Elucidation of Shearing Mechanism of Finish-type FB and Extrusion-type FB for Thin Foil of JIS SUS304 by Numerical and EBSD Analyses

Abstract

1. Introduction

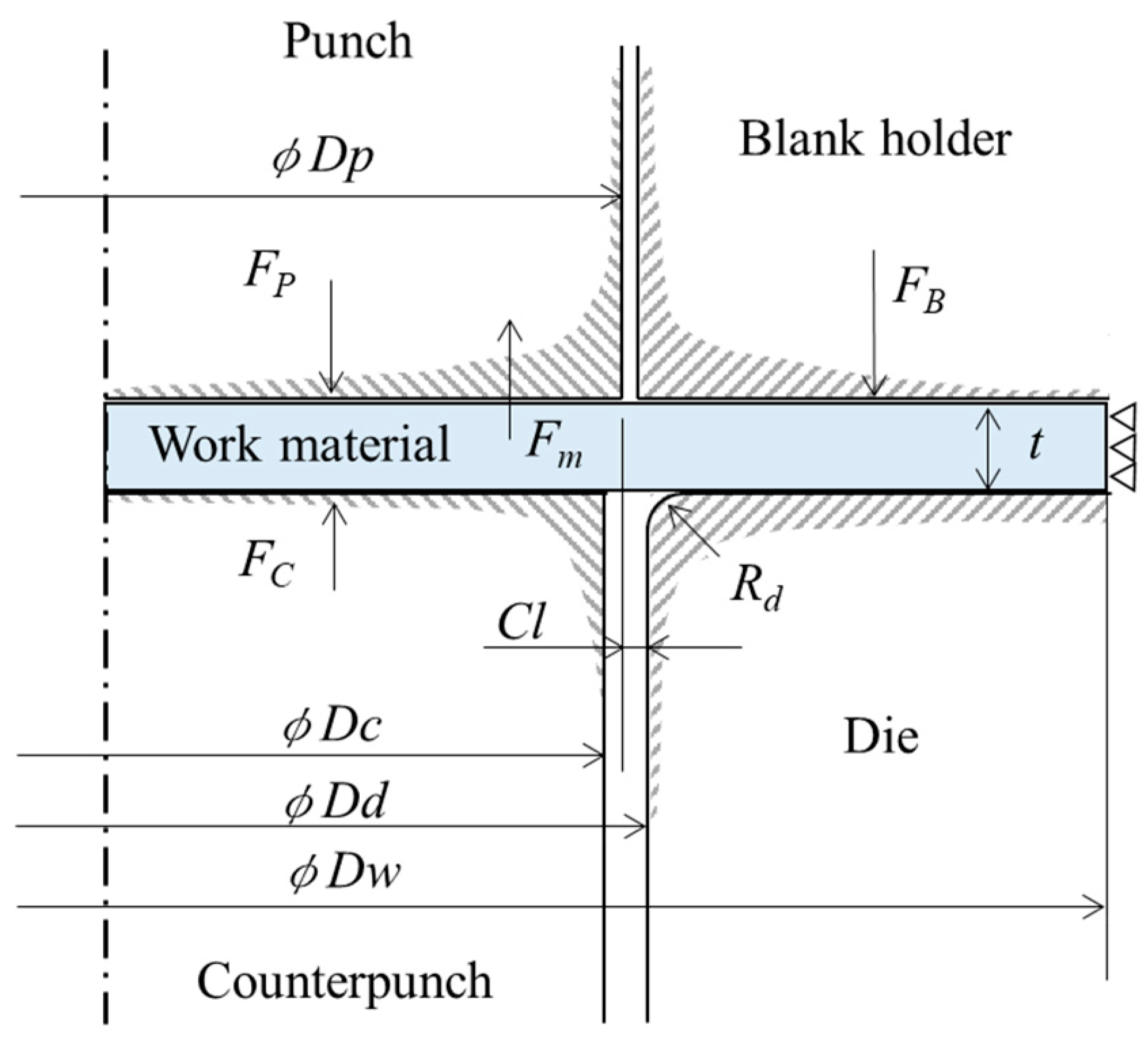

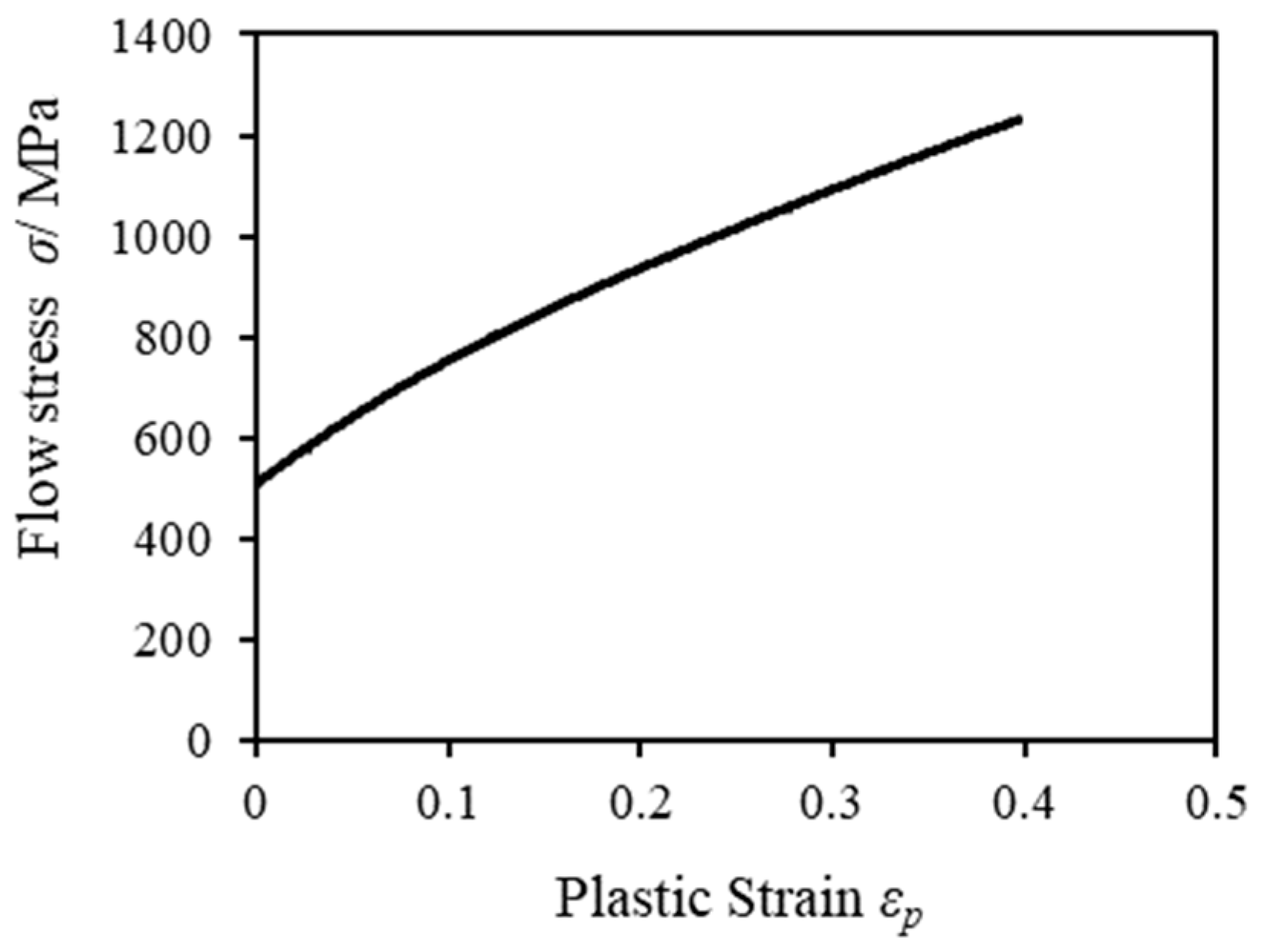

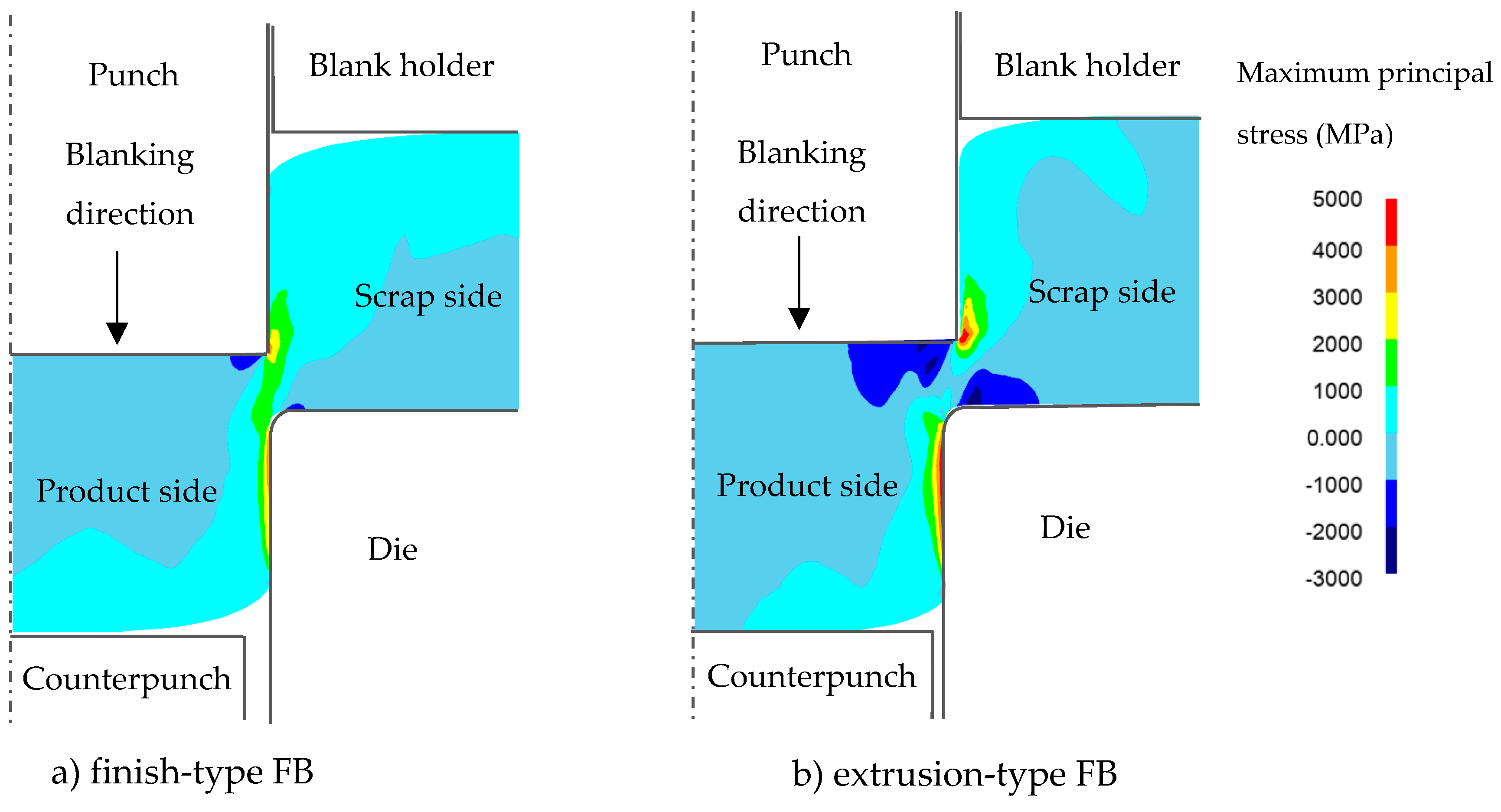

2. FEM Simulation Model and Conditions

