1. Introduction

Foam concrete (FC) is a lightweight cementitious material with a cellular structure produced by incorporating air voids into mortar or cement paste. It can be designed to have a density in the range of 200 to 1900 kg/m

3. Foam concrete of density lower than 400 kg/m

3 is used primarily as a filling or insulating material [

1,

2,

3]. Due to the technical and engineering unfamiliarity of most practitioners and the perceived difficulty in achieving sufficiently high strength, in the past few decades, foam concrete has been largely disregarded for use in structural applications. In most instances, foam concrete was used to fill voids, function as thermal insulation, and act as an acoustic damper. Advancements in chemical and mechanical foaming techniques, concrete admixtures, and other additives significantly improved the stability and mechanical properties of foam concrete. Currently, the potential of this material for structural applications is well recognized, and numerous research projects have been focusing on enhancing foam concrete properties, particularly in respect of its mechanical load-bearing performance [

2,

4,

5].

Groups working with foresight on digital fabrication have identified the future need for sustainable construction materials that are economically efficient and environmentally friendly [

6]. It is expected that when preliminary studies and descriptions of the fundamental principles of digital fabrication with cementitious materials are completed, a further step would be the rethinking of the technology, including the reduction of material outlays and environmental impact. Foam concrete has a low specific weight, which reduces dead loads and thus enables lessening the dimensions of foundations and amount of reinforcement. Furthermore, the low thermal conductivity of the foam concrete makes it possible to decrease the use of further insulation materials, which are mostly based on petrochemical polymers with a high CO

2 footprint and very limited recyclability. In contrast to such materials, foam concrete is made of mineral constituents with only minor contents of chemical admixtures [

7]. Additionally, since the application of extra insulation panels might be no longer required, significant cuts of energy consumption and time for transport and mounting can be expected along with the noise reduction on the construction site. To summarize, foam concrete is recognized as a versatile construction material that is environmentally friendly and technically efficient.

The Concrete on-site 3D-Prining (CONPrint3D) concept developed at the Technische Universität Dresden facilitates implementation of the advantages of the additive technology in the construction industry [

8]. In contrast to the concepts advancing the printing of integrated formwork, CONPrint3D emphasizes the reduction of secondary steps such as the filling of printed mold structures [

9,

10]. This technology enables the printing of walls of high thickness, whose purpose would be to replace masonry work. The application of foam concrete in the framework of the CONPrint3D concept is promising and potentially enables the production of load-bearing walls and structural elements with properties such as superior thermal insulation, sound absorption, and fire resistance [

11,

12]. The authors expect that the application of different cement-based materials in concrete 3D printing will simplify the formulation of new building standards and change over to the full automation of construction processes. By varying the density and thickness of 3D-printed foam concrete walls, the complete or partial elimination of additional insulation systems would be possible. A further aspect facilitating the application of foam concrete as a material with both insulating and structural functions is the ease of its recycling and disposal.

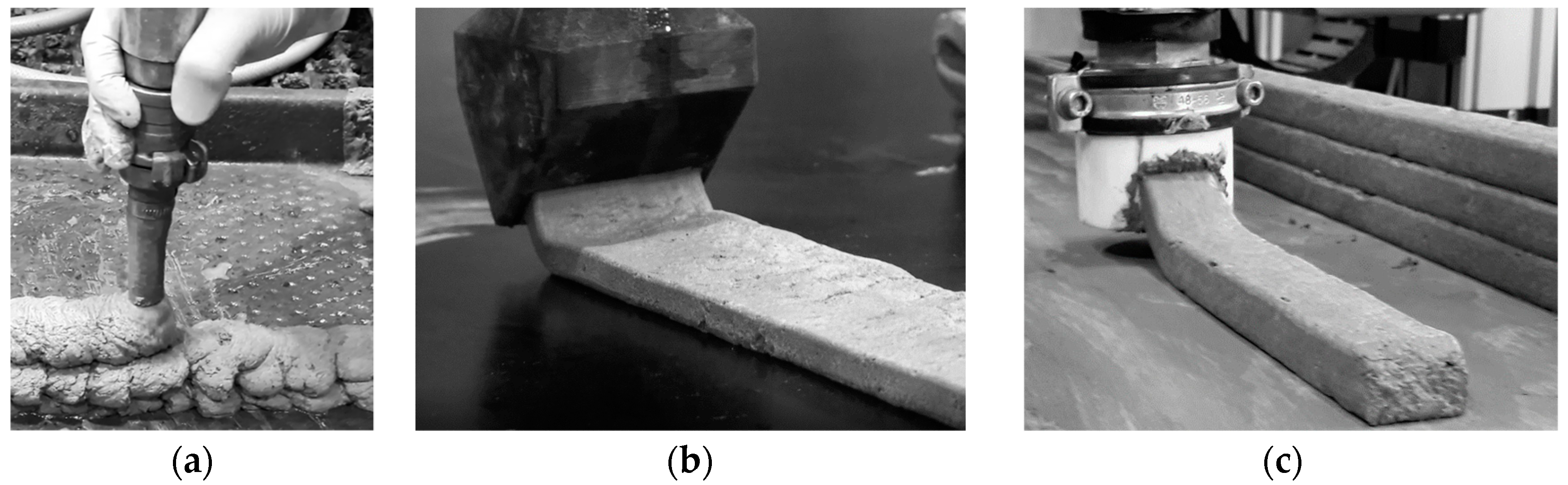

The literature contains an example that describes an automated application of foam concrete to vertical surfaces by means of an extrusion-based technique [

13]. The authors placed foam concrete onto the bare walls of existing buildings to gain a facade finish that insulates, is recyclable, and is free in design and form. The material that was used possessed apparent shape stability, whereas strength characteristics were not studied.

