Bending Flexibility of Moso Bamboo (Phyllostachys Edulis) with Functionally Graded Structure

Abstract

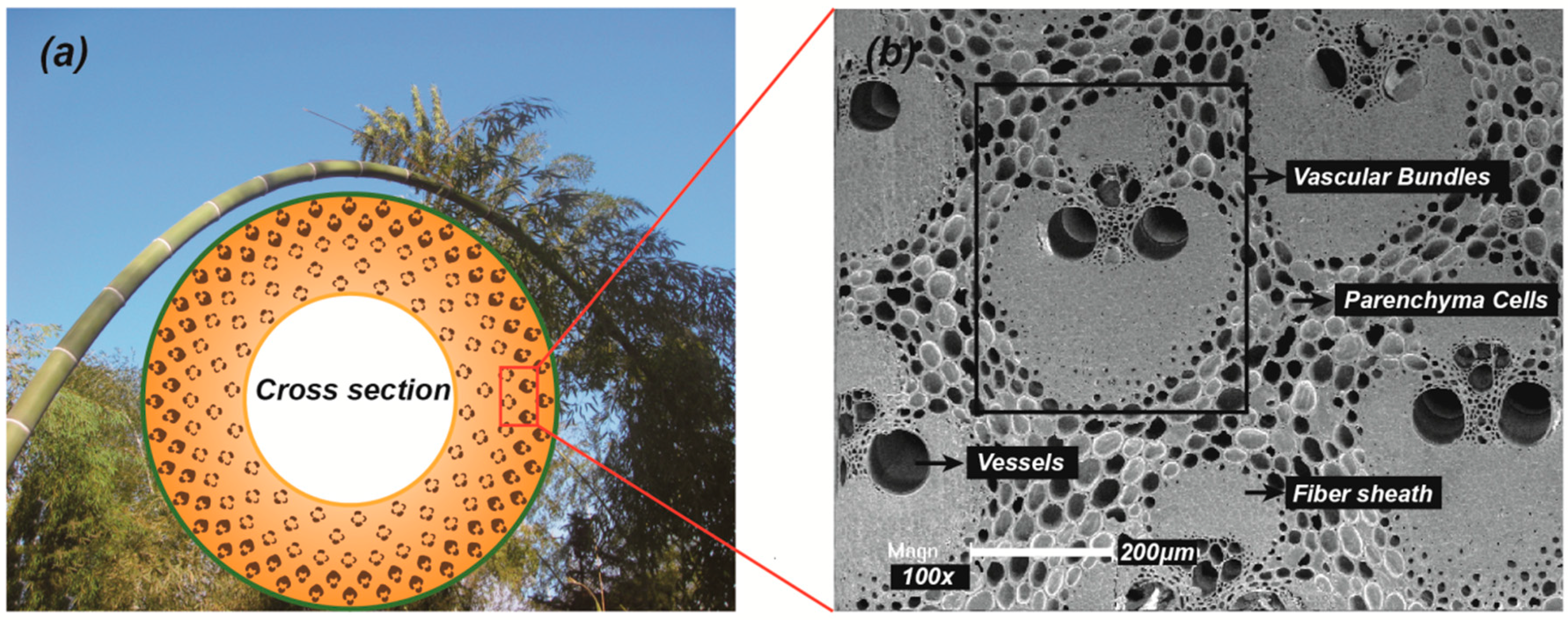

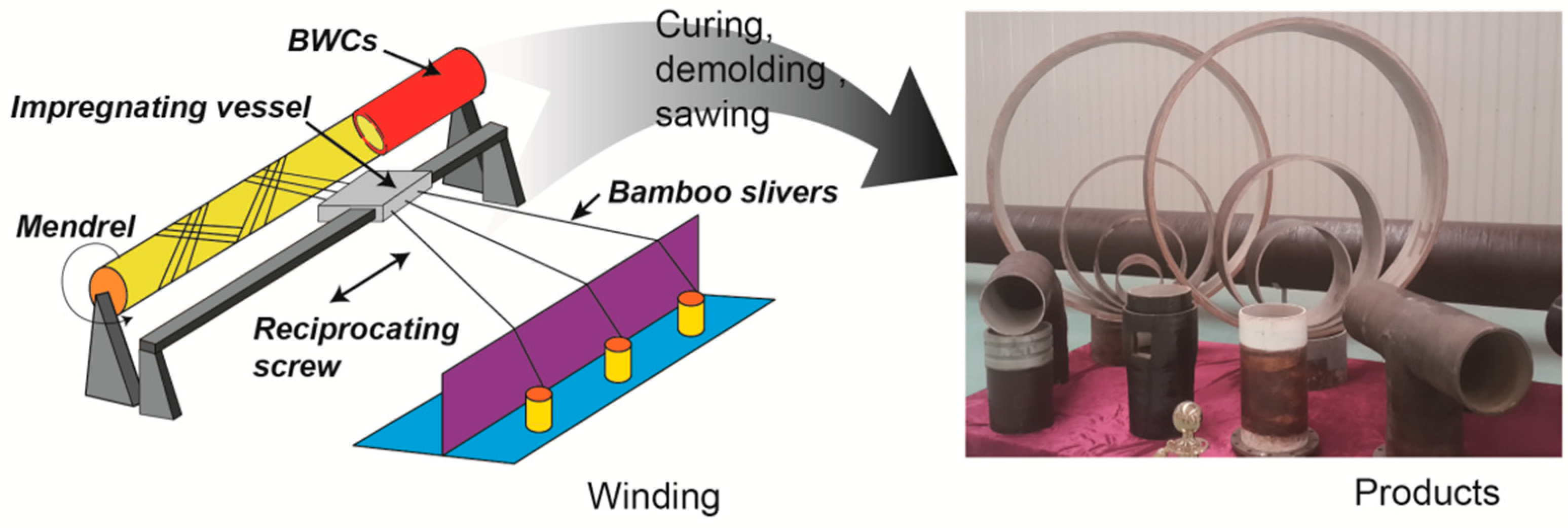

