Design and Development of Hybrid Al2O3 Based Composites with Toughening and Self-Lubricating Second-Phase Inclusions

Abstract

:1. Introduction

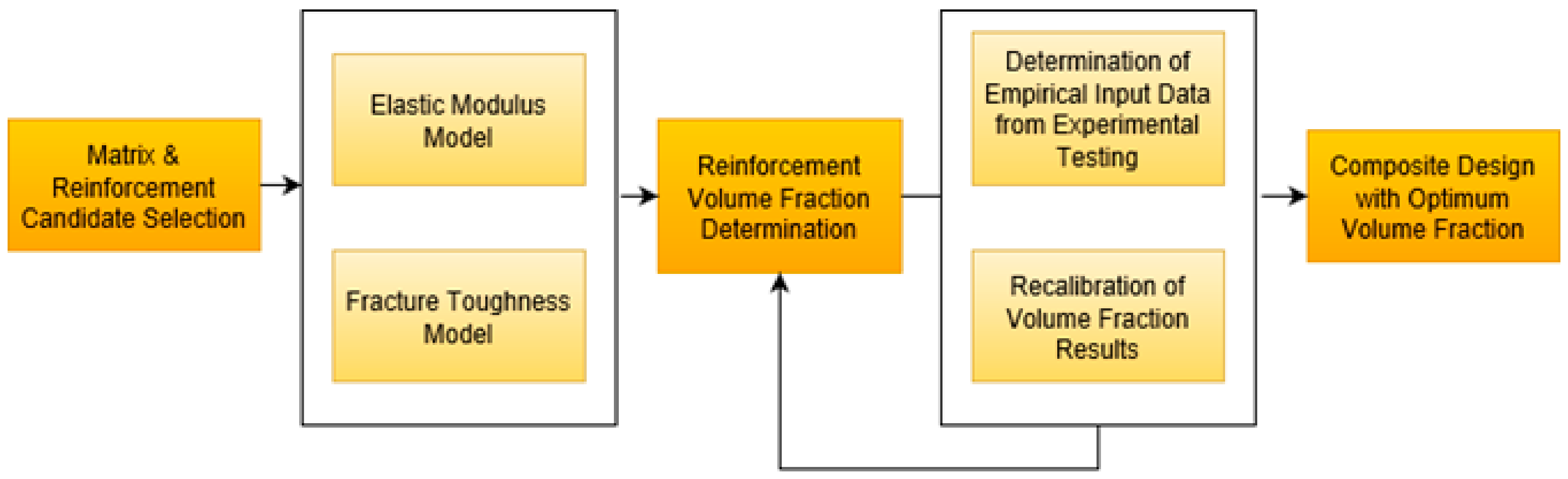

2. Mathematical Models Used at Material Design Stage

2.1. Fracture Toughness Model

2.2. Mean-Field Homogenization Scheme

2.3. Consideration of Second-Phase Inclusions

3. Experimental Setup

4. Results and Discussion

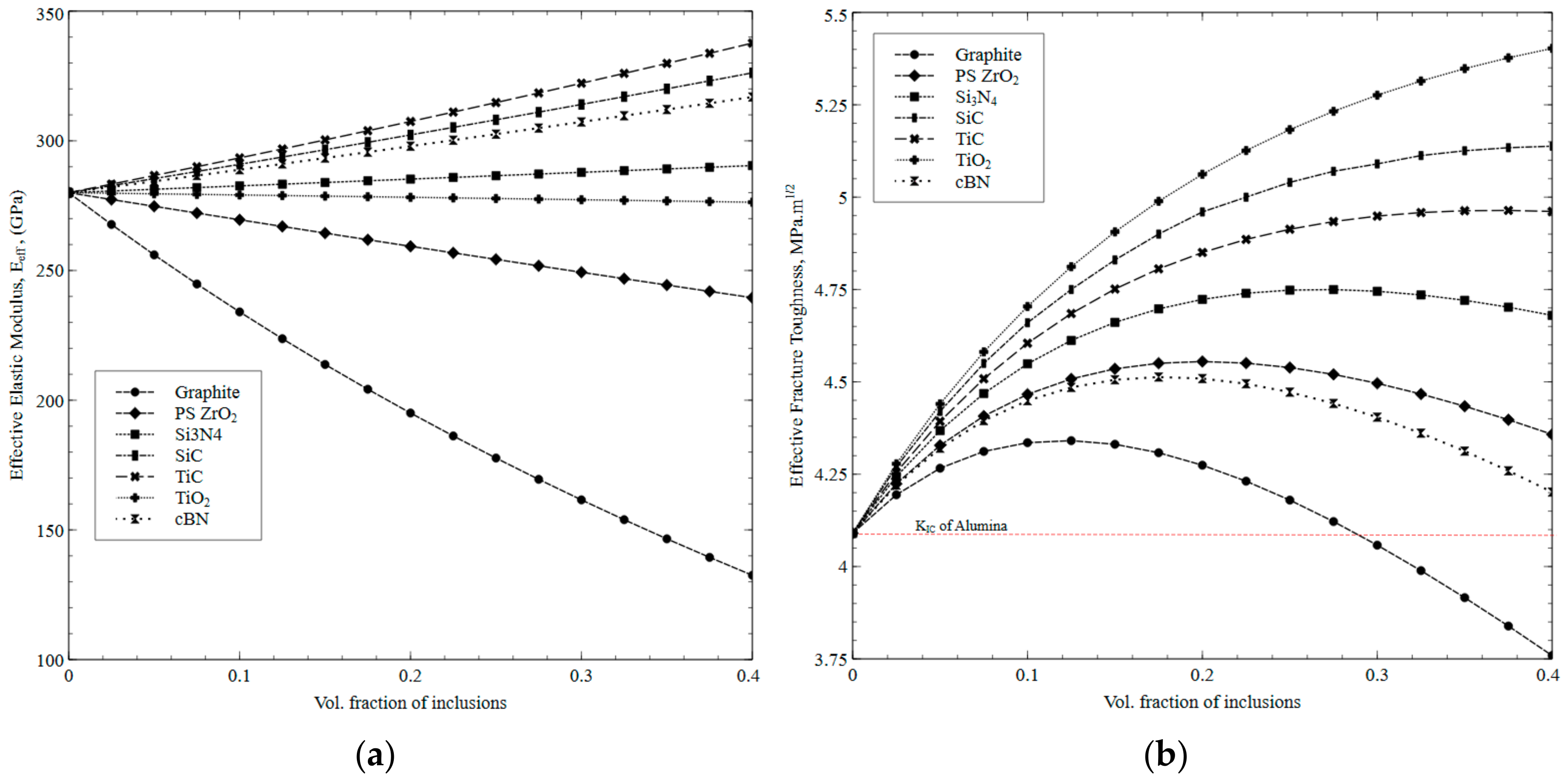

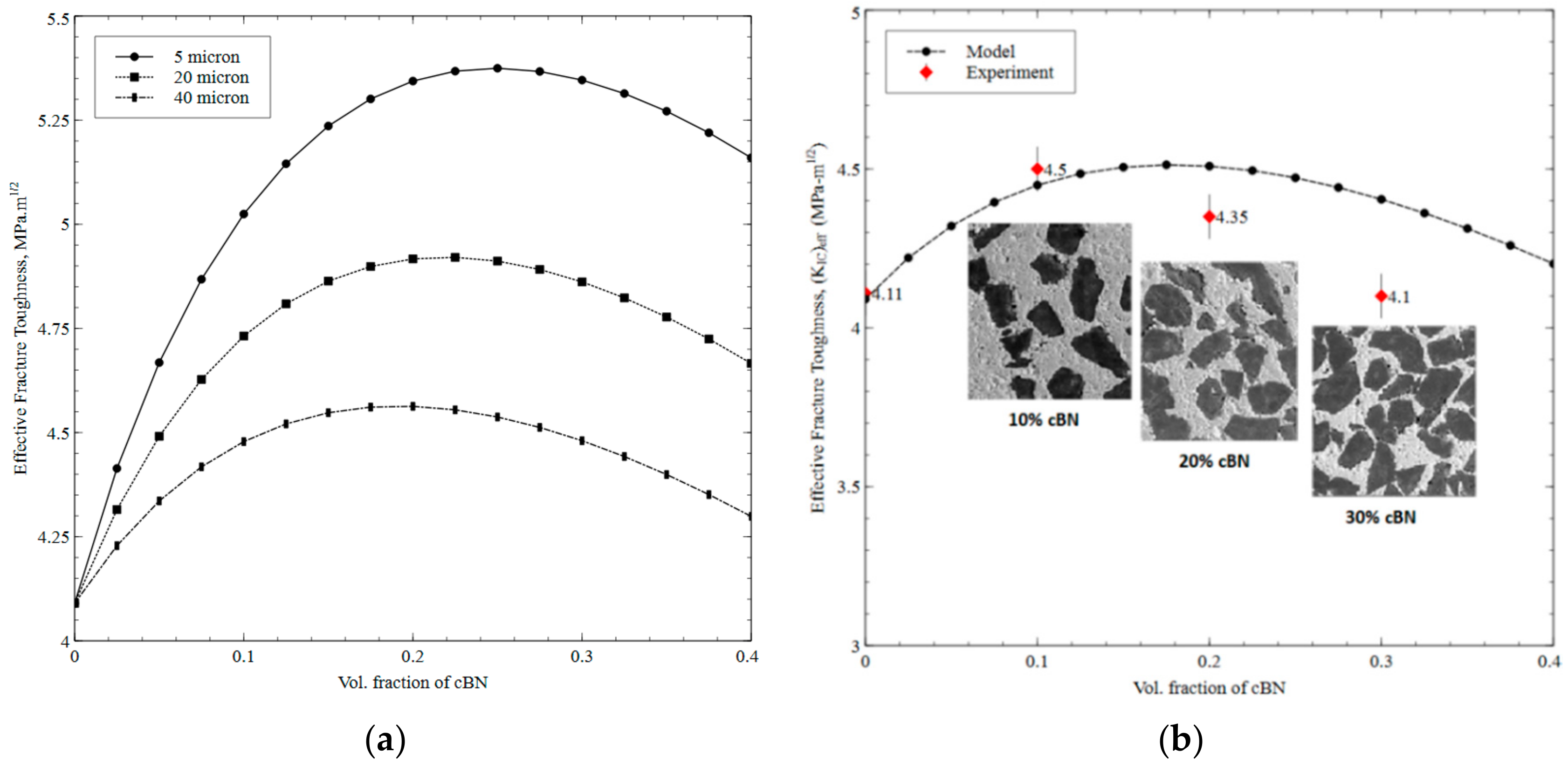

4.1. Correlation between Fracture Toughness and Single Second-Phase Inclusion in Al2O3 Matrix

