Influence of Waste Engine Oil Addition on the Properties of Zeolite-Foamed Asphalt

Abstract

1. Introduction

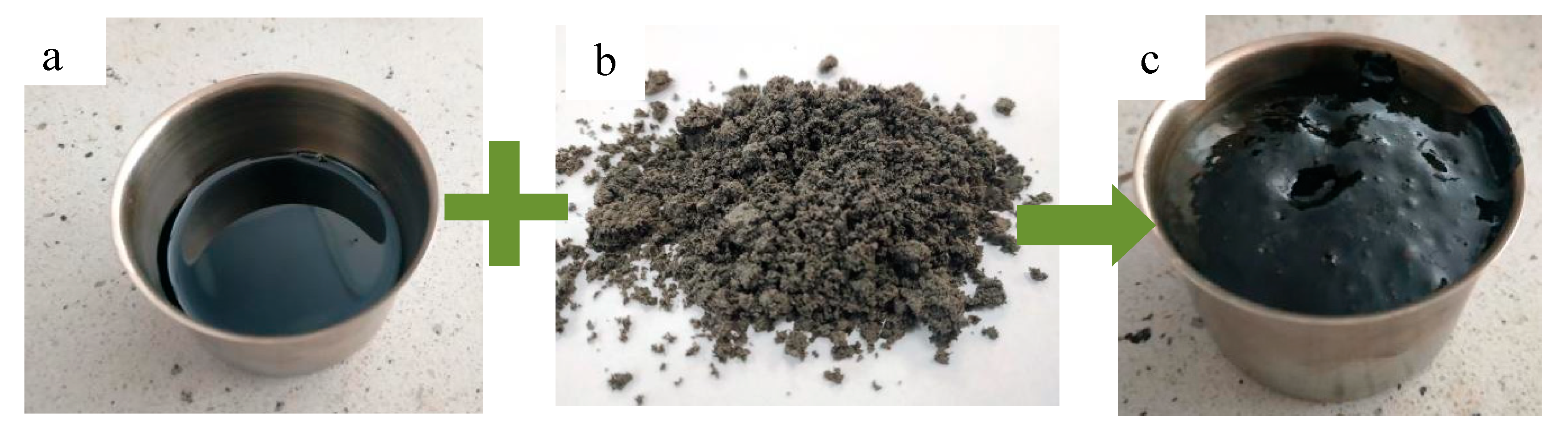

2. Experimental Materials

2.1. Asphalts

2.2. Waste Engine Oil