:1. Introduction

2. Materials and Methods

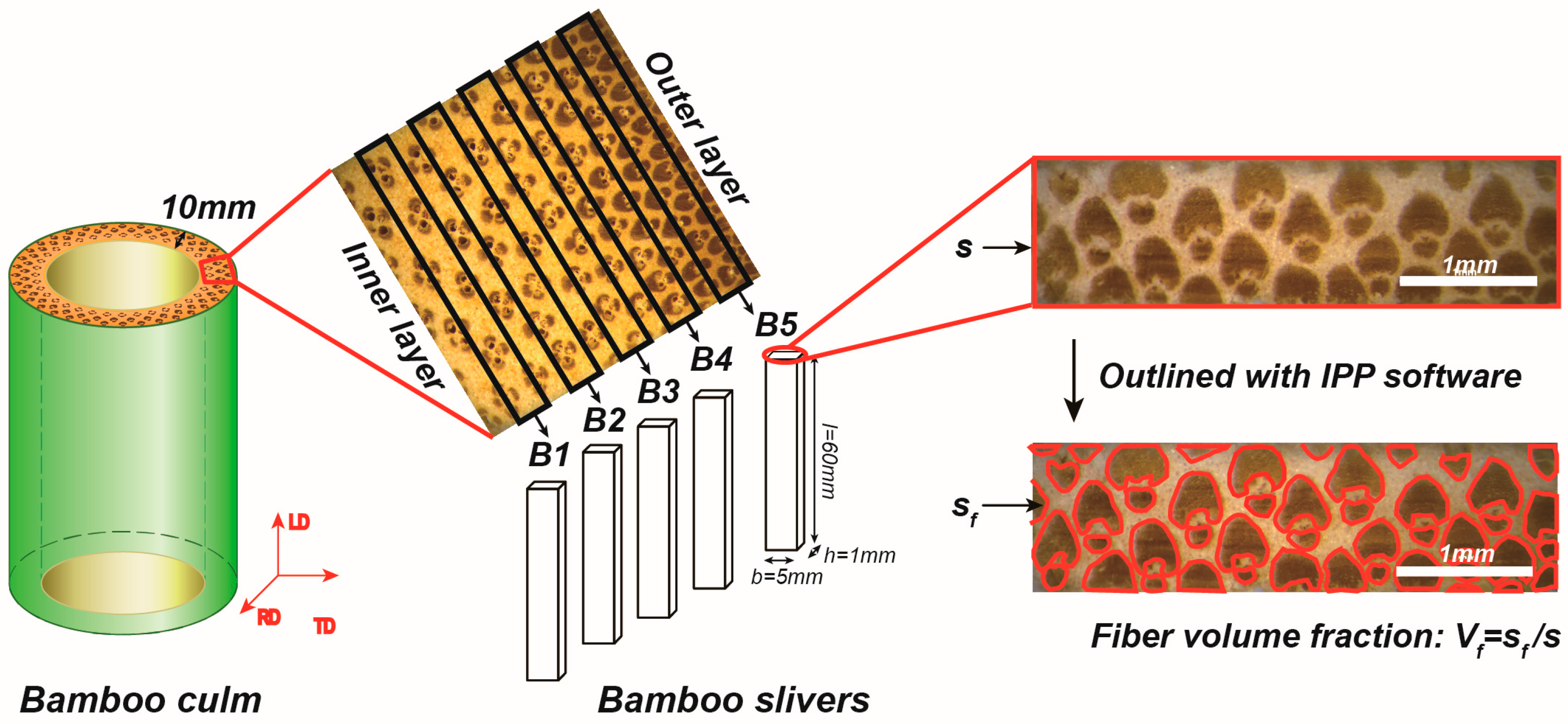

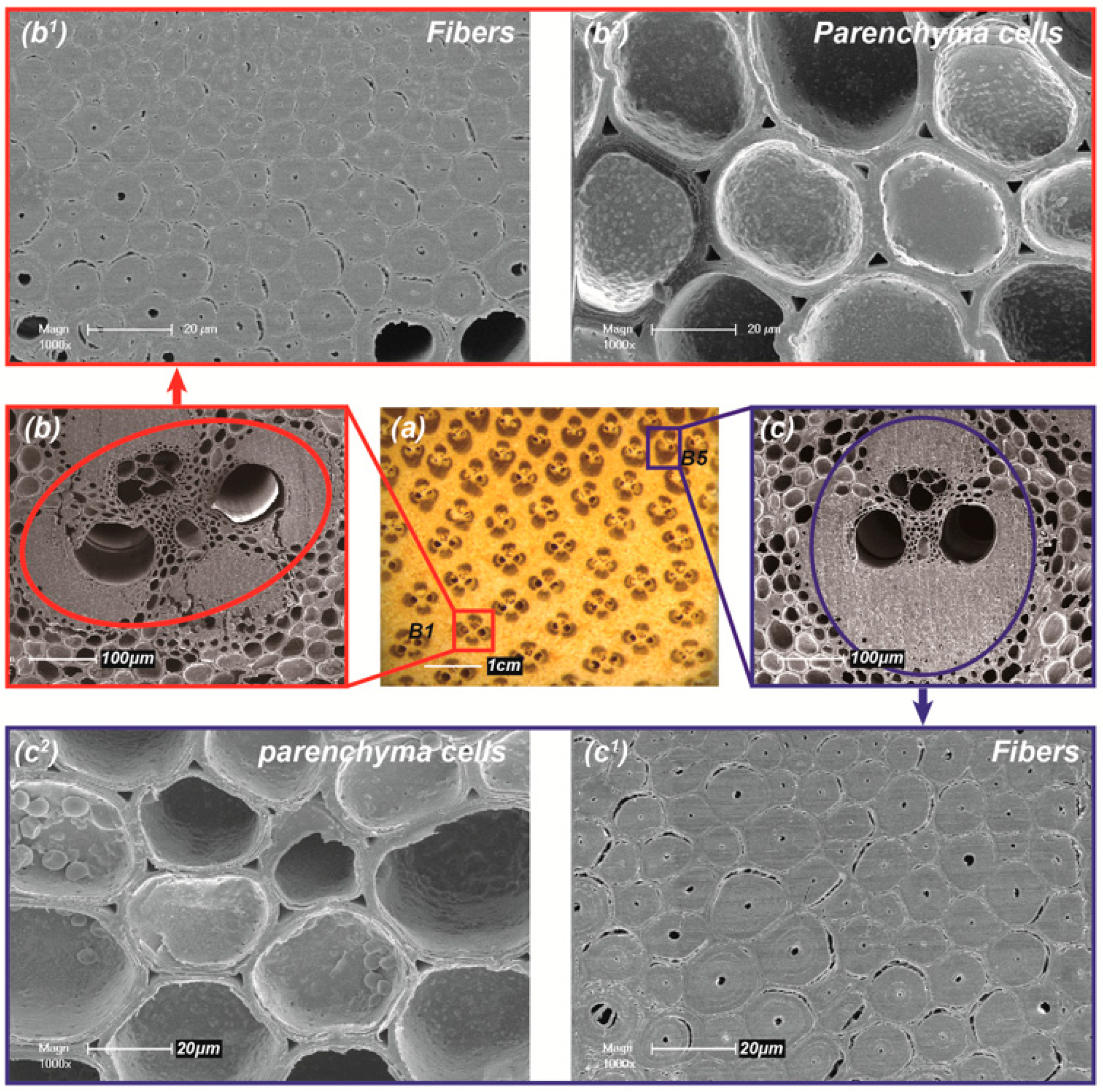

2.1. Sample Preparation

2.2. Fiber Volume Fraction Calculation

