Effect of Turning Amount on Metallurgical Qualities and Mechanical Properties of GH4169 Superalloy

Abstract

:1. Introduction

2. Materials and Methods

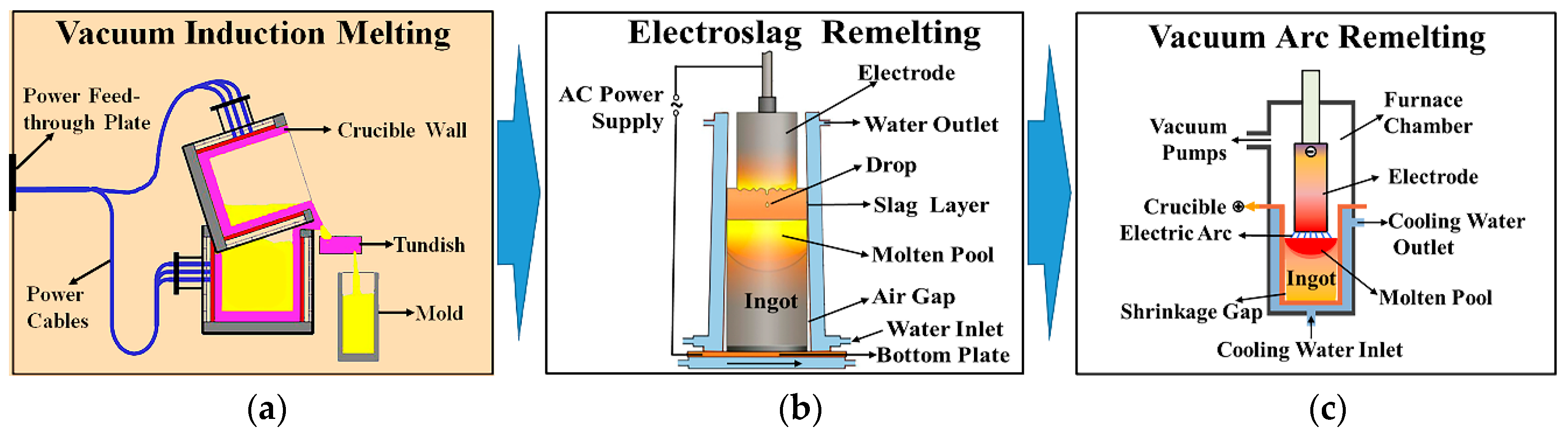

2.1. Melting

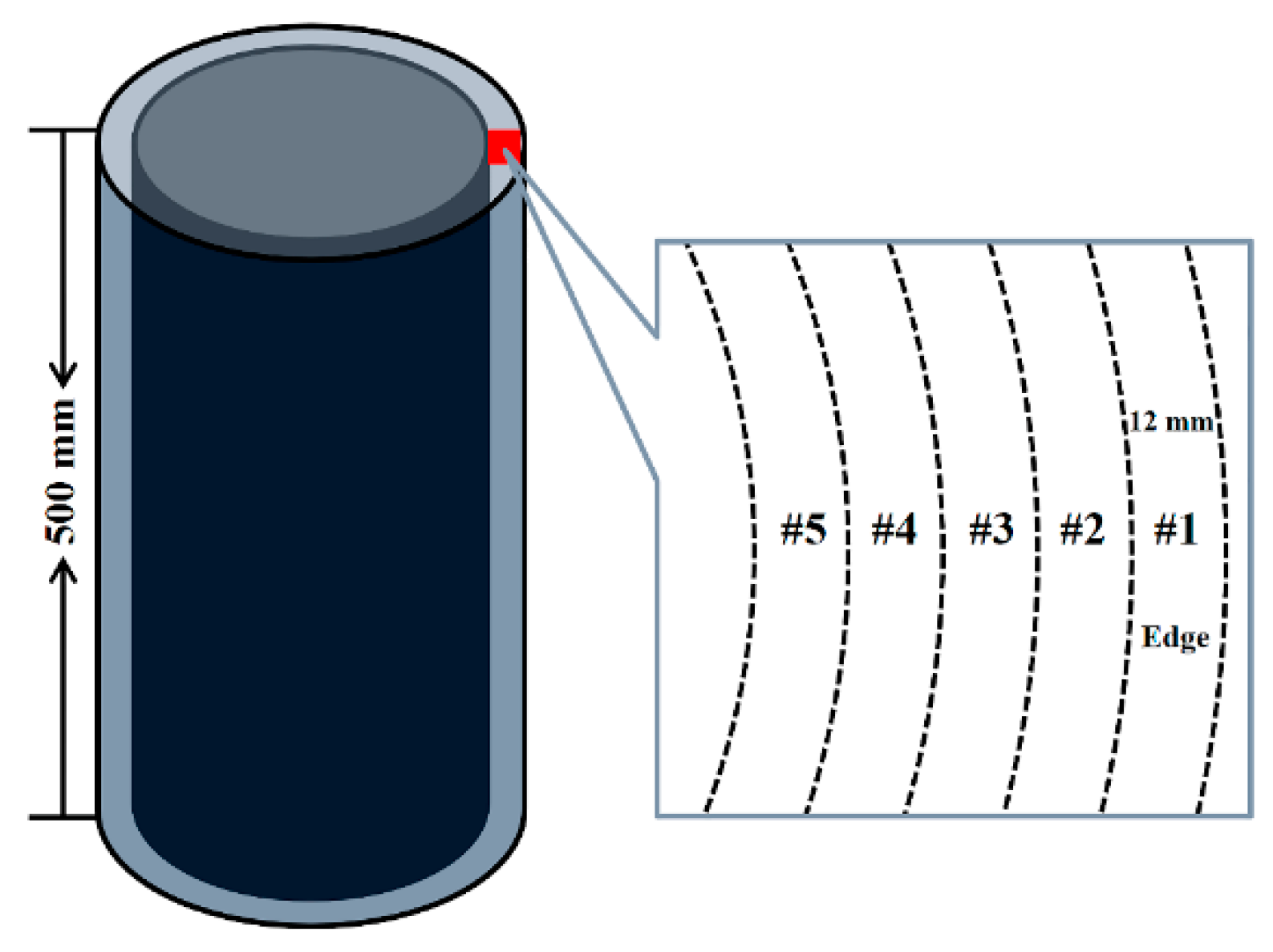

2.2. Experiment

3. Results and Discussion

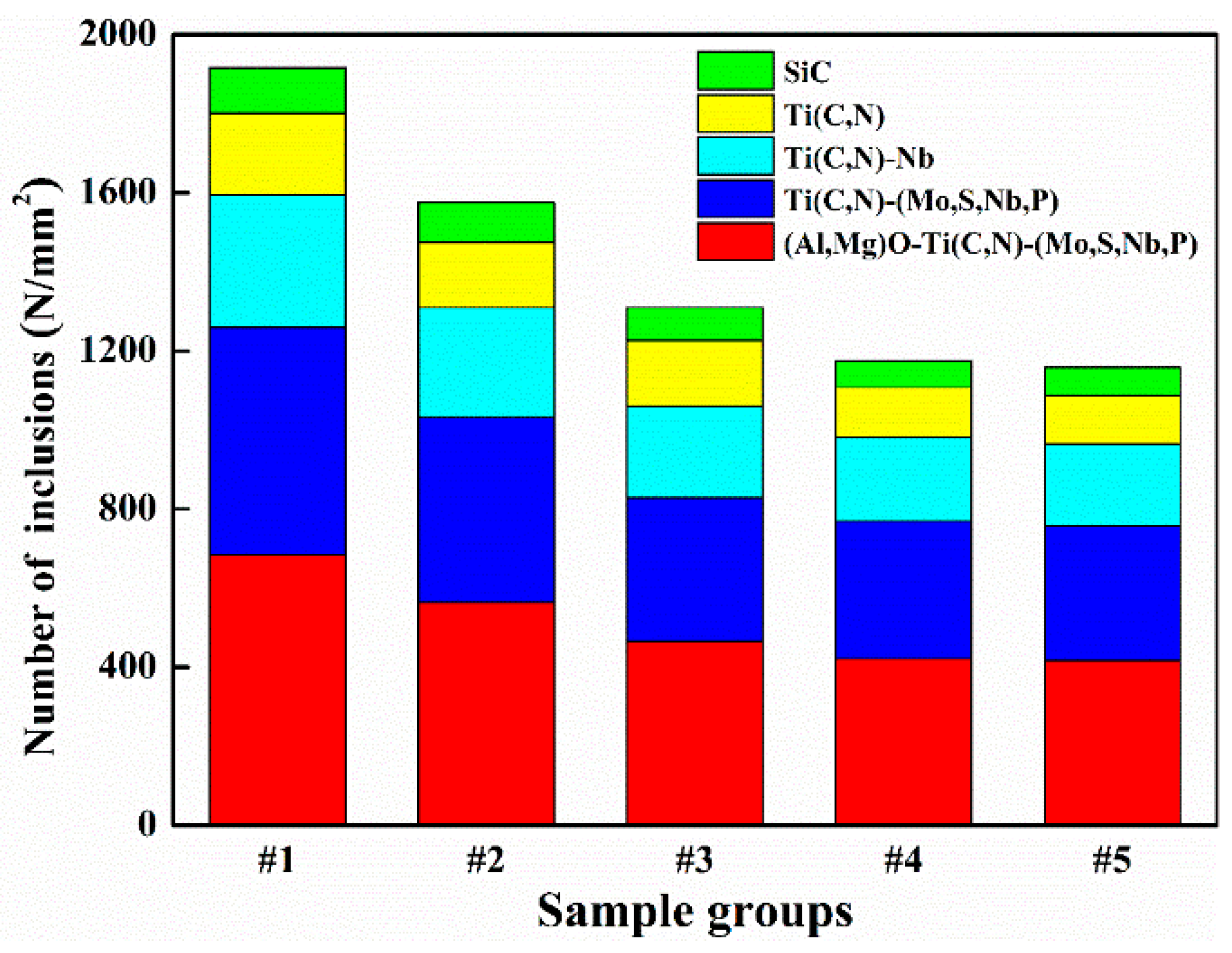

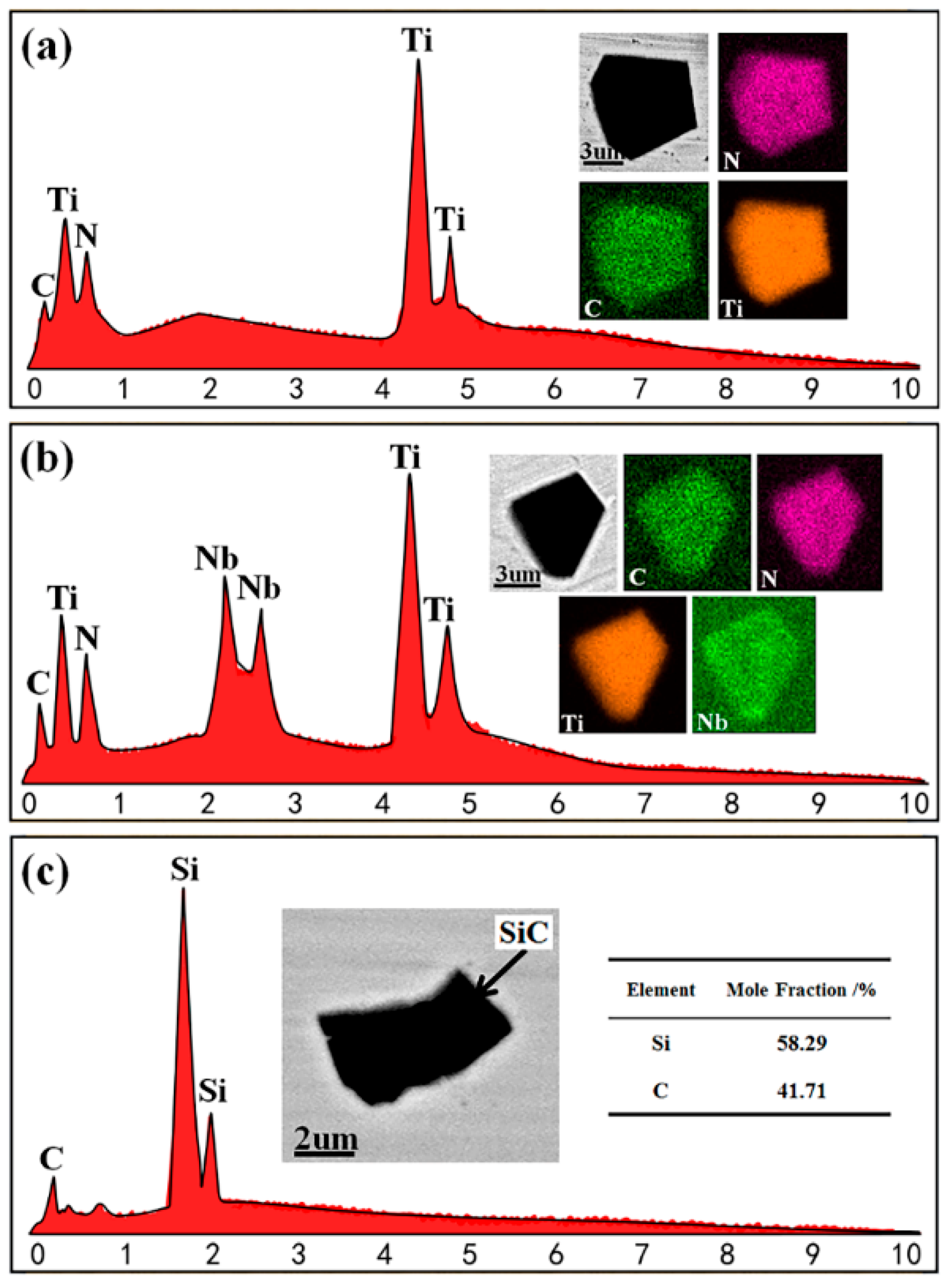

3.1. Analysis of Inclusion Formation

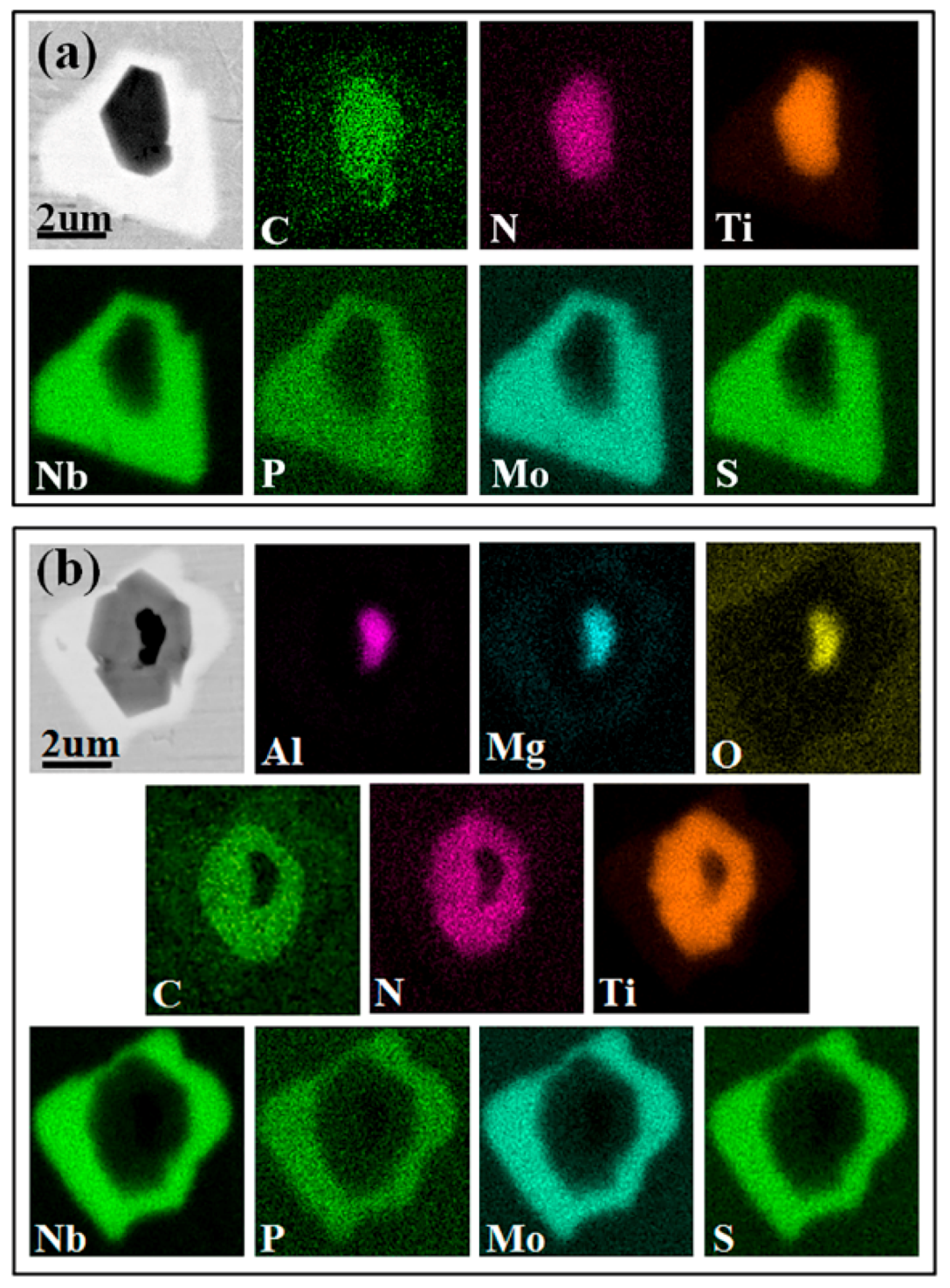

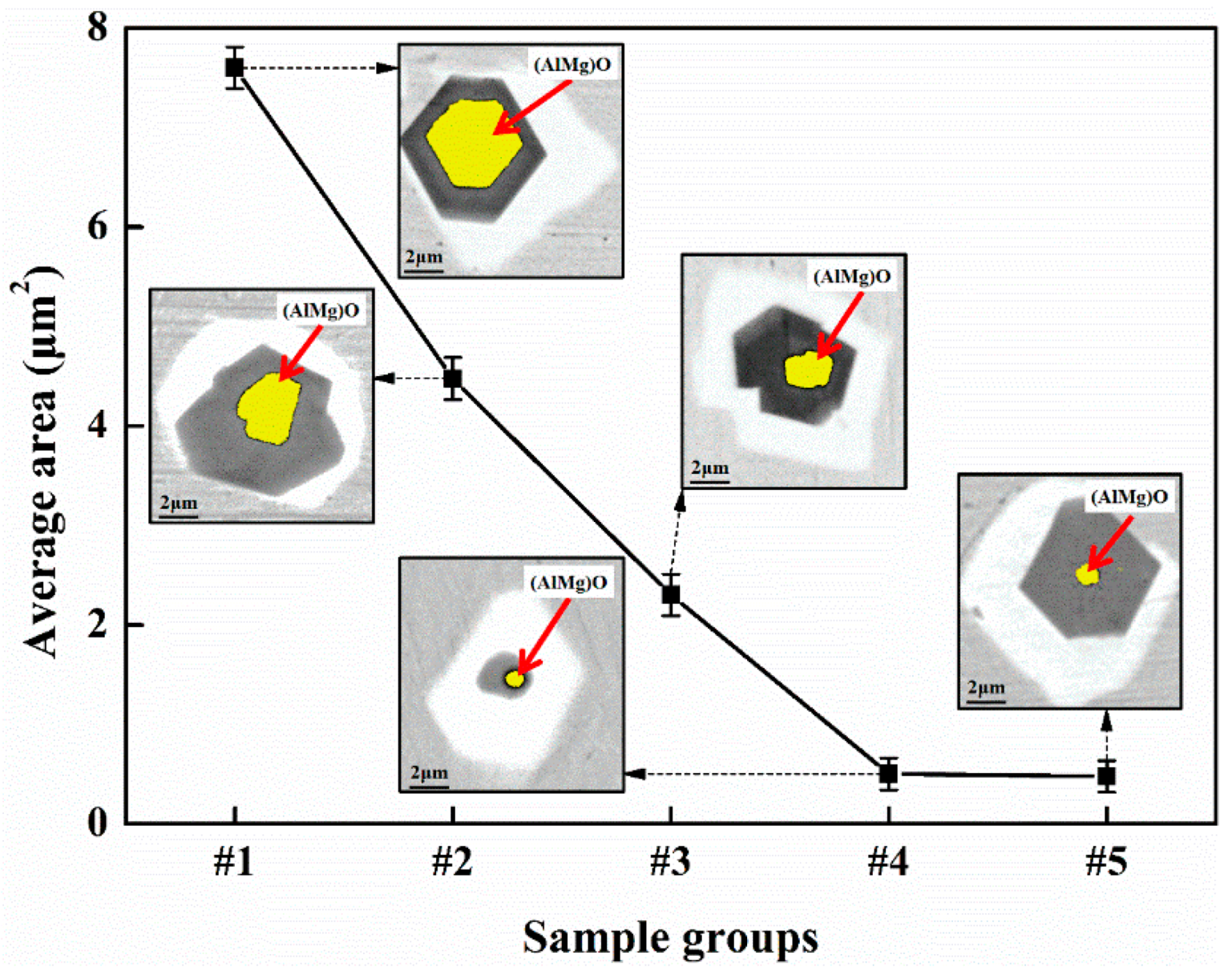

3.2. Analysis of (Al,Mg)O Inclusions

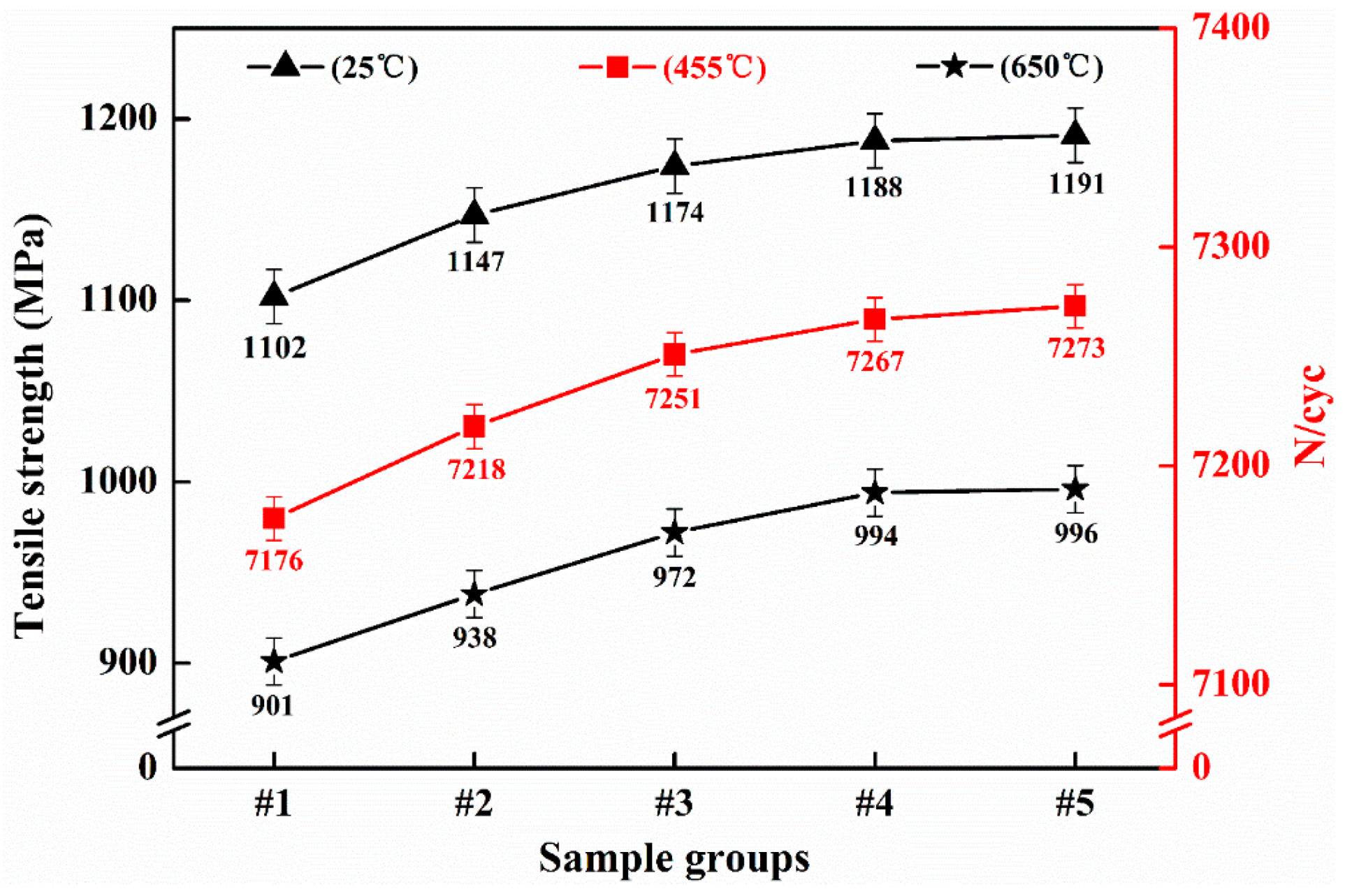

3.3. Analysis of Mechanical Properties

4. Conclusions

