Additive Manufacturing of Silicon Nitride Ceramic Floatation Spheres with Excellent Mechanical Properties

Abstract

1. Introduction

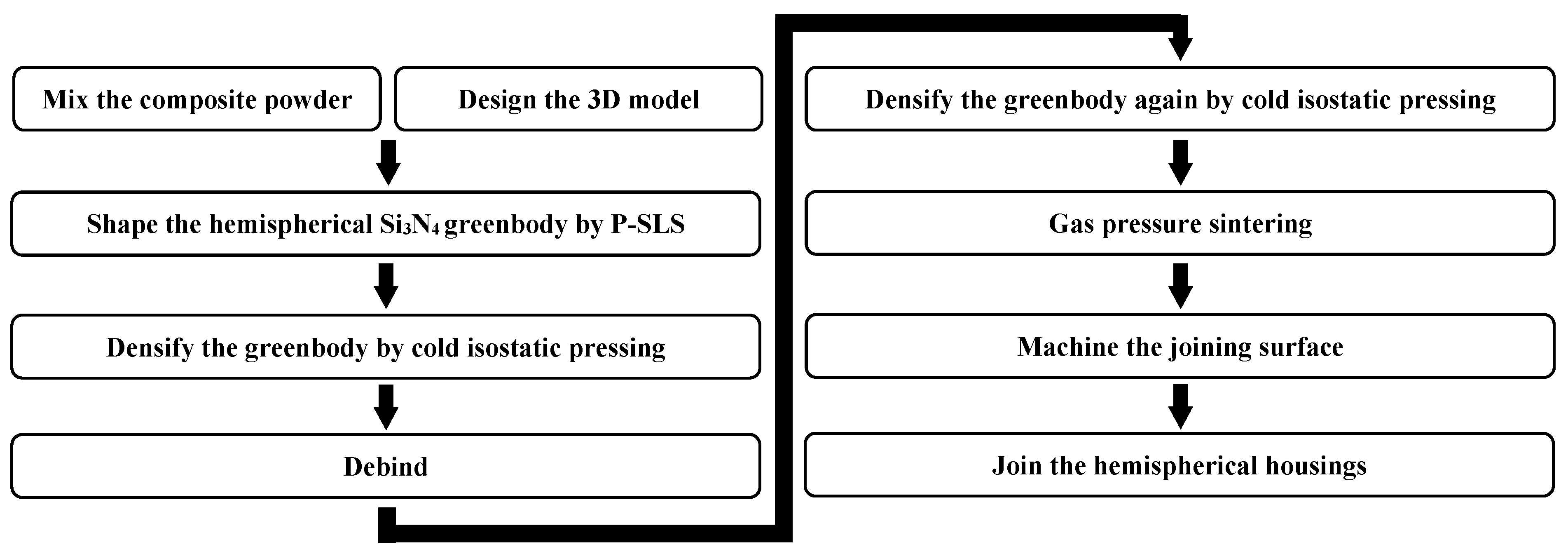

