Assessment of Standards and Codes Dedicated to CFRP Confinement of RC Columns

Abstract

1. Introduction

2. Overview of Contemporary Standards and Guidelines

2.1. General Information

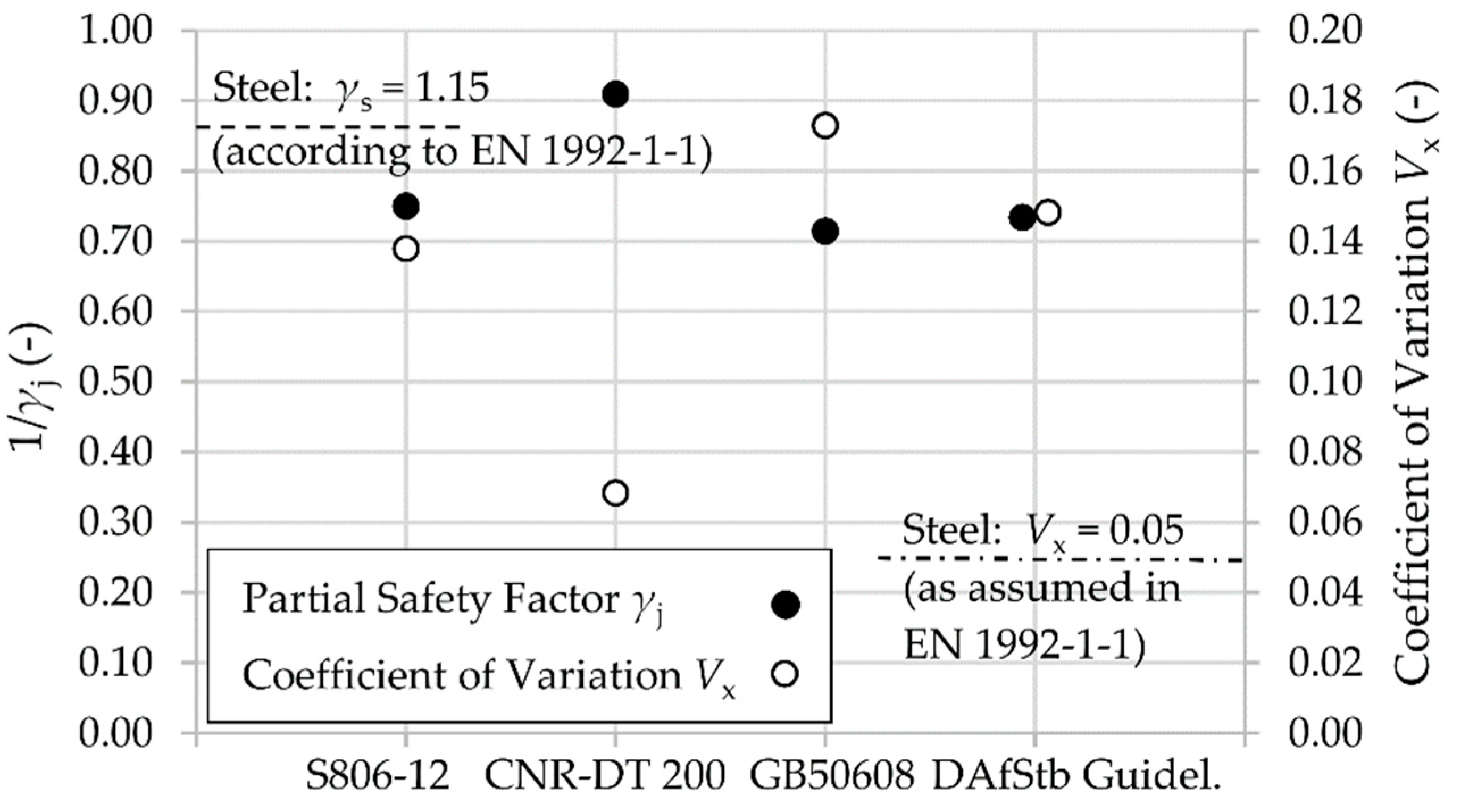

