Lightweight and Durable PVDF–SSPF Composites for Photovoltaics Backsheet Applications: Thermal, Optical and Technical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of Composites

2.2. Optical Testing of Composites

2.3. Thermal Testing of Composites

2.4. Technical Testing of Composites

3. Results and Discussion

3.1. Optical Properties

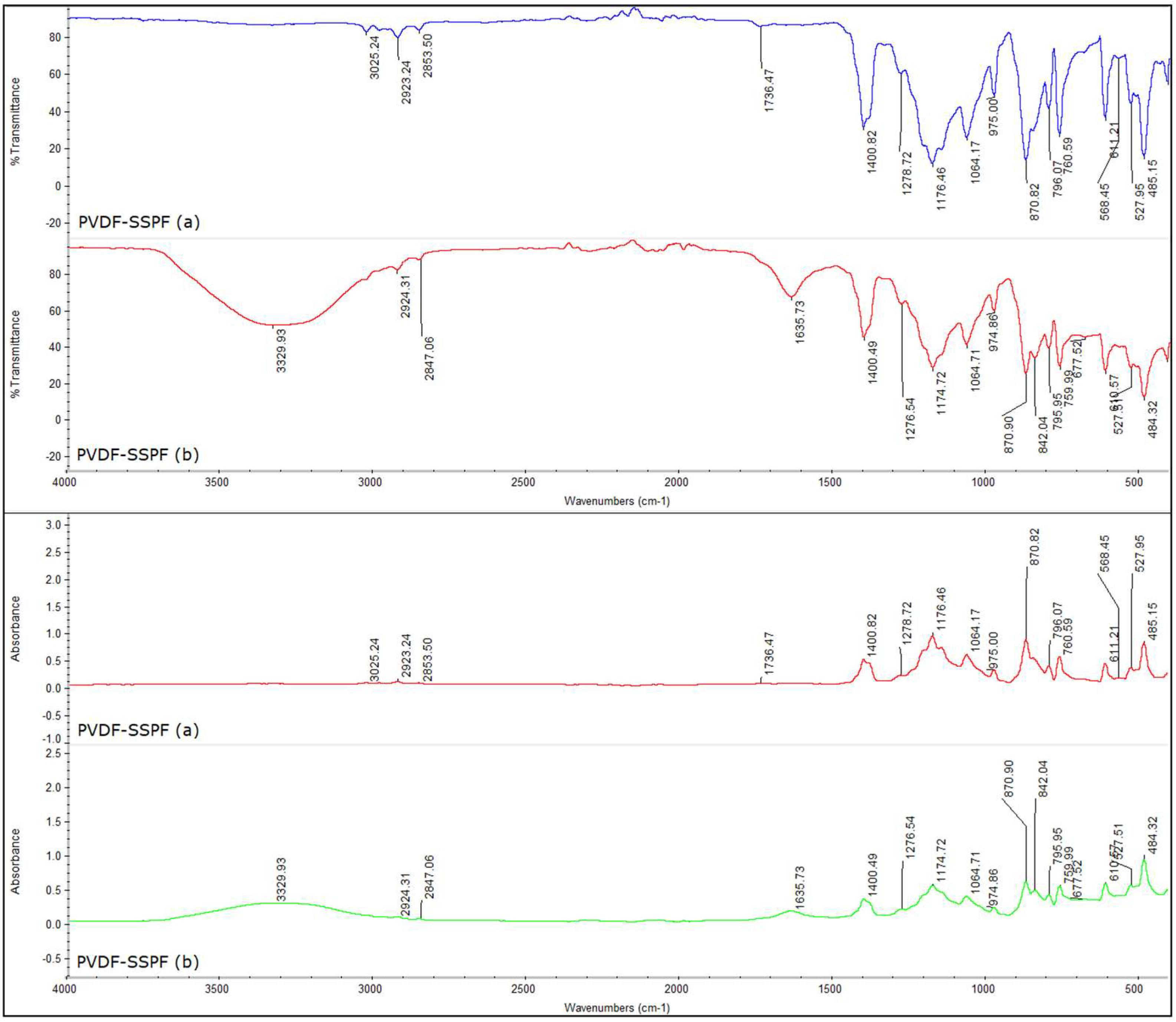

3.1.1. Fourier Transform Infrared Spectroscopy (FTIR)

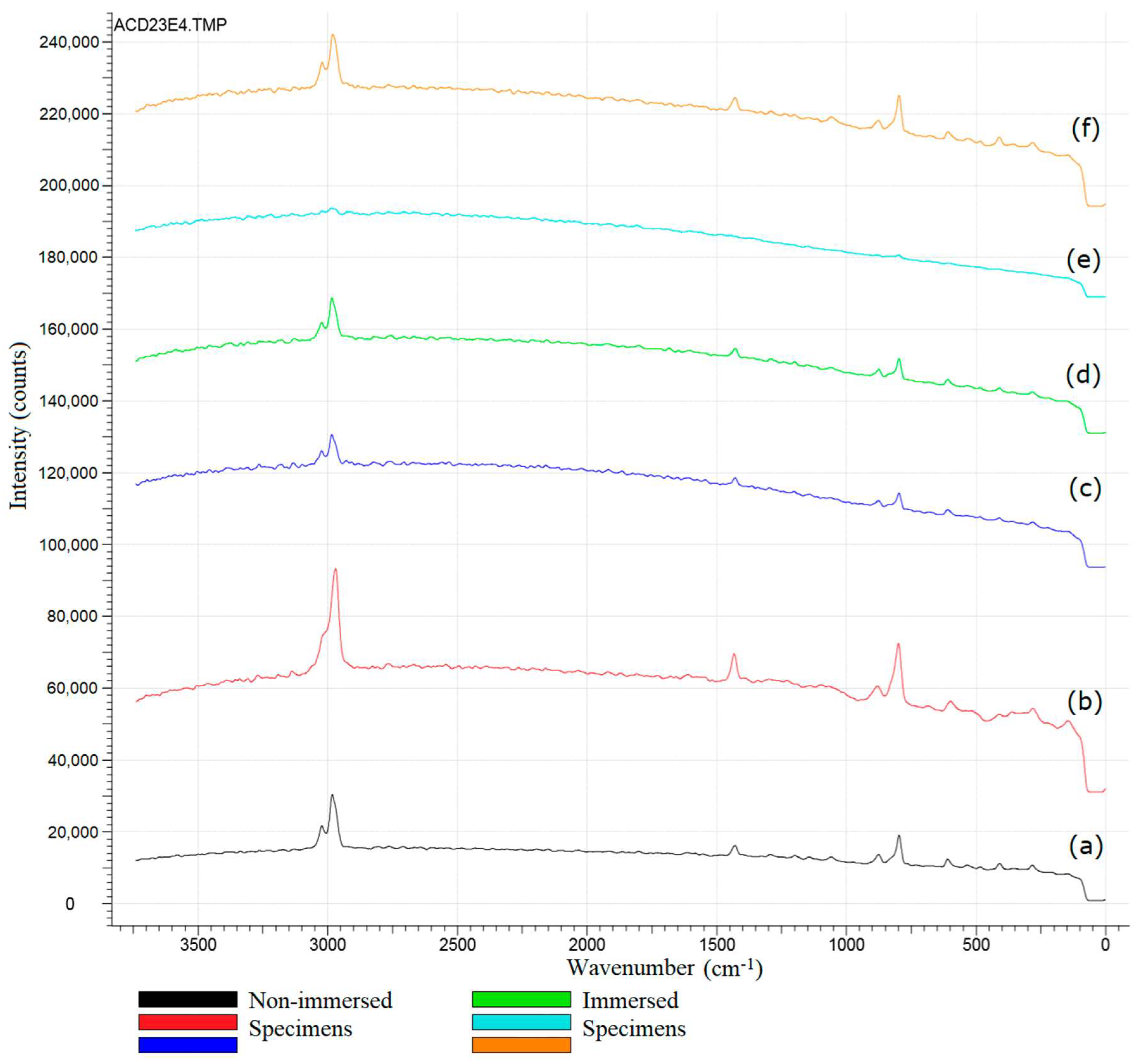