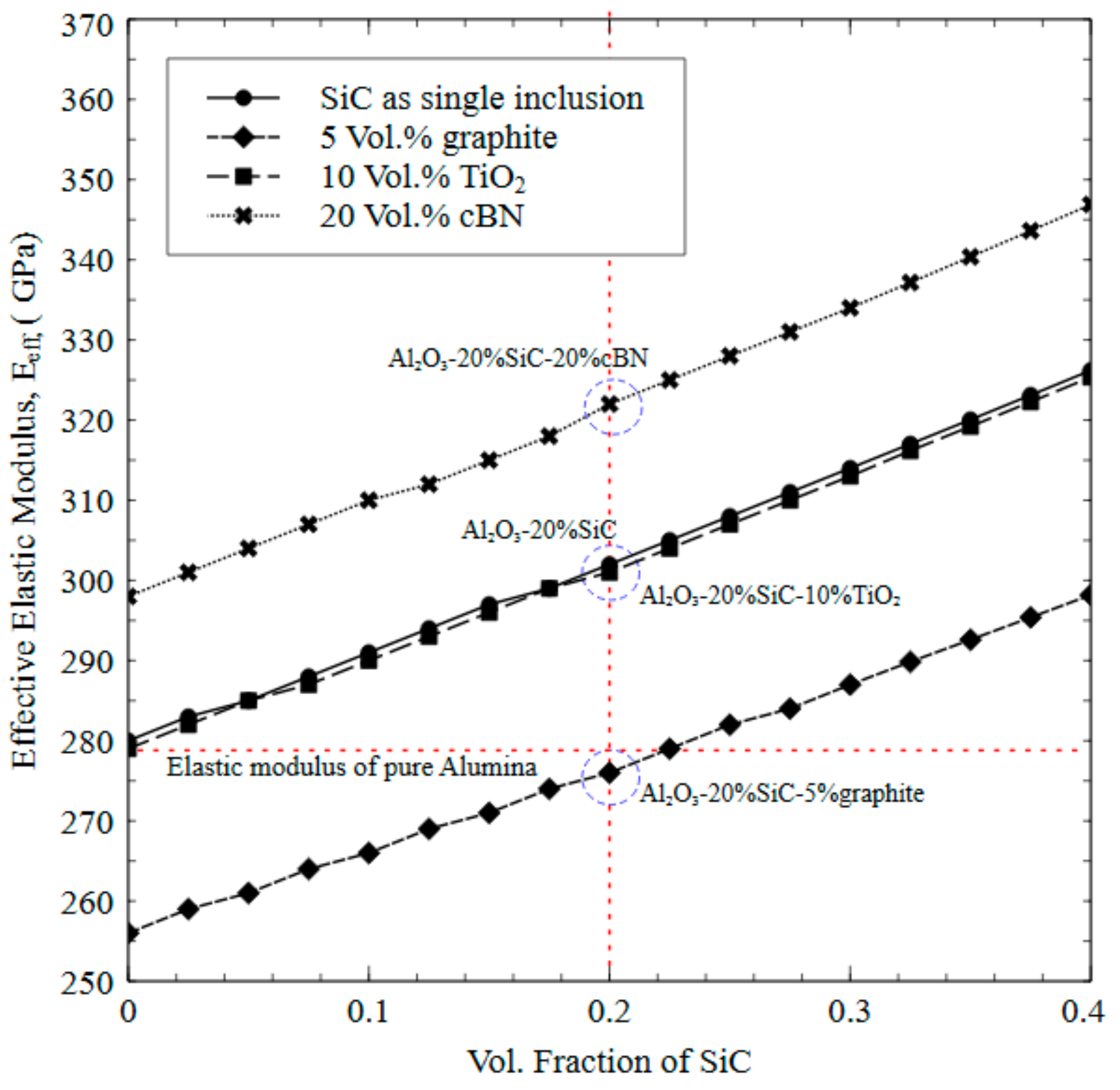

4.2. Hybrid Second-Phase Inclusions Mixed in Al2O3 Matrix

4.3. Validation of Results

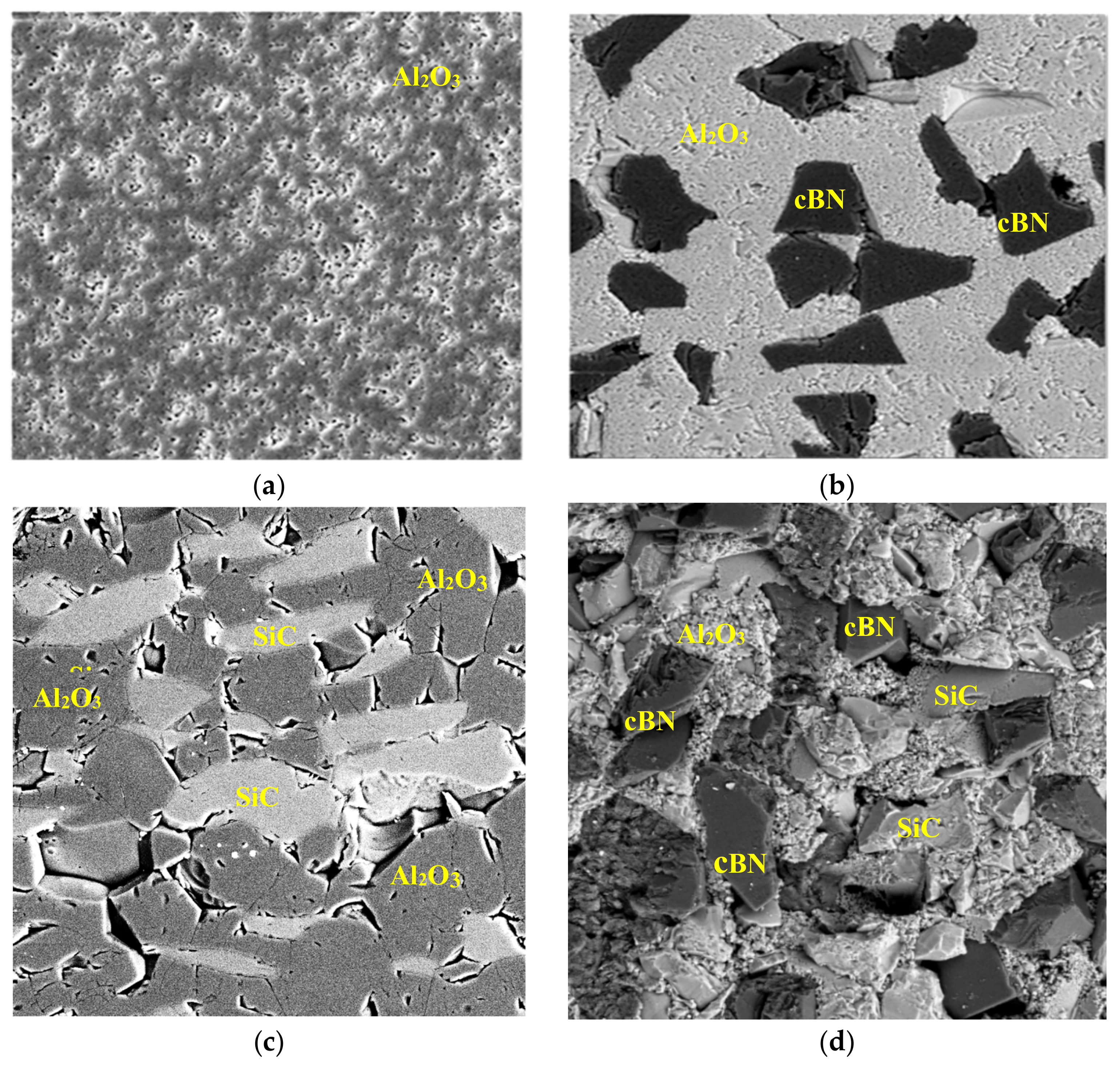

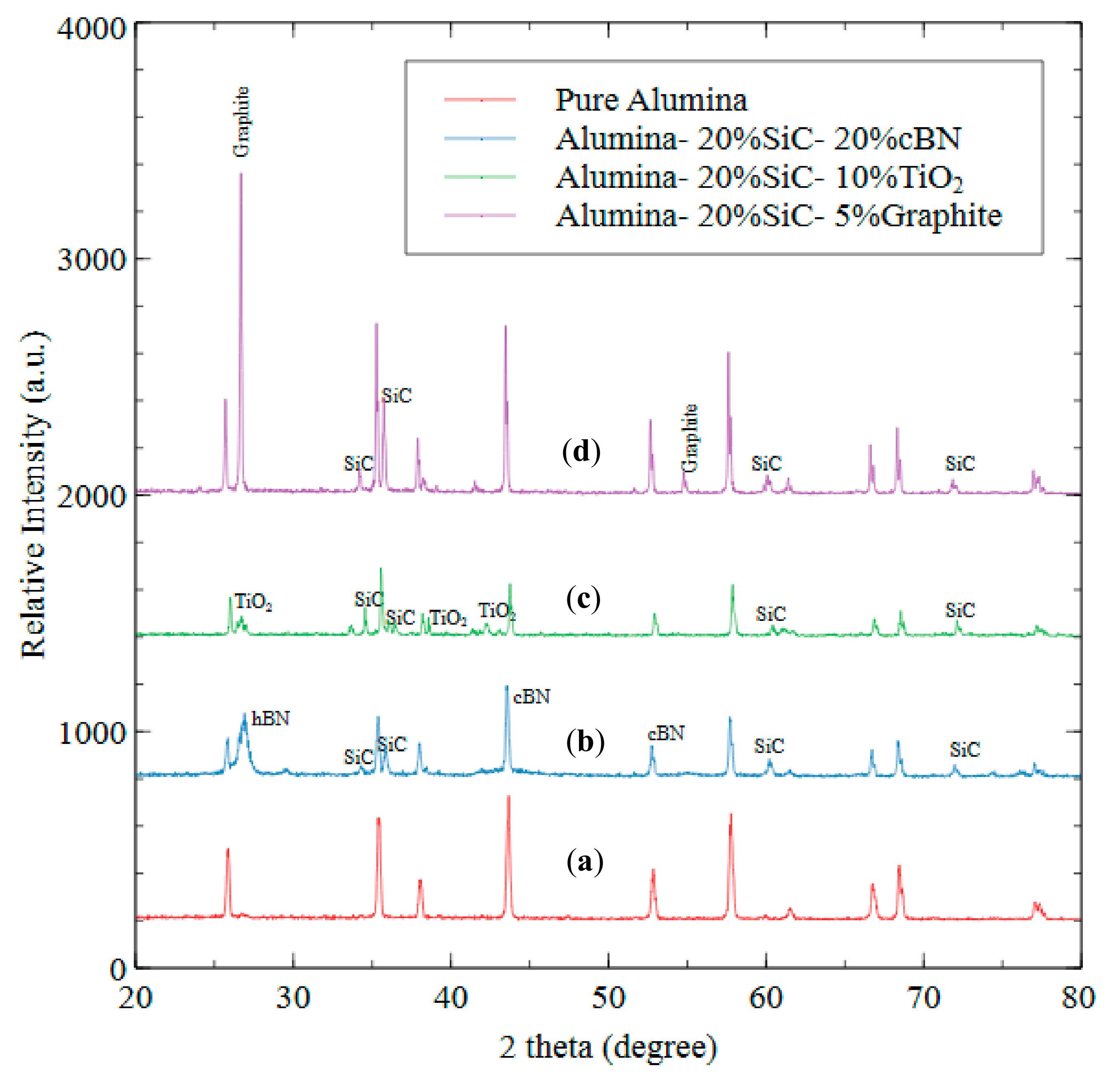

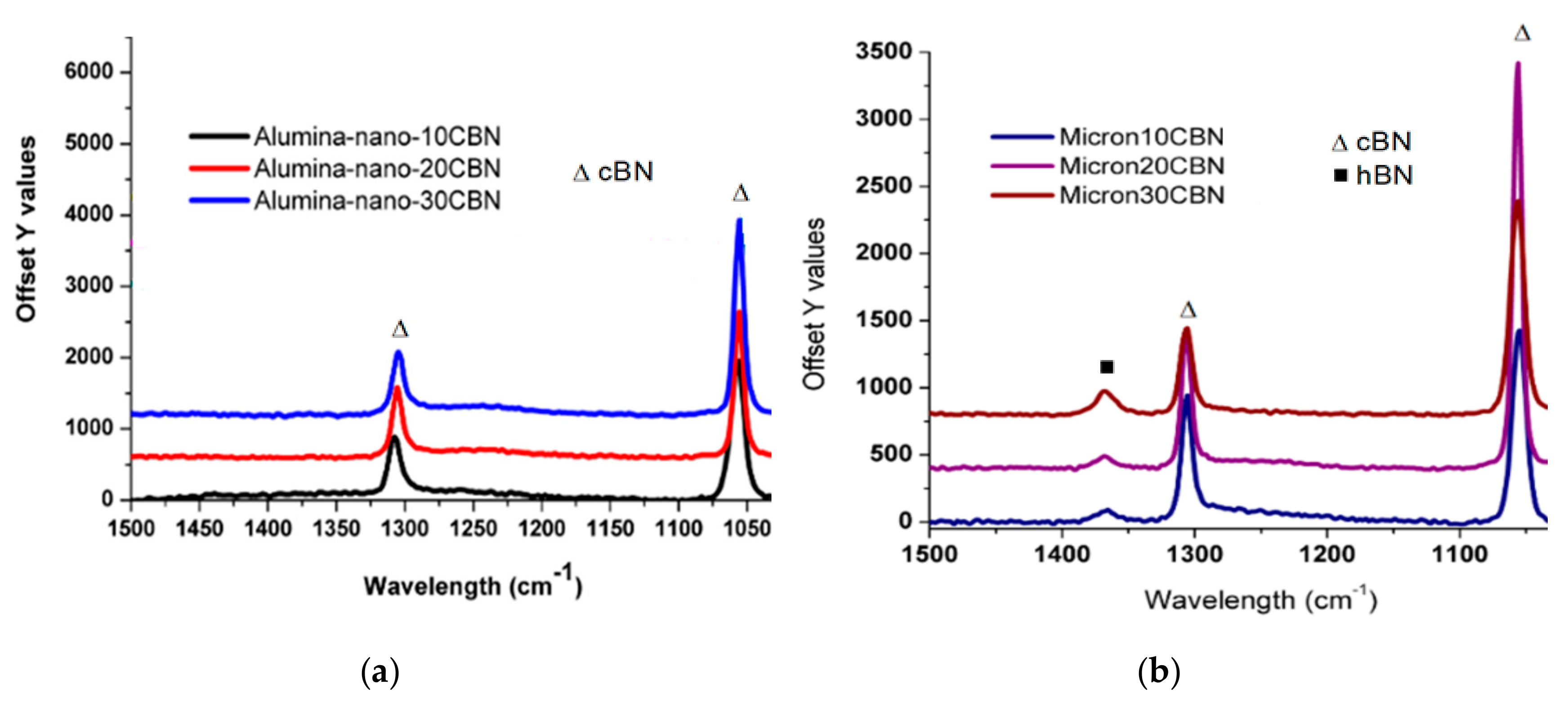

4.4. Composites Characterization

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Grzesik, W. Advanced Machining Processes of Metallic Materials: Theory, Modelling and Applications; Elsevier Science: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Schneider, C.G., Jr. Cutting