Microwave Sintering of Alumina at 915 MHz: Modeling, Process Control, and Microstructure Distribution

Abstract

:1. Introduction

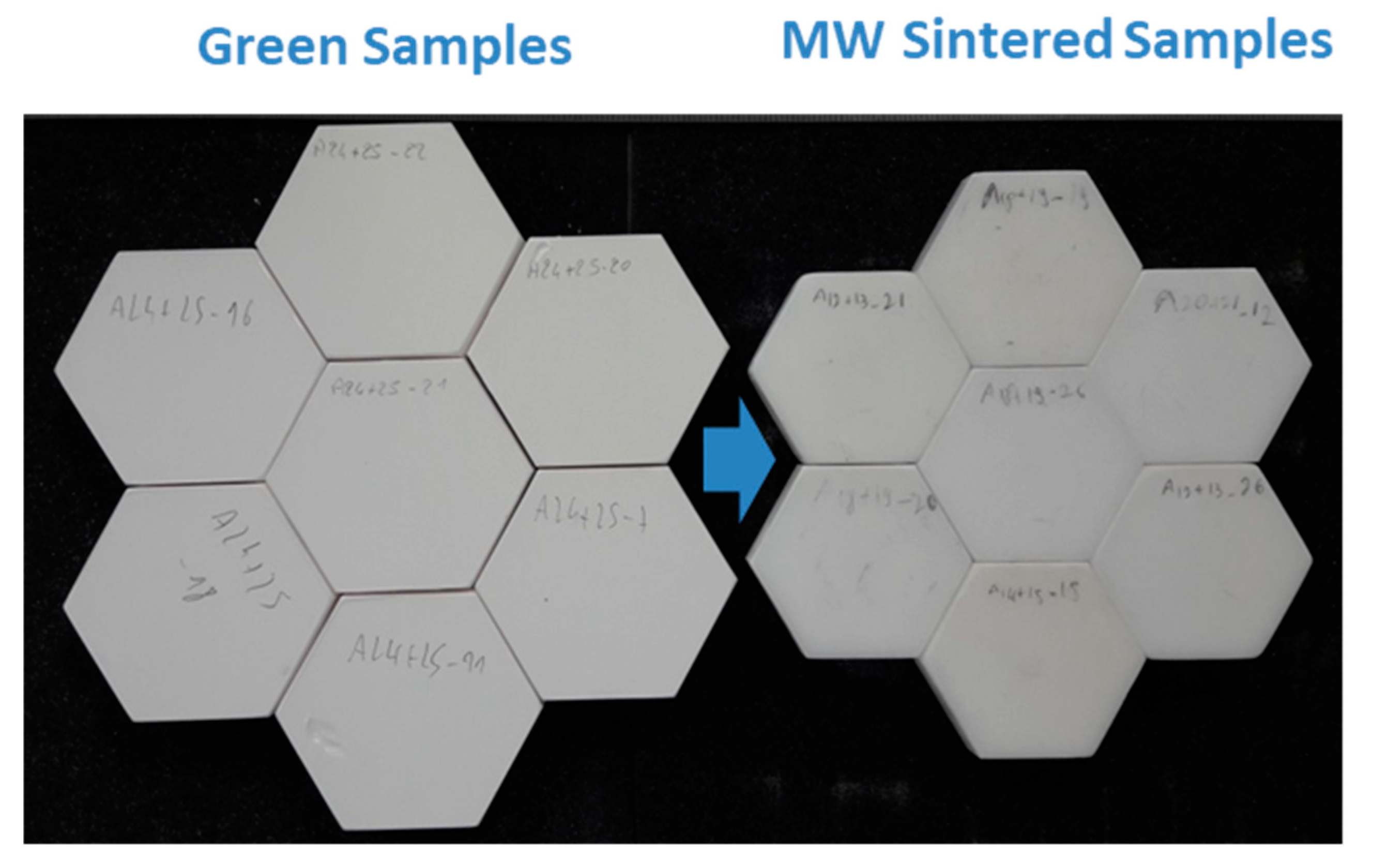

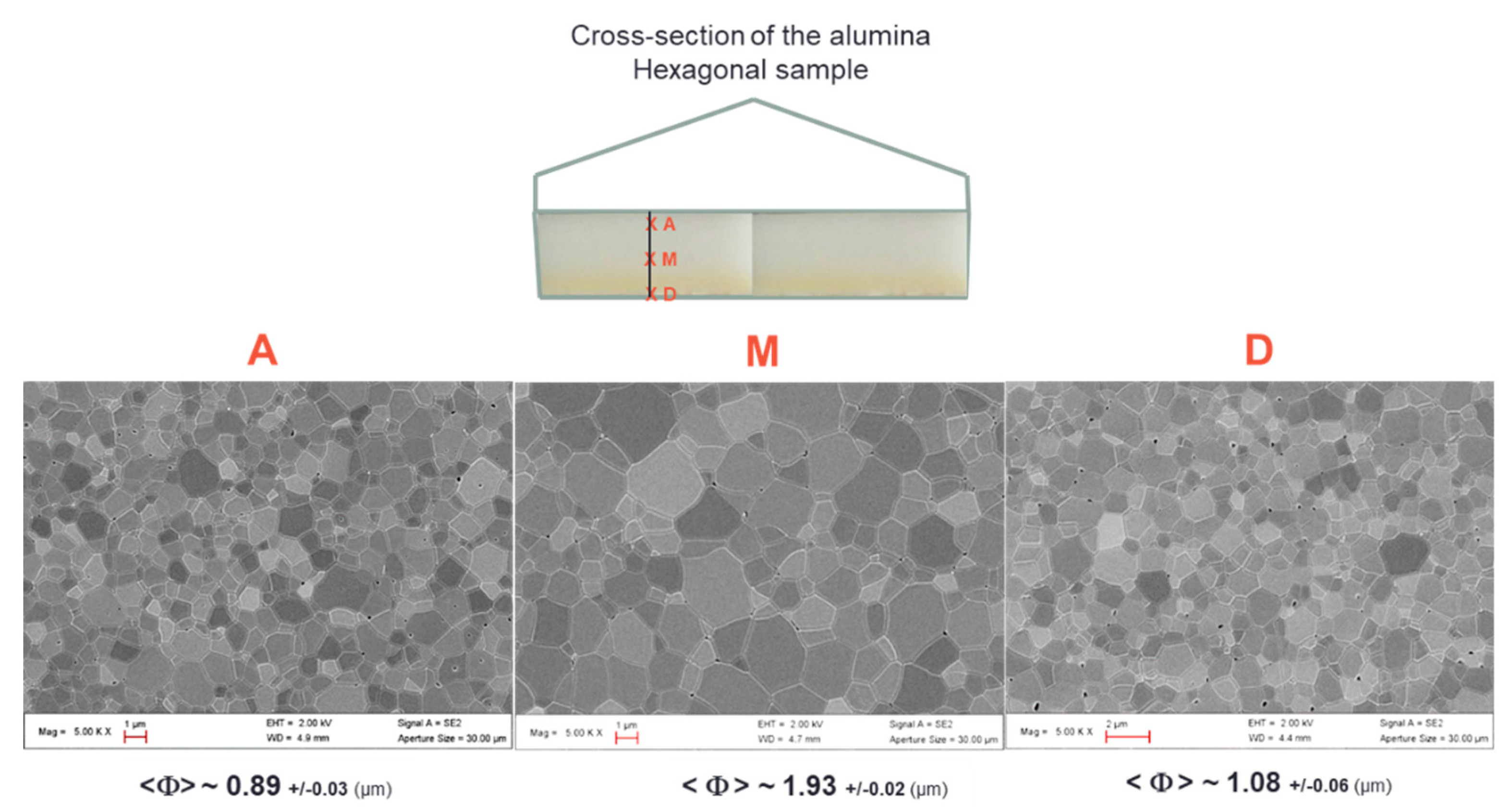

2. Experimental

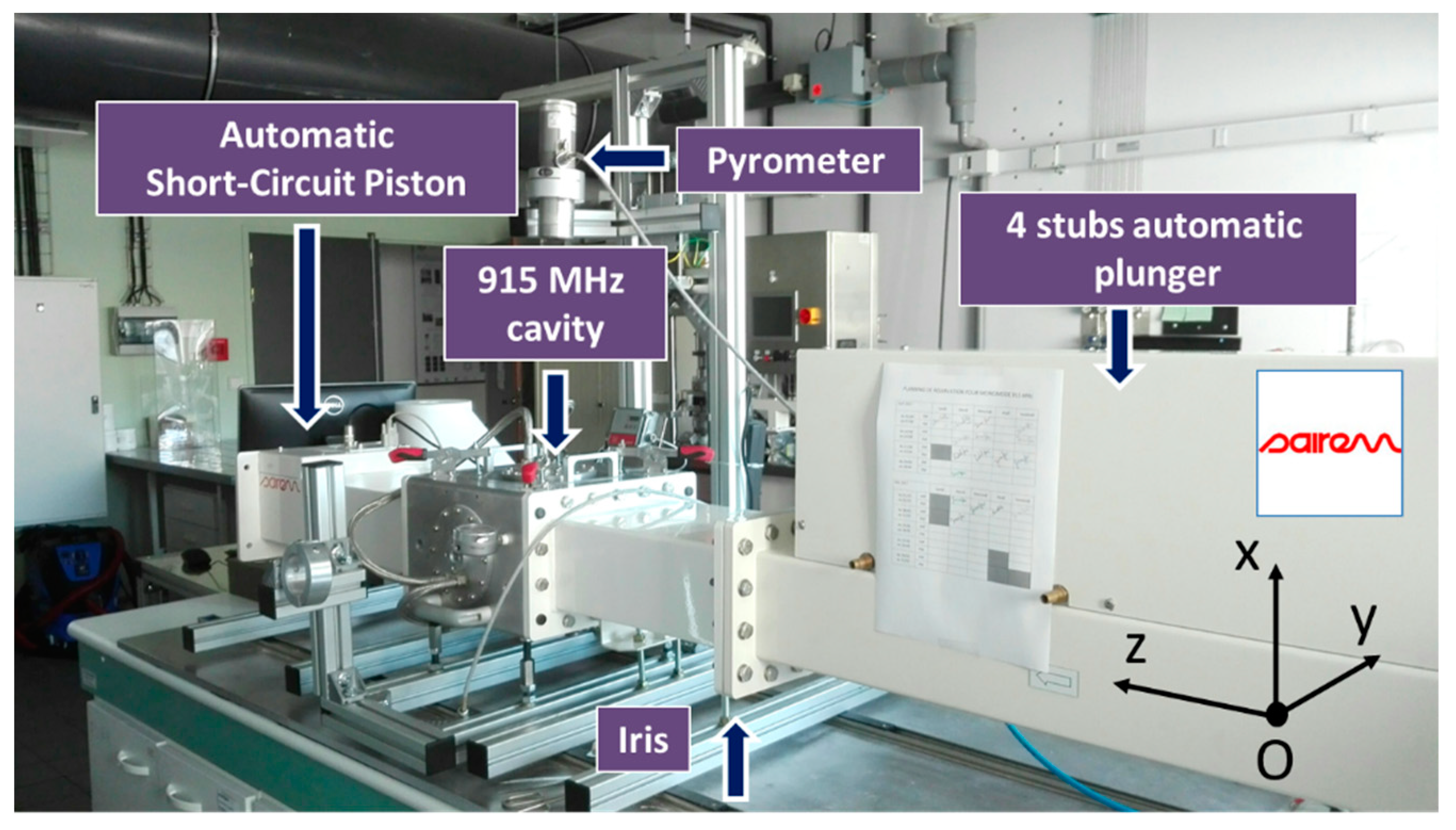

2.1. Experimental 915 MHz Equipment

2.2. Numerical Analysis

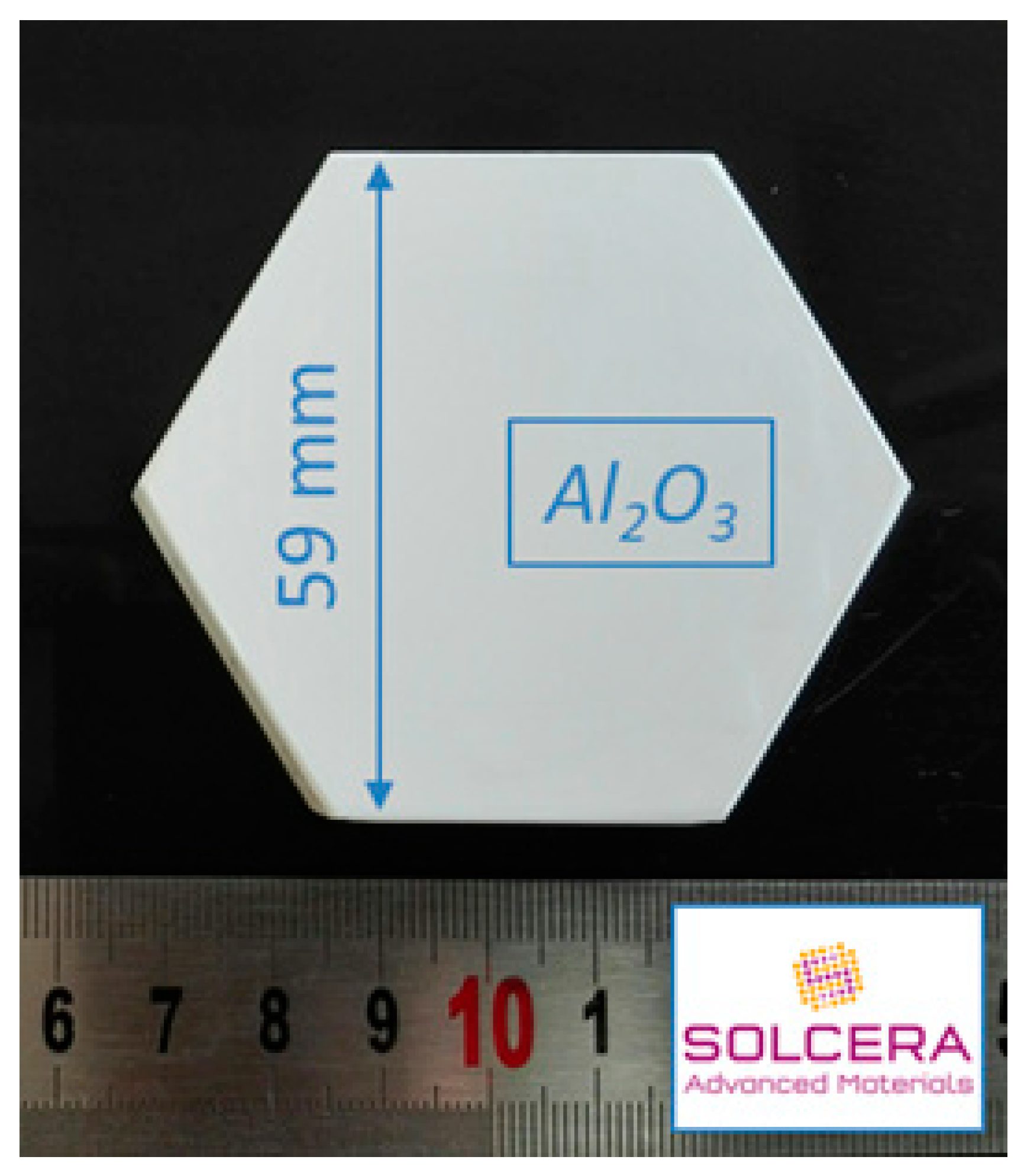

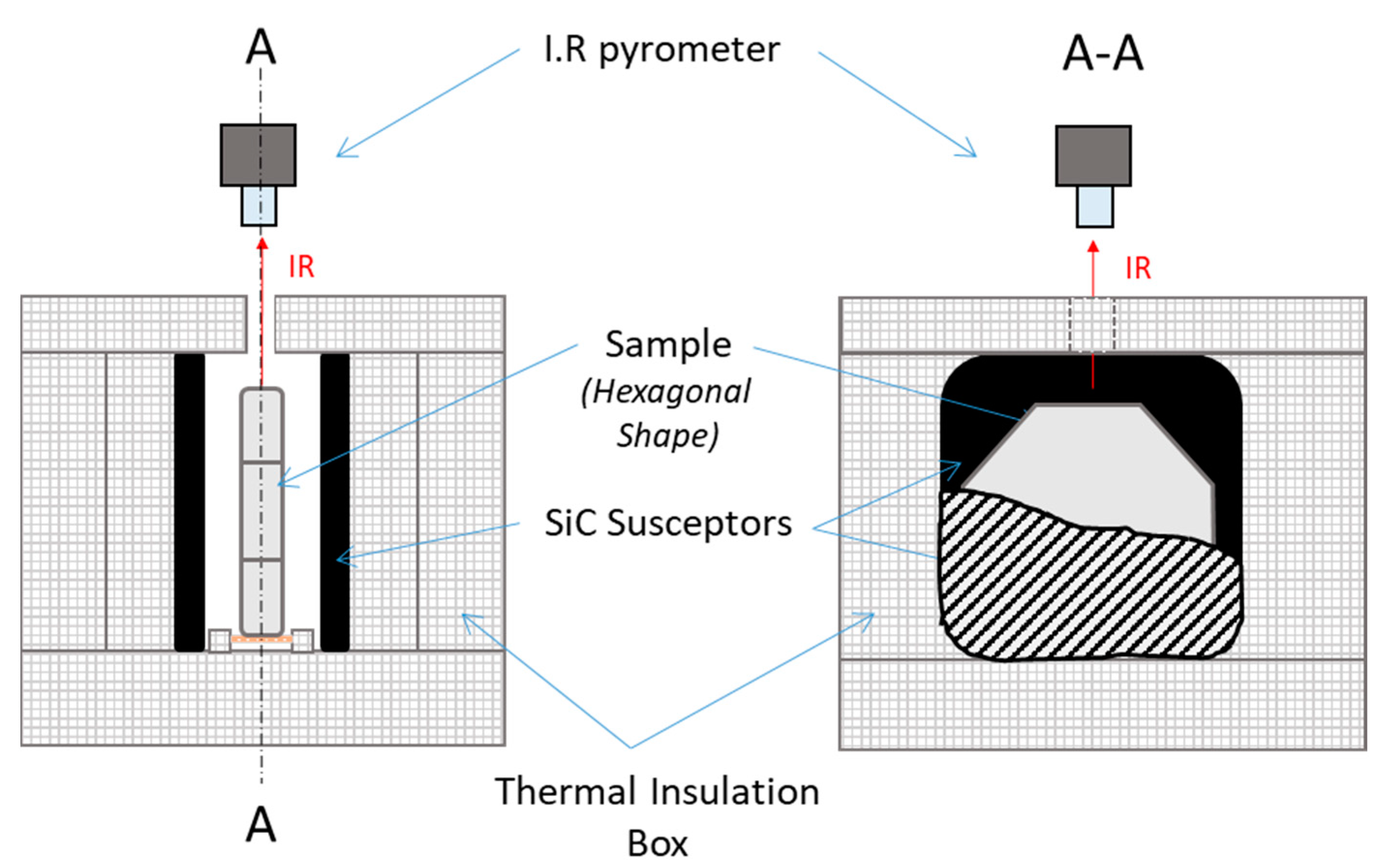

2.3. Materials Preparation and Characterization and the Microwave Assembly

3. Results and Discussions

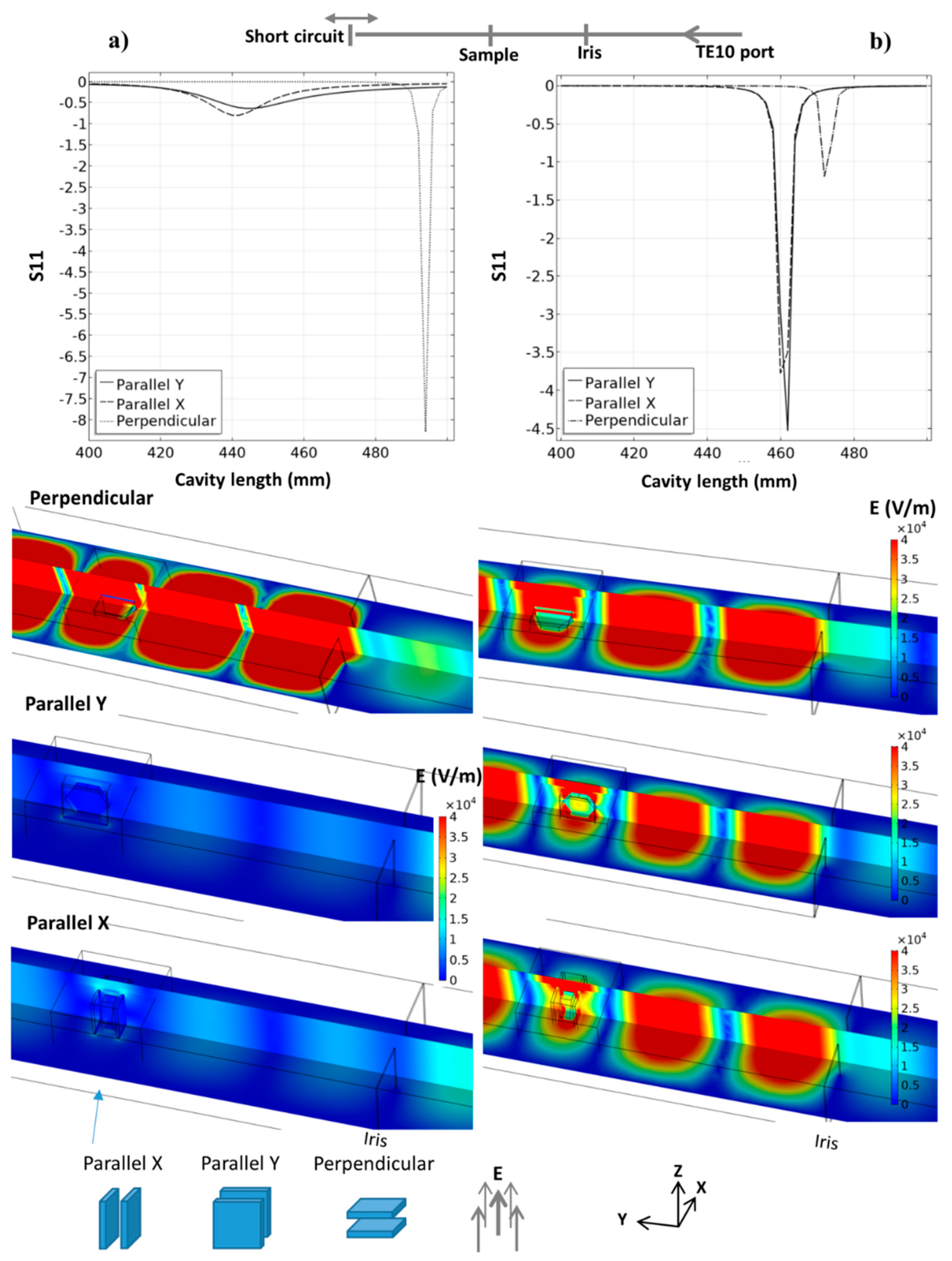

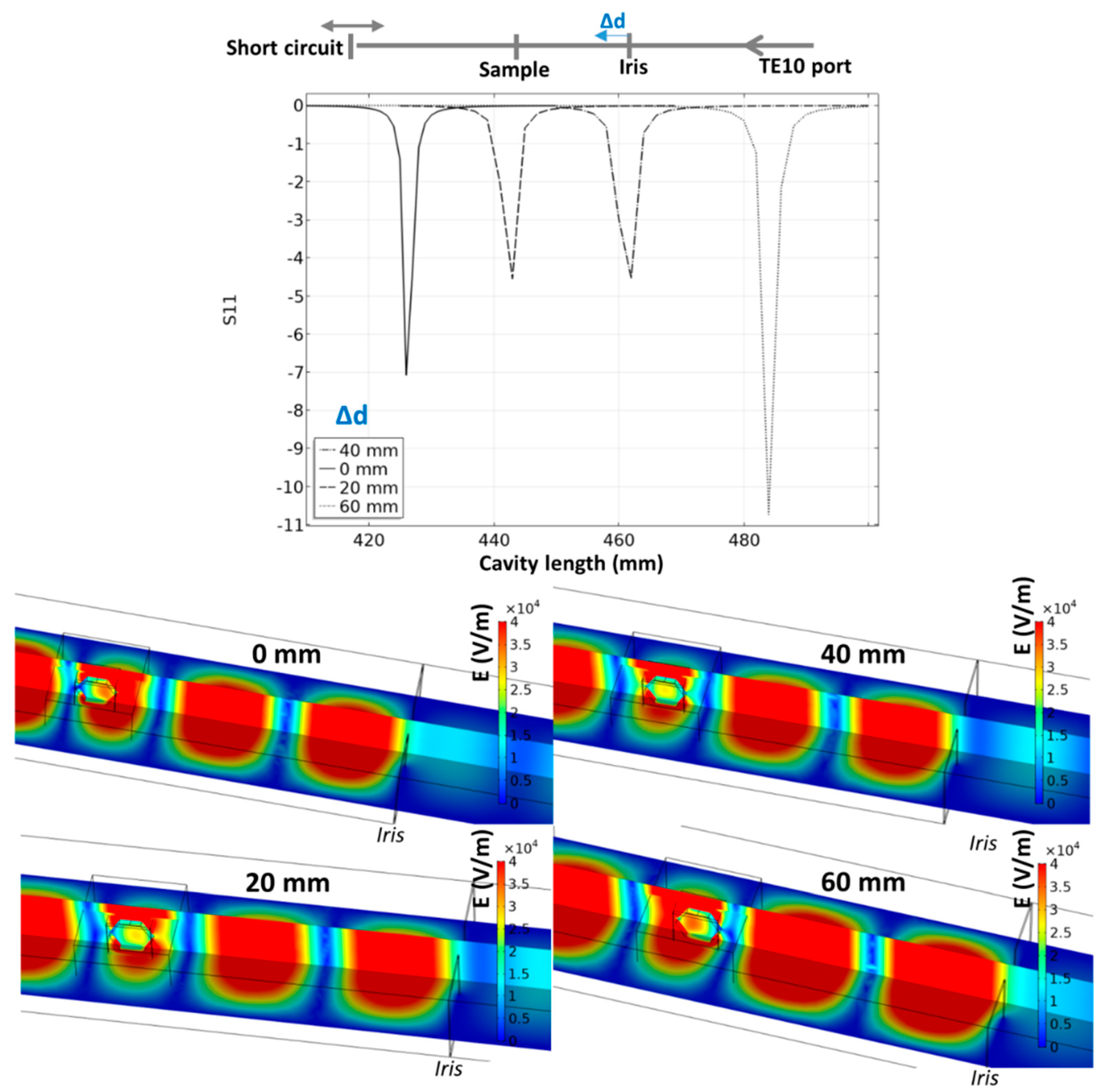

3.1. Microwave Cavity

3.2. Simulated Microwave Heating

