Development of Nano-SiO2 and Bentonite-Based Mortars for Corrosion Protection of Reinforcing Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Mixture Design

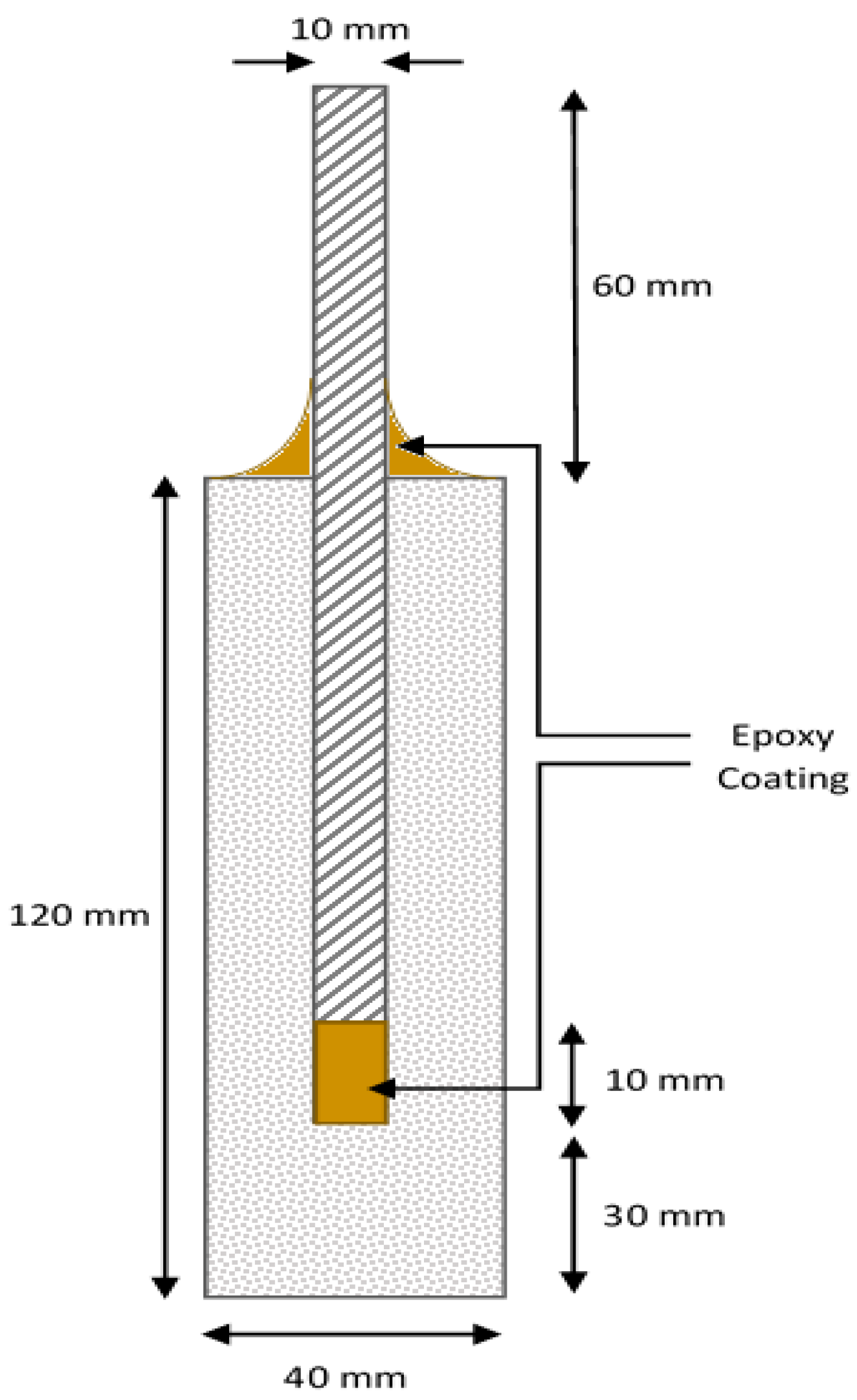

2.2. Specimen Preparation

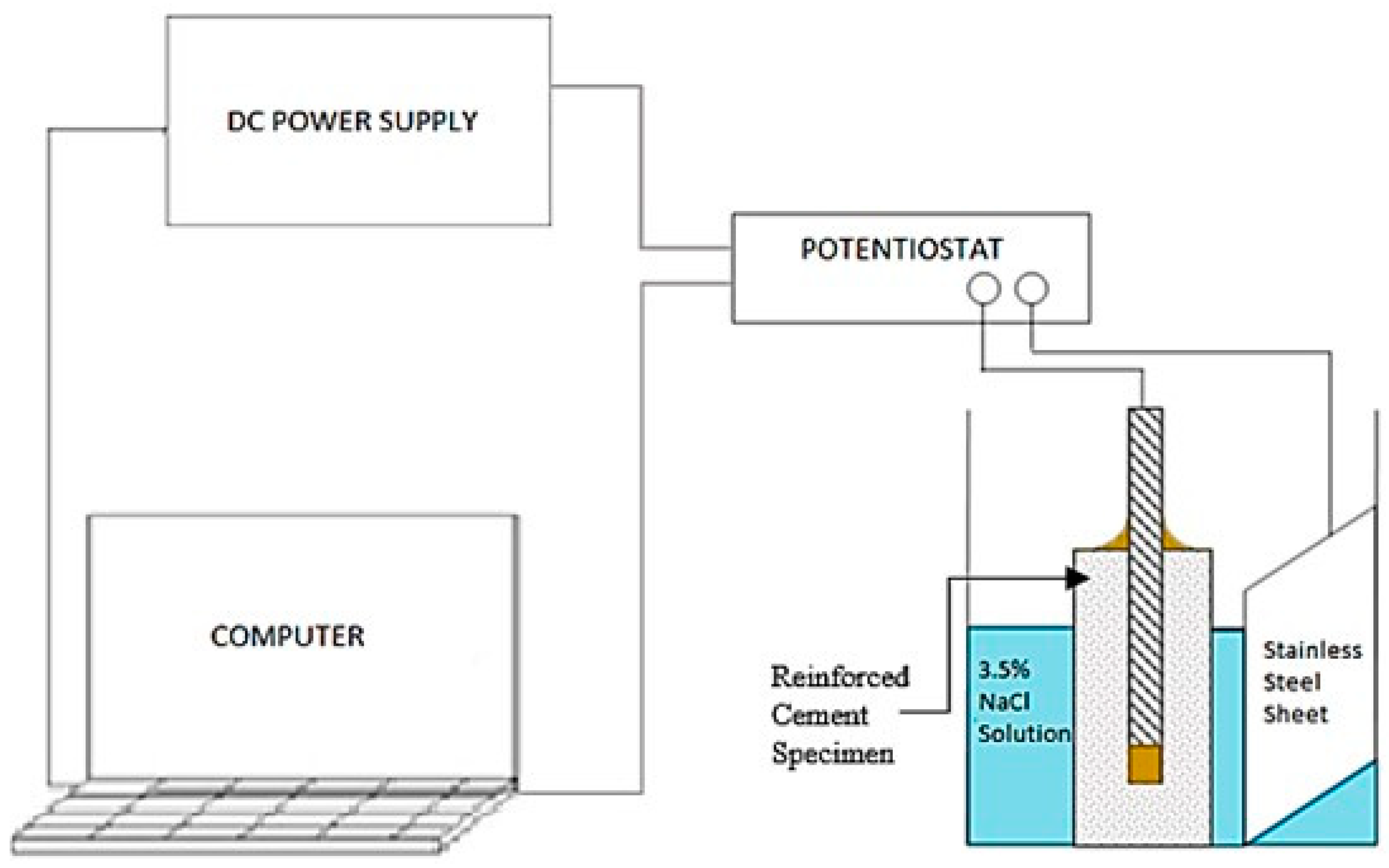

2.3. Accelerated Corrosion Testing

3. Results and Discussion

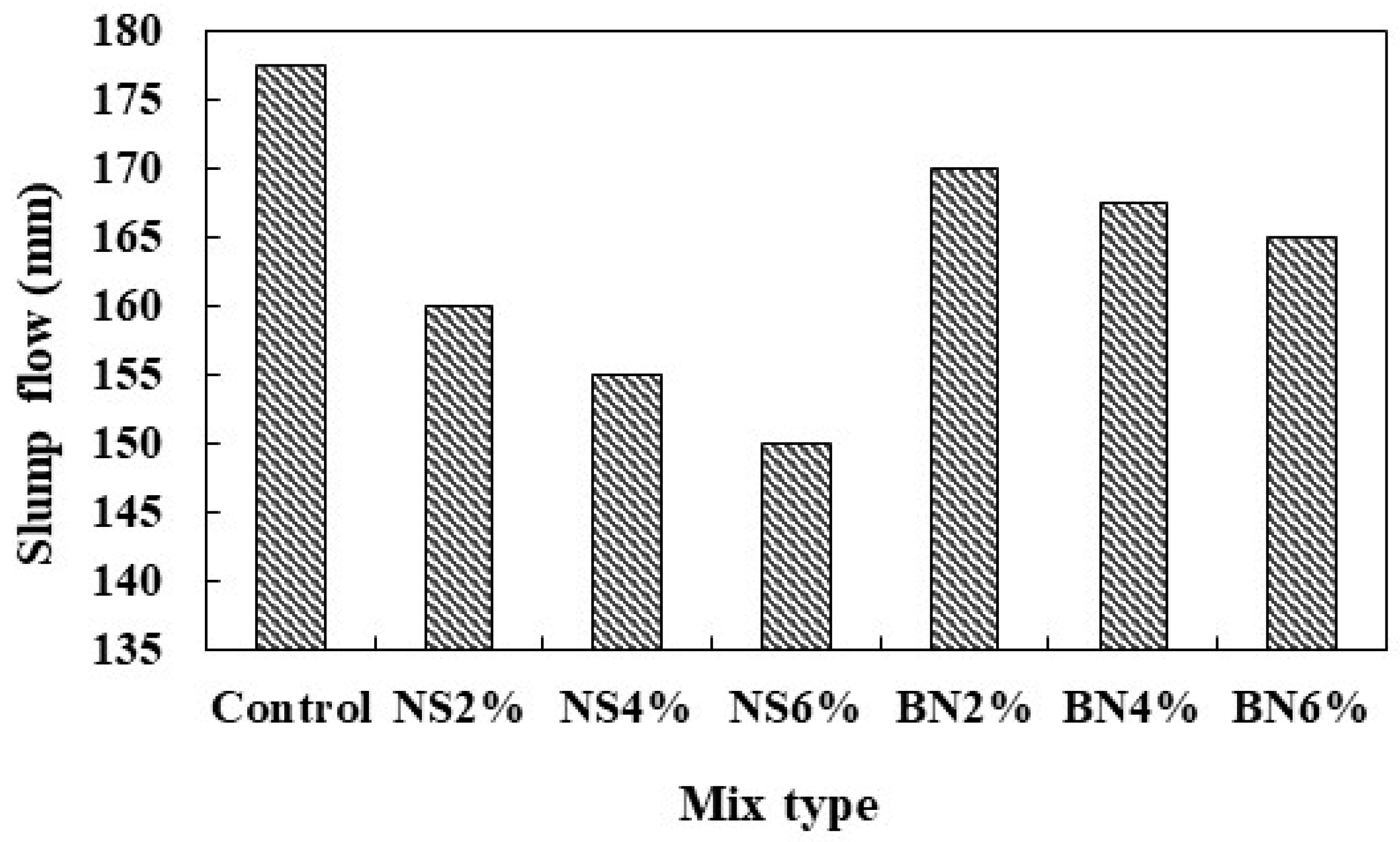

3.1. Slump Flow

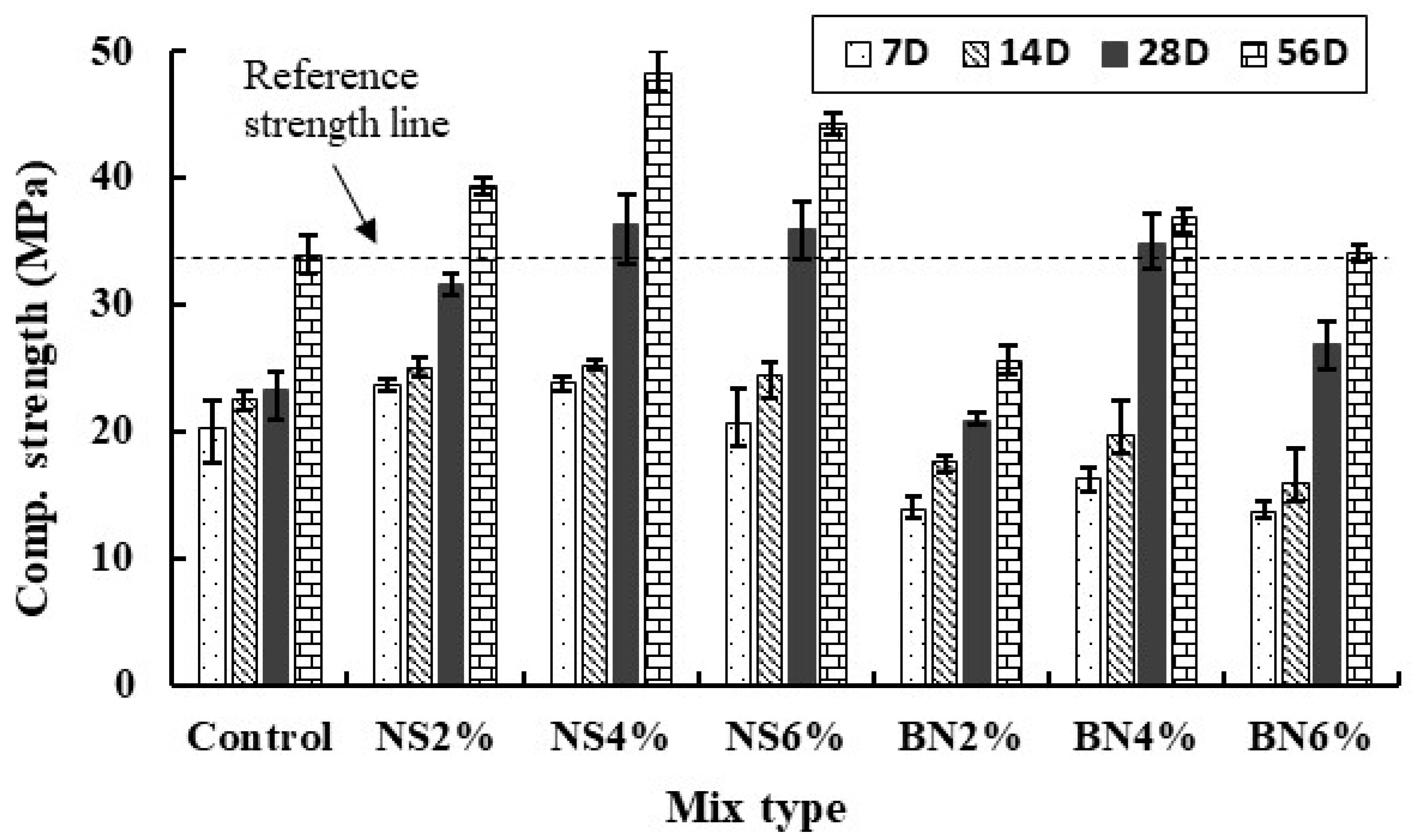