3.1.2. Raman Spectrum

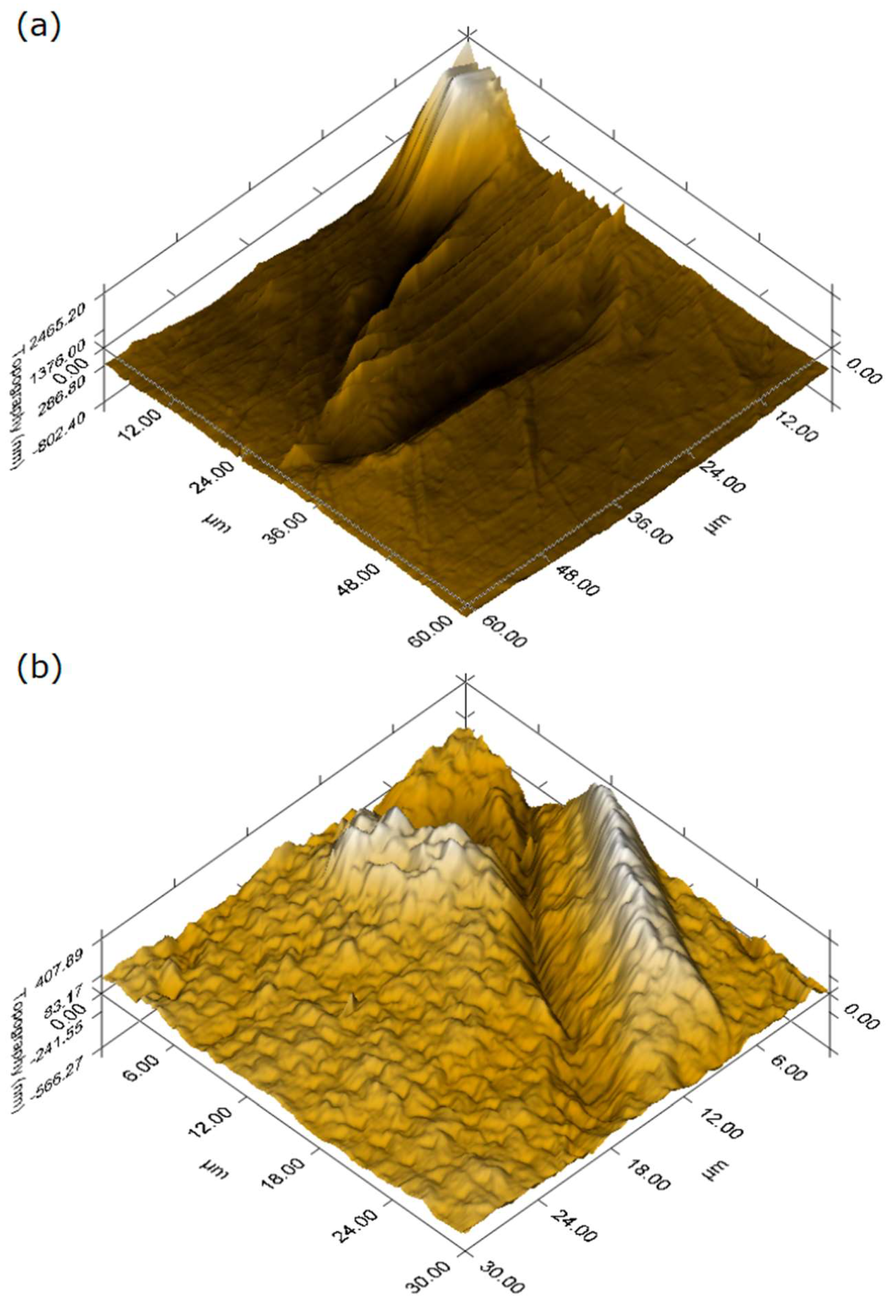

3.1.3. In-situ Scanning Probe Microscopy (SPM)

3.2. Thermal Properties

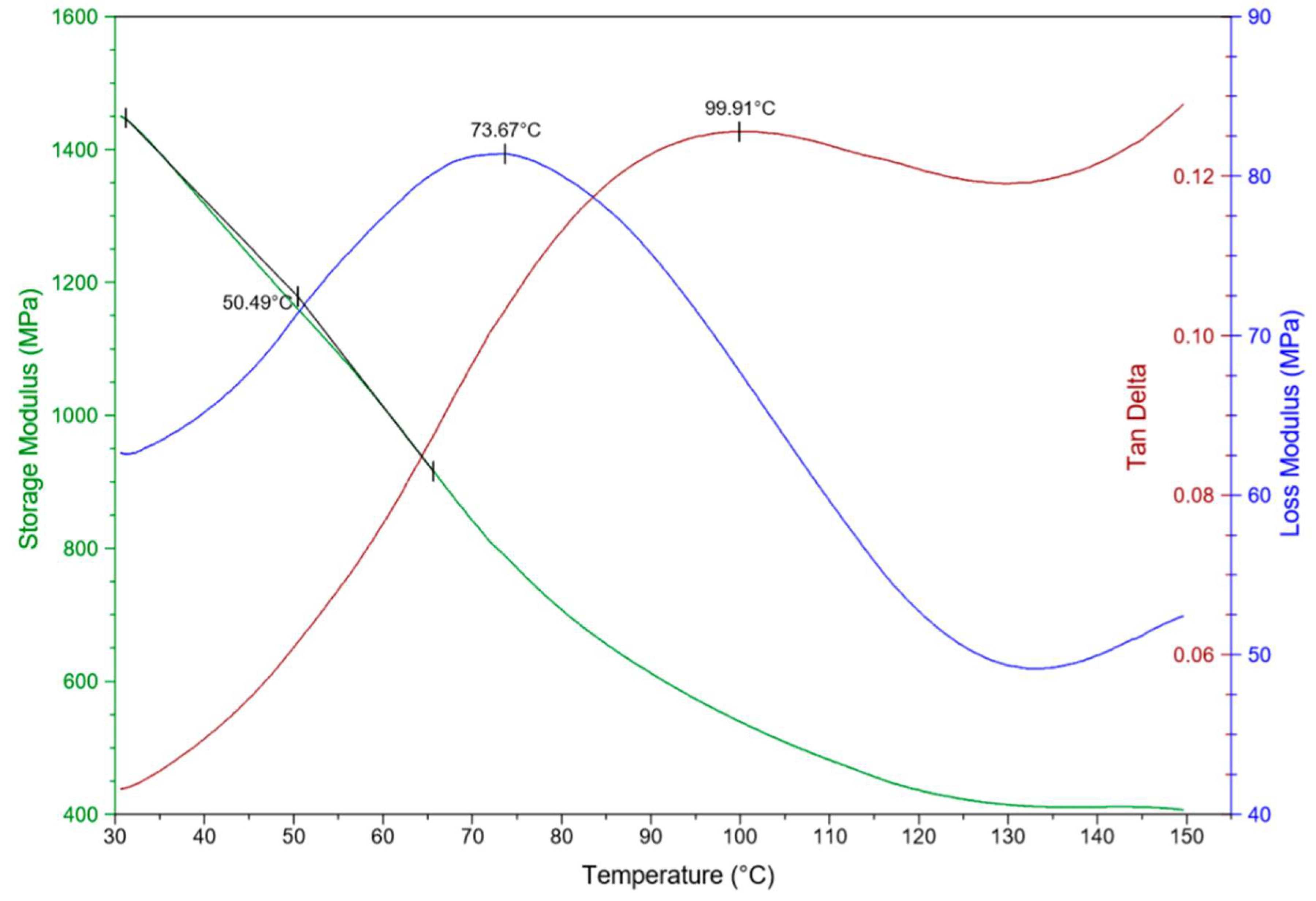

3.2.1. The Dynamic Mechanical Analysis (DMA)

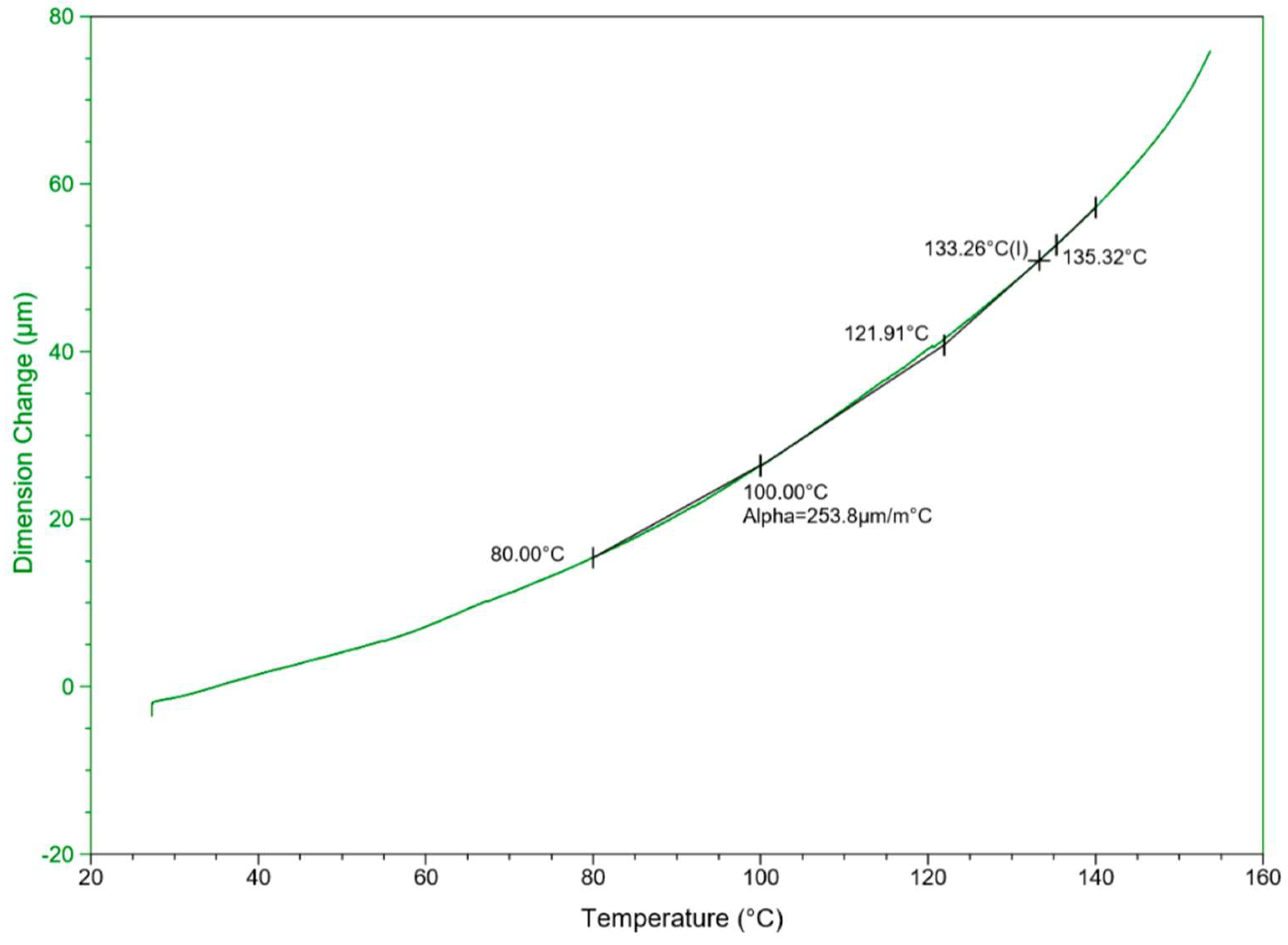

3.2.2. The Thermomechanical Analysis (TMA)

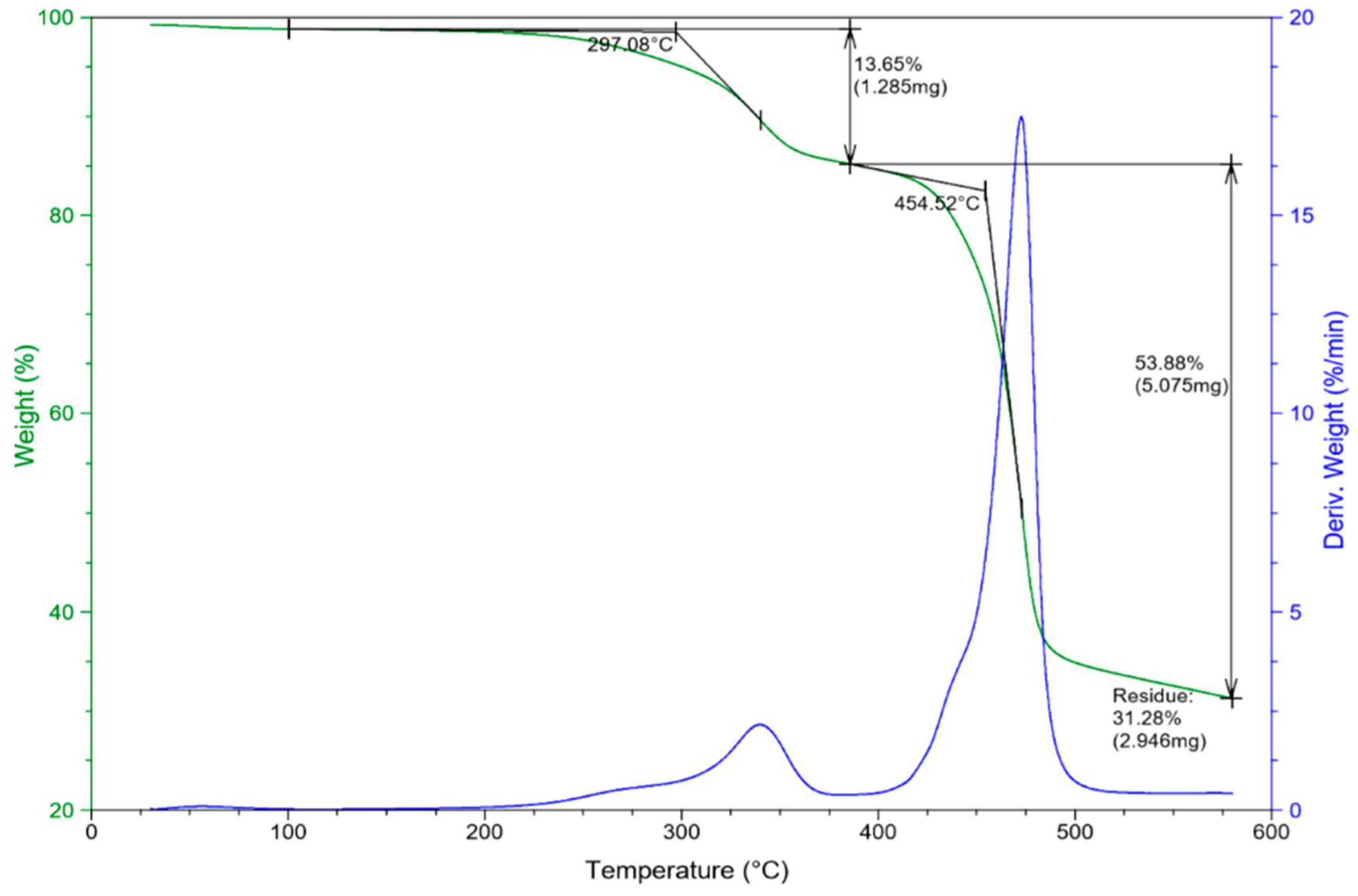

3.2.3. The Thermogravimetric Analysis (TGA)

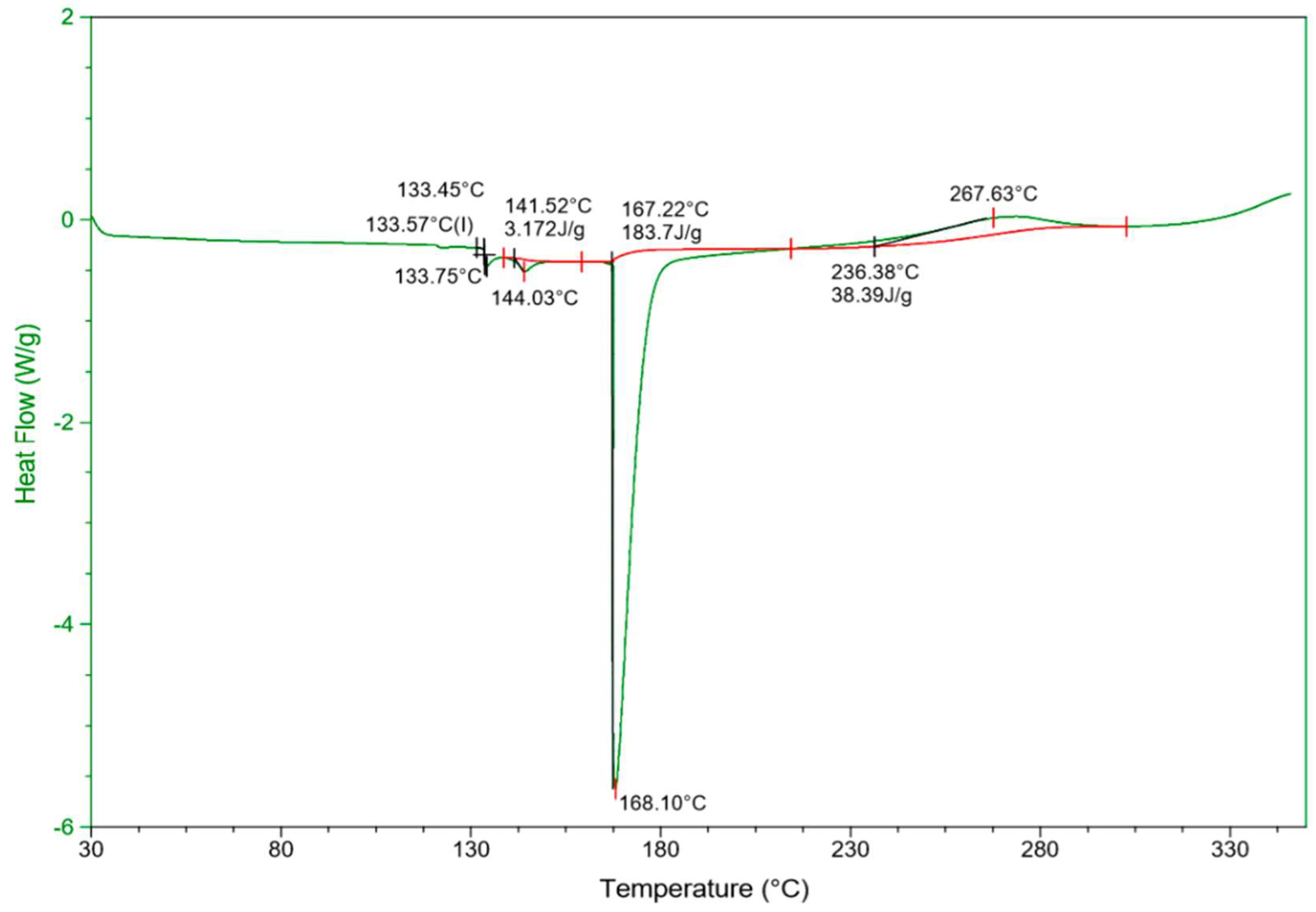

3.2.4. The Differential Scanning Calorimetry (DSC)

