Investigation of Electroplastic Effect on Four Grades of Duplex Stainless Steels

Abstract

:1. Introduction

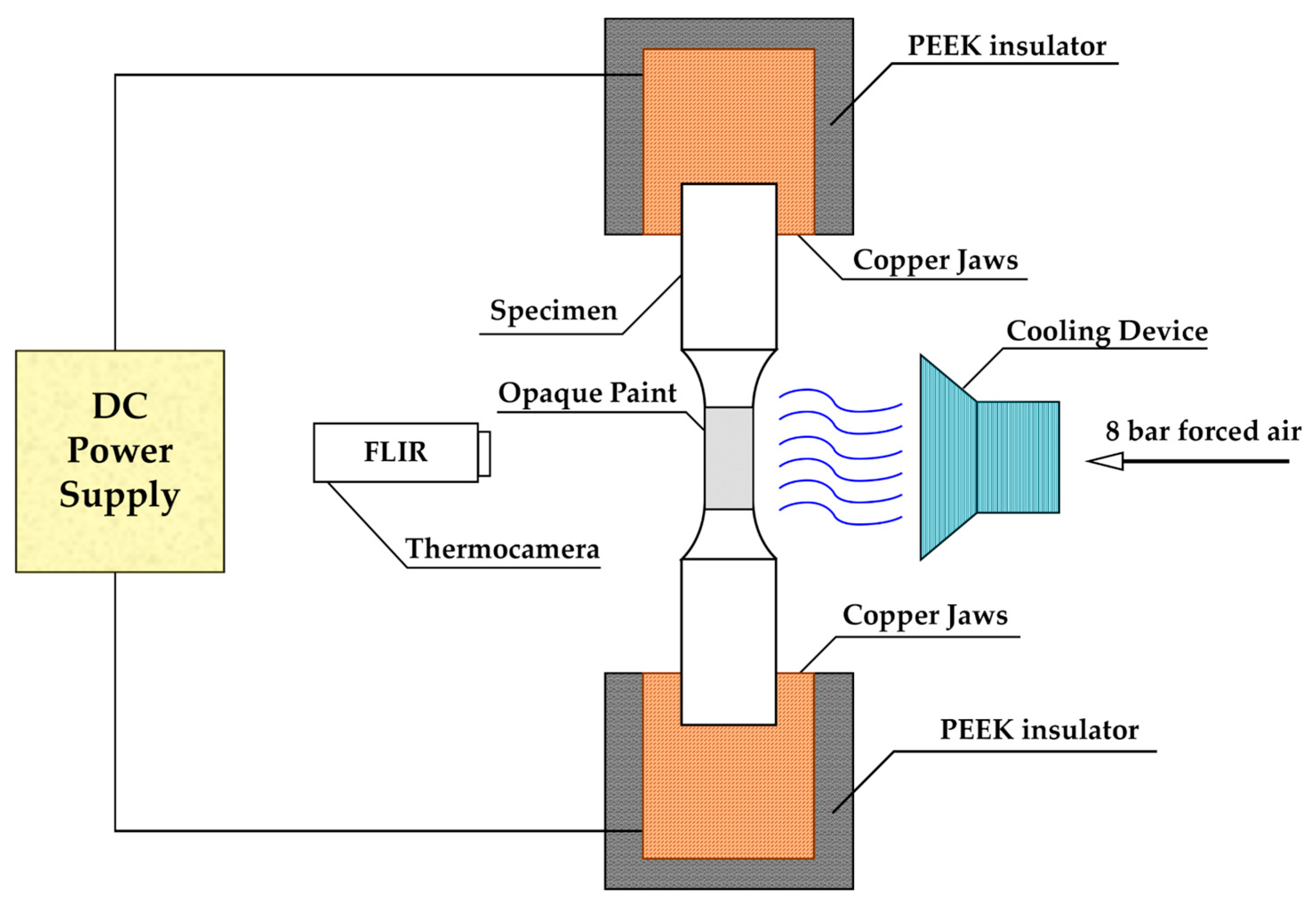

2. Materials and Methods

3. Results

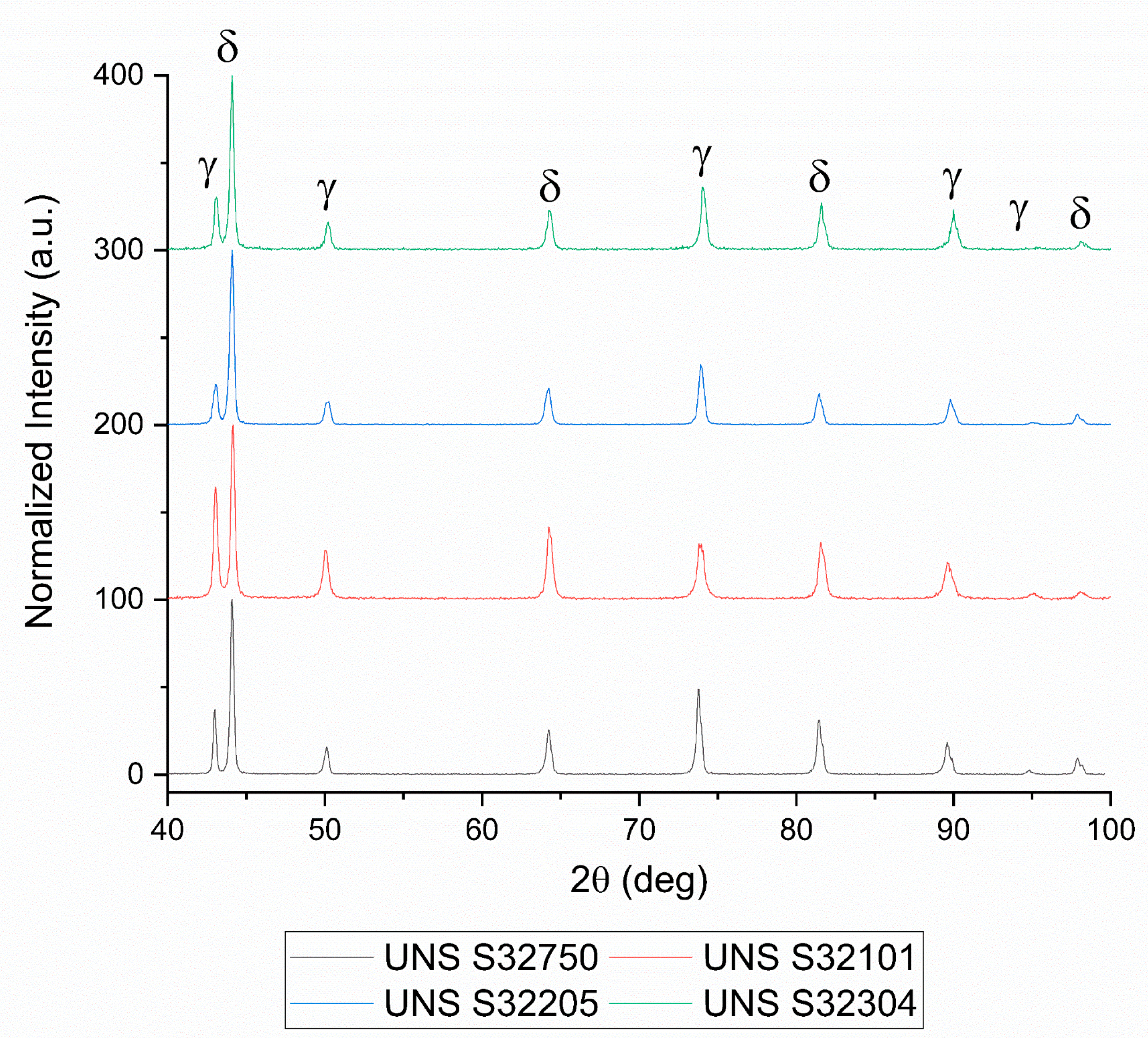

3.1. Characterization of the As-Received Material

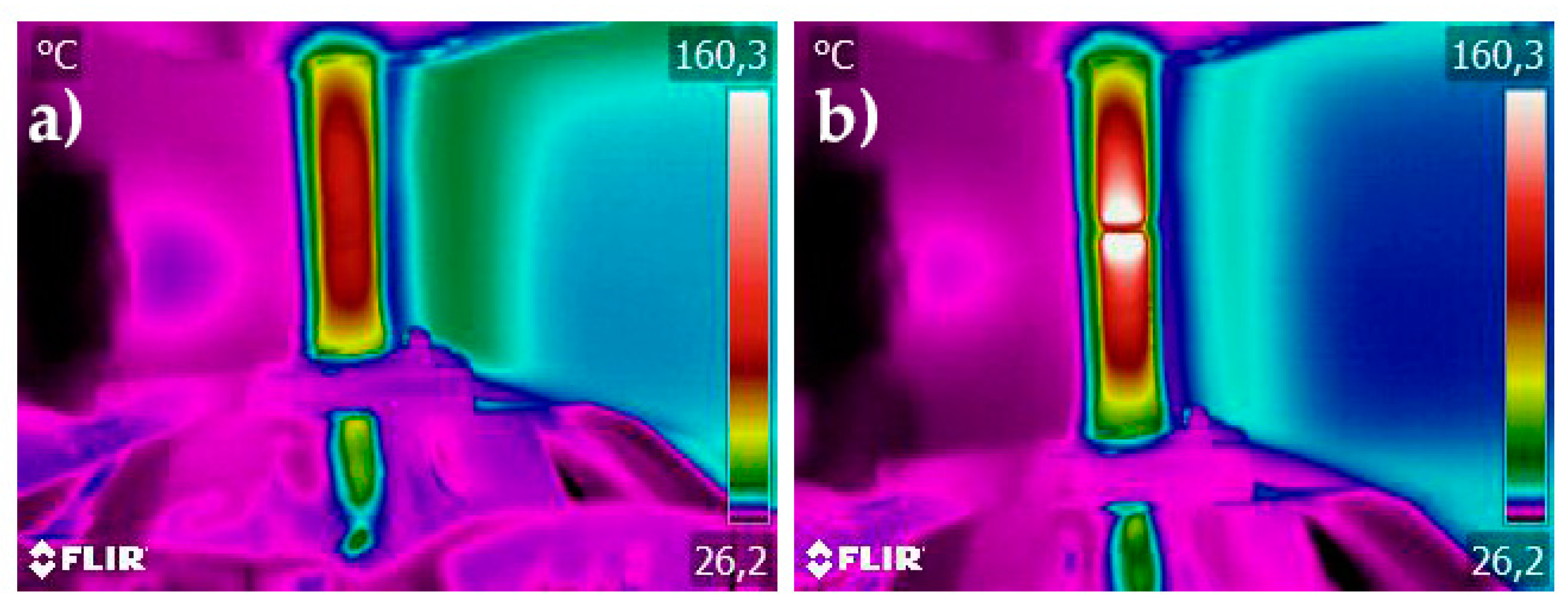

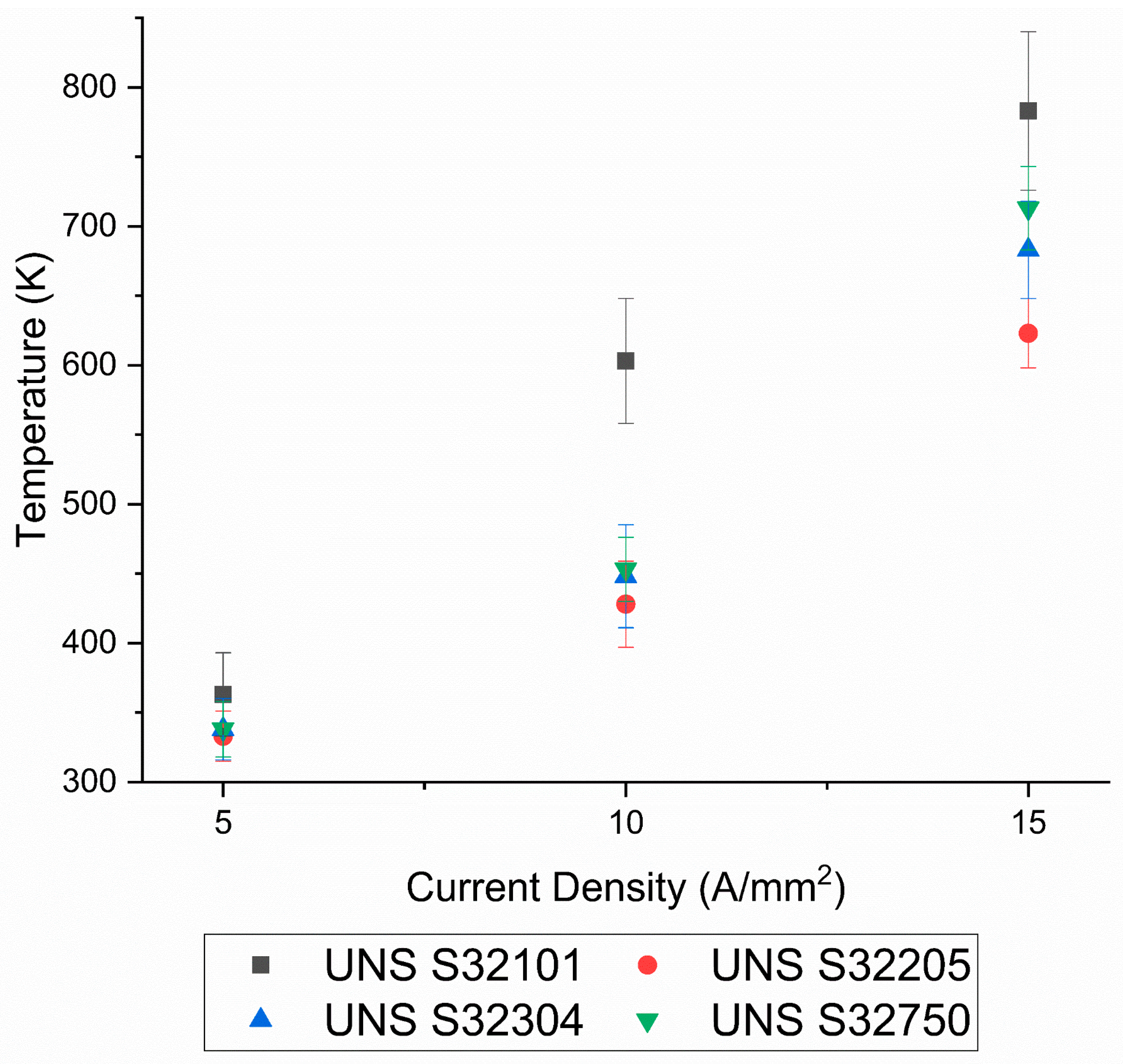

3.2. Temperature and Current Regime