3.2. Compressive Strength

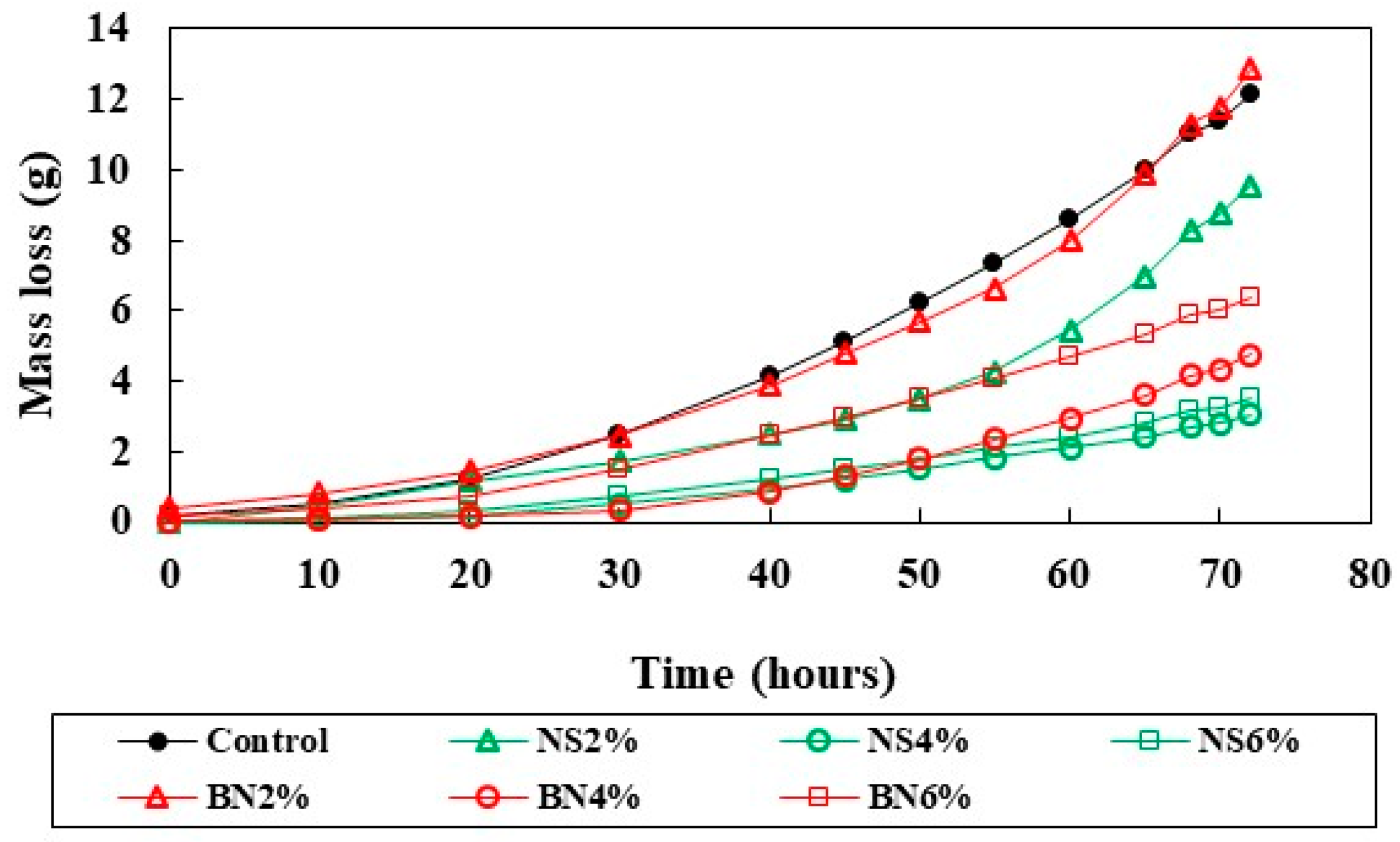

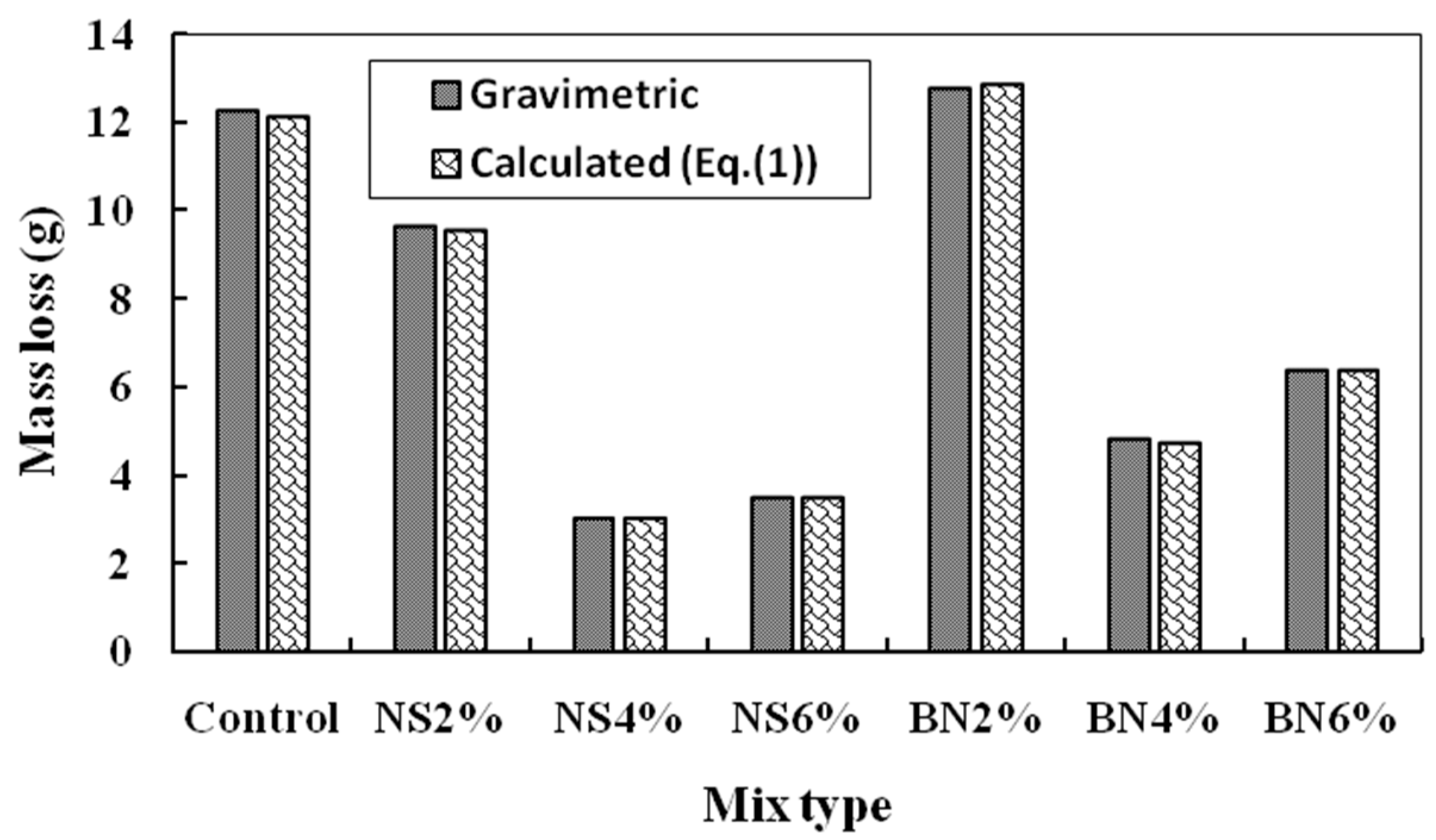

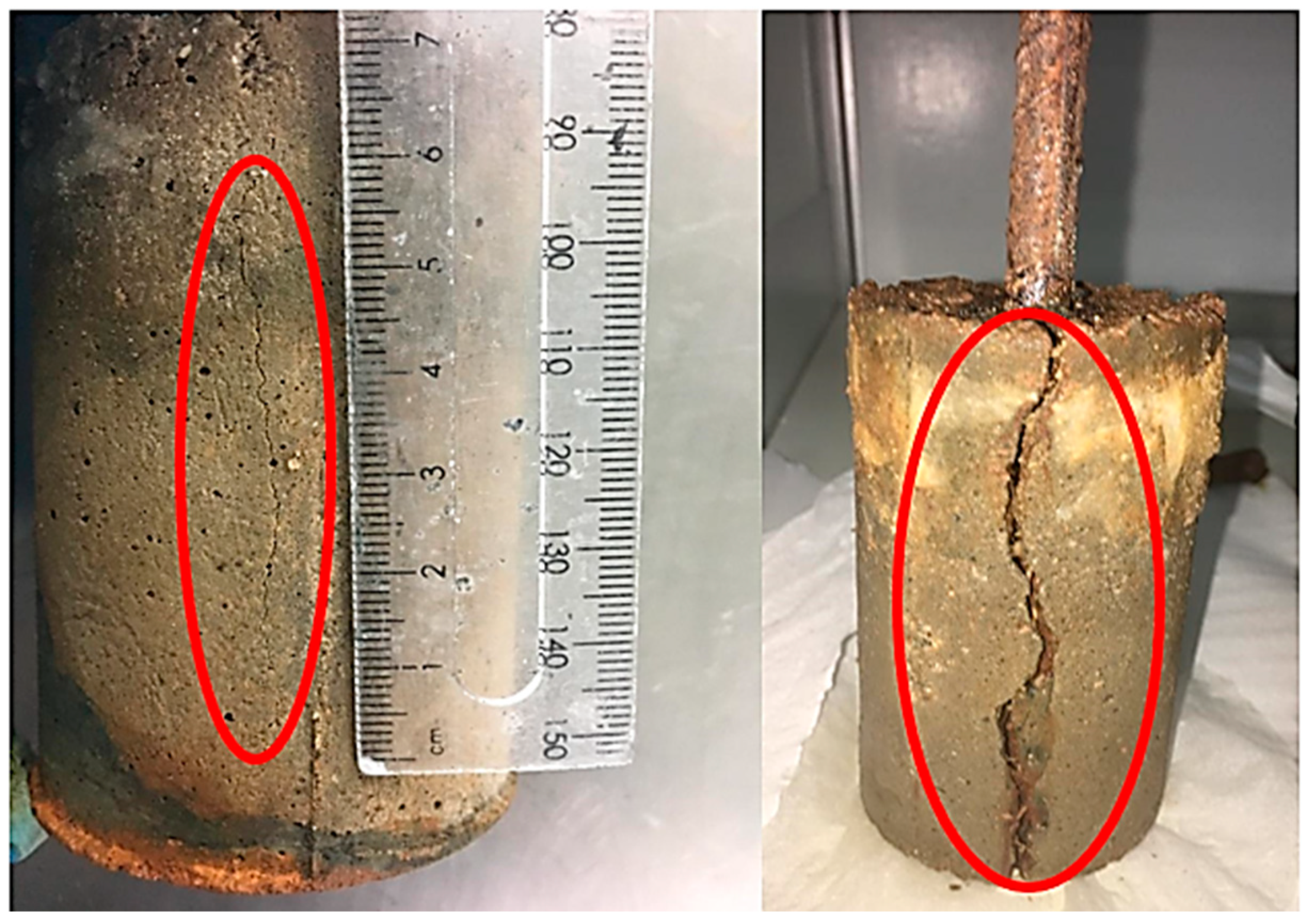

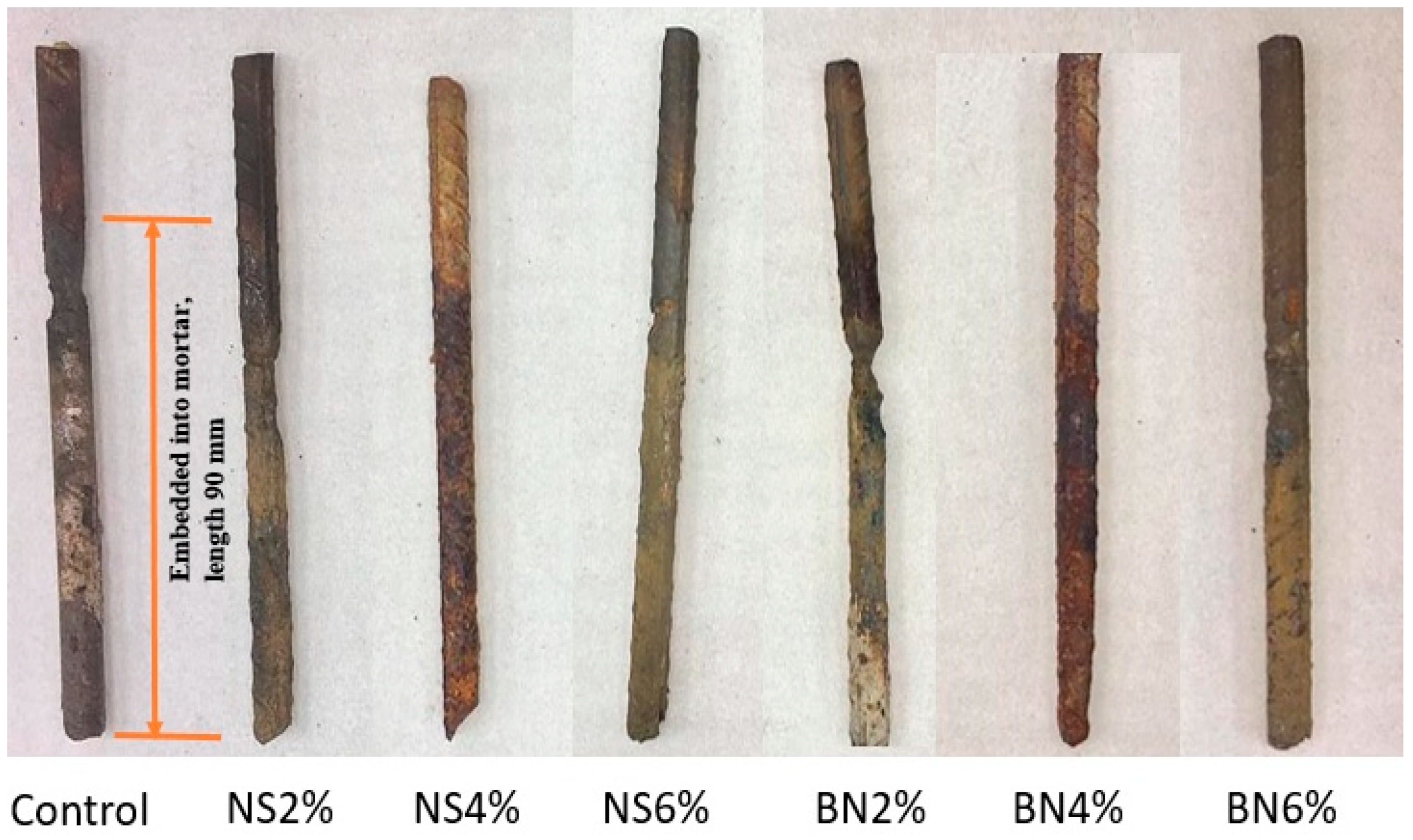

3.3. Mass Loss Due to Corrosion

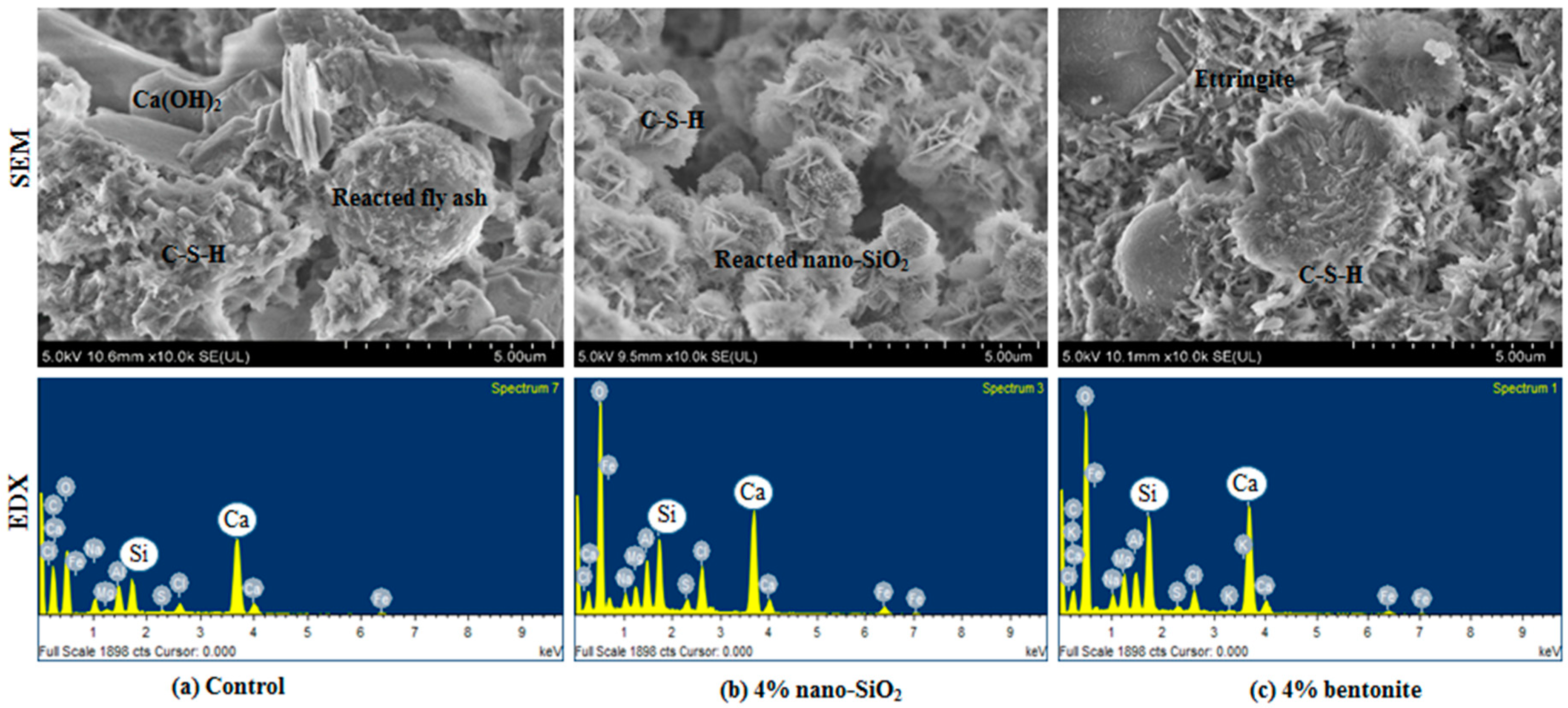

3.4. Microstructural Analysis

4. Conclusions

- Addition of nano-SiO2 and bentonite increases the compressive strength of the mortar. However, strength may decrease