47Br0.53 | LiBH4 + LiBr | - | - | 120 | 200 | [71] |

| Li(BH4)0.3I0.7 | LiBH4 + LiI | - | - | 120 | 200 | [72] |

| LiBH4-NaBH4 | LiBH4+NaBH4 | 1:1 | LiNaBH4 | 300 | 175 | [73,74] |

| LiBH4-NaBH4-Ni | LiBH4+NaBH4 +Ni | - | Ni4B3, Ni2B, Ni3B | 300 | 175 | [74] |

| Na(BH4)0.9Cl0.1 | NaBH4 + NaCl | - | - | 120 | 200 | [75] |

| Ca(BH4)1.6I0.4 | Ca(BH4)2 + CaI2 | - | - | 120 | 250 | [76] |

| LiLa(BH4)3Cl | La(BH4)3 + LiCl | 1:1 | unknown phase | 120 | 350 | [77] |

| LiLa(BH4)3Br | La(BH4)3 + LiBr | 1:1 | unknown phase | 120 | 350 | [77] |

| LiLa(BH4)3I | La(BH4)3 + LiI | 1:1 | unknown phase | 120 | 350 | [77] |

| NaCe(BH4)4 | NaBH4 + Ce(BH4)3 | 1:1 | β-Ce(BH4)3, unknown phase | 120 | 350 | [78] |

| NaPr(BH4)4 | NaBH4 + Pr(BH4)3 | 1:1 | unknown phase | 120 | 350 | [78] |

| NaEr(BH4)4 | NaBH4 + Er(BH4)3 | 1:1 | - | 120 | 350 | [78] |

| Na(BH4)1-xBrx | NaBH4 + NaBr | 1:1 | - | 360 | 200 | [79] |

| KEr(BH4)4 | KBH4 + Er(BH4)3 | 1:1 | - | 60 | - | [80] |

| System | Metastable Phase(s) | Ref. |

|---|---|---|

| Ti-V | bcc | [166] |

| Ti-Nb | bcc | [172] |

| Mg-Al | amorphous | [174] |

| Mg-Zn | amorphous | [174] |

| Mg-Sn | Hcp | [174] |

| Mg-Ti | bcc, hcp, fcc | [173] |

| Mg-Zr | bcc, hcp, fcc | [175] |

| Mg-V | bcc | [169] |

| Mg-V-Ni | bcc | [170] |

| Mg-V-Pd | bcc, CsCl-type | [170] |

| Mg-V-Sn | CsCl-type | [170] |

| Mg-V-Cr | bcc | [169] |

| Mg-Ni-Sn | amorphous | [170] |

| Mg-Ni-Pd | CsCl-type | [168] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huot, J.; Cuevas, F.; Deledda, S.; Edalati, K.; Filinchuk, Y.; Grosdidier, T.; Hauback, B.C.; Heere, M.; Jensen, T.R.; Latroche, M.; et al. Mechanochemistry of Metal Hydrides: Recent Advances. Materials 2019, 12, 2778. https://doi.org/10.3390/ma12172778

Huot J, Cuevas F, Deledda S, Edalati K, Filinchuk Y, Grosdidier T, Hauback BC, Heere M, Jensen TR, Latroche M, et al. Mechanochemistry of Metal Hydrides: Recent Advances. Materials. 2019; 12(17):2778. https://doi.org/10.3390/ma12172778

Chicago/Turabian StyleHuot, Jacques, Fermín Cuevas, Stefano Deledda, Kaveh Edalati, Yaroslav Filinchuk, Thierry Grosdidier, Bjørn C. Hauback, Michael Heere, Torben R. Jensen, Michel Latroche, and et al. 2019. "Mechanochemistry of Metal Hydrides: Recent Advances" Materials 12, no. 17: 2778. https://doi.org/10.3390/ma12172778

APA StyleHuot, J., Cuevas, F., Deledda, S., Edalati, K., Filinchuk, Y., Grosdidier, T., Hauback, B. C., Heere, M., Jensen, T. R., Latroche, M., & Sartori, S. (2019). Mechanochemistry of Metal Hydrides: Recent Advances. Materials, 12(17), 2778. https://doi.org/10.3390/ma12172778