Numerical Analysis and Experimental Studies on the Residual Stress of W/2024Al Composites

Abstract

1. Introduction

2. Materials and Methods

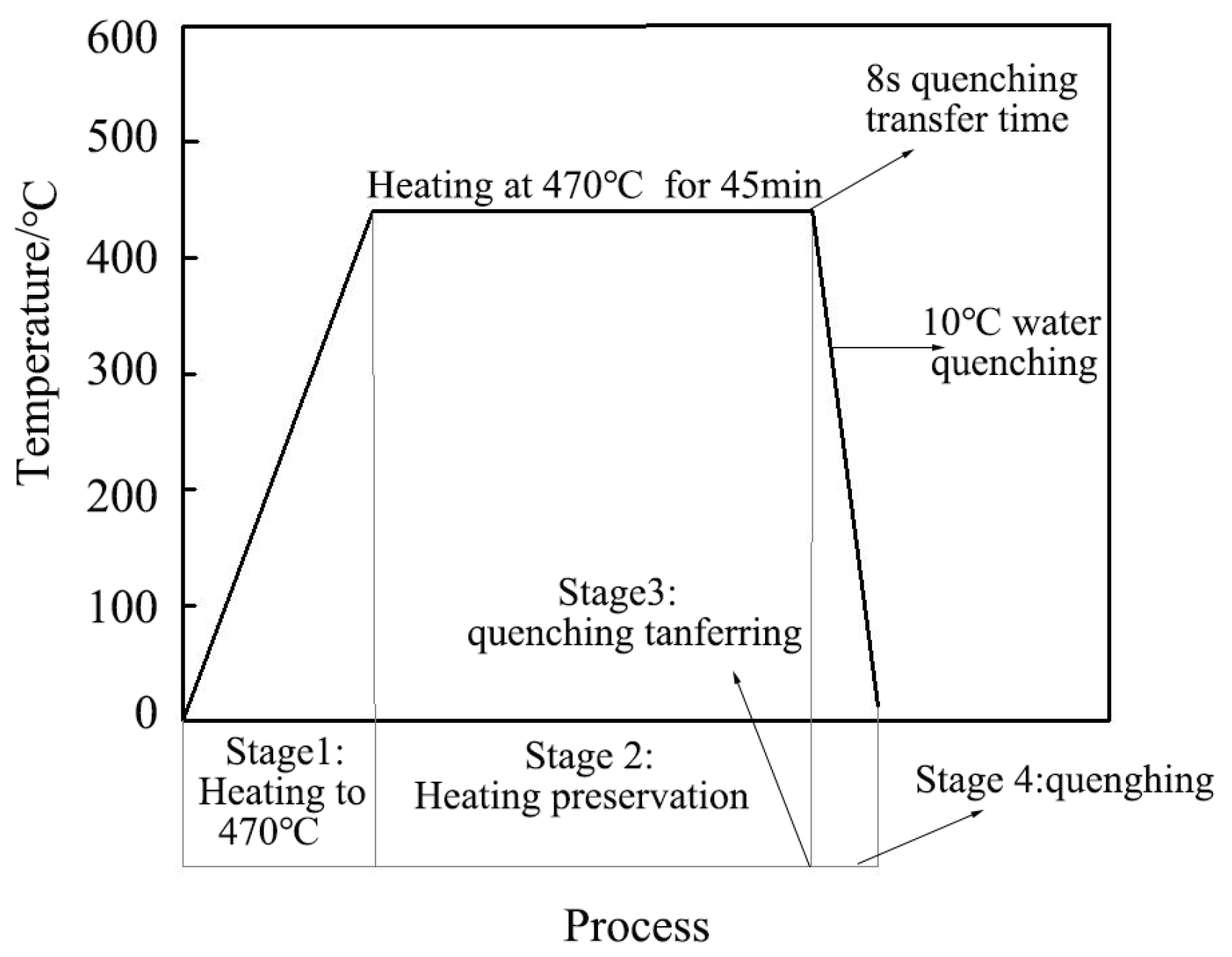

2.1. Materials and Heat Treatment

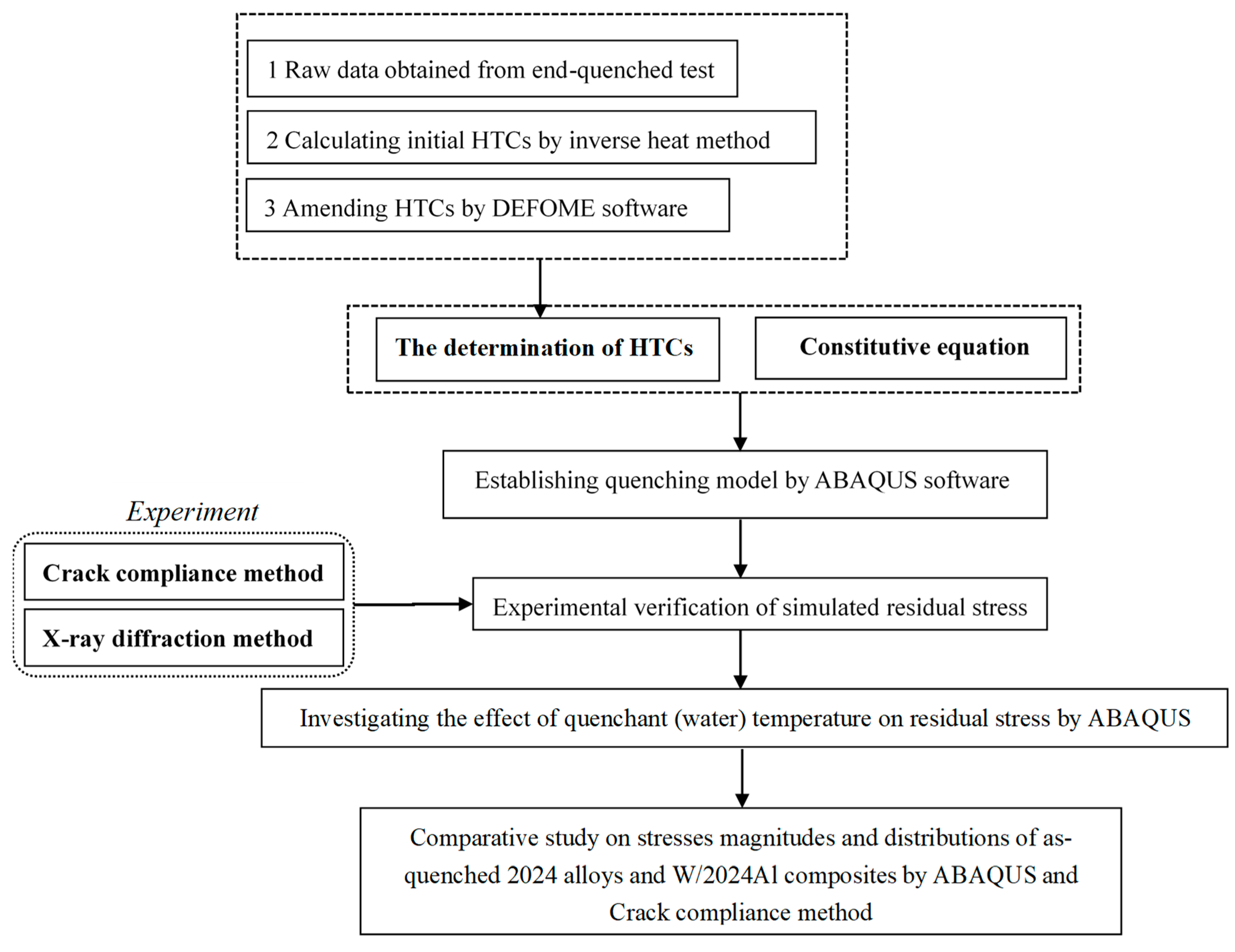

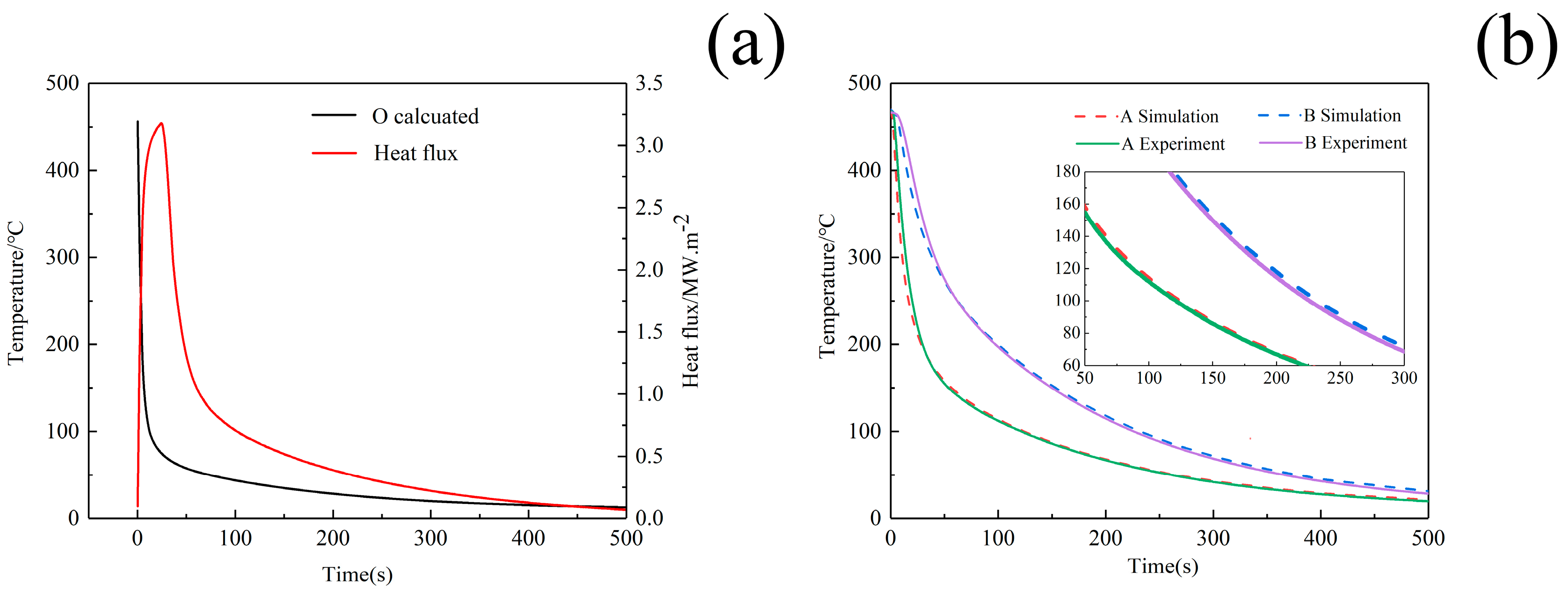

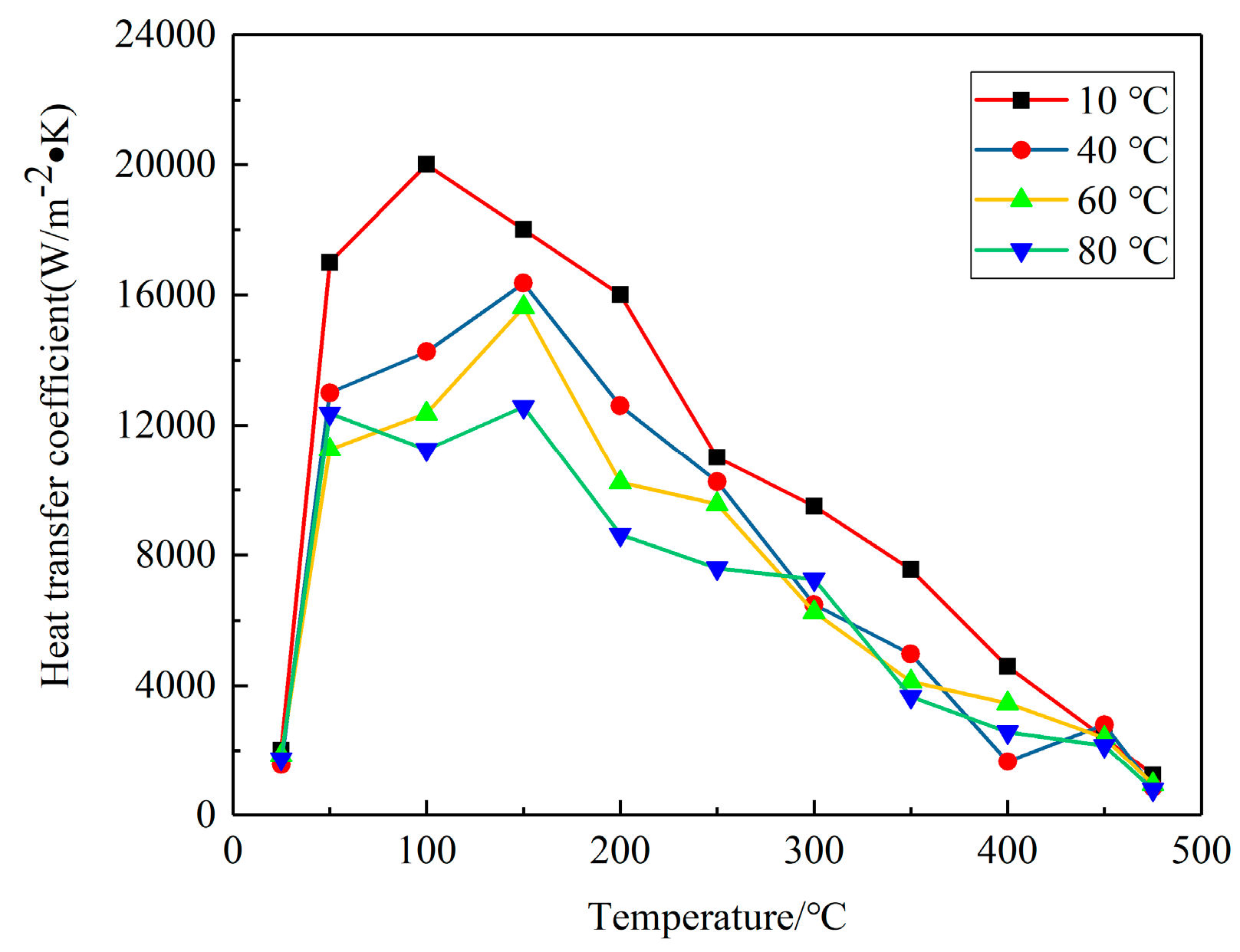

2.2. The Determination of Heat Transfer Coefficients

2.3. Hot Pressure Test for Characterization of Mechanical Properties

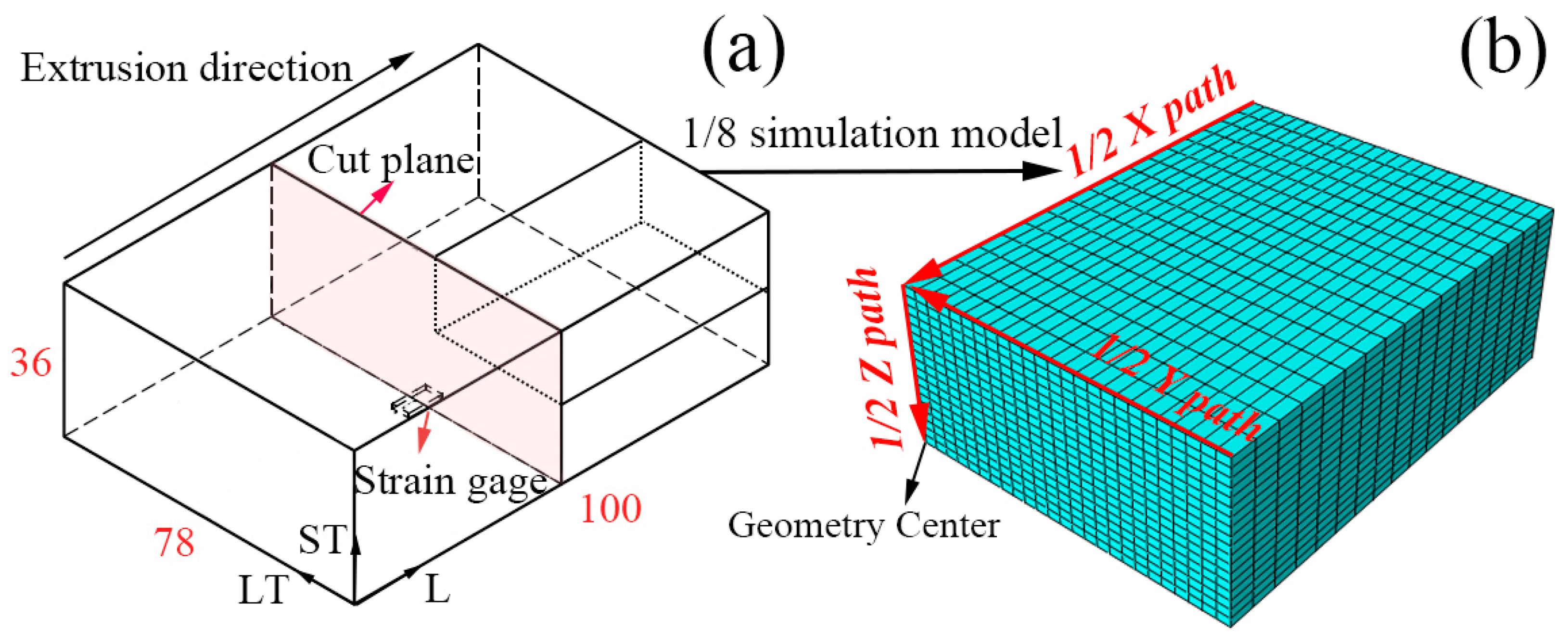

2.4. FEM Modeling of Quenching Process and Residual Stress Measurement

2.5. Research Procedure

3. Results and Discussion

3.1. The Results of the Heat Transfer Coefficients

