Preparation and Evaluation of Exhaust-Purifying Cement Concrete Employing Titanium Dioxide

Abstract

1. Introduction

2. Experiments

2.1. Materials

2.2. Methods

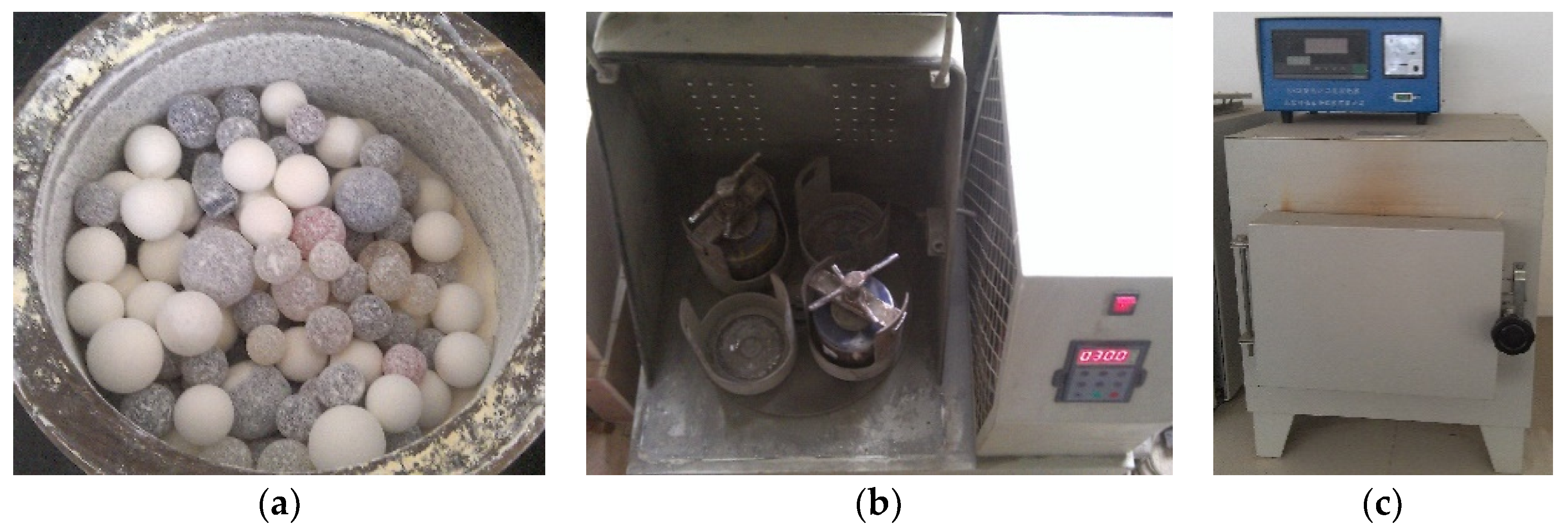

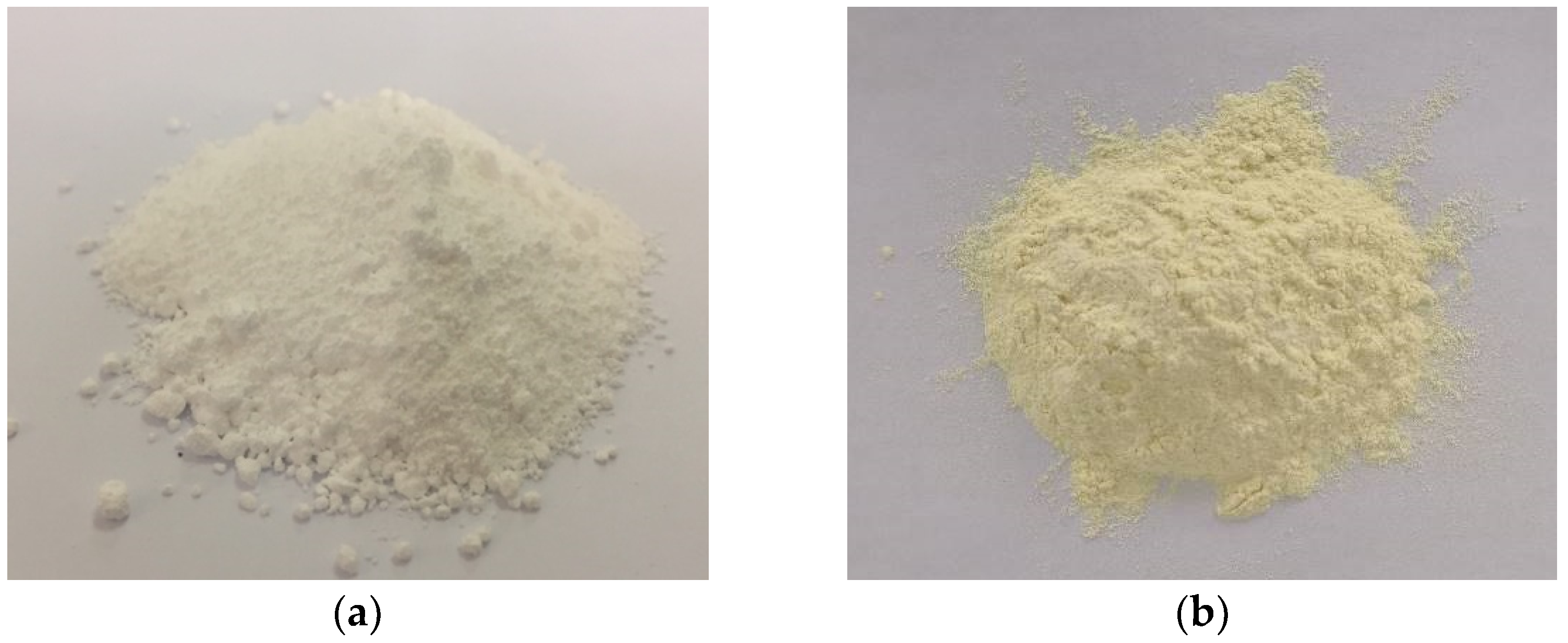

2.2.1. Preparation of Modified TiO2

2.2.2. Preparation of Concrete Samples

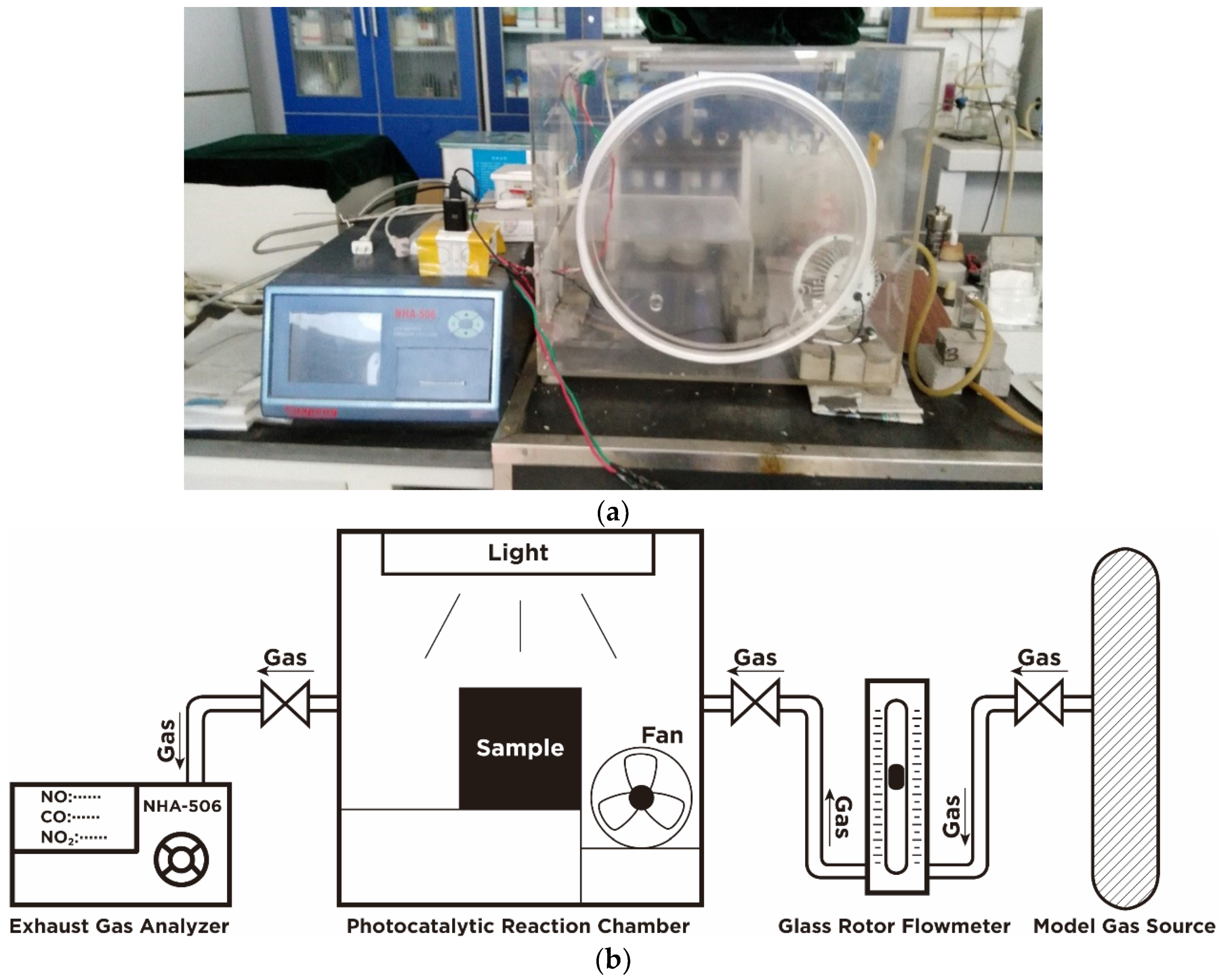

2.2.3. Test of Photocatalytic Degradation Efficiency

2.2.4. Microstructure Analysis

3. Results and Discussion

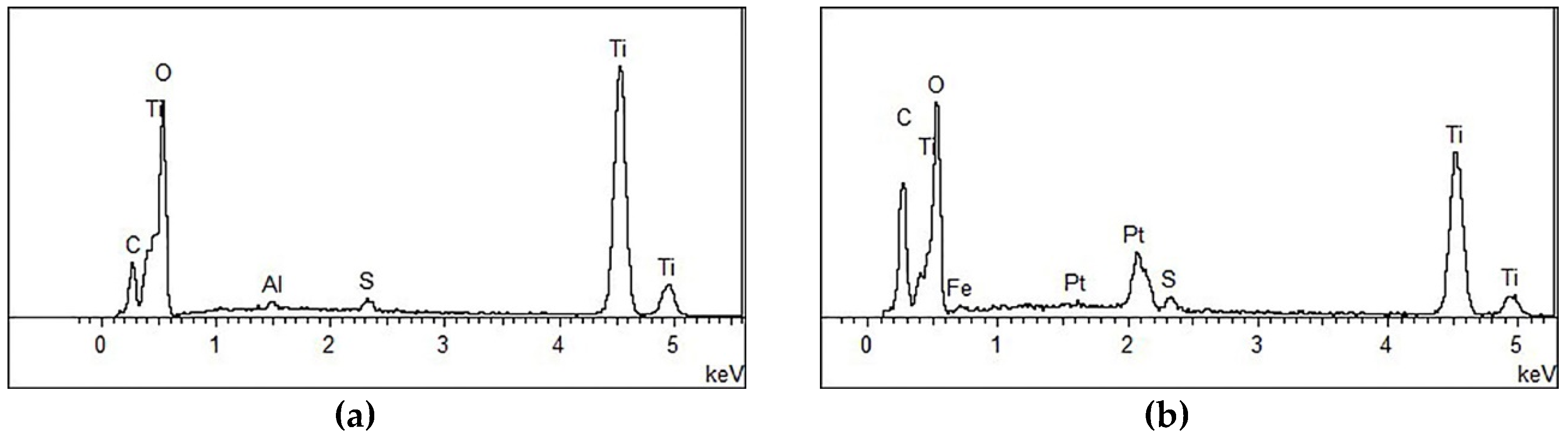

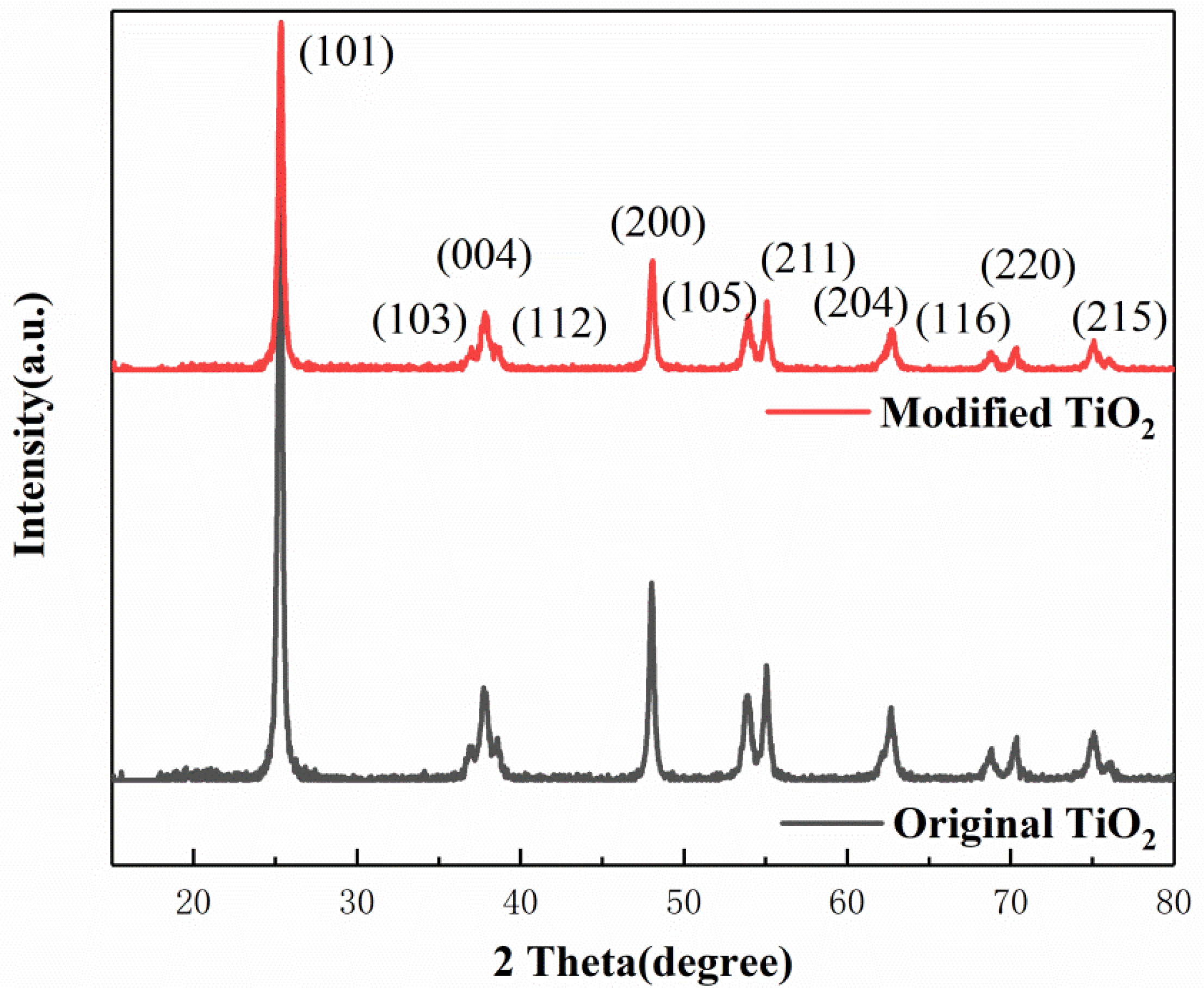

3.1. Characterization of TiO2 Samples

