Experimental and Electrochemical Research of an Efficient Corrosion and Scale Inhibitor

Abstract

:1. Introduction

2. Experiment

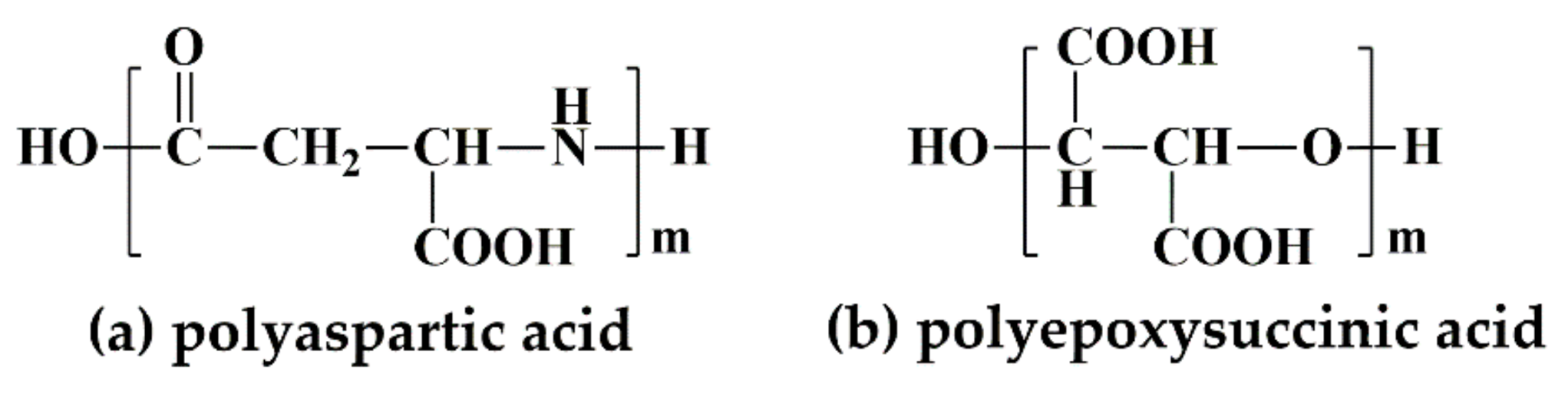

2.1. Materials

2.2. Corrosion Inhibition Performance

2.2.1. Weight Loss Measurements and Morphology Characterization

2.2.2. Electrochemical Measurements