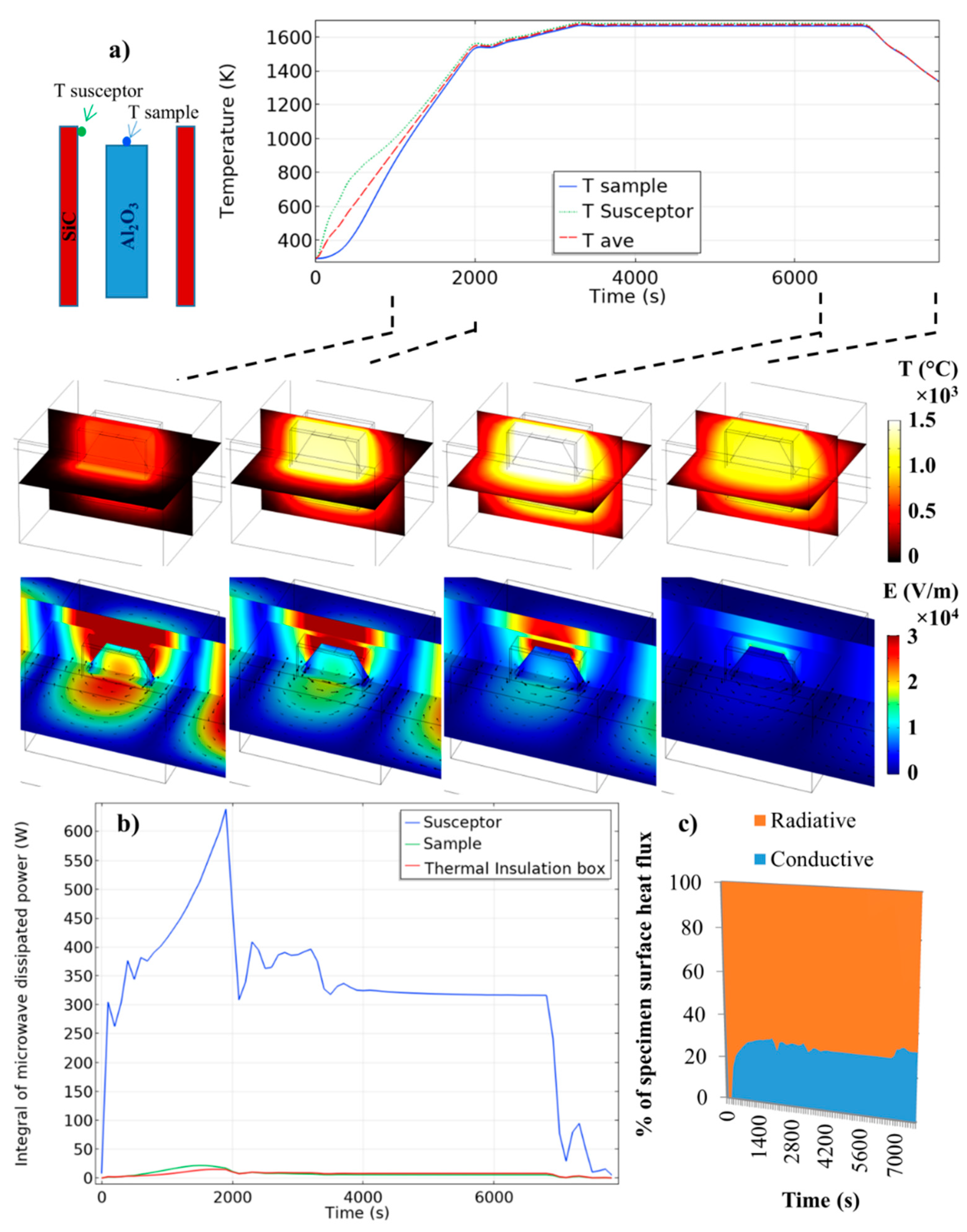

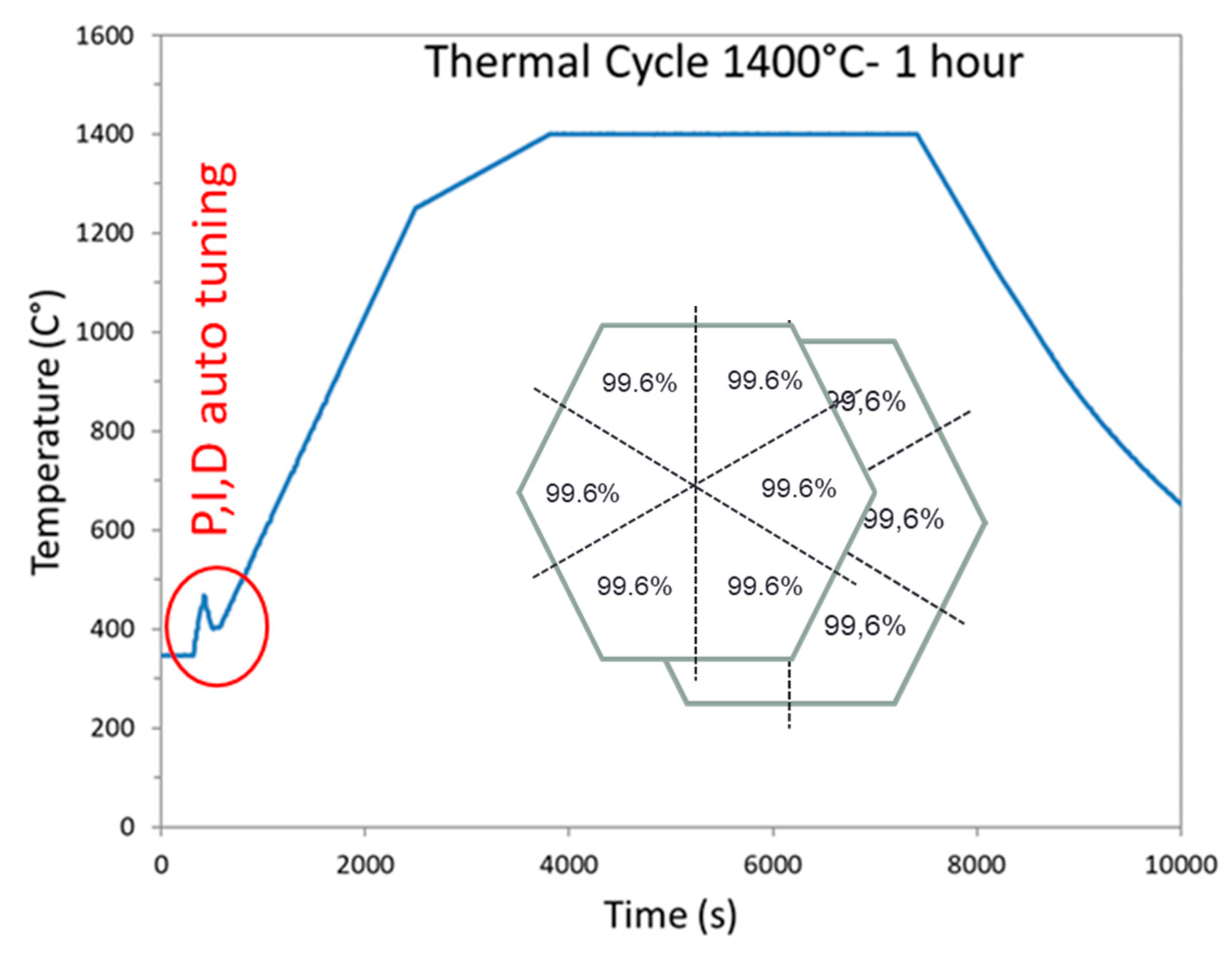

3.3. Temperature Cycle and Sample Density

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Density (kg m−3) | |

| Heat capacity (J·kg−1 K−1) | |

| T | Temperature (K) |

| Thermal conductivity (W m−1 K−1) | |

| Heat source (W m−3) | |

| Surface to ambient radiative heat flux (W m−2) | |

| Stefan Boltzmann constant (5.67 × 10−8 W m−2·K−4) | |

| Emissivity | |

| Tair | Air temperature (K) |

| Convective heat flux (W m−2) | |

| Surface conductivity (W m−2 K−1) | |

| J | Surface radiosity (W m−2) |

| G | Irradiation flux (W m−2) |