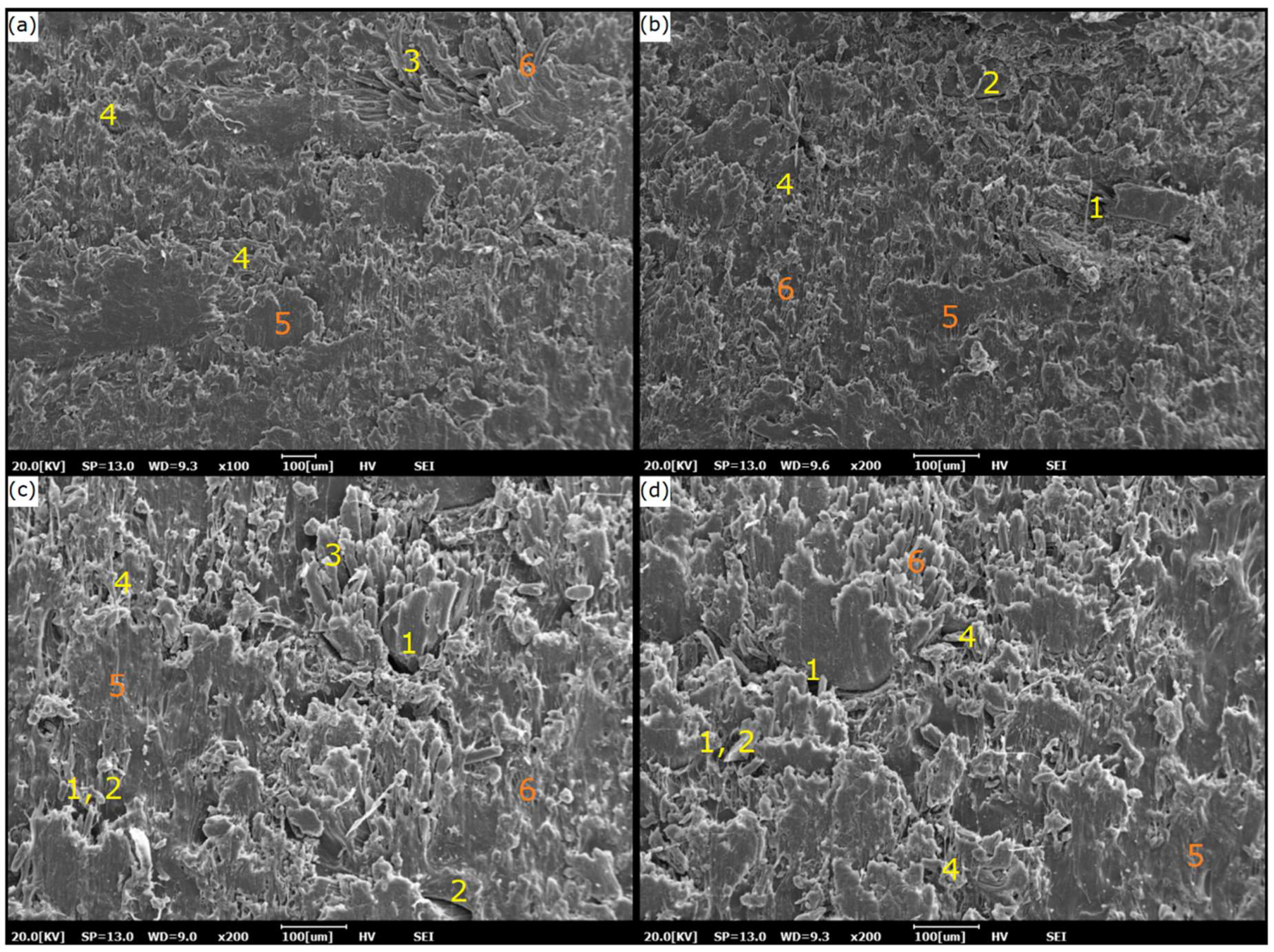

3.3. Technical Properties

3.3.1. Moisture Content

3.3.2. Water Absorption

3.3.3. Thickness Swelling

4. Conclusions

- -

- In the optical testing, exposing the specimens to water leads to slight changes in molecular interactions in which a minor shift in wavenumber can be observed. The FTIR spectra demonstrated the existence of specific chemical constituents in the PVDF–SSPF composites. Good stability in absorbance and transmittance values was observed.

- -

- The Raman spectra characterized the fiber and polymer and supported fibers based on their compositions. Minimized peaks were observed for immersed specimens. This was due to the water content within the composites. The optical analyses provide strong evidence that the fiber did interact with the polymer matrix. This was confirmed by the in-situ SPM imaging.

- -

- The composites exhibited excellent thermal stability. The proportional storage and loss modulus of DMA were examined. Typical dimensional changes and CTE expansion under constant heating rate in TMA were observed. Thermal expansion occurred as a natural correspondence to thermal increase, causing dimensional changes in the composites. In TGA, the weight loss and temperature indicated exceptional thermal stability despite the initial degradation of fiber. The composites withstood high temperature, causing mass loss to occur as a result.