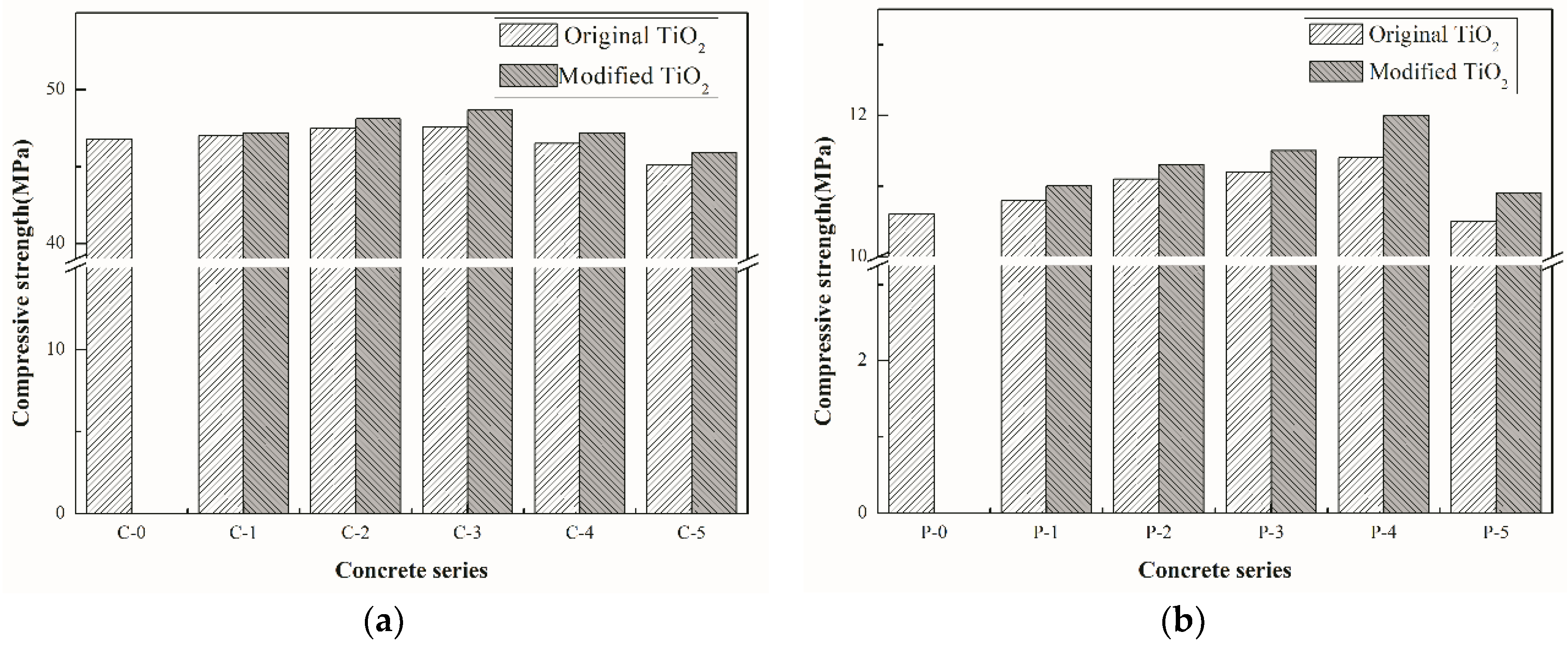

3.2. Mechanical Property Analysis

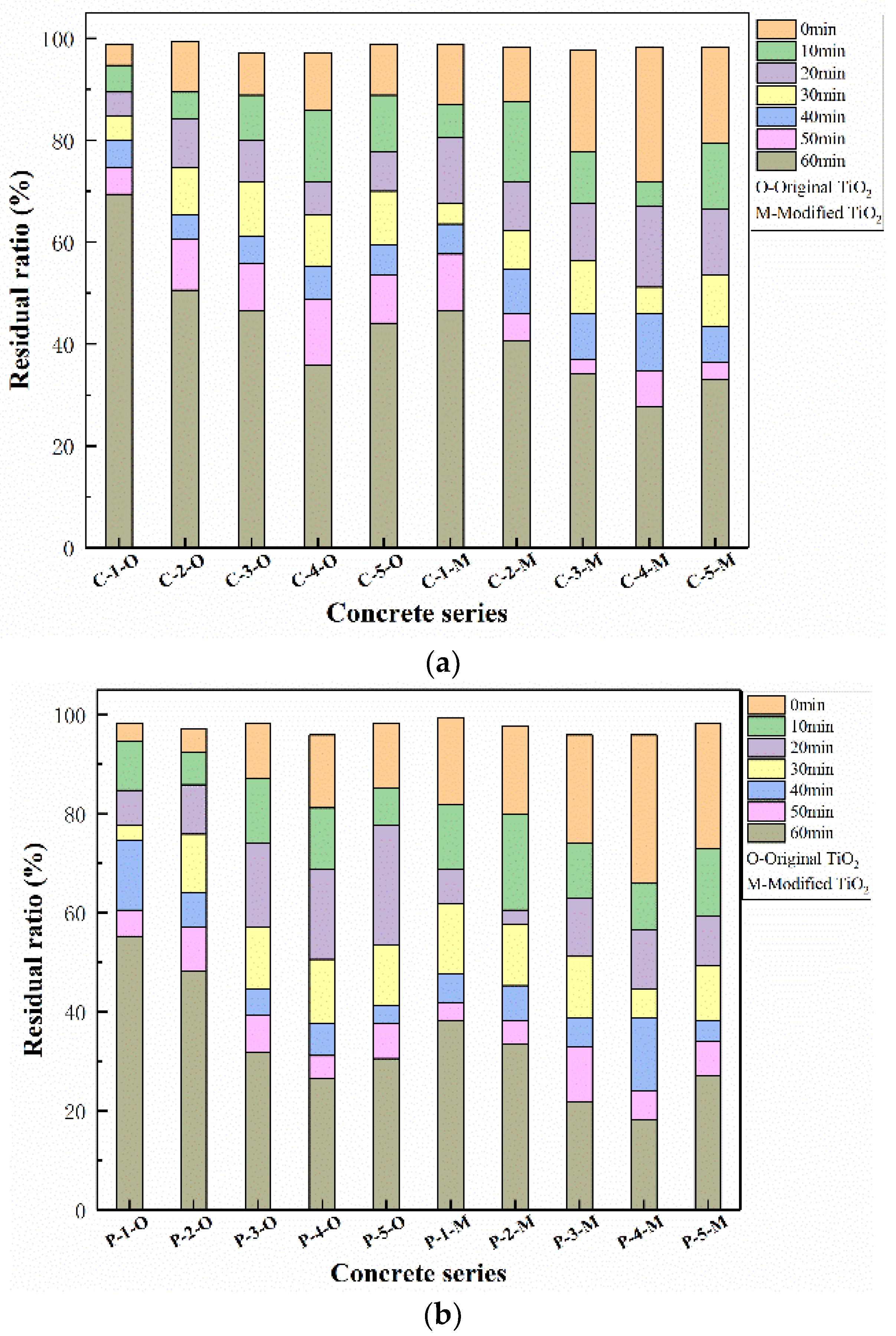

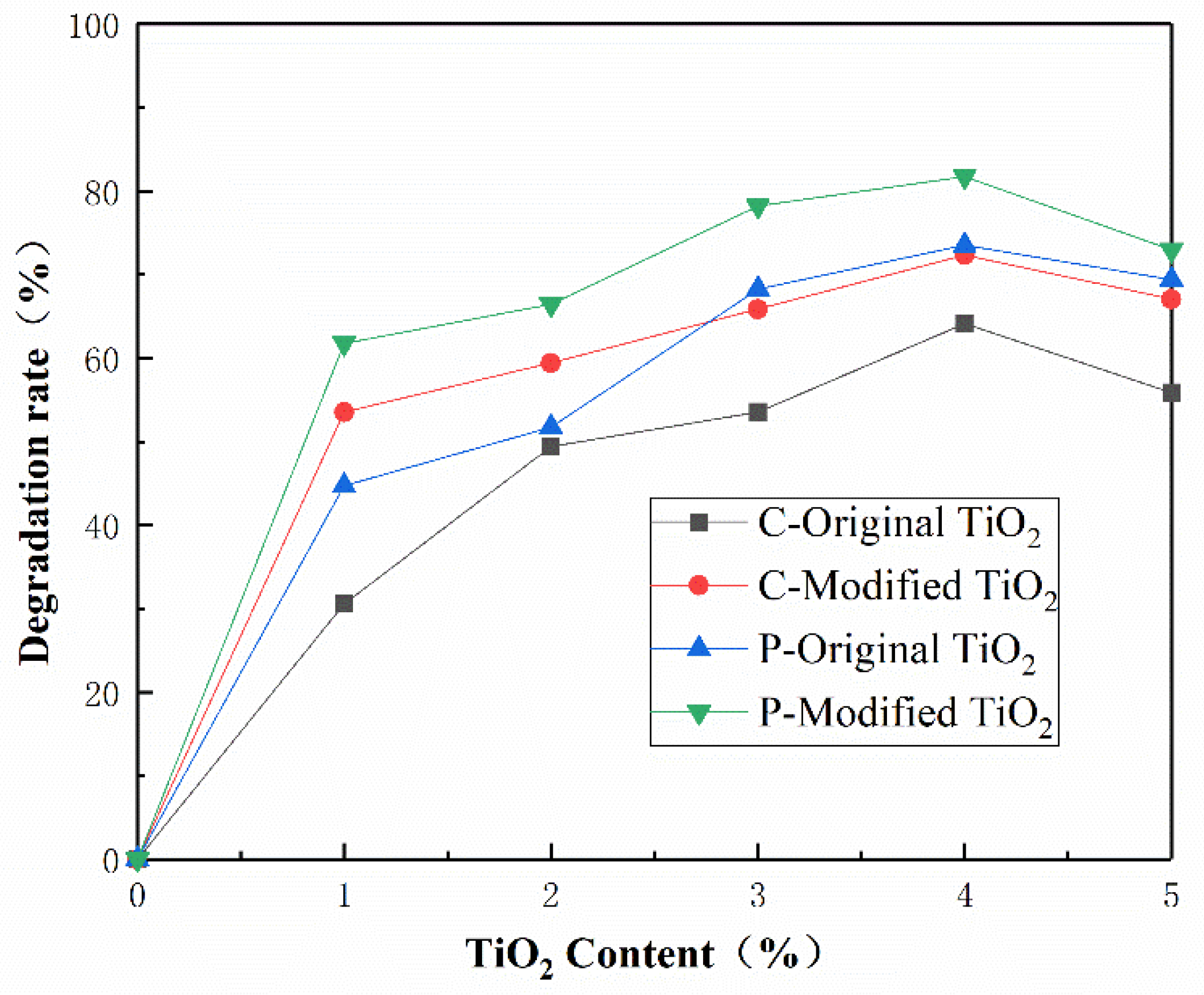

3.3. Photocatalytic Property Analysis

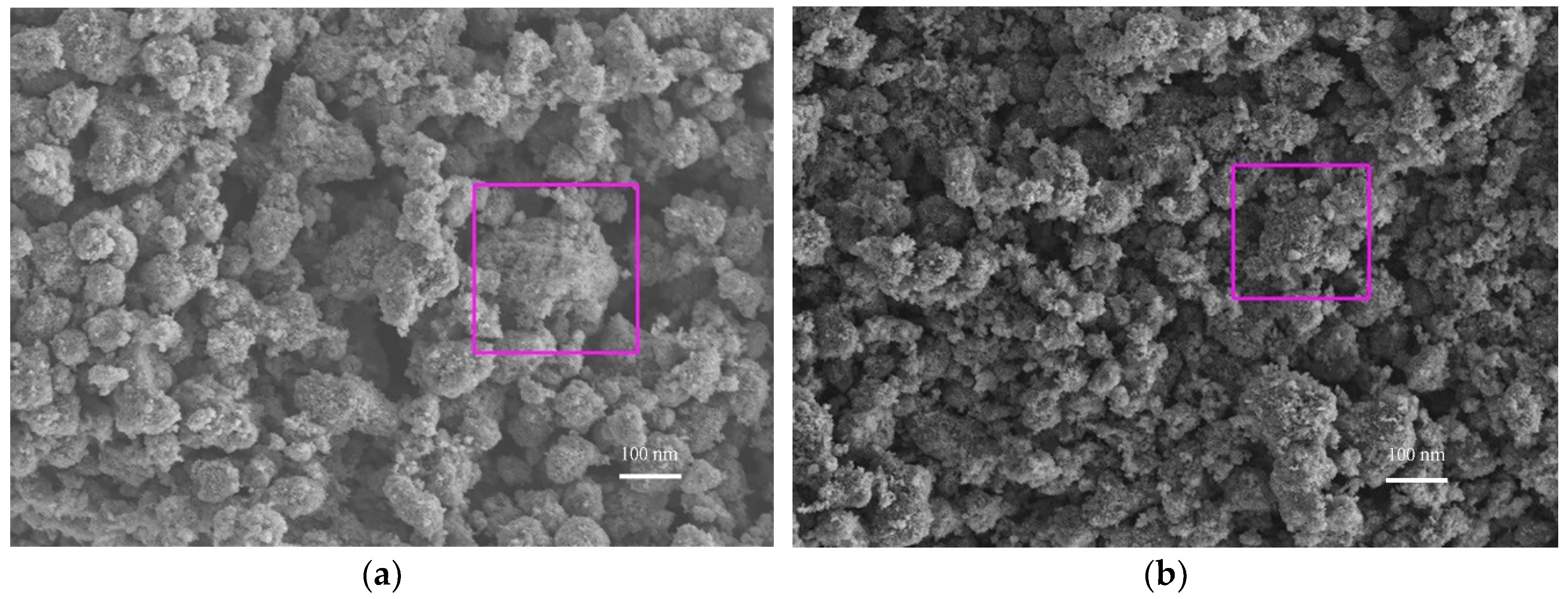

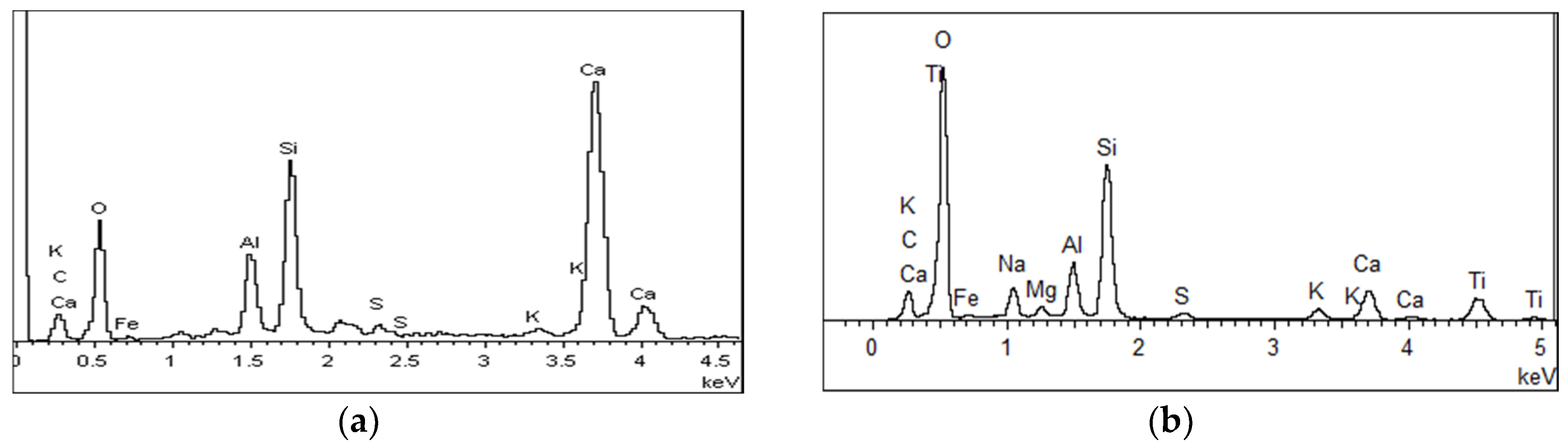

3.4. Microstructure Analysis of Modified Concrete

4. Conclusions

- (1)

- The modified nano-TiO2 doped with Fe3+ was successfully prepared by planetary high energy ball milling. The ball milling process caused significant changes to the feature parameters of TiO2, including decreased particle size, the more