4.1. Concrete Damaged Plasticity Model

The behavior of concrete is complex due to an array of morphological features as well as deformation and failure mechanisms inherent in the concrete microstructure. In recent years, many coupled plasticity–damage models have been proposed to describe the mechanical behavior of concrete [

44,

45,

46]. The model included in the ABAQUS package (Dassault Systèmes Simulia Corp., Providence, RI, USA) called concrete damaged plasticity (CDP) has been widely used for the description of static and dynamic mechanical behaviors of concrete-like materials. The model assumes that the uniaxial compressive and tensile responses of concrete are characterized by damaged plasticity. The typical stress–stain curve is shown in

Figure 15 and the stress–strain relationships under compression and tension are

where the subscripts

and

refer respectively to compression and tension;

is the initial elastic modulus,

and

are the equivalent plastic strain;

and

are damage variables used to characterize degradation of the elastic modulus in the strain softening phase of the stress–strain response, and are assumed to be functions of equivalent plastic strain.

A “pristine” stress tensor, denoted by

, is introduced, and refers to virtual stresses corresponding to the undamaged material state. Compressive and tensile uniaxial pristine stresses are then utilized to define the yield and failure surfaces.

For actual implementation in ABAQUS, artificial plastic strain, i.e., inelastic strain

for compression (

Figure 15a) and a cracking strain

for tension (

Figure 15b) are used to replace the actual plastic strain. They are defined as

The relationship between stress

and the inelastic strain

, together with the evolution of the damage variable

with

, is used to define the uniaxial compressive response. Similarly, the relationships between

and

, and between

and

, are employed to describe uniaxial tensile behavior. The actual plastic strains can be calculated from the artificial strains and damage variables, i.e.,

When the specimen is unloaded from any point on the strain softening branch of the stress–strain curves, the elastic stiffness of the material declines.

For three-dimensional multiaxial conditions, the stress–strain relationships are govern by:

where

is the initial (undamaged) elastic stiffness of the material;

is the degraded elastic stiffness.

The mortar and ITZ parts are simulated using the CDP model. For normal concrete, the coarse aggregates are usually of much higher strength than the mortar parts. It is acceptable to use a linear elastic model for aggregates under quasi-static loading, but this may not reasonable for high dynamic loading such as impact and blast.

4.3. Verification under Quasi-static Compression and Tension

The uniaxial compression tests had been performed by Van Vliet [

47]. The test specimens were normal strength concrete, accordingly, the 3D mesoscale model is simulated in normal strength range. The concrete mix proportions in experiment are shown in

Table 4 [

47]. The grain size distribution is not absolutely identical with the experiment used as the realistic concrete includes small size gravel and sand which is really difficult to build in a numerical model and it is generally considered as mortar phase [

10,

20]. Nonetheless, if we consider the grades of 2.0–8.0 mm range, the proportions are similar to the simulation.

The basic mechanical parameters of the mesoscale concrete model used in current simulations are listed in

Table 5. For this grade of concrete, the standard strength of mortar is around 35 MPa with Young’s modulus around 25 GPa [

6,

22]. As a composite material, concrete is a mixture of cement paste, aggregate with various sizes and the ITZ. Studies by other researchers showed that the ITZ has a layered structure, and it has a lower density than the bulk matrix and is more penetrable by fluids and gases [

48]. Also, the ITZ appears to be the weakest region of the composite material when exposed to external loads [

49]. However, it is difficult to determine the local mechanical properties in the ITZ due to the complex structure of the ITZ region and the constraints of existing measuring techniques [

50]. A constant factor can be used to describe the ratio of material strength between the ITZ and mortar. Different ratio values have been employed by various researchers. The ratios employed by different works vary from 0.5 to 0.9 [

33,

36]. For such a thin layer of equivalent ITZ, it has been found that the strength around 70% of the mortar is appropriate [

51], which is acceptable for a general range.

In the current model, 20 MPa compressive strength and 18 GPa Young’s modulus are employed for the ITZ elements. The properties of aggregates could significantly depend on the types in nature, and the Young’s modulus of aggregates is around 40–60 GPa for crushed stones [

52]. Moreover, the eccentricity and the K coefficient in CDP model are set to 0.1 and 2/3, respectively. The ratio of biaxial and uniaxial compressive strength is 1.16. The viscosity coefficient is 1.0e

−5 [

53]. The density parameter is not required in the implicit solver.

The mesh convergence study had been performed before the uniaxial load analysis. In the test, three different average element lengths

(i.e., 1 mm, 0.8 mm and 0.6 mm) were used, as shown in

Figure 18. The numbers for Meshes I and II and III are 134249, 201690, and 295364 solid elements, respectively. The frictional constraint between specimen and loading plate was set as 0.1.

The simulated stress–strain curves for different element length are shown in

Figure 19. Three positions named KP1, KP2, and KP3 have been marked in

Figure 18a to evaluate the computational error. The stress analysis—including Mises Stress, Max Principal Stress, Mid Principal Stress, and Min Principal Stress—have been listed in

Table 6,

Table 7 and

Table 8. The relative error is calculated by

where

represents the Mises Stress of different mesh sizes,

is the average of

.

