Study on ASJ Cutting of TC18, Based upon Multivariate Nonlinear Regression and SA-BP-AGA

Abstract

:1. Introduction

2. Experiment

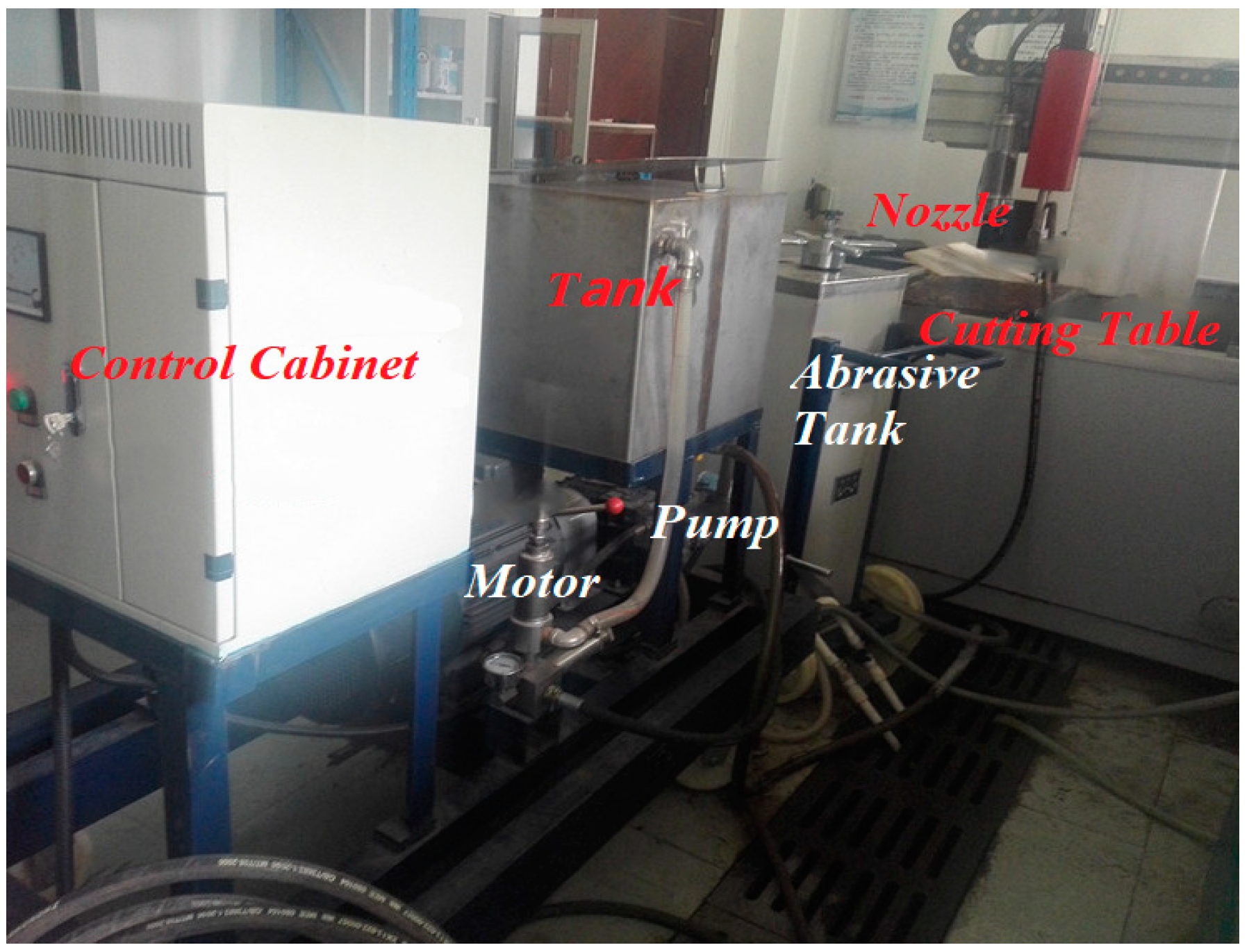

2.1. Experimental System

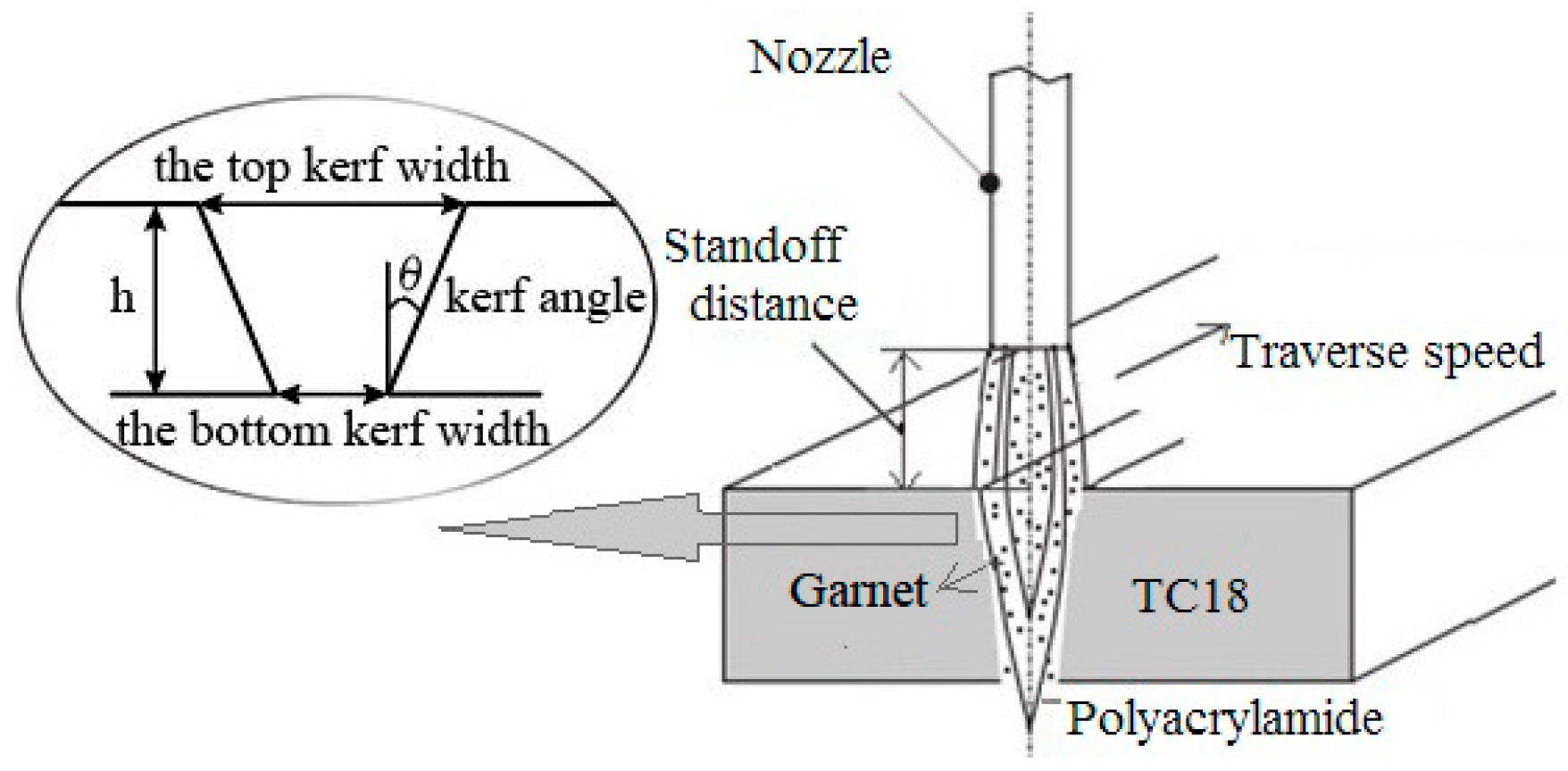

2.2. Experimental Scheme

2.3. Experimental Results