2.2. Strength Reduction and Material Safety Factors for the Different Guidelines

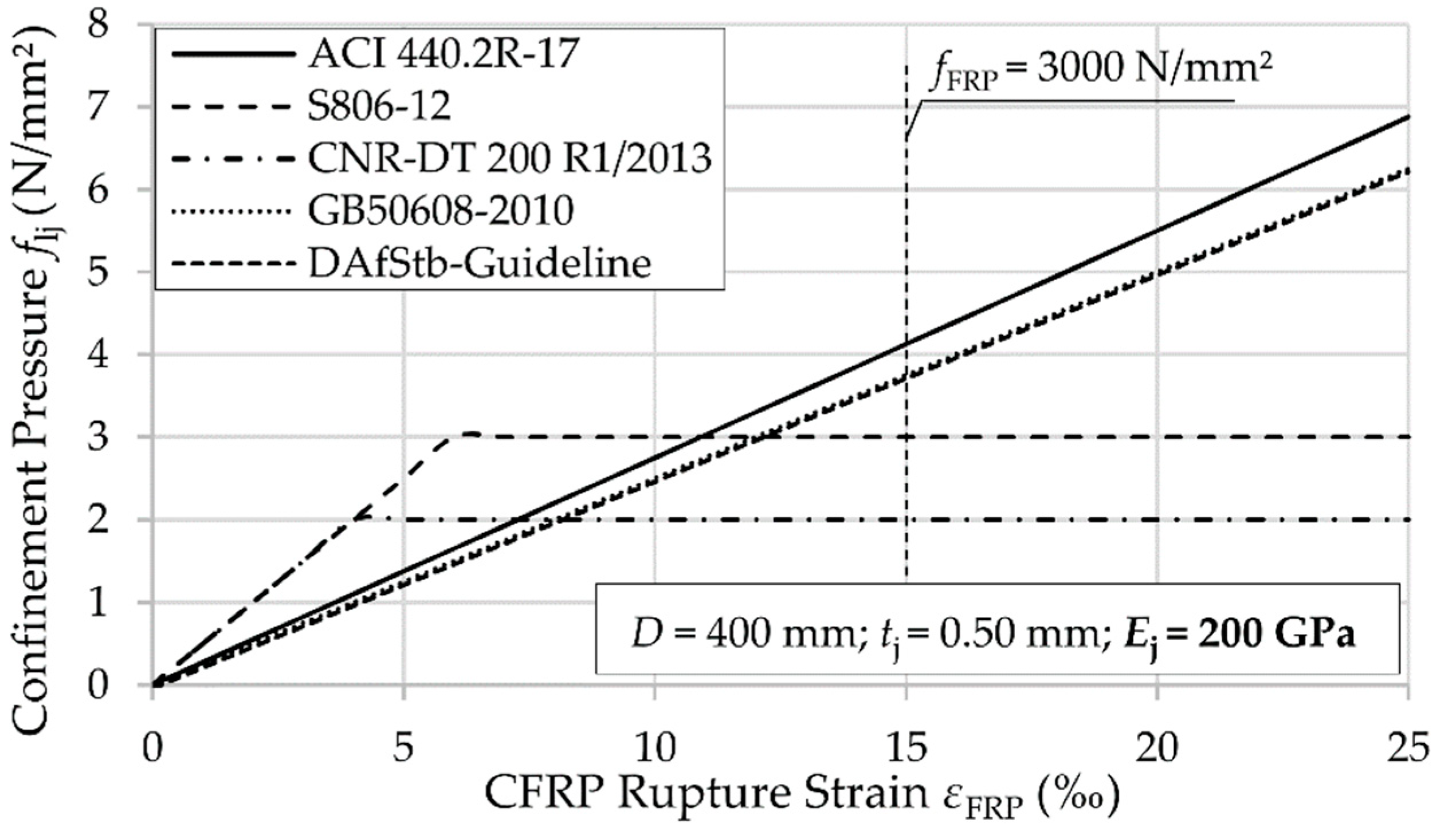

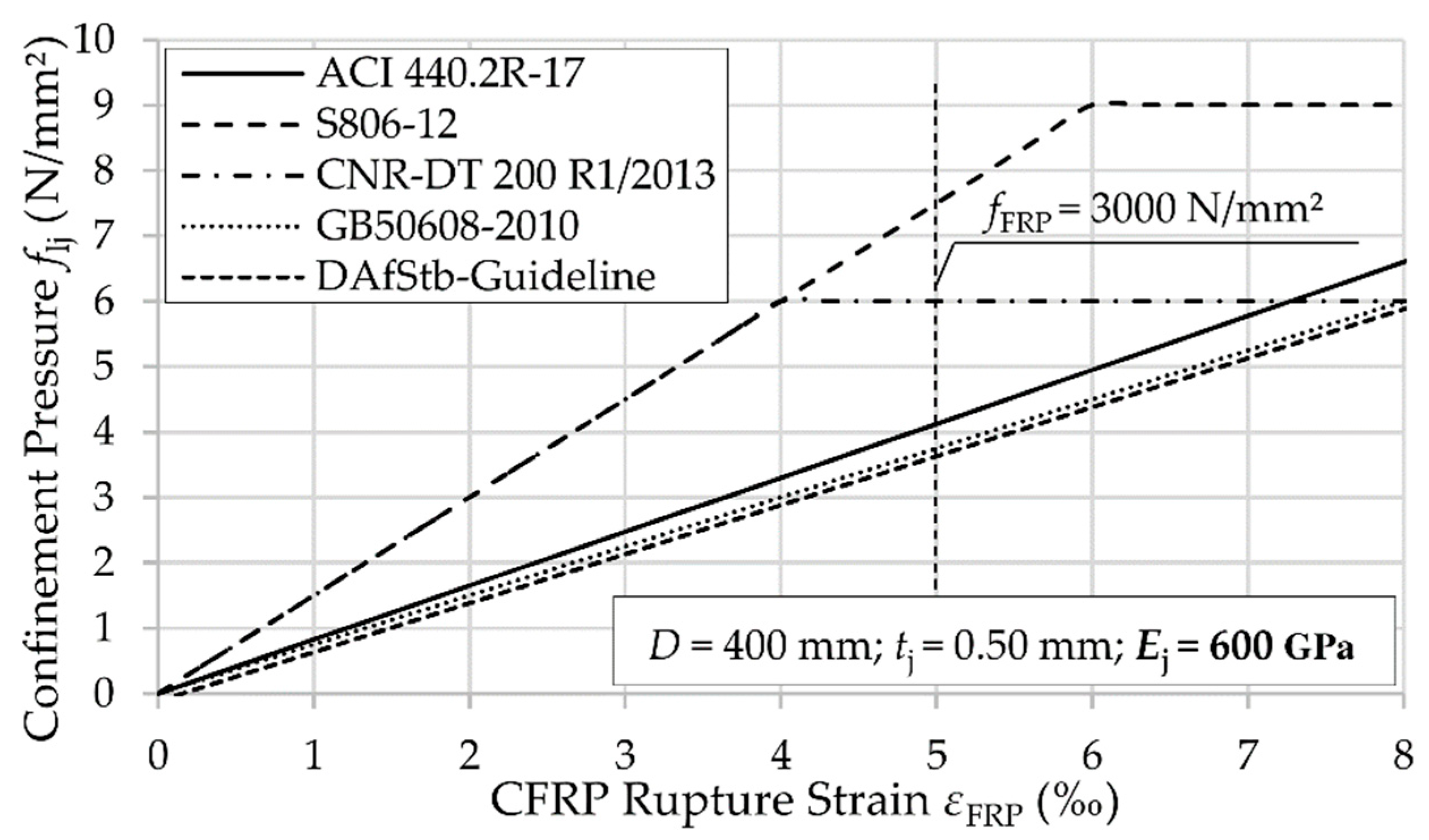

2.3. Rupture Strain of a CFRP Jacket