Effect of Hygrothermal Aging and Surface Treatment on the Dynamic Mechanical Behavior of Flax Fiber Reinforced Composites

Abstract

:1. Introduction

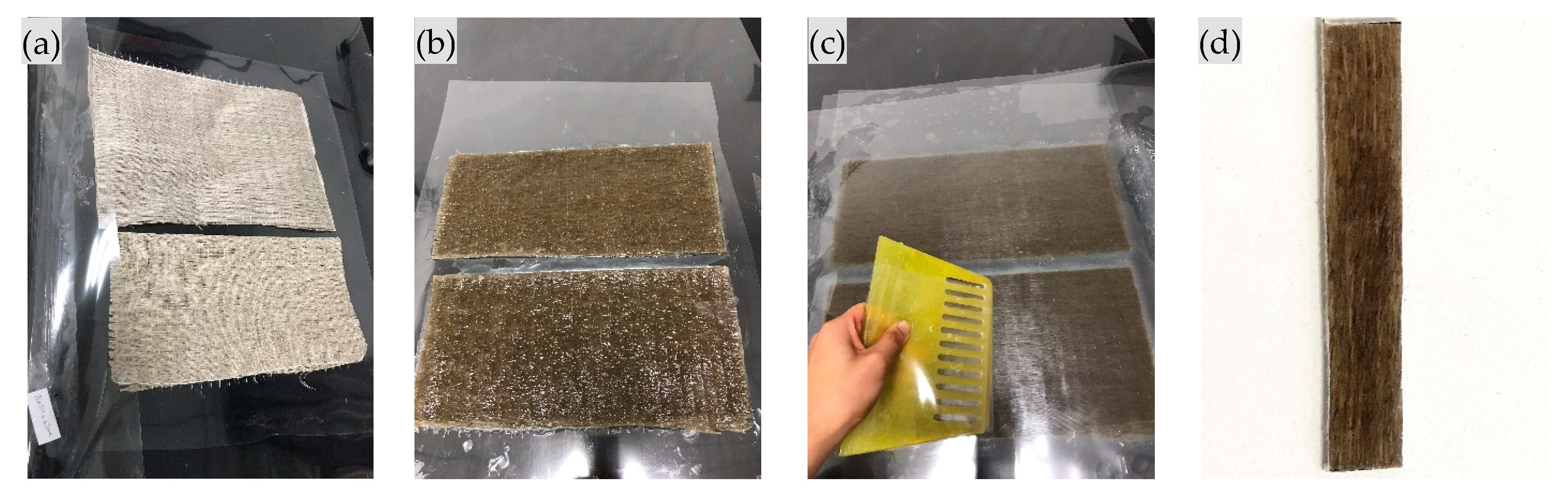

2. Materials and Methods

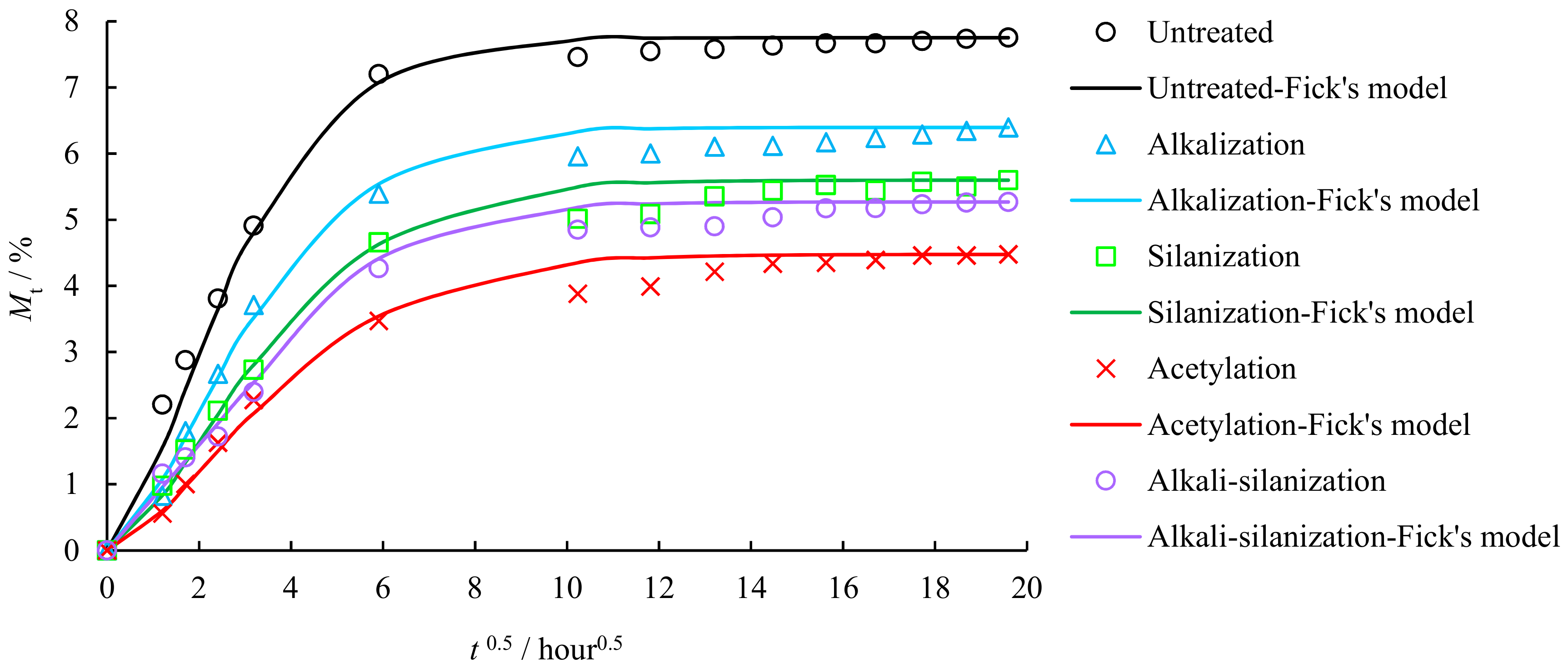

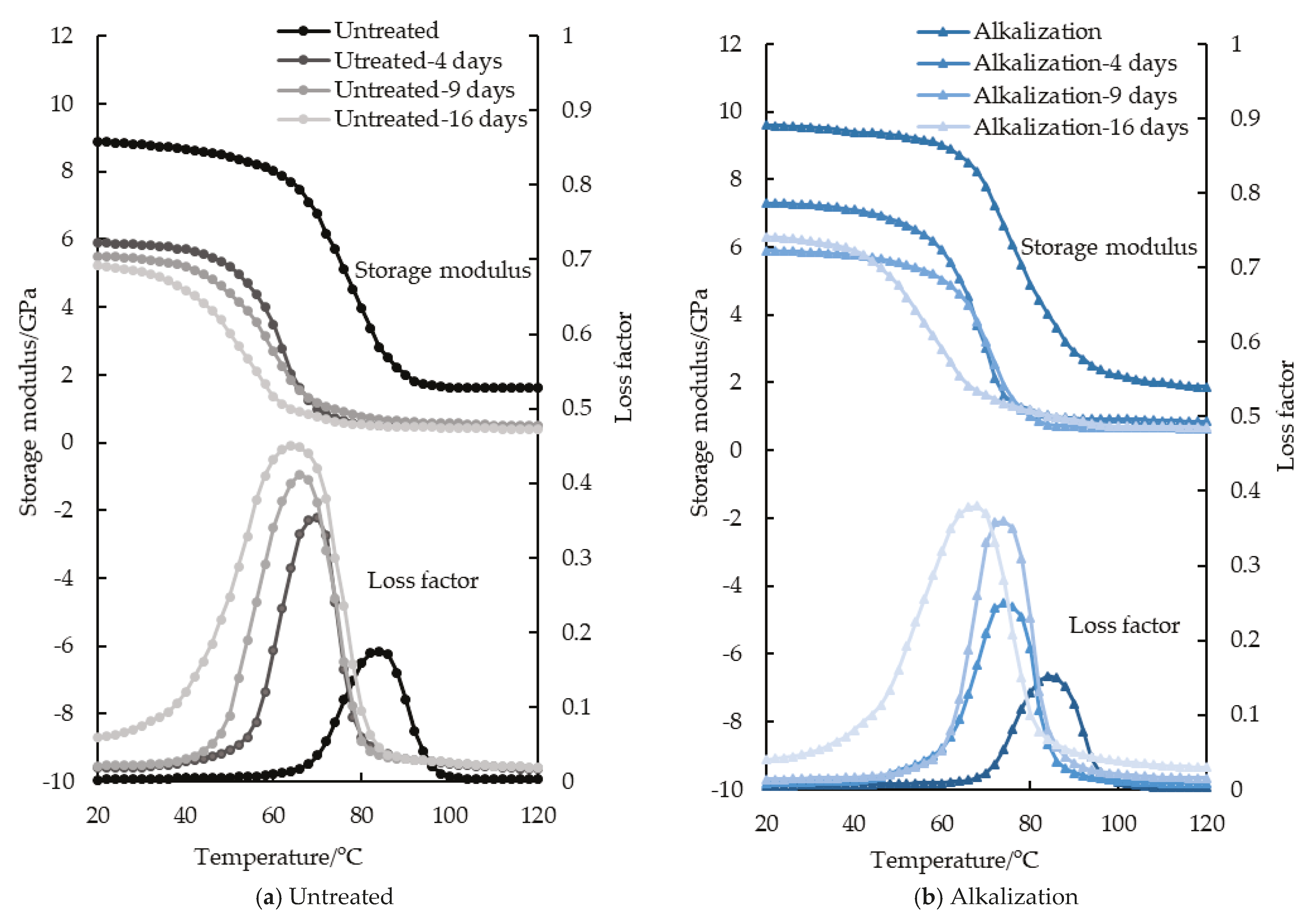

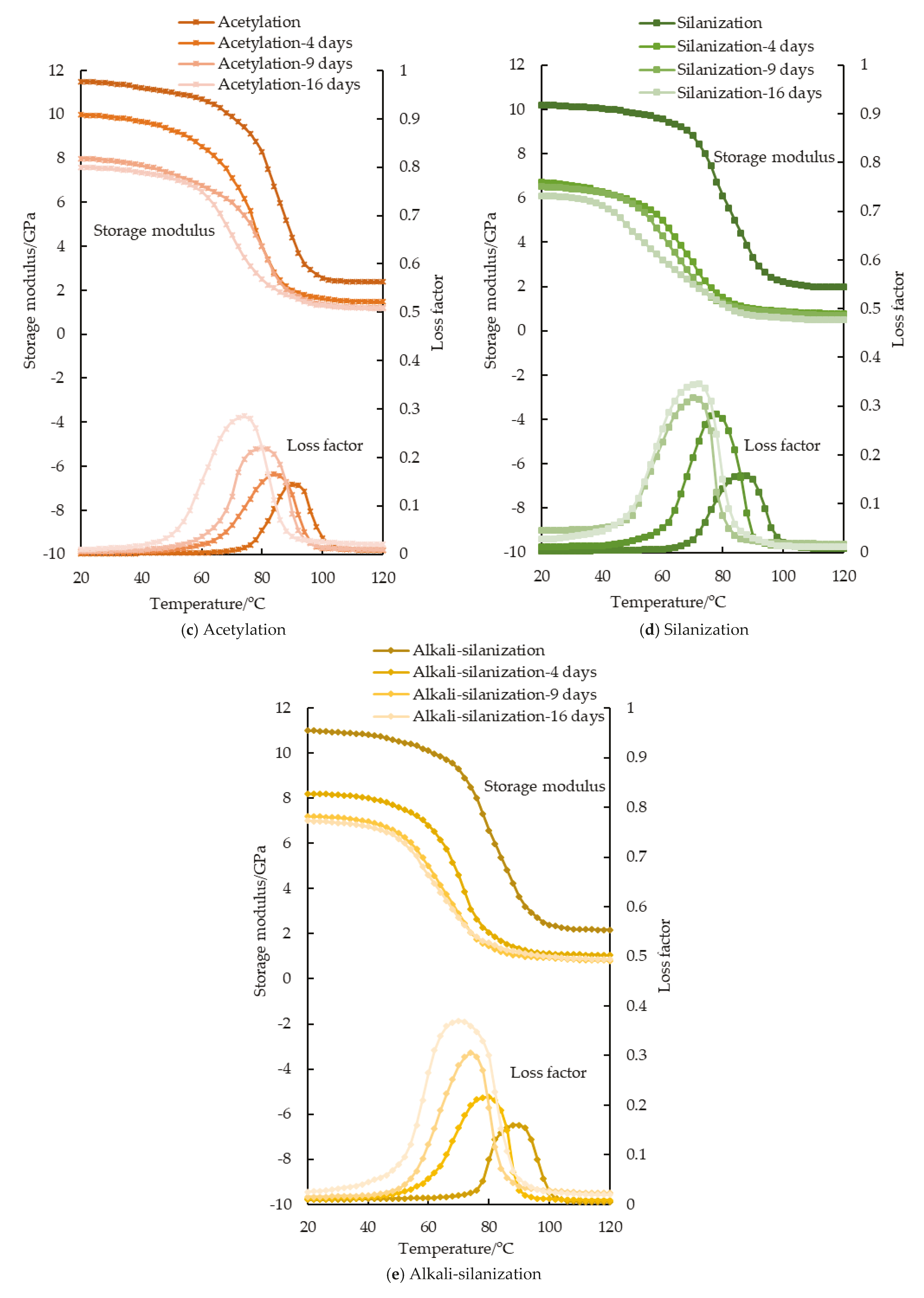

