Discrepancies in the Microstructures of Annealed Cu–Zr Bulk Alloy and Cu–Zr Alloy Films

Abstract

1. Introduction

2. Experimental Details

3. Results and Discussion

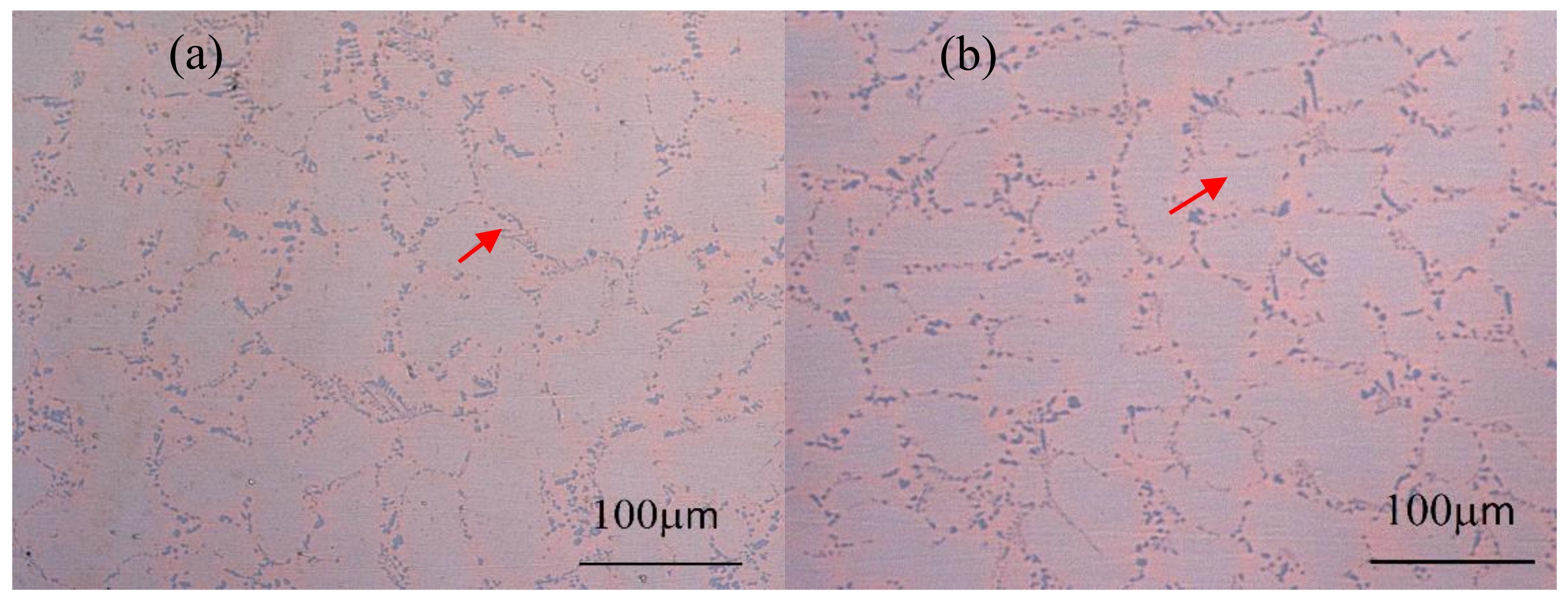

3.1. Microstructural Evolution in Annealed Cu–Zr Bulk Alloys

3.2. Microstructure in As-deposited and Annealed Cu–Zr Alloy Films

3.3. The Main Influencing Factors of Self-formed Cu Particles

3.4. Residual Stress in Cu–Zr Alloy Films

3.5. Formation Mechanism of Faceted Cu Particles on Cu–Zr Alloy Films

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lacour, S.P.; Jones, J.; Suo, Z.; Wagner, S. Design and performance of thin metal film interconnects for skin-like electronic circuits. IEEE Electr. Device Lett. 2004, 25, 179–181. [Google Scholar] [CrossRef]

- Li, G.L.; Tan, K.K.R.; Ng, S.H.; Chua, D.H.C. A multilevel zero-inflated model for the study of copper hillocks growth in integrated circuits manufacturing. IEEE Trans. Semiconduct. Manuf. 2018, 31, 385–394. [Google Scholar] [CrossRef]

- Weiss, D.; Gao, H.; Arzt, E. Constrained diffusional creep in UHV-produced copper thin films. Acta Mater. 2001, 49, 2395–2403. [Google Scholar] [CrossRef]

