Porous Open-Сell UHMWPE: Experimental Study of Structure and Mechanical Properties

Abstract

1. Introduction

- -

- Layered hybrids of porous and bulk UHMWPE;

- -

- Porous components with the gradient of pore sizes;

- -

- Components with controlled multimodal distribution of pore sizes;

- -

- Structures containing loose or embedded particles or fibers of another material.

2. Materials and Methods

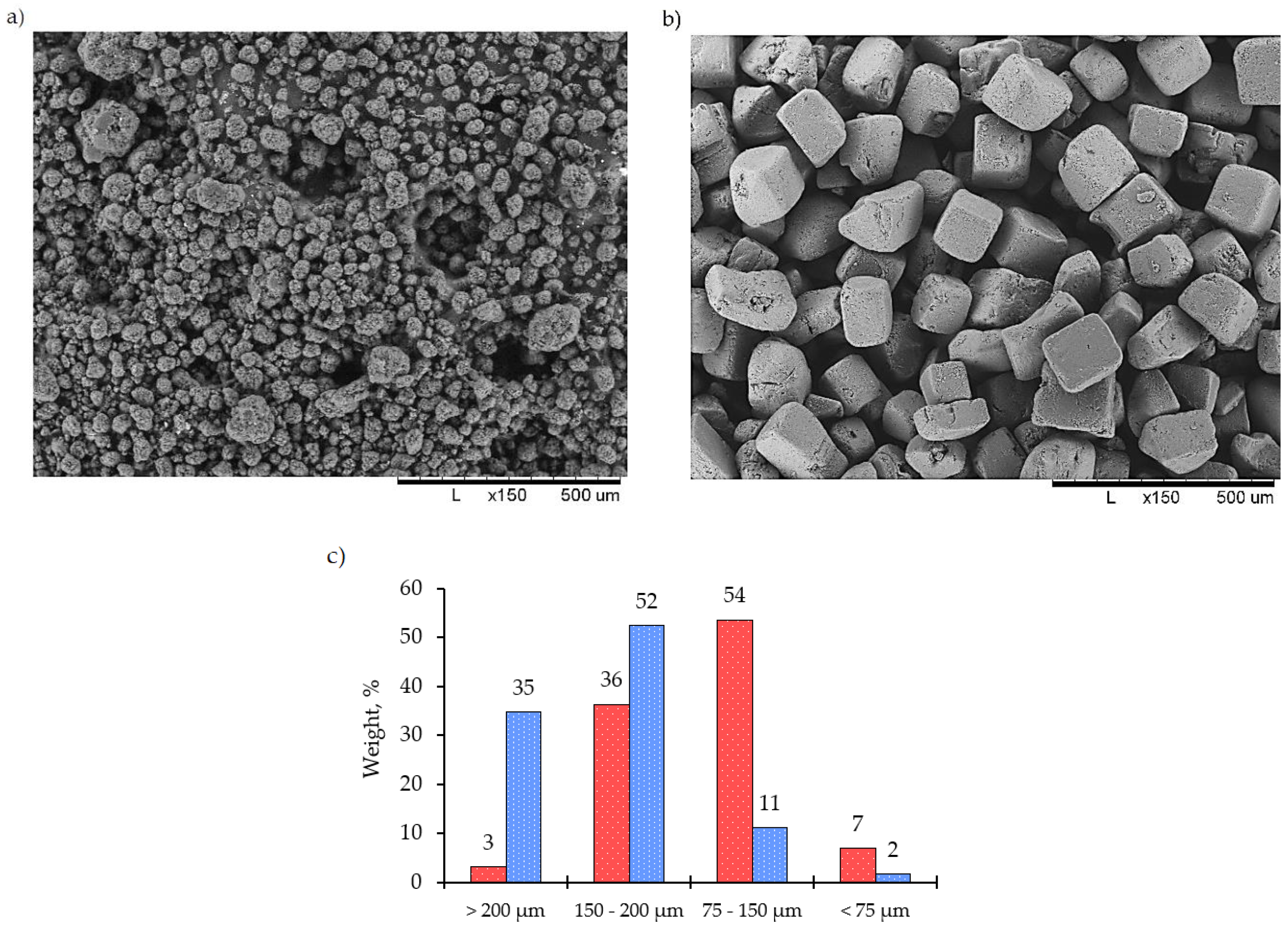

2.1. Sample Preparation

- (a)

- Bigger than 200 μm;

- (b)

- 150–200 μm;

- (c)

- 75–150 μm;

- (d)

- Smaller than 75 μm.