if the dosages higher than a certain amount are used. In this study, at 56 days, 4% nano-SiO2 and bentonite dosages (% replacement by cement weight) showed about 42% and 8.5% higher compressive strengths, respectively, than the control mortar mix;

- Mortar mixes with 30% of cement replacement by the fly ash show higher strength development at longer curing period, i.e., at 56 days. This is expected due to slow pozzolanic reaction of fly ash. However, addition of nano-SiO2 and bentonite can accelerate the hydration process of cement and fly ash based mortar and provides high early strength;

- Nano-silica and bentonite mixtures had lower Ca/Si ratios (about 25% and 11% lower), corresponding to higher compressive strength compared to control specimens. This is in accordance with known literature;

- Similar to compressive strength, lower steel mass loss due to corrosion was also found in the mortar specimens containing 4% of nano-SiO2(about 75% and 60% lower). Similarly, the corrosion induced crack length, width and pitting depth were also lower in 4% nano-SiO2 specimens. No improvement in corrosion resistance was found with 2% bentonite dosages. However, with higher dosages, a noticeable difference was found when compared with the control mortar mix.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bertolini, L.; Elsener, B.; Pedeferri, P.; Redaelli, E.; Polder, R. Corrosion of Steel in Concrete; Wiley-Vch: Weinheim, Germany, 2004. [Google Scholar]

- Böhni, H. Corrosion in Reinforced Concrete Structures; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Broomfield, J.P. Corrosion of Steel in Concrete: Understanding, Investigation and Repair; Taylor & Francis: New York, NY, USA, 2007. [Google Scholar]