- We identified five different types of inclusion in the five groups of samples taken from different regions: Ti(C,N) composite inclusions, Ti(C,N)-Nb composite inclusions, SiC inclusions, Ti(C,N)-(Nb,P,Mo,S) composite inclusions, and (Al,Mg)O-Ti(C,N)-(Nb,P,Mo,S) composite inclusions. With an increase in the distance between the sampling location and the edge of the ingot, the distribution of the number of inclusions first decreases from 1917 to 1310 N/mm2. It then fluctuated steadily within a range of 1166 ± 10 N/mm2.

- The average area of the (Al,Mg)O-Ti(C,N)-(Nb,P,Mo,S) composite inclusions decreased from 7.61 to 0.49 μm2 and then fluctuated steadily within a range of 0.49 ± 0.02 um2 as the distance between the sampling location and the edge of the ingot increased. The evolution process is similar to that of the quantity distribution of the inclusions.

- As the distance between the sampling location and the edge of the ingot gradually increased each of the five groups, the tensile strength, elongation, section shrinkage at 25 °C, and that at 650 °C, increased from 1102 to 1911 MPa, 901 to 996 MPa, 13.0% to 15.5%, 24.0% to 29.0%, 28.0% to 32.0%, and 55.0% to 60.0%, respectively. At the same time, the fatigue life at 455 °C increased from 7176 to 7273 cycles, and