2.2. Compressive Testing

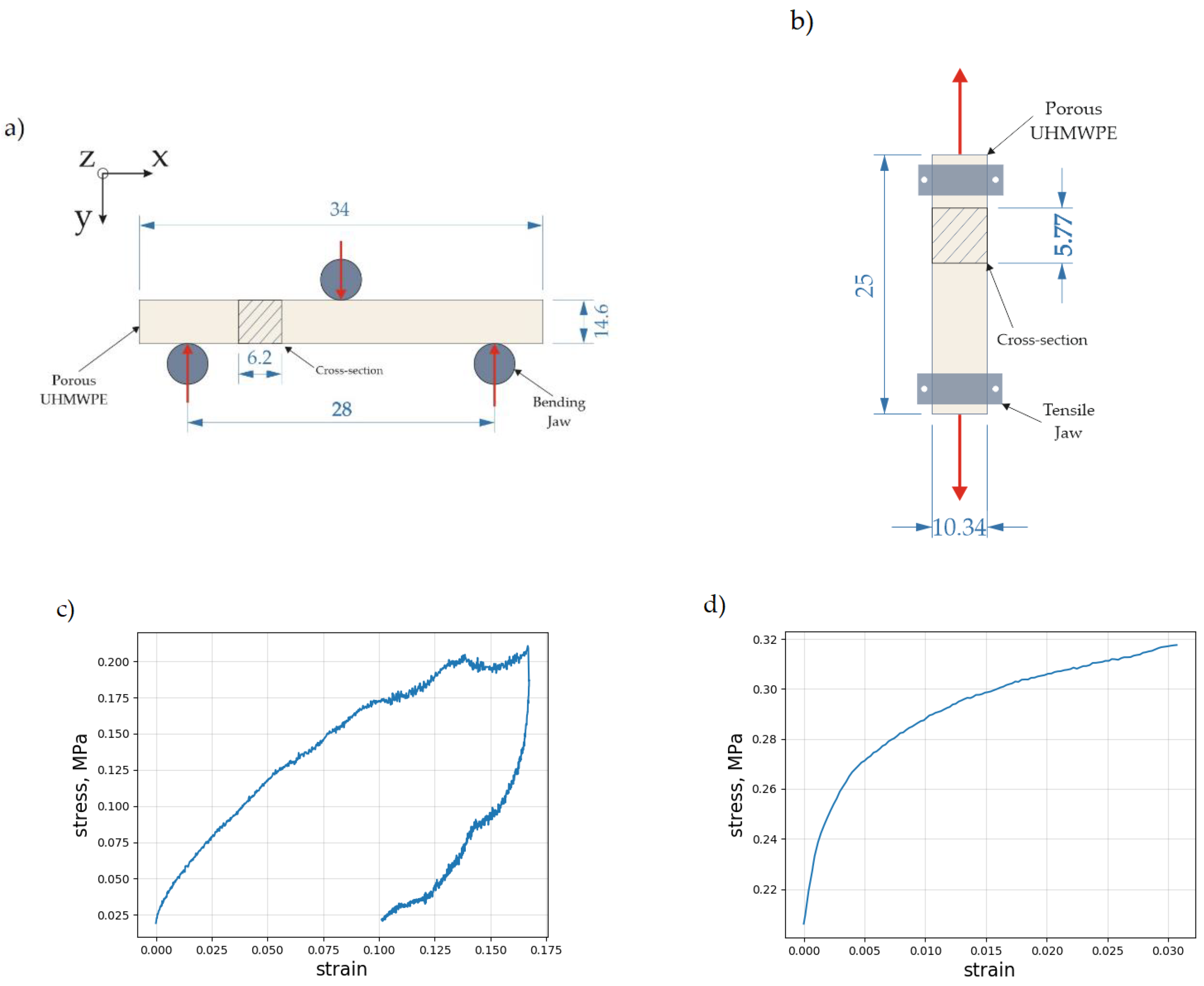

2.3. Tensile and Bending Testing

2.4. Scanning Electron Microscopy (SEM)