Tool Applications; ASM International: Russell, OH, USA, 2002. [Google Scholar]

- Wertheim, R.; Layyous, A.; Harpaz, J. Development and Application of New Cutting Tool Materials; Proc. Conf. Improv. Mach. Tool Performance, San Sebastian, Spain, 1998, pp. 303–313. Available online: https://pdfs.semanticscholar.org/02f1/f81593eb68de1747afad12f50d0c592dd019.pdf (accessed on 20 June 2019).

- Yallese, M.A.; Chaoui, K.; Zeghib, N.; Boulanouar, L.; Rigal, J.F. Hard machining of hardened bearing steel using cubic boron nitride tool. J. Mater. Process. Technol. 2009, 209, 1092–1104. [Google Scholar] [CrossRef]

- Sahin, Y. Comparison of tool life between ceramic and cubic boron nitride (CBN) cutting tools when machining hardened steels. J. Mater. Process. Technol. 2009, 209, 3478–3489. [Google Scholar] [CrossRef]

- Fabbri, L.; Scafè, E.; Dinelli, G. Thermal and elastic properties of alumina-silicon carbide whisker composites. J. Eur. Ceram. Soc. 1994, 14, 441–446. [Google Scholar] [CrossRef]

- Ortiz-Merino, J.L.; Todd, R.I. Relationship between wear rate, surface pullout and