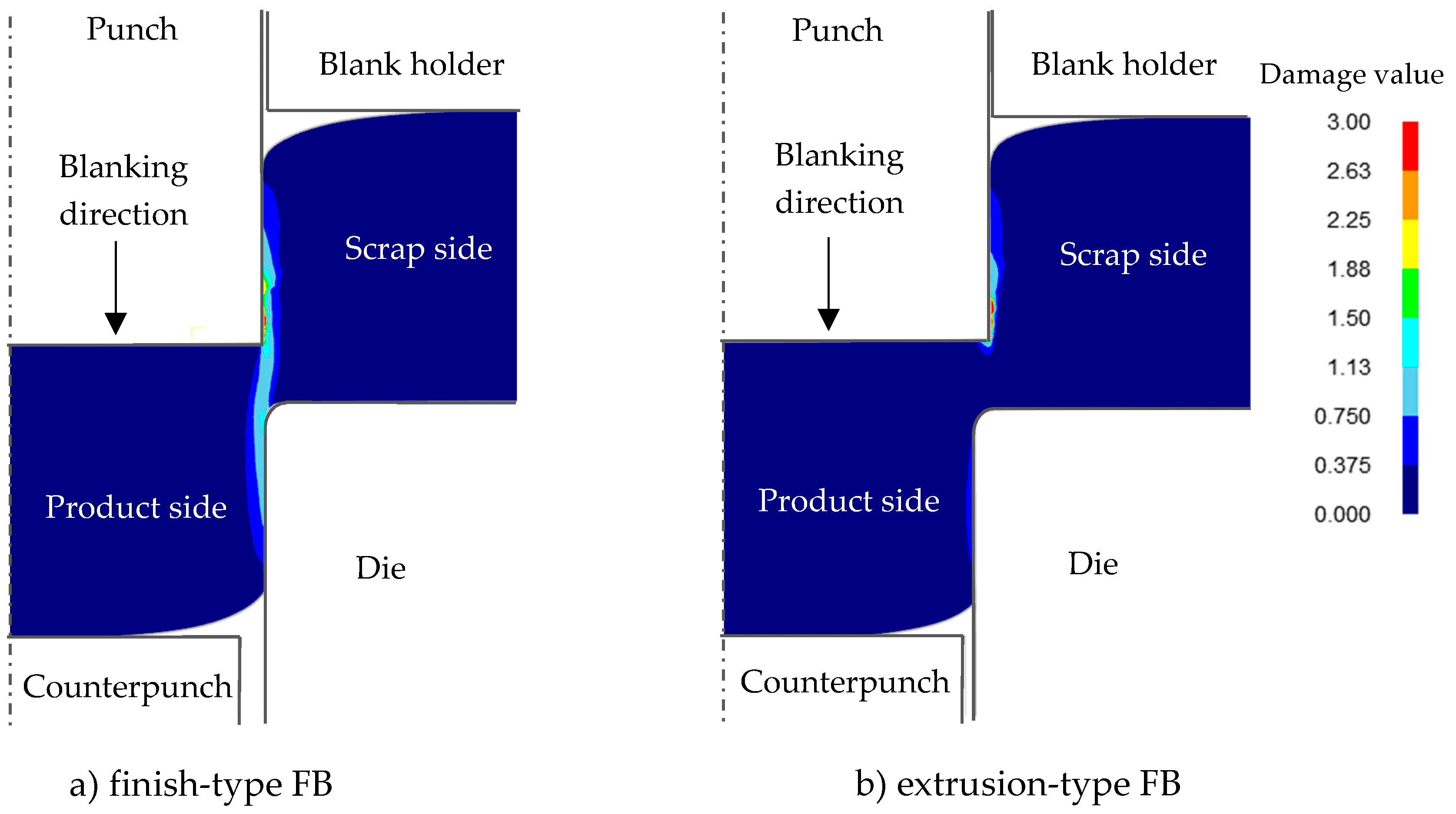

3. FEM Simulation Results and Discussion

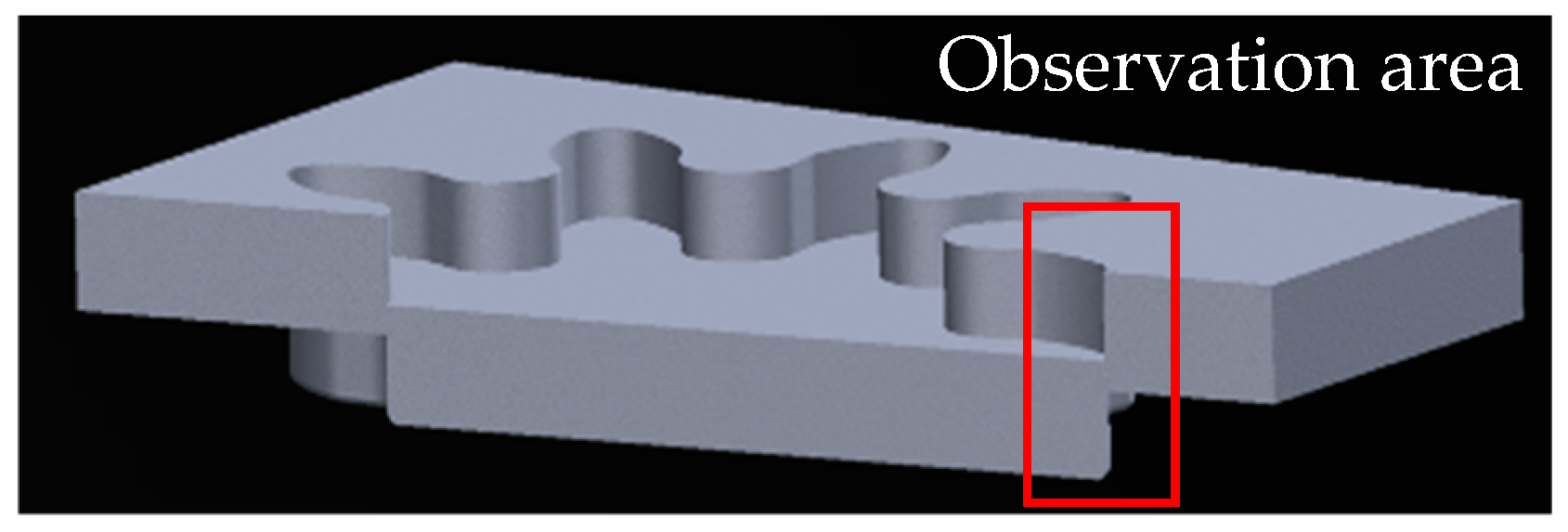

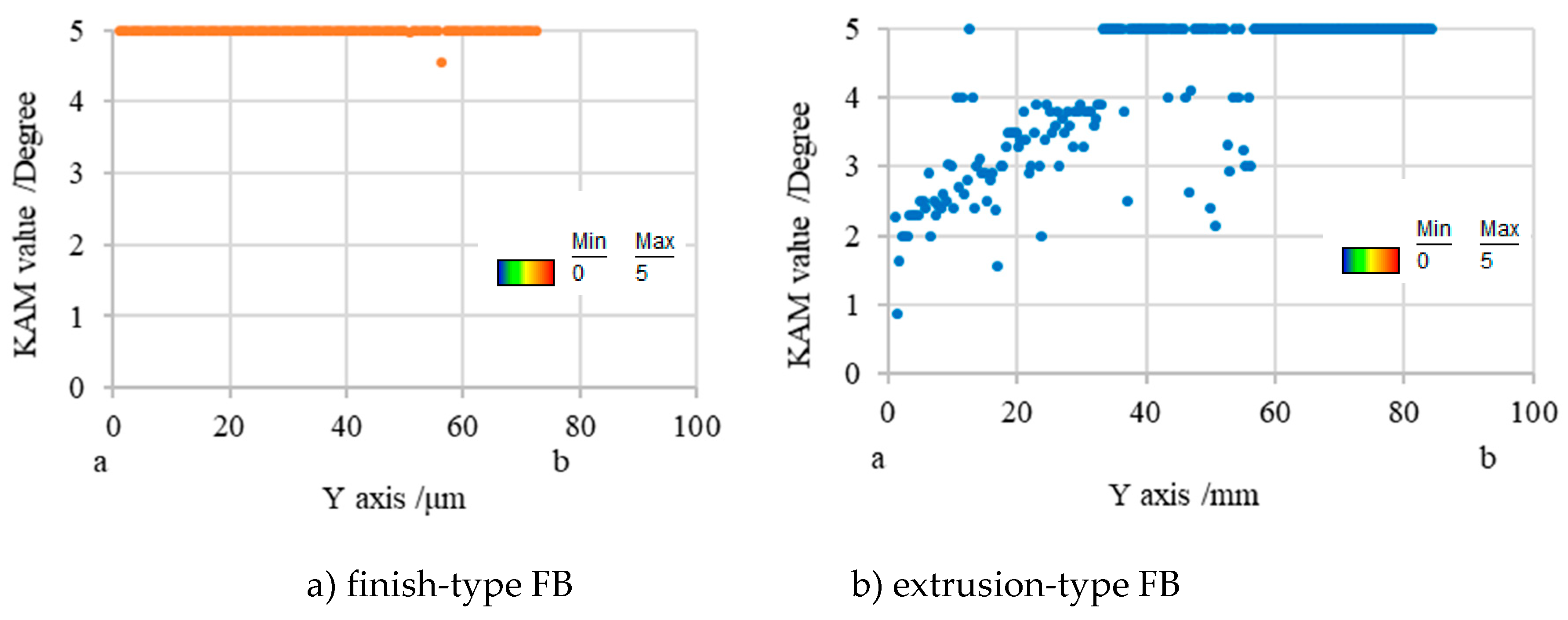

4. Discussion Based on EBSD Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, M. Micro integral forming technology in press die. J. Jpn. Soc. Technol. Plast. 2006, 47, 558–563. [Google Scholar] [CrossRef]