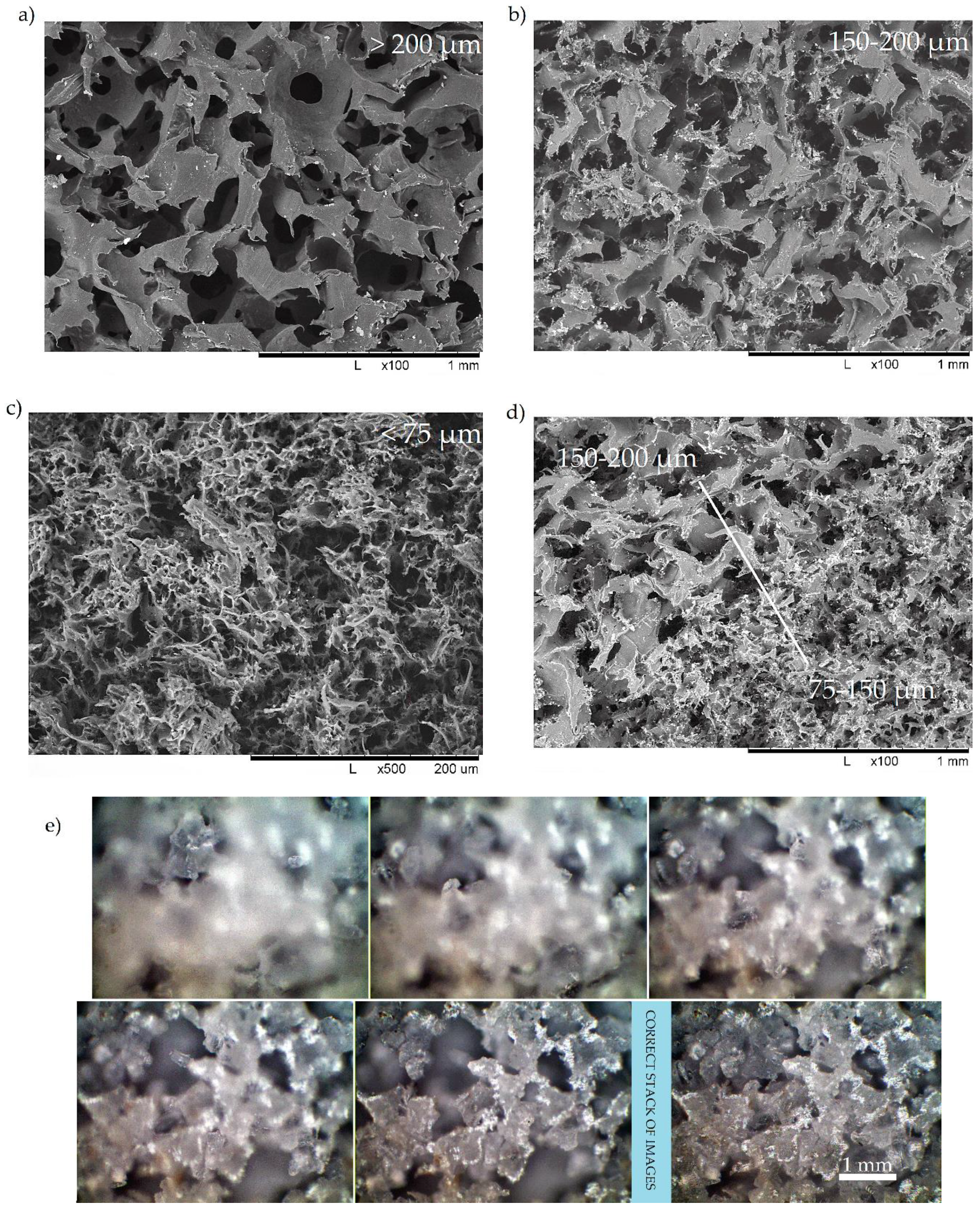

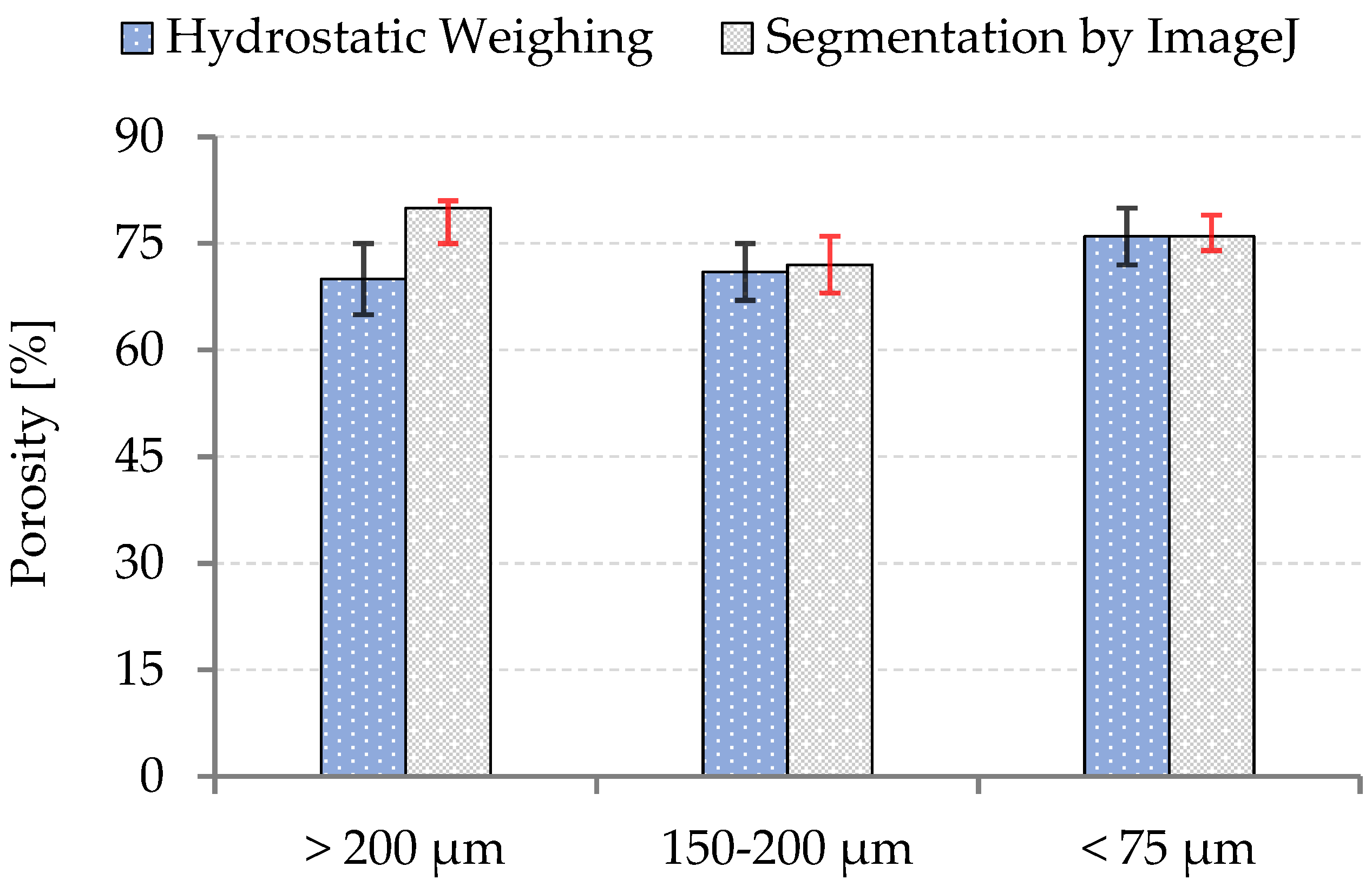

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kurtz, S.M. The Origins of UHMWPE in Total Hip Arthroplasty. In UHMWPE Biomaterials Handbook, 2nd ed.; Elsevier Inc.: London, UK, 2009; pp. 36–46. [Google Scholar]