3. Predictive Model of Kerf Angle based on Multivariate Nonlinear Regression Modeling

3.1. Methodology

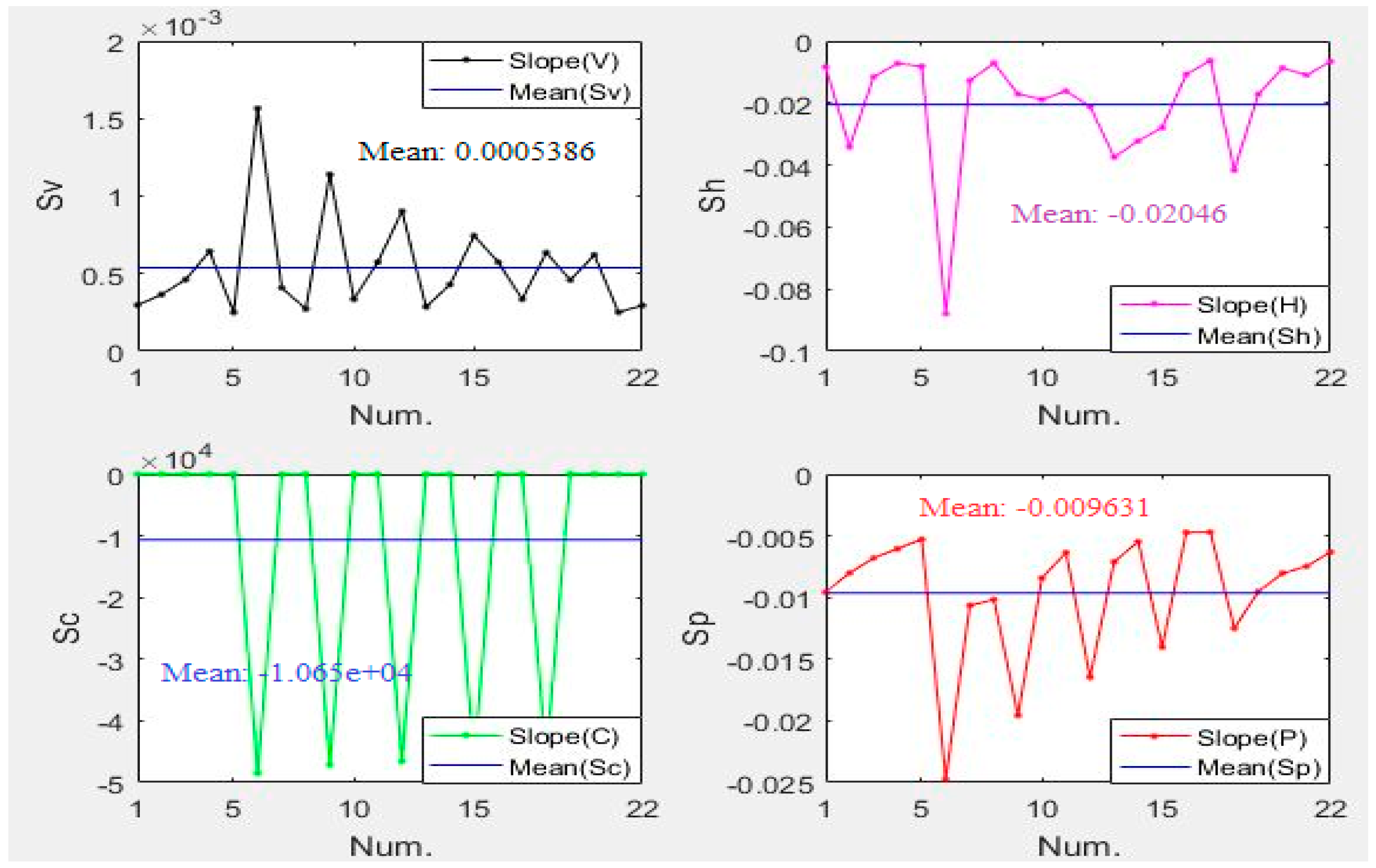

3.2. The Regression Model of Kerf Angle

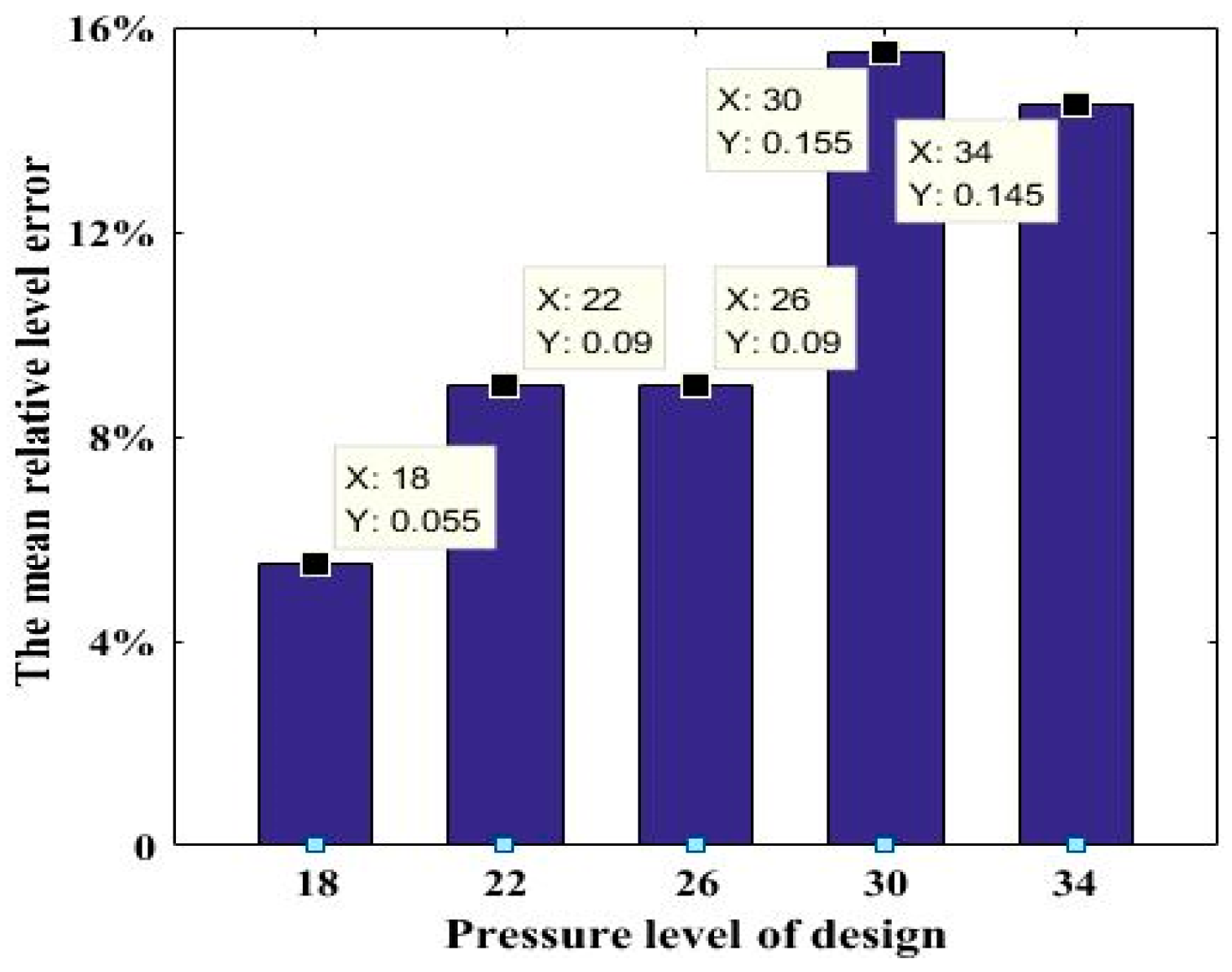

3.3. Analysis of Main Influencing Factors

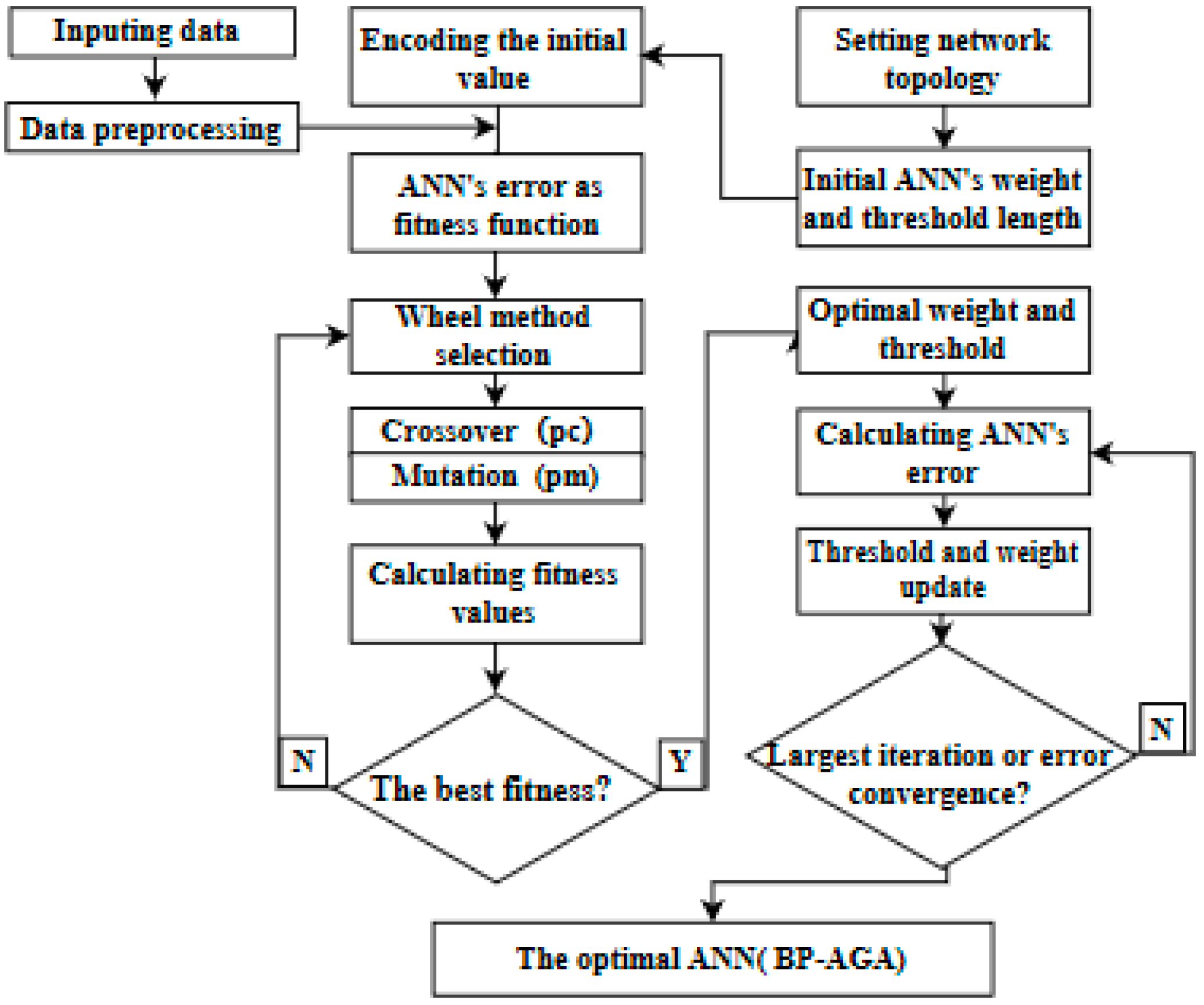

4. Predictive Model of Kerf Angle Based on ANN-AGA