- Nakagawa, T. Fine Blanking; The Nikkan Kogyo Shimbun: Tokyo, Japan, 1998; pp. 1–162. [Google Scholar]

- Maeda, T. Design of punching die. J. Jpn. Soc. Technol. Plast. 1960, 1, 309–316. [Google Scholar]

- Maeda, T. Experimental investigation on fine blanking 2nd Report. J. Jpn. Soc. Technol. Plast. 1968, 9, 627–636. [Google Scholar]

- Nakano, S.; Suzuki, Y.; Aihara, T.; Shiratori, T. Visualization technology and nanometric positioning die system for micropiercing. J. Jpn. Soc. Technol. Plast. 2015, 56, 213–218. [Google Scholar] [CrossRef]

- Xu, Z.T.; Peng, L.F.; Lai, X.M.; Fu, M.W. Geometry and grain size effects on the forming limit of sheet metals in micro-scaled plastic deformation. Mater. Sci. Eng. A 2014, 611, 345–353. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Guo, Y.Z.; Wei, Q.; Topping, T.D.; Dangelewicz, A.M.; Zhu, Y.T.; Langdon, T.G.; Lavernia, E.J. Influence of specimen dimensions and strain measurement methods on tensile stress–strain curves. Mater. Sci. Eng. A 2009, 525, 68–77. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Guo, Y.Z.; Wie, Q.; Dangelewicz, A.M.; Xu, C.; Zhu, Y.T.; Langdon, T.G.; Zhou, Y.Z.; Lavernia, E.J. Influence of specimen dimensions on the tensile behavior of ultrafine-grained Cu. Scr. Mater. 2008, 59, 627–630. [Google Scholar] [CrossRef]