2. Materials and Methods

2.1. Composite Powder Preparation

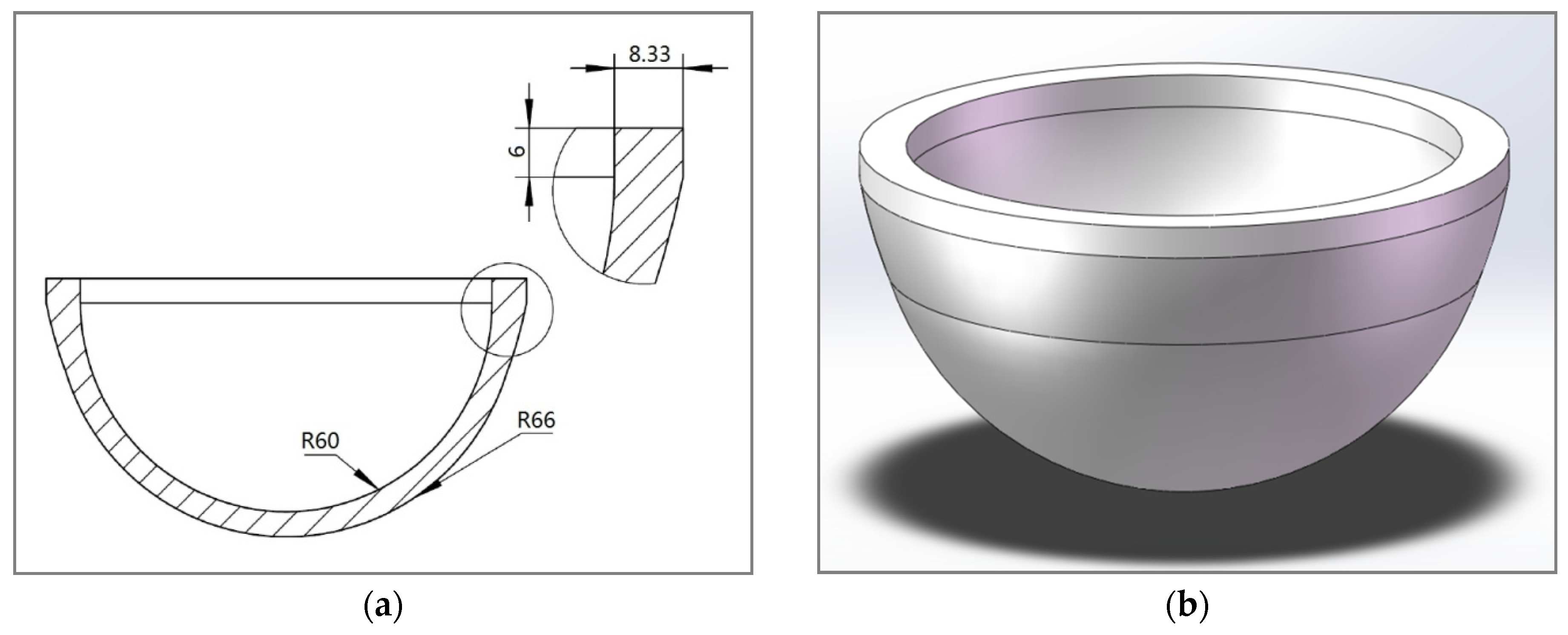

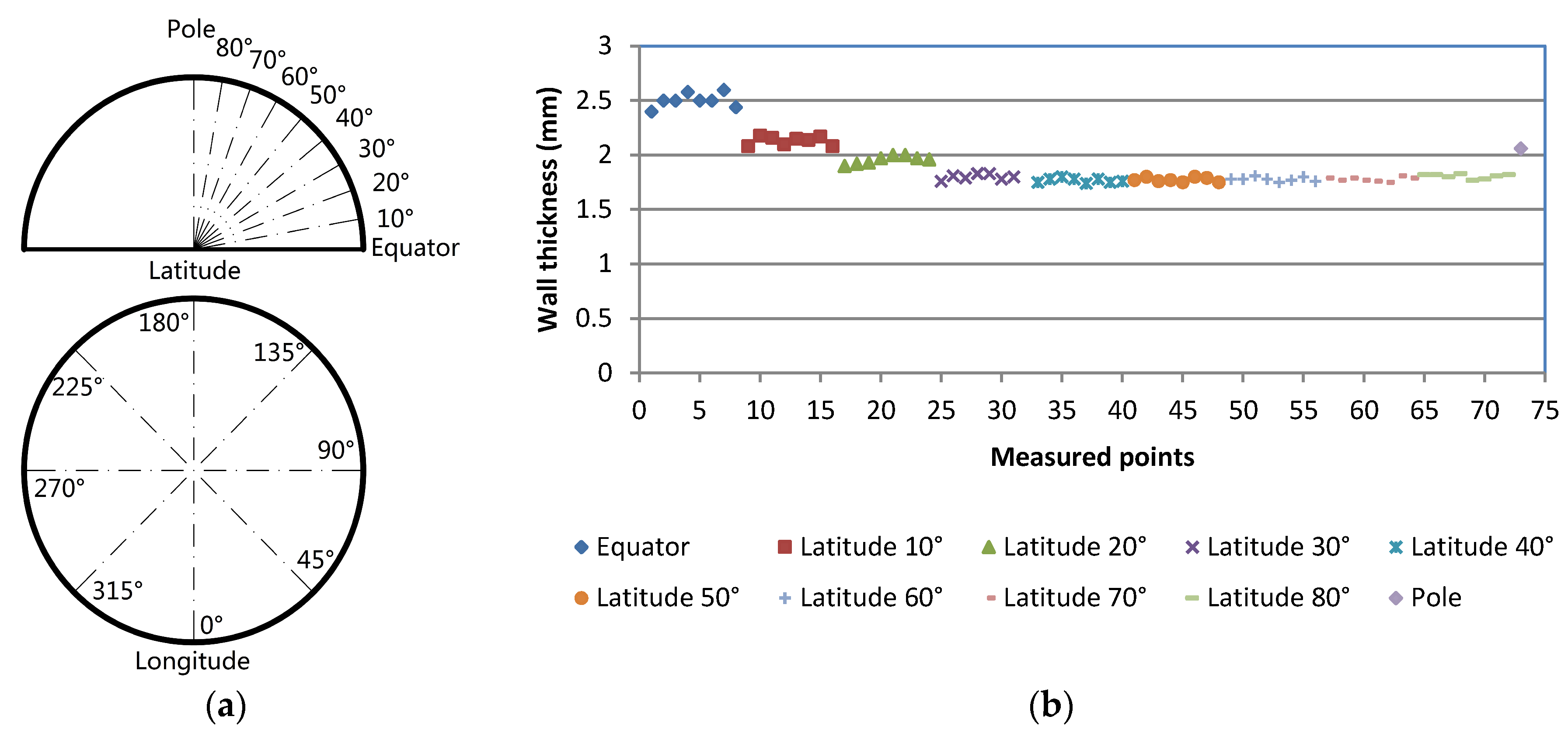

2.2. Description of the 3D Model