Faliano et al. [

14,

15] described foam concretes with a dry density between 400–800 kg/m

3 and compressive strength in the range of 1.5 to 9 MPa, and which in addition maintains its dimensional stability after extrusion. The water-to-cement ratio (w/c) was set to 0.3 in all the mixtures. Neither fillers nor aggregates were used. Preformed foam was prepared with a protein-based foaming agent. The research provides a wide range of results related to the influences of curing conditions on tensile and compressive strengths. However, the experimental procedure described did not represent typical 3D-printing procedures by robotic print heads. The material was rather filled into steel formwork and pushed down manually from the formwork in the early stage of hydration. The deposition technique used by Faliano et al. imitated automated extrusion and provided first filling of the material behavior in terms of form stability and green strength development.

There is no standard way of measuring the properties of buildability. Generally, buildability is evaluated by printing a certain number of layers at a specific rate [

16,

17,

18,

19]. At this point, it is hard to estimate the possible buildability of the foam concrete designed by Faliano et al. [

11,

12], since the resting time of the foam concrete and its rheological characteristics in the fresh state were not specified. The study emphasized the use of viscosity-enhancing agents (VEA) and indicated more need for research on the fresh state behavior of the extrudable foam concrete. The authors presumed the possibility of applying the extrudable foam concrete mixtures of density down to 200 kg/m

3. Both structural and non-structural applications for the extrudable elements made of foam concrete were denominated as effective and environmentally friendly. One of the suggested applications was to form multilayer insulating panels in situ.

In general, concrete that is suitable for digital construction must be well extrudable and demonstrate adequate buildability. Furthermore, printed layers need to have good interlayer bonds [

9,

16,

20,

21]. Finally, the material has to yield appropriate mechanical properties, e.g., compressive strength [

9,

21,

22,

23]. Conventional foam concrete features good workability and flowability, which are promising with respect to the process parameters of extrudability and pumpability, as required for 3D printing. In common applications, foam concrete is pumped to a point of placement and, in general, does not need compaction; foam concrete can successfully be pumped over significant distances and heights [

1]. Thus, from this perspective, it is suitable for extrusion-based 3D-printing techniques. However, the potential effects of pumping on the foam characteristics have to be taken into account, since they might influence the stability of the mixture and result in changes in its density.