- Kraft, O.; Arzt, E. Current density and line width effects in electromigration: A new damage-based lifetime model. Acta Mater. 1998, 46, 3733–3743. [Google Scholar] [CrossRef]

- Lu, H.M.; Jiang, Q. Size-dependent surface energies of nanocrystals. J. Phys. Chem. B 2004, 108, 5617–5619. [Google Scholar] [CrossRef]

- Kraft, O.; Arzt, E. Electromigration mechanisms in conductor lines: Void shape changes and slit-like failure. Acta Mater. 1997, 45, 1599–1611. [Google Scholar] [CrossRef]

- Ramanath, G.; Xiao, H.Z.; Yang, L.C.; Rockett, A.; Allen, L.H. Evolution of microstructure in nanocrystalline Mo-Cu thin films during thermal annealing. J. Appl. Phys. 1995, 78, 2435–2440. [Google Scholar] [CrossRef]

- Chu, J.P.; Lin, T.N. Deposition, microstructure and properties of sputtered copper films containing insoluble molybdenum. J. Appl. Phys. 1999, 85, 6462–6469. [Google Scholar] [CrossRef]

- Michael, L.N.; Kim, C.U. Electromigration in Cu thin films with Sn and Al cross strips. J. Appl. Phys. 2001, 90, 4370–4376. [Google Scholar] [CrossRef]

- Jung, W.W.; Choi, S.K.; Kweon, S.Y.; Yeom, S.J. Platinum(100) hillock growth in a Pt/Ti electrode stack for ferroelectric random access memory. Appl. Phys. Lett. 2003, 83, 2160–2162. [Google Scholar] [CrossRef]

- Hwang, S.J.; Lee, Y.D.; Jeong, C.O.; Joo, Y.C. Effect of film thickness and annealing temperature on hillock distributions in pure Al films. Scripta Mater. 2007, 56, 17–20. [Google Scholar] [CrossRef]

- Iwamura, E.; Ohnishi, T.; Yoshikawa, K. A study of hillock formation on Al-Ta alloy films for interconnections of TFT-LCDs. Thin Solid Films 1995, 270, 450–455. [Google Scholar] [CrossRef]

- Hsieh, J.H.; Cheng, M.K.; Li, C.; Chen, S.H.; Chang, Y.G. Study of Cu emergence on the surface of TaN-Cu nanocomposite thin films and its effects on tribological property. Thin Solid Films 2008, 516, 5430–5434. [Google Scholar] [CrossRef]

- Martin, B.C.; Tracy, C.J.; Mayer, J.W.; Hendrickson, L.E. A comparative study of Hillock formation in aluminum films. Thin Solid Films 1995, 271, 64–68. [Google Scholar] [CrossRef]

- Arzt, E. Size effects in materials due to microstructural and dimensional constraints: A comparative review. Acta Mater. 1998, 46, 5611–5626. [Google Scholar] [CrossRef]

- Adams, B.L.; Olson, T. The mesostructure—properties linkage in polycrystals. Prog. Mater. Sci. 1998, 43, 1–88. [Google Scholar] [CrossRef]

- Stoneham, A.M.; Harding, J.H. Not to big, not too small, the appropriate scale. Nat. Mater. 2003, 2, 77–83. [Google Scholar] [CrossRef]

- Haronian, D. A low-cost micromechanical accelerometer with integrated solid-state sensor. Sensors Actuators 2000, 84, 149–155. [Google Scholar] [CrossRef]

- Savaloni, H.; Taherizadeh, A.; Zendehnam, A. Residual stress and structural characteristics in Ti and Cu sputtered films on glass substrates at different substrate temperatures and film thickness. Phys. B 2004, 349, 44–55. [Google Scholar] [CrossRef]

- Ghidelli, M.; Gravier, S.; Blandin, J.J.; Djemia, P.; Mompiou, F.; Abadias, G.; Raskin, J.P.; Pardoen, T. Extrinsic mechanical size effects in thin ZrNi metallic glass films. Acta Mater. 2015, 90, 232–241. [Google Scholar] [CrossRef]

- Ghidelli, M.; Idrissi, H.; Gravier, S.; Blandin, J.J.; Raskin, J.P.; Schryvers, D.; Pardoen, T. Homogeneous flow and size dependent mechanical behavior in highly ductile Zr65Ni35 metallic glass films. Acta Mater. 2017, 131, 246–259. [Google Scholar] [CrossRef]