microstructure during abrasive wear of alumina and alumina/SiC nanocomposites. Acta Mater. 2005, 53, 3345–3357. [Google Scholar] [CrossRef]

- Tiegs, T. SiC Whisker Reinforced Alumina. In Handbook of Ceramic Composites; Springer: Boston, MA USA, 2006. [Google Scholar]

- Xu, C.; Ai, X.; Huang, C. Fabrication and performance of an advanced ceramic tool material. Wear 2001, 249, 503–508. [Google Scholar] [CrossRef]

- Yeomans, J. Ductile particle ceramic matrix composites—Scientific curiosities or engineering materials? J. Eur. Ceram. Soc. 2008, 28, 1543–1550. [Google Scholar] [CrossRef]

- Song, S.X.; Ai, X.; Zhao, J.; Huang, C.Z. Al2O3/Ti(C0.3N0.7) cutting tool material. Mater. Sci. Eng. A 2003, 356, 43–47. [Google Scholar] [CrossRef]

- Kumar, A.S.; Durai, A.R.; Sornakumar, T. Wear behaviour of alumina based ceramic cutting tools on machining steels. Tribol. Int. 2006, 39, 191–197. [Google Scholar] [CrossRef]

- Kumar, A.S.; Durai, A.R.; Sornakumar, T. Development of alumina—ceria ceramic composite cutting tool. Int. J. Refract. Met. Hard Mater. 2004, 22, 17–20. [Google Scholar] [CrossRef]