| n | Refractive index |

| Surface radiation produced (W m−2) | |

| Complex relative permeability | |

| Complex relative permittivity | |

| Relative permeability imaginary part | |

| Relative permittivity imaginary part | |

| The vacuum wave number (rad·m−1) | |

| The electric conductivity (S·m−1) | |

| The vacuum permittivity (8.854187817 × 10−12 F m−1) | |

| The vacuum permeability (1.2566370614 × 10−6 T·m/A) | |

| j | The complex number |

| ω | The angular frequency (rad Hz) |

| Electric field strength (V m−1) | |

| The magnetic field intensity (A m−1) |

Appendix A

| Material | Symbol (Unit) | Temperature Range (K) | Expression |

|---|---|---|---|

| Insulation | Cp (J·kg−1·K−1) | 273–1600 | (−5.31 × 10−4)T2 + 1.25T + 5.18 × 102 |

| κ (W·m−1·K−1) | 273–1700 | 1.70 × 10−2 + (1.4× 10−4)T | |

| ρ (kg·m−3) | 273–1700 | 4.43 × 102 – (1.04 × 10−4)T | |

| SiC | Cp (J·kg−1·K−1) | 273–673 673–1573 1573–1700 | −8.35 + 3.08T − 0.00293T2 + (1.0268 × 10−6)T3 772 + 0.431T − (2.10 × 10−5)T2 1400 |

| κ (W·m−1·K−1) | 273–1700 | 192 − 0.326T + (2.74 × 10−4)T2 − (7.71 × 10−8)T3 | |

| ρ (kg·m−3) | 273–1700 | 2977 + 0.0510T − (2.29 × 10−4)T2 + (2.98 × 10−7)T3 − (1.92 × 10−10)T4 + (4.77 × 10−14)T5 | |

| Al2O3 | Cp (J·kg−1·K−1) | 273–1700 | 850 |

| κ (W·m−1·K−1) | 273–1700 | 39,500T−1.26 | |