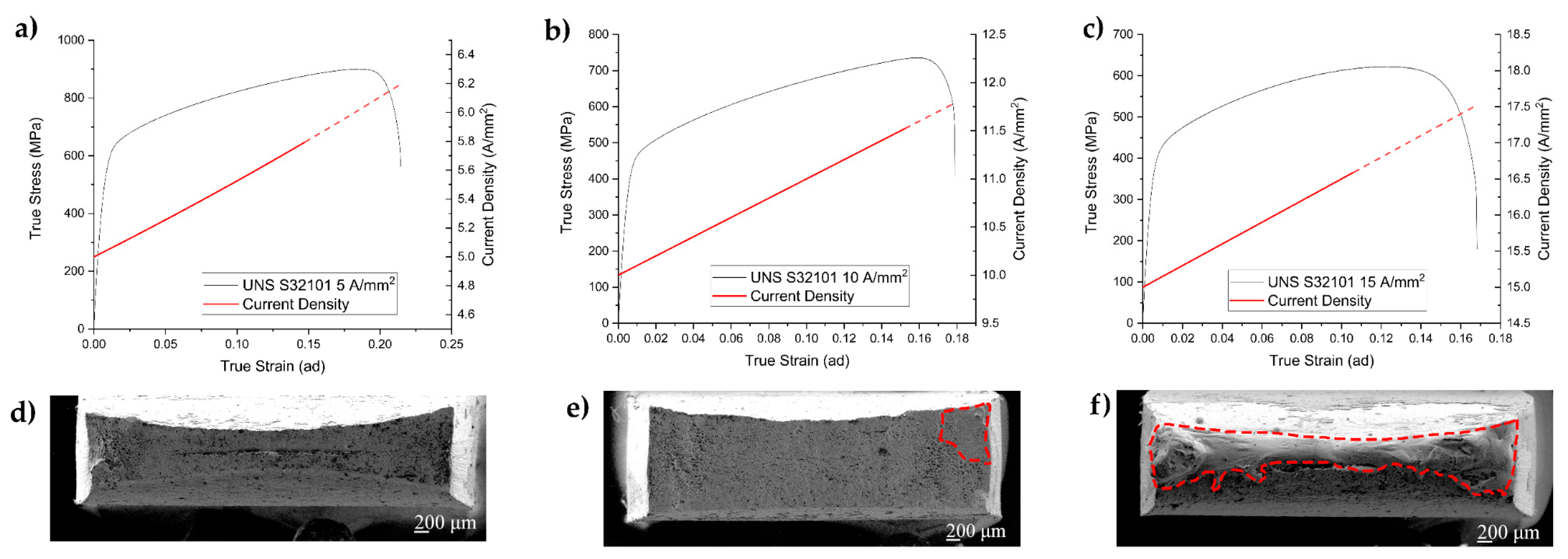

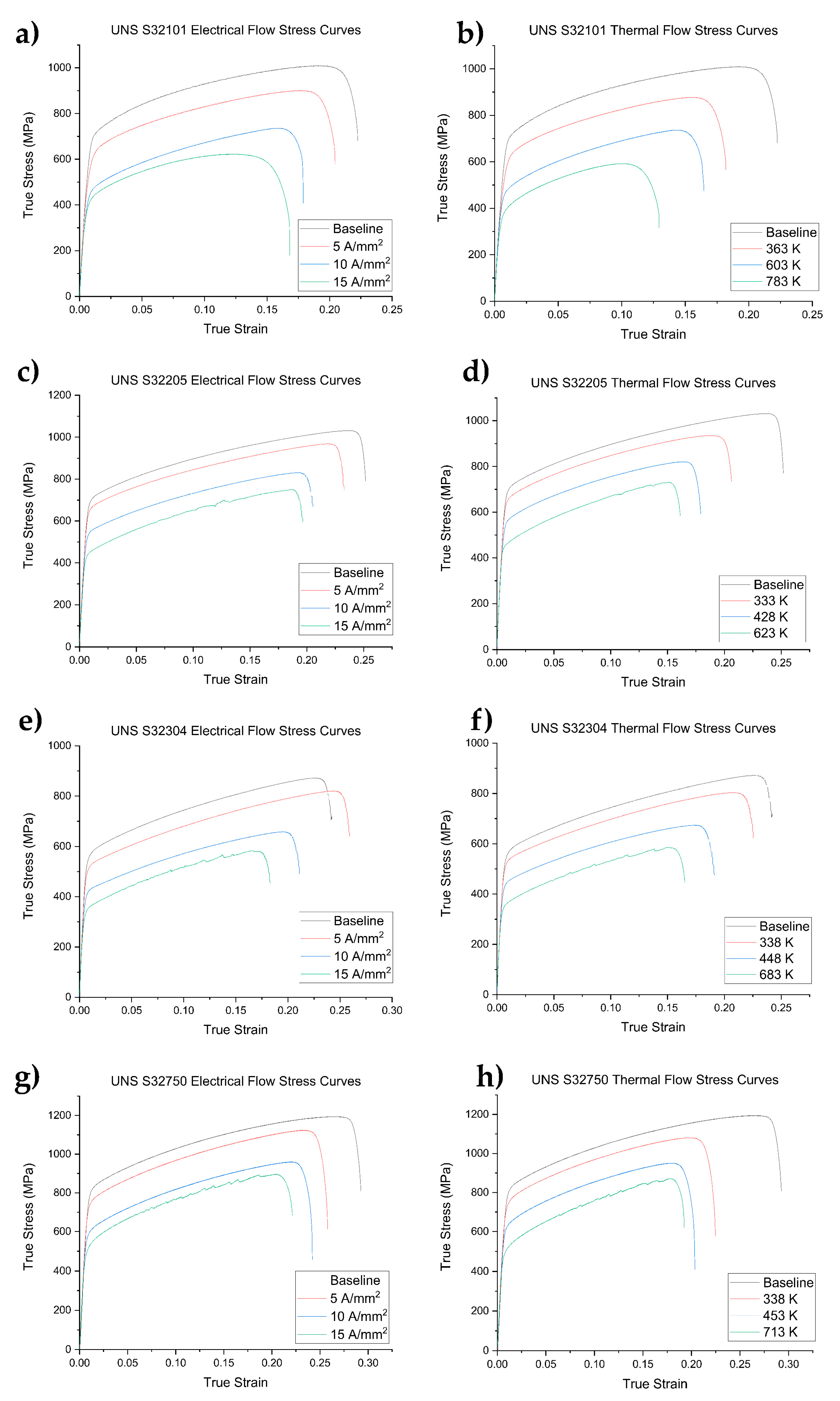

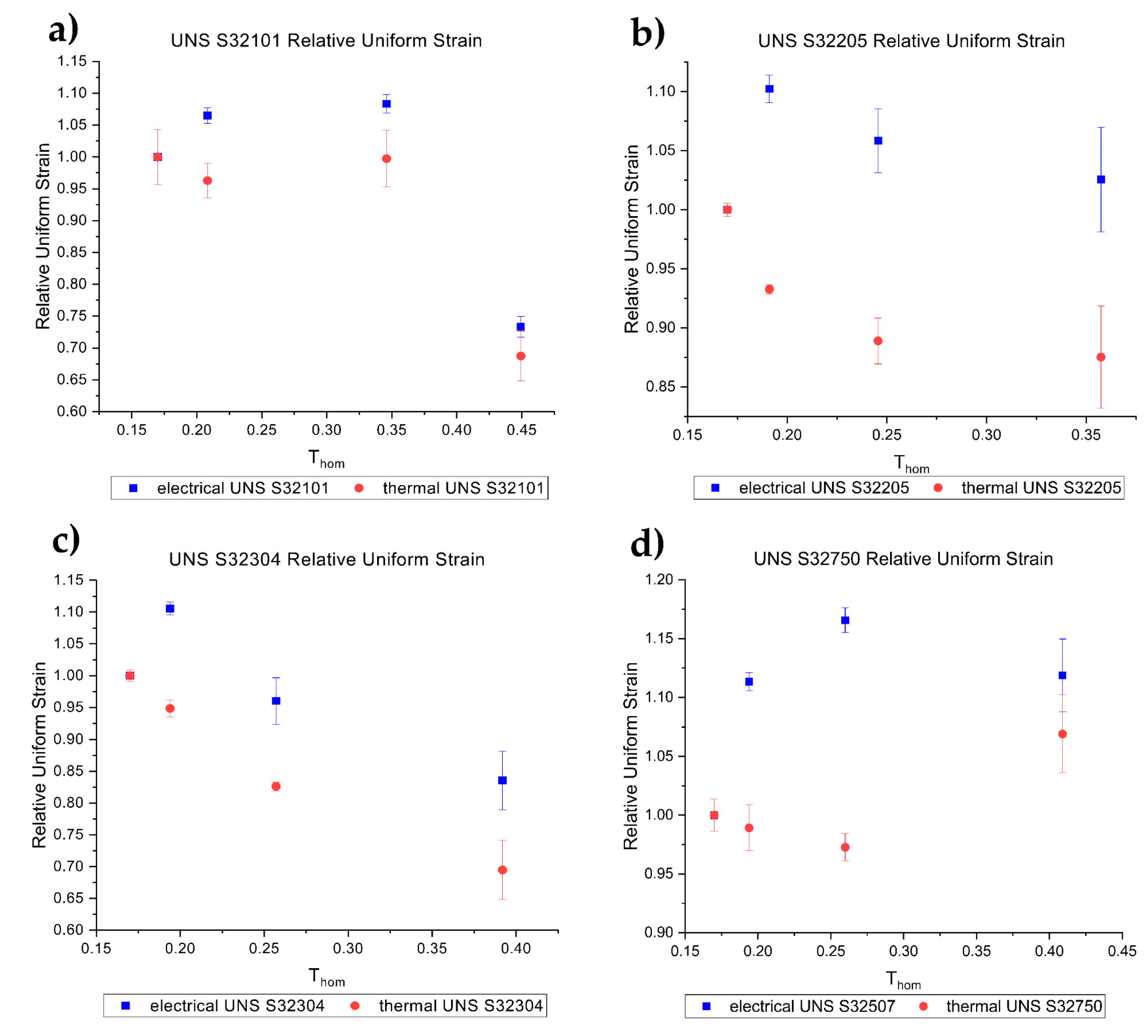

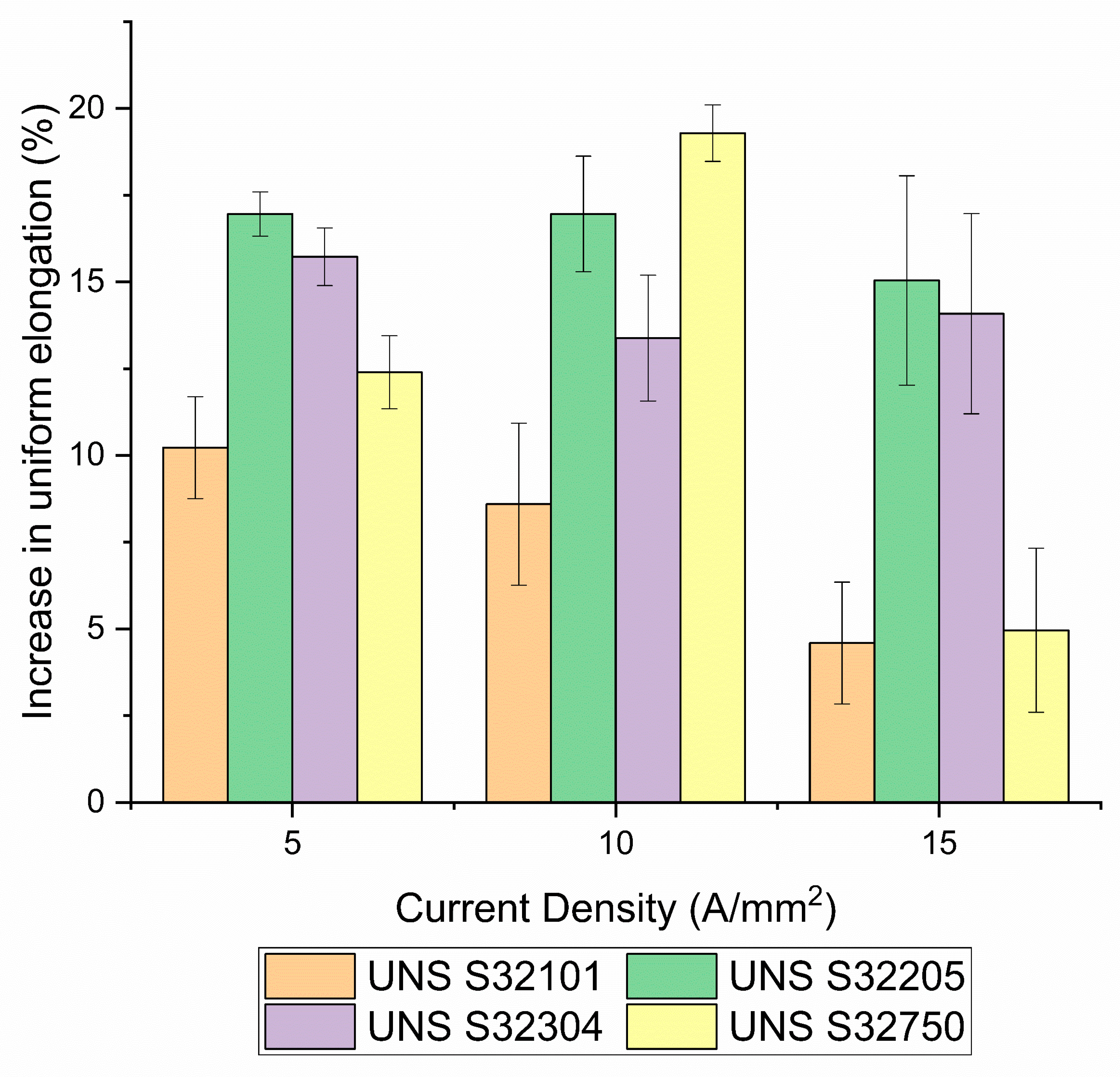

3.3. Mechanical Behavior

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Machlin, E.S. Applied voltage and the plastic properties of “brittle” rock salt. J. Appl. Phys. 1959, 30, 1109–1110. [Google Scholar] [CrossRef]