2.3. Bending Flexibility Test Methods

3. Results and Discussion

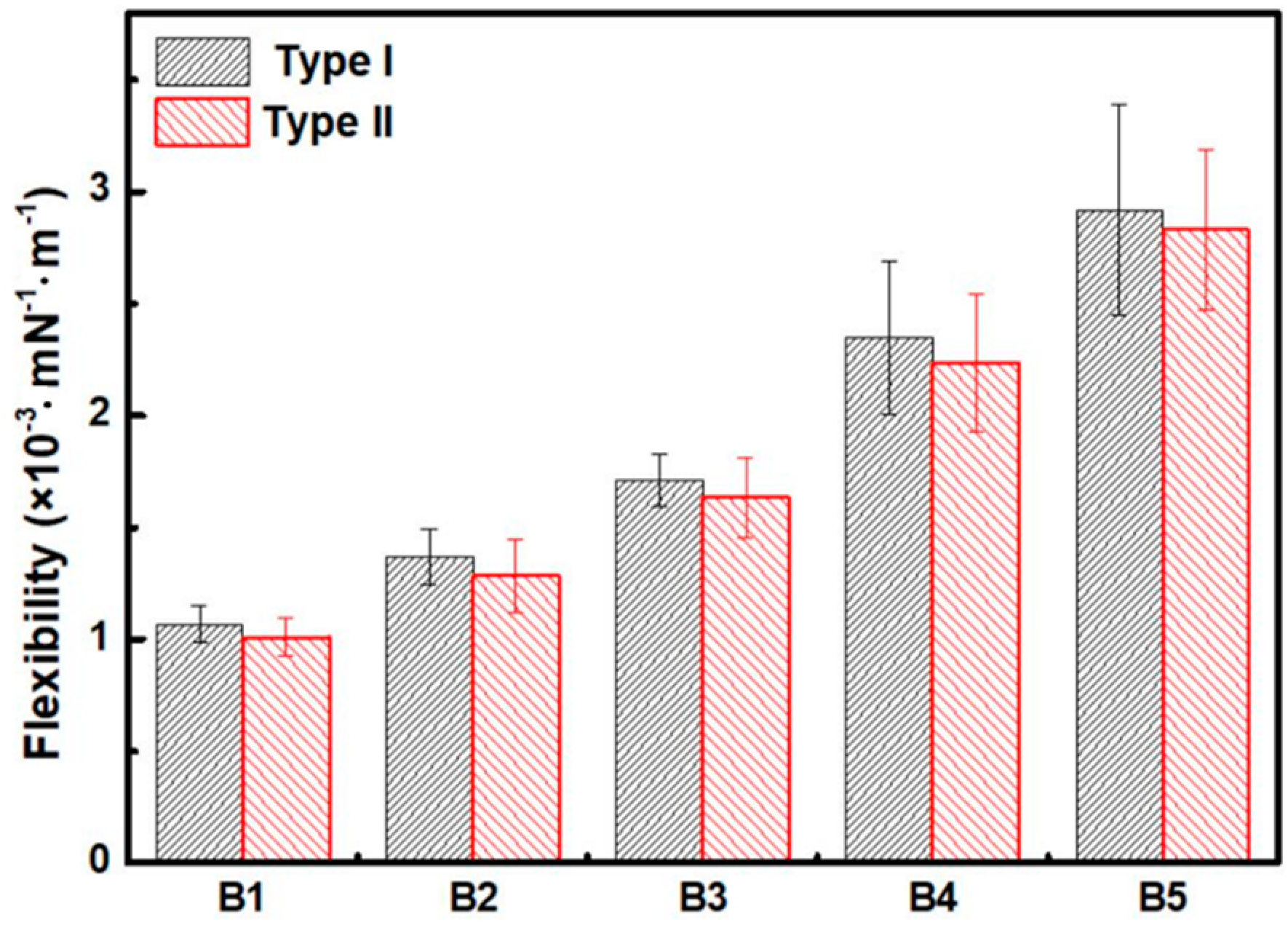

3.1. Gradient Bending Flexibility

3.2. Directional Bending Flexibility