3.2. Constitutive Equations for Representing Mechanical Properties of W/2024Al Composites

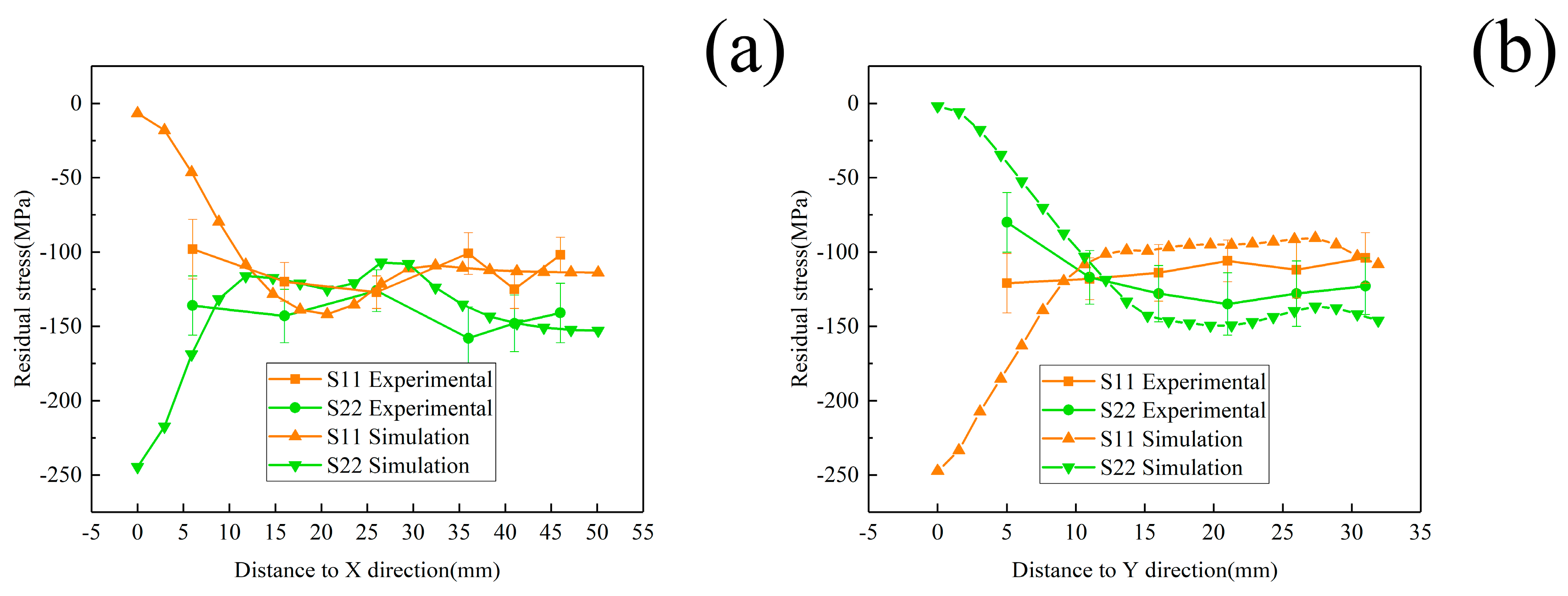

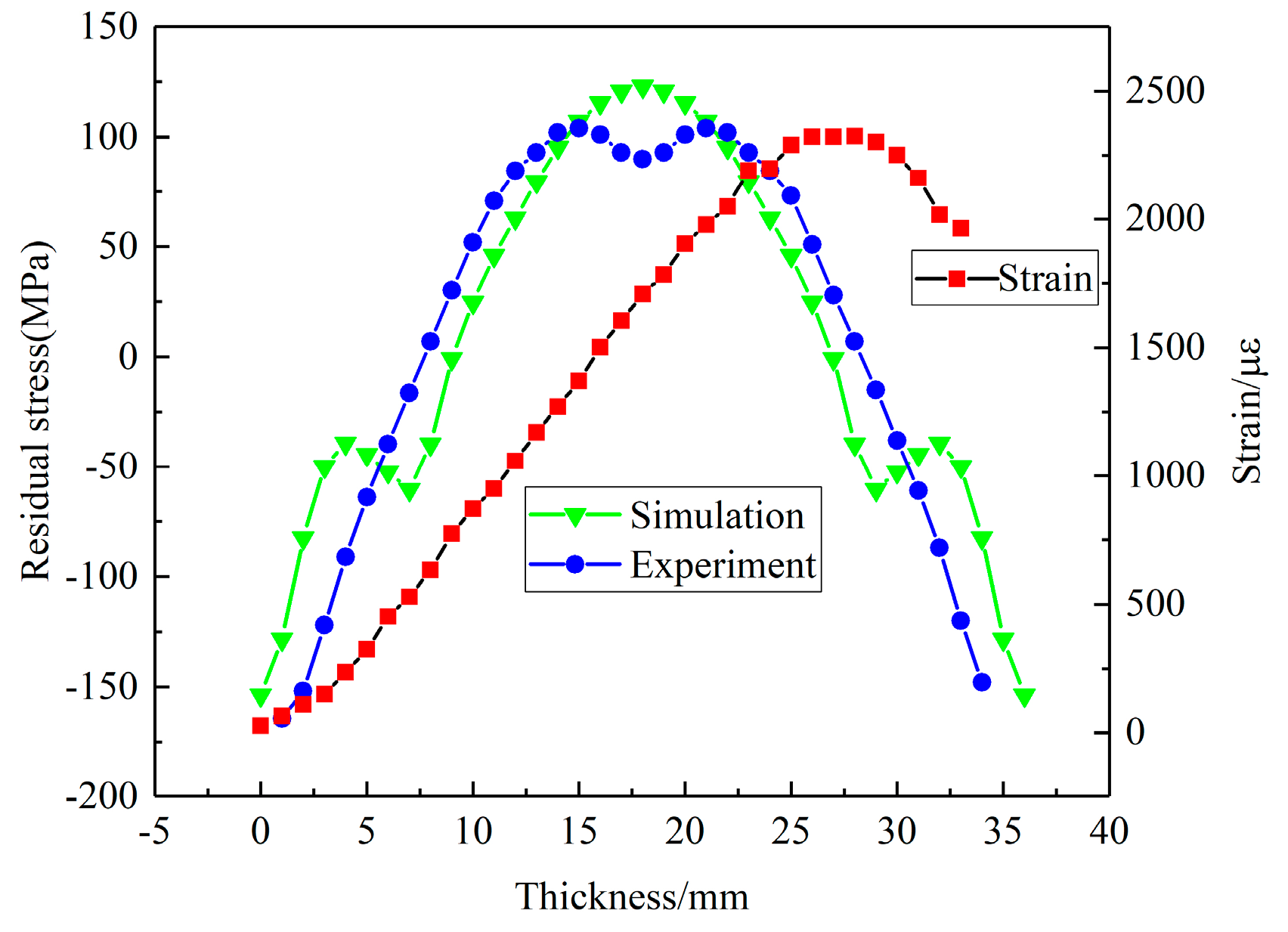

3.3. The Comparison between Simulated Results and Experimental Data

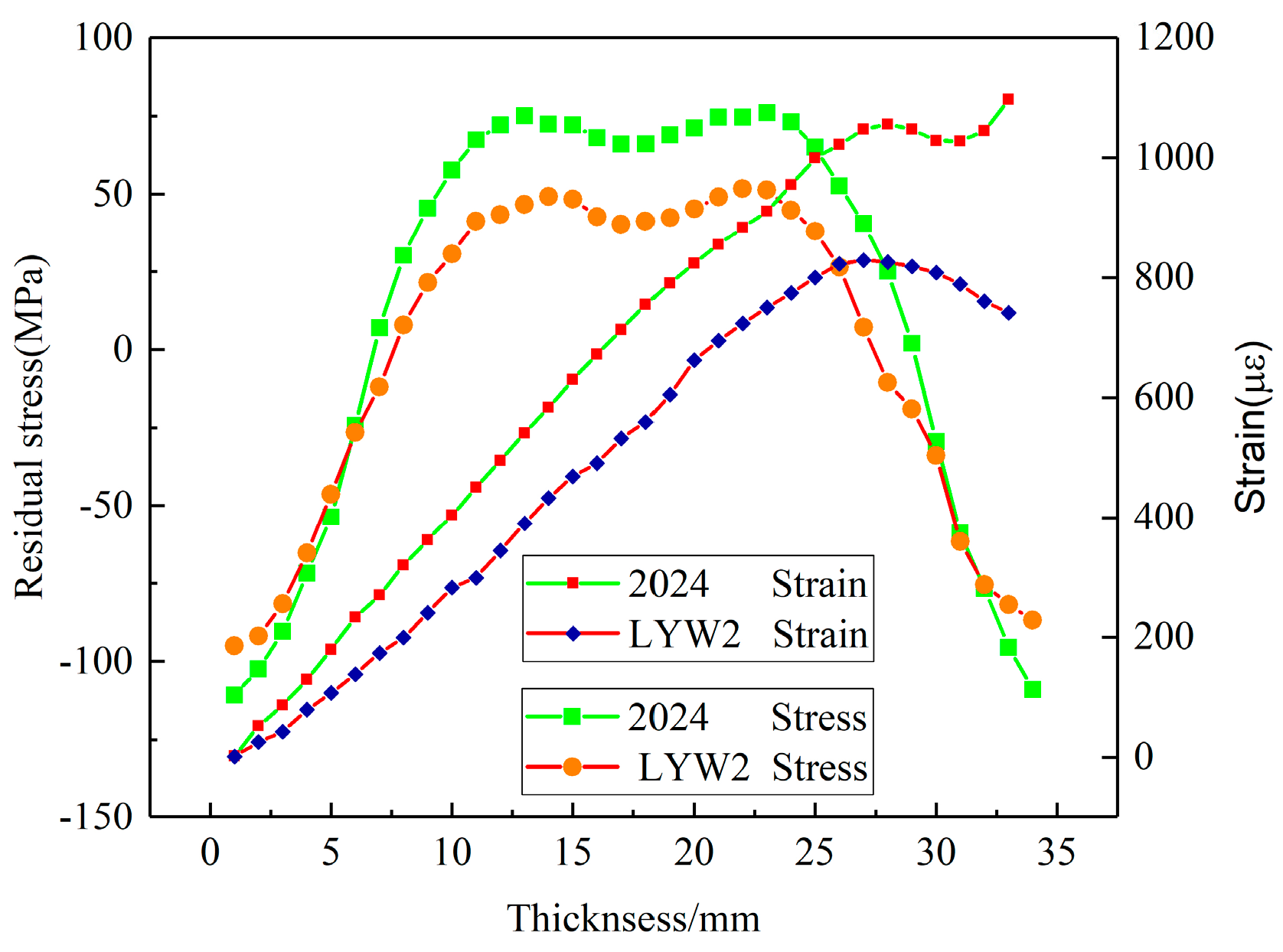

3.4. Influence of Water Temperature on Quenching Residual Stress of W/2024Al Composite Blocks

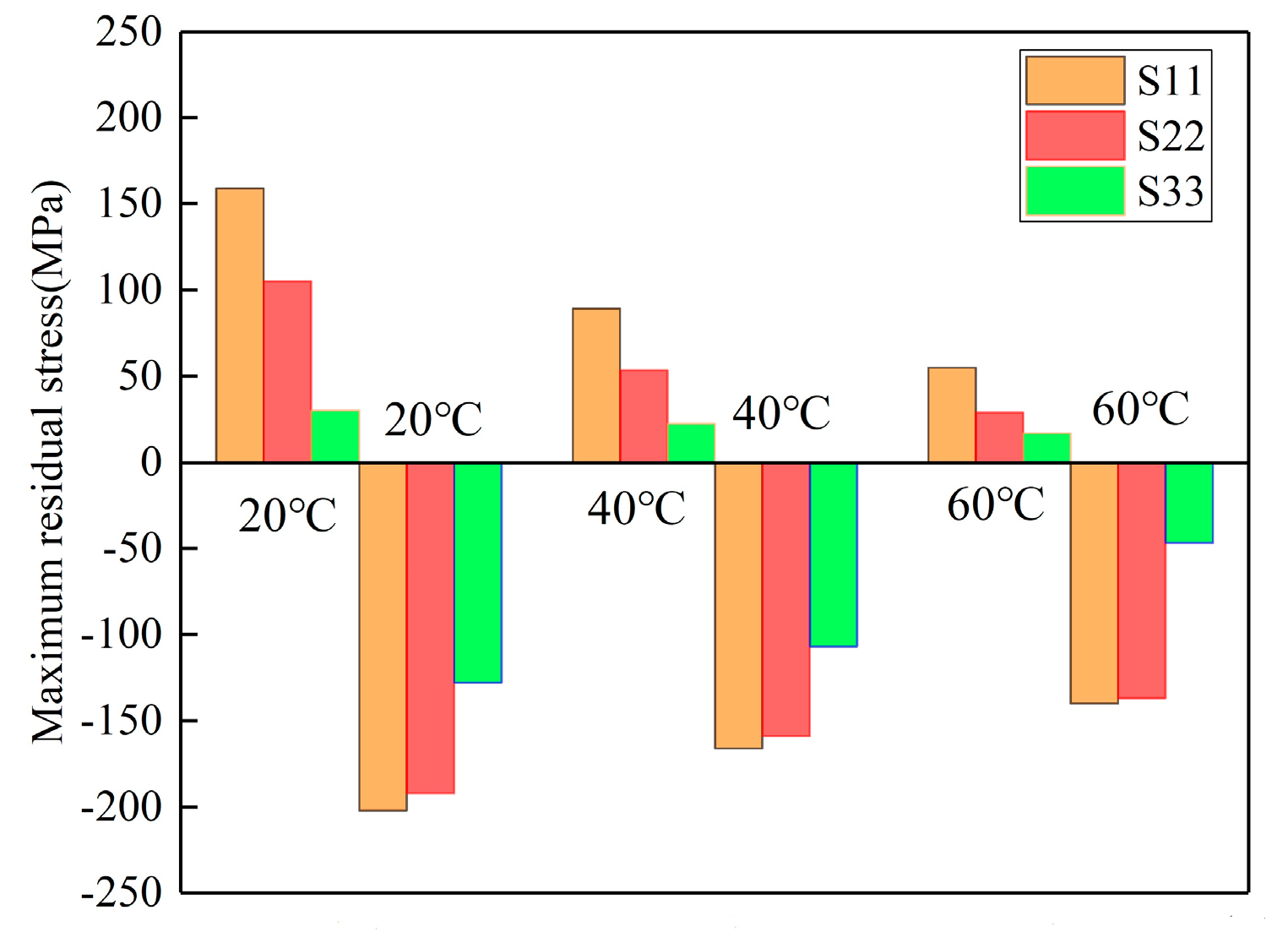

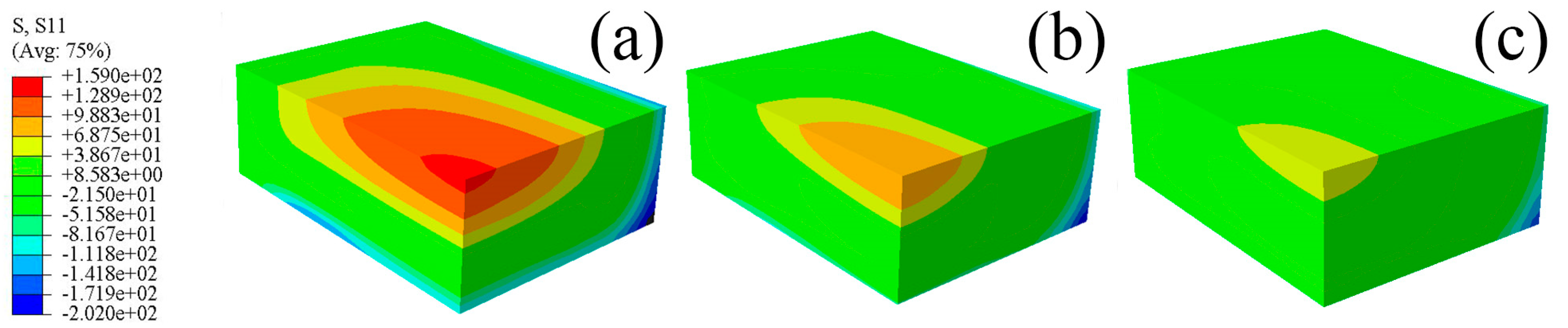

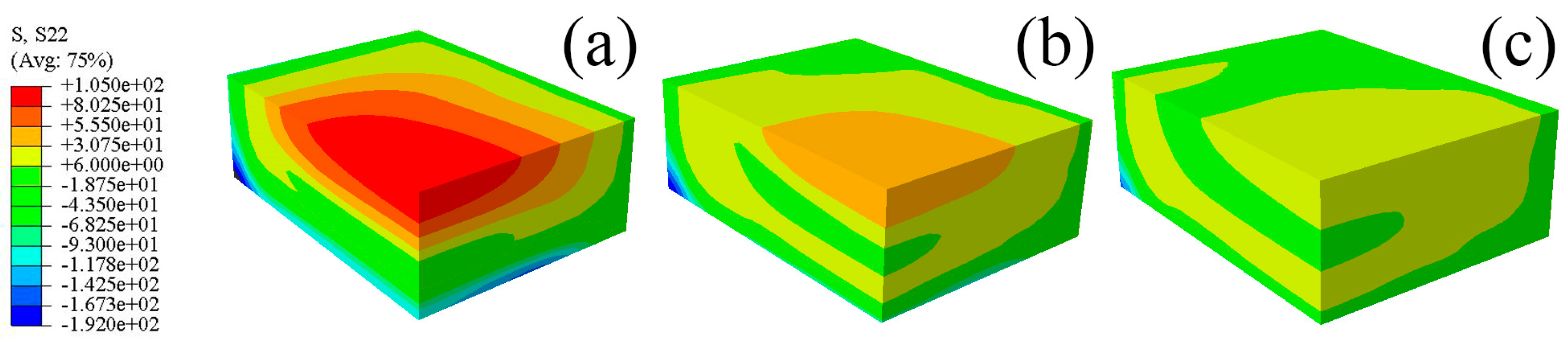

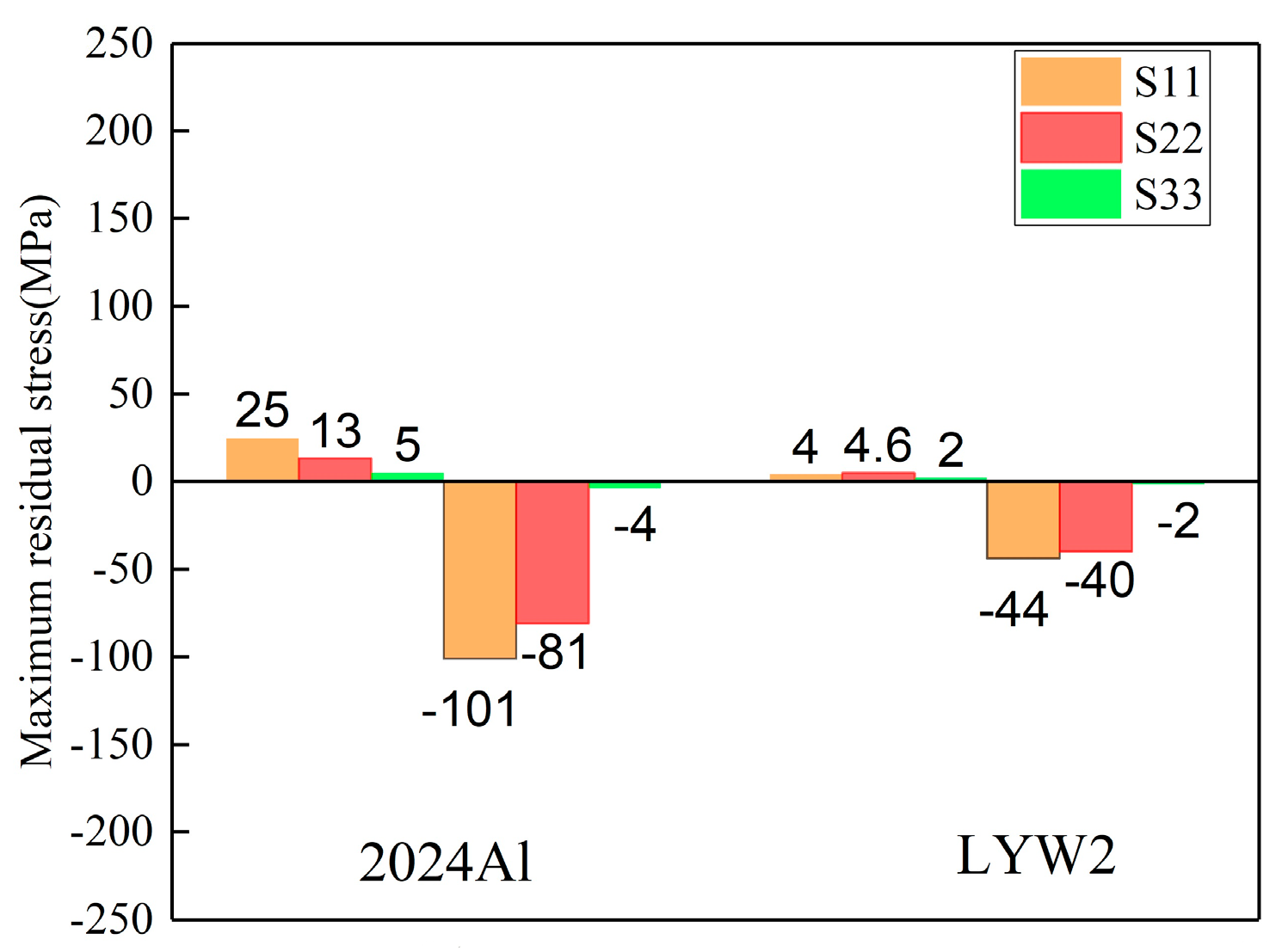

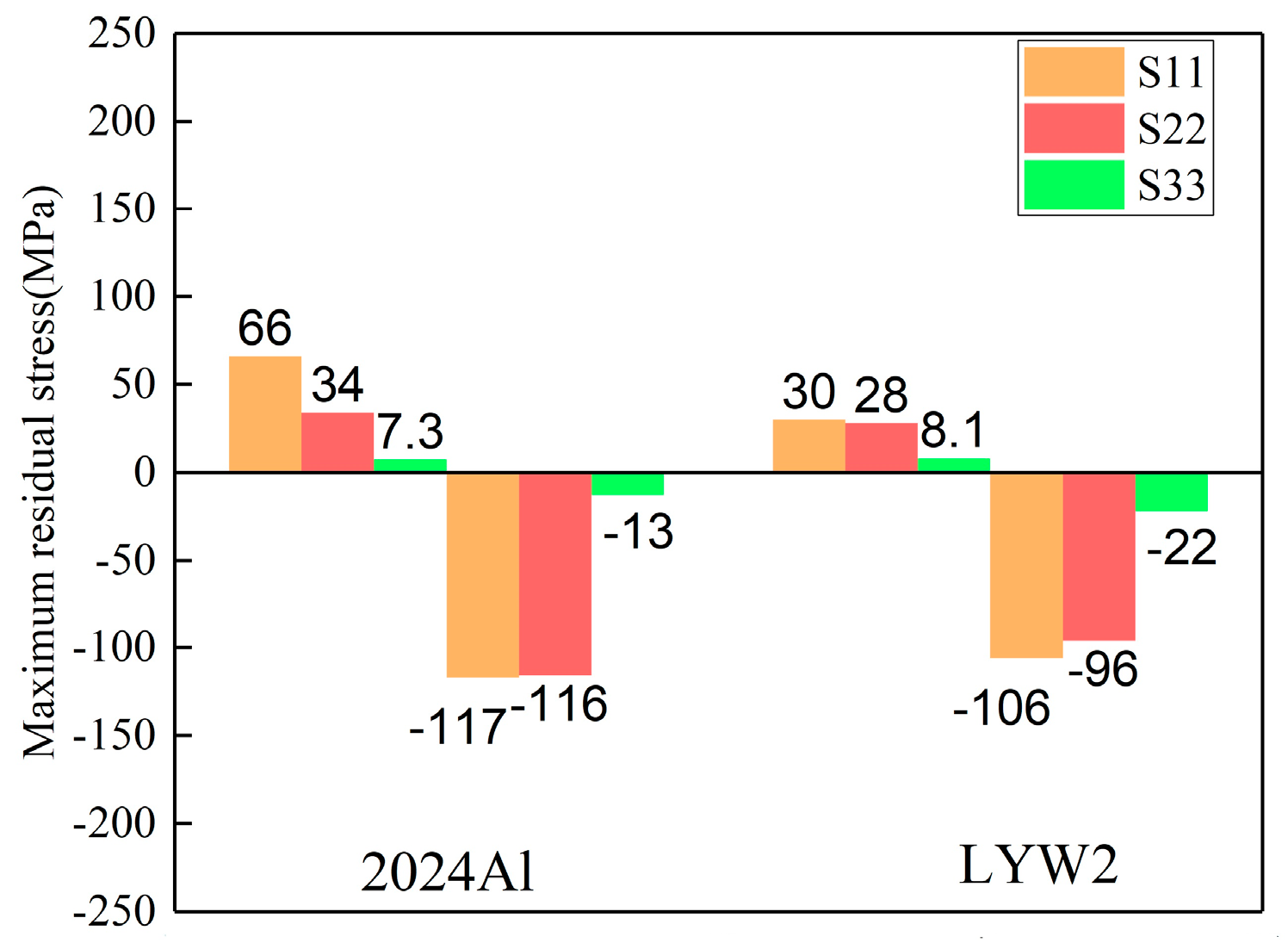

3.5. A Comparison of Residual Stress Magnitudes and Distributions among 2024 Aluminum Alloys and W/2024Al Composites after Quenching

4. Conclusions