and Confinement Pressure Provided by an FRP Jacket

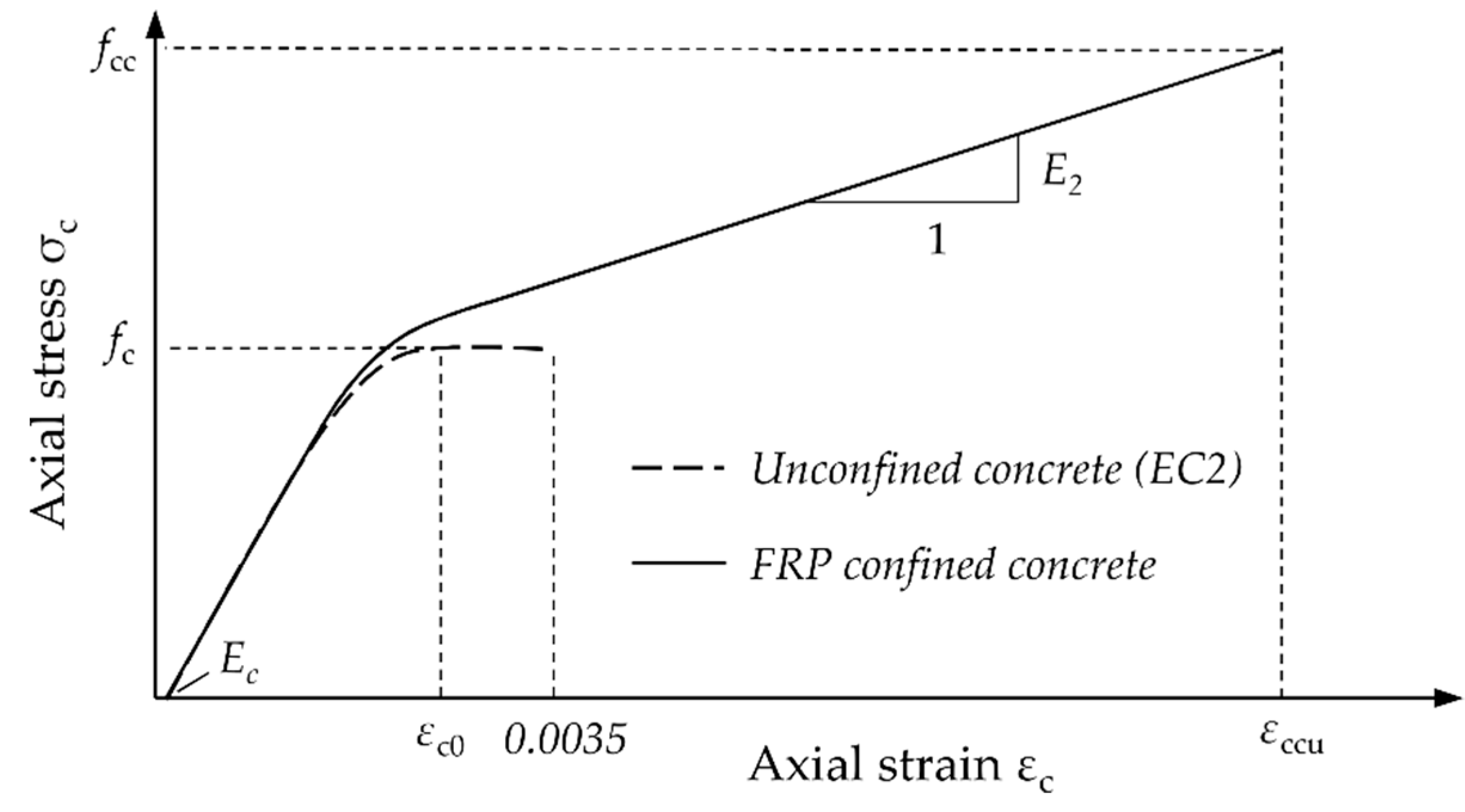

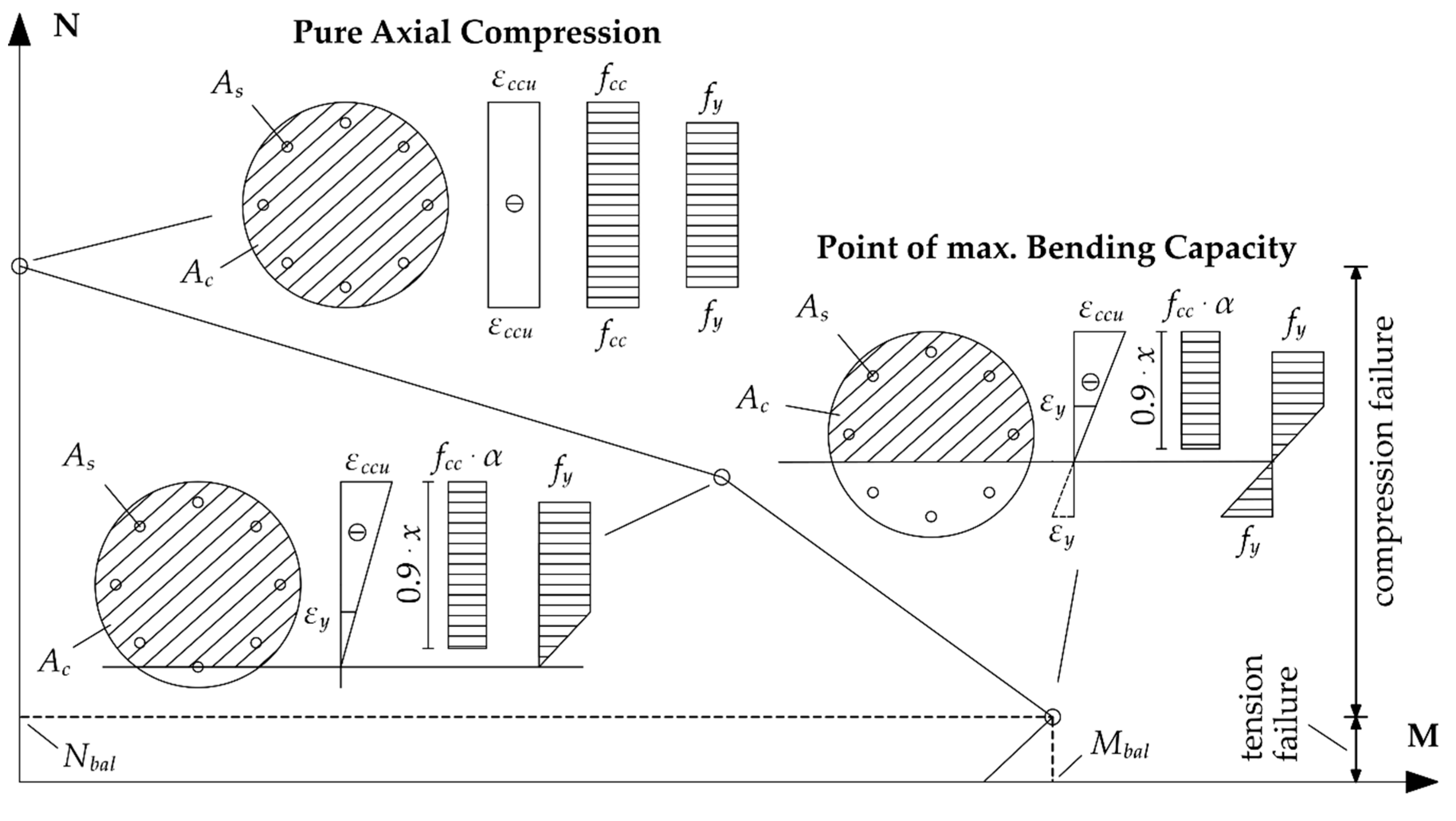

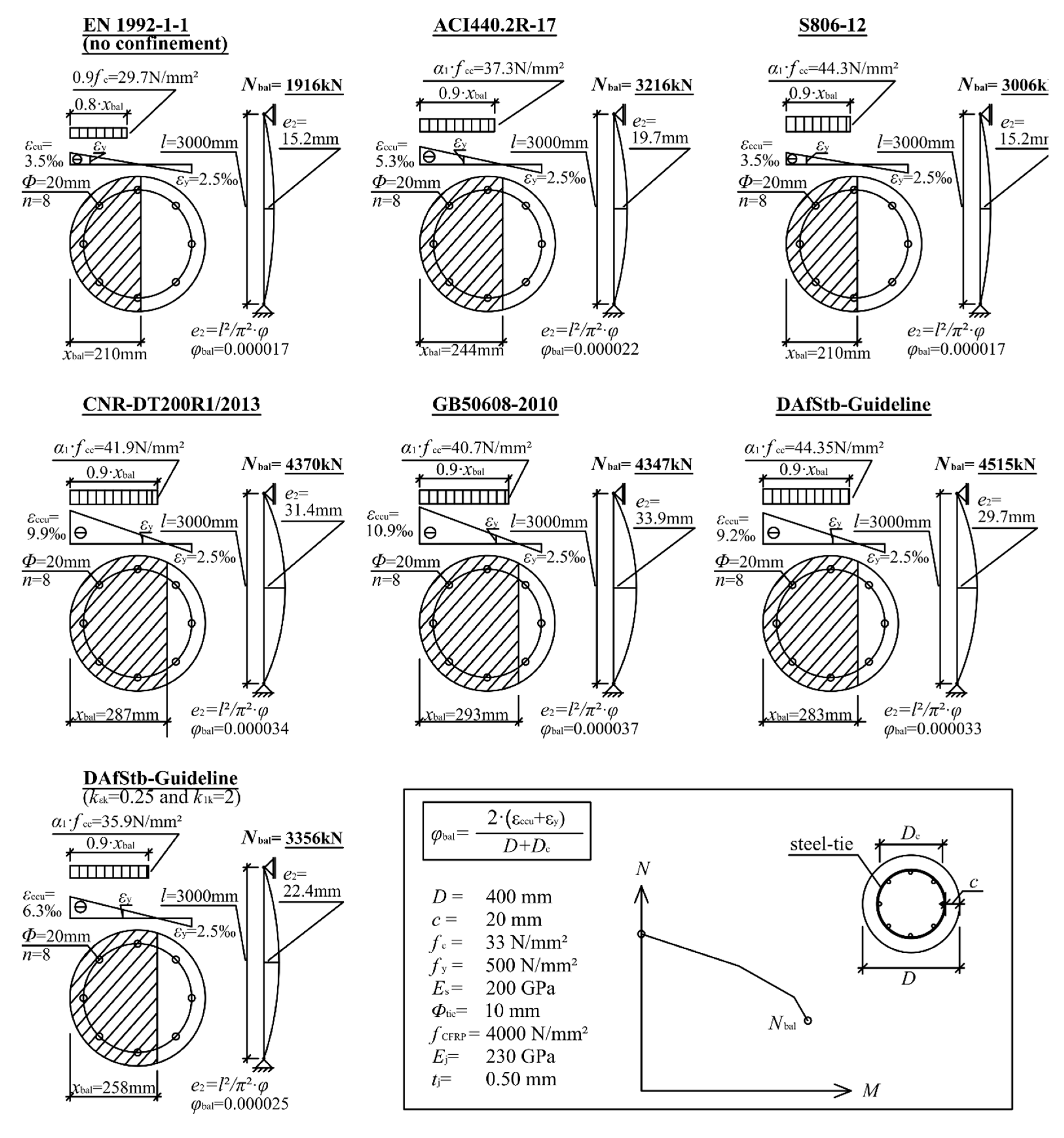

2.4. Maximum Confined Concrete Compressive