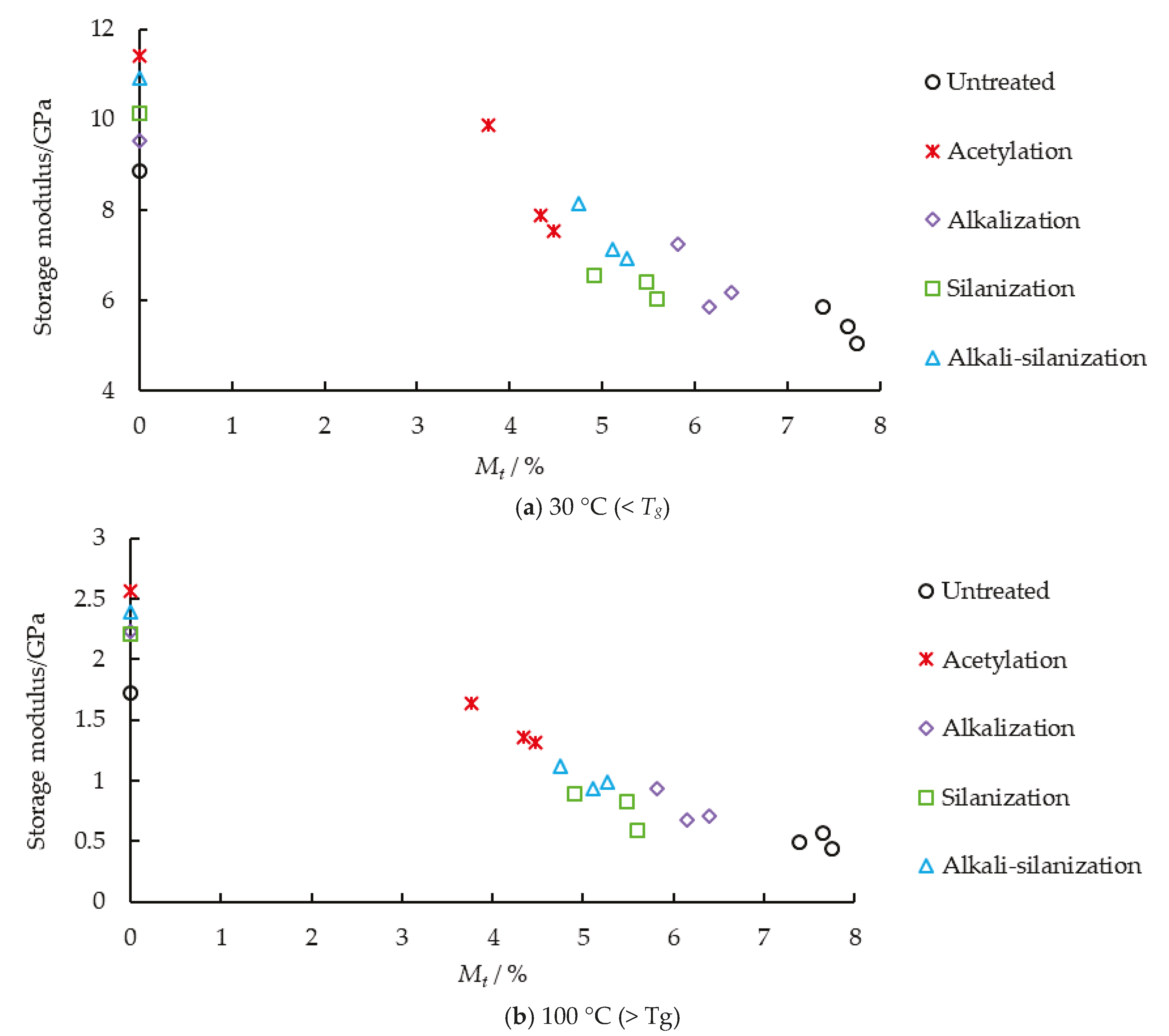

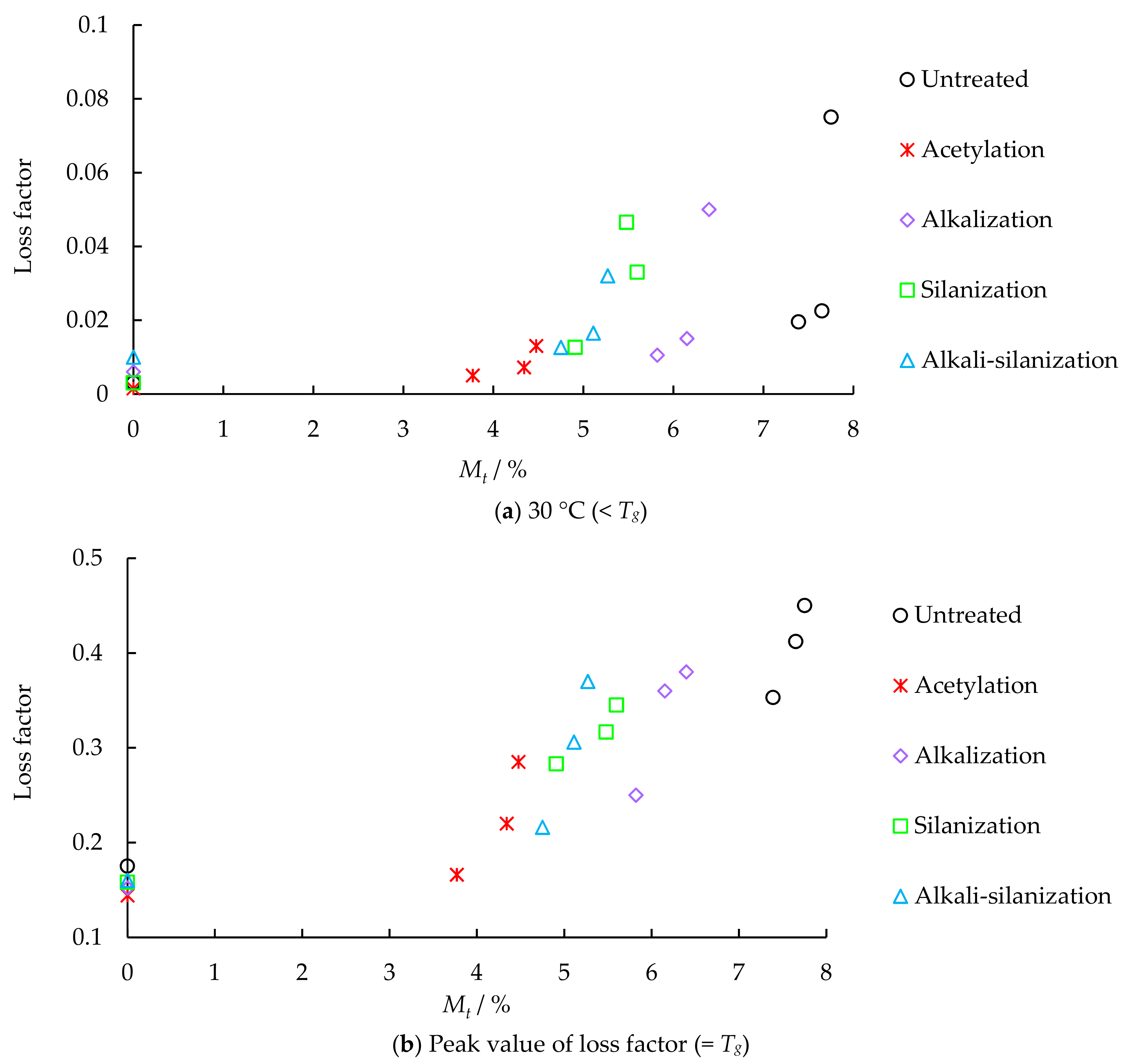

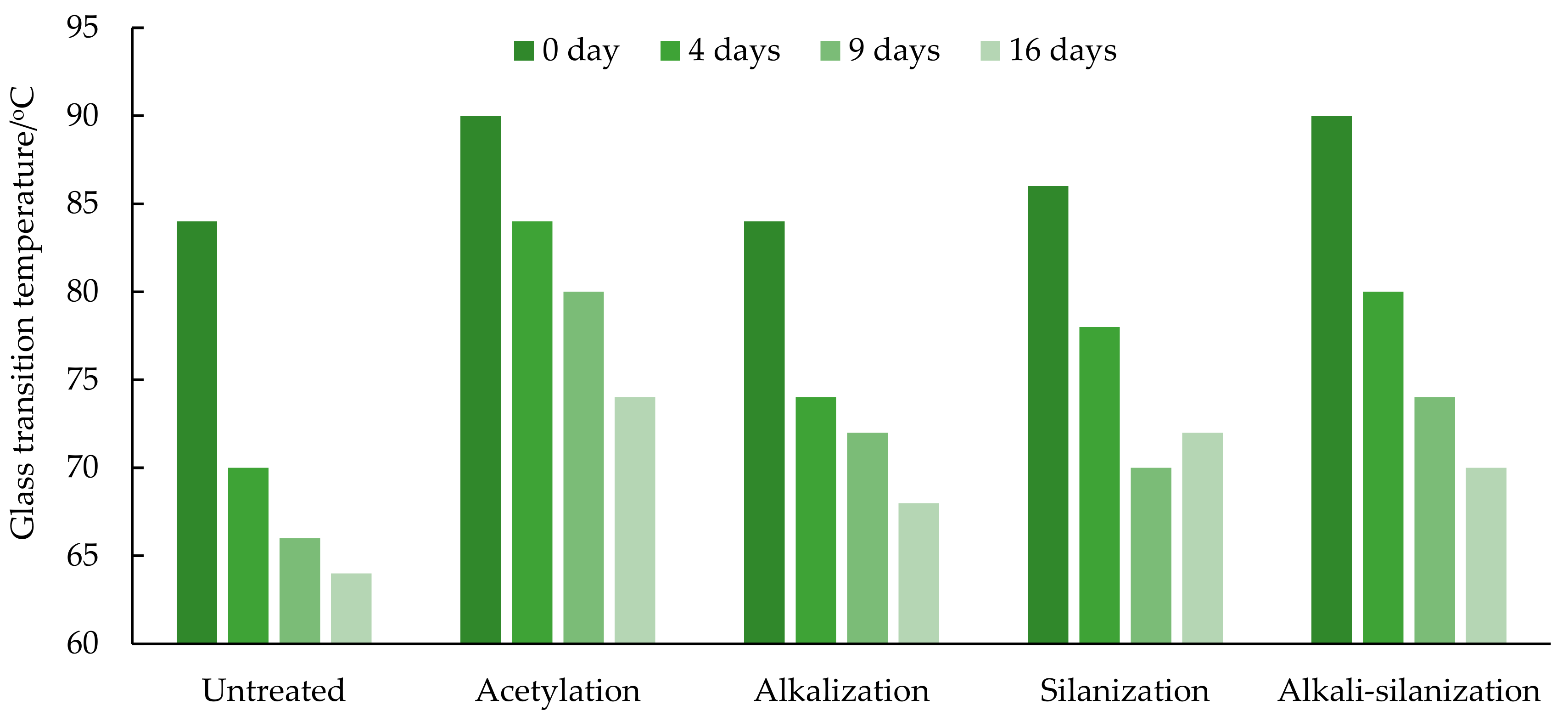

3. Test Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Begum, K.; Islam, M.A. Natural Fiber as a substitute to Synthetic Fiber in Polymer Composites: A Review. Res. J. Eng. Sci. 2013, 2, 46–53. [Google Scholar]