- Conrad, H.; Sprecher, A.F.; Cao, W.O.; Lu, X.P. The Effect of Electricity on the Mechanical Properties of Metals. J. Miner. Met. Mater. Soc. 1990, 42, 28–33. [Google Scholar] [CrossRef]

- Conrad, H. Effects of electric current on solid state phase transformations in metals. Mater. Sci. Eng. A 2000, 287, 227–237. [Google Scholar] [CrossRef]

- Conrad, H. Influence of an electric or magnetic field on the liquid–solid transformation in materials and on the microstructure of the solid. Mater. Sci. Eng. A 2000, 287, 205–212. [Google Scholar] [CrossRef]

- Conrad, H. A Study into the Mechanism(s) for the Electroplastic Effect in Metals and its Application to Metalworking, Processing and Fatigue; US Army Research Office: Adelphi, MD, USA, 1989. [Google Scholar]

- Sprecher, A.F.; Mannan, S.L.; Conrad, H. Overview no. 49. On the mechanisms for the electroplastic effect in metals. Acta Metall. 1986, 34, 1145–1162. [Google Scholar] [CrossRef]

- Conrad, H. Electroplasticity in metals and ceramics. Mater. Sci. Eng. A 2000, 287, 276–287. [Google Scholar] [CrossRef]

- Troitskii, O.A.; Stashenko, V.I. Electroplastic wire drawing: A promising method of production of lightweight wire and cable. J. Mach. Manuf. Reliab. 2015, 44, 758–765. [Google Scholar] [CrossRef]