- Wang, J.L.; Fu, M.W.; Shi, S.Q. Influences of size effect and stress condition on ductile fracture behavior in micro-scaled plastic deformation. Mater. Des. 2017, 131, 69–80. [Google Scholar] [CrossRef]

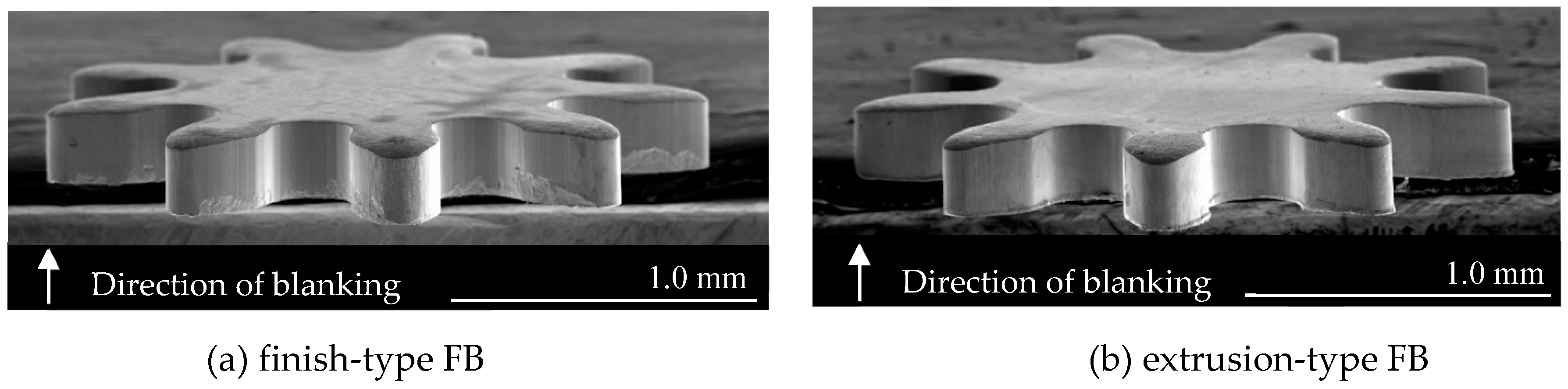

- Suzuki, Y.; Shiratori, T.; Yang, M.; Murakawa, M. Processing of metal microgear tooth profile by finish blanking and extrusion blanking and evaluation of cut-surface shape. J. Jpn. Soc. Technol. Plast. 2018, 60, 64–69. [Google Scholar] [CrossRef]

- Yoshida, Y. Finite element method analysis of shearing process. J. Jpn. Soc. Technol. Plast. 2012, 53, 800–804. [Google Scholar] [CrossRef]

- Tanaka, T.; Hagihara, S.; Tadano, Y.; Inada, T.; Mori, T.; Fuchiwaki, K. Application of finite element method to analysis of ductile fracture criteria for punched cutting surfaces. Mater. Trans. 2013, 43, 1697–1702. [Google Scholar] [CrossRef]

- Thipprakmas, S.; Jin, M.; Kanaizuka, T.; Yamamoto, K.; Murakawa, M. Prediction of Fineblanking surface characteristics using the finite element method (FEM). J. Mater. Process. Technol. 2008, 198, 391–398. [Google Scholar] [CrossRef]

- Cockcroft, M.G.; Latham, D.J. Ductility and the workability of metals. J. Inst. Met. 1968, 96, 33–39. [Google Scholar]

