Fracture Behavior of Bio-Inspired Functionally Graded Soft–Hard Composites Made by Multi-Material 3D Printing: The Case of Colinear Cracks

Abstract

:1. Introduction

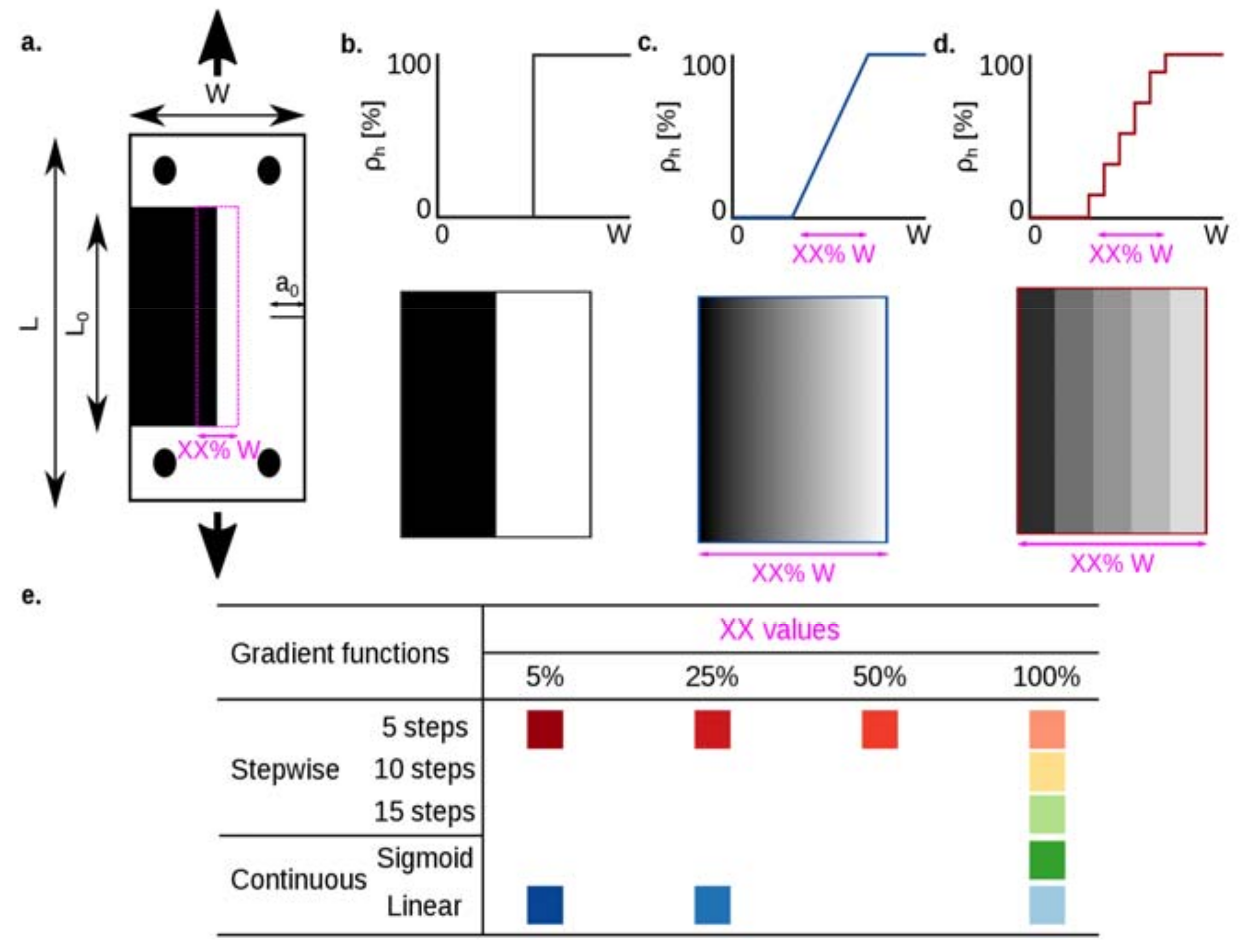

2. Material and Methods

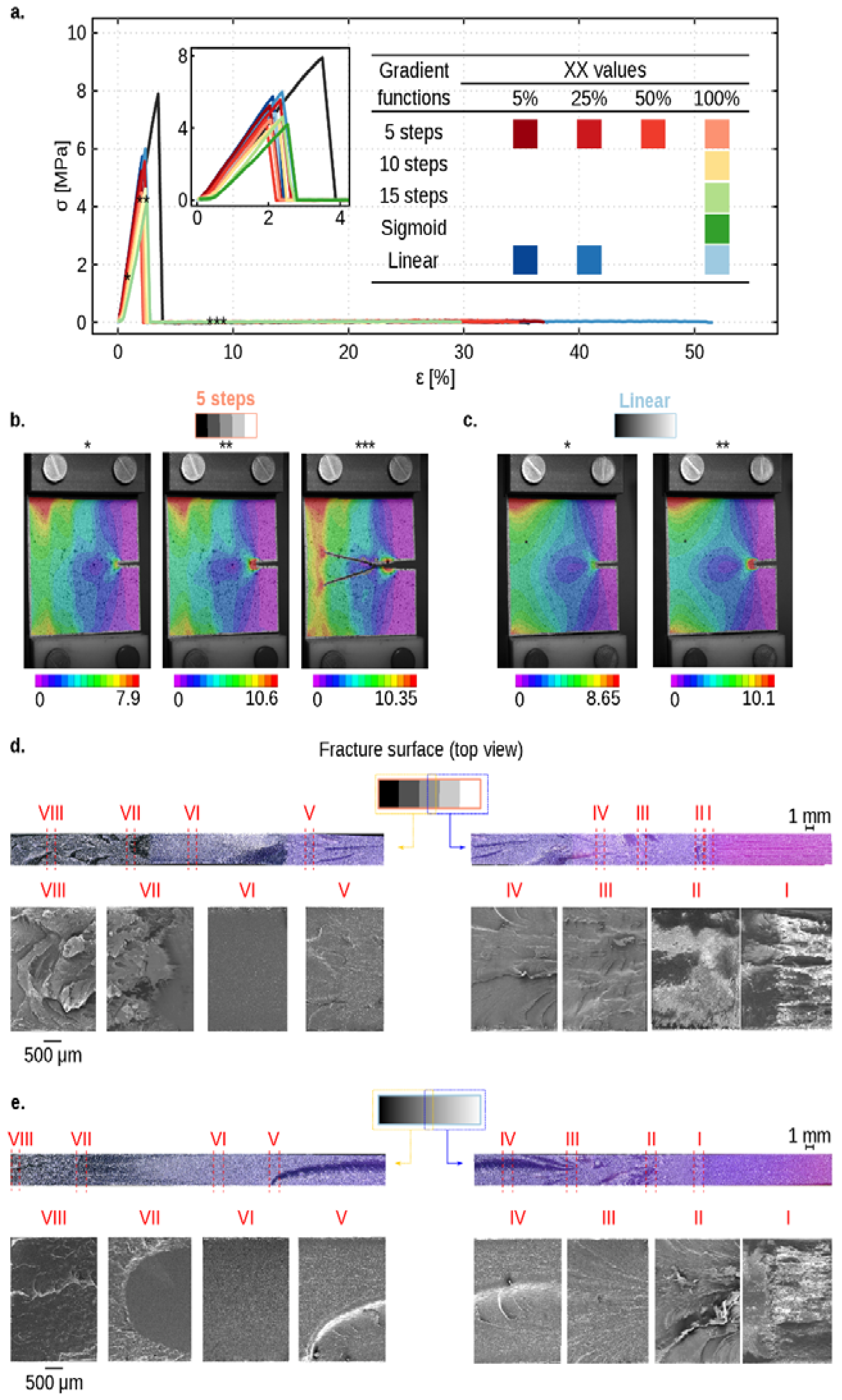

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ahankari, S.S.; Kar, K.K. Functionally Graded Composites: Processing and Applications. In Composite Materials; Springer: Berlin/Heidelberg, Germany, 2017; Volume 6, pp. 119–168. [Google Scholar]