amorphous morphology, the compromised percentage of the most thermodynamically stable crystal facet, and the increased percentage of other high gas sensing crystal facets.

- (2)

- The incorporation of nano-TiO2 is beneficial to the improvement of concrete strength because of the micro-filling effect of nano particles. The incorporation of Fe3+ can motivate the formation of iron-containing hydration products, leading to the further increase of concrete strength. In terms of the material strength, the best nano-TiO2 content of cement was 3% and 4% for the two types of concrete, respectively.

- (3)

- The employment of nano-TiO2 endow the concrete the functional properties of purifying exhaust gas. Due to the doping of Fe3+ in the crystal, the photocatalytic degradation effect of modified nano-TiO2 is better than that of the original nano-TiO2. The degradation rate of porous concrete is much higher than that of common concrete with the same content of photocatalyst. For both types of concrete, the photocatalytic degradation rate comes to the peak when the nano-TiO2 content is 4%.

- (4)

- The internal structure of the concrete was modified to be more compact with the adoption of nano-TiO2, so the strength is improved. In a comprehensive consideration of both mechanical performance and degradation efficiency, the recommended optimum dosage of TiO2 is 3% to 4% for concrete. It is the most promising strategy to develop functional pavements using photocatalytic porous concrete to purify the urban traffic pollutions.

Author Contributions

Funding

Conflicts of Interest

References

- Yang, W.; Li, L. Efficiency evaluation of industrial waste gas control in China: A study based on data envelopment analysis (DEA) model. J. Clean. Prod. 2018, 179, 1–11. [Google Scholar] [CrossRef]

- Ze-dong, Z.; Hao, L.; Yong-dong, L.; Zheng, X. Electrical highway application. China J. Highw. Transp. 2019, 32, 132–141. [Google Scholar]

- Wang, D.; Leng, Z.; Hüben, M.; Oeser, M.; Steinauer, B. Photocatalytic pavements with epoxy-bonded TiO2-containing spreading material. Constr. Build. Mater. 2016, 107, 44–51. [Google Scholar] [CrossRef]

- Wang, D.; Leng, Z.; Yu, H.; Hüben, M.; Kollmann, J.; Oeser, M. Durability of epoxy-bonded TiO2-modified aggregate as a photocatalytic coating layer for asphalt pavement under vehicle tire polishing. Wear 2017, 382–383, 1–7. [Google Scholar] [CrossRef]