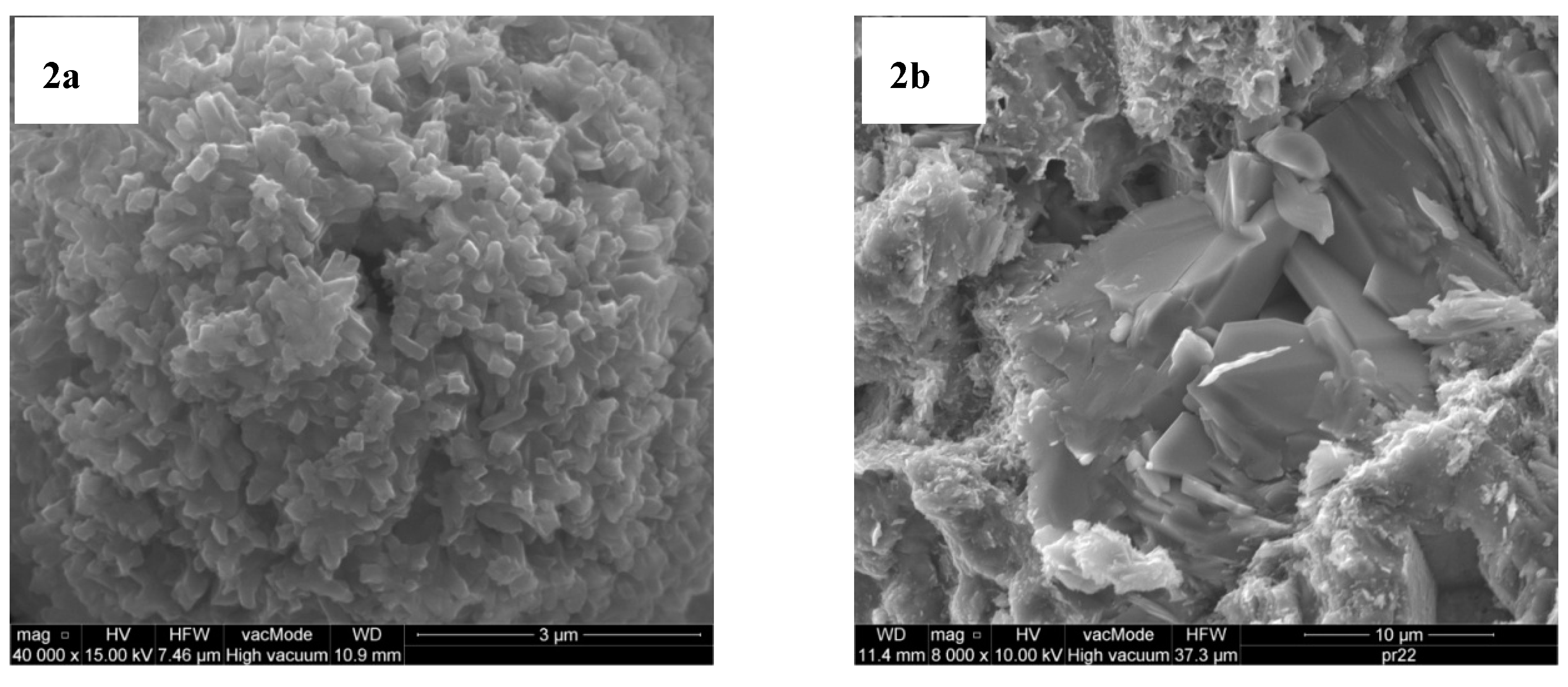

2.3. Zeolites

3. Research Method

3.1. Dynamic Viscosity

3.2. Softening Point

3.3. Penetration

3.4. XRF

4. Results and Discussion

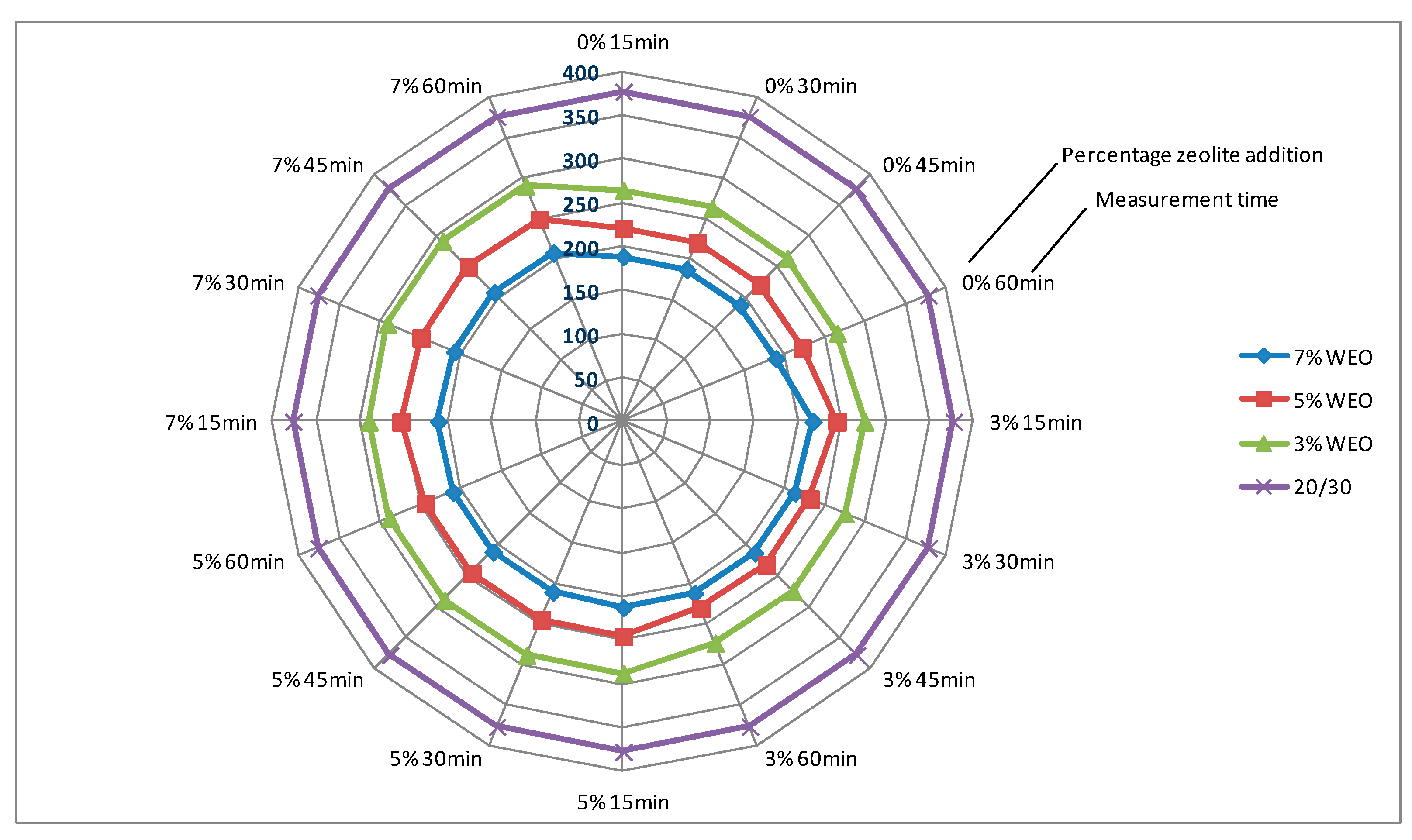

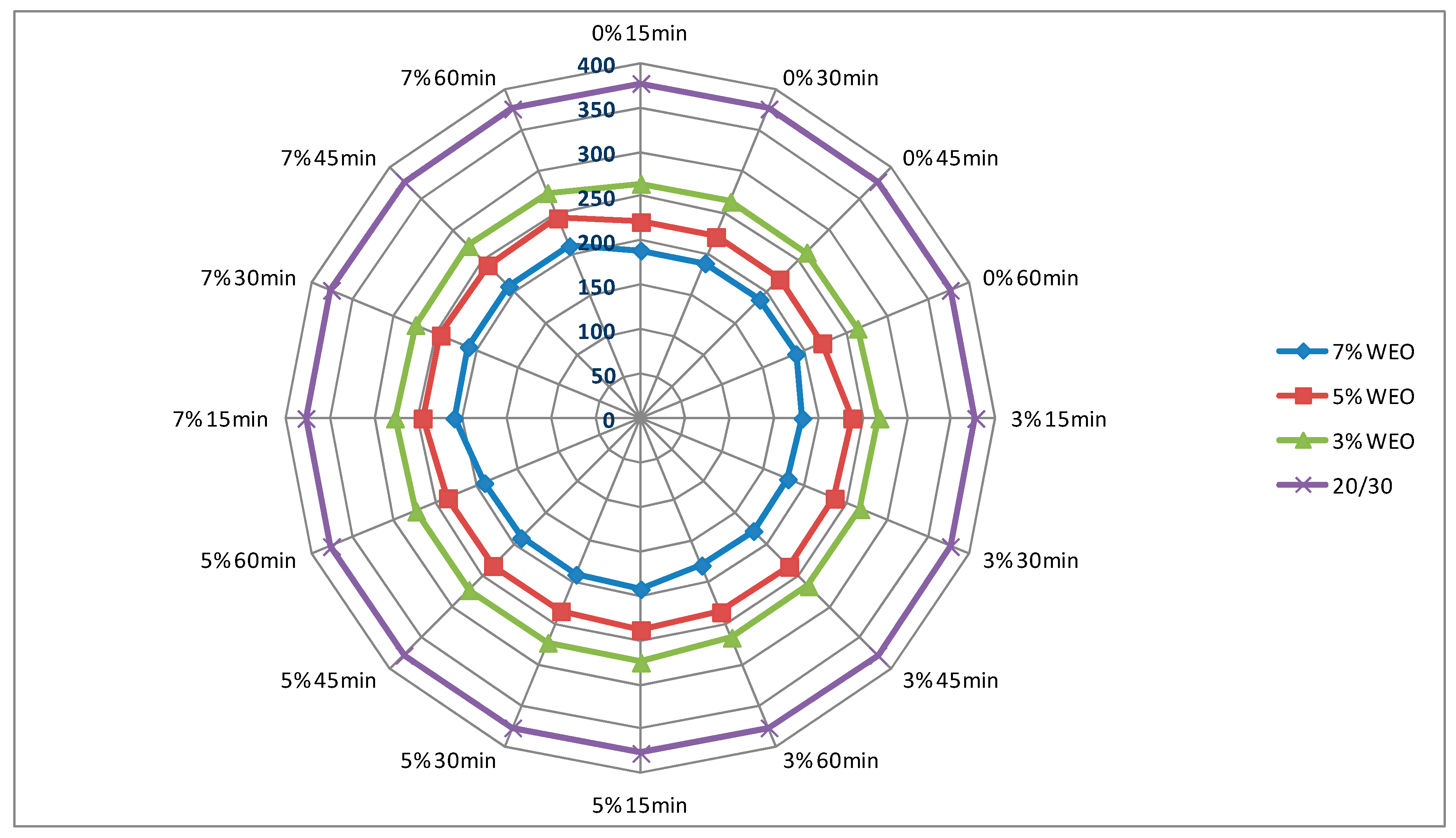