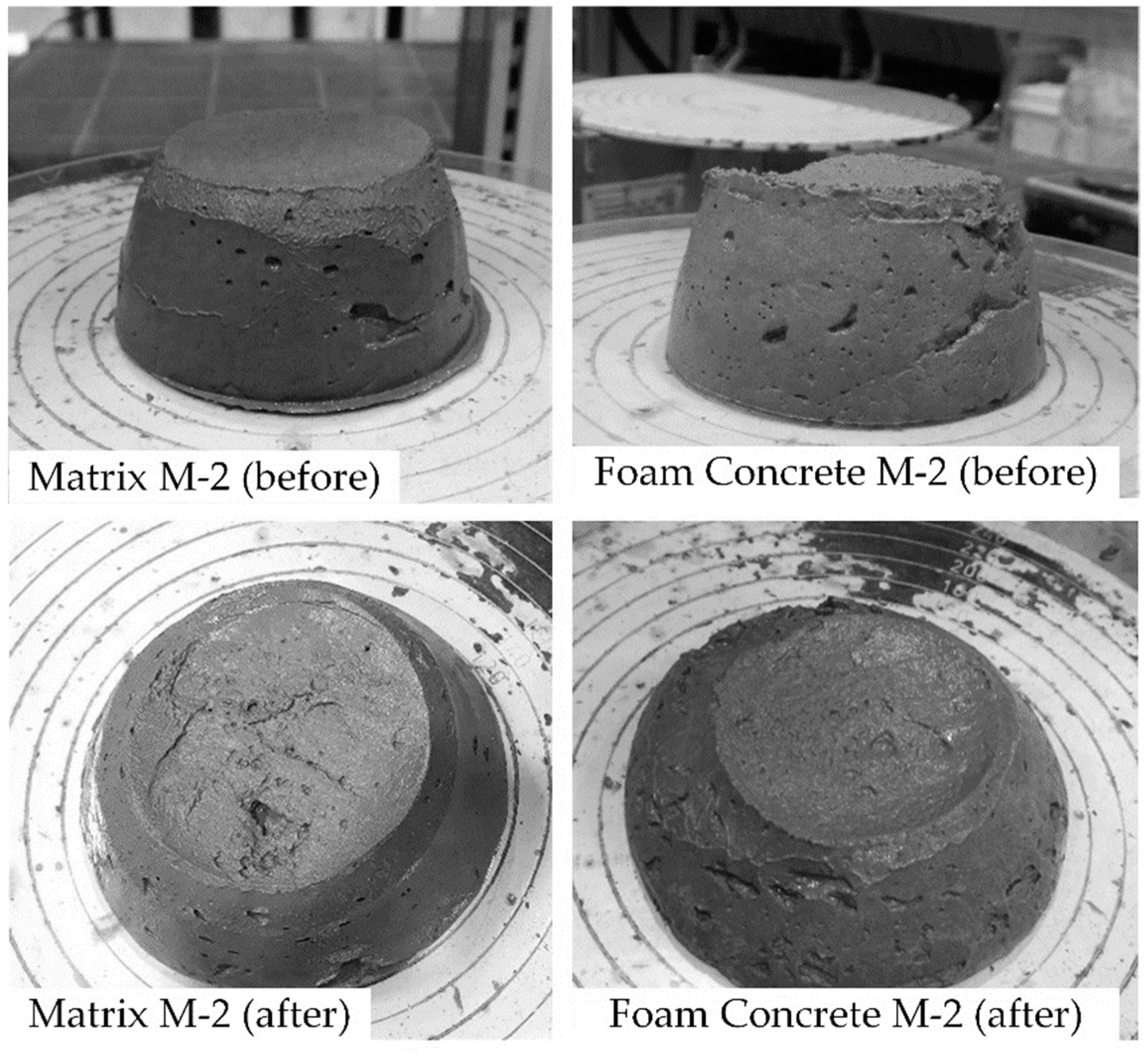

Another important feature of a printable material is its buildability, which is comprised of the shape stability of the printed layers under their self-weight and the ability to hold further layers with minimum deformation [

20]. In other words, the buildability of foam concrete can be described as a combination of self-stability and sufficient stiffness with early setting. Regarding self-stability, foam concrete is usually perceived as a free-flowing, self-compacting material. It is recognized that at lower densities, the flowability decreases due to the reduced self-weight and adhesion between the solid particles and air bubbles [

24]. However, previous research on foam concrete demonstrated that a decrease in flowability with respect to common applications such as void filling is often treated as a sign of poor quality or inappropriate mix design [

4]. Having 3D printing as the application technology in mind, achieving pumpable and self-stable foam concrete should be possible, but this approach has not been investigated thoroughly to date, and so, further research is needed.

In studies related to 3D printing with normal-weight concrete, quick setting is usually achieved by using accelerating admixtures or by choosing cements with shorter setting times, i.e., rapid-hardening sulfoaluminate or calcium aluminate cements [

6,

25]. The same approaches can be followed to achieve the quick setting of foam concrete. However, as reported in [

26], the use of setting-accelerating materials in foam concrete does not always have the same effect as in normal-weight concrete. Moreover, they can cause instability and affect the quality of the foam concrete. In some studies, different types of cement characterized by rapid setting were utilized [

27,

28]. Rapid-hardening Portland cement is often used to reduce the risks of instability and segregation and ensure that foam concrete will develop a strong homogeneous microstructure at a very early stage. It was also observed that the addition of aluminate cement, while shortening setting times, can decrease the compressive strength of foam concrete [

29]. Moreover, the special cementitious materials mentioned are relatively expensive, which limits their range of application.