Strength and Maximum Concrete Strain

2.4.1. Compressive Strength

2.4.2. Concrete Strain

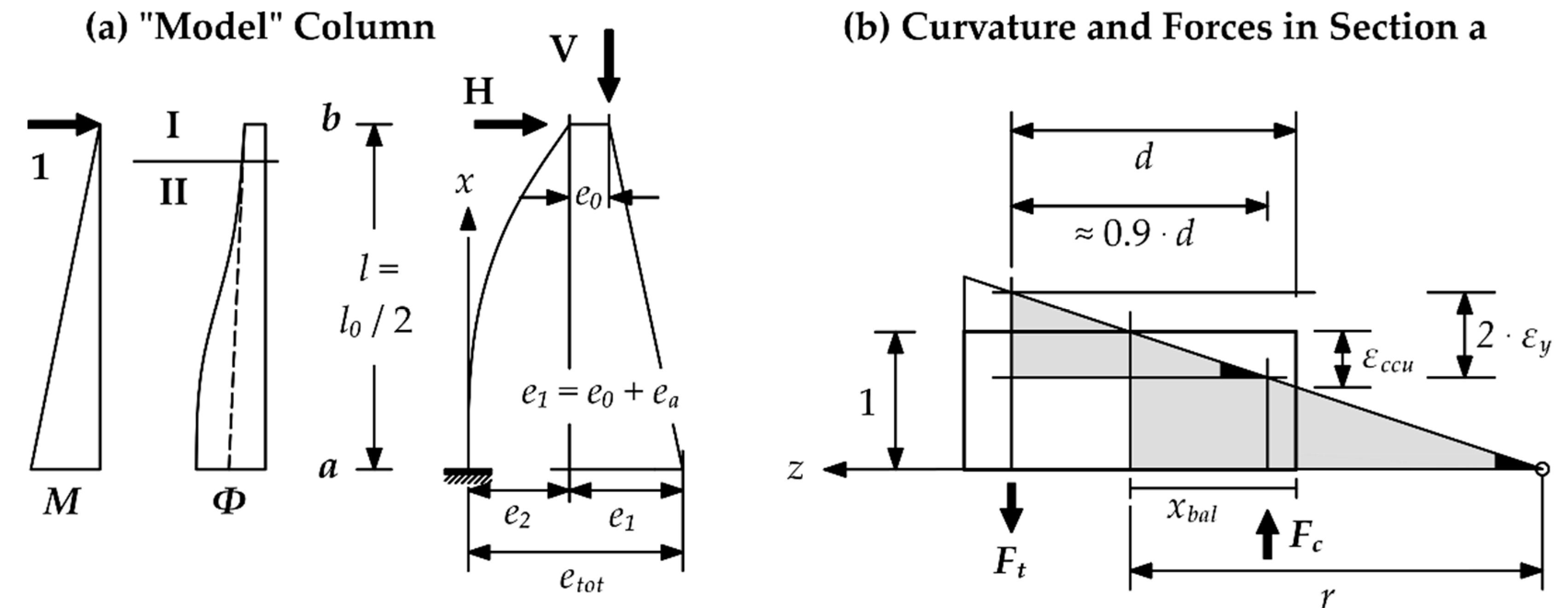

2.5. Example Calculation

2.6. Conclusion on Current Standards and Guidelines

- −

- the definition of the partial safety factors;

- −

- the commitment of the FRP efficiency factor kε;

- −

- the determination of k1; and

- −

- the estimation of the maximum longitudinal concrete strain.