2.3. Powder-Based Selective Laser Sintering

2.4. Cold Isostatic Pressing and Debinding

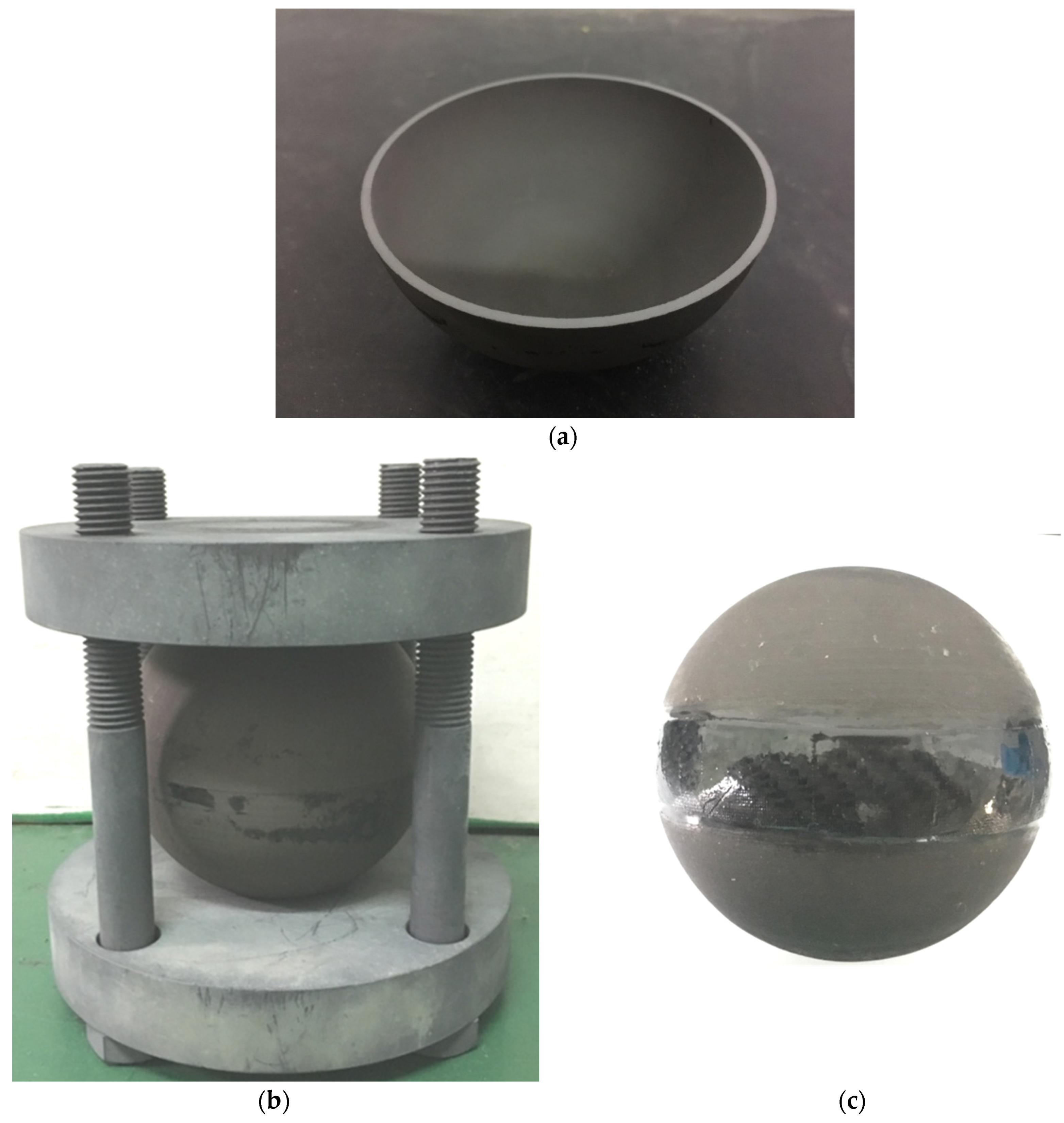

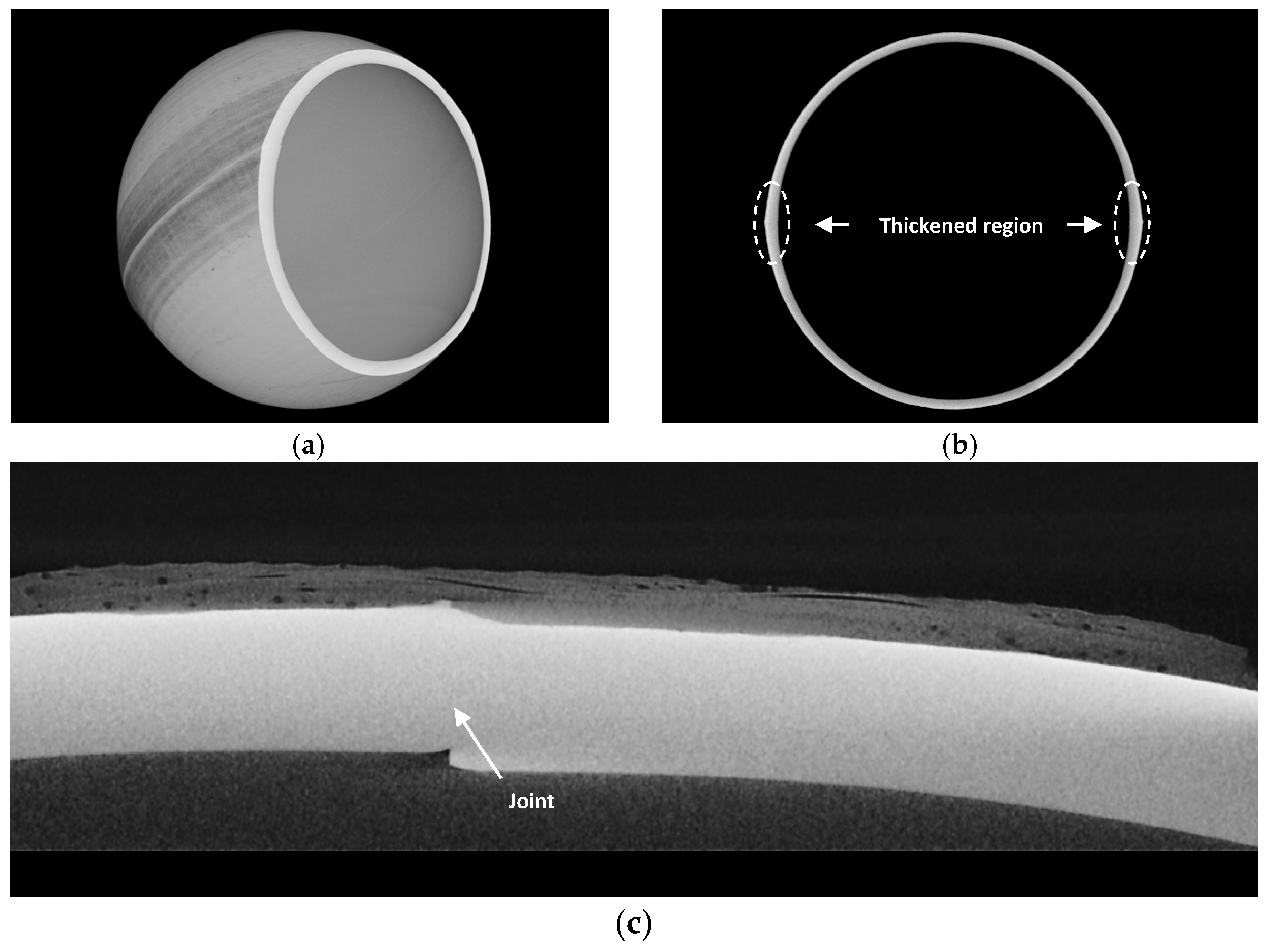