the hardness increased from 442 HB to 448 HB. However, the range of fluctuation of the mean values of the properties of samples #4 and #5 was less than 6.

- According to the results obtained for the type and quantity distribution of the inclusions in the five groups of samples, the change in the average area of the (Al,Mg)O composite inclusions, and the change trend of the various properties, it can be tentatively determined that a suitable turning amount for a GH4169 superalloy ingot is 36–48 mm.

Author Contributions

Funding

Conflicts of Interest

References

- Chen, Z.; Peng, L.R.; Moverare, J.; Avdovic, P.; Zhou, J.M.; Johansson, S. Surface integrity and structural stability of broached Inconel 718 at high temperatures. Metall. Mater. Trans. A 2016, 47, 3664–3676. [Google Scholar] [CrossRef]

- Kirka, M.M.; Unocic, K.A.; Raghavan, N.; Medina, F.; Dehoff, R.R.; Babu, S.S. Microstructure development in electron beam-melted Inconel 718 and associated tensile properties. JOM 2016, 68, 1012–1020. [Google Scholar] [CrossRef]

- Ivanoff, T.A.; Watt, T.J.; Taleff, E.M. Characterization of solidification microstructures in vacuum arc remelted nickel alloy 718. Metall. Mater. Trans. B 2019, 50, 700–715. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Yang, S.F.; Li, J.S.; Guo, H.; Zheng, H.B. Effects of different hot working techniques on inclusions in GH4738 superalloy produced by VIM and VAR. Materials 2018, 11, 1024. [Google Scholar] [CrossRef] [PubMed]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Study on the machinability characteristics of superalloy Inconel 718 during high speed turning. Mater. Des. 2009, 30, 1718–1725. [Google Scholar] [CrossRef]

- Hu, D.Y.; Gao, Y.; Meng, F.C.; Song, J.; Wang, R.Q. Experimental and numerical analysis of microstructures and stress states of shot-peened GH4169 superalloys. Metall. Mater. Trans. A 2018, 49, 1397–1409. [Google Scholar] [CrossRef]