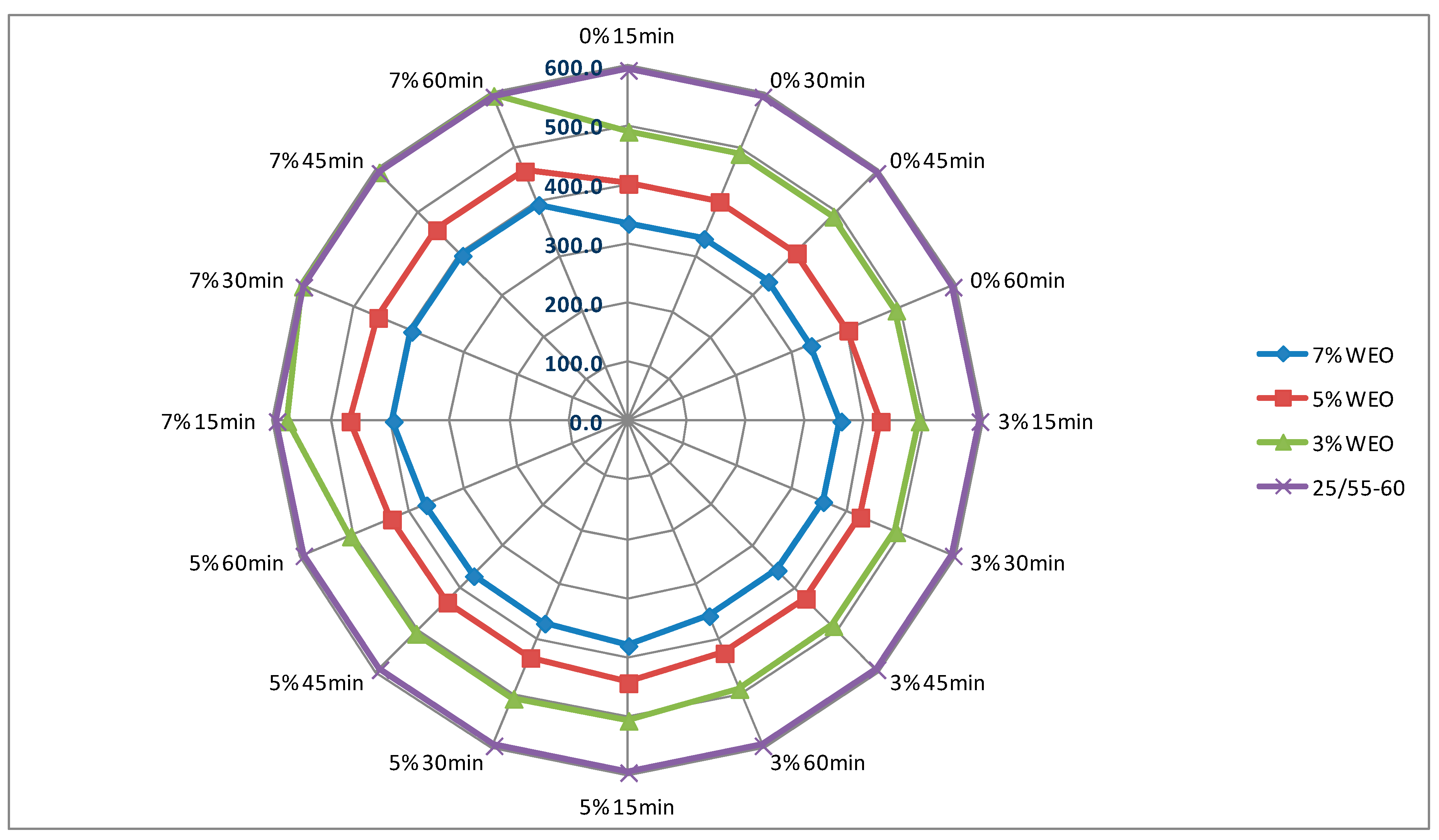

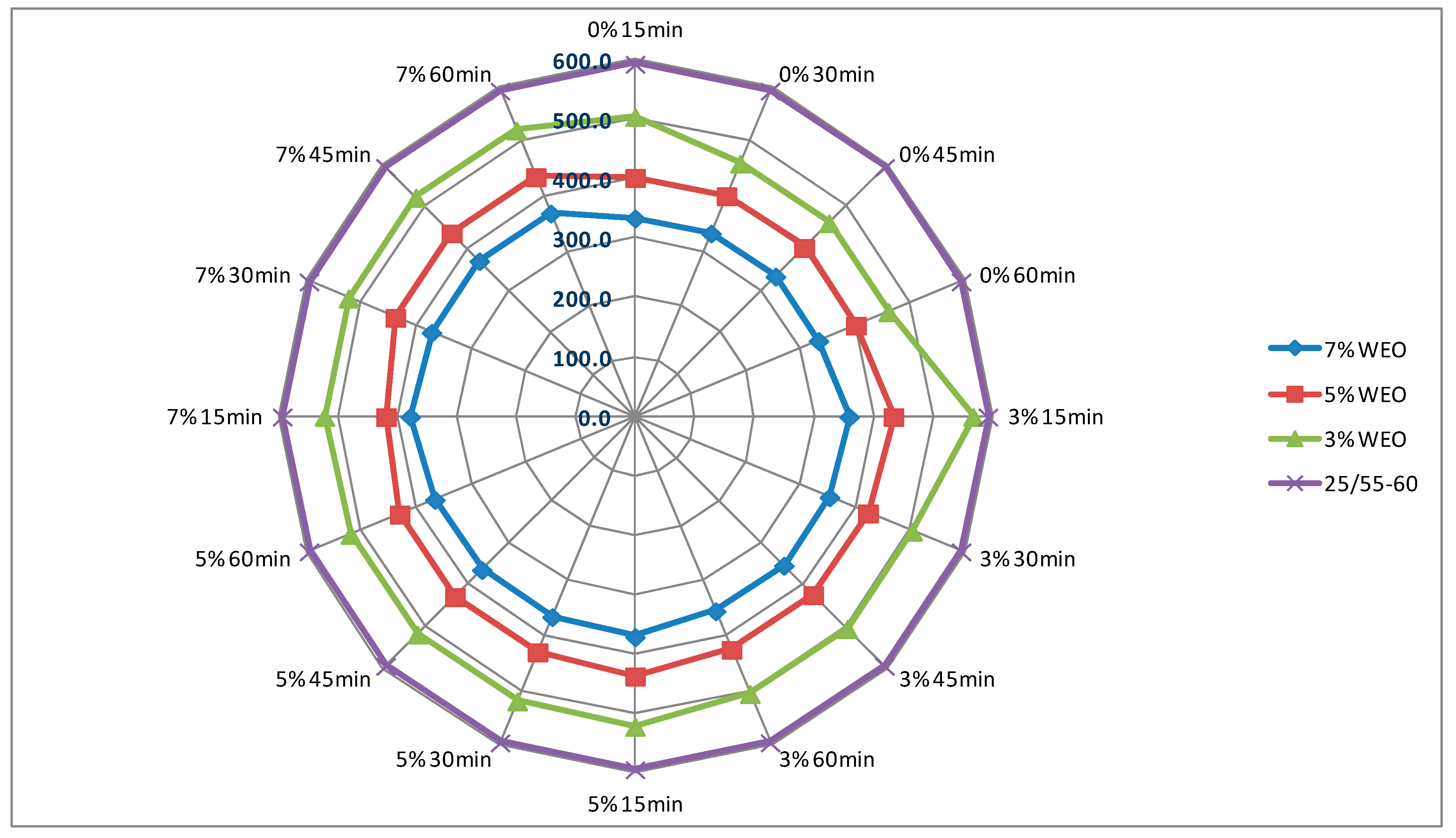

4.1. Dynamic Viscosity of Asphalt

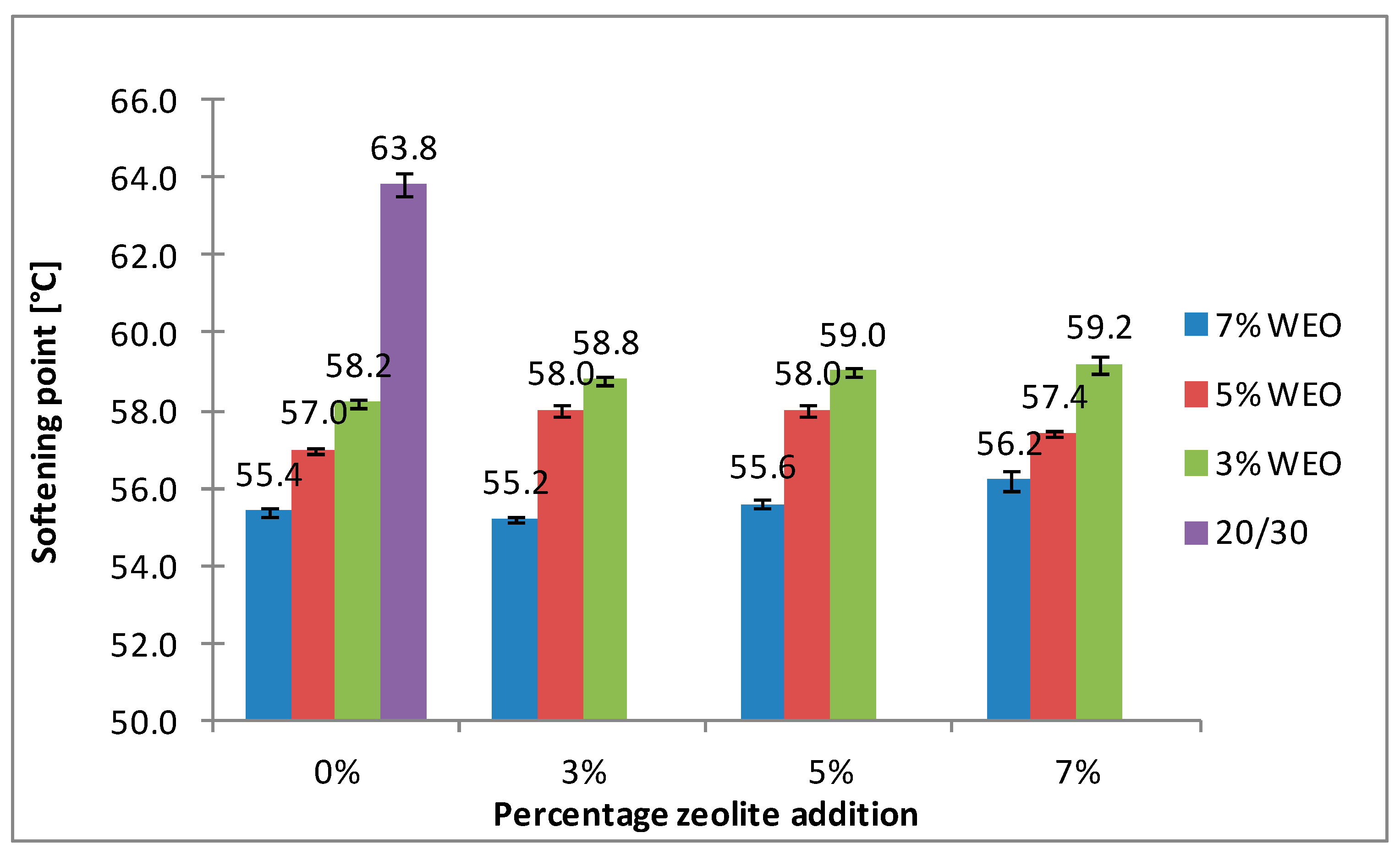

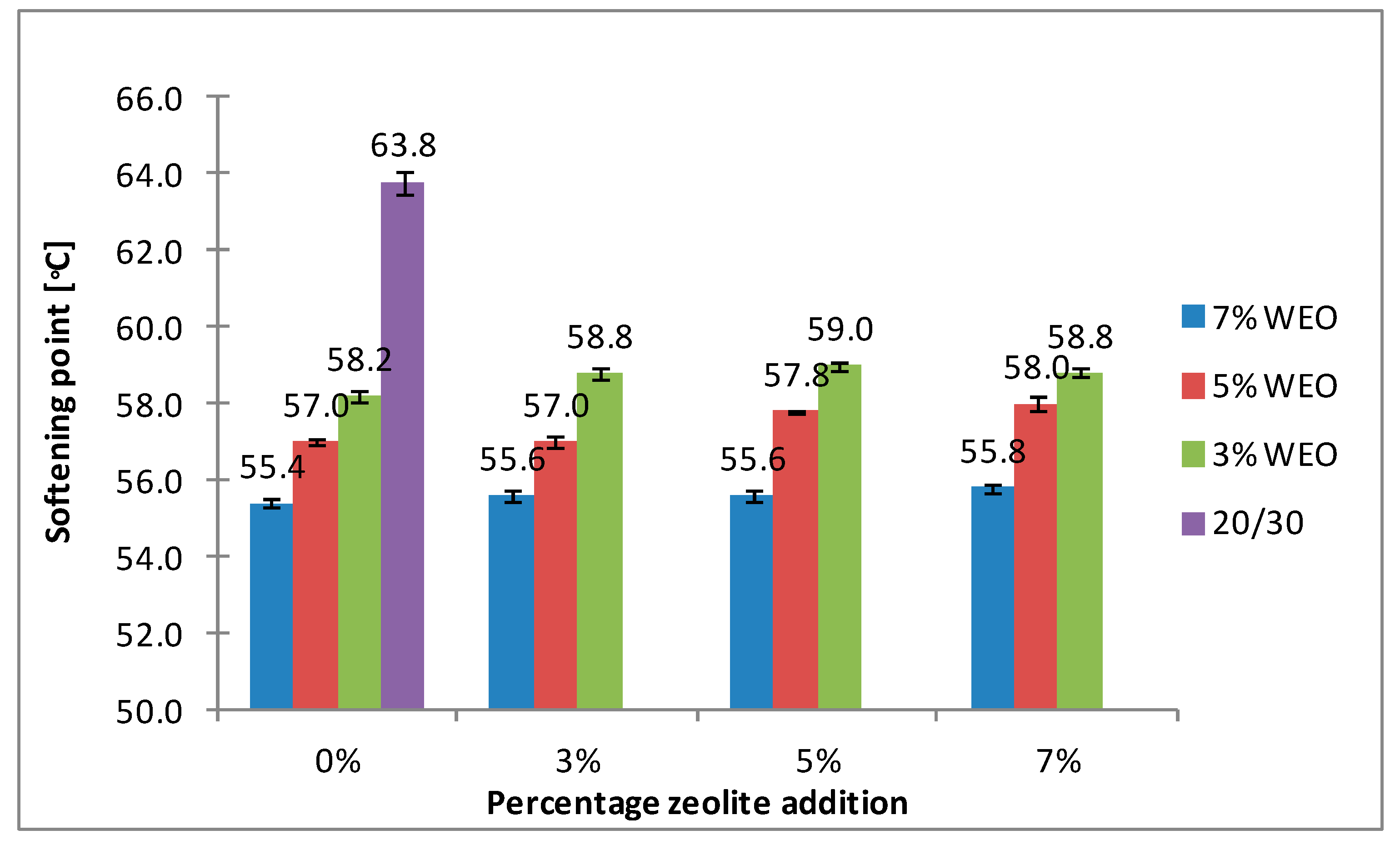

