Hot Deformation Behavior and Microstructural Evolution of a Novel β-Solidifying Ti–43Al–3Mn–2Nb–0.1Y Alloy

Abstract

1. Introduction

2. Experimental Procedures

3. Results and Discussion

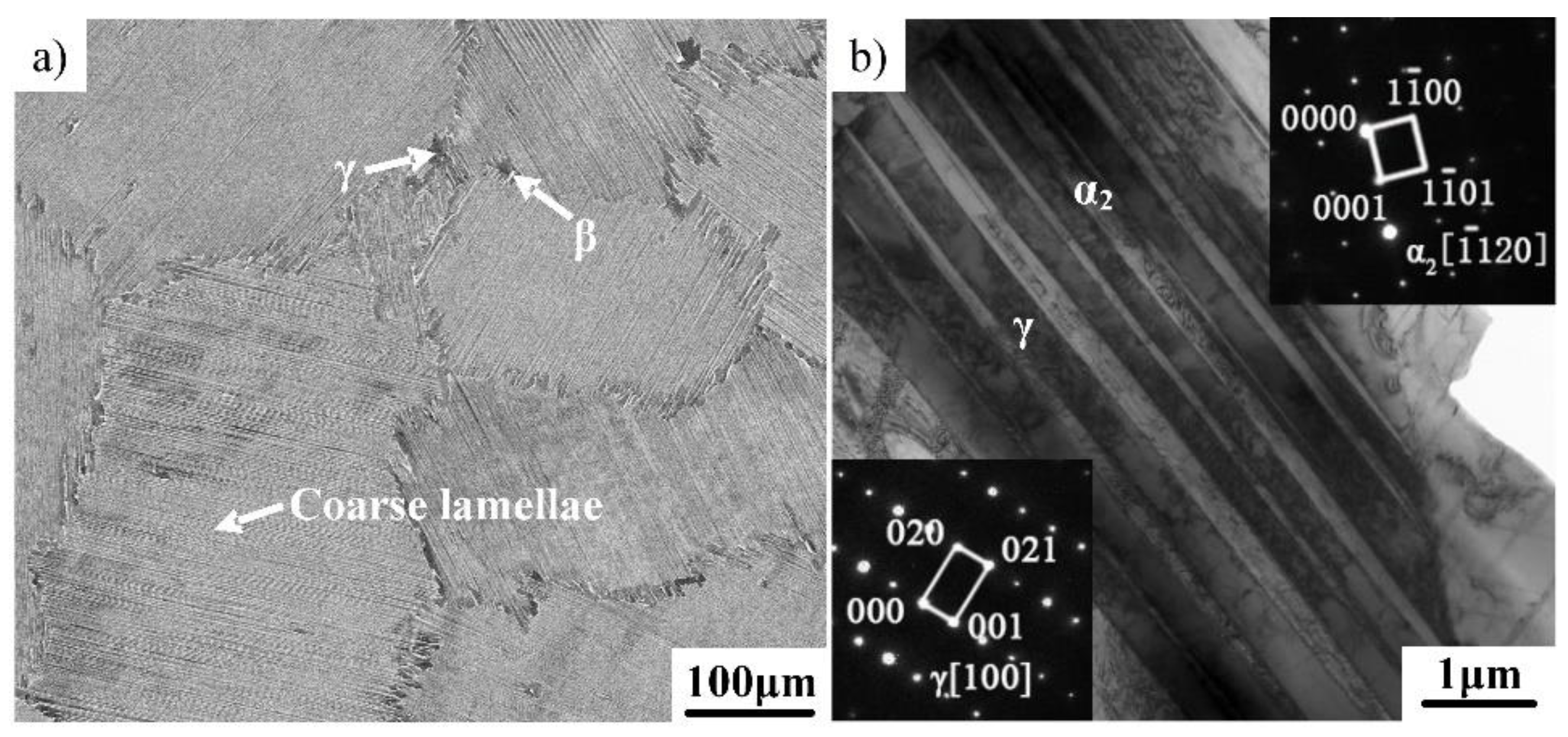

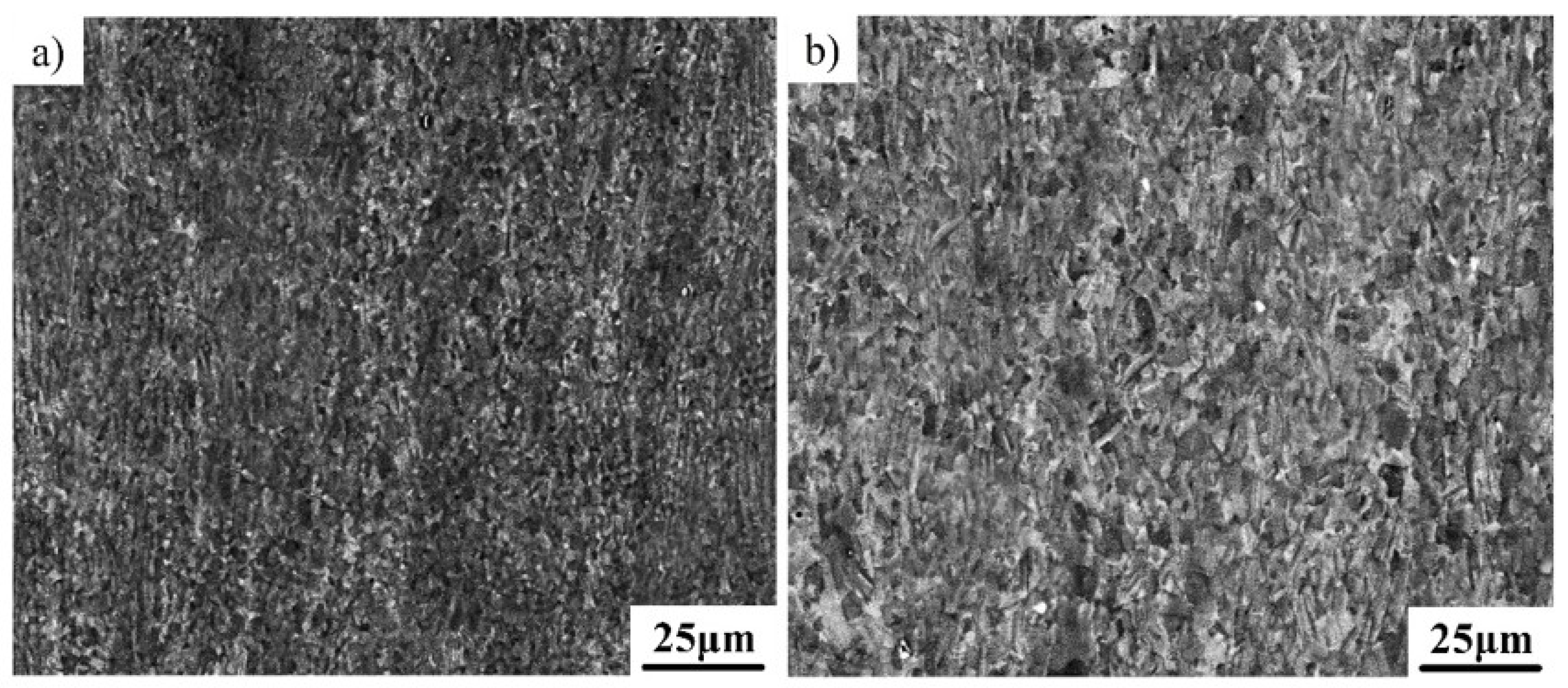

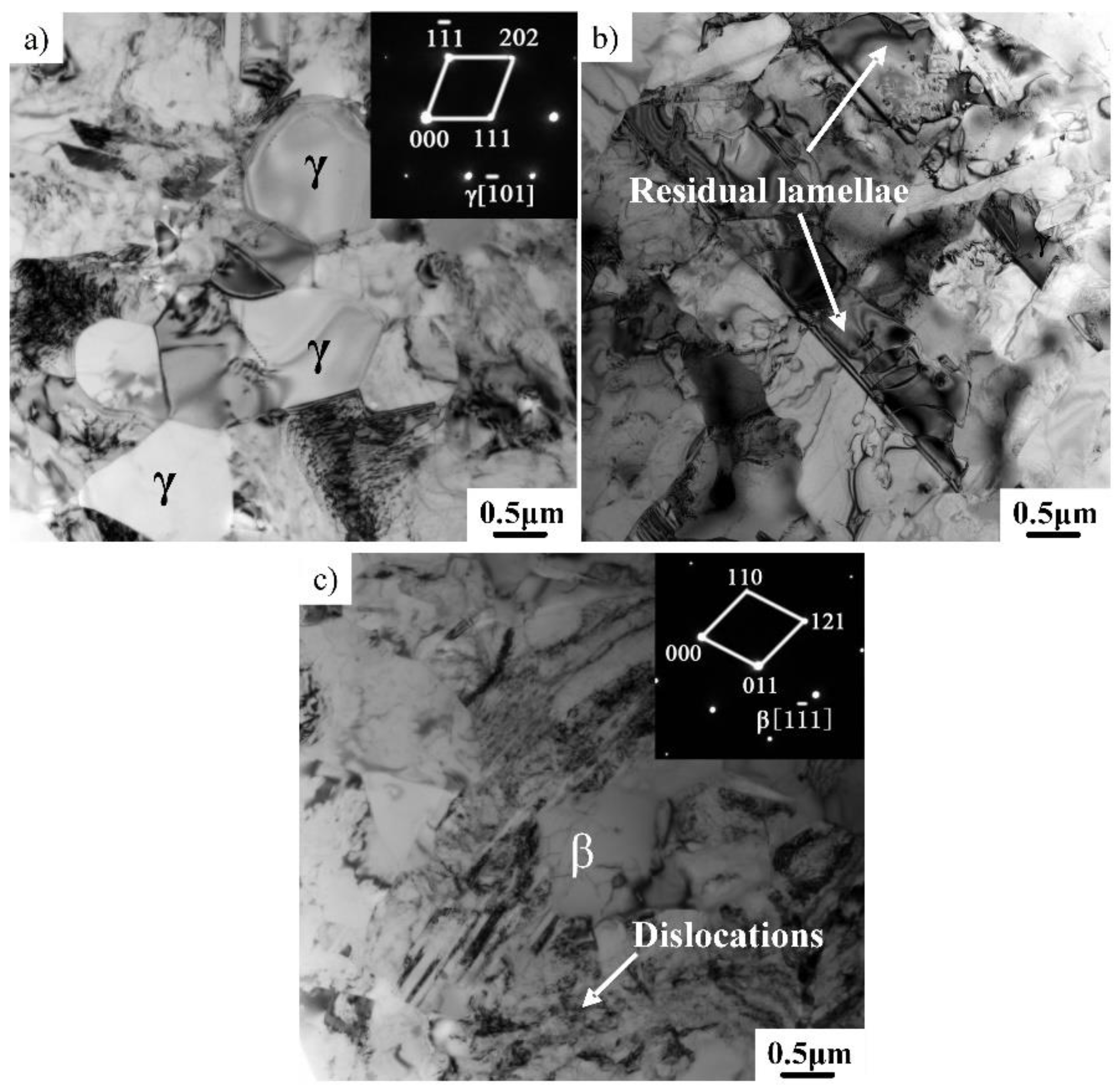

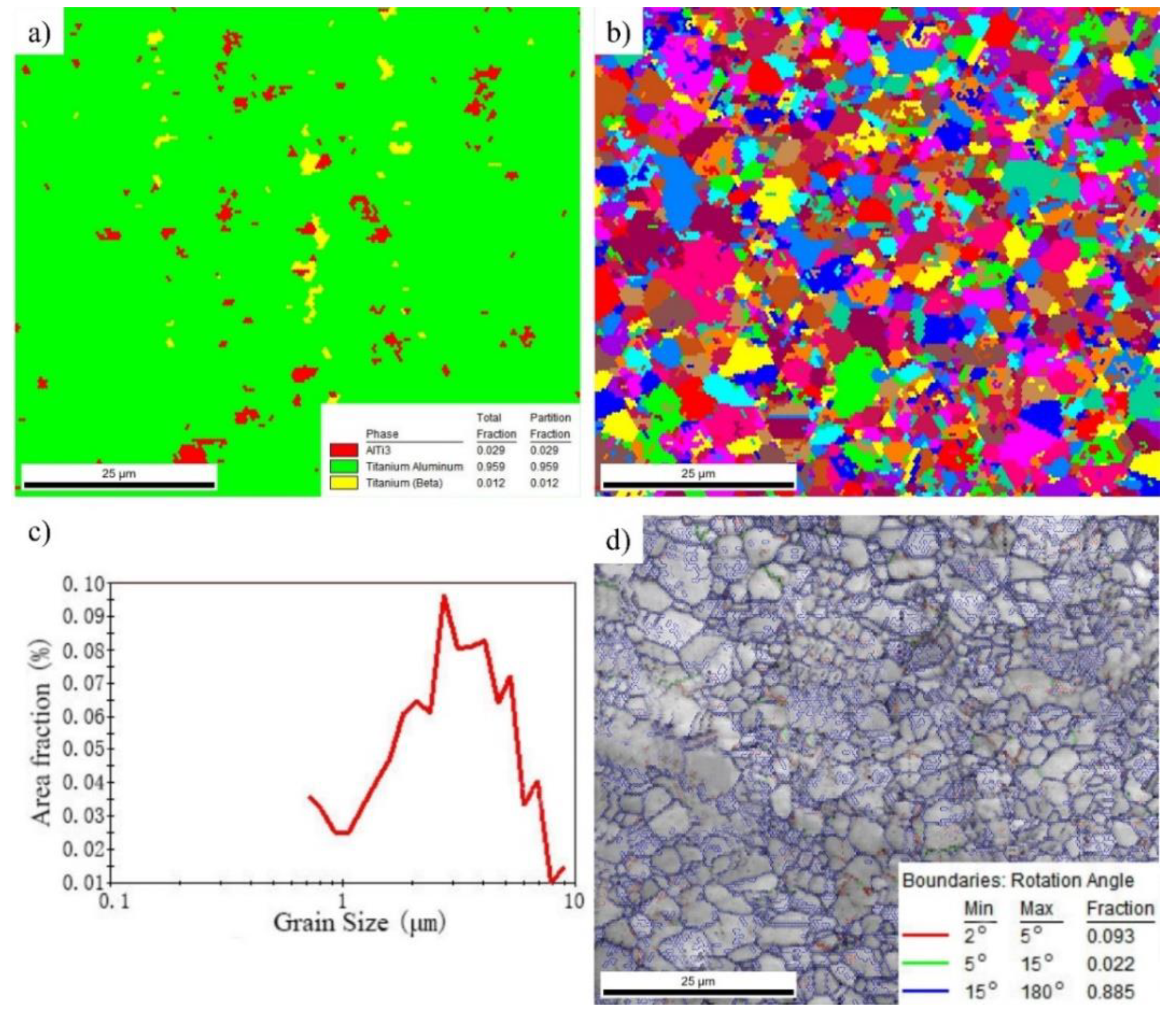

3.1. Initial Microstructure

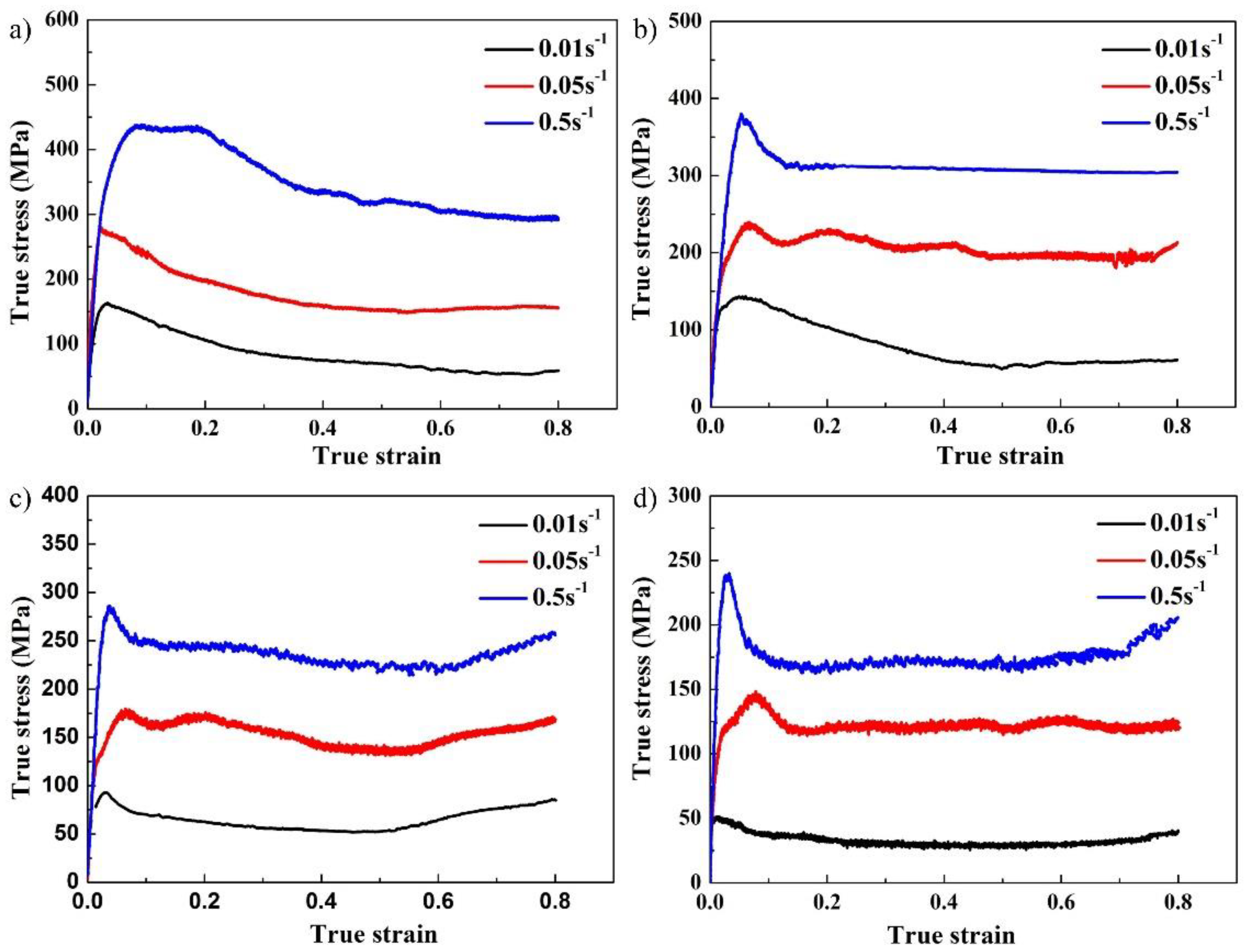

3.2. Flow Behavior and Hot Deformability

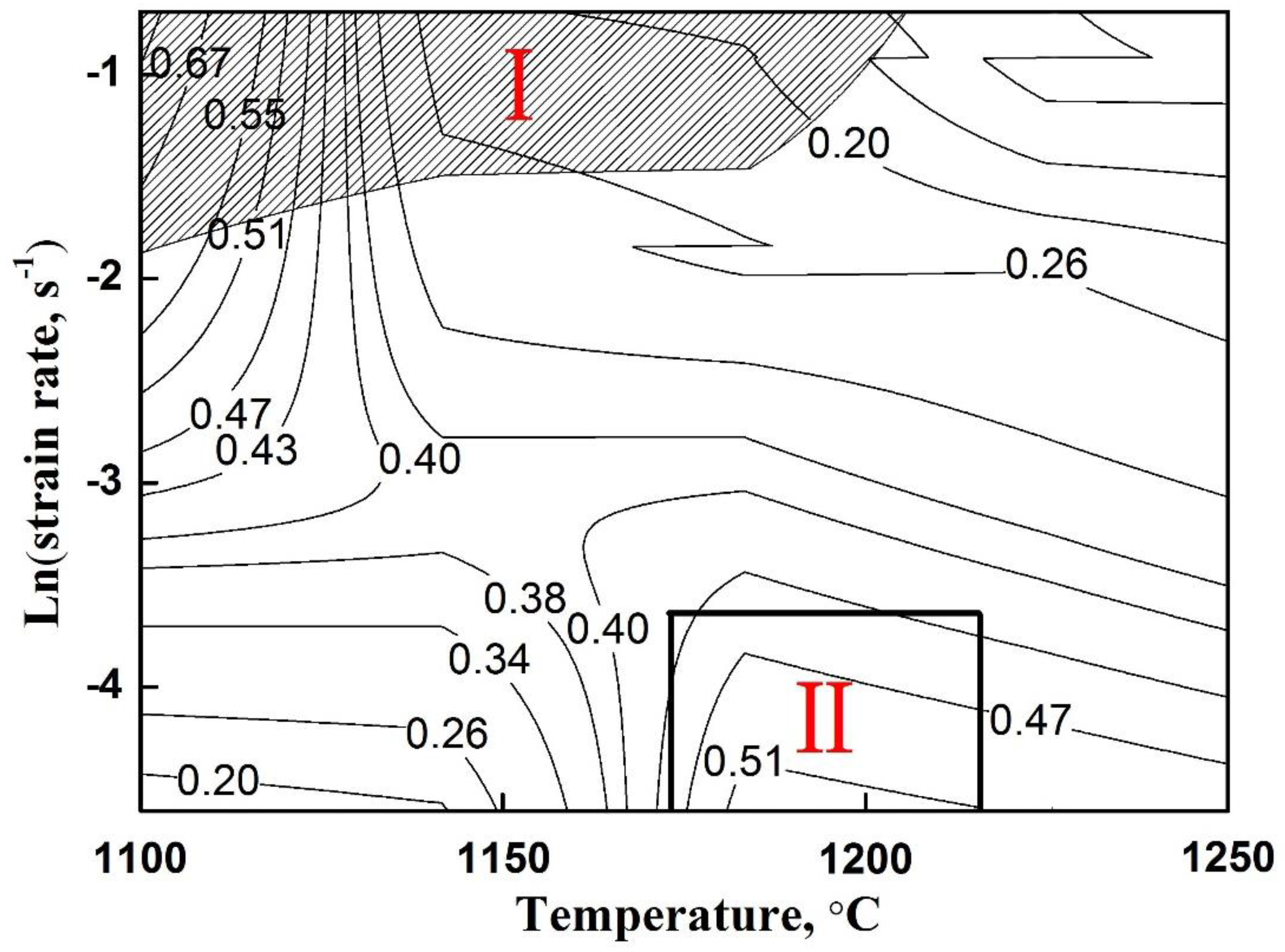