2.5. Sintering, Machining, and Joining

2.6. Measurements and Test Procedure

3. Results and Discussion

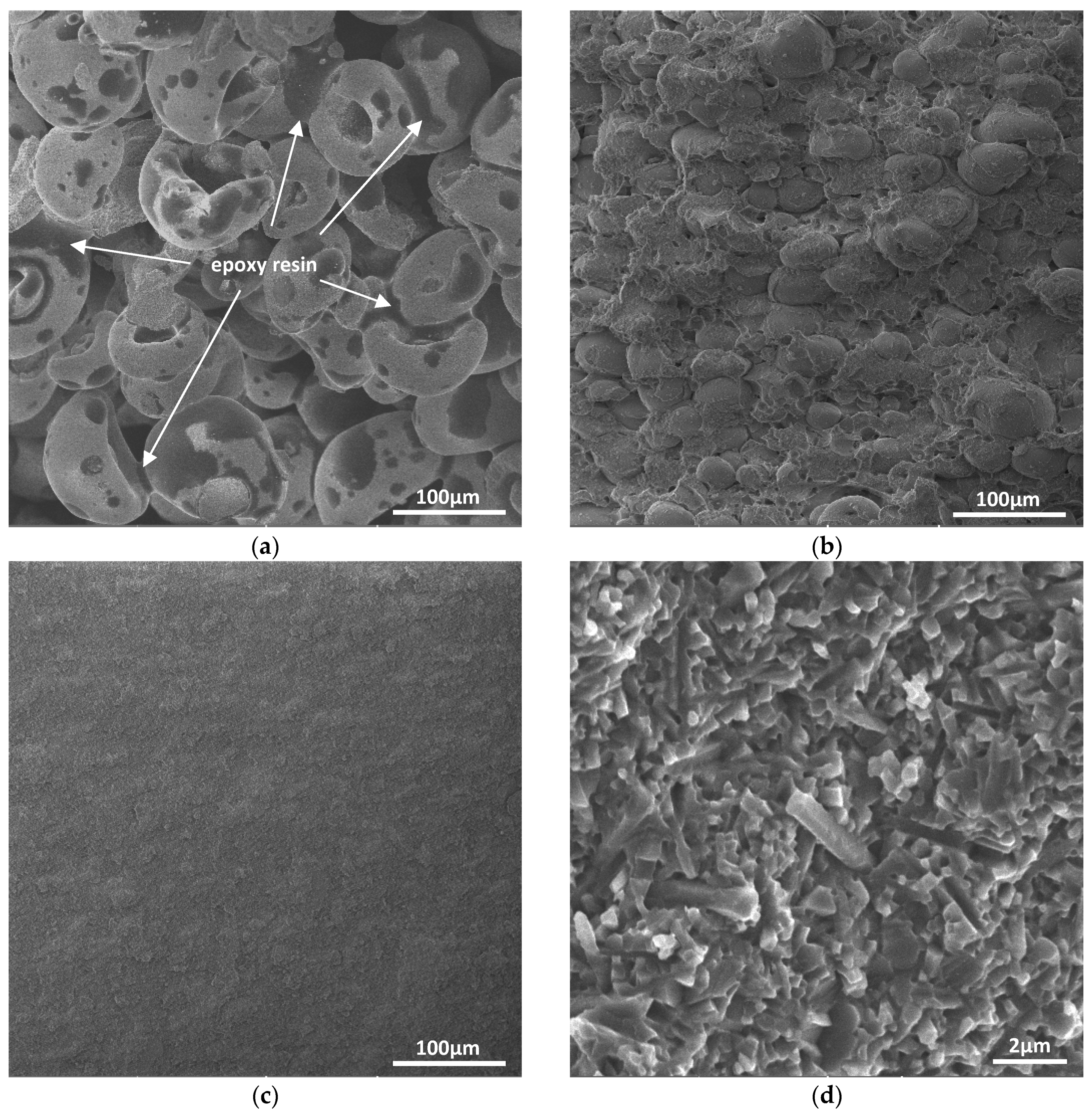

3.1. Preparation