- Bohidar, S.K.; Sharma, R.; Mishra, P.R. Functionally graded materials: A critical review. Int. J. Res. 2014, 1, 289–301. [Google Scholar]

- Naebe, M.; Shirvanimoghaddam, K. Functionally graded materials: A review of fabrication and properties. Appl. Mater. Today 2016, 5, 223–245. [Google Scholar] [CrossRef]

- Knoppers, G.E.; Gunnink, J.W.; Van Den Hout, J.; Van Vliet, W. The Reality of Functionally Graded Material Products; Elsevier: Amsterdam, The Netherlands, 2005; p. 467. [Google Scholar]

- Niino, M. Functionally gradient materials as thermal barrier for space plane. J. Jpn. Compos. Mater 1987, 13, 257–264. [Google Scholar] [CrossRef]

- Bodaghi, M.; Damanpack, A.R.; Aghdam, M.M.; Shakeri, M. Geometrically non-linear transient thermo-elastic response of FG beams integrated with a pair of FG piezoelectric sensors. Compos. Struct. 2014, 107, 48–59. [Google Scholar] [CrossRef]

- Gasik, M.; Bilotsky, Y. Optimisation of functionally gradated material thermoelectric cooler for the solar space power system. Appl. Therm. Eng. 2014, 66, 528–533. [Google Scholar] [CrossRef]

- Khoshgoftar, M.J.; Mirzaali, M.J.; Rahimi, G.H. Thermoelastic analysis of non-uniform pressurized functionally graded cylinder with variable thickness using first order shear deformation theory (FSDT) and perturbation method. Chin. J. Mech. Eng. 2015, 28, 1149–1156. [Google Scholar] [CrossRef]

- Mehrali, M.; Shirazi, F.S.; Mehrali, M.; Metselaar, H.S.C.; Kadri, N.A.B.; Osman, N.A.A. Dental implants from functionally graded materials. J. Biomed. Mater. Res. Part A Off. J. Soc. Biomater. Jpn. Soc. Biomater. Aust. Soc. Biomater. Korean Soc. Biomater. 2013, 101, 3046–3057. [Google Scholar] [CrossRef] [PubMed]

- Sunyer, R.; Jin, A.J.; Nossal, R.; Sackett, D.L. Fabrication of hydrogels with steep stiffness gradients for studying cell mechanical response. PLoS ONE 2012, 7, e46107. [Google Scholar] [CrossRef]

- Scharff, R.B.N.; Doornbusch, R.M.; Klootwijk, X.L.; Doshi, A.A.; Doubrovski, E.L.; Wu, J.; Geraedts, J.M.P.; Wang, C.C.L. Color-Based Sensing of Bending Deformation on Soft Robots. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, QLD, Australia, 21–25 May 2018; pp. 1–7. [Google Scholar]

- Leong, K.F.; Chua, S.C.K.; Sudarmadji, N.; Yeong, W.Y. Engineering functionally graded tissue engineering scaffolds. J. Mech. Behav. Biomed. Mater. 2008, 1, 140–152. [Google Scholar] [CrossRef]

- Fratzl, P.; Gupta, H.S.; Fischer, F.D.; Kolednik, O. Hindered crack propagation in materials with periodically varying Young’s modulus—Lessons from biological materials. Adv. Mater. 2007, 19, 2657–2661. [Google Scholar] [CrossRef]

- Kickelbick, G. Hybrid Materials: Synthesis, Characterization, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Wegst, U.G.K.; Bai, H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Bioinspired structural materials. Nat. Mater. 2015, 14, 23. [Google Scholar] [CrossRef] [PubMed]

- Ji, B.; Gao, H. Mechanical properties of nanostructure of biological materials. J. Mech. Phys. Solids 2004, 52, 1963–1990. [Google Scholar] [CrossRef]

- Askarinejad, S.; Choshali, H.A.; Flavin, C.; Rahbar, N. Effects of tablet waviness on the mechanical response of architected multilayered materials: Modeling and experiment. Compos. Struct. 2018, 195, 118–125. [Google Scholar] [CrossRef]