2.3. Scale Inhibition Performance

2.4. Dynamic Simulation Test

3. Results and Discussion

3.1. Weight-Loss Experiment

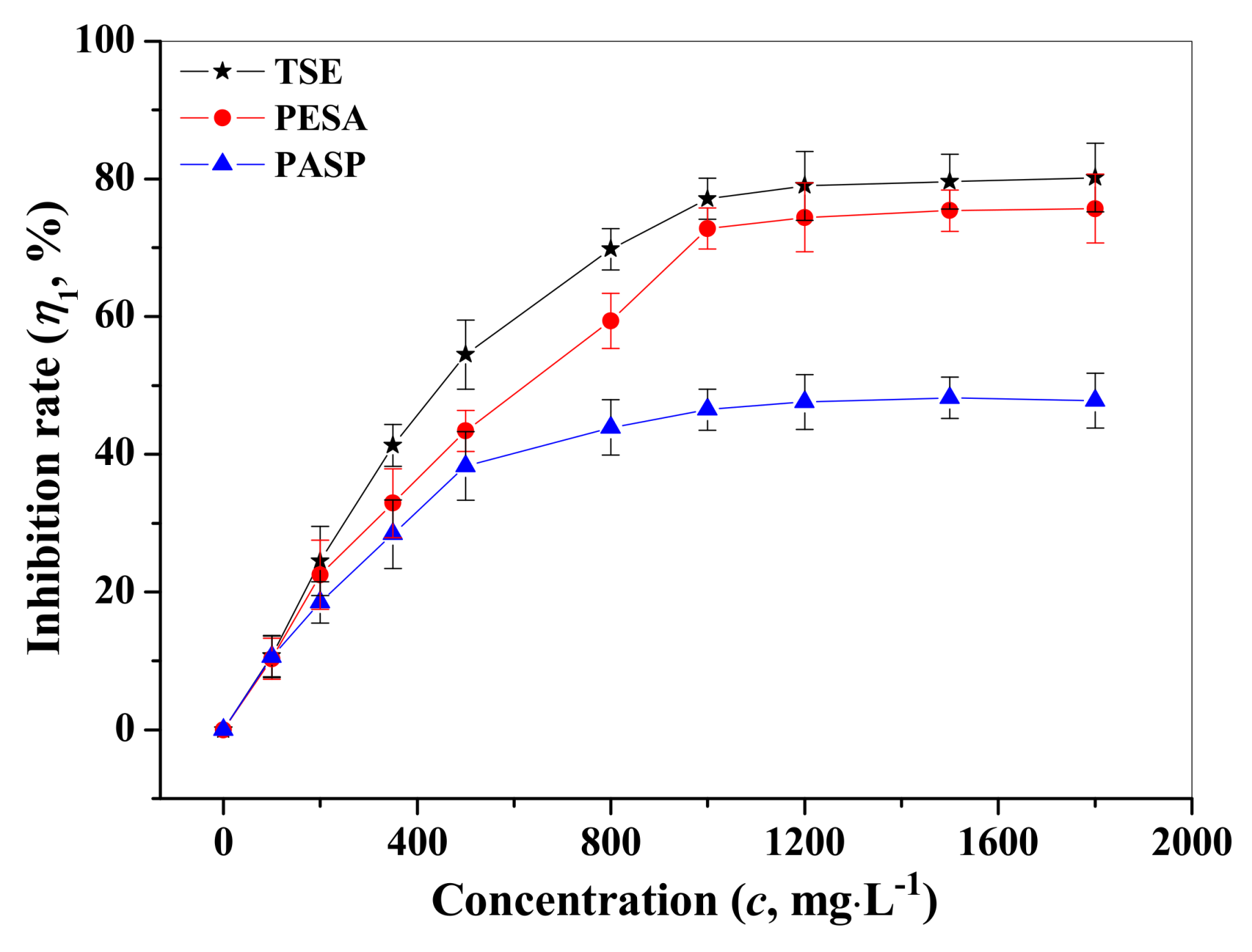

3.1.1. Corrosion Inhibition of TSE, PESA, and PASP

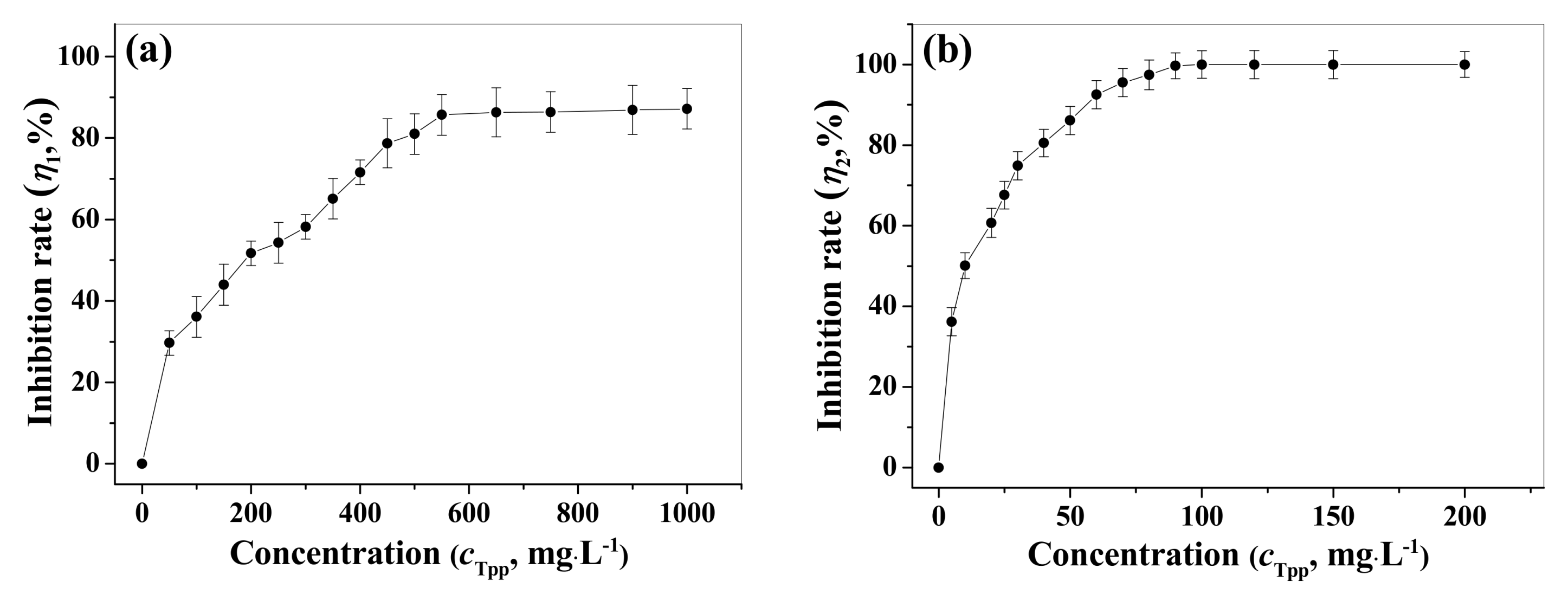

3.1.2. Corrosion Inhibition of Ternary Complex TPP