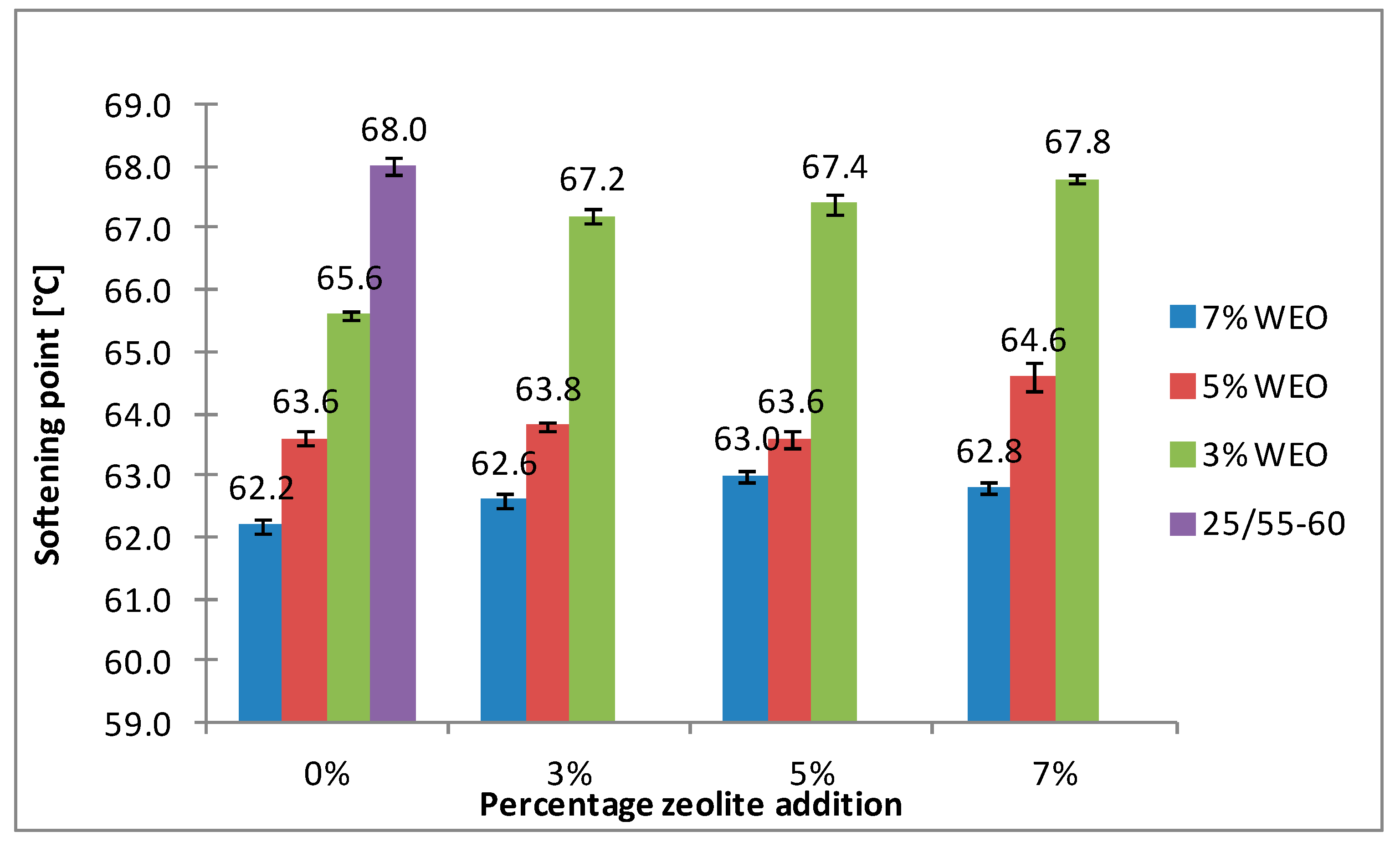

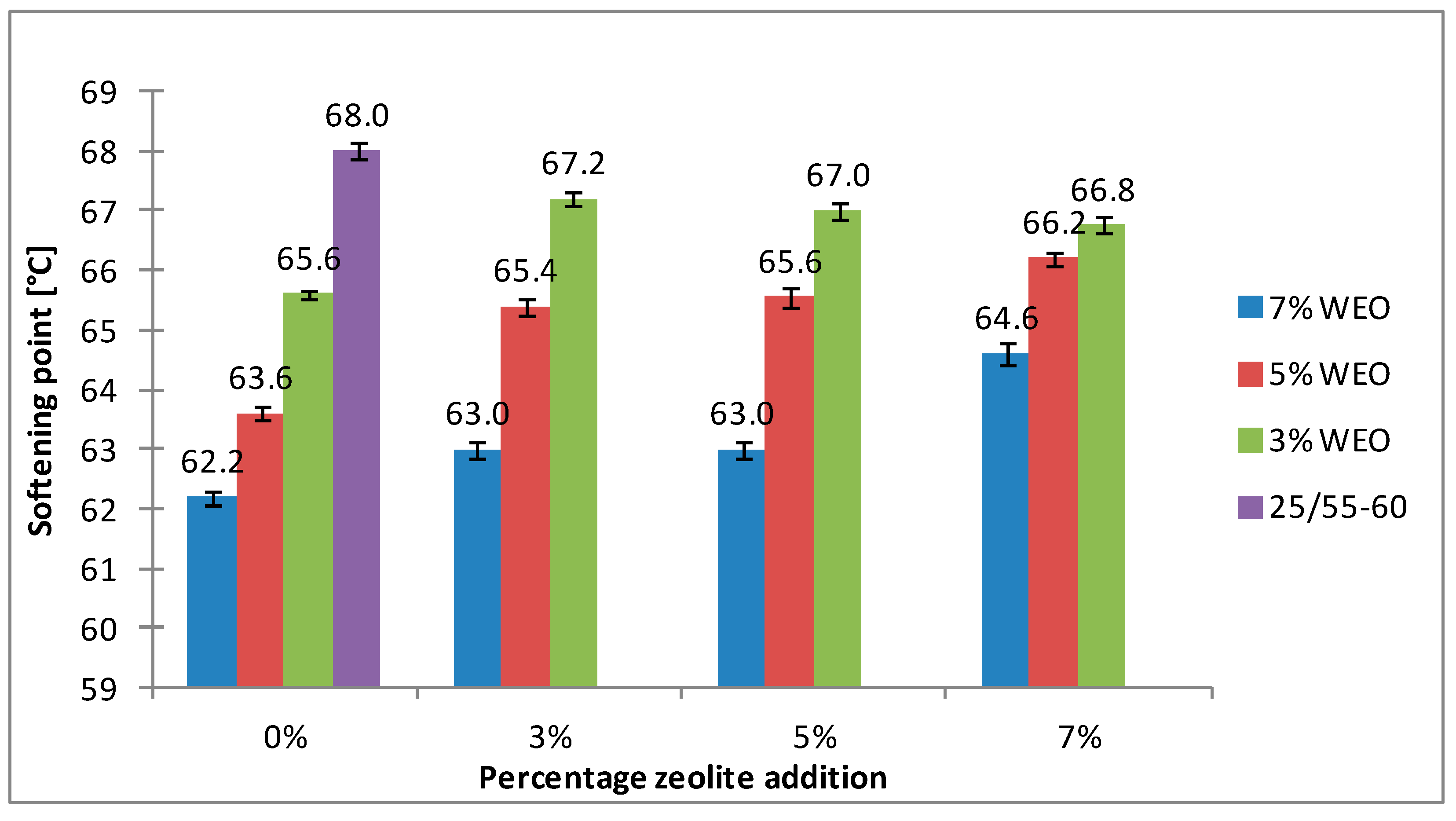

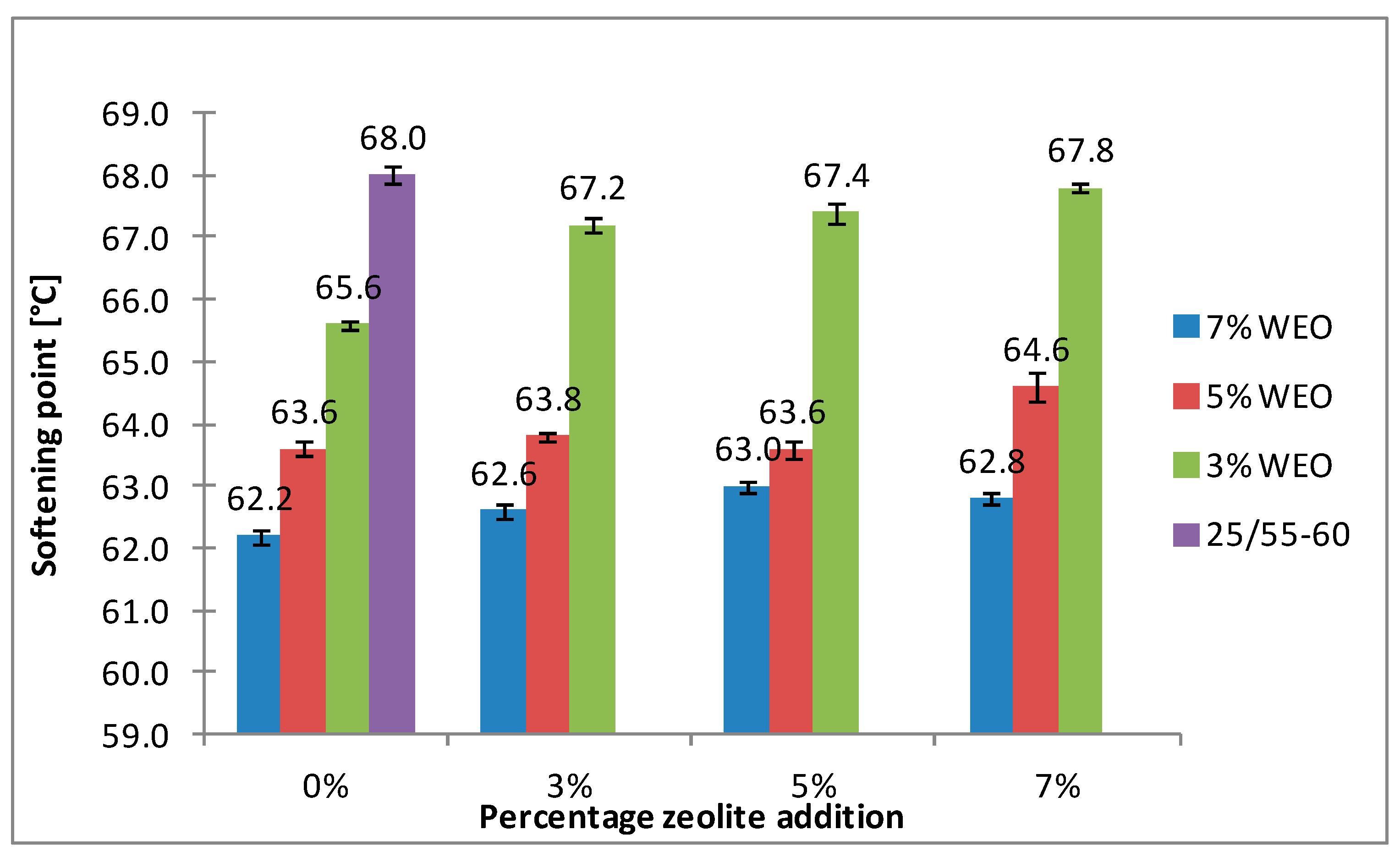

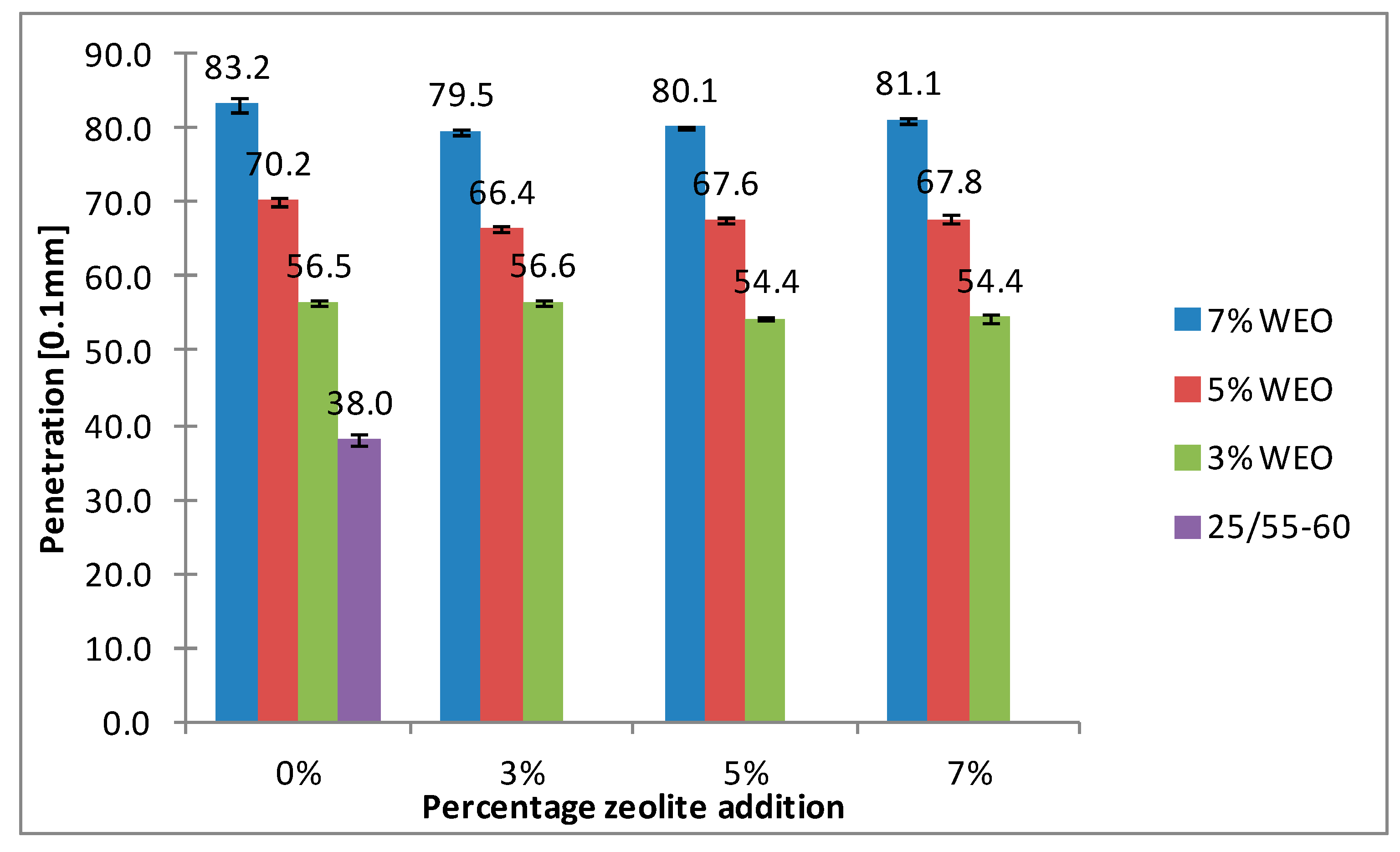

4.2. Softening Point

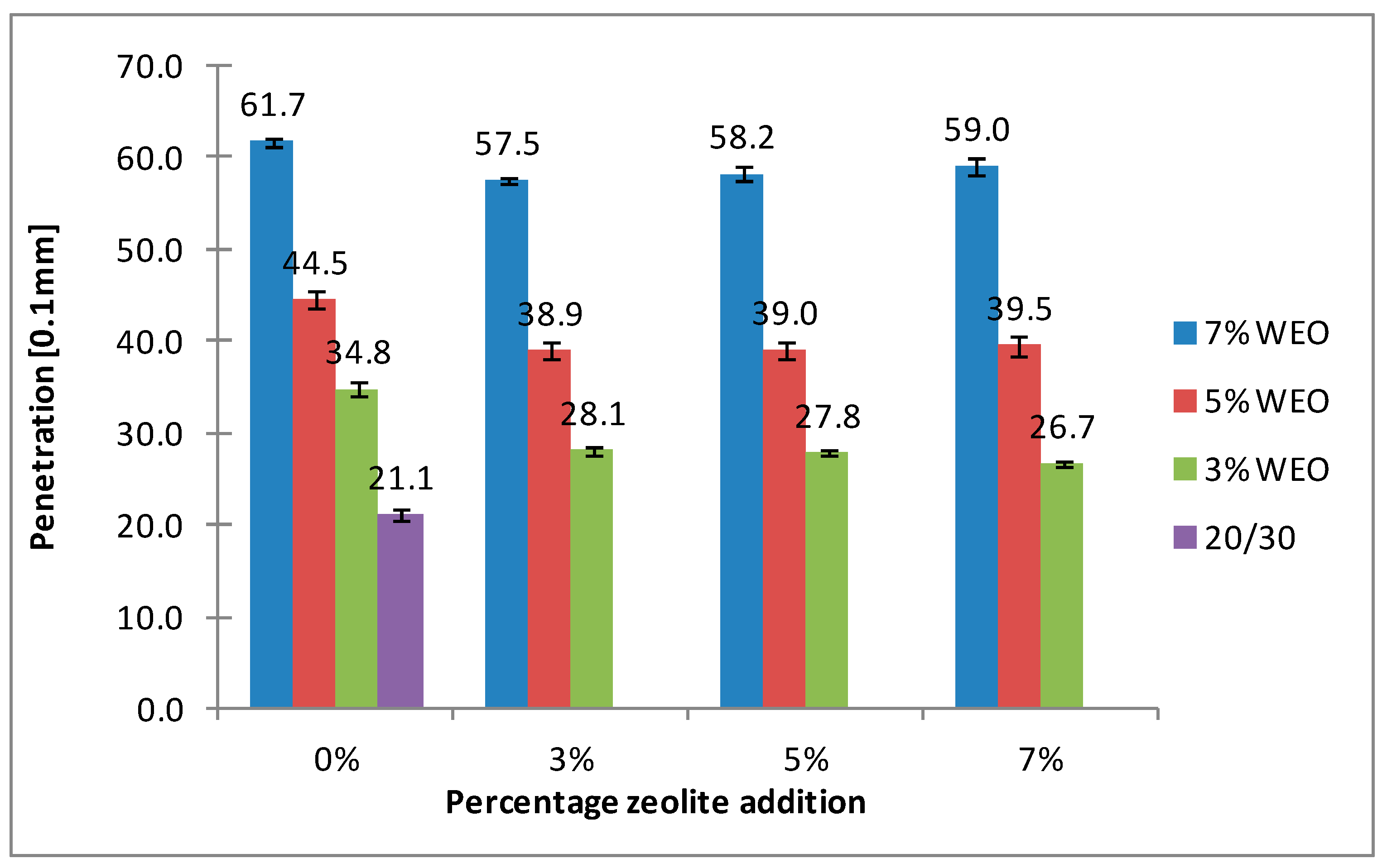

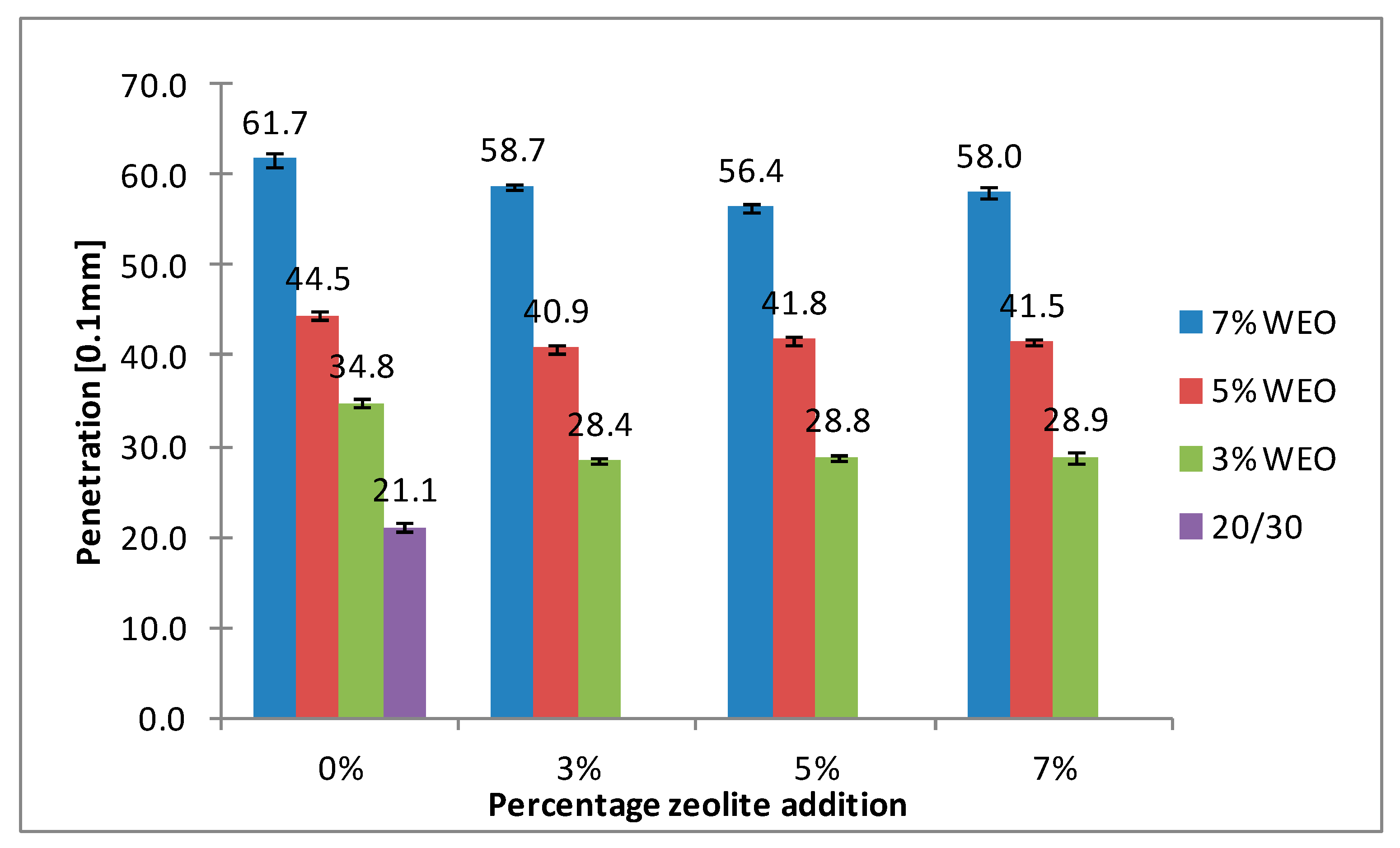

4.3. Penetration

- (1)

- Volumetric-filling reinforcement: The stiffening caused by the presence of rigid inclusions in a less rigid matrix,

- (2)

- Physicochemical reinforcement: The stiffening caused by the interfacial effects between filler particles and asphalt, including adsorption, absorption, and selective sorption.

- (3)

- Particle-interaction reinforcement: The stiffening beyond physicochemical reinforcement and volume filling.