- Cui, P.; Wu, S.; Xiao, Y.; Wan, M.; Cui, P. Inhibiting effect of Layered Double Hydroxides on the emissions of volatile organic compounds from bituminous materials. J. Clean. Prod. 2015, 10, 987–991. [Google Scholar] [CrossRef]

- Sikkema, J.K.; Ong, S.K.; Alleman, J.E. Photocatalytic concrete pavements: Laboratory investigation of NO oxidation rate under varied environmental conditions. Constr. Build. Mater. 2015, 100, 305–314. [Google Scholar] [CrossRef]

- Folli, A.; Pade, C.; Hansen, T.B.; de Marco, T.; Macphee, D.E. TiO2 photocatalysis in cementitious systems: Insights into self-cleaning and depollution chemistry. Cem. Concr. Res. 2012, 42, 539–548. [Google Scholar] [CrossRef]

- Liu, W.; Wang, S.; Zhang, J.; Fan, J. Photocatalytic degradation of vehicle exhausts on asphalt pavement by TiO2/rubber composite structure. Constr. Build. Mater. 2015, 81, 224–232. [Google Scholar] [CrossRef]

- Ballari, M.M.; Brouwers, H.J.H. Full scale demonstration of air-purifying pavement. J. Hazard. Mater. 2013, 254–255, 406–414. [Google Scholar] [CrossRef]

- Schneider, J.; Matsuoka, M.; Takeuchi, M.; Zhang, J.; Horiuchi, Y.; Anpo, M.; Bahnemann, D.W. Understanding TiO2 Photocatalysis: Mechanisms and Materials. Chem. Rev. 2014, 114, 9919–9986. [Google Scholar] [CrossRef]

- Liao, L.; Heylen, S.; Sree, S.P.; Vallaey, B.; Keulemans, M.; Lenaerts, S.; Roeffaers, M.B.J.; Martens, J.A. Photocatalysis assisted simultaneous carbon oxidation and NOx reduction. Appl. Catal. B 2017, 202, 381–387. [Google Scholar] [CrossRef]

- Zhao, Q.; Wang, M.; Yanga, H.; Shia, D.; Wang, Y. Preparation, characterization and the antimicrobial properties of metal iondoped TiO2 nano-powders. Ceram. Int. 2018, 44, 5145–5154. [Google Scholar] [CrossRef]

- Wu, D.; Li, C.; Zhang, D.; Wang, L.; Zhang, X.; Shi, Z.; Lin, Q. Enhanced photocatalytic activity of Gd3+ doped TiO2 and Gd2O3 modified TiO2 prepared via ball milling method. J. Rare Earths 2019, 37, 845–852. [Google Scholar] [CrossRef]

- Kuang, Y.; Zhang, Z.; Ji, X.; Zhang, X. Study on nano-TiO2 photocatalytic cement paste with automobile exhaust degradation capacity. J. Funct. Mater. 2017, 48, 2241–2246. [Google Scholar]

- Malengreaux, C.M.; Pirard, S.L.; Pirard, G.L.; Mahy, J.G.; Herlitschke, M.; Klobes, B.; Hermann, R.; Heinrichs, B.; Bartlett, J.R. Study of the photocatalytic activity of Fe3+, Cr3+, La3+ and Eu3+ single-doped and co-doped TiO2 catalysts produced by aqueous sol-gel processing. J. Alloys Compd. 2017, 691, 726–738. [Google Scholar] [CrossRef]

- Xiaoyan, P.; Dongmei, J.; Yan, L.; Xueming, M. Structural characterization and ferromagnetic behavior of Fe-doped TiO2 powder by high-energy ball milling. J. Magn. Magn. Mater. 2006, 305, 388–391. [Google Scholar] [CrossRef]

- Ivanov, E.; Suryanarayana, C. Materials and process design through mechanochemical routes. J. Mater. Synth. Process. 2000, 8, 235–244. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Miao, J.; Zhangd, R.; Zhang, L. Photocatalytic degradations of three dyes with different chemical structures using ball-milled TiO2. Mater. Res. Bull. 2018, 97, 109–114. [Google Scholar] [CrossRef]

- Liu, Q.; Cao, D. Research on Material Composition and Performance of Porous Asphalt Pavement. J. Mater. Civ. Eng. 2009, 21, 135–140. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, F.; Cui, P.; Lei, L.; Lin, J.; Yi, M. Evaluation of Fine Aggregate Morphology by Image Method and Its Effect on Skid-Resistance of Micro-Surfacing. Materials 2018, 11, 920. [Google Scholar] [CrossRef] [PubMed]

- Lim, E.; Tan, K.H.; Fwa, T.F. High-Strength High-Porosity Pervious Concrete Pavement. Adv. Mater. Res. 2013, 723, 361–367. [Google Scholar] [CrossRef]

- Zhong, M.; Wei, Z.H.; Si, Z.P.; Li, H.; Wei, G.Y.; Ge, H.L.; Han, G.R. Preparation of iron-doped titania nanocrystalline grains and its photocatalytic property. J. Chin. Ceram. Soc. 2010, 38, 69–73. [Google Scholar]

- People’s Republic of China Transportation Industry Standard JTG E30–2005 Test Methods of Cement and Concrete for Highway Engineering; Ministry of Communications of PRC: Beijing, China, 2005.