- Osman, K.A.; Ünver, H.Ö.; Şeker, U. Application of minimum quantity lubrication techniques in machining process of titanium alloy for sustainability: A review. Int. J. Adv. Manuf. Tech. 2019, 100, 2311–2332. [Google Scholar] [CrossRef]

- Kenda, J.; Pusavec, F.; Kopac, J. Analysis of residual stresses in sustainable cryogenic machining of nickel based alloy—Inconel 718. J. Manuf. Sci. Eng.-Trans. ASME 2011, 133, 041009. [Google Scholar] [CrossRef]

- Pawade, R.S.; Joshi, S.S.; Brahmankar, P.K. Effect of machining parameters and cutting edge geometry on surface integrity of high-speed turned Inconel 718. Int. J. Mach. Tools Manuf. 2008, 48, 15–28. [Google Scholar] [CrossRef]

- Suárez, A.; López de Lacalle, L.N.; Polvorosa, R.; Veiga, F.; Wretland, A. Effects of high pressure cooling on the wear patterns on turning inserts used on alloy IN718. Mater. Manuf. Process. 2017, 32, 678–686. [Google Scholar] [CrossRef]

- Pusavec, F.; Hamdi, H.; Kopac, J.; Jawahir, I.S. Surface integrity in cryogenic machining of nickel based alloy—Inconel 718. J. Mater. Process. Technol. 2011, 211, 773–783. [Google Scholar] [CrossRef]

- Feyzi, T.; Safavi, S.M. Improving machinability of Inconel 718 with a new hybrid machining technique. Int. J. Adv. Manuf. Tech. 2013, 66, 1025–1030. [Google Scholar] [CrossRef]

- Hecker, R.L.; Liang, S.Y. Predictive modeling of surface roughness in grinding. Int. J. Mach. Tools Manuf. 2003, 43, 755–761. [Google Scholar] [CrossRef]

- Suárez, A.; Veiga, F.; López de Lacalle, L.N.; Polvorosa, R.; Lutze, S.; Wretland, A. Effects of Ultrasonics-Assisted Face Milling on Surface Integrity and Fatigue Life of Ni-Alloy 718. J. Mater. Eng. Perform. 2016, 25, 5076–5086. [Google Scholar] [CrossRef]

- Guo, C.; Shi, Z.; Attia, H.; Mclntosh, D. Power and wheel wear for grinding nickel alloy with plated CBN wheels. CIRP Ann-Manuf. Technol. 2007, 56, 343–346. [Google Scholar] [CrossRef]

- D’Addona, D.M.; Raykar, S.J. Thermal modeling of tool temperature distribution during high pressure coolant assisted turning of Inconel 718. Materials 2019, 12, 408. [Google Scholar] [CrossRef] [PubMed]

- Shevchenko, D.M.; Ward, R.M. Liquid Metal Pool Behavior during the Vacuum Arc Remelting of INCONEL 718. Metall. Mater. Trans. B 2009, 40, 263–270. [Google Scholar] [CrossRef]

- Zagrebelnyy, D.; Krane, M.J.M. Segregation Development in Multiple Melt Vacuum Arc Remelting. Metall. Mater. Trans. B 2009, 40, 281–288. [Google Scholar] [CrossRef]

- Pericleous, K.; Djambazov, G.; Ward, M.; Yuan, L.; Lee, P.D. A Multi-Scale 3D Model of the Vacuum Arc Remelting Process. Metall. Mater. Trans. A 2013, 44, 5365–5376. [Google Scholar] [CrossRef]

- Li, B.; Gleeson, B. Effects of Silicon on the Oxidation Behavior of Ni-Base Chromia-Forming Alloys. Oxid. Met. 2006, 65, 101–122. [Google Scholar] [CrossRef]

- Woodford, D.A. Gas phase embrittlement and time dependent cracking of nickel based superalloys. Energ. Mater. Mater. Sci. Eng. Energ. Syst. 2006, 1, 59–79. [Google Scholar] [CrossRef]

- Pak, J.J.; Jeong, Y.S.; Hong, I.K.; Cha, W.Y. Thermodynamics of TiN Formation in Fe-Cr Melts. ISIJ Int. 2005, 45, 1106–1111. [Google Scholar] [CrossRef]

- Li, M.; Matsuura, H.; Tsukihashi, F. Investigation on the formation mechanism of Ti-bearing non-metallic inclusions in Fe-Al-Ti-O-N alloy by inductive separation method. Mater. Charact. 2018, 136, 358–366. [Google Scholar] [CrossRef]

- Liu, J.; Luo, X.h.; Hu, X.Q.; Liu, S. Effect of Ti and Nb micro-alloying on the microstructure of the ultra-purified 11% Cr ferrite stainless steels. Acta Metall. Sin. 2011, 47, 688–696. [Google Scholar]