3. Experimental Findings

3.1. Current Research Emphasis

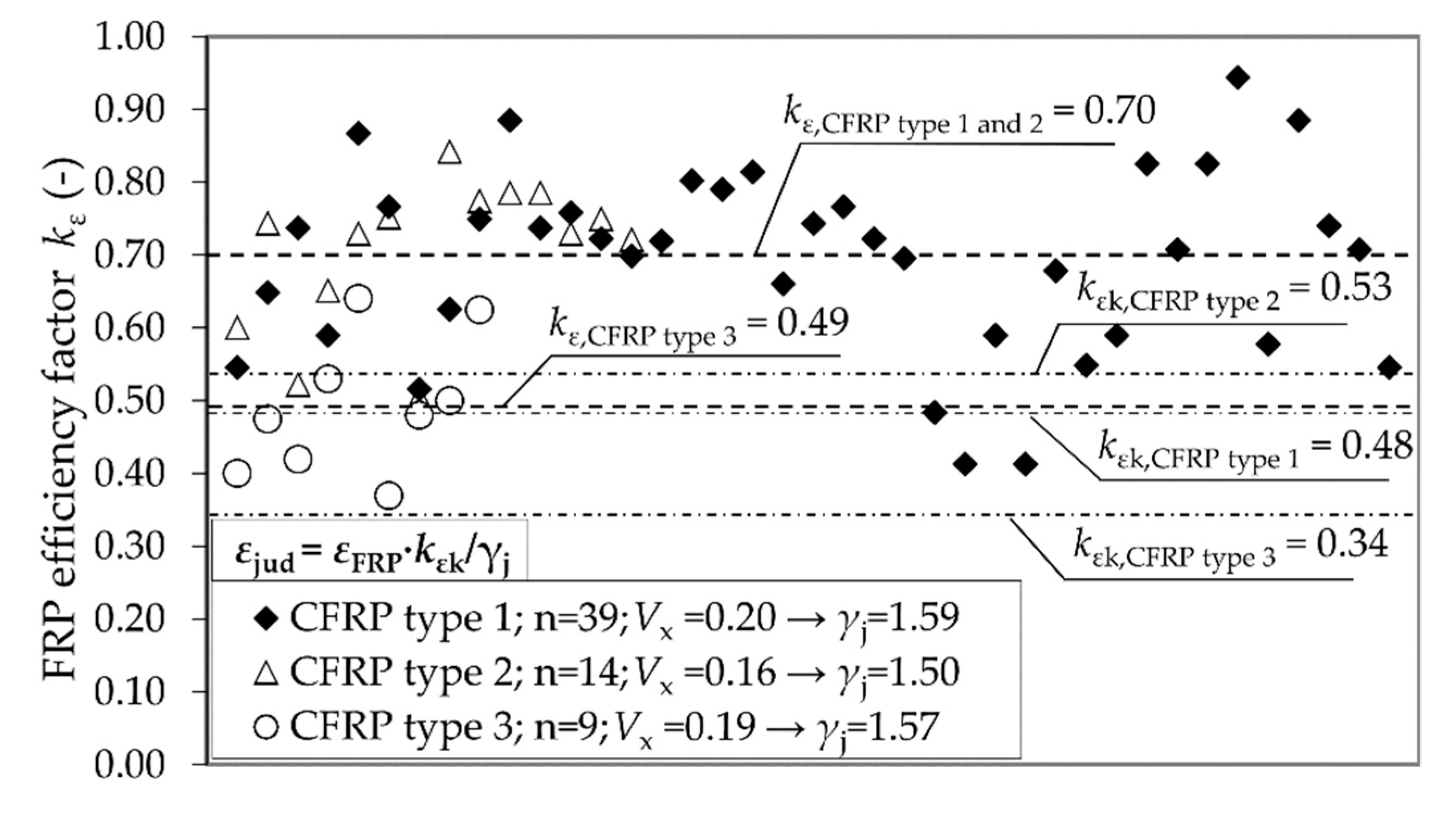

3.2. Results Concerning FRP Rupture Strain of the Jacket and Accompanied Partial Safety Factors

3.3. Results for the Maximum Confined Concrete Compressive Strength and Maximum Concrete Strain

4. Conclusions

Funding

Conflicts of Interest

References

- Matthys, S.; Toutanji, H.; Audenaert, K.; Taerwe, L. Axial Load Behavior of Large-Scale Columns Confined with Fiber-Reinforced Polymer Composites. ACI Struct. J. 2005, 102, 258–267. [Google Scholar]

- Lee, J.-Y.; Oh, Y.-J.; Park, J.-S.; Mansour, M.Y. Behavior of Concrete Columns Confined with Steel Spirals and FRP Composites. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, Canada, 1–6 August 2004. [Google Scholar]

- Lam, L.; Teng, J.G. Ultimate Condition of Fiber Reinforced Polymer-Confined Concrete. J. Compos. Constr. 2004, 8, 539–548. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H. Compressive Behavior of Concrete Confined by Various Types of FRP Composite Jackets. J. Reinf. Plast. Compos. 2003, 22, 1187–1201. [Google Scholar] [CrossRef]

- Eid, R.; Roy, N.; Paultre, P. Normal- and High-Strength Concrete Circular Elements Wrapped with FRP Composites. J. Compos. Constr. 2009, 13, 113–124. [Google Scholar] [CrossRef]

- Rousakis, T.C.; Rakitizis, T.D.; Karabinis, A.I. Design-Oriented Strength Model for FRP-Confined Concrete Members. J. Compos. Constr. 2012, 16, 615–625. [Google Scholar] [CrossRef]

- Rousakis, T.C.; Karabinis, A.I. Adequately FRP confined reinforced concrete columns under axial compressive monotonic or cyclic loading. Mater. Struct. 2012, 45, 957–975. [Google Scholar] [CrossRef]

- Achillopoulou, D.V.; Rousakis, T.C.; Karabinis, A.I. Square Reinforced Concrete Columns Strengthened Through Fiber Reinforced Polymer (FRP) Sheet Straps. In Proceedings of the 6th International Conference on FRP Composites in Civil Engineering (CICE 2012), Rome, Italy, 13–15 June 2012. [Google Scholar]

- Lin, G.; Teng, J.G. Stress-Strain Model for FRP-Confined Concrete in Eccentrically Loaded Circular Columns. J. Compos. Constr. 2019, 23. [Google Scholar] [CrossRef]

- Zeng, J.J.; Lin, G.; Teng, J.G.; Li, L.J. Behavior of large-scale FRP-confined rectangular RC columns under axial compression. Eng. Struct. 2018, 174, 629–645. [Google Scholar] [CrossRef]

- Ferrotto, M.F.; Fischer, O.; Niedermeier, R. Experimental investigation on the compressive behavior of short-term preloaded carbon fiber reinforced polymer-confined concrete columns. Struct. Concr. 2017, 19, 988–1001. [Google Scholar] [CrossRef]

- Pan, Y.; Rui, G.; Li, H.; Tang, H.; Xu, L. Study on stress-strain relation of concrete confined by CFRP under preload. Eng. Struct. 2017, 143, 52–63. [Google Scholar] [CrossRef]

- Jiang, C.; Yuan, F.; Wu, Y.-F.; Zhao, X.-M. Effect of Interfacial Bond on Plastic Hinge Length of FRP-Confined RC Columns. J. Compos. Constr. 2019, 23. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Jiang, C. Effect of load eccentricity on the stress-strain relationship of FRP-confined concrete columns. Compos. Struct. 2013, 98, 228–241. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-Oriented Stress-Strain Model for FRP-Confined Concrete in Rectangular Columns. J. Reinf. Plast. Compos. 2003, 22, 1149–1186. [Google Scholar] [CrossRef]

- Jiang, T.; Teng, J.G. Behavior and Design of Slender FRP-Confined Circular RC Columns. J. Compos. Constr. 2013, 17, 443–453. [Google Scholar] [CrossRef]

- Jiang, T. FRP-Confined RC Columns. Analysis, Behavior and Design. Ph.D. Thesis, Hong Kong Polytechnic University, Hong Kong, China, 2008. [Google Scholar]

- M/515 EN. Mandate for Amending Existing Eurocodes and Extending the Scope of Structural Eurocodes. European Commission, Enterprise and Industry Directorate: Brussels, Belgium, 2012. (Ref. Ares(2012)1516834). Available online: https://eurocodes.jrc.ec.europa.eu/doc/mandate/m515_EN_Eurocodes.pdf (accessed on 10 July 2019).