3.2. Evaluation

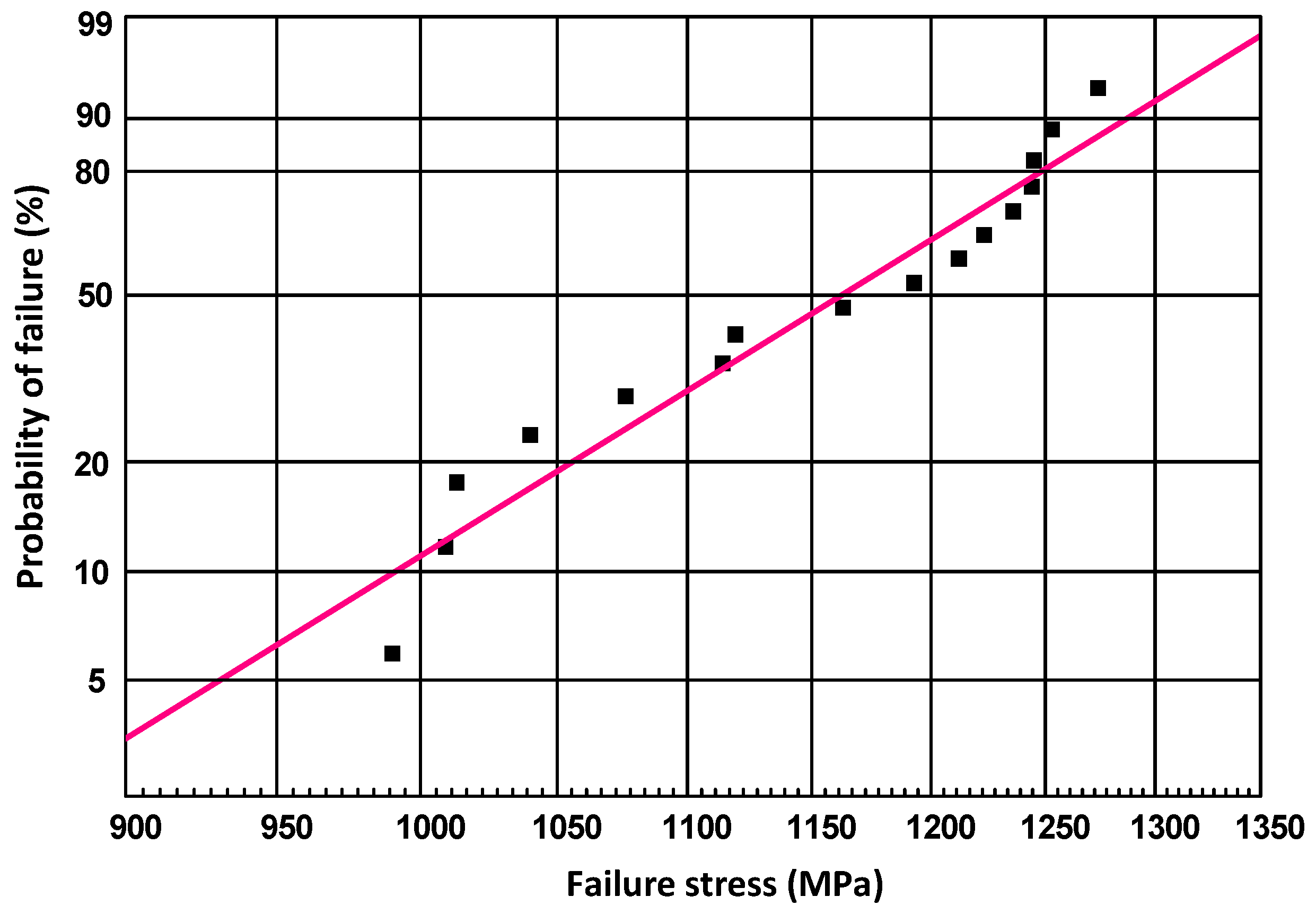

3.3. Pressure Tests

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stachiw, J.; Peters, D. Alumina Ceramic 10 in Flotation Spheres for Deep Submergence ROV/AUV Systems. In Proceedings of the OCEANS 2005 MTS/IEEE, Washington, DC, USA, 17–23 September 2005. [Google Scholar] [CrossRef]