3.3. Processing Map

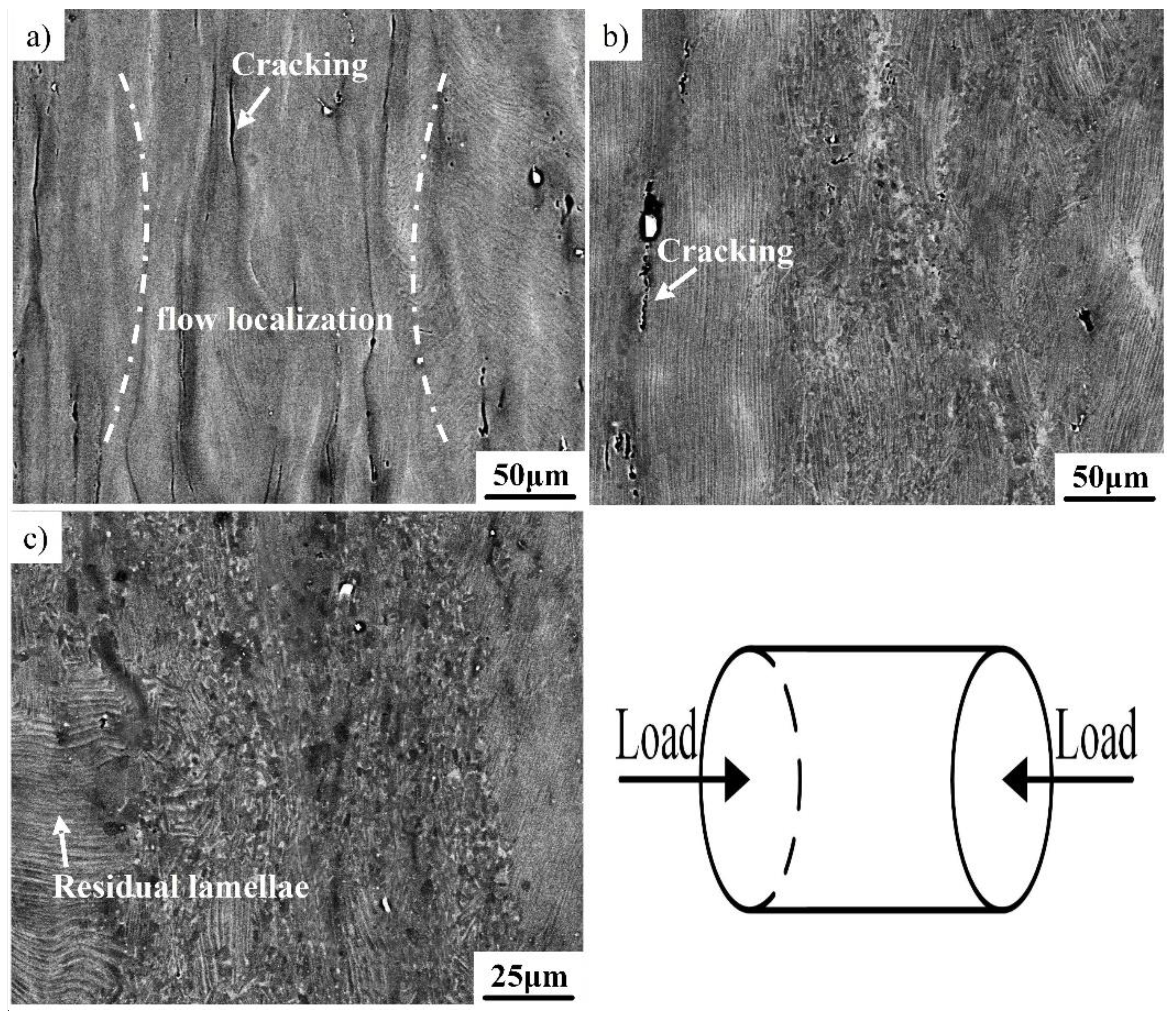

3.4. Nearly Isothermal Forging

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, Y.W.; Kim, S.L. Advances in gammalloy materials–processes–application technology: Successes, dilemmas, and future. JOM 2018, 5, 1–8. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Advanced Intermetallic TiAl Alloys. Mater. Sci. Forum 2017, 879, 113–118. [Google Scholar] [CrossRef]