- Angst, U.; Elsener, B.; Larsen, C.K.; Vennesland, Ø. Critical chloride content in reinforced concrete—A review. Cement Concr. Res. 2009, 39, 1122–1138. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M. Carbonation of cement paste: Understanding, challenges, and opportunities. Constr. Build. Mater. 2016, 117, 285–301. [Google Scholar] [CrossRef]

- Stefanoni, M.; Angst, U.; Elsener, B. Corrosion rate of carbon steel in carbonated concrete–A critical review. Cement Concr. Res. 2018, 103, 35–48. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M.; Hosseini, S.A.S.; Pacheco, J.; Schlangen, E. Corrosion induced cover cracking studied by X-ray computed tomography, nanoindentation, and energy dispersive X-ray spectrometry (EDS). Mater. Struct. 2015, 48, 2043–2062. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M.; Pacheco, J.; Schlangen, E. Cracking of the concrete cover due to reinforcement corrosion: a two-dimensional lattice model study. Constr. Build. Mater. 2013, 44, 626–638. [Google Scholar] [CrossRef]

- Blagojević, A. The Influence of Cracks on the Durability and Service Life of Reinforced Concrete Structures in Relation to Chloride-Induced Corrosion. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2016. [Google Scholar]

- Yoon, S.; Wang, K.; Weiss, W.J.; Shah, S.P. Interaction between loading, corrosion, and serviceability of reinforced concrete. Mater. J. 2000, 97, 637–644. [Google Scholar]

- Cabrera, J. Deterioration of concrete due to reinforcement steel corrosion. Cement Concr. Compos. 1996, 18, 47–59. [Google Scholar] [CrossRef]

- Fang, C.; Lundgren, K.; Chen, L.; Zhu, C. Corrosion influence on bond in reinforced concrete. Cement Concr. Res. 2004, 34, 2159–2167. [Google Scholar] [CrossRef]

- François, R.; Khan, I.; Dang, V.H. Impact of corrosion on mechanical properties of steel embedded in 27-year-old corroded reinforced concrete beams. Mater. Struct. 2013, 46, 899–910. [Google Scholar] [CrossRef]

- Yang, Z.; Fischer, H.; Polder, R. Laboratory investigation of the influence of two types of modified hydrotalcites on chloride ingress into cement mortar. Cement Concr. Compos. 2015, 58, 105–113. [Google Scholar] [CrossRef]

- Chung, D. Corrosion control of steel-reinforced concrete. J. Mater. Eng. Perform. 2000, 9, 585–588. [Google Scholar] [CrossRef]

- Smith, J.; Virmani, Y.P. Materials and Methods for Corrosion Control of Reinforced and Prestressed Concrete Structures in New Construction; Federal Highway Administration: Washington, DC, USA, 2000.

- Von Baeckmann, W.; Schwenk, W.; Prinz, W. Handbook of Cathodic Corrosion Protection; Gulf Professional Publishing: Houston, TX, USA, 1997. [Google Scholar]

- Koleva, D.; De Wit, J.; Van Breugel, K.; Lodhi, Z.; Van Westing, E. Investigation of corrosion and cathodic protection in reinforced concrete I. Application of electrochemical techniques. J. Electrochem. Soc. 2007, 154, P52–P61. [Google Scholar] [CrossRef]

- Koleva, D.; Guo, Z.; Van Breugel, K.; De Wit, J. Conventional and pulse cathodic protection of reinforced concrete: Electrochemical behavior of the steel reinforcement after corrosion and protection. Mater. Corros. 2009, 60, 344–354. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete–a review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Paul, S.C.; van Rooyen, A.S.; van Zijl, G.P.; Petrik, L.F. Properties of cement-based composites using nanoparticles: A comprehensive review. Constr. Build. Mater. 2018, 189, 1019–1034. [Google Scholar] [CrossRef]

- Björnström, J.; Martinelli, A.; Matic, A.; Börjesson, L.; Panas, I. Accelerating effects of colloidal nano-silica for beneficial calcium–silicate–hydrate formation in cement. Chem. Phys. Lett. 2004, 392, 242–248. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Singh, L.; Karade, S.; Bhattacharyya, S.; Yousuf, M.; Ahalawat, S. Beneficial role of nanosilica in cement based materials–A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Aggarwal, P.; Singh, R.P.; Aggarwal, Y. Use of nano-silica in cement based materials—A review. Cogent Eng. 2015, 2, 1078018. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R. Supplementary cementitious materials. Cement Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Paul, S.C.; Mbewe, P.B.; Kong, S.Y.; Šavija, B. Agricultural Solid Waste as Source of Supplementary Cementitious Materials in Developing Countries. Materials 2019, 12, 1112. [Google Scholar] [CrossRef] [PubMed]

- Paul, S.C.; Šavija, B.; Babafemi, A.J. A comprehensive review on mechanical and durability properties of cement-based materials containing waste recycled glass. J. Clean. Prod. 2018, 198, 891–906. [Google Scholar] [CrossRef]

- Memon, S.A.; Arsalan, R.; Khan, S.; Lo, T.Y. Utilization of Pakistani bentonite as partial replacement of cement in concrete. Constr. Build. Mater. 2012, 30, 237–242. [Google Scholar] [CrossRef]

- Mirza, J.; Riaz, M.; Naseer, A.; Rehman, F.; Khan, A.; Ali, Q. Pakistani bentonite in mortars and concrete as low cost construction material. Appl. Clay Sci. 2009, 45, 220–226. [Google Scholar] [CrossRef]

- Lorenz, W.; Mansfeld, F. Determination of corrosion rates by electrochemical DC and AC methods. Corros. Sci. 1981, 21, 647–672. [Google Scholar] [CrossRef]

- Paul, S.C.; Babafemi, A.J.; Conradie, K.; van Zijl, G.P. Applied voltage on corrosion mass loss and cracking behavior of steel-reinforced SHCC and mortar specimens. J. Mater. Civ. Eng. 2016, 29, 04016272. [Google Scholar] [CrossRef]

- Sahmaran, M.; Li, V.C.; Andrade, C. Corrosion resistance performance of steel-reinforced engineered cementitious composite beams. ACI Mater. J. 2008, 105, 243. [Google Scholar]