- Troitskii, O.A. Electroplastic deformation of metal. Strength Mater. 1976, 8, 1466–1471. [Google Scholar] [CrossRef]

- Troitskii, O.A. The electropalstic effect of metals. Dislocations Solids. 8 Basic Probl. Appl. 1984, 1, 497–540. [Google Scholar]

- Stashenko, V.I.; Troitskii, O.A.; Novikova, N.N. Electroplastic drawing medium-carbon steel. J. Mach. Manuf. Reliab. 2009, 38, 369–372. [Google Scholar] [CrossRef]

- Troitskii, O.A. Effect of the electron state of a metal on its mechanical properties and the phenomenon of electroplasticity. Strength Mater. 1977, 9, 35–45. [Google Scholar] [CrossRef]

- Troitskii, O.A.; Spitsyn, V.I.; Sokolov, N.V.; Ryzhkov, V.G. Application of high-density current in plastic working of metals. Phys. Status Solidi 1979, 52, 85–93. [Google Scholar] [CrossRef]

- Medentsov, V.E.; Stolyarov, V.V. Hardening VT6 alloy by electroplastic rolling. Steel Transl. 2013, 43, 626–629. [Google Scholar] [CrossRef]

- Wang, X.; Sánchez Egea, A.; Xu, J.; Meng, X.; Wang, Z.; Shan, D.; Guo, B.; Cao, J. Current-Induced Ductility Enhancement of a Magnesium Alloy AZ31 in Uniaxial Micro-Tension Below 373 K. Materials 2018, 12, 111. [Google Scholar] [CrossRef] [PubMed]

- Hameed, S.; González Rojas, H.A.; Sánchez Egea, A.; Alberro, A.N. Electroplastic cutting influence on power consumption during drilling process. Int. J. Adv. Manuf. Technol. 2016, 87, 1835–1841. [Google Scholar] [CrossRef] [Green Version]

- Sánchez Egea, A.; González Rojas, H.A.; Montilla Montaña, C.A.; Kallewaard Echeverri, V. Effect of electroplastic cutting on the manufacturing process and surface properties. J. Mater. Process. Technol. 2015, 222, 327–334. [Google Scholar] [CrossRef]

- Sánchez Egea, A.; González-Rojas, H.A.; Montilla-Montaña, C.A.; Kallewaard-Echeverri, V. Turning Process Assisted in situ by Short Time Current Pulses. Procedia Eng. 2015, 132, 507–512. [Google Scholar] [CrossRef] [Green Version]

- Hong, S.T.; Jeong, Y.H.; Chowdhury, M.N.; Chun, D.M.; Kim, M.J.; Han, H.N. Feasibility of electrically assisted progressive forging of aluminum 6061-T6 alloy. Cirp Ann. Manuf. Technol. 2015, 64, 277–280. [Google Scholar] [CrossRef]

- Jones, J.J.; Mears, L.; Roth, J.T. Electrically-Assisted Forming of Magnesium AZ31: Effect of Current Magnitude and Deformation Rate on Forgeability. J. Manuf. Sci. Eng. 2012, 134, 034504. [Google Scholar] [CrossRef]

- Gonzalez-Julian, J.; Guillon, O. Effect of Electric Field/Current on Liquid Phase Sintering. J. Am. Ceram. Soc. 2015, 98, 2018–2027. [Google Scholar] [CrossRef]

- Zapata-Solvas, E.; Gómez-García, D.; Domínguez-Rodríguez, A.; Todd, R.I. Ultra-fast and energy-efficient sintering of ceramics by electric current concentration. Sci. Rep. 2015, 5, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Jordan, A.; Kinsey, B.L. Investigation of thermal and mechanical effects during electrically-assisted microbending. J. Mater. Process. Technol. 2015, 221, 1–12. [Google Scholar] [CrossRef]

- Sánchez Egea, A.; González Rojas, H.A.; Celentano, D.J.; Travieso-Rodríguez, J.A.; Llumà i Fuentes, J. Electroplasticity-assisted bottom bending process. J. Mater. Process. Technol. 2014, 214, 2261–2267. [Google Scholar] [CrossRef]

- Kravchenko, V.Y. Effect of directed electron beam on moving dislocations. Sov. Phys. Jetp 1967, 24, 1135–1142. [Google Scholar]

- Bolko, I.; Geguzin, E.; Klinchuk, I. Drag of dislocations by an electron wind in metals. Zh. Eksp. Teor. Fiz. 1981, 54, 1156–1158. [Google Scholar]

- Okazaki, K.; Kagawa, M.; Conrad, H. An evaluation of the contributions of skin, pinch and heating effects to the electroplastic effect in titatnium. Mater. Sci. Eng. 1980, 45, 109–116. [Google Scholar] [CrossRef]

- Molotskii, M.I. Theoretical basis for electro- and magnetoplasticity. Mater. Sci. Eng. A 2000, 287, 248–258. [Google Scholar] [CrossRef]

- Molotskii, M.I.; Fleurov, V. Magnetic effect in electroplasticity of metals. Phys. Rev. 1995, 52, 829–834. [Google Scholar] [CrossRef]

- Fan, R.; Magargee, J.; Hu, P.; Cao, J. Influence of grain size and grain boundaries on the thermal and mechanical behavior of 70/30 brass under electrically-assisted deformation. Mater. Sci. Eng. A 2013, 574, 218–225. [Google Scholar] [CrossRef]

- Magargee, J.; Fan, R.; Cao, J. Analysis and Observations of Current Density Sensitivity and Thermally Activated Mechanical Behavior in Electrically-Assisted Deformation. J. Manuf. Sci. Eng. 2013, 135, 061022. [Google Scholar] [CrossRef]

- Breda, M.; Calliari, I.; Bruschi, S.; Forzan, M.; Ghiotti, A.; Michieletto, F.; Spezzapria, M.; Gennari, C. Influence of stacking fault energy in electrically assisted uniaxial tension of FCC metals. Mater. Sci. Technol. 2017, 33, 317–325. [Google Scholar] [CrossRef]