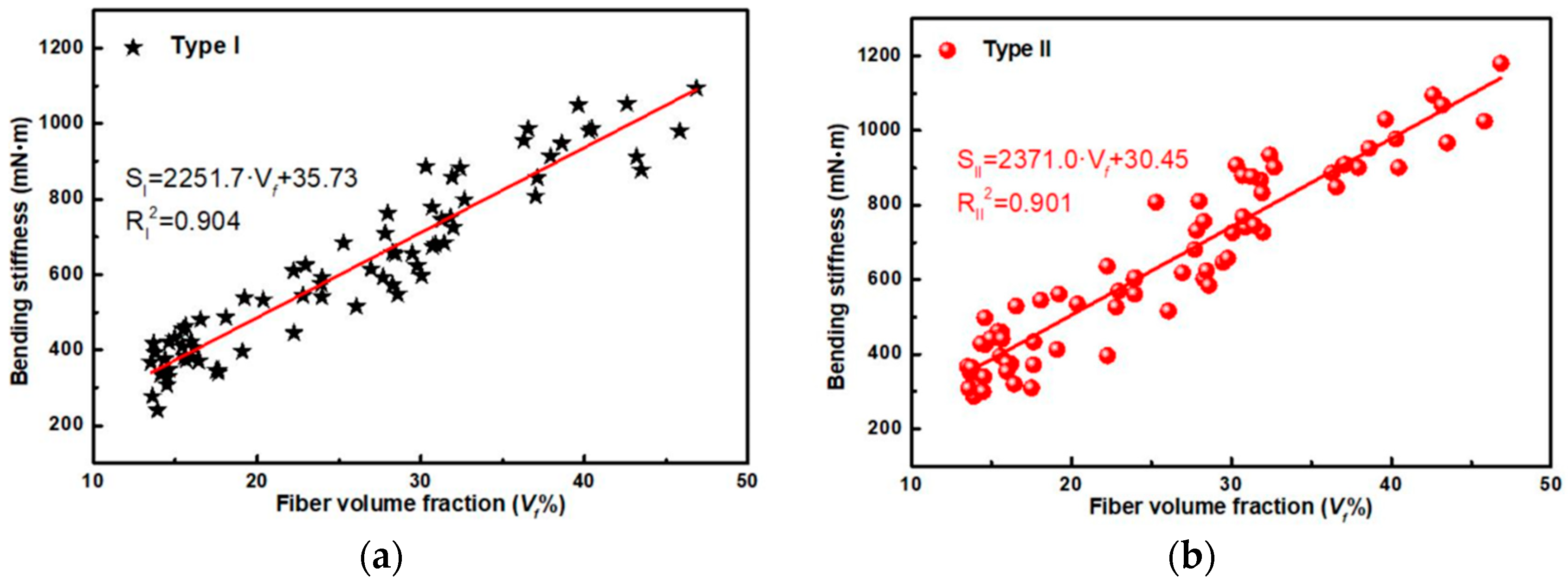

3.3. Modeling and Predicting of the Gradient Bending Flexibility

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brito, B.S.L.; Pereira, F.V.; Putaux, J.L.; Jean, B. Preparation, morphology and structure of cellulose nanocrystals from bamboo fibers. Cellulose 2012, 19, 1527–1536. [Google Scholar] [CrossRef]