- Zhang, Y.; Li, Y.; Ma, H.; Yu, T. Tensile and interfacial properties of unidirectional flax/glass fiber reinforced hybrid composites. Compos. Sci. Technol. 2013, 88, 172–177. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, H.; Njuguna, J.; Abhyankar, H. Recent development of flax fibres and their reinforced composites based on different polymeric matrices. Materials 2013, 6, 5171–5198. [Google Scholar] [CrossRef] [PubMed]

- Dittenber, D.B.; Gangarao, H.V.S. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp fiber and its composites—A review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Saidane, E.H.; Scida, D.; Assarar, M.; Ayad, R. Assessment of 3D moisture diffusion parameters on flax/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2016, 80, 53–60. [Google Scholar] [CrossRef]

- Stamboulis, A.; Baillie, C.A.; Peijs, T. Effects of environmental conditions on mechanical and physical properties of flax fibers. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1105–1115. [Google Scholar] [CrossRef]

- Hill, C.A.S.; Norton, A.; Newman, G. The water vapor sorption behavior of natural fibers. J. Appl. Polym. Sci. 2010, 112, 1524–1537. [Google Scholar] [CrossRef]

- Chen, H.; Miao, M.; Xin, D. Influence of moisture absorption on the interfacial strength of bamboo/vinyl ester composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 2013–2019. [Google Scholar] [CrossRef]