- (1)

- The reduction of cooling rate in interior regions where tensile residual stresses generated is distinct to that in the external regions where compressive stresses developed as quenchant temperature increases. Thus, the relief effect of tensile stresses achieved by increasing water temperature is more distinct. In addition, W/2024Al composites exhibit lower stresses with desirable mechanical properties when an elevated water temperature was adopted.

- (2)

- The comparative study shows stress magnitudes of as-quenched 2024Al are greater than those of the W/2024Al composites. The different thermal gradients mainly result in the occurrence of distinct differences in stress magnitudes of the two materials. W/2024Al exhibited low stress magnitudes compared with 2024Al due to lower quenching severity during the quenching process.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Araghchi, M.; Mansouri, H.; Vafaei, R.; Guo, Y. Optimization of the Mechanical Properties and Residual Stresses in 2024 Aluminum Alloy Through Heat Treatment. J. Mater. Eng. Perform. 2018, 27, 3234–3238. [Google Scholar] [CrossRef]

- Kotresh, M.; Benal, M.; Siddalingaswamy, N. Thermal residual stress investigation in Al 2024/ Cu-Al-Ni adaptive composites by X-Ray diffractometer. Mater. Today Proc. 2018, 5, 2830–2835. [Google Scholar] [CrossRef]

- Torralba, J.M.; Da Costa, C.; Velasco, F.J. P/M aluminum matrix composites: an overview. J. Mater. Process. Technol. 2003, 133, 203–206. [Google Scholar] [CrossRef]

- Kamat, S.; Hirth, J.; Mehrabian, R. Mechanical properties of particulate-reinforced aluminum-matrix composites. Acta Met. 1989, 37, 2395–2402. [Google Scholar] [CrossRef]

- Masubuchi, K. Analysis of Welded Structures; Pergamon Press Ltd: Oxford, UK, 1980. [Google Scholar]

- Canale, L.D.C.F.; Narazaki, M. Quenching and cooling, residual stress and distortion control. Int. Heat Treat. Surf. Eng. 2010, 4, 96–97. [Google Scholar] [CrossRef]

- Robinson, J.S.; A Tanner, D.; Van Petegem, S.; Evans, A.; Robinson, J. Influence of quenching and aging on residual stress in Al–Zn–Mg–Cu alloy 7449. Mater. Sci. Technol. 2012, 28, 420–430. [Google Scholar] [CrossRef]