4.1. Methodology

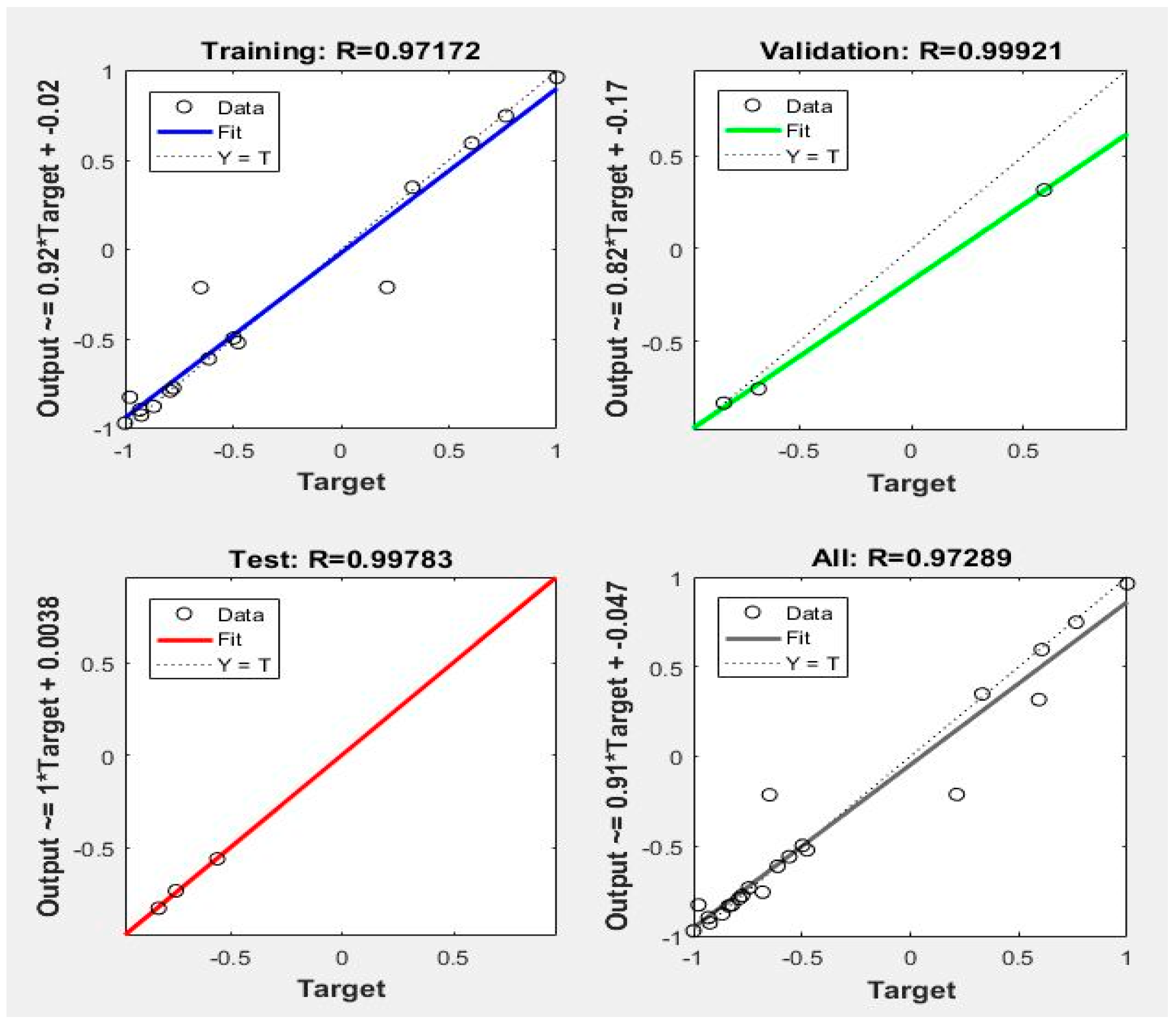

4.2. Neural Network Optimized by Adaptive Genetic Algorithm Based on Kerf Angle

5. Comparison of the Two Analysis Methods

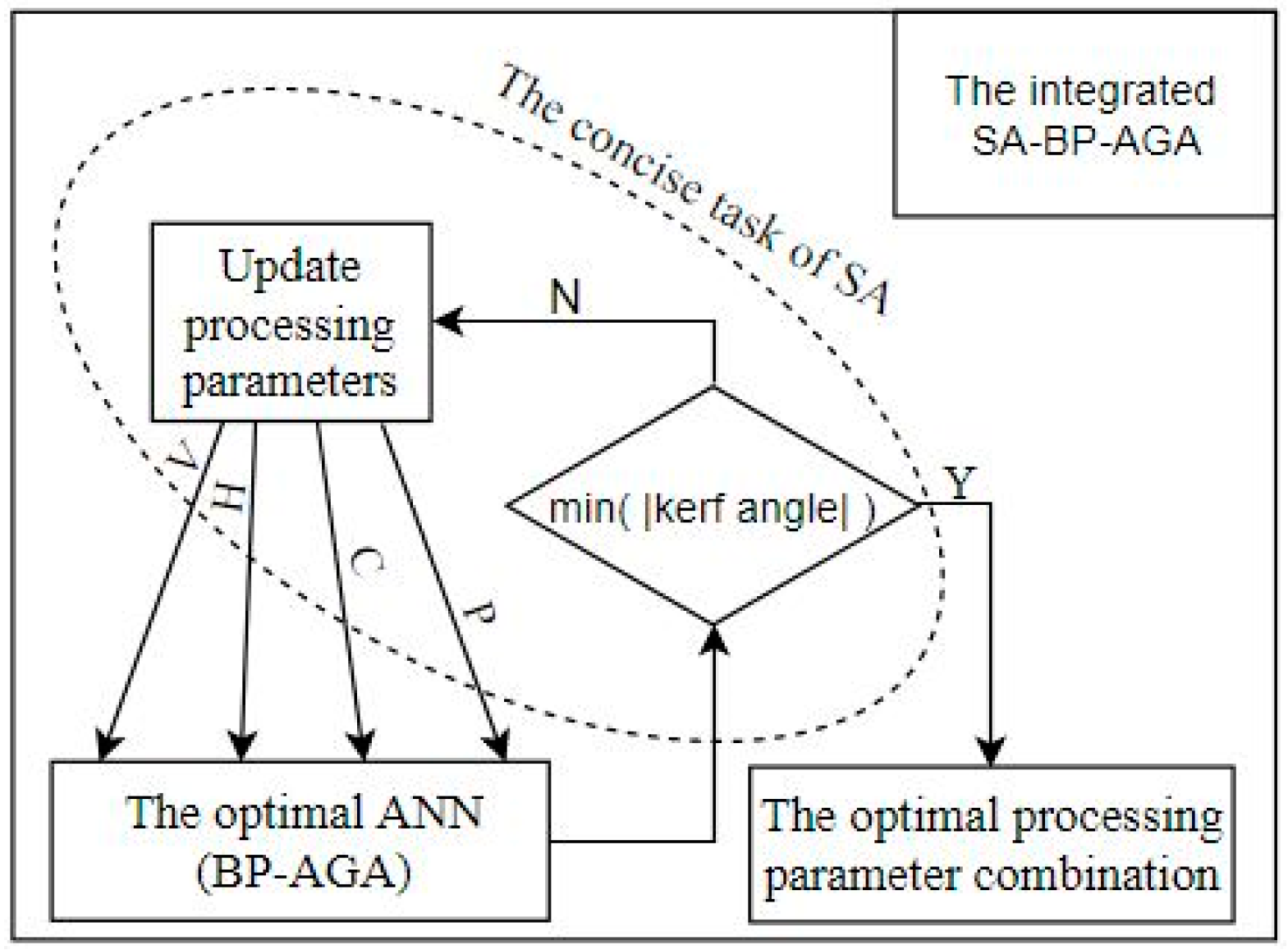

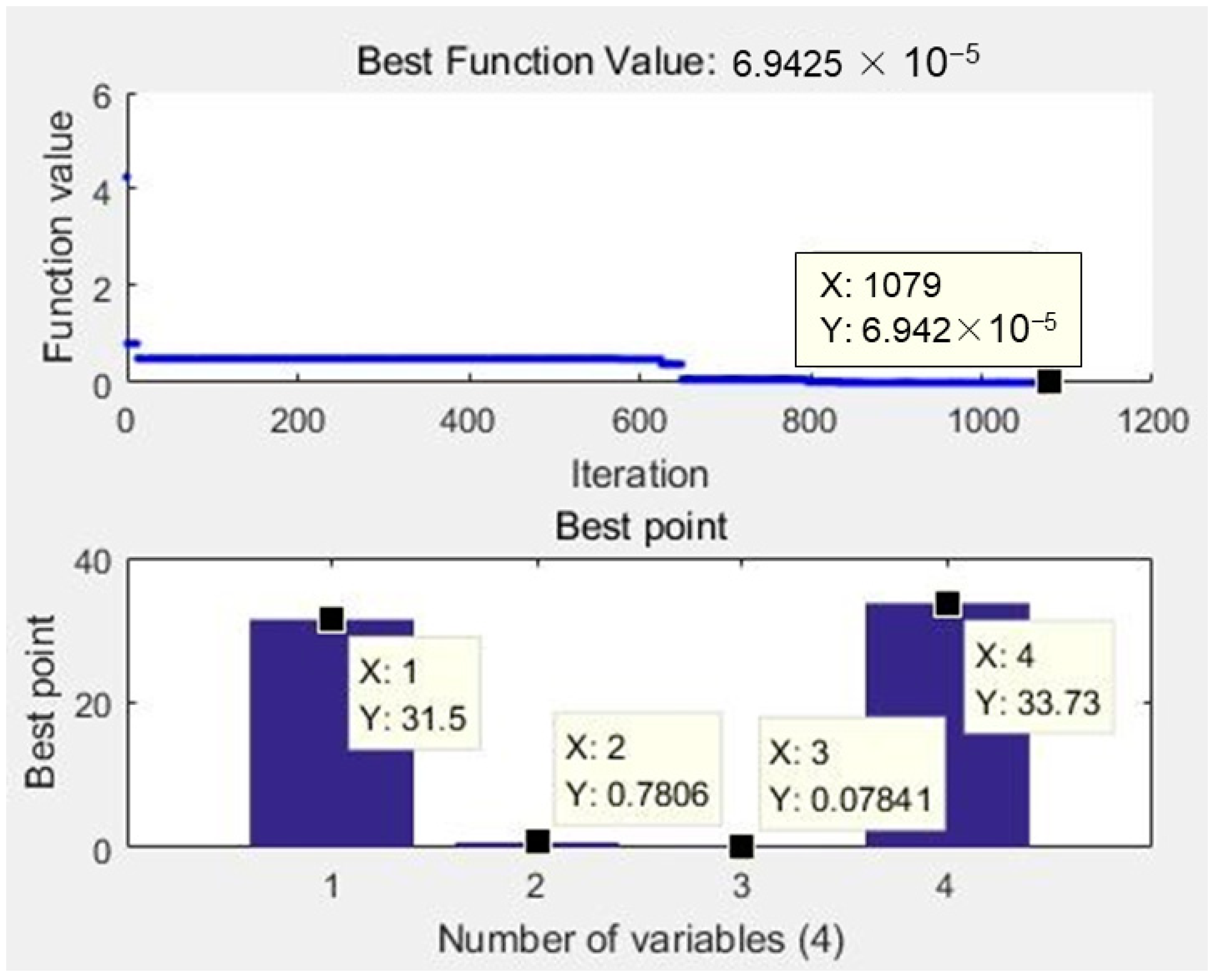

6. The Integrated SA-BP-AGA Optimization

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ulutan, D.; Ozel, T. Machining induced surface integrity in Titanium and Nickel Alloys: A review. Int. J. Mach. Tool Manuf. 2011, 51, 250–280. [Google Scholar] [CrossRef]

- Boyer, P.R.; Briggs, R.D. The use of β Titanium Alloys in the Aerospace Industry. J. Mater. Eng. Perform. 2005, 14, 681–685. [Google Scholar] [CrossRef]

- Vargas Pérez, R.G. Wear mechanisms of WC inserts on face milling of gamma titanium aluminides. Wear 2005, 259, 1160–1167. [Google Scholar] [CrossRef]

- Mitchell, A. Melting, Casting and forging problems in titanium alloys. Mater. Sci. Eng. 1998, 243, 257–262. [Google Scholar] [CrossRef]

- Lei, S.T.; Liu, W.J. High-speed machining of titanium alloys using the driven rotary tool. Int. J. Mach. Tool Manuf. 2002, 42, 653–661. [Google Scholar] [CrossRef]

- Nabhani, F. Machining of aerospace titanium alloys. Robot. Comput. Integr. Manuf. 2001, 17, 99–106. [Google Scholar] [CrossRef]