3.2. Morphology Analysis

3.3. Electrochemical Analysis

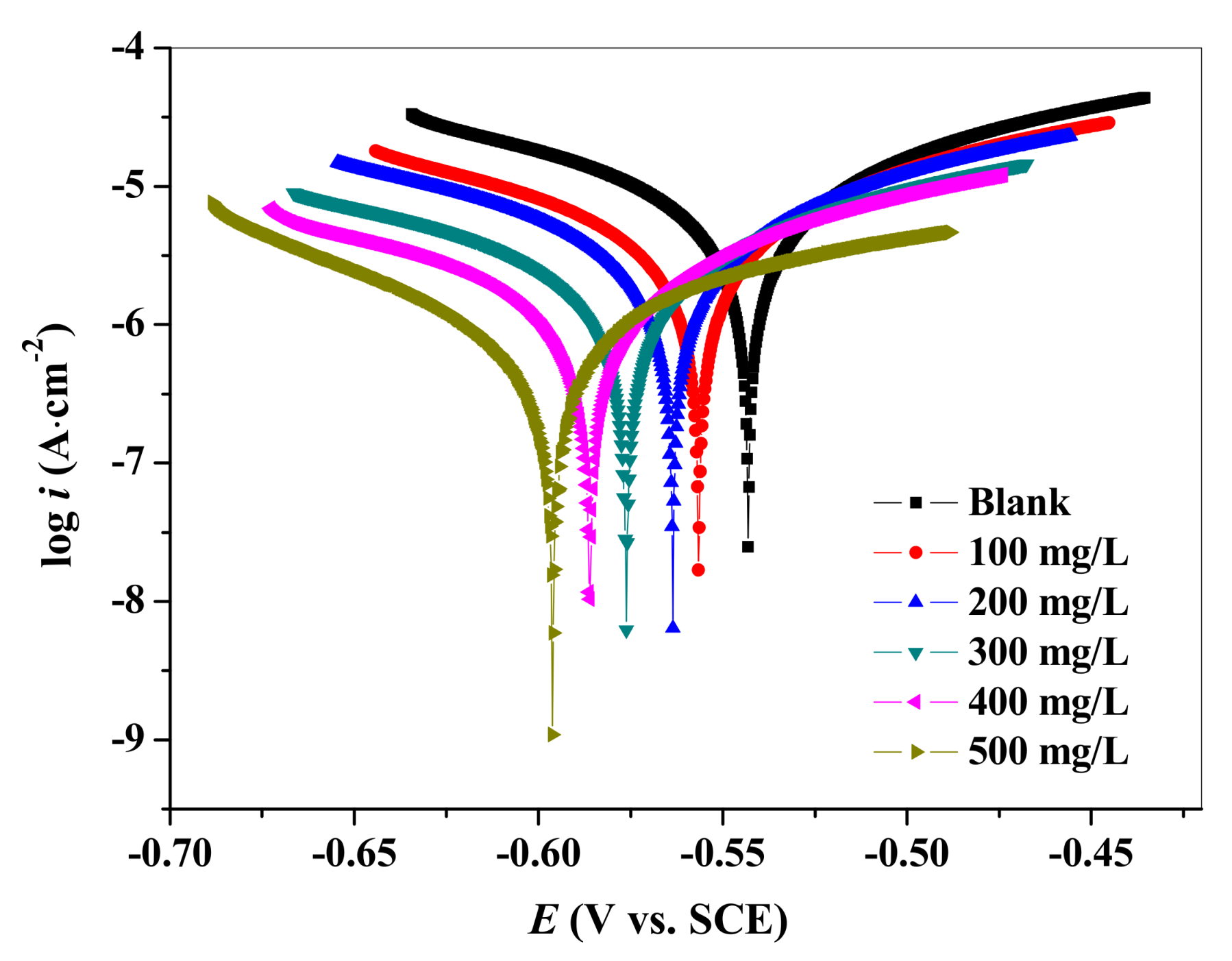

3.3.1. Potentiodynamic Polarization Curves

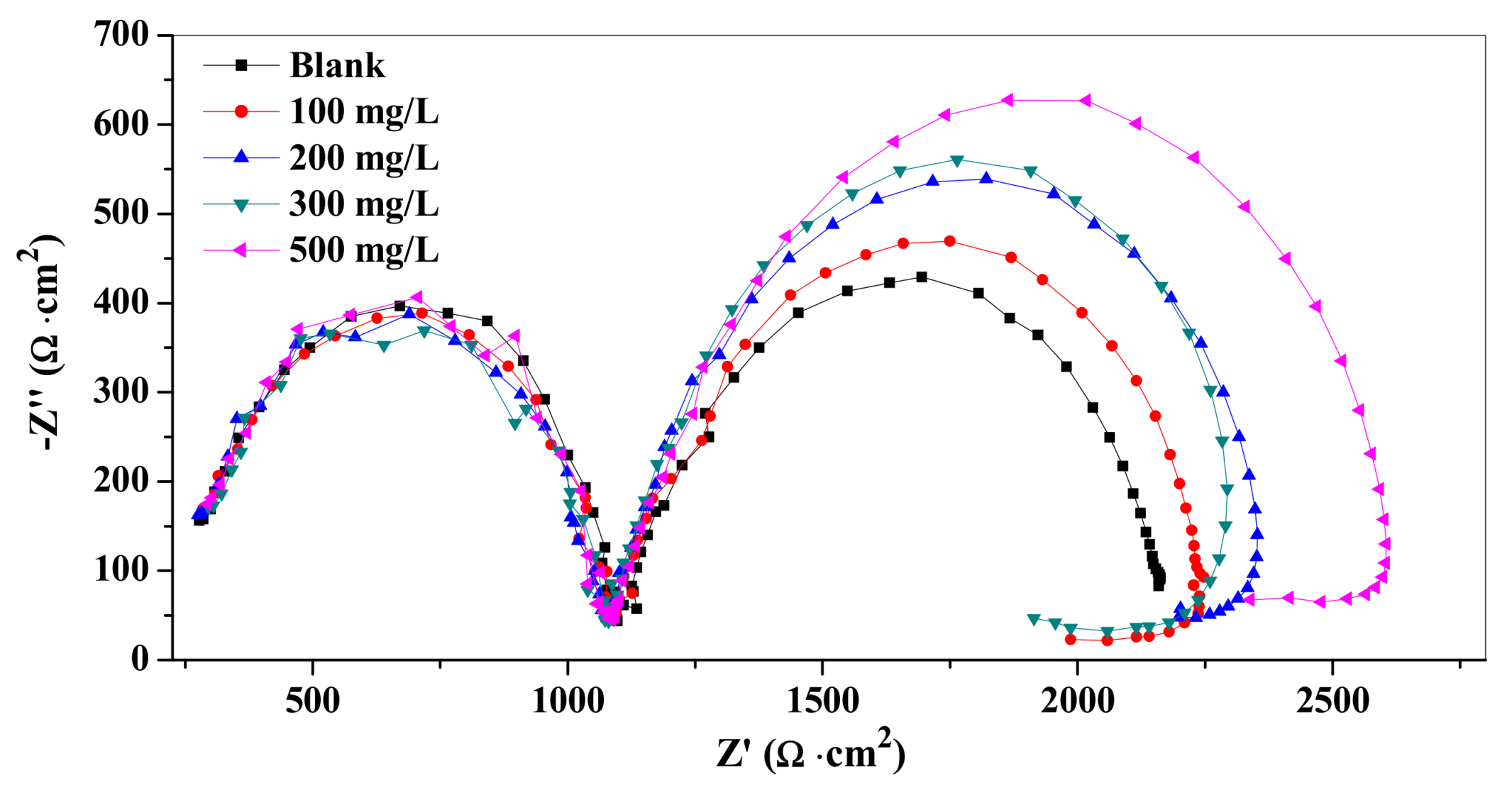

3.3.2. Electrochemical Impedance Spectroscopy (EIS)

3.4. Deposition Experiment

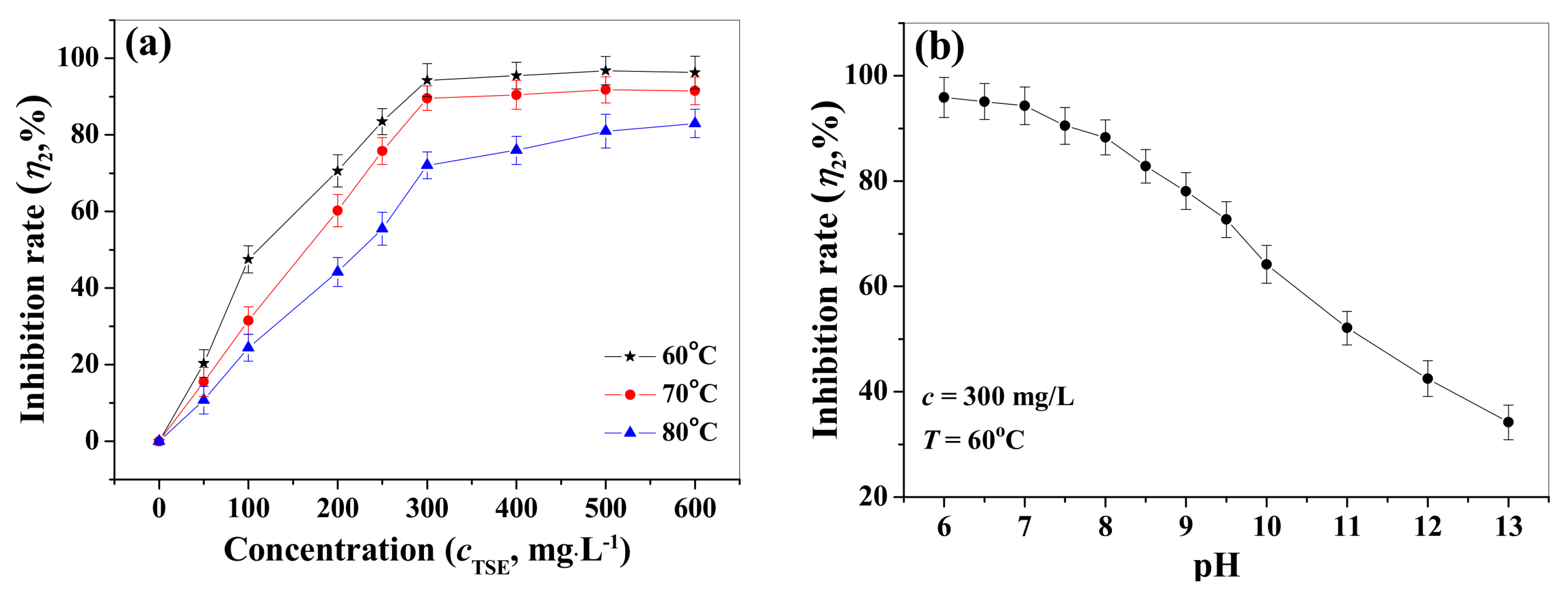

3.4.1. Scale Inhibition of TSE

3.4.2. Scale Inhibition of Ternary Complex TPP

3.5. Dynamic Simulation Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, B.R.; Zhang, L.; Li, F.T.; Hu, W.; Hannam, P.M. Testing the formation of Ca–phosphonate precipitates and evaluating the anionic polymers as Ca–phosphonate precipitates and CaCO3 scale inhibitor in simulated cooling water. Corros. Sci. 2010, 52, 3883–3890. [Google Scholar] [CrossRef]

- Garcia, C.; Courbin, G.; Ropital, F.; Fiaud, C. Study of the scale inhibition by HEDP in a channel flow cell using a quartz crystal microbalance. Electrochim. Acta 2001, 46, 973–985. [Google Scholar] [CrossRef]