- Ruszkiewicz, B.J.; Mears, L.; Roth, J.T. Investigation of Heterogeneous Joule Heating as the Explanation for the Transient Electroplastic Stress Drop in Pulsed Tension of 7075-T6 Aluminum. J. Manuf. Sci. Eng. 2018, 140, 091014. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.Y.; Zhang, K.F. Influence of electric current on superplastic deformation mechanism of 5083 aluminium alloy. Mater. Sci. Technol. 2016, 32, 540–546. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, Y.; Ma, B.; Zhang, M. Rapid precipitation of T-phase in the 2024 aluminum alloy via cyclic electropulsing treatment. J. Alloy. Compd. 2014, 610, 506–510. [Google Scholar] [CrossRef]

- Ghiotti, A.; Bruschi, S.; Simonetto, E.; Gennari, C.; Calliari, I.; Bariani, P. Electroplastic effect on AA1050 aluminium alloy formability. Cirp Ann. 2018, 67, 4–7. [Google Scholar] [CrossRef]

- Kuang, J.; Li, X.; Ye, X.; Tang, J.; Liu, H.; Wang, J.; Tang, G. Microstructure and Texture Evolution of Magnesium Alloys During Electropulse Treatment. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 46, 1789–1804. [Google Scholar] [CrossRef]

- Jeong, H.J.; Kim, M.J.; Park, J.W.; Yim, C.D.; Kim, J.J.; Kwon, O.D.; Madakashira, P.P.; Han, H.N. Effect of pulsed electric current on dissolution of Mg 17 Al 12 phases in as-extruded AZ91 magnesium alloy. Mater. Sci. Eng. A 2017, 684, 668–676. [Google Scholar] [CrossRef]

- Kuang, J.; Low, T.S.E.; Niezgoda, S.R.; Li, X.; Geng, Y.; Luo, A.A.; Tang, G. Abnormal texture development in magnesium alloy Mg-3Al-1Zn during large strain electroplastic rolling: Effect of pulsed electric current. Int. J. Plast. 2016, 87, 86–99. [Google Scholar] [CrossRef]

- Breda, M.; Michieletto, F.; Beridze, E.E.E.; Gennari, C. Experimental Study on Electroplastic Effect in AISI 316L Austenitic Stainless Steel. Appl. Mech. Mater. 2015, 792, 568–571. [Google Scholar] [CrossRef]

- Tang, G.; Zhang, J.; Zheng, M.; Zhang, J.; Fang, W.; Li, Q. Experimental study of electroplastic effect on stainless steel wire 304L. Mater. Sci. Eng. A 2000, 281, 263–267. [Google Scholar] [CrossRef]

- Sánchez Egea, A.; Peiró, J.J.; Signorelli, J.W.; González Rojas, H.A.; Celentano, D.J. On the microstructure effects when using electropulsing versus furnace treatments while drawing inox 308L. J. Mater. Res. Technol. 2019, 8, 2269–2279. [Google Scholar] [CrossRef]

- Ulutan, D.; Pleta, A.; Mears, L. Electrically-Assisted Machining of Titanium Alloy Ti-6Al-4V and Nickel-Based Alloy IN-738: An Investigation. In Proceedings of the ASME 2015 International Manufacturing Science and Engineering Conference, Charlotte, NC, USA, 8–12 June 2015. [Google Scholar] [CrossRef]

- Xie, H.; Dong, X.; Liu, K.; Ai, Z.; Peng, F.; Wang, Q.; Chen, F.; Wang, J. Experimental investigation on electroplastic effect of DP980 advanced high strength steel. Mater. Sci. Eng. A 2015, 637, 23–28. [Google Scholar] [CrossRef]

- Rahnama, A.; Qin, R. Room temperature texturing of austenite/ferrite steel by electropulsing. Sci. Rep. 2017, 7, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Gunn, N.R. Duplex Stainless Steels; Woodhead Publishing: Sawston & Cambridge, UK, 1997; ISBN 9781884207617. [Google Scholar]

- Nilsson, J.O. Super Duplex Stainless-Steels. Mater. Sci. Technol. 1992, 8, 685–700. [Google Scholar] [CrossRef]

- Nilsson, J.O. The physical metallurgy of duplex stainless steels. In Duplex Stainless Steels; Nilsson, J.O., Ed.; KCI Publishing: Maastricht, The Netherlands, 1997; pp. 73–82. [Google Scholar]

- Iza-Mendia, A.; Piñol-Juez, A.; Gutiérrez, I.; Urcola, J.J. Study of the Role of the Interface Coherence on the Hot Deformation Behaviour of Duplex Stainless Steels. Key Eng. Mater. 1997, 127–131, 1033–1042. [Google Scholar] [CrossRef]

- Haghdadi, N.; Cizek, P.; Hodgson, P.D.; Tari, V.; Rohrer, G.S.; Beladi, H. Effect of ferrite-to-austenite phase transformation path on the interface crystallographic character distributions in a duplex stainless steel. Acta Mater. 2018, 145, 196–209. [Google Scholar] [CrossRef]

- Gennari, C.; Pezzato, L.; Piva, E.; Gobbo, R.; Calliari, I. Influence of small amount and different morphology of secondary phases on impact toughness of UNS S32205 Duplex Stainless Steel. Mater. Sci. Eng. A 2018, 729, 149–156. [Google Scholar] [CrossRef]

- Breda, M.; Calliari, I.; Ramous, E.; Pizzo, M.; Corain, L.; Straffelini, G. Ductile-to-brittle transition in a Zeron© 100 SDSS in wrought and aged conditions. Mater. Sci. Eng. A 2013, 585, 57–65. [Google Scholar] [CrossRef]

- Chan, K.W.; Tjong, S.C. Effect of secondary phase precipitation on the corrosion behavior of duplex stainless steels. Materials 2014, 7, 5268. [Google Scholar] [CrossRef]

- Pezzato, L.; Lago, M.; Brunelli, K.; Breda, M.; Calliari, I. Effect of the Heat Treatment on the Corrosion Resistance of Duplex Stainless Steels. J. Mater. Eng. Perform. 2018, 27, 3859–3868. [Google Scholar] [CrossRef]