- Irshad, H.M.; Ahmed, B.A.; Ehsan, M.A.; Khan, T.I.; Laoui, T.; Yousaf, M.R.; Ibrahim, A.; Hakeem, A.S. Investigation of the structural and mechanical properties of micro-/nano-sized Al2O3 and cBN composites prepared by spark plasma sintering. Ceram. Int. 2017, 43, 10645–10653. [Google Scholar] [CrossRef]

- Jianxin, D.; Tongkun, C.; Xuefeng, Y.; Jianhua, L. Self-lubrication of sintered ceramic tools with CaF2 additions in dry cutting. Int. J. Mach. Tools Manuf. 2006, 46, 957–963. [Google Scholar] [CrossRef]

- Jianxin, D.; Lili, L.; Jianhua, L.; Jinlong, Z.; Xuefeng, Y. Failure mechanisms of TiB2 particle and SiC whisker reinforced Al2O3 ceramic cutting tools when machining nickel-based alloys. Int. J. Mach. Tools Manuf. 2005, 45, 1393–1401. [Google Scholar] [CrossRef]

- Broniszewski, K.; Wozniak, J.; Kostecki, M.; Olszyna, A. Properties of Alumina—Graphene Oxide Composites. Mater. Today Proc. 2015, 2, 370–375. [Google Scholar] [CrossRef]

- Dong, X.; Jahanmir, S.; Ives, L.K. Wear transition diagram for silicon carbide. Tribol. Int. 1995, 28, 559–572. [Google Scholar] [CrossRef]

- Dong, X.; Jahanmir, S. Wear transition diagram for silicon nitride. Wear 1993, 165, 169–180. [Google Scholar] [CrossRef]

- Kopeliovich, D. Tribological properties and applications of alumina. (n.d.). Available online: http://www.substech.com/dokuwiki/doku.php?id=tribological_properties_and_applications_of_alumina (accessed on 10 May 2019).

- Li, Y.; Zhou, M. Prediction of fracture toughness of ceramic composites as function of microstructure: I. Numerical simulations. J. Mech. Phys. Solids 2013, 61, 472–488. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, M. Prediction of fracturess toughness of ceramic composites as function of microstructure: II. Analytical model. J. Mech. Phys. Solids 2013, 61, 489–503. [Google Scholar] [CrossRef]

- Fracture Toughness/Fracture Energy Data for Ceramics; NIST Ceramics Data Portal; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1998. Available online: https://srdata.nist.gov/CeramicDataPortal/ftmain (accessed on 5 March 2019).

- Evans, A.G.; Dalgleish, B.J.; Charalambides, P.G. The fracture energy of bimaterial interfaces. Metall. Trans. A 1990, 21, 2419–2429. Available online: http://panos-group.umbc.edu/pdfs/papers/The_fracture_energy_of_bimaterial_interfaces_1990_Evans.pdf (accessed on 10 June 2019).

- Trice, R.W.; Halloran, J.W. Influence of microstructure and temperature on the interfacial fracture energy of silicon nitride/boron nitride fibrous monolithic ceramics. J. Am. Ceram. Soc. 1999, 82, 2502–2508. [Google Scholar] [CrossRef]

- Doghri, I.; Tinel, L. Micromechanical modeling and computation of elasto-plastic materials reinforced with distributed-orientation fibers. Int. J. Plast. 2005, 21, 1919–1940. [Google Scholar] [CrossRef]

- Geric, K. Ceramics Tool Materials With Alumina Matrix. Mach. Des. 2010, 3, 367–372. [Google Scholar]

- Shen, Z.; Johnsson, M.; Zhao, Z.; Nygren, M. Spark Plasma Sintering of Alumina. J. Am. Ceram. Soc. 2002, 85, 1921–1927. [Google Scholar] [CrossRef]

- Akhtar, S.; Kareem, L.T.; Arif, A.F.M.; Siddiqui, M.U.; Hakeem, A.S. Development of a ceramic-based composite for direct bonded copper substrate. Ceram. Int. 2017, 43, 5236–5246. [Google Scholar] [CrossRef]

- Hotta, M.; Goto, T. Densification and microstructure of Al2O3-cBN composites prepared by spark plasma sintering. J. Ceram. Soc. Jpn. 2008, 116, 744–748. [Google Scholar] [CrossRef]

- Akhtar, S.S.; Siddiqui, M.U.; Kabeer, R.; Hakeem, A.; Kareem, L.; Arif, A.F. A computational and experimental study on the effective properties of Al2O3-Ni composites. Int. J. Appl. Ceram. Technol. 2017, 14, 766–778. [Google Scholar] [CrossRef]

- Ceramic Materials And Ceramic Components, (n.d.). Available online: https://accuratus.com/ (accessed on 18 April 2019).

- AZO Materials, (n.d.). Available online: https://www.azom.com/articles.aspx (accessed on 20 April 2019).