- Cui, N.; Wu, Q.Q.; Bi, K.X.; Xu, T.W.; Kong, F.T. Effect of Heat Treatment on Microstructures and Mechanical Properties of a Novel β-Solidifying TiAl Alloy. Materials 2019, 12, 1672. [Google Scholar] [CrossRef] [PubMed]

- Kothari, K.; Radhakrishnan, R.; Wereley, N.M. Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aerosp. Sci. 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Intermetallic titanium aluminides in aerospace applications–processing, microstructure and properties. Mater. High Temp. 2016, 33, 1–11. [Google Scholar] [CrossRef]

- Lin, J.P.; Zhao, L.L.; Li, G.Y.; Zhang, L.Q.; Song, X.P.; Ye, F.; Chen, G.L. Effect of Nb on oxidation behavior of high Nb containing TiAl alloys. Intermetallics 2011, 19, 131–136. [Google Scholar] [CrossRef]

- Xu, X.J.; Lin, J.P.; Wang, Y.L.; Gao, J.F.; Lin, Z.; Chen, G.L. Effect of forging on microstructure and tensile properties of Ti-45Al-(8-9)Nb-(W,B,Y) alloy. J. Alloys Compd. 2006, 414, 175–180. [Google Scholar] [CrossRef]

- Zhang, W.J.; Deevi, S.C.; Chen, G.L. On the origin of superior high strength of Ti–45Al–10Nb alloys. Intermetallics 2002, 10, 403–406. [Google Scholar] [CrossRef]

- Liu, Z.C.; Lin, J.P.; Li, S.J.; Chen, G.L. Effects of Nb and Al on the microstructures and mechanical properties of high Nb containing TiAl base alloys. Intermetallics 2002, 10, 653–659. [Google Scholar] [CrossRef]

- Su, Y.J.; Kong, F.T.; Chen, Y.Y.; Gao, N.; Zhang, D.L. Microstructure and mechanical properties of large size Ti-43Al-9V-0.2Y alloy pancake produced by pack-forging. Intermetallics 2013, 34, 29–34. [Google Scholar] [CrossRef]

- Su, Y.J. Research on forging and microstructure and mechanical properties of TiAl alloy containing β/B2 phase. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2013. [Google Scholar]

- Janschek, P. Wrought TiAl Blades. Mater. Today 2015, 2, 92–97. [Google Scholar] [CrossRef]

- Lee, D.B. Effect of Cr, Nb, Mn, V, W and Si on high temperature oxidation of TiAl alloys. Met. Mater. Int. 2005, 11, 141–147. [Google Scholar] [CrossRef]