| ρ (kg·m−3) | 273–1700 | 3899 | |

| mAir | Cp (J·kg−1·K−1) | 273–1600 | 0.177T + 961 |

| κ (W·m−1·K−1) | 273–1600 | (6 × 10−5)T + 0.0035 | |

| ρ (kg·m−3) | 273–1700 | 0.02897P/(RT) | |

| Dynamic viscosity (Pa s) | 273–1700 | 2.82 × 10−6 + (7.51 × 10−8)T – (3.01 × 10−11)T2 + (8.88 × 10−1)T3 (−1.01 × 10−18)T4 | |

| Insulation SiC Al2O3 | Emissivity ϵ | 273–1700 | 0.83 0.9 0.8 |

| Insulation | 273–1700 | (5.03 × 10−8)T2 + (1.37 × 10−5)T + 1.5 | |

| 273–1700 | (2.5 × 10−9)T2 − (1.64 × 10−6)T + 3.96 × 10−4 | ||

| Al2O3 | 273–1700 | (1.34 × 10−3)T + 8.3 | |

| 273–1700 | (4.62 × 10−5)T − 8.87 × 10−3 |

References

- Agrawal, D. Microwave sintering of ceramics, composites and metallic materials, and melting of glasses. Trans. Indian Ceram. Soc. 2006, 65, 129–144. [Google Scholar] [CrossRef]

- Kitchen, H.J.; Vallance, S.R.; Kennedy, J.L.; Tapia-Ruiz, N.; Carassiti, L.; Harrison, A.; Whittaker, A.G.; Drysdale, T.D.; Kingman, S.W.; Gregory, D.H. Modern microwave methods in solid-state inorganic materials chemistry: From fundamentals to manufacturing. Chem. Rev. 2014, 114, 1170–1206. [Google Scholar] [CrossRef]

- Croquesel, J.; Bouvard, D.; Chaix, J.; Carry, C.P.; Saunier, S. Development of an instrumented and automated single mode cavity for ceramic microwave sintering: Application to an alpha pure alumina powder. Mater. & Des. 2015, 88, 98–105. [Google Scholar] [CrossRef]

- Mishra, R.R.; Sharma, A.K. Microwave–material interaction phenomena: Heating mechanisms, challenges and opportunities in material processing. Compos. Part A: Appl. Sci. Manuf. 2016, 81, 78–97. [Google Scholar] [CrossRef]

- Oghbaei, M.; Mirzaee, O. Microwave versus conventional sintering: A review of fundamentals, advantages and applications. J. Alloy. Compd. 2010, 494, 175–189. [Google Scholar] [CrossRef]

- Biesuz, M.; Sglavo, V.M. Flash sintering of ceramics. J. Eur. Ceram. Soc. 2019, 39, 115–143. [Google Scholar] [CrossRef]