- Zakaria, S.; Kok, P.L. Polystyrene-benzoylated EFB reinforced composites. J. Macromol. Sci. Part D Rev. Polym. Process. 2002, 41, 951–962. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Li, Y.; Xue, B. Hydrothermal ageing mechanisms of unidirectional flax fabric reinforced epoxy composites. Polym. Degrad. Stab. 2016, 126, 144–158. [Google Scholar] [CrossRef]

- Assarar, M.; Scida, D.; Mahi, A.E.; Poilâne, C.; Ayad, R. Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: Flax-fibres and glass-fibres. Mater. Des. 2011, 32, 788–795. [Google Scholar] [CrossRef]

- Mak, K.; Fam, A.; Macdougall, C. The effects of long term exposure of flax fiber reinforced polymer to salt solution at high temperature on tensile properties. Polym. Compos. 2016, 37, 3234–3244. [Google Scholar] [CrossRef]

- Ventura, H.; Claramunt, J.; Rodríguez-Pérez, M.A.; Ardanuy, M. Effects of hydrothermal aging on the water uptake and tensile properties of PHB/flax fabric biocomposites. Polym. Degrad. Stab. 2017, 142, 129–138. [Google Scholar] [CrossRef]

- Scida, D.; Assarar, M.; Poilâne, C.; Ayad, R. Influence of hygrothermal ageing on the damage mechanisms of flax-fibre reinforced epoxy composite. Compos. Part B 2013, 48, 51–58. [Google Scholar] [CrossRef]

- Thuault, A.; Eve, S.; Blond, D.; Breard, J.; Gomina, M. Effects of the hygrothermal environment on the mechanical properties of flax fibres. J. Compos. Mater. 2014, 48, 1699–1707. [Google Scholar] [CrossRef]

- Yan, L.; Chow, N.; Yuan, X. Improving the mechanical properties of natural fibre fabric reinforced epoxy composites by alkali treatment. J. Reinf. Plast. Compos. 2012, 31, 425–437. [Google Scholar] [CrossRef]

- Amiri, A.; Ulven, C.; Huo, S. Effect of chemical treatment of flax fiber and resin manipulation on service life of their composites using time-temperature superposition. Polymers 2015, 7, 1965–1978. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Lucka-Gabor, M.; Gutowski, V.S. The effects of acetylation on properties of flax fibre and its polypropylene composites. Express Polym. Lett. 2008, 2, 413–422. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Lucka, M.; Mamun, A.A.; Michalski, J. Biological and electrical resistance of acetylated flax fibre reinforced polypropylene composites. Bioresources 2008, 4, 111–125. [Google Scholar]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Georgiopoulosa, P.; Kontoua, E.; Georgousisa, G. Effect of silane treatment loading on the flexural properties of PLA/flax unidirectional composites. Compos. Commun. 2018, 10, 6–10. [Google Scholar] [CrossRef]

- Amidi, S.; Wang, J. Engineering FRP-to-concrete bonded joints for better durability. In Proceedings of the American Society for Composites, University of California San Diego, La Jolla, CA, USA, 8–10 September 2014. Vol. Twenty-ninth Technical Conference on Composite Materials. [Google Scholar]

- Chandra, R.; Singh, S.; Gupta, K. Experimental evaluation of damping of fiber-reinforced composites. J. Compos. Technol. Res. 2003, 25, 96–107. [Google Scholar]

- Duc, F.; Bourban, P.E.; Plummer, C.J.G.; Månson, J.-A.E. Damping of thermoset and thermoplastic flax fibre composites. Compos. Part A Appl. Sci. Manuf. 2014, 64, 115–123. [Google Scholar] [CrossRef]

- Cheour, K.; Assarar, M.; Scida, D.; Ayad, R.; Gong, X.-L. Effect of water ageing on the mechanical and damping properties of flax-fibre reinforced composite materials. Compos. Struct. 2016, 152, 259–266. [Google Scholar] [CrossRef]

- Berges, M.; Léger, R.; Placet, V.; Person, V.; Corn, S.; Gabrion, X.; Rousseau, J.; Ramasso, E.; Ienny, P.; Fontaine, S. Influence of moisture uptake on the static, cyclic and dynamic behaviour of unidirectional flax fibre-reinforced epoxy laminates. Compos. Part A Appl. Sci. Manuf. 2016, 88, 165–177. [Google Scholar] [CrossRef] [Green Version]

- Tayfun, U.; Dogan, M.; Bayramli, E. Influence of surface modifications of flax fiber on mechanical and flow properties of thermoplastic polyurethane based eco-composites. J. Nat. Fibers 2016, 13, 309–320. [Google Scholar] [CrossRef]