- Zhang, H.Z.; Dong, C.Q.; Bian, L.; Zhao, Q. Experiment study on corrosion control using coking wastewater as circulating cooling water. Front. Earth Sci. 2008, 15, 186–189. [Google Scholar] [CrossRef]

- Rao, B.V.A.; Rao, S.S. Electrochemical and surface analytical studies of synergistic effect of phosphonate, Zn2+ and ascorbate in corrosion control of carbon steel. Mater. Corros. 2010, 61, 285–301. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Y.Y.; Bu, Y.T.; Liu, T.Q. Corrosion and scale inhibition performance of compound inhibitors for Q235 carbon steel in simulated circulating cooling water. Mater. Prot. 2017, 50, 29–33. [Google Scholar]

- Pan, Z.G.; Liu, L.Z.; Qin, Y.H.; Ding, L.X.; Shen, X.Y. Optimization of circulating cooling water treatment agents for Guangzhou Metro. Guangdong Chem. Ind. 2017, 44, 44–45. [Google Scholar]

- Yang, J.; Zhou, Z.N.; Ma, Y. Application of phosphorus-free corrosion and scale inhibitor to largescale circulating cooling water system in petrochemical industry. Ind. Water Wastewater 2016, 47, 55–57. [Google Scholar]

- Chen, Y.Y.; Zhou, Y.M.; Yao, Q.Z.; Bu, Y.Y.; Wang, H.C.; Wu, W.D.; Sun, W. Preparation of a low-phosphorous terpolymer as a scale, corrosion inhibitor, and dispersant for ferric oxide. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- He, C.J.; Tian, Z.P.; Zhang, B.R.; Lin, Y.; Chen, X.; Wang, M.J.; Li, F.T. Inhibition effect of environment-friendly inhibitors on the corrosion of carbon steel in recirculating cooling water. Ind. Eng. Chem. Res. 2015, 54, 1971–1981. [Google Scholar] [CrossRef]

- Demadis, K.D.; Mantzaridis, C.; Lykoudis, P. Effects of structural differences on metallic corrosion inhibition by metal-polyphosphonate thin films. Ind. Eng. Chem. Res. 2006, 45, 7795–7800. [Google Scholar] [CrossRef]

- Zhu, T.Z.; Wang, L.D.; Sun, W.; Yang, Z.Q.; Wang, S.L.; Zhou, Y.Z.; He, S.H.; Wang, Y.W.; Liu, G.C. Corrosion-induced performance degradation of phosphorus-containing scale inhibitors at carbon steel-water interface. Ind. Eng. Chem. Res. 2018, 57, 5183–5189. [Google Scholar] [CrossRef]

- Goyal, M.; Kumar, S.; Bahadur, I.; Verma, C.; Ebenso, E.E. Organic corrosion inhibitors for industrial cleaning of ferrous and non-ferrous metals in acidic solutions: A review. J. Mol. Liq. 2018, 256, 565–573. [Google Scholar] [CrossRef]

- Menzri, R.; Ghizellaoui, S.; Tlili, M. Calcium carbonate inhibition by green inhibitors: Thiamine and pyridoxine. Desalination 2017, 404, 147–154. [Google Scholar] [CrossRef]

- Bao, J.P.; Zhang, H.Y.; Zhao, X.H.; Deng, J.P. Biomass polymeric microspheres containing aldehyde groups: Immobilizing and controlled-releasing amino acids as green metal corrosion inhibitor. Chem. Eng. J. 2018, 341, 146–156. [Google Scholar] [CrossRef]

- Zeino, A.; Abdulazeez, I.; Khaled, M.; Jawich, M.W.; Obot, I.B. Mechanistic study of polyaspartic acid (PASP) as eco-friendly corrosion inhibitor on mild steel in 3% NaCl aerated solution. J. Mol. Liq. 2018, 250, 50–62. [Google Scholar] [CrossRef]

- Arukalam, I.O. Durability and synergistic effects of KI on the acid corrosion inhibition of mild steel by hydroxypropyl methylcellulose. Carbohyd. Polym. 2014, 112, 291–299. [Google Scholar] [CrossRef] [PubMed]