- Sasada, M.; Shimura, K.; Aoki, I. Study on coefficient of friction between tool and material in Shearing. Trans. Jpn. Soc. Mech. Eng. Ser. C 2005, 71, 249–255. [Google Scholar] [CrossRef][Green Version]

- Maeda, T.; Nakagawa, T. Experimental investigation on fine blanking 1st Report. J. Jpn. Soc. Technol. Plast. 1968, 9, 618–626. [Google Scholar]

- Huang, X.; Xiang, H.; Zhuang, X.; Zhao, Z. Improvement of die-roll quality in compound fine-blanking forming process. Adv. Mater. Res. 2011, 337, 236–241. [Google Scholar] [CrossRef]

- Thipprakmas, S.; Jin, M.; Murakawa, M. An investigation of material flow analysis in fineblanking process. J. Mater. Process. Technol. 2007, 192, 237–242. [Google Scholar] [CrossRef]

- Kimura, H.; Wang, Y.; Akiniwa, Y.; Tanaka, K. Misorientation analysis of plastic deformation of autenitic srainless steel by EBSD and X-ray diffraction methods. Trans. Jpn. Soc. Mech. Eng. 2005, 71, 118–124. [Google Scholar] [CrossRef]

- Shiratori, T. Effects of Grain Size and Process Condition on Stability of Sheared Surface in Micropunching at SUS304. Ph.D. Thesis, Tokyo Metropolitan University, Tokyo, Japan, 2017. [Google Scholar]

| Simulation Model Type | Axisymmetric Model |

|---|---|

| Object type | Workpiece: elasto-plastic (φDw:3.5 mm) |

| Punch /Die: rigid (φDp:1.748 mm, φDd1:1.752 mm, φDd2:1.732 mm) | |

| Blank holder /Stripper: rigid | |

| Counterpunch: rigid (φDc:1.720 mm) | |

| Clearance (Cl) | Finish-type FB: 2 μm |

| Extrusion-type FB: −8 μm | |

| Blank holder force (FB) | 1000 N (50% of maximum blanking force) |

| Counterpunch force (FC) | 400 N (20% of maximum blanking force) |

| Blanking force (FP) | Non-constant value |

| Radii of tool cutting edges | Rp = 0.00 mm, Rd = 0.01 mm |

| Work material (Workpiece) | SUS304 t = 0.178 mm Young’s modulus: 193 GPa Poisson’s ratio: 0.3 |

| Fracture criterion equation | Cockcroft and Latham |

| Friction coefficient (μ) | 0.08 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suzuki, Y.; Shiratori, T.; Yang, M.; Murakawa, M. Elucidation of Shearing Mechanism of Finish-type FB and Extrusion-type FB for Thin Foil of JIS SUS304 by Numerical and EBSD Analyses. Materials 2019, 12, 2143. https://doi.org/10.3390/ma12132143

Suzuki Y, Shiratori T, Yang M, Murakawa M. Elucidation of Shearing Mechanism of Finish-type FB and Extrusion-type FB for Thin Foil of JIS SUS304 by Numerical and EBSD Analyses. Materials. 2019; 12(13):2143. https://doi.org/10.3390/ma12132143

Chicago/Turabian StyleSuzuki, Yohei, Tomomi Shiratori, Ming Yang, and Masao Murakawa. 2019. "Elucidation of Shearing Mechanism of Finish-type FB and Extrusion-type FB for Thin Foil of JIS SUS304 by Numerical and EBSD Analyses" Materials 12, no. 13: 2143. https://doi.org/10.3390/ma12132143

APA StyleSuzuki, Y., Shiratori, T., Yang, M., & Murakawa, M. (2019). Elucidation of Shearing Mechanism of Finish-type FB and Extrusion-type FB for Thin Foil of JIS SUS304 by Numerical and EBSD Analyses. Materials, 12(13), 2143. https://doi.org/10.3390/ma12132143