It can be observed that the relative error is less than 2%. As a result, the mesh dependence is negligible for the selected element sizes. Fine mesh would lead to large-scale nonlinear equation systems and the computational costs often become prohibitively expensive. Thus, a 1 mm element length is selected in the following analysis, where the mortar has 72114 elements and the aggregate has 36727 elements. The numbers for the ITZ phase have 25408 elements. As a reference regarding the computational cost, a mesh in 1 mm took about 6 h for compression and 10 h for tension with 18 Intel Xeon CPUs, respectively.

Figure 20 plots the simulated axial stress–strain curve versus experiment curve. Three loading directions of the

x-,

y- and

z- axes are taken into consideration to improve the representative of numerical model. The effective stress is measured as

, where

is the reaction force of rigid plate at the time

,

is the area of specimen surface. Respectively, effective strain is calculated as

, where

is the displacement of rigid plate at the time

and

is the length of specimen side. As can be seen, the result from the mesoscale model shows good agreement with the experimental data in terms of peak strain and softening phase. Though the peak stress is slightly lower than the corresponding test data, the relative difference between two values is 7%, which is in an acceptable range for FE validation. Remarkably, the numerical results over-predict experimental data for strains greater than 0.006. The main reason is the damaged elements are not deleted in the loading process. In lab experiments, partial concrete splits from the test specimen. The split concrete cannot sustain any loads, which eventually results in the failure of concrete. And the stress decreases to zero. In the FE analysis, the stiffness of damaged elements decreases but cannot be zero because of the computational convergence. It means that the load capacity of finite elements is over predicted compared with the realistic concrete.

It is generally known that the compressive behavior of concrete test can be strongly influenced by the frictional constraint between the specimen and the loading platen [

47]. The classical isotropic Coulomb friction model is applied in the simulation of varying frictional constraint. The model assumes that no relative motion occurs if the equivalent frictional stress

is less than the critical stress,

, which is proportional to the contact pressure,

, in the form

where

is the friction coefficient that can be defined as a function of the contact pressure.

In the current 3D mesoscale model, it is possible to simulate the varying frictional constraint by changing frictional coefficient

at the loading face through a surface-to-surface contact approach. For example, Guo et al. [

55] studied the effect of friction between the specimen and the rigid plates. As the reference mentioned, friction coefficients from 0.1 to 0.7 is realistic in experiments, which is the range we selected in this paper. Three stress-strain curves for different

mean 0, 0.1, 0.3, and 0.6 are plotted in

Figure 21. The stress–strain curve when

shows that peak stress is obviously lower than frictional constraint. The major failure regions focus on the top surface which contacts with the rigid plate directly. It can be seen that frictional constraint has a strong influence on peak stress value and the softening phase. When the frictional coefficient increases from 0.1 to 0.3, the peak stress increases to 126%. From 0.3 to 0.6, the value of maximum stress has a little increase, but the tendency after peak stress has obvious change.

Figure 22 shows the damage patterns of different

values. In CDP models, the tensile damage factor

represents the degree of stiffness degradation from 0—which means no degradation, to 1—that cannot support loading completely. In other words, the output

from the model could be equivalent to a cracking pattern in real tests when the value of

is close or equal to 1. For a low frictional constraint (

Figure 22a) condition, the specimen is obviously separated into a series of columns due to primary cracks almost parallel to the applied load. With

increasing, oblique cracks rise and cracks develop in the triangular zones near the top and bottom surfaces, leading to the well-known “hour glass” failure mode (

Figure 22b,c).

Figure 23 and

Figure 24 compare the damage evolutions with different frictional coefficients. When the

is closer to 0, no additional lateral constrains are applied in the interaction surfaces. The lateral tensile stress, which is considered to be easier to cause the damage to concrete than compressive stress, would arise and grow to the damage threshold. The connected cracks are formed from top surface to bottom surface. With the increasing of the coefficient

, the tangential constrains are applied on the top and bottom surfaces. Damage begins in the middle of the model. The tangential constrain limits the development of lateral tensile stress. Therefore, the damage elements cannot directly propagate parallel to the loading direction and develop to oblique cracks.

The comparisons of failure modes between the experiment and the simulation are plotted in