- Pierpaoli, M.; Favoni, O.; Fava, G.; Ruello, M.L. A Novel Method for the Combined Photocatalytic Activity Determination and Bandgap Estimation. Methods Protoc. 2018, 1, 22. [Google Scholar] [CrossRef] [PubMed]

- Xia, H.Y.; Zhang, R.; Song, L.F.; Gao, L.N.; Liu, G.Y. Test Device for Photocatalytic Coating Degradation Performance of Automobile Exhaust Gas. Chinese Patent CN201621076982.3, 23 September 2016. [Google Scholar]

- Kochany, J.; Maguire, J. Sunlight Photodegradation of Metolachlor in Water. J. Agric. Food Chem. 1994, 42, 406–412. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, S.; Xiao, Y.; Zeng, W.; Yi, M.; Wan, J. Effect of hydration and silicone resin on Basic Oxygen Furnace slag and its asphalt mixture. J. Clean. Prod. 2016, 112, 392–400. [Google Scholar] [CrossRef]

- Liu, C.; Lu, H.; Zhang, J.; Gao, J.; Zhu, G.; Yang, Z.; Yin, F.; Wang, C. Crystal facet-dependent p-type and n-type sensing responses of TiO2 nanocrystals. Sens. Actuators B 2018, 263, 557–567. [Google Scholar] [CrossRef]

- Han, X.G.; Han, X.; Sun, L.Q.; Gao, S.G.; Li, L.; Kuang, Q.; Xie, Z.X.; Wang, C. Synthesis of trapezohedral indium oxide nanoparticles with high-index {211} facets and high gas sensing activity. Chem. Commun. 2015, 51, 9612–9615. [Google Scholar] [CrossRef]

- Kibasomba, P.M.; Dhlamini, S.; Maaza, M.; Liu, C.; Rashad, M.M.; Rayan, D.A.; Mwakikunga, B.W. Strain and grain size of TiO2 nanoparticles from TEM, Raman spectroscopy and XRD: The revisiting of the Williamson-Hall plot method. Results Phys. 2018, 9, 628–635. [Google Scholar] [CrossRef]

- Han, F.; Song, S.; Liu, J.; Huang, S. Properties of steam-cured precast concrete containing iron tailing powder. Powder Technol. 2019, 345, 292–299. [Google Scholar] [CrossRef]

- Hertel, T.; Neubauer, J.; Goetz-Neunhoeffer, F. Study of hydration potential and kinetics of the ferrite phase in iron-rich CAC. Cem. Concr. Res. 2016, 83, 79–85. [Google Scholar] [CrossRef]

- Arata, K. Preparation of superacids by metal oxides for reactions of butanes and pentanes. Appl. Catal. A 1996, 146, 3–32. [Google Scholar] [CrossRef]

- Miao, S.; Lin-hai, Y.; Zhe-de, X. Photocatalytic activity of iron doping TiO2 prepared by several methods. Acta Phys. Chim. Sin. 2001, 17, 282–285. [Google Scholar]

- Aba-Guevara, C.G.; Medina-Ramírez, I.E.; Hernández-Ramírez, A.; Jáuregui-Rincón, J.; Lozano-Álvarez, J.A.; Rodríguez-López, J.L. Comparison of two synthesis methods on the preparation of Fe, N-Co-doped TiO2 materials for degradation of pharmaceutical compounds under visible light. Ceram. Int. 2017, 43, 5068–5079. [Google Scholar] [CrossRef]

- Nejadsadeghi, N.; Placidi, L.; Romeo, M.; Misra, A. Frequency band gaps in dielectric granular metamaterials modulated by electric field. Mech. Res. Commun. 2019, 95, 96–103. [Google Scholar] [CrossRef]

- Misra, A.; Nejadsadeghi, N. Longitudinal and transverse elastic waves in 1D granular materials modeled as micromorphic continua. Wave Motion 2019, 90, 175–195. [Google Scholar] [CrossRef]

| Appearance | Average Particle Size/nm | Specific Surface Area/m2⋅g−1 | Crystal Type | TiO2 Content/% | Photocatalytic Efficiency/% | pH Value |

|---|---|---|---|---|---|---|

| White powder | 10 | 70.2 | Mixed crystal type (anatase, rutile) | >92 | ≥68 | Partial acidity |

| Sieve/mm | 2.36 | 4.75 | 9.5 | 13 |

|---|---|---|---|---|

| Passing Rate/% | 0 | 6.5 | 85.7 | 100 |

| Concrete Type | Common Concrete | Porous Concrete | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nano-TiO2 content/% | 0 | 1 | 2 | 3 | 4 | 5 | 0 | 1 | 2 | 3 | 4 | 5 |

| Code | C-0 | C-1 | C-2 | C-3 | C-4 | C-5 | P-0 | P-1 | P-2 | P-3 | P-4 | P-5 |

| Crystal Facets | Percentage (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| (101) | (103) | (004) | (112) | (200) | (105) | (211) | (204) | (116) | |

| Original TiO2 | 51.84 | 1.35 | 5.75 | 1.45 | 16.23 | 6.48 | 9.02 | 5.75 | 2.13 |

| Modified TiO2 | 48.47 | 2.57 | 7.51 | 2.52 | 15.03 | 7.03 | 9.21 | 5.48 | 2.18 |

| Total Amount of Pollutant Gas | Flow Rate | Relative Humidity | Detection Time | Concrete Age |

|---|---|---|---|---|

| 12 L | 1.2 L/min | 50% | 10 min/once total 1 h | 28 days |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, R.; Huang, X.; Zhang, J.; Geng, Y.; Guo, H. Preparation and Evaluation of Exhaust-Purifying Cement Concrete Employing Titanium Dioxide. Materials 2019, 12, 2182. https://doi.org/10.3390/ma12132182

He R, Huang X, Zhang J, Geng Y, Guo H. Preparation and Evaluation of Exhaust-Purifying Cement Concrete Employing Titanium Dioxide. Materials. 2019; 12(13):2182. https://doi.org/10.3390/ma12132182

Chicago/Turabian StyleHe, Rui, Xin Huang, Jiansong Zhang, Yao Geng, and Haidong Guo. 2019. "Preparation and Evaluation of Exhaust-Purifying Cement Concrete Employing Titanium Dioxide" Materials 12, no. 13: 2182. https://doi.org/10.3390/ma12132182

APA StyleHe, R., Huang, X., Zhang, J., Geng, Y., & Guo, H. (2019). Preparation and Evaluation of Exhaust-Purifying Cement Concrete Employing Titanium Dioxide. Materials, 12(13), 2182. https://doi.org/10.3390/ma12132182