- -

- The DSC analysis revealed a single melting with a maximum endothermic peak at 168.10 °C. The maximum peak integration was addressed. The composites responded to constantly increasing heat and resisted degradation at low temperatures. The degradation of PVDF–SSPF composites’ mechanical properties occurred under increased temperature. Thermal stability was proven by the overall performance of specimens and the rate of mass reduction in composites under high temperature.

- -

- The application of short fiber contributed to interfacial bonding of the fiber matrix with stress-transfer efficiency and resulted in a homogenous structure within the composites. The composites’ excellent technical properties were addressed while considering prolonged water immersions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, N.; Lee, S.; Zhao, X.G.; Kim, D.; Oh, C.; Kang, H. Reflection and durability study of different types of backsheets and their impact on c-Si PV module performance. Sol. Energy Mater. Sol. Cells 2016, 146, 91–98. [Google Scholar] [CrossRef]

- Kim, N.; Kang, H.; Hwang, K.-J.; Han, C.; Hong, W.S.; Kim, D.; Lyu, E.; Kim, H. Study on the degradation of different types of backsheets used in PV module under accelerated conditions. Sol. Energy Mater. Sol. Cells 2014, 120, 543–548. [Google Scholar] [CrossRef]

- Geretschläger, K.J.; Wallner, G.M.; Fischer, J. Structure and basic properties of photovoltaic module backsheet films. Sol. Energy Mater. Sol. Cells 2016, 144, 451–456. [Google Scholar] [CrossRef]

- Kim, K.; Yoo, M.; Ahn, K.; Kim, J. Thermal and mechanical properties of AlN/BN-filled PVDF composite for solar cell backsheet application. Ceram. Int. 2015, 41, 179–187. [Google Scholar] [CrossRef]

- Oumer, A.; Bachtiar, D. Modeling and experimental validation of tensile properties of sugar palm fiber reinforced high impact polystyrene composites. Fibers Polym. 2014, 15, 334–339. [Google Scholar] [CrossRef][Green Version]

- Chauhan, A.; Chauhan, P.; Kaith, B. Natural fiber reinforced composite: A concise review article. J. Chem. Eng. Process Technol. 2012, 3, 10001323. [Google Scholar] [CrossRef]

- Begum, K.; Islam, M. Natural fiber as a substitute to synthetic fiber in polymer composites: A review. Res. J. Eng. Sci. 2013, 2278, 9472. [Google Scholar]

- Huzaifah, M.R.M.; Sapuan, M.S.; Leman, Z.; Ishak, M.R. Comparative study on chemical composition, physical, tensile, and thermal properties of sugar palm fiber (Arenga pinnata) obtained from different geographical locations. BioResources 2017, 12, 9366–9382. [Google Scholar]

- Torres, J.; Vandi, L.-J.; Veidt, M.; Heiztmann, M. Statistical data for the tensile properties of natural fibre composites. Data Br. 2017, 12, 222–226. [Google Scholar] [CrossRef]

- Bambach, M. Geometric optimisation and compression design of natural fibre composite structural channel sections. Compos. Struct. 2018, 185, 549–560. [Google Scholar] [CrossRef]

- Knausz, M.; Oreski, G.; Eder, G.C.; Voronko, Y.; Duscher, B.; Koch, T.; Pinter, G.; Berger, K.A. Degradation of photovoltaic backsheets: Comparison of the aging induced changes on module and component level. J. Appl. Polym. Sci. 2015, 132, 42093. [Google Scholar] [CrossRef]

- Martins, A.C.; Chapuis, V.; Sculati-Meillaud, F.; Virtuani, A.; Ballif, C. Light and durable: C omposite structures for building-integrated photovoltaic modules. Prog. Photovolt. Res. Appl. 2018, 26, 718–729. [Google Scholar] [CrossRef]

- Alaaeddin, M.; Sapuan, S.; Zuhri, M.; Zainudin, E.; AL-Oqla, F.M. Properties and Common Industrial Applications of Polyvinyl fluoride (PVF) and Polyvinylidene fluoride (PVDF). IOP Conf. Ser. Mater. Sci. Eng. 2018, 409, 012021. [Google Scholar] [CrossRef]

- Li, H.; Kikuchi, R.; Kumagai, M.; Amano, T.; Tang, H.; Lin, J.-M.; Fujiwara, K.; Ogawa, N. Nondestructive estimation of strength deterioration in photovoltaic backsheets using a portable near infrared spectrometer. Sol. Energy Mater. Sol. Cells 2012, 101, 166–169. [Google Scholar] [CrossRef]

- Oreski, G.; Wallner, G. Delamination behaviour of multi-layer films for PV encapsulation. Sol. Energy Mater. Sol. Cells 2005, 89, 139–151. [Google Scholar] [CrossRef]

- Alaaeddin, M.; Sapuan, S.; Zuhri, M.; Zainudin, E.; Al-Oqla, F.M. Photovoltaic applications: Status and manufacturing prospects. Renew. Sustain. Energy Rev. 2019, 102, 318–332. [Google Scholar] [CrossRef]

- Peike, C.; Hülsmann, P.; Blüml, M.; Schmid, P.; Weiß, K.-A.; Köhl, M. Impact of permeation properties and backsheet-encapsulant interactions on the reliability of PV modules. ISRN Renew. Energy 2012, 2012, 459731. [Google Scholar] [CrossRef]

- Aji, I.; Sapuan, S.; Zainudin, E.; Abdan, K. Kenaf fibres as reinforcement for polymeric composites: A review. Int. J. Mechan. Mater. Eng. 2009, 4, 239–248. [Google Scholar]

- El-Shekeil, Y.; Sapuan, S.; Abdan, K.; Zainudin, E. Influence of fiber content on the mechanical and thermal properties of Kenaf fiber reinforced thermoplastic polyurethane composites. Mater. Des. 2012, 40, 299–303. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Ishak, M.; Sapuan, S. Moisture absorption and thickness swelling behaviour of sugar palm fibre reinforced thermoplastic polyurethane. Procedia Eng. 2017, 184, 581–586. [Google Scholar] [CrossRef]

- Sanyang, M.; Sapuan, S.; Jawaid, M.; Ishak, M.; Sahari, J. Recent developments in sugar palm (Arenga pinnata) based biocomposites and their potential industrial applications: A review. Renew. Sustain. Energy Rev. 2016, 54, 533–549. [Google Scholar] [CrossRef]

- Mosiewicki, M.; Marcovich, N.; Aranguren, M. Characterization of fiber surface treatments in natural fiber composites by infrared and Raman spectroscopy. Interface Eng. Nat. Fibre Compos. Maximum Perform. 2011, 117–145. [Google Scholar] [CrossRef]