- Kurtz, S.M. The Clinical Performance of UHMWPE in the Spine. In the UHMWPE Handbook Ultra-High Molecular Weight Polyethylene in Total Joint Replacement; Elsevier Inc.: London, UK, 2004; pp. 219–243. [Google Scholar]

- Carneiro, J.T.; Hemerson, P.; Voss, D.; Carneiro, C. Custom-Made Titanium Miniplates Associated with Ultrahigh-Molecular-Weight Polyethylene Graft in Orthognathic Surgery: An Adjunct to Maxillary Advancement. J. Oral Maxillofac. Surg. 2018, 76, 1091.e1–1091.e8. [Google Scholar] [CrossRef]

- Senatov, F.S.; Niaza, K.V.; Salimon, A.I.; Maksimkin, A.V.; Kaloshkin, S.D. Architected UHMWPE simulating trabecular bone tissue. Mater. Today Commun. 2018, 14, 124–127. [Google Scholar] [CrossRef]

- Zalepugin, D.Y.; Maksimkin, A.V.; Senatov, F.S.; Tilkunova, N.A.; Chernyshova, I.V.; Vlasov, M.I. Formation of porous ultrahigh molecular weight polyethylene using subcritical water. Mendeleev Commun. 2017, 27, 527–528. [Google Scholar] [CrossRef]

- Maksimkin, A.V.; Senatov, F.S.; Anisimova, N.Y.; Kiselevskiy, M.V.; Zalepugin, D.Y.; Chernyshova, I.V.; Tilkunova, N.A.; Kaloshkin, S.D. Multilayer porous UHMWPE scaffolds for bone defects replacement. Mater. Sci. Eng. 2017, 73, 366–372. [Google Scholar] [CrossRef] [PubMed]

- Fouad, H. Effect of long-term natural aging on the thermal, mechanical, and viscoelastic behavior of biomedical grade of Ultra High Molecular Weight Polyethylene. J. Appl. Polym. Sci. 2010, 118, 17–24. [Google Scholar] [CrossRef]

- Zhang, G.; Chita, O.R.; Evans, K.E. Dynamic thermo-mechanical and impact properties of helical auxetic yarns. Compos. Part B Eng. 2016, 99, 494–505. [Google Scholar] [CrossRef]

- Wang, H.; Ren, J.; Gao, G.; Chen, S.; Wang, J.; Yang, S. Effect of Compatibilization on Reciprocating Frictional Behavior of Polyamide 66/UHMWPE Blends. Tribol. Trans. 2016, 59, 560–568. [Google Scholar]

- Zhang, H.; Wang, L.; Dai, Y.; Shen, C.; Zhou, A.; Cao, X. Preparation and performances of ternary layered ceramic Ti3AlC2/ultrahigh molecular weight polyethylene composites. Fuhe Cailiao Xuebao/Acta Mater. Compos. Sin. 2017, 24, 1177–1184. [Google Scholar]

- Babiker, M.E.; Muhuo, Y. The thermal and mechanical properties of ultra-high molecular polyethylene/montmorillonite clay (UHMWPE/MMT) nanocomposites using gel and pressure-induced flow process (PIF). Polym. Polym. Compos. 2011, 19, 685–696. [Google Scholar] [CrossRef]

- Lu, S.H.; Liang, G.Z.; Zhou, Z.W.; Li, F. Structure and properties of UHMWPE fiber/carbon fiber hybrid composites. J. Appl. Polym. Sci. 2006, 101, 1880–1884. [Google Scholar] [CrossRef]

- Rodriguez-Perez, M.A.; Rodriguez-Lorente, S.; Saja, J.A. Dynamic mechanical properties of polyolefin foams studied by DMA techniques. Polym. Eng. Sci. 1997, 37, 959–965. [Google Scholar] [CrossRef]

- Almanza, O.; Rodriguez-Perez, M.A.; Saja, J.A. The microstructure of polyethylene foams produced by a nitrogen solution process. Polymer 2001, 42, 7117–7126. [Google Scholar] [CrossRef]