- Rémy, L.; Pineau, A.; Thomas, B. Temperature dependence of stacking fault energy in close-packed metals and alloys. Mater. Sci. Eng. 1978, 36, 47–63. [Google Scholar] [CrossRef]

- Liu, X.; Lan, S.; Ni, J. Experimental study of Electro-Plastic Effect on Advanced High Strength Steels. Mater. Sci. Eng. A 2013, 582, 211–218. [Google Scholar] [CrossRef]

- Breda, M.; Brunelli, K.; Grazzi, F.; Scherillo, A.; Calliari, I. Effects of Cold Rolling and Strain-Induced Martensite Formation in a SAF 2205 Duplex Stainless Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 46, 577–586. [Google Scholar] [CrossRef]

- Taylor, G.I.; Quinney, H. The Latent Energy Remaining in a Metal after Cold Working. Proc. R. Soc. A Math. Phys. Eng. Sci. 1934, 143, 307–326. [Google Scholar] [CrossRef]

- Alvarez-Armas, I.; Degallaix-Moreuil, S. Duplex Stainless Steels; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; ISBN 978-1-848-21137-7. [Google Scholar]

- Herenu, S.; Alvarez-Armas, I.; Armas, A.F. The influence of dynamic strain aging on the low cycle fatigue of duplex stainless steel. Scr. Mater. 2001, 45, 739–745. [Google Scholar] [CrossRef]

- Fang, Y.L.; Liu, Z.Y.; Song, H.M.; Jiang, L.Z. Hot deformation behavior of a new austenite-ferrite duplex stainless steel containing high content of nitrogen. Mater. Sci. Eng. A 2009, 526, 128–133. [Google Scholar] [CrossRef]

- Bannister, A.C.; Ruiz Ocejo, J.; Gutierrez-Solana, F. Implications of the yield stress/tensile stress ratio to the SINTAP failure assessment diagrams for homogeneous materials. Eng. Fract. Mech. 2000, 67, 547–562. [Google Scholar] [CrossRef]

- Ma, B.; Shuai, J. Influence of Plastic Deformation Capacity on Failure Behavior of Pipelines. J. Fail. Anal. Prev. 2018, 18, 508–518. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, G.X.; Dong, Y.; Ye, C. Multiscale modeling of localized resistive heating in nanocrystalline metals subjected to electropulsing. J. Appl. Phys. 2017, 122. [Google Scholar] [CrossRef]

- Bohnenkamp, U.; Sandström, R.; Grimvall, G. Electrical resistivity of steels and face-centered-cubic iron. J. Appl. Phys. 2002, 92, 4402–4407. [Google Scholar] [CrossRef]

- Peng, R.L.; Gibmeier, J.; Eulert, S.; Johansson, S.; Chai, G.C. In Situ X-Ray Diffraction Study of Load Partitioning and Microyielding for the Super Duplex Stainless Steel SAF2507 (UNS S32750). Mater. Sci. Forum 2006, 524–525, 847–852. [Google Scholar] [CrossRef]

- Zheng, Y.S.; Tang, G.Y.; Kuang, J.; Zheng, X.P. Effect of electropulse on solid solution treatment of 6061 aluminum alloy. J. Alloy. Compd. 2014, 615, 849–853. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | Mo | N | P | S | Cu | Ti | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS S32101 | 0.025 | 0.65 | 5.13 | 21.57 | 1.56 | 0.28 | 0.229 | 0.019 | 0.001 | 0.3 | - |

| UNS S32304 | 0.03 | 0.56 | 1.43 | 23.17 | 4.29 | 0.18 | 0.13 | 0.027 | 0.001 | 0.16 | - |

| UNS S32205 | 0.027 | 0.58 | 1.52 | 22.75 | 5.04 | 3.19 | 0.16 | 0.027 | 0.001 | - | - |

| UNS S32705 | 0.014 | 0.35 | 0.68 | 24.99 | 3.63 | 6.41 | 0.253 | 0.021 | 0.001 | 0.06 | 0.002 |

| DSS Grade | Austenite | Ferrite |

|---|---|---|

| UNS S32101 | 0.51 ± 0.02 | 0.49 ± 0.03 |

| UNS S32205 | 0.53 ± 0.03 | 0.47 ± 0.04 |

| UNS S32304 | 0.51 ± 0.01 | 0.49 ± 0.02 |

| UNS S32750 | 0.48 ± 0.04 | 0.52 ± 0.05 |

| DSS Grade | Current Density (A/mm2) | Mean Temperature (K) | Homologous Temperature (ad) |

|---|---|---|---|

| UNS S32101 | 5 | 363 | 0.21 |

| 10 | 603 | 0.35 | |

| 15 | 783 | 0.45 | |

| UNS S32205 | 5 | 333 | 0.19 |

| 10 | 428 | 0.25 | |

| 15 | 623 | 0.36 | |

| UNS S32304 | 5 | 338 | 0.19 |

| 10 | 448 | 0.26 | |

| 15 | 683 | 0.39 | |

| UNS S32750 | 5 | 338 | 0.19 |

| 10 | 453 | 0.26 | |

| 15 | 713 | 0.41 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gennari, C.; Pezzato, L.; Simonetto, E.; Gobbo, R.; Forzan, M.; Calliari, I. Investigation of Electroplastic Effect on Four Grades of Duplex Stainless Steels. Materials 2019, 12, 1911. https://doi.org/10.3390/ma12121911

Gennari C, Pezzato L, Simonetto E, Gobbo R, Forzan M, Calliari I. Investigation of Electroplastic Effect on Four Grades of Duplex Stainless Steels. Materials. 2019; 12(12):1911. https://doi.org/10.3390/ma12121911

Chicago/Turabian StyleGennari, Claudio, Luca Pezzato, Enrico Simonetto, Renato Gobbo, Michele Forzan, and Irene Calliari. 2019. "Investigation of Electroplastic Effect on Four Grades of Duplex Stainless Steels" Materials 12, no. 12: 1911. https://doi.org/10.3390/ma12121911

APA StyleGennari, C., Pezzato, L., Simonetto, E., Gobbo, R., Forzan, M., & Calliari, I. (2019). Investigation of Electroplastic Effect on Four Grades of Duplex Stainless Steels. Materials, 12(12), 1911. https://doi.org/10.3390/ma12121911