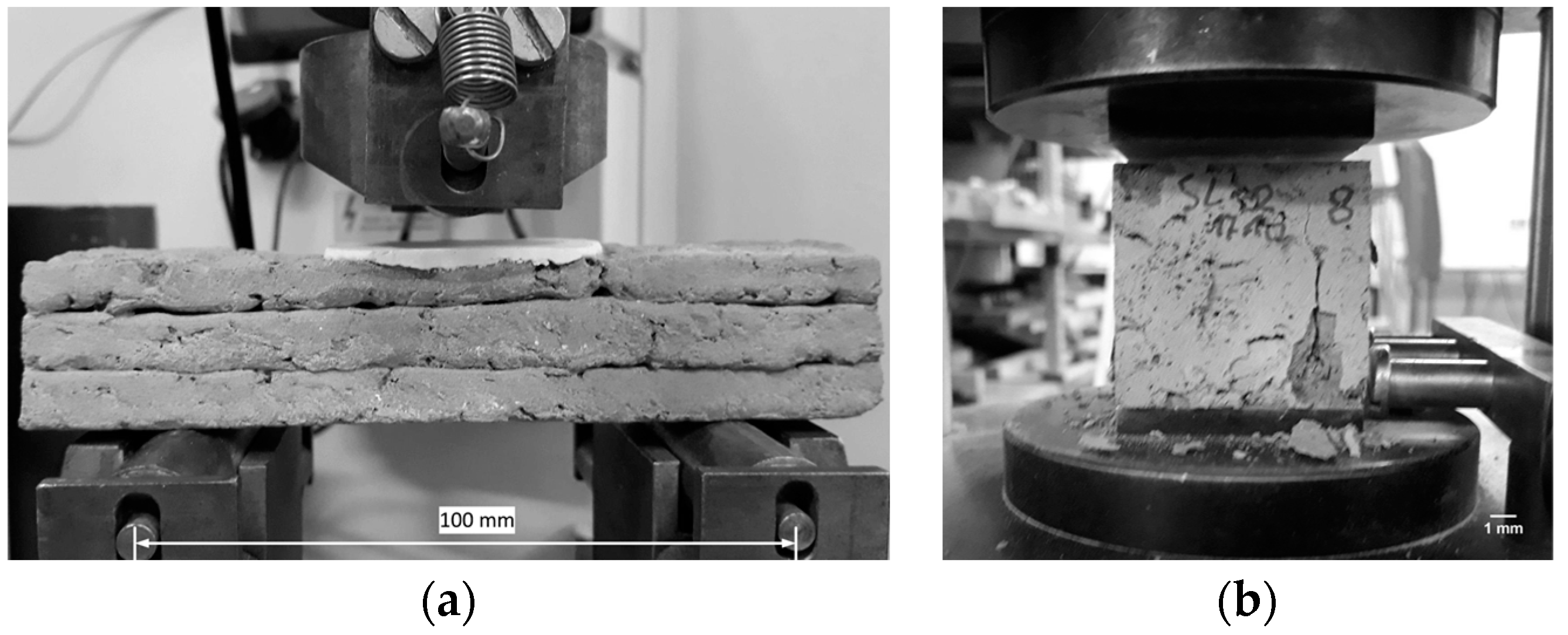

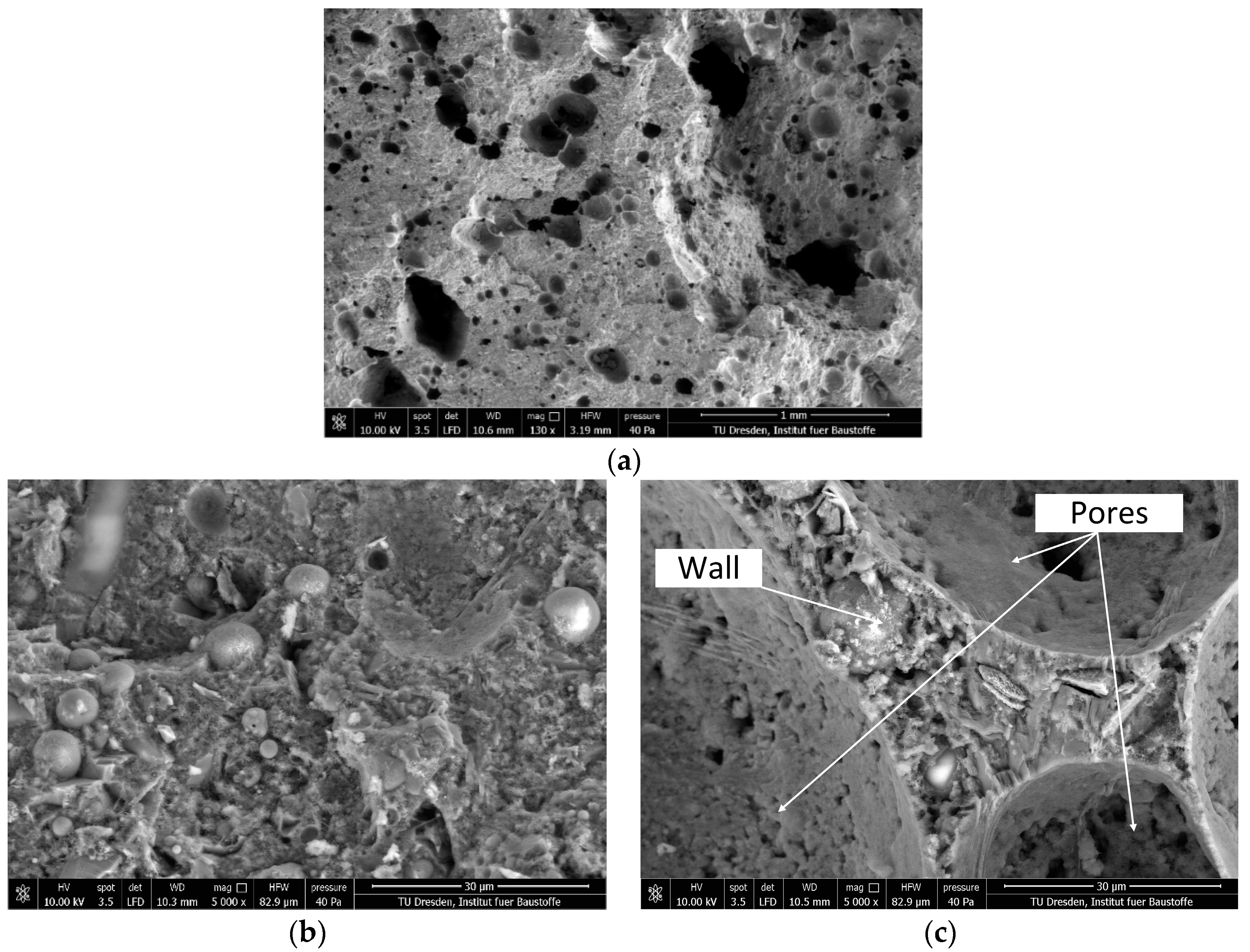

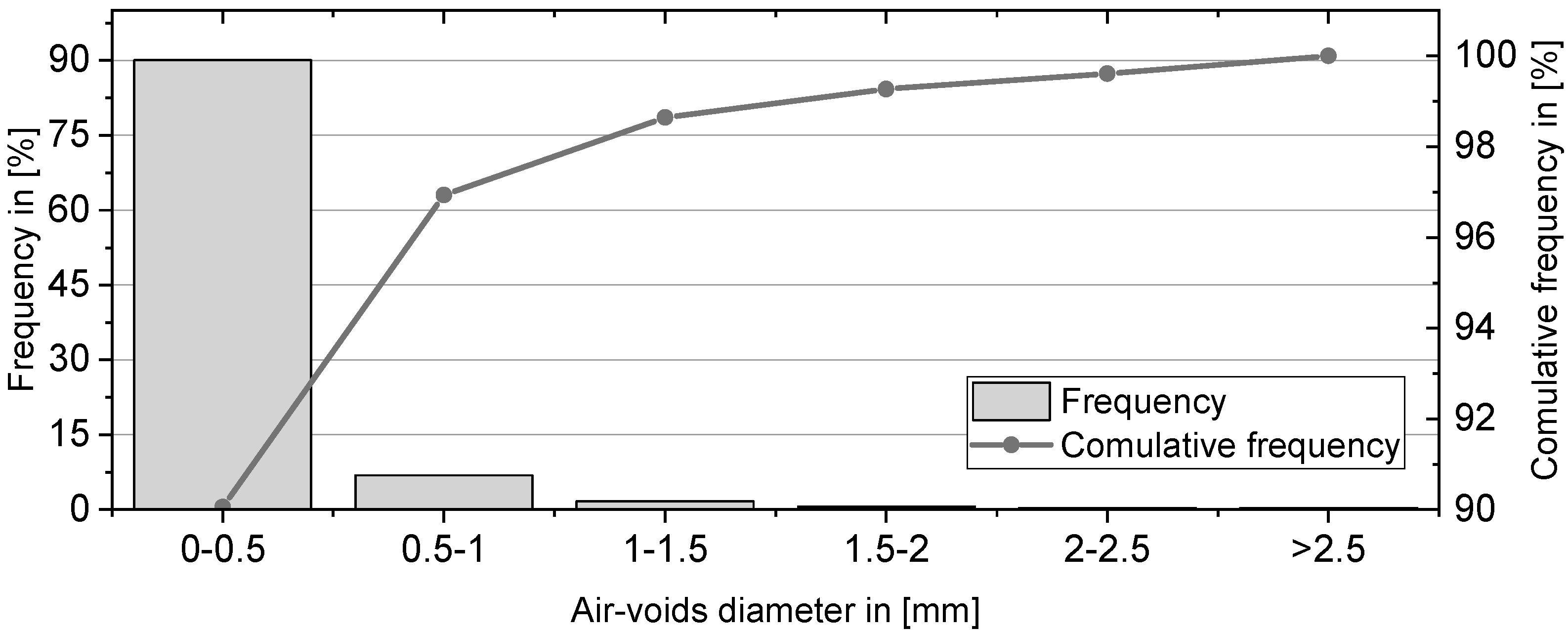

Another important aspect of printed elements is their interlayer bonding. It strongly influences the mechanical properties, durability, and serviceability of 3D printed structures; see e.g., [

30,

31,

32]. The quality of the interlayer bond depends on numerous factors related to the properties of the fresh concrete and the printing technique, i.e., the time interval between layers, filament shape and size, etc. No literature was found that could help estimate foam concrete’s behavior from this point of view. Regarding foam concrete’s permeability and resistance to aggressive