- Rodriguez-Perez, M.A.; Saja, J.A. Morphology of semicrystalline foams based on polyethylene. J. Macromol. Sci. 2002, 41, 761–775. [Google Scholar] [CrossRef]

- Velasco, J.I.; Antunes, M.; Ayyad, O.; Saiz-Arroyo, C.; Rodriguez-Perez, M.A.; Hidalgo, F.; Saja, J.A. Foams based on low density polyethylene/hectorite nanocomposites: Thermal stability and thermomechanical properties. J. Appl. Polym. Sci. 2007, 105, 1658–1667. [Google Scholar] [CrossRef]

- Luo, W.Z.; Zhu, Y.; Zou, H.W.; Fan, P.B.; Xu, W. Effect of ozone oxidation on structure and properties of super light EVA/LDPE foam material. Gaofenzi Cailiao Kexue Yu Gongcheng/Polym. Mater. Sci. Eng. 2008, 24, 154–158. [Google Scholar]

- Zwynenburg, J. Characterizing foam hinged lid containers utilizing Dynamic Mechanical Analysis (DMA). In Proceedings of the 7th International Conference on Foam Processing and Technology, Iselin, NJ, USA, 16–17 September 2009; pp. 133–144. [Google Scholar]

- Di Prima, M.; Gall, K.; McDowell, D.L.; Guldberg, R.; Lin, A.; Sanderson, T.; Campbell, D.; Arzberger, S.C. Deformation of epoxy shape memory polymer foam. Mech. Mater. 2010, 42, 304–314. [Google Scholar] [CrossRef]

- Tsyntsarski, B.; Pusz, S.; Kumanek, B.; Stoycheva, I.; Szeluga, U. Porous carbon materials from polyethylene wax—Production and properties. In Proceedings of the International Multidisciplinary Scientific Geo Conference Surveying Geology and Mining Ecology Management, Albena, Bulgaria, 18–24 June 2015; pp. 157–163. [Google Scholar]

- Ustyugov, A.A.; Chicheva, M.M.; Lysikova, E.A.; Vikhareva, E.A.; Sipyagina, N.A.; Malkova, A.N.; Straumal, E.A.; Bovina, E.V.; Senatov, F.S.; Salimon, A.I.; et al. Development of 3D cell culture on ultra-high molecular weight polyethylene (UHMWPE) as the basis of cellular matrix. Biomed. Chem. Res. Methods 2018, 1, 1–5. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Torres-Sanchez, C.; McLaughlin, J.; Bonallo, R. Effect of Pore Size, Morphology and Orientation on the Bulk Stiffness of a Porous Ti35Nb4Sn Alloy. J. Mater. Eng. Perform. 2018, 27, 2899–2909. [Google Scholar] [CrossRef]

- Leibinger, A.; Forte, A.E.; Tan, Z.; Oldfield, M.J.; Beyrau, F.; Dini, D.; Rodriguez, F. Soft Tissue Phantoms for Realistic needle Insertion: A Comparative Study. Ann. Biomed. Eng. 2016, 44, 2442–2452. [Google Scholar] [CrossRef] [PubMed]