4.4. XRF

4.5. Statistical Data Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bernier, A.; Zofka, A.; Yut, I. Laboratory evaluation of rutting susceptibility of polymer-modified asphalt mixtures containing recycled pavements. Constr. Build. Mater. 2012, 31, 58–66. [Google Scholar] [CrossRef]

- Iwański, M.; Chomicz-Kowalska, A. Moisture and frost resistance of the recycled base rehabilitated with the foamed bitumen technology. Arch. Civ. Eng. 2012, 58, 185–198. [Google Scholar] [CrossRef][Green Version]

- Pérez, I.; Pasandín, A.R. Moisture damage resistance of hot-mix asphalt made with recycled concrete aggregates and crumb rubber. J. Clean. Prod. 2017, 165, 405–414. [Google Scholar] [CrossRef]

- Al-Bayati, H.K.A.; Tighe, S.L.; Achebe, J. Influence of recycled concrete aggregate on volumetric properties of hot mix asphalt. Resour. Conserv. Recycl. 2018, 130, 200–214. [Google Scholar] [CrossRef]

- Martinho, F.C.G.; Picado-Santos, L.G.; Capitão, S.D. Feasibility Assessment of the Use of Recycled Aggregates for Asphalt Mixtures. Sustainability 2018, 10, 1737. [Google Scholar] [CrossRef]

- Andrzejuk, W.; Barnat-Hunek, D.; Siddique, R.; Zegardło, B.; Łagód, G. Application of recycled ceramic aggregates for the production of mineral-asphalt mixtures. Materials 2018, 11, 658. [Google Scholar] [CrossRef] [PubMed]

- Andrzejuk, W.; Barnat-Hunek, D.; Fic, S.; Styczeń, J. Wettability and surface free energy of mineral-asphalt mixtures with dolomite and recycled aggregate. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471. [Google Scholar] [CrossRef]

- Muniandy, R.; Ismail, D.H.; Hassim, S. Performance of recycled ceramic waste as aggregates in hot mix asphalt (HMA). J. Mater. Cycles Waste 2018, 20, 844–849. [Google Scholar] [CrossRef]

- Rongalia, U.; Singhb, G.; Chourasiyac, A.; Jaind, P.K. Laboratory performance of stone matrix asphalt containing composite of fly ash and plastic waste. J. Sci. Ind. Res. India 2013, 72, 186–192. [Google Scholar]

- Mistry, R.; Roy, T.K. Effect of using fly ash as alternative filler in hot mix asphalt. ScienceDirect 2016, 8, 186–192. [Google Scholar] [CrossRef]

- Raport o stanie technicznym nawierzchni sieci dróg krajowych na koniec 2018 roku. Generalna Dyrekcja Dróg Krajowych i Autostrad. Warszawa. 2019. Available online: https://www.gddkia.gov.pl/frontend/web/userfiles/articles/r/raporty_18751/2018/Raport%20stan%20na%20koniec%202018.pdf (accessed on 27 May 2019).

- Ryś, D. Loading of roads by heavy vehicles and their impact on fatigue life of flexible and semi-rigid pavement structures. Ph.D. Thesis, Gdańsk University of Technology, Gdańsk, Poland, June 2015. [Google Scholar]

- Mogawer, W.; Bennert, T.; Daniel, J.S.; Bonaquist, R.; Austerman, A.; Booshehrian, A. Performance characteristics of plant produced high rap mixtures. Road Mater. Pavement Des. 2012, 13, 183–208. [Google Scholar] [CrossRef]

- Mamun, A.A.; Arifuzzaman, M.; Taha, R. Nano scale aging characterization of carbon nanotube modified asphalt binders. In Proceedings of the Advances in Materials and Pavement Prediction, Doha, Qatar, 16–18 April 2018; p. 403. [Google Scholar]

- Elkashef, M.; Podolsky, J.; Williams, R.C.; Cochran, E. Preliminary examination of soybean oil derived material as a potential rejuvenator through superpave criteria and asphalt bitumen rheology. Constr. Build. Mater. 2017, 149, 826–836. [Google Scholar] [CrossRef]

- Mazzoni, G.; Bocci, E.; Canestrari, F. Influence of rejuvenators on bitumen ageing in hot recycled asphalt mixtures. J. Traffic Tranp. Eng. Engl. Ed. 2018, 5, 157–168. [Google Scholar] [CrossRef]

- Mamun, A.A.; Al-Abdul Wahhab, H.I. Evaluation of Waste Engine Oil-Rejuvenated Asphalt Concrete Mixtures with High RAP Content. Adv. Mater. Sci. Eng. 2018, 6, 1–8. [Google Scholar] [CrossRef]

- Shoukat, T.; Jun Yoo, P. Rheology of Asphalt Binder Modified with 5W30 Viscosity Grade Waste Engine Oil. Appl. Sci. 2018, 8, 1194. [Google Scholar] [CrossRef]

- Qurashi, I.A.; Swamy, A.K. Viscoelastic properties of recycled asphalt binder containing waste engine oil. J. Clean. Prod. 2018, 182, 992–1000. [Google Scholar] [CrossRef]

- Fernandes, S.; Peralta, J.; Oliveira, J.R.M.; Williams, R.C.; Silva, H.M.R.D. Improving asphalt mixture performance by partially replacing bitumen with waste motor oil and elastomer modifiers. Appl. Sci. 2017, 7, 794. [Google Scholar] [CrossRef]

- You, T.; Balamurugan, S.S.; Nazzal, M.D.; Mohammad, L.N.; Negulescua, I.; Daly, W.H. Rheological, chemical, micromechanical, and mechanical properties of re-refined engine oil bottoms (REOB) modified binders. In Proceedings of the Transportation Research Board 97th Annual Meeting, Washington, DC, USA, 7–11 January 2018. [Google Scholar]

- Yang, T.; Chen, M.; Zhou, X.; Xie, J. Evaluation of Thermal-Mechanical Properties of Bio-Oil Regenerated Aged Asphalt. Materials 2018, 11, 2224. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; You, Z.; Mohd Hasan, M.R. Research on properties of bio-asphalt binders based on time and frequency sweep test. Constr. Build. Mater. 2018, 160, 786–793. [Google Scholar] [CrossRef]

- Cuadri, A.; García-Morales, M.; Navarro, F.; Partal, P. Processing of bitumens modified by a bio-oil-derived polyurethane. Fuel 2014, 118, 83–90. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Miller, J.A. Effects of rejuvenating agents on superpave mixtures containing reclaimed asphalt pavement. J. Mater. Civ. Eng. 2007, 19, 376–384. [Google Scholar] [CrossRef]

- Jia, X.; Huang, B.; Moore, J.A.; Zhao, S. Influence of waste engine oil on asphalt mixtures containing reclaimed asphalt pavement. J. Mater. Civ. Eng. 2015, 27, 04015–04042. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of reclaimed asphalt pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Qiu, Y.; Ding, H.; Rahman, A.; Wang, W. Damage characteristics of waste engine oil bottom rejuvenated asphalt binder in the non-linear range and its microstructure. Constr. Build. Mater. 2018, 174, 202–209. [Google Scholar] [CrossRef]

- Wu, S.; Muhunthan, B. Evaluation of the Effects of Waste Engine Oil on the Rheological Properties of Asphalt Binders. J. Mater. Civ. Eng. 2018, 30. [Google Scholar] [CrossRef]

- Woszuk, A.; Franus, W. A review of the application of zeolite materials in Warm Mix Asphalt technologies. Appl. Sci. 2017, 7, 293. [Google Scholar] [CrossRef]

- Tutu, K.A.; Tuffour, Y.A. Warm-Mix Asphalt and Pavement Sustainability: A Review. Open J. Civ. Eng. 2016, 6, 84–93. [Google Scholar] [CrossRef]

- Vaitkus, A.; Cygas, A.; Laurinavicius, A.; Perveneckas, Z. Analysis and evaluation of possibilities for the use of warm mix asphalt in Lithuania. Balt. J. Road Bridge E 2009, 4, 80–86. [Google Scholar] [CrossRef]

- Tao, M.; Mallick, R.B. Effects of warm-mix asphalt additives on workability and mechanical properties of reclaimed asphalt pavement material. Transport Res. Rec. 2009, 2126, 151–160. [Google Scholar] [CrossRef]

- Woszuk, A.; Franus, W. Properties of the Warm Mix Asphalt involving clinoptilolite and Na-P1 zeolite additives. Constr. Build. Mater. 2016, 114, 556–563. [Google Scholar] [CrossRef]

- Woszuk, A.; Zofka, A.; Bandura, L.; Franus, W. Effect of zeolite properties on asphalt foaming. Constr. Build. Mater. 2017, 139, 247–255. [Google Scholar] [CrossRef]

- Liu, S.; Peng, A.; Wu, J.; Bo Zhou, S.B. Waste engine oil influences on chemical and rheological properties of different asphalt binders. Constr. Build. Mater. 2018, 191, 1210–1220. [Google Scholar] [CrossRef]

- Woszuk, A. Application of fly ash derived zeolites in warm-mix asphalt technology. Materials 2018, 11, 1542. [Google Scholar] [CrossRef] [PubMed]

- Woszuk, A.; Panek, R.; Madej, J.; Zofka, A.; Franus, W. Mesoporous silica material MCM-41: Novel additive 410 for warm mix. Constr. Build. Mater. 2018, 183, 270–274. [Google Scholar] [CrossRef]

- Zargar, M.; Ahmadinia, E.; Asli, H.; Karim, M.R. Investigation of the possibility of using waste cooking oil as a rejuvenating agent for aged bitumen. J. Hazard. Mater. 2012, 233–234, 254–258. [Google Scholar] [CrossRef] [PubMed]

- Nciri, N.; Shin, T.; Lee, H.; Cho, N. Potential of Waste Oyster Shells as a Novel Biofiller for Hot-Mix Asphalt. Appl. Sci. 2018, 8, 415. [Google Scholar] [CrossRef]

- Mirzababaei, P. Effect of zycotherm on moisture susceptibility of Warm Mix Asphalt mixtures prepared with different aggregate types and gradations. Constr. Build. Mater. 2016, 116, 403–412. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Perez, I.; Ramírez, A.; Cano, M.M. Moisture damage resistance of hot-mix asphalt made with paper industry wastes as filler. J. Clean. Prod. 2016, 112, 853–862. [Google Scholar] [CrossRef]