- Peng, H.; Wang, N.; Hu, Z.; Yu, Z.; Liu, Y.; Zhang, J.; Ruan, R. Physicochemical characterization of hemicelluloses from bamboo (Phyllostachys pubescens Mazel) stem. Ind. Crop. Prod. 2012, 37, 41–50. [Google Scholar] [CrossRef]

- Scurlock, J. Bamboo: an over-looked biomass resource? Biomass Bioenergy 2000, 19, 229–244. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Yin, H. Analysis on Significance of Bamboo Products Based on Sustainable Development. Adv. Mater. Res. 2014, 1010, 1944–1948. [Google Scholar] [CrossRef]

- Wang, G.; Deng, J.C.; Chen, F.M.; Cheng, H.T.; Ye, L. Exploitation and application of bamboo fiber-reinforced filament-wound pressure pipe. Sci. Silvae Sinicae 2016, 52, 127–132. [Google Scholar]

- Low, I.; Che, Z.; Latella, B. Mapping the structure, composition and mechanical properties of bamboo. J. Mater. Res. 2006, 21, 1969–1976. [Google Scholar] [CrossRef]

- Liu, H.R.; Jiang, Z.H.; Fei, B.H. Tensile behaviour and fracture mechanism of moso bamboo (Phyllostachys pubescens). Holzforschung 2015, 69, 47–52. [Google Scholar] [CrossRef]

- Obataya, E.; Kitin, P.; Yamauchi, H. Bending characteristics of bamboo (Phyllostachys pubescens) with respect to its fiber–foam composite structure. Wood Sci. Technol. 2007, 41, 385–400. [Google Scholar] [CrossRef]

- An, X.J. Multi-scale tensile mechanical behavior and toughness mechanism of bamboo; Chinese Academy of Forestry: Beijing, China, 2013. [Google Scholar]

- Britvec, S.J. The stability of elastic systems; Pergamon Press: New York, NY, USA, 1973. [Google Scholar]

- An, Y.L.; Liu, Z.M.; Wang, G.; Wu, W.J. Three-Point Bending Fracture Behaviors of Bamboo. Adv. Mater. Res. 2011, 261, 464–468. [Google Scholar] [CrossRef]

- Babiak, M.; Gaff, M.; Sikora, A.; Hysek, Š. Modulus of elasticity in three- and four-point bending of wood. Compos. Struct. 2018, 204, 454–465. [Google Scholar] [CrossRef]

- Fischer, W.J.; Hirn, U.; Bauer, W.; Schennach, R. Fischer Testing of individual fiber-fiber joints under biaxial load and simultaneous analysis of deformation. Nord. Pulp Pap. Res. J. 2012, 27, 237–244. [Google Scholar] [CrossRef]

- Yang, L.; Raza, A.; Si, Y.; Mao, X.; Shang, Y.; Ding, B.; Yu, J.; Al-Deyab, S.S. Synthesis of superhydrophobic silica nanofibrous membranes with robust thermal stability and flexibility via in situ polymerization. Nanoscale 2012, 4, 6581–6587. [Google Scholar] [CrossRef] [PubMed]

- DIN 53121: 2014-08. Testing of Paper and Board–Determination of the Bending Stiffness by the Beam Method; Deutsches Institut für Normung e.V. (DIN): Berlin, German, 2014. [Google Scholar]

- Habibi, M.K.; Samaei, A.T.; Gheshlaghi, B.; Lu, J.; Lu, Y. Asymmetric flexural behavior from bamboo’s functionally graded hierarchical structure: Underlying mechanisms. Acta Biomater. 2015, 16, 178–186. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.L.; Shao, Z.P.; Wu, Y.J. Mode II interlaminar fracture properties of Moso bamboo. Compos. Part B Eng. 2013, 44, 242–247. [Google Scholar] [CrossRef]