environments, it was proven that its cellular, porous structure does not necessarily make it less resistant to the penetration of moisture in comparison to conventional, dense concrete, since the air voids are not interconnected and appear to act as a buffer preventing capillary suction and other transport processes.

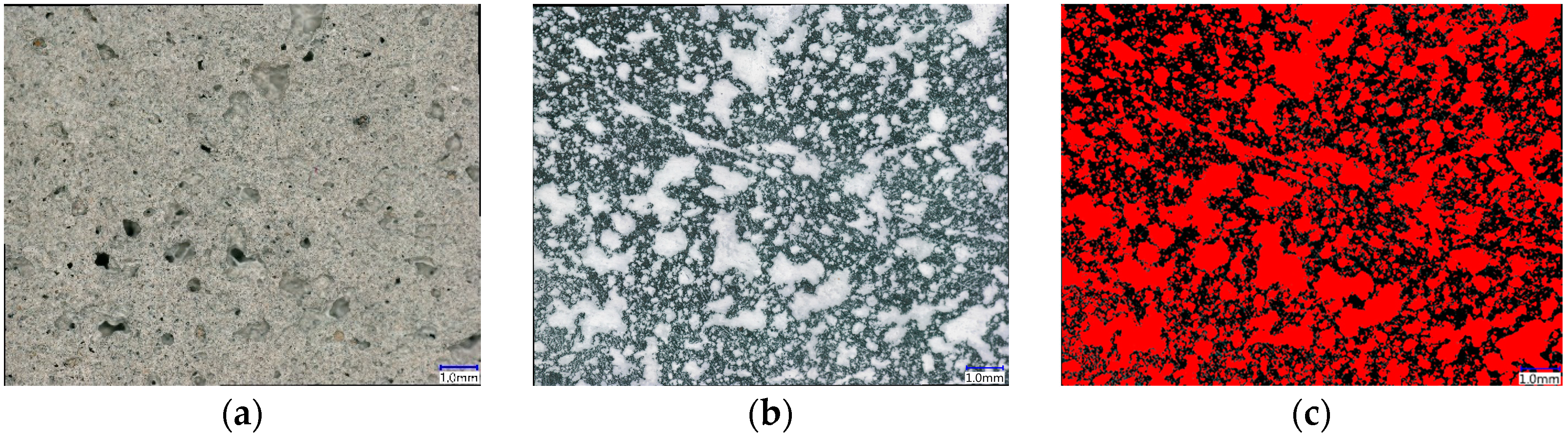

Generally, there are two mechanisms to introduce large volumes of air voids into the mixture: (1) the use of gas-forming chemicals such as aluminum powder, and (2) the use of foaming agents. Addition of the gas-forming agents results in bubble formation through chemical reactions with alkaline hydration products, e.g., calcium hydroxide [