- Lopez, J.; Sain, M.; Cooper, P. Performance of natural-fiber–plastic composites under stress for outdoor applications: Effect of moisture, temperature, and ultraviolet light exposure. J. Appl. Polym. Sci. 2006, 99, 2570–2577. [Google Scholar] [CrossRef]

- Prachayawarakorn, J.; Limsiriwong, N.; Kongjindamunee, R.; Surakit, S. Effect of agar and cotton fiber on properties of thermoplastic waxy rice starch composites. J. Polym. Environ. 2012, 20, 88–95. [Google Scholar] [CrossRef]

- Jumaidin, R.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Thermal, mechanical, and physical properties of seaweed/sugar palm fibre reinforced thermoplastic sugar palm starch/agar hybrid composites. Int. J. Biol. Macromol. 2017, 97, 606–615. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.; Sapuan, S.; Ishak, M. Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga Pinnata). Carbohydr. Polym. 2018, 181, 1038–1051. [Google Scholar] [CrossRef] [PubMed]

- Gwon, J.G.; Lee, S.Y.; Doh, G.H.; Kim, J.H. Characterization of chemically modified wood fibers using FTIR spectroscopy for biocomposites. J. App. Polym. Sci. 2010, 116, 3212–3219. [Google Scholar] [CrossRef]

- Ishak, M.; Sapuan, S.; Leman, Z.; Rahman, M.; Anwar, U.; Siregar, J. Sugar palm (Arenga pinnata): Its fibres, polymers and composites. Carbohydr. Polym. 2013, 91, 699–710. [Google Scholar] [CrossRef]

- Edhirej, A.; Sapuan, S.; Jawaid, M.; Zahari, N.I. Cassava/sugar palm fiber reinforced cassava starch hybrid composites: Physical, thermal and structural properties. Int. J. Biol. Macromol. 2017, 101, 75–83. [Google Scholar] [CrossRef]

- Tzounis, L.; Debnath, S.; Rooj, S.; Fischer, D.; Mäder, E.; Das, A.; Stamm, M.; Heinrich, G. High performance natural rubber composites with a hierarchical reinforcement structure of carbon nanotube modified natural fibers. Mater. Des. 2014, 58, 1–11. [Google Scholar] [CrossRef]

- Chen, C.; Chen, G.; Li, X.; Guo, H.; Wang, G. The influence of chemical treatment on the mechanical properties of windmill palm fiber. Cellulose 2017, 24, 1611–1620. [Google Scholar] [CrossRef]

- Gierlinger, N.; Sapei, L.; Paris, O. Insights into the chemical composition of Equisetum hyemale by high resolution Raman imaging. Planta 2008, 227, 969–980. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, F.; Riboni, N.; Trolla, V.; Furlan, G.; Avantaggiato, G.; Iacobellis, G.; Careri, M. Differentiation of aged fibers by Raman spectroscopy and multivariate data analysis. Talanta 2016, 154, 467–473. [Google Scholar] [CrossRef] [PubMed]

- Eichhorn, S.; Young, R. Composite micromechanics of hemp fibres and epoxy resin microdroplets. Compos. Sci. Technol. 2004, 64, 767–772. [Google Scholar] [CrossRef]

- Zafeiropoulos, N.E. Interface Engineering of Natural Fibre Composites for Maximum Performance; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Jawaid, M.; Khalil, H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Alaaeddin, M.; Sapuan, S.; Zuhri, M.; Zainudin, E.; Al-Oqla, F.M. Physical and Mechanical Properties of Polyvinylidene Fluoride - Short Sugar Palm Fiber Nanocomposites. J. Clean. Prod. 2019. accepted. [Google Scholar]

- Jacob, M.; Francis, B.; Thomas, S.; Varughese, K. Dynamical mechanical analysis of sisal/oil palm hybrid fiber-reinforced natural rubber composites. Polym. Compos. 2006, 27, 671–680. [Google Scholar] [CrossRef]

- Romanzini, D.; Lavoratti, A.; Ornaghi, H.L., Jr.; Amico, S.C.; Zattera, A.J. Influence of fiber content on the mechanical and dynamic mechanical properties of glass/ramie polymer composites. Mater. Des. 2013, 47, 9–15. [Google Scholar] [CrossRef]

- Bachtiar, D.; Sapuan, S.; Khalina, A.; Zainudin, E.; Dahlan, K. The flexural, impact and thermal properties of untreated short sugar palm fibre reinforced high impact polystyrene (HIPS) composites. Polym. Polym. Compos. 2012, 20, 493–502. [Google Scholar] [CrossRef]

- Kumar, S.S.; Duraibabu, D.; Subramanian, K. Studies on mechanical, thermal and dynamic mechanical properties of untreated (raw) and treated coconut sheath fiber reinforced epoxy composites. Mater. Des. 2014, 59, 63–69. [Google Scholar] [CrossRef]

- Lee, M.W.; Han, S.O.; Seo, Y.B. Red algae fibre/poly (butylene succinate) biocomposites: The effect of fibre content on their mechanical and thermal properties. Compos. Sci. Technol. 2008, 68, 1266–1272. [Google Scholar] [CrossRef]

- Rashid, B.; Leman, Z.; Jawaid, M.; Ghazali, M.J.; Ishak, M. Physicochemical and thermal properties of lignocellulosic fiber from sugar palm fibers: Effect of treatment. Cellulose 2016, 23, 2905–2916. [Google Scholar] [CrossRef]

- Morán, J.I.; Alvarez, V.A.; Cyras, V.P.; Vázquez, A. Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 2008, 15, 149–159. [Google Scholar] [CrossRef]

- Ramírez, M.G.L.; Satyanarayana, K.G.; Iwakiri, S.; de Muniz, G.B.; Tanobe, V.; Flores-Sahagun, T.S. Study of the properties of biocomposites. Part I. Cassava starch-green coir fibers from Brazil. Carbohydr. Polym. 2011, 86, 1712–1722. [Google Scholar] [CrossRef]

- Leman, Z.; Sapuan, S.; Saifol, A.; Maleque, M.; Ahmad, M. Moisture absorption behavior of sugar palm fiber reinforced epoxy composites. Mater. Des. 2008, 29, 1666–1670. [Google Scholar] [CrossRef]

- Ponce-Alcántara, S.; Arangú, A.V.; Plaza, G.S. The importance of optical characterization of PV backsheets in improving solar module power. In Proceedings of the 8th International Photovoltaic Power Generation Conference Exhibition, Shanghai, China, 20 May 2014. [Google Scholar]