- Yang, Z.; Polder, R.; Mol, J.; Andrade, C. The effect of two types of modified Mg-Al hydrotalcites on reinforcement corrosion in cement mortar. Cement Concr. Res. 2017, 100, 186–202. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Karaboğa, F.; Mermerdaş, K. Corrosion behavior of reinforcing steel embedded in chloride contaminated concretes with and without metakaolin. Compos. Part B Eng. 2013, 45, 1288–1295. [Google Scholar] [CrossRef]

- Hou, P.-K.; Kawashima, S.; Wang, K.-J.; Corr, D.J.; Qian, J.-S.; Shah, S.P. Effects of colloidal nanosilica on rheological and mechanical properties of fly ash–cement mortar. Cement Concr. Compos. 2013, 35, 12–22. [Google Scholar] [CrossRef]

- Abyaneh, M.R.Z.; Mousavi, S.M.; Mehran, A.; Hoseini, S.M.M.; Naderi, S.; Irandoost, F.M. Effects of nano-silica on permeability of concrete and steel bars reinforcement corrosion. Aust. J. Basic Appl. Sci. 2013, 7, 464–467. [Google Scholar]

- Ji, T. Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2. Cement Concr. Res. 2005, 35, 1943–1947. [Google Scholar] [CrossRef]

- Jo, B.-W.; Kim, C.-H.; Tae, G.-h.; Park, J.-B. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Nili, M.; Ehsani, A. Investigating the effect of the cement paste and transition zone on strength development of concrete containing nanosilica and silica fume. Mater. Des. 2015, 75, 174–183. [Google Scholar] [CrossRef]

- Hou, P.-K.; Wang, K.-J.; Qian, J.-S.; Kawashima, S.; Kong, D.; Shah, S.P. Effect of colloidal nanoSiO2 on fly ash hydration. Cement Concr. Compos. 2012, 34, 1095–1103. [Google Scholar] [CrossRef]

- Hou, P.; Kawashima, S.; Kong, D.; Corr, D.J.; Qian, J.; Shah, S.P. Modification effects of colloidal nanoSiO2 on cement hydration and its gel property. Compos. Part B Eng. 2013, 45, 440–448. [Google Scholar] [CrossRef]

- Paul, S.C. The role of cracks and chlorides in corrosion of reinforced strain hardening cement-based composites (R/SHCC). Ph.D Thesis, Stellenbosch University, Stellenbosch, South Africa, 2015. [Google Scholar]

- Šavija, B. Experimental and numerical investigation of chloride ingress in cracked concrete. Ph.D Thesis, Delft University of Technology, Delft, The Netherlands, 2014. [Google Scholar]

- Chen, J.; Kou, S.-C.; Poon, C.-S. Hydration and properties of nano-TiO2 blended cement composites. Cement Concr. Compos. 2012, 34, 642–649. [Google Scholar] [CrossRef]

- Hosseini, P.; Booshehrian, A.; Farshchi, S. Influence of nano-SiO2 addition on microstructure and mechanical properties of cement mortars for ferrocement. Transp.Res. Rec. 2010, 2141, 15–20. [Google Scholar] [CrossRef]

- Krakowiak, K.J.; Thomas, J.J.; Musso, S.; James, S.; Akono, A.-T.; Ulm, F.-J. Nano-chemo-mechanical signature of conventional oil-well cement systems: Effects of elevated temperature and curing time. Cement Concr. Res. 2015, 67, 103–121. [Google Scholar] [CrossRef]

- Kunther, W.; Ferreiro, S.; Skibsted, J. Influence of the Ca/Si ratio on the compressive strength of cementitious calcium–silicate–hydrate binders. J. Mater. Chem. A 2017, 5, 17401–17412. [Google Scholar] [CrossRef]

| Materials (kg/m3) | Control | NS2% | NS4% | NS6% | BN2% | BN4% | BN6% |

|---|---|---|---|---|---|---|---|

| Fly ash (class F) | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Cement (OPC CEM I 42.5) | 280 | 272 | 264 | 256 | 272 | 264 | 256 |

| Nano-silica | 0 | 8 | 16 | 24 | 0 | 0 | 0 |

| Bentonite | 0 | 0 | 0 | 0 | 8 | 16 | 24 |

| Sand | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Water | 194 | 194 | 194 | 194 | 194 | 194 | 194 |

| Specimen | Crack Length (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Control | NS2% | NS4% | NS6% | BN2% | BN4% | BN6% | |

| 1 | 120 | 75 | 60 | 68.5 | 100 | 72.5 | 90 |

| 2 | 112 | 70 | 60 | 70 | 105 | 70 | 85 |

| Average | 116 | 72.5 | 60 | 69.25 | 102.5 | 71.25 | 87.5 |

| Mixture | Average Maximum Pitting Depth (mm) |

|---|---|

| Control | 4 |

| NS2% | 4 |

| NS4% | 1 |

| NS6% | 3 |

| BN2% | 7 |

| BN4% | 4 |

| BN6% | 3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karunarathne, V.K.; Paul, S.C.; Šavija, B. Development of Nano-SiO2 and Bentonite-Based Mortars for Corrosion Protection of Reinforcing Steel. Materials 2019, 12, 2622. https://doi.org/10.3390/ma12162622

Karunarathne VK, Paul SC, Šavija B. Development of Nano-SiO2 and Bentonite-Based Mortars for Corrosion Protection of Reinforcing Steel. Materials. 2019; 12(16):2622. https://doi.org/10.3390/ma12162622

Chicago/Turabian StyleKarunarathne, Venura Kiloshana, Suvash Chandra Paul, and Branko Šavija. 2019. "Development of Nano-SiO2 and Bentonite-Based Mortars for Corrosion Protection of Reinforcing Steel" Materials 12, no. 16: 2622. https://doi.org/10.3390/ma12162622

APA StyleKarunarathne, V. K., Paul, S. C., & Šavija, B. (2019). Development of Nano-SiO2 and Bentonite-Based Mortars for Corrosion Protection of Reinforcing Steel. Materials, 12(16), 2622. https://doi.org/10.3390/ma12162622