- Weston, S.; Stachiw, J.; Merewether, R.; Olsson, M.; Jemmott, G. Alumina ceramic 3.6 in flotation spheres for 11 km ROV/AUV systems. In Proceedings of the OCEANS 2005 MTS/IEEE, Washington, DC, USA, 17–23 September 2005. [Google Scholar] [CrossRef]

- Jiang, B.; Blugan, G.; Sturzenegger, P.; Gonzenbach, U.; Mission, M.; Thornberry, J.; Stenerud, R.; Cartlidge, D.; Kuebler, J. Ceramic spheres—A novel solution to deep sea buoyancy modules. Material 2016, 9, 529. [Google Scholar] [CrossRef] [PubMed]

- Stachiw, J.; Peters, D.; McDonald, G. Ceramic External Pressure Housings for Deep Sea Vehicles. In Proceedings of the OCEANS 2006, Boston, MA, USA, 18–21 September 2006. [Google Scholar] [CrossRef]

- Takagawa, S. New ceramic pressure hull design for deep water applications. In Proceedings of the OCEANS’10 IEEE Sydney, Sydney, Australia, 24–27 May 2010. [Google Scholar] [CrossRef]

- Askawa, K.; Ito, M.; Hyakudome, T. Evaluation of small models of ceramic housings for 11,000 m ocean bottom seismometers. In Proceedings of the OCEANS’10 IEEE SYDNEY, Sydney, Australia, 24–27 May 2010. [Google Scholar] [CrossRef]

- Askawa, K.; Hyakudome, T.; Yoshida, M.; Okubo, N.; Ito, M.; Terada, I. Ceramic pressure-tight housings for ocean-bottom seismometers applicable to 11-km water depth. IEEE J. Ocean. Eng. 2012, 37, 756–763. [Google Scholar] [CrossRef]

- Maeda, Y.; Askawa, K.; Obana, K.; Terada, I. Super-deep-sea ocean bottom seismometers using ceramic spheres. In Proceedings of the 2013 IEEE International Underwater Technology Symposium (UT), Tokyo, Japan, 5–8 March 2013. [Google Scholar] [CrossRef]

- Biswas, S.K.; Riley, F.L. Gas pressure sintering of silicon nitride—Current status. Mater. Chem. Phys. 2001, 67, 175–179. [Google Scholar] [CrossRef]

- Weston, S.; Olsson, M.; Merewether, R.; Sanderson, J. Flotation in ocean trenches using hollow ceramic spheres. Mar. Technol. Soc. J. 2009, 43, 110–114. [Google Scholar] [CrossRef]

- Yano, Y.; Takagawa, S. Exploratory study on engineering ceramics pressure hulls for deep-sea submergence services. Mar. Technol. Soc. J. 2005, 39, 49–55. [Google Scholar] [CrossRef]

- Breddermann, K.; Drescher, P.; Polzin, C.; Seitz, H.; Paschen, M. Printed pressure housings for underwater applications. Ocean Eng. 2016, 113, 57–63. [Google Scholar] [CrossRef]

- Deckers, J.; Shahzad, K.; Vleugels, J.; Kruth, J.P. Isostatic pressing assisted indirect selective laser sintering of alumina components. Rapid Prototyp. J. 2012, 18, 409–419. [Google Scholar] [CrossRef]

- Liu, K.; Shi, Y.; Li, C.; Hao, L.; Liu, J.; Wei, Q. Indirect selective laser sintering of epoxy resin—Al2O3 ceramic powders combined with cold isostatic pressing. Ceram. Int. 2014, 40, 7099–7106. [Google Scholar] [CrossRef]