- Heuguet, R.; Marinel, S.; Thuault, A.; Badev, A. Effects of the susceptor dielectric properties on the microwave sintering of alumina. J. Am. Ceram. Soc. 2013, 96, 3728–3736. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Basak, T. A review on the susceptor assisted microwave processing of materials. Energy 2016, 97, 306–338. [Google Scholar] [CrossRef]

- Zhai, D.; Wei, C.; Zhang, F.; Shang, X.; Chen, J.; Liu, M.; Peng, J. Microwave transmission performance of fused silica ceramics in microwave high-temperature heating. Ceram. Int. 2019, 45, 6157–6162. [Google Scholar] [CrossRef]

- Marinel, S.; Renaut, N.; Savary, E.; Macaigne, R.; Riquet, G.; Coureau, C.; Gadeyne, T.; Guillet, D. Tuning, impedance matching, and temperature regulation during high-temperature microwave sintering of ceramics. Adv. Mater. Sci. Eng. 2018. [Google Scholar] [CrossRef]

- Manière, C.; Zahrah, T.; Olevsky, E.A. Fully coupled electromagnetic-thermal-mechanical comparative simulation of direct vs hybrid microwave sintering of 3Y-ZrO2. J. Am. Ceram. Soc. 2017, 100, 2439–2450. [Google Scholar] [CrossRef]

- Manière, C.; Chan, S.; Olevsky, E.A. Microwave sintering of complex shapes: From multiphysics simulation to improvements of process scalability. J. Am. Ceram. Soc. 2019, 102, 611–620. [Google Scholar] [CrossRef]

- Manière, C.; Lee, G.; Zahrah, T.; Olevsky, E.A. Microwave flash sintering of metal powders: From experimental evidence to multiphysics simulation. Acta Mater. 2018, 147, 24–34. [Google Scholar] [CrossRef]

- Manière, C.; Zahrah, T.; Olevsky, E.A. Fluid dynamics thermo-mechanical simulation of sintering: Uniformity of temperature and density distributions. Appl. Therm. Eng. 2017, 123, 603–613. [Google Scholar] [CrossRef]

- Egorov, S.V.; Rybakov, K.I.; Semenov, V.E.; Bykov, Y.V.; Kanygina, O.N.; Kulumbaev, E.B.; Lelevkin, V.M. Role of convective heat removal and electromagnetic field structure in the microwave heating of materials. J. Mater. Sci. 2007, 42, 2097–2104. [Google Scholar] [CrossRef]

- Macaigne, R.; Marinel, S.; Goeuriot, D.; Meunier, C.; Saunier, S.; Riquet, G. Microwave sintering of pure and TiO2 doped MgAl2O4 ceramic using calibrated, contactless in-situ dilatometry. Ceram. Int. 2016, 42, 16997–17003. [Google Scholar] [CrossRef]

- Yakovlev, V.; Allan, S.M.; Fall, M.L.; Shulman, H. Computational study of microwave processing of zirconia: Effects of frequency and temperature-dependent material parameters. In Proceedings of the 13th Seminar Computer Modeling in Microwave Engineering & Applications—Advances in Determining Material Parameters, Thun, Switzerland, 7–8 March 2011. [Google Scholar]

- Manière, C.; Zahrah, T.; Olevsky, E.A. Inherent heating instability of direct microwave sintering process: Sample analysis for porous 3Y-ZrO2. Scr. Mater. 2017, 128, 49–52. [Google Scholar] [CrossRef]

- Olevsky, E.A.; Maximenko, A.L.; Grigoryev, E.G. Ponderomotive effects during contact formation in microwave sintering. Model. Simul. Mater. Sci. Eng. 2013, 21, 055022. [Google Scholar] [CrossRef]

- Benaissa, S.; Hamidouche, M.; Kolli, M.; Fantozzi, G. Optical and mechanical characterization of transparent α-alumina fabricated by spark plasma sintering. Int. J. Appl. Ceram. Technol. 2019, 16, 638–646. [Google Scholar] [CrossRef]

- Baeraky, T.A. Microwave measurements of the dielectric properties of silicon carbide at high temperature. Egypt. J. Sol. 2002, 25, 263–273. [Google Scholar]

- Batt, J.; Sutton, W.H.; Binner, J.G.P.; Cross, T.E. A Parallel Measurement Programme in High Temperature Dielectric Property Measurement: An Update; American Ceramic Society: Westerville, OH, USA, 1995. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marinel, S.; Manière, C.; Bilot, A.; Bilot, C.; Harnois, C.; Riquet, G.; Valdivieso, F.; Meunier, C.; Coureau, C.; Barthélemy, F. Microwave Sintering of Alumina at 915 MHz: Modeling, Process Control, and Microstructure Distribution. Materials 2019, 12, 2544. https://doi.org/10.3390/ma12162544

Marinel S, Manière C, Bilot A, Bilot C, Harnois C, Riquet G, Valdivieso F, Meunier C, Coureau C, Barthélemy F. Microwave Sintering of Alumina at 915 MHz: Modeling, Process Control, and Microstructure Distribution. Materials. 2019; 12(16):2544. https://doi.org/10.3390/ma12162544

Chicago/Turabian StyleMarinel, Sylvain, Charles Manière, Anthony Bilot, Christelle Bilot, Christelle Harnois, Guillaume Riquet, François Valdivieso, Christophe Meunier, Christophe Coureau, and François Barthélemy. 2019. "Microwave Sintering of Alumina at 915 MHz: Modeling, Process Control, and Microstructure Distribution" Materials 12, no. 16: 2544. https://doi.org/10.3390/ma12162544

APA StyleMarinel, S., Manière, C., Bilot, A., Bilot, C., Harnois, C., Riquet, G., Valdivieso, F., Meunier, C., Coureau, C., & Barthélemy, F. (2019). Microwave Sintering of Alumina at 915 MHz: Modeling, Process Control, and Microstructure Distribution. Materials, 12(16), 2544. https://doi.org/10.3390/ma12162544