- Eurocode 2: Design of Concrete Structures; EN 1992-1-1; European Committee for Standardization: Brussels, Belgium, 2004.

- Design and Construction of Building Structures with Fibre-Reinforced Polymers; CSA S806-2012 (R2017); Canadian Standards Association: Ontario, ON, Canada, 2012; (Reaffirmed 2017).

- CNR-DT 200 R1/2013. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures. National Research Council—Advisory Committee on Technical Recommendations for Construction: Rome, Italy, 2013. Available online: https://www.cnr.it/en/node/2636 (accessed on 16 June 2019).

- Technical code for Infrastructure Application of FRP Composites; GB50608-2010; Ministry of Housing and Urban-Rural Development, General Administration of Quality Supervision, Inspection and Quarantine: Beijing, China, 2010. (In Chinese)

- DAfStb-Richtlinie Verstärken von Betonbauteilen mit geklebter Bewehrung; Deutscher Ausschuss für Stahlbeton e. V. (DAfStb): Berlin, Germany, 2012. (In German)

- Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; ACI 440.2R-17; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2017.

- Teng, J.G.; Jiang, T.; Lam, L.; Luo, Y.Z. Refinement of a Design-Oriented Stress-Strain Model for FRP-Confined Concrete. J. Compos. Constr. 2009, 13, 269–278. [Google Scholar] [CrossRef]

- Niedermeier, R. Verstärkung von Stahlbetondruckgliedern durch Umschnürung. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2009. (In German). [Google Scholar]

- FIB Bulletin No. 80. Partial Factor Methods for Existing Concrete Structures; Fédération Internationale du Béton (fib): Lausanne, Switzerland, 2016; ISBN 978-2-88394-120-5.

- Smith, S.T.; Kim, S.J.; Zhang, H. Behavior and Effectiveness of FRP Wrap in the Confinement of Large Concrete Cylinders. J. Compos. Constr. 2010, 14, 573–582. [Google Scholar] [CrossRef]

- Toutanji, H.; Matthys, S.; Taerwe, L.; Audenaert, K. Behaviour of large-scale columns confined with FRP composites in compression. In Proceedings of the 2nd International Conference on FRP Composites in Civil Engineering (CICE 2004), Adelaide, Australia, 8–10 December 2004. [Google Scholar]

- Pellegrino, C.; Modena, C. Analytical Model for FRP Confinement of Concrete Columns with and without Internal Steel Reinforcement. J. Compos. Constr. 2010, 14, 693–705. [Google Scholar] [CrossRef]

- Samaan, M.; Mirmiran, A.; Shahawy, M. Model of Concrete Confined by Fiber Composites. J. Struct. Eng. 1998, 124, 1025–1031. [Google Scholar] [CrossRef]

- Cui, C.; Sheikh, S.A. Analytical Model for Circular Normal- and High-Strength Concrete Columns Confined with FRP. J. Compos. Constr. 2010, 14, 562–572. [Google Scholar] [CrossRef]

- Hu, H.; Seracino, R. Analytical Model for FRP-and-Steel-Confined Circular Concrete Columns in Compression. J. Compos. Constr. 2014, 18. [Google Scholar] [CrossRef]

- Eid, R.; Paultre, P. Analytical Model for FRP-Confined Circular Reinforced Concrete Columns. J. Compos. Constr. 2008, 12, 541–552. [Google Scholar] [CrossRef]

- Teng, J.G.; Lin, G.; Yu, T. Analysis-Oriented Stress-Strain Model for Concrete under Combined FRP-Steel Confinement. J. Compos. Constr. 2015, 19. [Google Scholar] [CrossRef]

- Deutscher Ausschuss für Stahlbeton e. V. Erläuterungen zu DIN EN 1992-1-1 und DIN EN 1992-1-1/NA (Eurocode 2), 1st ed.; Beuth Verlag GmbH: Berlin, Germany, 2012; ISBN 978-3-410-65218-2. (In German)

- Käseberg, S. Verstärkung von Stahlbetonstützen mit Kreisquerschnitt durch Umschnürung mit CFK-Werkstoffen. Ph.D. Thesis, Technische University Dresden, Dresden, Germany, 2016. (In German). [Google Scholar]

- Käseberg, S.; Holschemacher, K. Dual Confinement of Circular Concrete Columns Consisting of CFRP Sheets and Steel Ties or Spirals. J. Civil. Eng. Archit. Res. 2015, 2, 469–479. [Google Scholar]

- Käseberg, S.; Holschemacher, K.; Curbach, M. Zum Tragverhalten CFK-umschnürter Stahlbetonstützen mit Kreisquerschnitt. Beton- und Stahlbetonbau 2018, 113, 505–514. (In German) [Google Scholar] [CrossRef]