- Willeke, G.P.; Weber, E.R. Advances in Photovoltaics; Newnes: Newton, MA, USA, 2013. [Google Scholar]

| The Dynamic Mechanical Analysis (DMA) | ||||||||||||||||||||

| Onset Point | Signal Maximum | |||||||||||||||||||

| Start °C | Stop °C | Onset °C | Onset Y MPa/Storage Modulus | Start °C | Stop °C | Maximum °C | - | |||||||||||||

| 31.21 | 65.67 | 50.49 | 1179 | 30.69 | 129.68 | 99.91 | Tan Delta | |||||||||||||

| 30.69 | 129.68 | 73.67 | Loss Modulus | |||||||||||||||||

| The Thermomechanical Analysis (TMA) | ||||||||||||||||||||

| Step Transition/Signal (Dimension Change) | Alpha X1 to X2 / Signal (Dimension Change) | |||||||||||||||||||

| Onset °C | Midpoint (I) °C | End °C | Height µm | Start °C | Manual Onset °C | Alpha µm/(m·°C) | ||||||||||||||

| 121.91 | 133.26 | 135.32 | 30.87 | 80.00 | 100.00 | 253.84 | ||||||||||||||

| The Thermogravimetric Analysis (TGA) | ||||||||||||||||||||

| Onset Point | Weight Change | Residue | ||||||||||||||||||

| Start °C | Stop °C | Onset °C | Onset Y % | Start °C | Stop °C | Weight mg | Weight % | Temperature °C | Weight mg | Weight % | ||||||||||

| 100.23 | 340.17 | 297.08 | 98.55 | 100.23 | 385.61 | 1.285 | 13.65 | 579.94 | 2.946 | 31.28 | ||||||||||

| 385.73 | 472.90 | 454.52 | 82.49 | 385.73 | 579.38 | 5.075 | 53.88 | |||||||||||||

| The Differential Scanning Calorimetry (DSC) | ||||||||||||||||||||

| Peak Integration | Glass Transition | |||||||||||||||||||

| Start °C | Onset °C | Maximum °C | Stop °C | Area J/g | Onset °C | Midpoint (I) °C | End °C | Height W/g | Delta Cp J/(g·°C) | |||||||||||

| 138.64 | 141.52 | 144.03 | 159.20 | 3.172 | 133.45 | 133.57 | 133.75 | 0.1604 | 0.9735 | |||||||||||

| 159.20 | 167.22 | 168.10 | 214.47 | 183.7 | ||||||||||||||||

| 214.47 | 236.38 | 267.63 | 302.68 | 38.39 | ||||||||||||||||

| SPs | Weight/g | Room Temperature °C | Test Temperature °C | Moisture (%) | Total Time/s | Immersion Time/h |

|---|---|---|---|---|---|---|

| 1–5 | 2.0± | 27± | 120 | 0.79 | 202 | 1500 |

| SPs | Weight/g | 300 h | Water Absorption (%) | 1000 h | Water Absorption (%) |

| SP1 | 0.731 | 0.771 | 5.471956224 | 0.779 | 6.566347469 |

| SP2 | 0.712 | 0.723 | 1.54494382 | 0.725 | 1.825842697 |

| SP3 | 0.770 | 0.783 | 1.688311688 | 0.787 | 2.207792208 |

| SP4 | 0.719 | 0.732 | 1.808066759 | 0.736 | 2.364394993 |

| SP5 | 0.737 | 0.754 | 2.306648575 | 0.759 | 2.985074627 |

| Mean | 0.7338 | 0.7526 | 2.562005996 | 0.7572 | 3.188879804 |

| SPs | Weight/g | 1500 h | Water Absorption (%) | 2000 h | Water Absorption (%) |

| SP1 | 0.731 | 0.786 | 7.52393981 | 0.787 | 7.66073871 |

| SP2 | 0.712 | 0.728 | 2.24719101 | 0.733 | 2.9494382 |

| SP3 | 0.770 | 0.79 | 2.5974026 | 0.794 | 3.11688312 |

| SP4 | 0.719 | 0.739 | 2.78164117 | 0.742 | 3.19888734 |

| SP5 | 0.737 | 0.763 | 3.52781547 | 0.767 | 4.07055631 |

| Mean | 0.7338 | 0.7612 | 3.73398746 | 0.7646 | 4.19732897 |

| SPs | Room Temperature °C | Water Temp. °C | 3-points Averaged Dimensions (mm) | 3-points Averaged Swellings (mm) | 1500 h Thickness Swelling (%) |

|---|---|---|---|---|---|

| SP1 | 27 ± 0.5 | 25.4 ± 0.01 | 2.09 | 2.15 | 2.86 ± 0.01 |

| SP2 | 27 ± 0.5 | 25.4 ± 0.01 | 2.14 | 2.19 | 2.64 ± 0.01 |

| SP3 | 27 ± 0.5 | 25.4 ± 0.01 | 2.01 | 2.06 | 2.14 ± 0.01 |

| SP4 | 27 ± 0.5 | 25.4 ± 0.01 | 2.05 | 2.12 | 3.24 ± 0.01 |

| SP5 | 27 ± 0.5 | 25.4 ± 0.01 | 1.98 | 2.02 | 2.18 ± 0.01 |

| Mean | 2.05 | 2.11 | 2.62 ± 0.01 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alaaeddin, M.H.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S.; M. AL- Oqla, F. Lightweight and Durable PVDF–SSPF Composites for Photovoltaics Backsheet Applications: Thermal, Optical and Technical Properties. Materials 2019, 12, 2104. https://doi.org/10.3390/ma12132104

Alaaeddin MH, Sapuan SM, Zuhri MYM, Zainudin ES, M. AL- Oqla F. Lightweight and Durable PVDF–SSPF Composites for Photovoltaics Backsheet Applications: Thermal, Optical and Technical Properties. Materials. 2019; 12(13):2104. https://doi.org/10.3390/ma12132104

Chicago/Turabian StyleAlaaeddin, M. H., S. M. Sapuan, M. Y. M. Zuhri, E. S. Zainudin, and Faris M. AL- Oqla. 2019. "Lightweight and Durable PVDF–SSPF Composites for Photovoltaics Backsheet Applications: Thermal, Optical and Technical Properties" Materials 12, no. 13: 2104. https://doi.org/10.3390/ma12132104

APA StyleAlaaeddin, M. H., Sapuan, S. M., Zuhri, M. Y. M., Zainudin, E. S., & M. AL- Oqla, F. (2019). Lightweight and Durable PVDF–SSPF Composites for Photovoltaics Backsheet Applications: Thermal, Optical and Technical Properties. Materials, 12(13), 2104. https://doi.org/10.3390/ma12132104