- Shida, Y.; Anada, H. The effect of various ternary additives on the oxidation behavior of TiAl in high-temperature air. Oxid. Met. 1996, 45, 197–219. [Google Scholar] [CrossRef]

- Shu, S.L.; Qiu, F.; Xing, B.; Jin, S.B.; Wang, Y.W.; Jiang, Q.C. Study of effect of Mn addition on the mechanical properties of Ti2AlC/TiAl composites through first principles study and experimental investigation. Intermetallics 2012, 28, 65–70. [Google Scholar] [CrossRef]

- Tetsui, T.; Shindo, K.; Kaji, S.; Kobayashi, S.; Takeyama, M. Fabrication of TiAl components by means of hot forging and machining. Intermetallics 2005, 13, 971–978. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Tsukihashi, F. Thermodynamics of yttrium and oxygen in molten Ti, Ti3Al, and TiAl. Metall. Mater. Trans. B 1998, 29, 1037–1042. [Google Scholar] [CrossRef]

- Cui, N.; Wang, X.P.; Kong, F.T.; Chen, Y.Y.; Zhou, H.T. Microstructure and properties of a beta-solidifying TiAl-based alloy with different refiners. Rare Met. 2016, 35, 42–47. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Kong, F.T.; Han, J.C.; Chen, Z.Y.; Tian, J. Influence of yttrium on microstructure, mechanical properties and deformability of Ti-43Al-9V alloy. Intermetallics 2005, 13, 263–266. [Google Scholar] [CrossRef]

- Cui, N.; Wu, Q.Q.; Bi, K.X.; Wang, J.; Xu, T.W.; Kong, F.T. Effect of multi-directional forging on the microstructure and mechanical properties of β-solidifying TiAl alloy. Materials 2019, 12, 1381. [Google Scholar] [CrossRef]

- Takeyama, M.; Kobayashi, S. Physical metallurgy for wrought gamma titanium aluminides microstructure control through phase transformations. Intermetallics 2005, 13, 993–999. [Google Scholar] [CrossRef]

- Cheng, L.; Chang, H.; Tang, B.; Kou, H.; Li, J. Deformation and dynamic recrystallization behavior of a high Nb containing TiAl alloy. J. Alloys Compd. 2013, 552, 363–369. [Google Scholar] [CrossRef]

- Zhu, Y.C.; Zeng, W.D.; Feng, F.; Sun, Y.; Han, Y.F.; Zhou, Y.G. Characterization of hot deformation behavior of as-cast TC21 titanium alloy using processing map. Mater. Sci. Eng. A 2011, 528, 1757–1763. [Google Scholar] [CrossRef]

- Jin, Z.; Cady, C.; Gray, G.T.; Kim, Y.W. Mechanical behavior of a fine-grained duplex gamma-TiAl alloy. Metall. Mater. Trans. A 2000, 31, 1007–1016. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Frey, N.; Thompson, C.R.; Bryant, J.D.; El-Soudani, S.; Tisler, R. Plastic flow behavior of Ti-48Al-2.5Nb-0.3Ta at hot-working temperatures. Scr. Metall. Mater. 1990, 24, 1403–1408. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Frey, N.; El-Soudani, S.M.; Bryant, J.D. Flow softening and microstructure evolution during hot working of wrought near-gamma titanium aluminides. Metall. Trans. A 1992, 23, 1719–1735. [Google Scholar] [CrossRef]

- Zhou, H.T.; Kong, F.T.; Wang, X.P.; Chen, Y.Y. Hot deformation behavior and microstructural evolution of as-forged Ti-44Al-8Nb-(W, B, Y) alloy with nearly lamellar microstructure. Intermetallics 2017, 81, 62–72. [Google Scholar] [CrossRef]

- Bystrzanowski, S.; Bartels, A.; Clemens, H.; Gerling, R. Characteristics of the tensile flow behavior of Ti–46Al–9Nb sheet material—Analysis of thermally activated processes of plastic deformation. Intermetallics 2008, 16, 717–726. [Google Scholar] [CrossRef]

- Gupta, R.K.; Murty, S.V.S.N.; Pant, B.; Agarwala, V.; Sinha, P. Hot workability of γ+α2 titanium aluminide: Development of processing map and constitutive equations. Mater. Sci. Eng. A 2012, 551, 169–186. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, Y.; Li, H.Z.; Li, Z.; Wang, H.; Liu, B. Constitutive modeling and processing map for elevated temperature flow behaviors of a powder metallurgy titanium aluminide alloy. J. Mater. Process. Technol. 2009, 209, 5363–5370. [Google Scholar] [CrossRef]

- Herzig, C.; Przeorski, T.; Mishin, Y. Self-diffusion in γ-TiAl: an experimental study and atomistic calculations. Intermetallics 1999, 7, 389–404. [Google Scholar] [CrossRef]

- Tian, S.; Jiang, H.; Guo, W.; Zhang, G.; Zeng, S. Hot deformation and dynamic recrystallization behavior of TiAl-based alloy. Intermetallics 2019, 112, 106521. [Google Scholar] [CrossRef]