- China National Standardization Management Committee; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Test Method for Aging Properties of Glass Fiber Reinforced Plastics; China Building Industry Press: Beijing, China, 2008; pp. 1–13. [Google Scholar]

- Luo, H.L.; Lian, J.J.; Wan, Y.Z.; Huang, Y.; Wang, Y.L.; Jiang, H.J. Moisture absorption in VARTMed three-dimensional braided carbon-epoxy composites with different interface conditions. Mater. Sci. Eng. A 2006, 425, 70–77. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Xian, G. Hygrothermal effects on high pultruded unidirectional carbon/epoxy composites: Moisture Uptake. Compos. Part B Eng. 2009, 40, 41–49. [Google Scholar] [CrossRef]

- Georgiopoulos, P.; Christopoulos, A.; Koutsoumpis, S.; Kontou, E. The effect of surface treatment on the performance of flax/biodegradable composites. Compos. Part B Eng. 2016, 106, 88–98. [Google Scholar] [CrossRef]

- Anna, D.K.F.; Balan, A.; Bin, H.; Xian, G.; Thomas, S. Effect of surface modification of jute fiber on the mechanical properties and durability of jute fiber-reinforced epoxy composites. Polym. Compos. 2018, 1–10. [Google Scholar]

- Jacob, M.; Francis, B.; Thomas, S.; Varughese, K.T. Dynamical mechanical analysis of sisal/oil palm hybrid fiber-reinforced natural rubber composites. Polym. Compos. 2006, 27, 671–680. [Google Scholar] [CrossRef]

- Shanmugam, D.; Thiruchitrambalam, M. Static and dynamic mechanical properties of alkali treated unidirectional continuous Palmyra Palm Leaf Stalk Fiber/jute fiber reinforced hybrid polyester composites. Mater. Des. 2013, 50, 533–542. [Google Scholar] [CrossRef]

- Pothan, L.A.; Oommen, Z.; Thomas, S. Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compos. Sci. Technol. 2003, 63, 283–293. [Google Scholar] [CrossRef]

- Afaghi-Khatibi, A.; Mai, Y.-W. Characterisation of fibre/matrix interfacial degradation under cyclic fatigue loading using dynamic mechanical analysis. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1585–1592. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Vitale, G.; Valenza, A. Static and dynamic mechanical properties of Arundo Donax fillers-epoxy composites. Mater. Des. 2014, 57, 456–464. [Google Scholar] [CrossRef]

- Fiore, V.; Bella, G.D.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Chandra, R.; Singh, S.P.; Gupta, K. Damping studies in fiber-reinforced composites—A review. Compos. Struct. 1999, 46, 41–51. [Google Scholar] [CrossRef]

- Gao, Y. Study on Environment Behavior and Aging Mechanism of Epoxy Adhesive; Beijing University of Chemical Technology: Beijing, China, 2006. [Google Scholar]

- Júnior, J.H.S.A.; Júnior, H.L.O.; Amico, S.C.; Amado, F.D.R. Study of hybrid intralaminate curaua/glass composites. Mater. Des. 2012, 42, 111–117. [Google Scholar] [CrossRef]

| Surface Treatment | Untreated | Alkalization | Silanization | Acetylation | Alkali-Silanization |

|---|---|---|---|---|---|

| Mm (%) | 7.75 | 6.40 | 5.60 | 4.48 | 5.27 |

| D (10−6 mm2/s) | 4.19 | 2.93 | 2.36 | 2.21 | 2.27 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Petrů, M. Effect of Hygrothermal Aging and Surface Treatment on the Dynamic Mechanical Behavior of Flax Fiber Reinforced Composites. Materials 2019, 12, 2376. https://doi.org/10.3390/ma12152376

Wang X, Petrů M. Effect of Hygrothermal Aging and Surface Treatment on the Dynamic Mechanical Behavior of Flax Fiber Reinforced Composites. Materials. 2019; 12(15):2376. https://doi.org/10.3390/ma12152376

Chicago/Turabian StyleWang, Xiaomeng, and Michal Petrů. 2019. "Effect of Hygrothermal Aging and Surface Treatment on the Dynamic Mechanical Behavior of Flax Fiber Reinforced Composites" Materials 12, no. 15: 2376. https://doi.org/10.3390/ma12152376

APA StyleWang, X., & Petrů, M. (2019). Effect of Hygrothermal Aging and Surface Treatment on the Dynamic Mechanical Behavior of Flax Fiber Reinforced Composites. Materials, 12(15), 2376. https://doi.org/10.3390/ma12152376