- Meyers, M.A.E.; Lin, A.Y.-M.; Chen, P.-Y.; Muyco, J. Mechanical strength of abalone nacre: Role of the soft organic layer. J. Mech. Behav. Biomed. Mater. 2008, 1, 76–85. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Meyers, M.A.; Zhang, Z.; Ritchie, R.O. Functional gradients and heterogeneities in biological materials: Design principles, functions, and bioinspired applications. Prog. Mater. Sci. 2017, 88, 467–498. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T.; Shukla, M.; Pityana, S. Functionally Graded Material: An Overview. In Proceedings of the World Congress on Engineering 2012 Vol III, London, UK, 4–6 July 2012. [Google Scholar]

- Hill, M.R.; Carpenter, R.D.; Paulino, G.H.; Munir, Z.A.; Gibeling, J.C. Fracture testing of a layered functionally graded material. In Fracture Resistance Testing of Monolithic and Composite Brittle Materials; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- Kieback, B.; Neubrand, A.; Riedel, H. Processing techniques for functionally graded materials. Mater. Sci. Eng. A 2003, 362, 81–106. [Google Scholar] [CrossRef]

- Chung, H.; Das, S. Processing and properties of glass bead particulate-filled functionally graded Nylon-11 composites produced by selective laser sintering. Mater. Sci. Eng. A 2006, 437, 226–234. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Roberts, S.; Otis, R.; Kolodziejska, J.; Dillon, R.P.; Suh, J.-O.; Shapiro, A.A.; Liu, Z.-K.; Borgonia, J.-P. Developing gradient metal alloys through radial deposition additive manufacturing. Sci. Rep. 2014, 4, 5357. [Google Scholar] [CrossRef]

- Ratilal, P. Fracture Toughness Characterisation of Functionally Graded Grade 5 Titanium Alloy with Titanium Carbide. Ph.D. Thesis, University of Johannesburg, Johannesburg, South Africa, April 2016. [Google Scholar]

- ASTM Committee F42 on Additive Manufacturing Technologies; Subcommittee F42. 91 on Terminology. Standard Terminology for Additive Manufacturing Technologies; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Doubrovski, E.L.; Tsai, E.Y.; Dikovsky, D.; Geraedts, J.M.P.; Herr, H.; Oxman, N. Voxel-based fabrication through material property mapping: A design method for bitmap printing. Comput.-Aided Des. 2015, 60, 3–13. [Google Scholar] [CrossRef]

- Kaweesa, D.V.; Meisel, N.A. Quantifying fatigue property changes in material jetted parts due to functionally graded material interface design. Addit. Manuf. 2018, 21, 141–149. [Google Scholar] [CrossRef]

- Mirzaali, M.J.; Edens, M.E.; de la Nava, A.H.; Janbaz, S.; Vena, P.; Doubrovski, E.L.; Zadpoor, A.A. Length-scale dependency of biomimetic hard-soft composites. Sci. Rep. 2018, 8, 12052. [Google Scholar] [CrossRef]

- Spillane, D.R.; Meisel, N.A. A Voxel-Based Design Approach for Creating Functionally Graded Structures Via Material Extrusion Additive Manufacturing. In Proceedings of the ASME 2018 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Quebec City, QC, Canada, 26–29 August 2018; p. V02AT03A032. [Google Scholar]

- Colombo, P.; Zordan, F.; Medvedovski, E. Ceramic—Polymer composites for ballistic protection. Adv. Appl. Ceram. 2006, 105, 78–83. [Google Scholar] [CrossRef]

- Schroer, A.; Wheeler, J.M.; Schwaiger, R. Deformation behavior and energy absorption capability of polymer and ceramic-polymer composite microlattices under cyclic loading. J. Mater. Res. 2018, 33, 274–289. [Google Scholar] [CrossRef]

- Dziadek, M.; Stodolak-Zych, E.; Cholewa-Kowalska, K. Biodegradable ceramic-polymer composites for biomedical applications: A review. Mater. Sci. Eng. C 2017, 71, 1175–1191. [Google Scholar] [CrossRef]