- Xia, Z.H.; Zhang, S.R.; Cao, Y.R.; Zhong, Q.M.; Wang, G.Y.; Li, T.; Xu, X.X. Remediation of cadmium, lead and zinc in contaminated soil with CETSA and MA/AA. J. Hazard. Mater. 2019, 366, 177–183. [Google Scholar] [CrossRef] [PubMed]

- Qian, B.; Wang, J.; Zheng, M.; Hou, B.R. Synergistic effect of polyaspartic acid and iodide ion on corrosion inhibition of mild steel in H2SO4. Corros. Sci. 2013, 75, 184–192. [Google Scholar] [CrossRef]

- Yang, W.J.; Wang, Q.H.; Xu, K.; Yin, Y.J.; Bao, H.B.; Li, X.M.; Niu, L.D.; Chen, S.Q. Enhanced corrosion resistance of carbon steel in hydrochloric acid solution by Eriobotrya japonica Thunb. leaf extract: Electrochemical study. Materials 2017, 10, 956. [Google Scholar] [CrossRef] [PubMed]

- Farahmand, R.; Sohrabi, B.; Ghaffarinejad, A.; Meymian, M.R.Z. Synergistic effect of molybdenum coating and SDS surfactant on corrosion inhibition of mild steel in presence of 3.5% NaCl. Corros. Sci. 2018, 136, 393–401. [Google Scholar] [CrossRef]

- El-Lateef, H.M.A. Synergistic effect of polyethylene glycols and rare earth Ce4+ on the corrosion inhibition of carbon steel in sulfuric acid solution: Electrochemical, computational, and surface morphology studies. Res. Chem. Intermed. 2016, 42, 3219–3240. [Google Scholar] [CrossRef]

- Jokar, M.; Farahani, T.S.; Ramezanzadeh, B. Electrochemical and surface characterizations of morus alba pendula leaves extract (MAPLE) as a green corrosion inhibitor for steel in 1M HCl. J. Taiwan Inst. Chem. Eng. 2016, 63, 436–452. [Google Scholar] [CrossRef]

- Deng, S.; Li, X. Inhibition by Ginkgo leaves extract of the corrosion of steel in HCl and H2SO4 solutions. Corros. Sci. 2012, 55, 407–415. [Google Scholar] [CrossRef]

- Ji, G.; Anjum, S.; Sundaram, S.; Prakash, R. Musa paradisica peel extract as green corrosion inhibitor for mild steel in HCl solution. Corros. Sci. 2015, 90, 107–117. [Google Scholar] [CrossRef]

- Bentrah, H.; Rahali, Y.; Chala, A. Gum Arabic as an eco-friendly inhibitor for API 5L X42 pipeline steel in HCl medium. Corros. Sci. 2014, 82, 426–431. [Google Scholar] [CrossRef]

- Saxena, A.; Prasad, D.; Haldhar, R.; Singh, G.; Kumar, A. Use of Sida cordifolia extract as green corrosion inhibitor for mild steel in 0.5 M H2SO4. J. Environ. Chem. Eng. 2018, 6, 694–700. [Google Scholar] [CrossRef]

- de Assunção Araújo Pereira, S.S.; Pêgas, M.M.; Fernández, T.L.; Magalhães, M.; Schöntag, T.G.; Lago, D.C.; de Senna, L.F.; D’Elia, E. Inhibitory action of aqueous garlic peel extract on the corrosion of carbon steel in HCl solution. Corros. Sci. 2012, 65, 360–366. [Google Scholar] [CrossRef]

- Ei-Etre, A.Y. Inhibition of acid corrosion of carbon steel using aqueous extract of olive leaves. J. Colloid Interface Sci. 2007, 314, 578–583. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, H.F.; Liu, Z.Y. Scale and corrosion inhibition performance of tobacco rob extract. CIESC J. 2014, 65, 298–304. [Google Scholar]

- Yang, Y.; Jin, S.P.; Lin, Y.X.; Huang, S.Y.; Yang, H.P. Catalytic gasification of tobacco rob in steam-nitrogen mixture: Kinetic study and fuel gas analysis. Energy 2012, 44, 509–514. [Google Scholar] [CrossRef]

- Tang, M.; Li, J.; Ye, Z.; Kou, Z.; Fu, L. A aovel eco-friendly scale and corrosion inhibitor modified by-cyclodextrin. Aust. J. Chem. 2017, 70, 933–942. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Zhu, C.J.; Sun, B.J.; Li, L.; Bai, Y. Determination of Scale Inhibition Performance of Water Treatment Agents–Calcium Carbonate Precipitation Method; GB/T 16632-2008; Standards Press of China: Beijing, China, 2008. [Google Scholar]