- Liu, H.R. Study on Fracture Characteristics and Fracture Mechanism of Bamboo; Chinese Academy of Forestry: Beijing, China, 2010. [Google Scholar]

- Jiang, Z.H. Bamboo and Rattan in the World; China Forestry Pub. House: Beijing, China, 2007. [Google Scholar]

- Amada, S.; Untao, S. Fracture properties of bamboo. Compo. Part B 2001, 32, 451–459. [Google Scholar] [CrossRef]

- Habibi, M.K.; Lu, Y. Crack Propagation in Bamboo’s Hierarchical Cellular Structure. Sci. Reps. 2014, 4, 5598. [Google Scholar] [CrossRef] [PubMed]

- Ritchie, R.O. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef] [PubMed]

| Sample | Air-dried Density (ρ) (g/cm3) | Fiber Volume Fraction (Vf) (%) | Loading Modes | Bending Stiffness (S) (mN·m) | Bending Flexibility (F) (mN−1·m−1 × 10−3) | Difference of Flexibility (%) |

|---|---|---|---|---|---|---|

| B1 | 0.55 ± 0.03 a | 14.9 ± 2.7 a | Type I | 349 ± 48 a | 2.92 ± 0.38 a | 3.05 |

| Type II | 359 ± 46 a | 2.83 ± 0.48 a | ||||

| B2 | 0.60 ± 0.03 b | 15.8 ± 2.8 a | Type I | 434 ± 61 b | 2.35 ± 0.34 b | 4.89 |

| Type II | 450 ± 65 b | 2.23 ± 0.31 b | ||||

| B3 | 0.67 ± 0.03 c | 26.1 ± 2.7 b | Type I | 586 ± 39 c | 1.71 ± 0.11 c | 4.57 |

| Type II | 619 ± 69 c | 1.63 ± 0.18 c | ||||

| B4 | 0.72 ± 0.03 d | 30.3 ± 2.1 c | Type I | 737 ± 71 d | 1.37 ± 0.12 d | 6.19 |

| Type II | 790 ± 91 d | 1.28 ± 0.16 d | ||||

| B5 | 0.80 ± 0.03 e | 38.9 ± 5.8 d | Type I | 942 ± 71 e | 1.07 ± 0.08 e | 5.31 |

| Type II | 996 ± 86 e | 1.01 ± 0.08 e |

| Types | Bending Stiffness (S) (mN·m) | Flexural Modulus (E) (GPa) | Flexibility (F) (mN−1·m−1 × 10−3) | |||

|---|---|---|---|---|---|---|

| Parenchyma Cells | Fibers | Parenchyma Cells | Fibers | Parenchyma Cells | Fibers | |

| Type I | 35.73 | 2287 | 0.429 | 27.45 | 27.99 | 0.44 |

| Type II | 30.45 | 2401 | 0.365 | 28.82 | 32.84 | 0.42 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, X.; Zhou, H.; Chen, F.; Wang, G. Bending Flexibility of Moso Bamboo (Phyllostachys Edulis) with Functionally Graded Structure. Materials 2019, 12, 2007. https://doi.org/10.3390/ma12122007

Wei X, Zhou H, Chen F, Wang G. Bending Flexibility of Moso Bamboo (Phyllostachys Edulis) with Functionally Graded Structure. Materials. 2019; 12(12):2007. https://doi.org/10.3390/ma12122007

Chicago/Turabian StyleWei, Xin, Haiying Zhou, Fuming Chen, and Ge Wang. 2019. "Bending Flexibility of Moso Bamboo (Phyllostachys Edulis) with Functionally Graded Structure" Materials 12, no. 12: 2007. https://doi.org/10.3390/ma12122007

APA StyleWei, X., Zhou, H., Chen, F., & Wang, G. (2019). Bending Flexibility of Moso Bamboo (Phyllostachys Edulis) with Functionally Graded Structure. Materials, 12(12), 2007. https://doi.org/10.3390/ma12122007