- Novovic, D.; Dewes, R.C. The effect of machined topography and integrity on fatigue life. Int. J. Mach. Tool Manuf. 2004, 44, 125–134. [Google Scholar] [CrossRef]

- Che-Haron, C.H. Tool life and surface integrity in turning titanium alloy. J. Mater. Process. Technol. 2001, 118, 231–237. [Google Scholar] [CrossRef]

- Wang, J.J.; Guo, H.Z.; Liang, H.Q.; Zhao, Z.L. Study of TC18 alloy forging process parameters based on BP neural network. Hot Working Technol. 2014, 43, 1–6. [Google Scholar]

- Liu, X.Z.; Tao, H.; Li, M.W. Optimization of parameters for milling titanium alloy TC18 with improve genetic algorithm. Modul. Mach. Tool Autom. Manuf. Tech. 2010, 5, 41–43. [Google Scholar]

- Qi, H.; Wen, D.H.; Yuan, Q.L. Numerical investigation on particle influence erosion in ultrasonic-assisted abrasive slurry jet micro-machining of glasses. Powder Technol. 2017, 314, 627–634. [Google Scholar] [CrossRef]

- Wang, J.; Kuriyagawa, T.; Huang, C. An experimental study to enhance the cutting performance in abrasive waterjet machining. Mach. Sci. Technol. 2003, 7, 191–207. [Google Scholar] [CrossRef]

- Aznrir, M.A.; Ahsan, A.K. A study of abrasive water jet machining process on glass/epoxy composite laminate. J. Mater. Process. Technol. 2009, 209, 6168–6173. [Google Scholar] [CrossRef]

- Alberdi, A.; Rivero, A.; Lacalle, L.N.L. Effect of process parameter on the kerf geometry in abrasive water jet milling. Int. J. Adv. Manuf. Technol. 2010, 5, 467–480. [Google Scholar] [CrossRef]

- Feng, D.C.; Shi, L.L.; Guo, C.W.; Wang, F.C.; Chen, Y.Q. Numerical and experimental study on the flow characteristics of abrasive slurry jet with polymer additives. Int. J. Adv. Manuf. Technol. 2018, 95, 3289–3299. [Google Scholar] [CrossRef]

- Wang, F.C.; Xu, Q.W.; Feng, D.C.; Guo, C.W. Experiment study on performance of abrasive slurry jet with or without high polymer in stainless steel machining. Int. J. Adv. Manuf. Technol. 2018, 95, 2449–2456. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Maruda, R.W.; Krolczyk, G.M.; Niesłony, P. Application of signal to noise ratio and grey relational analysis to minimize forces and vibrations during precise ball end milling. Precis. Eng. 2017, 51, 582–596. [Google Scholar] [CrossRef]

- Karabulut, S. Optimization of surface roughness and cutting force during AA7039/Al2O3 metal matrix composites milling using neural networks and Taguchi method. Measurement 2015, 66, 139–149. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Maruda, R.W.; Barrans, S.; Nieslony, P.; Krolczyk, G.M. Optimisation of machining parameters during ball end milling of hardened steel with various surface inclinations. Measurement 2017, 111, 18–28. [Google Scholar] [CrossRef] [Green Version]

- Azlan, M.Z.; Habibollah, H.; Safian, S. Optimization of process parameters in the abrasive waterjet machining using integrated SA-GA. Appl. Soft Comput. 2010, 11, 5350–5359. [Google Scholar] [CrossRef]

- Srinivasu, D.S.; Ramesh, B.N. A neuro-genetic approach for selection of process parameters in abrasive waterjet cutting considering variation in diameter of focusing nozzle. Appl. Soft Comput. 2008, 8, 809–819. [Google Scholar] [CrossRef]

- Durakbasa, M.N.; Akdogan, A.; Vanli, A.S.; Bulutsuz, A.G. Optimization of end milling parameters and determination of the effects of edge profile for high surface quality of AISI H13 steel by using precise and fast measurements. Measurement 2015, 68, 92–99. [Google Scholar] [CrossRef]

- Caydas, U.; Hascalik, A. A study on surface roughness in abrasive waterjet machining process using artificial neural networks and regression analysis method. J. Mater. Process. Technol. 2008, 202, 574–582. [Google Scholar] [CrossRef]

- Wibowo, A. Hybrid kernel principal component regression and penalty strategy of multiple adaptive genetic algorithms for estimating optimum parameters in abrasive waterjet machining. Appl. Soft Comput. 2018, 62, 1102–1112. [Google Scholar] [CrossRef]

- Steinbrunn, M.; Moerkotte, G.; Kemper, A. Heuristic and randomized optimization for the Join Ordering Problem. VLDB J. 1997, 6, 8–17. [Google Scholar] [CrossRef]

| Number | Variables | L1 | L2 | L3 | L4 | L5 |

|---|---|---|---|---|---|---|

| 1 | Traverse speed V (mm/min) | 30 | 40 | 50 | 60 | 70 |

| 2 | Standoff distance H (mm) | 0.5 | 1 | 1.5 | 2 | 2.5 |

| 3 | Slurry concentration C (%) | 0 | 0.05 | 0.1 | 0.15 | 0.2 |

| 4 | System pressure P (MPa) | 18 | 22 | 26 | 30 | 34 |

| Invariables | Values |

|---|---|

| Material size | 200 × 30 × 5 (mm3) |

| Nozzle diameter | 1.0 (mm) |

| Volume fraction of abrasive | 20% |

| High Polymer | PAM |

| Average diameter of abrasive | 0.27 (mm) or 80 (mesh) |

| Abrasive material type | garnet |

| Angle of influence | 0 (degree) |

| NO. | Operating Variables | Result | ||||||

|---|---|---|---|---|---|---|---|---|

| V | H | C | P | Actual P | Top Kerf Width (mm) | Bottom Kerf Width (mm) | Kerf Angle (°) | |