- Bai, Y.-L.; Dai, J.-G.; Teng, J.G. Buckling of steel reinforcing bars in FRP-confined RC columns: An experimental study. Constr. Build. Mater. 2017, 140, 403–415. [Google Scholar] [CrossRef]

| Title | Country | Publishing Institution | Introduced | Confinement Section Length (pages) | Reference |

|---|---|---|---|---|---|

| ACI 440.2R-17 | USA | American Concrete Institute (ACI) | 2017 | 4 | [24] |

| S806-12 | Canada | Canadian Standards Association (CSA) | 2012 | 1 | [20] |

| CNR-DT 200 R1/2013 | Italy | Advisory Committee on Technical Recommendations for Construction (CNR) | 2014 | 6 | [21] |

| GB 50608-2010 | China | Standardization Administration of the People’s Republic of China | 2011 | 8 | [22] |

| DAfStb-Guideline | Germany | German Committee for Structural Concrete (DAfStb) | 2012 | 5 | [23] |

| Standard/Guideline | Loading Condition | Limitations | Limit State | Model |

|---|---|---|---|---|

| ACI 440.2R-17 | AC AC + B | SR-section: h/b ≤ 2.0; h or b ≤ 900 mm; fully wrapped only | ULS SLS | Lam and Teng [15] |

| S806-12 | AC + B | SR-section: h/b ≤ 1.5; R ≥ 20 mm; fully wrapped only | ULS | not specified |

| CNR-DT 200 R1/2013 | AC AC + B | SR-section: h/b ≤ 2.0; h or b ≤ 900 mm; discontinuous wrapping: s ≤ D/2 | ULS | not specified |

| GB 50608-2010 | AC + B | SR-section: h/b ≤ 1.5; h or b ≤ 600 mm; R ≥ 20 mm; fully wrapped only | ULS | Teng et al. [25]; Jiang [17] |

| DAfStb-Guideline | AC + B | circular only: D ≥ 120 mm; λ ≤ 40; e0/D ≤ 0.25 fc ≤ 58 N/mm²; fully wrapped only | ULS SLS | Niedermeier [26]; Jiang [17] |

| Standard/Guideline | Input Value | Strength Reduction or Partial Safety Factor | Partial Safety Factor Environment | Additional Factor |

|---|---|---|---|---|

| ACI 440.2R-17 | mean values | φ = 0.75 (spiral); φ = 0.70 (steel-tie) | CE for C, G, or A under I, E, or Agg | Ψf = 0.95 |

| S806-12 | mean values | γj = 0.75; γc = 0.65; γs = 0.85 | not used | not used |

| CNR-DT 200 R1/2013 | characteristic values | γj = 1.10; γc = 1.50; γs = 1.15 | ηa for C, G, or A under I, E, or Agg | γRd = 1.10 |

| GB 50608-2010 | characteristic values | γj = 1.40 | γe for C, G, B, or A under I, E, or Agg | not used |

| DAfStb-Guideline | characteristic values | γj = 1.35; γc = 1.50; γs = 1.15 | αT = 0.70 (temperature); αE = 1.00 (loading); αF = 1.00 (moisture); αZ = 0.75 (loading duration) | αcc = 0.85 |

| Standard/Guideline | Efficiency Factor kε | Characteristic Value kεk | Rupture Hoop Strain Model | Further Limit |

|---|---|---|---|---|

| ACI 440.2R-17 | 0.55 | not used | εju = kε · εFRP · CE | εju ≤ 0.004 if AC + B |

| S806-12 | 1.00 | not used | εjud = γj · εFRP | εjud ≤ 0.006 |

| CNR-DT 200 R1/2013 | 1.00 | not used | εjud= ηa · εFRP,k/γj | εjud ≤ 0.004 |

| GB 50608-2010 | 0.50 (CFRP) 0.70 (GFRP) | not used | εjud= kε · εFRP,k/(γj · γe) | not used |

| DAfStb-Guideline | 0.50 | 0.25 | εjuk= kεk · εFRP,k · αT · αE · αF · αZ | not used |

| Standard/Guideline | Factor k1 | Factor k1k | Particularities |

|---|---|---|---|

| ACI 440.2R-17 | 3.30 | not used | additional, k1 is multiplied with Ψf |

| S806-12 | 6.70 · (flj)−0.17 | not used | no |

| CNR-DT 200 R1/2013 | 2.60 | not used | instead of flj, k1 is multiplied with fcd · (fljd/fcd)2/3 |

| GB 50608-2010 | 3.50 | not used | additional, k1 is multiplied with (1–6.5/βj); βj = (Ej · tj)/(fck · D/2) |

| DAfStb-Guideline | 3.66 | 2.00 | instead of flj, k1 is multiplied with (fljk + (ρw · fyk−Δp) · ke); ke = ((Dc−s/2)/D)2 |

| Standard/Guideline | Approach | Factors/Particularities |

|---|---|---|

| ACI 440.2R-17 | Equation (2) | k2 = 1.50, k3 = 12, k4 = 0.45; εccu ≤ 0.01 |

| S806-12 | not provided (refer to CAN/CSA-A23.3→εccu = 0.0035) | no |

| CNR-DT 200 R1/2013 | for calculation of fljd→ | |

| GB 50608-2010 | no | |

| DAfStb-Guideline | Equation (2) | k2 = 1.75, k3 = 19, k4 = 0; in Equation (2): (flj/fc) is replaced by (fljk/fc) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaeseberg, S.; Messerer, D.; Holschemacher, K. Assessment of Standards and Codes Dedicated to CFRP Confinement of RC Columns. Materials 2019, 12, 2390. https://doi.org/10.3390/ma12152390

Kaeseberg S, Messerer D, Holschemacher K. Assessment of Standards and Codes Dedicated to CFRP Confinement of RC Columns. Materials. 2019; 12(15):2390. https://doi.org/10.3390/ma12152390

Chicago/Turabian StyleKaeseberg, Stefan, Dennis Messerer, and Klaus Holschemacher. 2019. "Assessment of Standards and Codes Dedicated to CFRP Confinement of RC Columns" Materials 12, no. 15: 2390. https://doi.org/10.3390/ma12152390

APA StyleKaeseberg, S., Messerer, D., & Holschemacher, K. (2019). Assessment of Standards and Codes Dedicated to CFRP Confinement of RC Columns. Materials, 12(15), 2390. https://doi.org/10.3390/ma12152390