33]. This method is used to produce gas concrete, which is also called aerated concrete. As reported by Holt and Raivio [

31], aerated concrete produced by adding aluminum powder has some significant drawbacks, such as its relatively high cost as well as its lower strength, higher moisture content, and more pronounced shrinkage when compared to traditional concrete. The properties of aerated concrete can be considerably improved by autoclave high-pressure steam curing. However, such curing would be counterproductive, since the main benefit of the production technique of 3D-concrete printing is the reduction of interim steps such as elaborate casting and curing.

In the alternative approach, foam concrete can be produced either by adding the foaming agent to the cement paste, followed by intense mixing, which is called the mixed foaming method, or by intermixing a separately produced foam into cement paste, which is known as the prefoaming method [

1,

4]. In contrast to the addition of gas-forming chemicals, the use of foaming agents in producing the foam concrete has a higher potential for application in 3D printing. This is mostly explained by the fresh and hardened properties’ relative ease of adjustment by varying raw materials and chemical admixtures [

1,

2,

7,

24,

26,

34].

The mixed foaming method is widely used in the construction industry to produce foam concrete. However, this method is limited according to the use of the synthetic foaming agents and is highly dependent on the mixing device used. In contrast, the prefoaming method enables the defining of the material density by the exact addition of the required amount of the foam to the base mixture. Since the ratio of foam to base material could be greater than 1:1, foam becomes a major influencing factor [

35]. The stability of the air voids during pumping and intermixing to the cement-based matrix are essential to ensure the required performance of the foam concrete in the fresh and hardened states. For foam concrete applications, synthetic foaming agents are easier to handle, less susceptible to extreme temperatures, and they can be stored longer. Synthetic foaming agents can be used in both prefoaming and mixed-foaming techniques. Moreover, they are generally less expensive and require considerably less energy to produce high-quality foams [

35]. Nevertheless, synthetic surfactants cannot match the performance of protein-based agents due to their larger bubble size and less isolated cells, which result in lower concrete strengths [

35,

36]. The foams produced with protein-based foaming agents are characterized by the smaller size of air bubbles, higher stability, i.e., lower water drainage, and stronger isolated bubble structure in comparison to foams produced by synthetic foaming agents [

1,

2]. It was also reported that foam concrete produced with the use of protein-based surfactants has a strength-to-density ratio from 50% to 100% higher compared to foam concrete produced with the use of synthetic foaming agent [

35,

36].

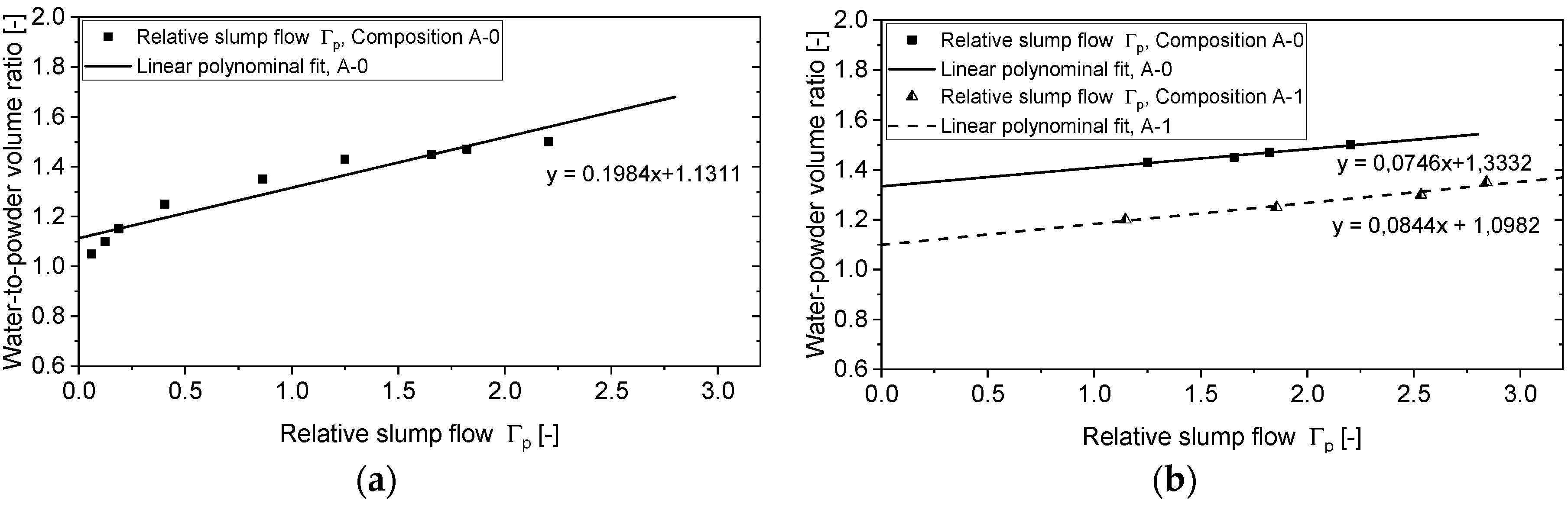

Based on the considerations mentioned regarding the performance of two existing surfactants, this study focuses on the prefoaming production technique using a protein-based foaming agent.