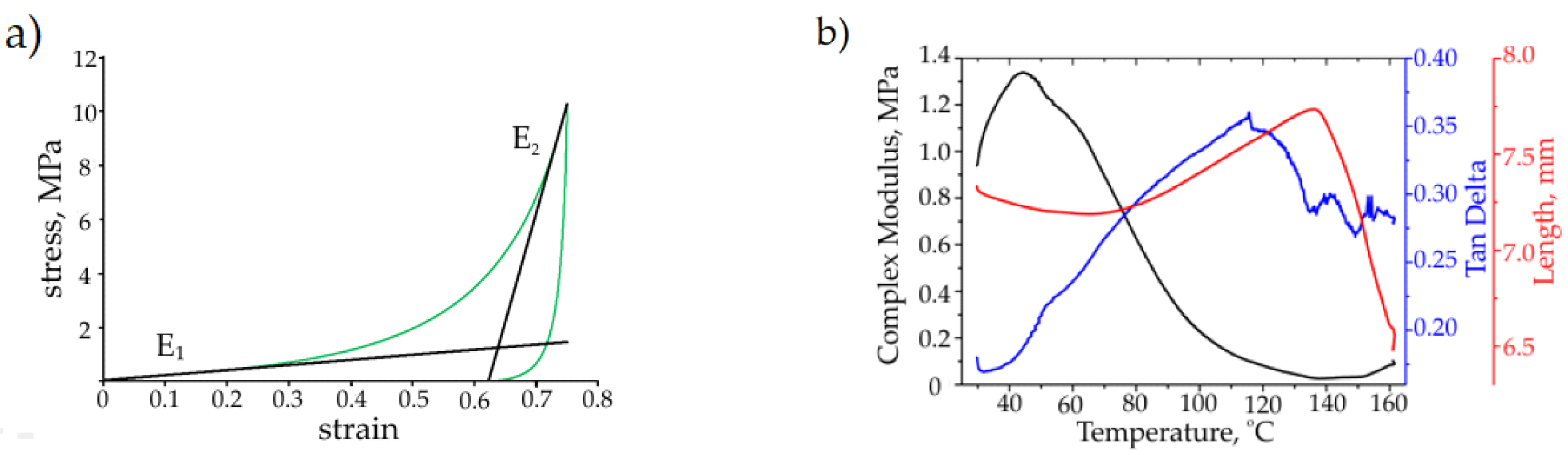

| Powder particle size, mm | Compression | Dynamic mechanical analysis | ||||

|---|---|---|---|---|---|---|

| E1, MPa | E2, MPa | Complex Modulus E*, MPa | Tan δ | |||

| 40 °C | 100 °C | 40 °C | 100 °C | |||

| >200 | 1.80 ± 0.50 | 60 ± 25 | 4.70 ± 1.60 | 0.80 ± 0.22 | 0.185 ± 0.019 | 0.310 ± 0.012 |

| 150–200 | 1.96 ± 0.50 | 42.5 ± 22 | 6.84 ± 2.09 | 1.28 ± 0.43 | 0.207 ± 0.009 | 0.325 ± 0.002 |

| 75–150 | 1.26 ± 0.18 | 56 ± 7 | 1.13 ± 0.43 | 0.25 ± 0.10 | 0.173 ± 0.004 | 0.326 ± 0.009 |

| <75 | 2.14 ± 0.45 | 64 ± 18 | 1.20 ± 0.62 | 0.36 ± 0.14 | 0.191 ± 0.017 | 0.314 ± 0.008 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salimon, A.I.; Statnik, E.S.; Zadorozhnyy, M.Y.; Senatov, F.S.; Zherebtsov, D.D.; Safonov, A.A.; Korsunsky, A.M. Porous Open-Сell UHMWPE: Experimental Study of Structure and Mechanical Properties. Materials 2019, 12, 2195. https://doi.org/10.3390/ma12132195

Salimon AI, Statnik ES, Zadorozhnyy MY, Senatov FS, Zherebtsov DD, Safonov AA, Korsunsky AM. Porous Open-Сell UHMWPE: Experimental Study of Structure and Mechanical Properties. Materials. 2019; 12(13):2195. https://doi.org/10.3390/ma12132195

Chicago/Turabian StyleSalimon, Alexei I., Eugene S. Statnik, Michael Yu. Zadorozhnyy, Fedor S. Senatov, Dmitry D. Zherebtsov, Alexander A. Safonov, and Alexander M. Korsunsky. 2019. "Porous Open-Сell UHMWPE: Experimental Study of Structure and Mechanical Properties" Materials 12, no. 13: 2195. https://doi.org/10.3390/ma12132195

APA StyleSalimon, A. I., Statnik, E. S., Zadorozhnyy, M. Y., Senatov, F. S., Zherebtsov, D. D., Safonov, A. A., & Korsunsky, A. M. (2019). Porous Open-Сell UHMWPE: Experimental Study of Structure and Mechanical Properties. Materials, 12(13), 2195. https://doi.org/10.3390/ma12132195