- Sobczak-Kupiec, A.; Pluta, K.; Drabczyk, A.; Włoś, M.; Tyliszczak, B. Synthesis and characterization of ceramic-polymer composites containing bioactive synthetic hydroxyapatite for biomedical applications. Ceram. Int. 2018, 44, 13630–13638. [Google Scholar] [CrossRef]

- Chen, F.; Song, J.; Lu, Y.; Huang, S.; Liu, X.; Sun, J.; Carmalt, C.J.; Parkin, I.P.; Xu, W. Creating robust superamphiphobic coatings for both hard and soft materials. J. Mater. Chem. A 2015, 3, 20999–21008. [Google Scholar] [CrossRef] [Green Version]

- Domingues Dos Santos, F.; Fabre, P.; Drujon, X.; Meunier, G.; Leibler, L. Films from soft-core/hard-shell hydrophobic latexes: Structure and thermomechanical properties. J. Polym. Sci. Part B Polym. Phys. 2000, 38, 2989–3000. [Google Scholar] [CrossRef]

- Ko, S.H.; Pan, H.; Grigoropoulos, C.P.; Luscombe, C.K.; Fréchet, J.M.; Poulikakos, D. All-inkjet-printed flexible electronics fabrication on a polymer substrate by low-temperature high-resolution selective laser sintering of metal nanoparticles. Nanotechnology 2007, 18, 345202. [Google Scholar] [CrossRef]

- Sun, Y.; Rogers, J.A. Inorganic semiconductors for flexible electronics. Adv. Mater. 2007, 19, 1897–1916. [Google Scholar] [CrossRef]

- Wang, B. Numerical Simulation and Experiments of Fatigue Crack Growth in Multi-Layer Structures of MEMS and Microelectronic Devices. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, May 2007. [Google Scholar]

- Wong, W.S.; Salleo, A. Flexible electronics: Materials and applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009; Volume 11. [Google Scholar]

- Siczek, K.J. Chapter 7-Valve train tribology. In Tribological Processes in the Valve Train Systems with Lightweight Valves; Siczek, K.J., Ed.; Butterworth-Heinemann: Oxford, UK, 2016; pp. 85–180. [Google Scholar]

- Holmberg, K.; Matthews, A.; Ronkainen, H. Coatings tribology—Contact mechanisms and surface design. Tribol. Int. 1998, 31, 107–120. [Google Scholar] [CrossRef]

- Greensmith, H.W. Rupture of rubber. X. The change in stored energy on making a small cut in a test piece held in simple extension. J. Appl. Polym. Sci. 1963, 7, 993–1002. [Google Scholar] [CrossRef]

- Long, R.; Hui, C.-Y. Fracture toughness of hydrogels: Measurement and interpretation. Soft Matter 2016, 12, 8069–8086. [Google Scholar] [CrossRef]

- Hild, F.c.o.; Roux, S.e.p. Digital image correlation: From displacement measurement to identification of elastic properties—A review. Strain 2006, 42, 69–80. [Google Scholar] [CrossRef]

- Pan, B.; Qian, K.; Xie, H.; Asundi, A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas. Sci. Technol. 2009, 20, 062001. [Google Scholar] [CrossRef]

- Team, R.C. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2013. [Google Scholar]

- Libanori, R.; Erb, R.M.; Reiser, A.; Le Ferrand, H.; Süess, M.J.; Spolenak, R.; Studart, A.R. Stretchable heterogeneous composites with extreme mechanical gradients. Nat. Commun. 2012, 3, 1265. [Google Scholar] [CrossRef] [Green Version]

- Henriques, B. Inhomogeneous materials perform better: Functionally graded materials for biomedical application. J. Powder Met. Min. 2013, 2, 1–2. [Google Scholar] [CrossRef]

- Engler, A.J.; Sen, S.; Sweeney, H.L.; Discher, D.E. Matrix elasticity directs stem cell lineage specification. Cell 2006, 126, 677–689. [Google Scholar] [CrossRef]