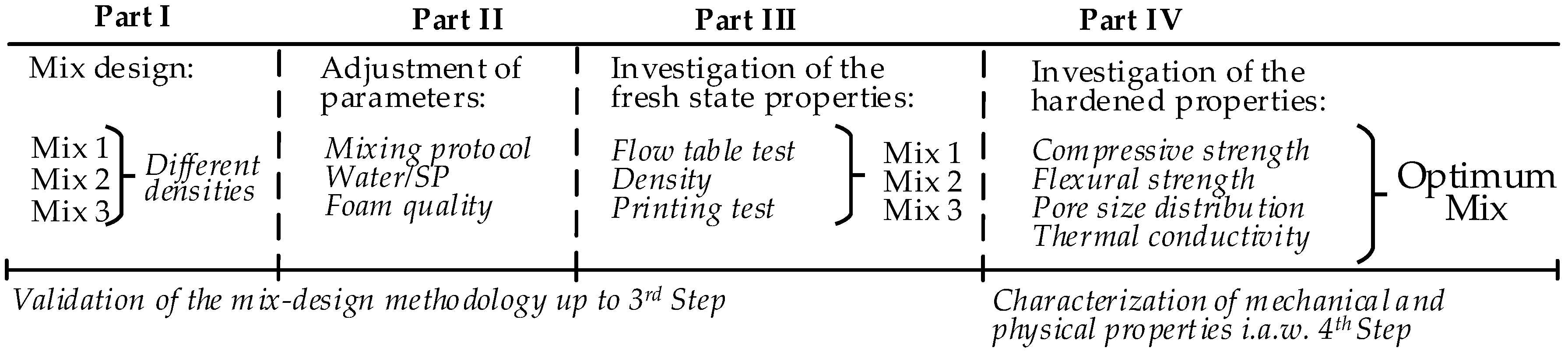

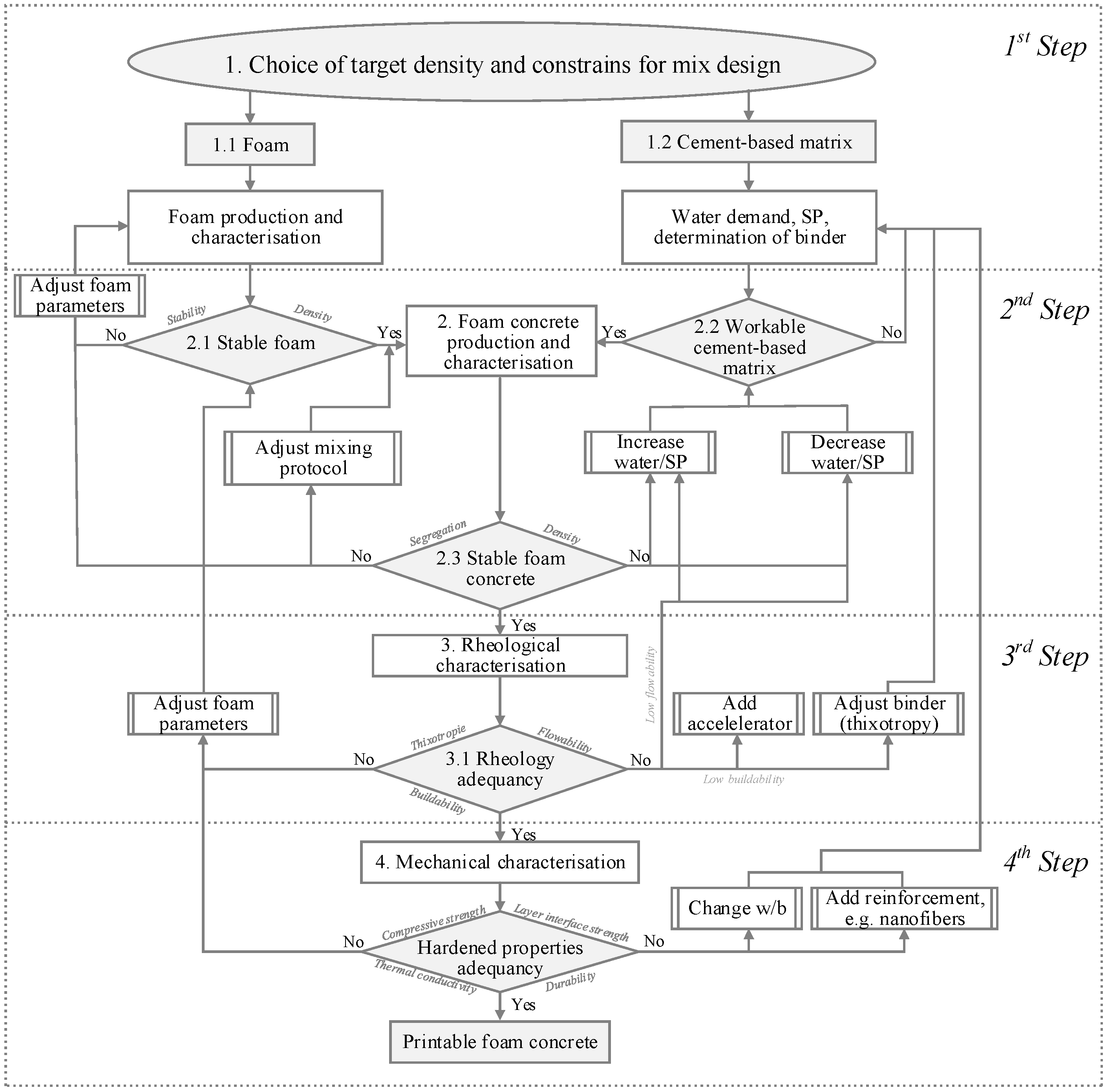

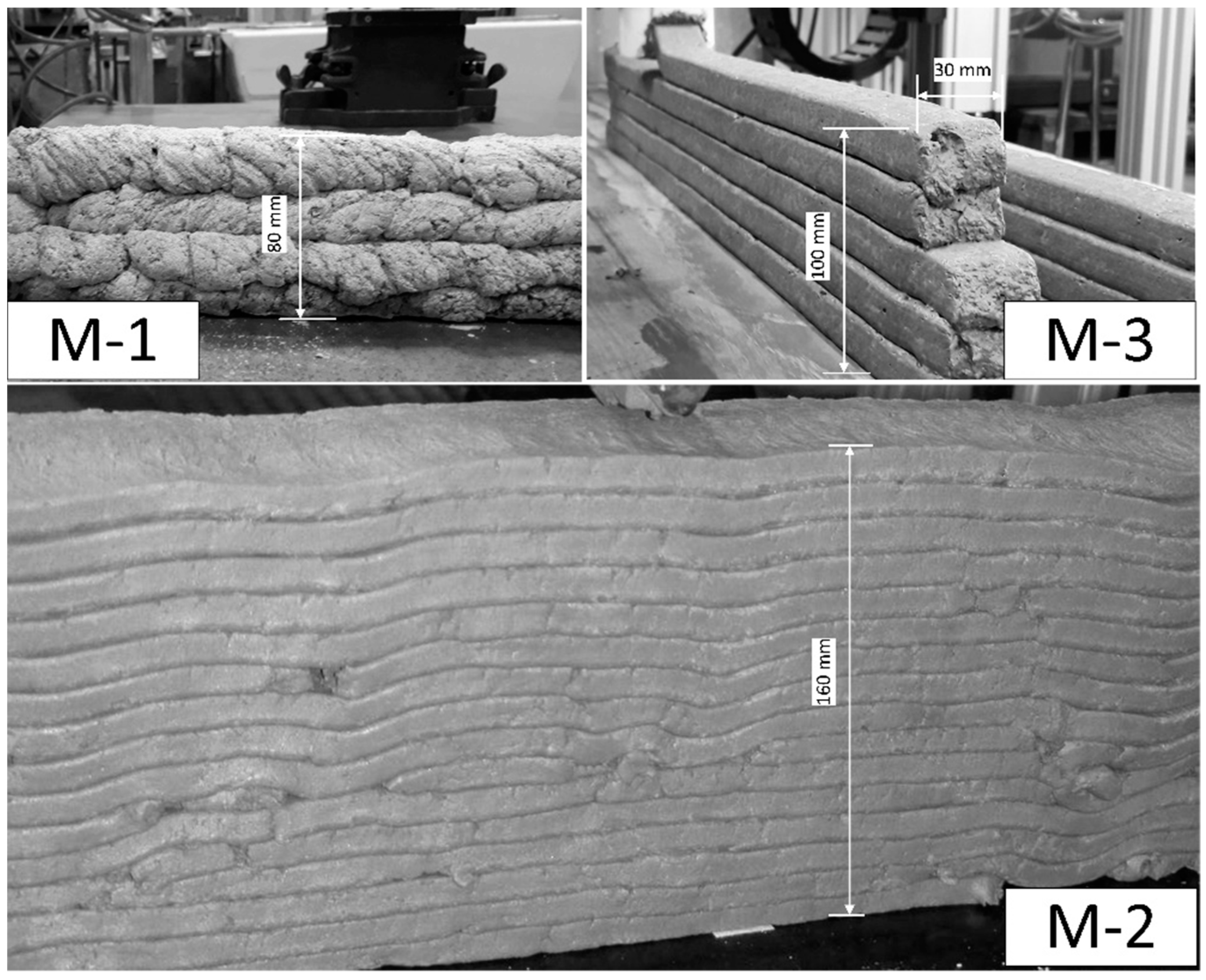

Figure 1 shows the structure of the experimental part of the presented study. The study at hand is dedicated to achieving a printable foam concrete, which is stable and yields adequate rheological and mechanical properties that are suitable for 3D printing. The constituent materials were chosen purposefully to achieve sufficient cohesiveness and form stability right after the deposition of the material by the print head, as well as adequate long-term mechanical properties for structural applications. Four recipes were prepared. The desired density of the fresh mixes was specified between 1100–1600 kg/m

3. Finally, the insulating properties of the printable foam concrete were compared to those of normal-weight printable concrete (the reference material is described in [

37]).