- Sokolovsky, V.S.; Stepanov, N.D.; Zherebtsov, S.V.; Nochovnaya, N.A.; Panin, P.V.; Zhilyakova, M.A.; Popov, A.A.; Salishchev, G.A. Hot deformation behavior and processing maps of B and Gd containing β-solidified TiAl based alloy. Intermetallics 2018, 94, 138–151. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Seshacharyulu, T. Modelling of hot deformation for microstructural control. Int. Mater. Rev. 1998, 43, 243–258. [Google Scholar] [CrossRef]

- Zhang, S.; Kong, F.; Chen, Y.; Liu, Z.; Lin, J. Evolution of grain boundary and texture in as-forged Ti–45Al–9Nb–Y alloy during tensile test at different temperature. Intermetallics 2012, 27, 31–37. [Google Scholar] [CrossRef]

- Cui, N.; Wu, Q.Q.; Wang, J.; Lv, B.J.; Kong, F.T. The directional solidification, microstructural characterization and deformation behavior of β-solidifying TiAl alloy. Materials 2019, 12, 1203. [Google Scholar] [CrossRef] [PubMed]

- Rollett, A.; Humphreys, F.J.; Rohrer, G.S.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 3rd ed.; Elsevier press: Oxford, UK, 2004; pp. 416–417. [Google Scholar]

- Skrotzki, B.; Rudolf, T.; Dlouhy, A.; Eggeler, G. Microstructural evidence for dynamic recrystallization during creep of a duplex near-γ TiAl-alloy. Scr. Mater. 1998, 39, 1545–1551. [Google Scholar] [CrossRef]

- Kwasniak, P.; Garbacz, H. Screw dislocation mediated solution strengthening of substitutional α-Ti alloys-First principles investigation. Acta Mater. 2017, 141, 405–418. [Google Scholar] [CrossRef]

- Kwasniak, P.; Garbacz, H.; Kurzydlowski, K. Solid solution strengthening of hexagonal titanium alloys: Restoring forces and stacking faults calculated from first principles. Acta Mater. 2016, 102, 304–314. [Google Scholar] [CrossRef]

- Zhang, W.J.; Lorenz, U.; Appel, F. Recovery, recrystallization and phase transformations during thermomechanical processing and treatment of TiAl-based alloys. Acta Mater. 2000, 48, 2803–2813. [Google Scholar] [CrossRef]

- Clemens, H.; Wallgram, W.; Kremmer, S.; Güther, V.; Otto, A.; Bartels, A. Design of novel β-solidifying TiAl alloys with adjustable β/B2-phase fraction and excellent hot-workability. Adv. Eng. Mater. 2008, 10, 707–713. [Google Scholar] [CrossRef]

- Paul, J.D.H.; Lorenz, U.; Oehring, M.; Appel, F. Up-scaling the size of TiAl components made via ingot metallurgy. Intermetallics 2013, 32, 318–328. [Google Scholar] [CrossRef]

- Liang, Y.F.; Xu, X.J.; Lin, J.P. Advances in phase relationship for high Nb-containing TiAl alloys. Rare Met. 2016, 35, 15–25. [Google Scholar] [CrossRef]

- Niu, H.Z.; Chen, Y.Y.; Xiao, S.L.; Xu, L.J. Microstructure evolution and mechanical properties of a novel beta γ-TiAl alloy. Intermetallics 2012, 31, 225–231. [Google Scholar] [CrossRef]

- Zhang, S.Z.; Zhao, Y.B.; Zhang, C.J.; Han, J.C.; Sun, M.J.; Xu, M. The microstructure, mechanical properties, and oxidation behavior of beta-gamma TiAl alloy with excellent hot workability. Mater. Sci. Eng. A 2017, 700, 366–373. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Q.; Cui, N.; Xiao, X.; Wang, X.; Zhao, E. Hot Deformation Behavior and Microstructural Evolution of a Novel β-Solidifying Ti–43Al–3Mn–2Nb–0.1Y Alloy. Materials 2019, 12, 2172. https://doi.org/10.3390/ma12132172

Wu Q, Cui N, Xiao X, Wang X, Zhao E. Hot Deformation Behavior and Microstructural Evolution of a Novel β-Solidifying Ti–43Al–3Mn–2Nb–0.1Y Alloy. Materials. 2019; 12(13):2172. https://doi.org/10.3390/ma12132172

Chicago/Turabian StyleWu, Qianqian, Ning Cui, Xiaohong Xiao, Xiaopeng Wang, and Ertuan Zhao. 2019. "Hot Deformation Behavior and Microstructural Evolution of a Novel β-Solidifying Ti–43Al–3Mn–2Nb–0.1Y Alloy" Materials 12, no. 13: 2172. https://doi.org/10.3390/ma12132172

APA StyleWu, Q., Cui, N., Xiao, X., Wang, X., & Zhao, E. (2019). Hot Deformation Behavior and Microstructural Evolution of a Novel β-Solidifying Ti–43Al–3Mn–2Nb–0.1Y Alloy. Materials, 12(13), 2172. https://doi.org/10.3390/ma12132172