- Hahn, T.A.; Armstrong, R.W. Thermal expansion properties of 6061 Al alloy reinforced with SiC particles or short fibers. Int. J. Thermophys. 1988, 9, 861–871. [Google Scholar] [CrossRef]

- Lloyd, D.J. Particle reinforced aluminium and magnesium matrix composites. Int. Mater. Rev. 1994, 39, 1–23. [Google Scholar] [CrossRef]

- Ibrahim, I.A.; Mohamed, F.A.; Lavernia, E.J. Particulate reinforced metal matrix composites—a review. J. Mater. Sci. 1991, 26, 1137–1156. [Google Scholar] [CrossRef]

- Lee, S.-J.; Lee, Y.-K. Finite element simulation of quench distortion in a low-alloy steel incorporating transformation kinetics. Acta Mater. 2008, 56, 1482–1490. [Google Scholar] [CrossRef]

- Dolan, G.; Robinson, J.; Robinson, J. Residual stress reduction in 7175-T73, 6061-T6 and 2017A-T4 aluminium alloys using quench factor analysis. J. Mater. Process. Technol. 2004, 153, 346–351. [Google Scholar] [CrossRef]

- Cho, Y.-G.; Suh, D.-W.; Lee, J.K.; Han, H.N. Finite-element analysis of dimensional non-isotropy during phase transformation in microstructurally banded steel. Scr. Mater. 2011, 65, 569–572. [Google Scholar] [CrossRef]

- Robinson, J.; Hossain, S.; Truman, C.; Paradowska, A.; Hughes, D.; Wimpory, R.; Fox, M.; Robinson, J.; Truman, C. Residual stress in 7449 aluminium alloy forgings. Mater. Sci. Eng. A 2010, 527, 2603–2612. [Google Scholar] [CrossRef]