- Miao, X.; Sun, D. Graded/Gradient Porous Biomaterials. Materials 2010, 3, 26–47. [Google Scholar] [CrossRef]

- Hedayati, R.; Mirzaali, M.J.; Vergani, L.; Zadpoor, A.A. Action-at-a-distance metamaterials: Distributed local actuation through far-field global forces. APL Mater. 2018, 6, 036101. [Google Scholar] [CrossRef] [Green Version]

- Mirzaali, M.J.; Habibi, M.; Janbaz, S.; Vergani, L.; Zadpoor, A.A. Crumpling-based soft metamaterials: The effects of sheet pore size and porosity. Sci. Rep. 2017, 7, 13028. [Google Scholar] [CrossRef]

- Mirzaali, M.J.; Janbaz, S.; Strano, M.; Vergani, L.; Zadpoor, A.A. Shape-matching soft mechanical metamaterials. Sci. Rep. 2018, 8, 965. [Google Scholar] [CrossRef]

- Mirzaali, M.J.; Hedayati, R.; Vena, P.; Vergani, L.; Strano, M.; Zadpoor, A.A. Rational design of soft mechanical metamaterials: Independent tailoring of elastic properties with randomness. Appl. Phys. Lett. 2017, 111, 051903. [Google Scholar] [CrossRef] [Green Version]

- Zadpoor, A.A. Mechanical meta-materials. Mater. Horiz. 2016, 3, 371–381. [Google Scholar] [CrossRef] [Green Version]

- Mirzaali, M.J.; Pahlavani, H.; Zadpoor, A.A. Auxeticity and stiffness of random networks: Lessons for the rational design of 3D printed mechanical metamaterials. J. Appl. Phys. Lett. 2019, 115, 021901. [Google Scholar] [CrossRef]

- Janbaz, S.; McGuinness, M.; Zadpoor, A.A. Multimaterial Control of Instability in Soft Mechanical Metamaterials. Phys. Rev. Appl. 2018, 9, 064013. [Google Scholar] [CrossRef] [Green Version]

- Mirzaali, M.J.; Caracciolo, A.; Pahlavani, H.; Janbaz, S.; Vergani, L.; Zadpoor, A.A. Multi-material 3D printed mechanical metamaterials: Rational design of elastic properties through spatial distribution of hard and soft phases. Appl. Phys. Lett. 2018, 113, 241903. [Google Scholar] [CrossRef]

- Janbaz, S.; Bobbert, F.S.L.; Mirzaali, M.J.; Zadpoor, A.A. Ultra-programmable buckling-driven soft cellular mechanisms. J. Mater. Horiz. 2019, 6, 1138–1147. [Google Scholar] [CrossRef] [Green Version]

- Mueller, J.; Shea, K. Stepwise graded struts for maximizing energy absorption in lattices. Extrem. Mech. Lett. 2018, 25, 7–15. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirzaali, M.J.; Herranz de la Nava, A.; Gunashekar, D.; Nouri-Goushki, M.; Doubrovski, E.L.; Zadpoor, A.A. Fracture Behavior of Bio-Inspired Functionally Graded Soft–Hard Composites Made by Multi-Material 3D Printing: The Case of Colinear Cracks. Materials 2019, 12, 2735. https://doi.org/10.3390/ma12172735

Mirzaali MJ, Herranz de la Nava A, Gunashekar D, Nouri-Goushki M, Doubrovski EL, Zadpoor AA. Fracture Behavior of Bio-Inspired Functionally Graded Soft–Hard Composites Made by Multi-Material 3D Printing: The Case of Colinear Cracks. Materials. 2019; 12(17):2735. https://doi.org/10.3390/ma12172735

Chicago/Turabian StyleMirzaali, Mohammad J., Alba Herranz de la Nava, Deepthi Gunashekar, Mahdyieh Nouri-Goushki, Eugeni. L. Doubrovski, and Amir A. Zadpoor. 2019. "Fracture Behavior of Bio-Inspired Functionally Graded Soft–Hard Composites Made by Multi-Material 3D Printing: The Case of Colinear Cracks" Materials 12, no. 17: 2735. https://doi.org/10.3390/ma12172735