- Rubab, S.; Burke, K.; Wright, L.; Hesp, S.A.M.; Marks, P.; Raymond, C. Effects of Engine Oil Residues on Asphalt Cement Quality. In Proceedings of the Fifty-Sixth Annual Conference of the Canadian Technical Asphalt Association (CTAA), Quebec City, QC, Canada, November 2011. [Google Scholar]

- Soleimani, A.; Walsh, S.; Hesp, S.A.M. Asphalt Cement Loss Tangent as Surrogate Performance Indicator for Control of Thermal Cracking. Transp. Res. Rec. 2009, 2126, 39–46. [Google Scholar] [CrossRef]

| Test | Specification | Result | |

|---|---|---|---|

| 20/30 Asphalt | 25/55-60 Asphalt | ||

| Penetration (25 °C; 0.1 mm) | EN 1426:2009 | 21.1 | 29.3 |

| Viscosity at (135 °C), mPa·s | ASTM D 4402 | 377.0 | 593.5 |

| Softening point, °C | EN 1427:2009 | 63.8 | 68.0 |

| WEO 5W40 | 35/50 Asphalt (A) | PMB 25/55-60 (B) | A + 3% WEO | A + 5% WEO | A + 7% WEO | B + 3% WEO | B + 5% WEO | B + 7% WEO | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Al | % | 0.038 | 0.027 | 0.025 | 0.025 | 0.027 | 0.024 | 0.026 | 0.024 | 0.024 |

| Si | % | 0.066 | 0.007 | 0.007 | 0.005 | 0.006 | 0.007 | 0.007 | 0.004 | 0.006 |

| P | % | 0.089 | 0.035 | 0.035 | 0.038 | 0.041 | 0.039 | 0.038 | 0.039 | 0.039 |

| S | % | 0.186 | 3.600 | 3.461 | 3.465 | 3.370 | 3.379 | 3.341 | 3.304 | 3.267 |

| Ca | % | 0.208 | 0.013 | 0.014 | 0.019 | 0.025 | 0.026 | 0.020 | 0.023 | 0.025 |

| V | % | nd * | 0.026 | 0.024 | 0.025 | 0.025 | 0.024 | 0.024 | 0.023 | 0.023 |

| Ti | ppm | 4.1 | nd | nd | nd | nd | nd | nd | nd | nd |

| Fe | % | 0.002 | 0.006 | 0.005 | 0.006 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

| Ni | % | nb | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 | 0.005 |

| Zn | ppm | 680 | nd | 5 | 30 | 40 | 50 | 30 | 40 | 60 |

| Sn | ppm | 60 | nd | nd | 50 | 60 | 60 | 60 | 60 | 60 |

| CH2 | % | 99.338 | 96.280 | 96.422 | 96.403 | 96.485 | 96.477 | 96.525 | 96.562 | 96.595 |

| Asphalt 20/30 | |||||

| Na-P1 Zeolite | |||||

| Penetration test | |||||

| Source | SS | df | MS | F | p |

| Percentage WEO addition | 1808.72 | 2 | 904.36 | 696.02 | 0.0000 |

| Percentage zeolite addition | 65.00 | 3 | 21.67 | 16.67 | 0.0026 |

| Error | 7.80 | 6 | 1.30 | - | - |

| Total | 1881.51 | 11 | - | - | - |

| Softening point test | |||||

| Source | SS | df | MS | F | p |

| Percentage WEO addition | 20.91 | 2 | 10.45333333 | 73.5 | 0.0001 |

| Percentage zeolite addition | 0.99 | 3 | 0.328888889 | 2.3125 | 0.1758 |

| Error | 0.85 | 6 | 0.142222222 | - | - |

| Total | 22.75 | 11 | - | - | - |

| Dynamic viscosity test | |||||

| Source | SS | df | MS | F | p |

| Percentage WEO addition | 11257.64 | 2 | 5628.82 | 189.88 | 0.0000 |

| Percentage zeolite addition | 1217.31 | 3 | 405.77 | 13.69 | 0.0043 |

| Error | 177.86 | 6 | 29.64 | - | - |

| Total | 12652.81 | 11 | - | - | - |

| Clinoptilolite zeolite | |||||

| Penetration test | |||||

| Source | SS | df | MS | F | p |

| Percentage WEO addition | 1636.14 | 2 | 818.07 | 751.97 | 0.0000 |

| Percentage zeolite addition | 43.76 | 3 | 14.59 | 13.41 | 0.0045 |

| Error | 6.53 | 6 | 1.09 | - | - |

| Total | 1686.43 | 11 | - | - | - |

| Softening point test | |||||

| Source | SS | df | MS | F | p |

| Percentage WEO addition | 19.46 | 2 | 9.73 | 143.56 | 0.0000 |

| Percentage zeolite addition | 0.86 | 3 | 0.29 | 4.25 | 0.0626 |

| Error | 0.41 | 6 | 0.07 | ||

| Total | 20.73 | 11 | |||

| Dynamic viscosity test | |||||

| Source | SS | df | MS | F | p |

| Percentage WEO addition | 12075.28 | 2 | 6037.64 | 132.13 | 0.0000 |

| Percentage zeolite addition | 569.54 | 3 | 189.85 | 4.15 | 0.0652 |

| Error | 274.18 | 6 | 45.70 | - | - |

| Total | 12919.00 | 11 | - | - | - |

| Asphalt PMB 25/55-60 | |||||

| Na-P1 Zeolite | |||||

| Penetration test | |||||

| Source | SS | df | MS | F | p |

| Percentage WEO addition | 1419.98 | 2 | 709.99 | 1811.56 | 0.0000 |

| Percentage zeolite addition | 16.06 | 3 | 5.35 | 13.66 | 0.0043 |

| Error | 2.35 | 6 | 0.39 | - | - |

| Total | 1438.40 | 11 | - | - | - |

| Softening point test | |||||

| Source | SS | df | MS | F | p |

| Percentage WEO addition | 40.13 | 2 | 20.06 | 91.66 | 0.0000 |

| Percentage zeolite addition | 2.52 | 3 | 0.84 | 3.83 | 0.0759 |

| Error | 1.31 | 6 | 0.22 | - | - |

| Total | 43.96 | 11 | - | - | - |

| Dynamic viscosity test | |||||

| Source | SS | df | MS | F | p |

| Percentage WEO addition | 49484.32 | 2 | 24742.16 | 75.72 | 0.0001 |

| Percentage zeolite addition | 9364.63 | 3 | 3121.54 | 9.55 | 0.0106 |

| Error | 1960.54 | 6 | 326.76 | - | - |

| Total | 60809.49 | 11 | - | - | - |

| Clinoptilolite zeolite | |||||

| Penetration test | |||||

| Source | SS | df | MS | F | p |

| Percentage WEO addition | 1303.20 | 2 | 651.60 | 604.81 | 0.0000 |

| Percentage zeolite addition | 13.57 | 3 | 4.52 | 4.20 | 0.0639 |

| Error | 6.46 | 6 | 1.08 | - | - |

| Total | 1323.24 | 11 | - | - | - |

| Softening point test | |||||

| Source | SS | df | MS | F | p |

| Percentage WEO addition | 23.83 | 2 | 11.91 | 44.92 | 0.0002 |

| Percentage zeolite addition | 6.71 | 3 | 2.24 | 8.43 | 0.0143 |

| Error | 1.59 | 6 | 0.27 | - | - |

| Total | 32.12 | 11 | - | - | - |

| Dynamic viscosity test | |||||

| Source | SS | df | MS | F | p |

| Percentage WEO addition | 42428.67 | 2 | 21214.33 | 371.10 | 0.0000 |

| Percentage zeolite addition | 3402.75 | 3 | 1134.25 | 19.84 | 0.0016 |

| Error | 343.00 | 6 | 57.17 | - | - |

| Total | 46174.42 | 11 | - | - | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woszuk, A.; Wróbel, M.; Franus, W. Influence of Waste Engine Oil Addition on the Properties of Zeolite-Foamed Asphalt. Materials 2019, 12, 2265. https://doi.org/10.3390/ma12142265

Woszuk A, Wróbel M, Franus W. Influence of Waste Engine Oil Addition on the Properties of Zeolite-Foamed Asphalt. Materials. 2019; 12(14):2265. https://doi.org/10.3390/ma12142265

Chicago/Turabian StyleWoszuk, Agnieszka, Michał Wróbel, and Wojciech Franus. 2019. "Influence of Waste Engine Oil Addition on the Properties of Zeolite-Foamed Asphalt" Materials 12, no. 14: 2265. https://doi.org/10.3390/ma12142265

APA StyleWoszuk, A., Wróbel, M., & Franus, W. (2019). Influence of Waste Engine Oil Addition on the Properties of Zeolite-Foamed Asphalt. Materials, 12(14), 2265. https://doi.org/10.3390/ma12142265