- Kumai, S.; King, J.E.; Knott, J.F. Fatigue in SiC-particulate-reinforced aluminium alloy composites. Mater. Sci. Eng. A 1991, 146, 317–326. [Google Scholar] [CrossRef]

- Evans, A.G. Perspective on the Development of High-Toughness Ceramics. J. Am. Ceram. Soc. 1990. [Google Scholar] [CrossRef]

- Lin, T.; Evans, A.G.; Ritchie, R.O. Statistical analysis of cleavage fracture ahead of sharp cracks and rounded notches. Acta Metall. 1986. [Google Scholar] [CrossRef]

- Waqar, T.; Akhtar, S.S.; Arif, A.F.M.; Hakeem, A.S. Design and development of ceramic-based composites with tailored properties for cutting tool inserts. Ceram. Int. 2018, 44, 22421–22431. [Google Scholar] [CrossRef]

| Candidates | Elastic Modulus (GPa) | Poisson’s Ratio | Bulk Modulus (GPa) | Shear Modulus (GPa) | Fracture Energy (J/m2) | Density (g/cm3) |

|---|---|---|---|---|---|---|

| Alumina (Al2O3) | 280 | 0.22 | 165 | 124 | 54 | 3.96 |

| Titanium Carbide (TiC) | 450 | 0.18 | 250 | 152 | 45 | 4.94 |

| Cubic Boron Nitride (cBN) | 381 | 0.15 | 228 | 180 | 15 | 3.35 |

| Silicon Nitride (Si3N4) | 306 | 0.28 | 241 | 127 | 40.5 | 3.20 |

| Titanium dioxide (TiO2) | 270 | 0.28 | 210 | 112 | 68 | 4.09 |

| Silicon Carbide (SiC) | 410 | 0.14 | 250 | 180 | 27 | 3.1 |

| Graphite | 27.6 | 0.20 | 15.3 | 11.5 | 85 | 2.25 |

| Partially Stabilized Zirconia (PSZ) | 210 | 0.34 | 142 | 72 | 21 | 6.03 |

| Composition of Composite | Elastic Modulus, E (GPa) | Fracture Toughness, KIC (MPa·m1/2) | Measured Porosity (%) | ||

|---|---|---|---|---|---|

| Experimental | Predicted | Experimental | Predicted | ||

| Pure Al2O3 | 280 ± 10 | - | 4.09 ± 0.35 | - | 2.37 |

| Al2O3/10% SiC | 305 ± 10 | 291 | 4.46 ± 0.20 | 4.66 | 2.63 |

| Al2O3/20% SiC | 312 ± 15 | 302 | 4.57 ± 0.10 | 4.96 | 2.69 |

| Al2O3/30% SiC | 321 ± 10 | 314 | 4.90 ± 0.20 | 5.09 | 2.76 |

| Al2O3/10% cBN | 301 ± 15 | 289 | 4.50 ± 0.40 | 4.45 | 3.10 |

| Al2O3/20% cBN | 313 ± 20 | 298 | 4.35 ± 0.30 | 4.50 | 3.26 |

| Al2O3/30% cBN | 306 ± 15 | 308 | 4.10 ± 0.25 | 4.40 | 3.28 |

| Al2O3/20% SiC/20% cBN | 328 ± 20 | 322 | 4.23 ± 0.20 | 4.53 | 3.43 |

| Al2O3/20% SiC/10% TiO2 | 317 ± 15 | 301 | 4.55 ± 0.30 | 4.95 | 2.65 |

| Al2O3/20% SiC/5% graphite | 297 ± 15 | 276 | 4.62 ± 0.10 | 4.77 | 2.77 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhtar, S.S.; Waqar, T.; Hakeem, A.S.; Arif, A.F.M.; Al-Athel, K.S. Design and Development of Hybrid Al2O3 Based Composites with Toughening and Self-Lubricating Second-Phase Inclusions. Materials 2019, 12, 2378. https://doi.org/10.3390/ma12152378

Akhtar SS, Waqar T, Hakeem AS, Arif AFM, Al-Athel KS. Design and Development of Hybrid Al2O3 Based Composites with Toughening and Self-Lubricating Second-Phase Inclusions. Materials. 2019; 12(15):2378. https://doi.org/10.3390/ma12152378

Chicago/Turabian StyleAkhtar, Syed Sohail, Taha Waqar, Abbas Saeed Hakeem, Abul Fazal M. Arif, and Khaled Saleh Al-Athel. 2019. "Design and Development of Hybrid Al2O3 Based Composites with Toughening and Self-Lubricating Second-Phase Inclusions" Materials 12, no. 15: 2378. https://doi.org/10.3390/ma12152378

APA StyleAkhtar, S. S., Waqar, T., Hakeem, A. S., Arif, A. F. M., & Al-Athel, K. S. (2019). Design and Development of Hybrid Al2O3 Based Composites with Toughening and Self-Lubricating Second-Phase Inclusions. Materials, 12(15), 2378. https://doi.org/10.3390/ma12152378