- Deville, S.; Chevalier, J.; Gremillard, L. Influence of surface finish and residual stresses on the ageing sensitivity of biomedical grade zirconia. Biomaterials 2006, 27, 2186–2192. [Google Scholar] [CrossRef]

- Yang, X.; Zhu, J.; Nong, Z.; Lai, Z.; He, D. FEM simulation of quenching process in A357 aluminum alloy cylindrical bars and reduction of quench residual stress through cold stretching process. Comput. Mater. Sci. 2013, 69, 396–413. [Google Scholar] [CrossRef]

- Huang, X.; Sun, J.; Li, J. Finite element simulation and experimental investigation on the residual stress-related monolithic component deformation. Int. J. Adv. Manuf. Tech. 2015, 77, 1035–1041. [Google Scholar] [CrossRef]

- Gou, R.; Zhang, Y.; Xu, X.; Sun, L.; Yang, Y. Residual stress measurement of new and in-service X70 pipelines by X-ray diffraction method. NDT E Int. 2011, 44, 387–393. [Google Scholar] [CrossRef]

- Prime, M.B. Residual Stress Measurement by Successive Extension of a Slot: The Crack Compliance Method. Appl. Mech. Rev. 1999, 52, 75–96. [Google Scholar] [CrossRef]

- Van Puymbroeck, E.; Nagy, W.; Fang, H.; De Backer, H. Determination of residual weld stresses with the incremental hole-drilling method in tubular steel bridge joints. Procedia Eng. 2018, 213, 651–661. [Google Scholar] [CrossRef]

- Xu, W.; Liu, J.; Zhu, H. Analysis of residual stresses in thick aluminum friction stir welded butt joints. Mater. Des. 2011, 32, 2000–2005. [Google Scholar] [CrossRef]

- Smit, T.C.; Reid, R.G. Residual Stress Measurement in Composite Laminates Using Incremental Hole-Drilling with Power Series. Exp. Mech. 2018, 58, 1221–1235. [Google Scholar] [CrossRef]

- Ersoy, N.; Vardar, O. Measurement of Residual Stresses in Layered Composites by Compliance Method. J. Compos. Mater. 2000, 34, 575–598. [Google Scholar] [CrossRef]

- Simsir, C.; Gur, C.H. 3D FEM simulation of steel quenching and investigation of the effect of asymmetric geometry on residual stress distribution. J. Mater. Process. Technol. 2008, 207, 211–221. [Google Scholar] [CrossRef]

- Li, H.; Zhao, G.; Niu, S.; Huang, C. FEM simulation of quenching process and experimental verification of simulation results. Mater. Sci. Eng. A 2007, 452, 705–714. [Google Scholar]

- Xiao, B.; Li, K.; Wang, Q.; Rong, Y. Numerical Simulation and Experimental Validation of Residual Stresses in Water-Quenched Aluminum Alloy Castings. J. Mater. Eng. Perform. 2011, 20, 1648–1657. [Google Scholar] [CrossRef]

- Liscic, B.; Singer, S. Calculation of the Heat Transfer Coefficient Based on Experiments by the Liscic Probes. Compr. Mater. Process. 2014, 123–176. [Google Scholar]

- Ozisik, M.N.; Orlande, H.R.B.; Kassab, A.J. Inverse Heat Transfer: Fundamentals and Applications. Appl. Mech. Rev. 2002, 55, B18–B19. [Google Scholar] [CrossRef]

- Koç, M.; Culp, J.; Altan, T. Prediction of residual stresses in quenched aluminum blocks and their reduction through cold working processes. J. Mater. Process. Technol. 2006, 174, 342–354. [Google Scholar] [CrossRef]

- Tanner, D.; Robinson, J.; Tanner, D.; Robinson, J. Reducing residual stress in 2014 aluminium alloy die forgings. Mater. Des. 2008, 29, 1489–1496. [Google Scholar] [CrossRef]

- Nervi, S.; Szabo, B.A. On the estimation of residual stresses by the crack compliance method. Comput. Methods Appl. Mech. Eng. 2007, 196, 3577–3584. [Google Scholar] [CrossRef]

- Prime, M.B.; Hill, M.R. Residual stress, stress relief, and inhomogeneity in aluminum plate. Scr. Mater. 2002, 46, 77–82. [Google Scholar] [CrossRef]

- Woo, W.; Feng, Z.; Wang, X.L.; Hubbard, C.R.J.S.M. Neutron diffraction measurements of time-dependent residual stresses generated by severe thermomechanical deformation. Scr. Mater. 2009, 61, 624–627. [Google Scholar] [CrossRef]

- Chobaut, N.; Carron, D.; Arsène, S.; Schloth, P.; Drezet, J.-M. Quench induced residual stress prediction in heat treatable 7xxx aluminium alloy thick plates using Gleeble interrupted quench tests. J. Mater. Process. Technol. 2015, 222, 373–380. [Google Scholar] [CrossRef]

- Gur, C.H. Investigation of the influence of specimen geometry on quench behaviour of steels by X-ray determination of surface residual stresses. Int. J. Mech. Sci. 2002, 44, 1335–1347. [Google Scholar] [CrossRef]

- Zhang, L.; Feng, X.; Li, Z.; Liu, C. FEM simulation and experimental study on the quenching residual stress of aluminum alloy 2024. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 2013, 227, 954–964. [Google Scholar] [CrossRef]

| Water Temperature (°C) | Ultimate Tensile Stress (MPa) | Yield Stress (MPa) | Elongation (%) |

|---|---|---|---|

| 20 | 350 | 218 | 11 |

| 40 | 355 | 223 | 13 |

| 60 | 343 | 210 | 10 |

| T (°C) | 50 | 100 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

|---|---|---|---|---|---|---|---|---|---|

| 2024 alloys | 182 | 155 | 116 | 99 | 83 | 72 | 41 | 34 | 25 |

| W/2024Al | 267 | 190 | 160 | / | 135 | 111 | 70 | 50 | / |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Mao, C.; Wang, J.; Fan, N.; Guo, T. Numerical Analysis and Experimental Studies on the Residual Stress of W/2024Al Composites. Materials 2019, 12, 2746. https://doi.org/10.3390/ma12172746

Zhang G, Mao C, Wang J, Fan N, Guo T. Numerical Analysis and Experimental Studies on the Residual Stress of W/2024Al Composites. Materials. 2019; 12(17):2746. https://doi.org/10.3390/ma12172746

Chicago/Turabian StyleZhang, Guosong, Changhui Mao, Jian Wang, Ning Fan, and Tiantian Guo. 2019. "Numerical Analysis and Experimental Studies on the Residual Stress of W/2024Al Composites" Materials 12, no. 17: 2746. https://doi.org/10.3390/ma12172746

APA StyleZhang, G., Mao, C., Wang, J., Fan, N., & Guo, T. (2019). Numerical Analysis and Experimental Studies on the Residual Stress of W/2024Al Composites. Materials, 12(17), 2746. https://doi.org/10.3390/ma12172746