- Chen, X.C.; Shi, C.B.; Guo, H.J.; Wang, F.; Hao, R.; Feng, D. Investigation of Oxide Inclusions and Primary Carbonitrides in Inconel 718 Superalloy Refined through Electroslag Remelting Process. Metall. Mater. Trans. B 2012, 43, 1596–1607. [Google Scholar] [CrossRef]

- Shen, J.; Xia, T.D.; Wang, X.J.; Feng, X.C. Characterization and analysis of non-metallic inclusions in Ni42-Fe expansive alloy. Trans. Nonferrous Met. Soc. China 2007, 17, S1165–S1171. (In Chinese) [Google Scholar]

- Tang, Z.J.; Guo, T.M.; Kou, Z.S.; Fu, Y.; Jin, S. Feature and formation mechanism of inclusions in K4169 Ni-based superalloy. China J. Nonferrous Metal. 2015, 25, 2403–2413. (In Chinese) [Google Scholar]

- Chen, Z.Y.; Yang, S.F.; Qu, J.L.; Li, J.S.; Dong, A.P.; Gu, Y. Effects of Different Melting Technologies on the Purity of Superalloy GH4738. Materials 2018, 11, 1838. [Google Scholar] [CrossRef]

- Mitchell, A. Solidification in remelting processes. Mat. Sci. Eng. A. 2005, 413, 10–18. [Google Scholar] [CrossRef]

- Chapelle, P.; Bellot, J.P.; Duval, H.; Jardy, A.; Ablitzer, D. Modelling of plasma generation and expansion in a vacuum arc: Application to the vacuum arc remelting process. J. Phys. D-Appl. Phys. 2001, 35, 137–150. [Google Scholar] [CrossRef]

- Damien, T.; Ana, C.G.; Stéphane, P.; Jean-Michel, F.; Tresa, M.P.; Patrick, V.; Jonathan, C. Microstructural Features Controlling the Variability in Low-Cycle Fatigue Properties of Alloy Inconel 718DA at Intermediate Temperature. Metall. Mater. Trans. A 2016, 47, 1096–1109. [Google Scholar]

- Campbell, J. Melting, remelting, and casting for clean steel. Steel Res. Int. 2017, 88, 1–13. [Google Scholar] [CrossRef]

| Ni | Cr | Nb | Ti | Al | Mo | Co | C | Fe |

|---|---|---|---|---|---|---|---|---|

| 50.0–55.0 | 17.0–21.0 | 4.7–5.5 | 0.6–1.1 | 0.2–0.8 | 2.8–3.3 | ≤1.0 | ≤0.08 | Balance |

| Mechanical Properties | #1 | #2 | #3 | #4 | #5 |

|---|---|---|---|---|---|

| Elongation (25 °C, %) | 13.0 ± 0.5 | 14.0 ± 0.5 | 15.0 ± 0.5 | 15.5 ± 0.5 | 15.5 ± 0.5 |

| Elongation (650 °C, %) | 24.0 ± 0.5 | 25.5 ± 0.5 | 28.0 ± 0.5 | 29.0 ± 0.5 | 29.0 ± 0.5 |

| Section shrinkage (25 °C, %) | 28.0 ± 0.5 | 30.0 ± 0.5 | 31.0 ± 0.5 | 32.0 ± 0.5 | 32.0 ± 0.5 |

| Section shrinkage (650 °C, %) | 55.0 ± 0.5 | 57.0 ± 0.5 | 59.0 ± 0.5 | 60.0 ± 0.5 | 60.0 ± 0.5 |

| Hardness (HB) | 442 ± 1 | 445 ± 1 | 446 ± 1 | 447 ± 1 | 448 ± 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, J.; Yang, S.; Chen, Z.; Du, J.; Li, J.; Wang, D. Effect of Turning Amount on Metallurgical Qualities and Mechanical Properties of GH4169 Superalloy. Materials 2019, 12, 1852. https://doi.org/10.3390/ma12111852

Qu J, Yang S, Chen Z, Du J, Li J, Wang D. Effect of Turning Amount on Metallurgical Qualities and Mechanical Properties of GH4169 Superalloy. Materials. 2019; 12(11):1852. https://doi.org/10.3390/ma12111852

Chicago/Turabian StyleQu, Jinglong, Shufeng Yang, Zhengyang Chen, Jinhui Du, Jingshe Li, and Di Wang. 2019. "Effect of Turning Amount on Metallurgical Qualities and Mechanical Properties of GH4169 Superalloy" Materials 12, no. 11: 1852. https://doi.org/10.3390/ma12111852

APA StyleQu, J., Yang, S., Chen, Z., Du, J., Li, J., & Wang, D. (2019). Effect of Turning Amount on Metallurgical Qualities and Mechanical Properties of GH4169 Superalloy. Materials, 12(11), 1852. https://doi.org/10.3390/ma12111852