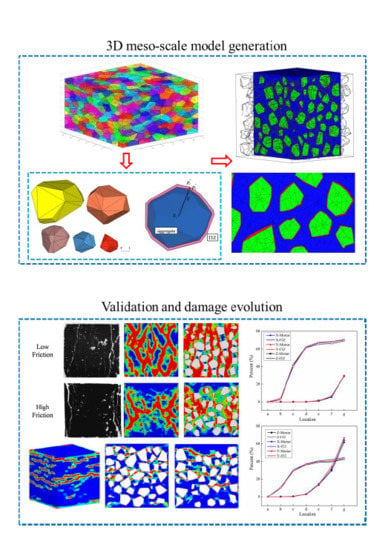

Figure 25. Under the low friction condition, the vertical cracks in the experimental picture are most visible and dominate the picture of the crack pattern. The inclined cracks have opened less than the vertical cracks and are less visible. The numerical specimen is effectively separated into a series of columns by the formation of the major cracks almost parallel to the applied load, and the cracks appear to follow the weakest path along the ITZ. Under the high friction condition, confining stresses are built up in the experiment and prevent crack formation. Cracking starts from the more uniaxially stressed sides of the test specimen and results in the well-known “hour glass” failure mode. Significant confinement develops in the cone-shaped zones in the numerical results. The damage patterns appear to follow closely the weakest links formed by the ITZ around the aggregates. The crack patterns agree well with experimental observations both in low and high friction conditions, which demonstrates that the 3D mesoscale FE model is again acceptable under compressive loading.

The data of the tension experiment came from reference [

57]. According to the reference paper, the 101 × 202 mm cylindrical tensile specimen with notches at mid-height was considered in the experiment. The top and bottom surfaces were fixed in stiff-frame by an epoxy adhesive layer. In the tensile simulation, in the present paper, a tie constraint is applied between the specimen surface and the rigid plate in order to fit the experimental boundary condition. The material parameters in the tension analysis are listed in

Table 5, No lateral constraint is considered in the simulation of tension.

Figure 26 depicts the comparison of test and simulation curves, and the corresponding crack mode is given in

Figure 27. It can be observed that the present results agree very well with the experimental data. The crack lines are clearly perpendicular to the loading direction which is a well-known phenomenon in tension failure mode. Furthermore, the failure bands can be observed clearly through the specimen and along with the distribution change of aggregates in the section patterns. Several damage lines develop along weakest path (the ITZ phase). From the viewpoint of the internal section, the cross-cutting crack is located at the middle of specimen.

4.4. Analysis of ITZ Damage Evolution

The finite element model used in this section is the same as mentioned in

Figure 20. In order to investigate the damage initiation and evolution of a 3D mesoscale model under uniaxial loading, eight key points standing for different time moments during loading history are marked in the stress–strain curves both in compressive and tension condition (

Figure 28). The stress–strain curves are divided three phases as elastic phase (a

0–a), hardening phase (a–c), and softening phase (c–g).

Figure 29 shows the initiation evolution (a–g) of the compressive damage factor

for mortar and ITZ parts. The factor

represents stiffness degradation from 0—with no degradation, to 1—with complete failure subjected to compressive stress. From the pictures, initial damage appears in the ITZ part firstly, and then the damage in the ITZ grows and expands to more areas. With the damage area reaching a certain range in ITZ elements, the damage bands tend to propagate towards nearby mortar parts to form a connected damage network with complicated crack bridging and branching. The process illustrates that the evolution of compressive damage starts at ITZ parts, which is considered as a weaker phase in concrete, and develops into mortar phase. The similar process is shown in

Figure 30 for tensile damage factor

. However, the damage range is really different in both the mortar and ITZ phases. The compressive and tensile damage region of the ITZ phase is plotted in

Figure 31. From the specific ITZ elements around a single aggregate, compressive damage mainly distributes on the top and bottom region, while tensile damage focuses on the medium region. That means the stress state is clearly different around single aggregates under compression. The element where the computational factor

or

is greater than 0.9 is defined as an damaged element. A damaged fraction is defined as a ratio of damaged element and whole element within one material. The percentage curves of the mortar and ITZ phases under compressive condition are shown in

Figure 32. Damage firstly starts in the ITZ phase and develops, while mortar phase has no damaged element until the ITZ fraction increases to a high value (almost 65% from

Figure 32a). Moreover, the damaged fraction in ITZ elements is over two times that of mortar elements, which means that compressive damage mainly takes place in ITZ parts. Compared with

Figure 32a, the tensile damage fraction in the mortar phase quickly increased especially on the softening range (f–g) and is higher than in the ITZ phase. In other words, tensile damage is the main cause of mortar failure. On the contrary, compressive damage is the main cause of ITZ failure from the mesoscale viewpoint. Combined with the stress–strain curve, the damaged element in the ITZ part has a quick increase around macro maximum stress. On the contrary, damaged elements in the mortar are generated until the softening phase.

Figure 33 plots the initiation and evolution of the tensile damage factor

under an uniaxial tensile load. Initial damage starts from ITZ parts and develops to the mortar. Different from compression, the propagation range clearly concentrates on bends which is perpendicular to the loading direction. The damage diagram of whole ITZ element is plotted in

Figure 34. Tensile damage focuses on the top and bottom areas around single aggregates; while in compressive condition, compressive damage occurs here. The volume percentage of tensile damaged element is shown in

Figure 35. The damaged elements have a great increment in the initial softening phase. About half of ITZ elements are damaged due to the weakness of ITZ properties. The result demonstrates that tensile damage is the primary cause of ITZ failure. As quite localized cracks could lead to concrete failure, the damaged element in mortar is much less than in the ITZ under tensile loading.