- Apreutesei, M.; Steyer, P.; Joly-Pottuz, L.; Billard, A.; Qiao, J.; Cardinal, S.; Sanchette, F.; Pelletier, J.M.; Esnouf, C. Microstructural, thermal and mechanical behavior of co-sputtered binary Zr-Cu thin film metallic glasses. Thin Solid Films 2014, 561, 53–59. [Google Scholar] [CrossRef]

- Khobragade, N.; Sikdar, K.; Kumar, B.; Roy, D. Effect of annealing on microstructure, grain growth and hardness of nanocrystalline Cu–Zr alloy prepared by cryogenic ball milling. J. Mater. Sci. Res. 2018, 7, 69–77. [Google Scholar] [CrossRef]

- Sun, H.L.; Song, Z.X.; Ma, F.; Zhan, J.M.; Xu, K.W. Microstructure, formation mechanism and compression plasticity of regularly faceted Cu particles. Scripta Mater. 2009, 60, 305–308. [Google Scholar] [CrossRef]

- Ma, F.; Sun, H.L.; Zhan, J.M.; Xu, K. Self-formation of single-crystal metal particles driven by inhomogeneous stress in thin films. Thin Solid Films 2011, 519, 5188–5193. [Google Scholar] [CrossRef]

- Lahiri, S.K. Stress relief and hillock formation in thin lead films. J. Appl. Phys. 1970, 41, 3172–3176. [Google Scholar] [CrossRef]

- Stoney, G.G. The tension of metallic films deposited by electrolysis. Proc. Royal Soc. London A 1909, 82, 172–175. [Google Scholar] [CrossRef]

- Northwood, D.O.; London, I.M.; Bahen, L.E. Elastic constants of Zirconium alloys. J. Nucl. Mater. 1975, 55, 299–310. [Google Scholar] [CrossRef]

- Chaudhari, P. Hillock growth in thin films. J. Appl. Phys. 1974, 45, 4339–4346. [Google Scholar] [CrossRef]

- Kim, D.K.; Nix, W.D.; Deal, M.D.; Plummer, J.D. Creep-controlled diffusional hillock formation in blanket aluminum thin films as a mechanism of stress relaxation. J. Mater. Res. 2000, 15, 1709–1718. [Google Scholar] [CrossRef]

- Hwang, S.J.; Nix, W.D.; Joo, Y.C. A model for hillock growth in Al thin films controlled by plastic deformation. Acta Mater. 2007, 55, 5297–5301. [Google Scholar] [CrossRef]

- Berla, A.; Joo, Y.C.; Nix, W.D. A model for power law creep controlled hillock growth. Mater. Sci. Eng. A 2008, 488, 594–600. [Google Scholar] [CrossRef]

- Huang, X.X.; Sun, H.L.; Wang, G.X.; Stock, H.R. Self-formation of Ag particles/Ag-Zr alloy films on flexible polyimide as SERS substrates. Appl. Surf. Sci. 2019, 487, 1341–1347. [Google Scholar] [CrossRef]

| Sample | Film Thickness (nm) | Zr Content (Atomic Atom%) |

|---|---|---|

| Cu–Zr bulk alloy | 1.1 | |

| Cu–Zr alloy thin film | 50 | 7.3 |

| 225 | 17.1 | |

| 420 | 0 | |

| 7.3 | ||

| 12.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Huang, X.; Lian, X.; Wang, G. Discrepancies in the Microstructures of Annealed Cu–Zr Bulk Alloy and Cu–Zr Alloy Films. Materials 2019, 12, 2467. https://doi.org/10.3390/ma12152467

Sun H, Huang X, Lian X, Wang G. Discrepancies in the Microstructures of Annealed Cu–Zr Bulk Alloy and Cu–Zr Alloy Films. Materials. 2019; 12(15):2467. https://doi.org/10.3390/ma12152467

Chicago/Turabian StyleSun, Haoliang, Xiaoxue Huang, Xinxin Lian, and Guangxin Wang. 2019. "Discrepancies in the Microstructures of Annealed Cu–Zr Bulk Alloy and Cu–Zr Alloy Films" Materials 12, no. 15: 2467. https://doi.org/10.3390/ma12152467

APA StyleSun, H., Huang, X., Lian, X., & Wang, G. (2019). Discrepancies in the Microstructures of Annealed Cu–Zr Bulk Alloy and Cu–Zr Alloy Films. Materials, 12(15), 2467. https://doi.org/10.3390/ma12152467