| 1 | 1 | 1 | 1 | 1 | 18.1 | 0.880234 | 0.51703 | 4.1547 |

| 2 | 2 | 2 | 4 | 18.4 | 0.901138 | 0.752207 | 1.7061 | |

| 3 | 3 | 3 | 2 | 18.3 | 0.940592 | 0.820456 | 1.3764 | |

| 4 | 4 | 4 | 5 | 17.8 | 0.896659 | 0.708886 | 2.1507 | |

| 5 | 5 | 5 | 3 | 17.9 | 1.013852 | 0.867836 | 1.6727 | |

| 6 | 1 | 4 | 3 | 2 | 22.1 | 1.027128 | 0.852151 | 2.0043 |

| 7 | 2 | 5 | 1 | 22.2 | 1.003986 | 0.516018 | 5.574 | |

| 8 | 3 | 1 | 4 | 21.7 | 0.913358 | 0.732508 | 2.0715 | |

| 9 | 4 | 2 | 2 | 22.8 | 0.909006 | 0.77915 | 1.4877 | |

| 10 | 5 | 3 | 5 | 22.4 | 0.908018 | 0.767484 | 1.61 | |

| 11 | 1 | 2 | 5 | 3 | 25.9 | 0.901708 | 0.785861 | 1.3273 |

| 12 | 2 | 3 | 3 | 25.9 | 0.940733 | 0.59944 | 3.9049 | |

| 13 | 3 | 4 | 1 | 26.1 | 0.958826 | 0.514941 | 5.0732 | |

| 14 | 4 | 5 | 4 | 26.7 | 0.999784 | 0.786822 | 2.4389 | |

| 15 | 5 | 1 | 2 | 26.8 | 0.925032 | 0.767567 | 1.8038 | |

| 16 | 1 | 5 | 2 | 4 | 30.5 | 1.048323 | 0.919693 | 1.4737 |

| 17 | 2 | 1 | 5 | 30 | 0.923354 | 0.768629 | 1.7725 | |

| 18 | 3 | 2 | 3 | 30.6 | 0.979514 | 0.822616 | 1.7973 | |

| 19 | 4 | 3 | 1 | 30.4 | 0.946768 | 0.532342 | 4.7381 | |

| 20 | 5 | 4 | 4 | 31.6 | 0.996658 | 0.798935 | 2.2646 | |

| 21 | 1 | 3 | 4 | 5 | 34.8 | 1.027287 | 0.864021 | 1.8702 |

| 22 | 2 | 4 | 2 | 33.5 | 0.965137 | 0.852903 | 1.2859 | |

| 23 | 3 | 5 | 5 | 34.1 | 0.991862 | 0.782701 | 2.3954 | |

| 24 | 4 | 1 | 3 | 35.4 | 0.927152 | 0.855971 | 0.8156 | |

| 25 | 5 | 2 | 1 | 33.9 | 0.960782 | 0.54892 | 4.709 | |

| Model | Fitting or Training Quality | ||

|---|---|---|---|

| MSE | MAPE (%) | R2 | |

| Regression | 0.3647 | 19.5027 | 0.9558 |

| network | 0.0987 | 6.0343 | 0.9881 |

| Model | Number | Prediction Quality | ||||

|---|---|---|---|---|---|---|

| 18 | 22 | 24 | MSE | MAPE (%) | R2 | |

| Regression | 1.9460 | 2.0897 | 1.9359 | 0.6415 | 69.4384 | 0.8383 |

| network | 1.8161 | 1.2147 | 0.8946 | 0.0039 | 5.4244 | 0.9979 |

| experiment | 1.7973 | 1.2859 | 0.8156 | |||

| Parameters | Setting Value/Function Type |

|---|---|

| Objective limit | 1 × 10−4 |

| Annealing function | Boltzmann annealing |

| Reannealing interval | 100 |

| Temperature update function | Exponential temperature |

| Initial temperature | 100 |

| Acceptance probability function | Simulated annealing acceptance |

| Data type | Double |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.; Zhou, X.; Zhang, H.; Wang, F.; Xu, Q.; Guo, C. Study on ASJ Cutting of TC18, Based upon Multivariate Nonlinear Regression and SA-BP-AGA. Materials 2019, 12, 1902. https://doi.org/10.3390/ma12121902

Lin J, Zhou X, Zhang H, Wang F, Xu Q, Guo C. Study on ASJ Cutting of TC18, Based upon Multivariate Nonlinear Regression and SA-BP-AGA. Materials. 2019; 12(12):1902. https://doi.org/10.3390/ma12121902

Chicago/Turabian StyleLin, Jie, Xin Zhou, Hui Zhang, Fengchao Wang, Qiwen Xu, and Chuwen Guo. 2019. "Study on ASJ Cutting of TC18, Based upon Multivariate Nonlinear Regression and SA-BP-AGA" Materials 12, no. 12: 1902. https://doi.org/10.3390/ma12121902

APA StyleLin, J., Zhou, X., Zhang, H., Wang, F., Xu, Q., & Guo, C. (2019). Study on ASJ Cutting of TC18, Based upon Multivariate Nonlinear Regression and SA-BP-AGA. Materials, 12(12), 1902. https://doi.org/10.3390/ma12121902