- Liu, K.; Sun, H.; Shi, Y.; Liu, J.; Zhang, S.; Huang, S.; Wang, M. Research on selective laser sintering of Kaolin—Epoxy resin ceramic powders combined with cold isostatic pressing and sintering. Ceram. Int. 2016, 42, 10711–10718. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.; Gunster, J. Additive manufacturing of ceramics: Issues, potentialities and opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Zhang, P.; He, C.; Wu, F.; Han, W.; Guo, F.; Qi, H. Ceramic Hollow Buoyancy Balls and Method of Manufacture. China Patent CN108975937-A, 31 May 2017. [Google Scholar]

- Lukasiewicz, S.J. Spray-drying ceramic powders. J. Am. Ceram. Soc. 1989, 72, 617–624. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, X.; Feng, M.; Zhang, P.; He, C.; Qi, H.; Han, W.; Guo, F. Underwater implosion of silicon nitride ceramic flotation spheres. Mar. Struct. under review.

| Properties | Si3N4 (Gas Pressure Sintered) | Al2O3 (High Purity, ≥99%) |

|---|---|---|

| Density (g/cm3) | 3.2 | 3.9 |

| Flexural Strength (3 point, MPa) | 900–1200 | 300–500 |

| Compressive Strength (MPa) | 3000–4000 | 2000–3500 |

| Fracture Toughness (MPa·m1/2) | 6.5 | 4.0 |

| Young’s Modulus (GPa) | 300 | 380 |

| Poisson’s Ratio | 0.27 | 0.23 |

| Sample Number | Diameter (Uncoated, mm) | Weight-to-Displacement Ratio (Coated, g/cm3) | Pressure (MPa) | Remarks |

|---|---|---|---|---|

| 1 | 101.43 | 0.35 | 200 | Collapsed |

| 2 | 101.52 | 0.35 | 236 | Collapsed |

| 3 | 101.72 | 0.34 | 216 | Collapsed |

| 4 | 101.66 | 0.35 | 186 | Collapsed |

| 5 | 101.62 | 0.34 | 198 | Collapsed |

| 6 | 101.56 | 0.34 | 164 | Collapsed |

| 7 | 101.51 | 0.34 | 218 | Collapsed |

| 8 | 101.62 | 0.33 | 173 | Collapsed |

| 9 | 101.78 | 0.33 | 234 | Collapsed |

| 10 | 101.33 | 0.35 | 225 | Collapsed |

| Average value | 101.58 | 0.34 | 205 | - |

| Sample Number | Diameter (Uncoated, mm) | Weight-to-Displacement Ratio (Coated, g/cm3) | Test Condition | Remarks |

|---|---|---|---|---|

| 11 | 101.55 | 0.34 | Sustained 1 | Not failed |

| 12 | 101.31 | 0.35 | Sustained | Not failed |

| 13 | 101.79 | 0.33 | Sustained | Not failed |

| 14 | 101.83 | 0.33 | Sustained | Not failed |

| 15 | 101.42 | 0.35 | Sustained | Not failed |

| 16 | 101.63 | 0.33 | Cyclic 2 | Not failed |

| 17 | 101.59 | 0.34 | Cyclic | Not failed |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, H.; He, C.; Zhang, P.; Han, W.; Guo, F.; Wu, F.; Du, M. Additive Manufacturing of Silicon Nitride Ceramic Floatation Spheres with Excellent Mechanical Properties. Materials 2019, 12, 2717. https://doi.org/10.3390/ma12172717

Qi H, He C, Zhang P, Han W, Guo F, Wu F, Du M. Additive Manufacturing of Silicon Nitride Ceramic Floatation Spheres with Excellent Mechanical Properties. Materials. 2019; 12(17):2717. https://doi.org/10.3390/ma12172717

Chicago/Turabian StyleQi, Hai, Chenggui He, Peizhi Zhang, Weiyue Han, Fangquan Guo, Fen Wu, and Miaofeng Du. 2019. "Additive Manufacturing of Silicon Nitride Ceramic Floatation Spheres with Excellent Mechanical Properties" Materials 12, no. 17: 2717. https://doi.org/10.3390/ma12172717

APA StyleQi, H., He, C., Zhang, P., Han, W., Guo, F., Wu, F., & Du, M. (2019). Additive Manufacturing of Silicon Nitride Ceramic Floatation Spheres with Excellent Mechanical Properties. Materials, 12(17), 2717. https://doi.org/10.3390/ma12172717