- Coelho, L.B.; Cossement, D.; Olivier, M.G. Benzotriazole and cerium chloride as corrosion inhibitors for AA2024-T3: An EIS investigation supported by SVET and ToF-SIMS analysis. Corros. Sci. 2018, 130, 177–189. [Google Scholar] [CrossRef]

- Tang, M.J.; Li, J.B.; Li, Z.D.; Fu, L.P.; Zeng, B.; Lv, J. Mannich base as corrosion inhibitors for N80 steel in a CO2 saturated solution containing 3 wt % NaCl. Materials 2019, 12, 449. [Google Scholar] [CrossRef] [PubMed]

- Xiu, W.; Ye, W.; Qing, W.; Ying, M. Study of inhibitive effect of 1,4-bis(benzimidazolyl)benzene on mild steel corrosion in 0.5 M HCl and 0.25 M H2SO4 solutions. Int. J. Electrochem. Sci. 2013, 8, 806–820. [Google Scholar]

- Liu, D.; Dong, W.B.; Li, F.T.; Hui, F.; Lédion, J. Comparative performance of polyepoxysuccinic acid and polyaspartic acid on scaling inhibition by static and rapid controlled precipitation methods. Desalination 2012, 304, 1–10. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, B.; Zhao, L.L.; Cui, Y.C. Synthesis of polyaspartic acid/5-aminoorotic acid graft copolymer and evaluation of its scale inhibition and corrosion inhibition performance. Desalination 2013, 311, 156–161. [Google Scholar] [CrossRef]

- Li, Z.Y.; Zhang, L.X.; Wang, X.M. Research on the application of non−phosphorus water treatment technology. Ind. Water Treat. 2017, 37, 107–108. [Google Scholar]

| Concentration (mg/L) | η1,TSE (%) | η1,PESA (%) | η1,PASP (%) |

|---|---|---|---|

| 100 | 10.7 | 10.3 | 10.6 |

| 200 | 24.5 | 22.5 | 18.5 |

| 350 | 41.3 | 32.9 | 28.4 |

| 500 | 54.5 | 43.4 | 38.3 |

| 800 | 69.8 | 59.4 | 43.9 |

| 1000 | 77.1 | 72.8 | 46.5 |

| 1200 | 79.0 | 74.4 | 47.6 |

| 1500 | 79.6 | 75.4 | 48.2 |

| 1800 | 80.2 | 75.7 | 47.8 |

| No. | cTSE/cPESA/cPASP | η1 (%) ctotal = 1000 mg/L | η2 (%) ctotal = 300 mg/L |

|---|---|---|---|

| 1 | 1:1:1 | 81.6 | 97.6 |

| 2 | 1:2:2 | 80.9 | 97.3 |

| 3 | 1:3:3 | 79.2 | 97.1 |

| 4 | 2:1:2 | 81.9 | 97.8 |

| 5 | 2:2:3 | 82.4 | 98.2 |

| 6 | 2:3:1 | 83.6 | 98.6 |

| 7 | 3:1:3 | 84.1 | 99.0 |

| 8 | 3:2:1 | 86.4 | 99.6 |

| 9 | 3:3:2 | 87.2 | 100 |

| η1 | η2 | |||||

|---|---|---|---|---|---|---|

| TSE | PESA | PASP | TSE | PESA | PASP | |

| k1 | 80.6 | 82.5 | 83.9 | 97.3 | 98.1 | 98.6 |

| k2 | 82.6 | 82.9 | 83.3 | 98.2 | 98.4 | 98.4 |

| k3 | 85.9 | 85.9 | 81.9 | 99.5 | 98.6 | 98.1 |

| R | 5.4 | 3.4 | 2.0 | 2.2 | 0.5 | 0.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Xing, W.; Wang, L.; Chen, L. Experimental and Electrochemical Research of an Efficient Corrosion and Scale Inhibitor. Materials 2019, 12, 1821. https://doi.org/10.3390/ma12111821

Chen Y, Xing W, Wang L, Chen L. Experimental and Electrochemical Research of an Efficient Corrosion and Scale Inhibitor. Materials. 2019; 12(11):1821. https://doi.org/10.3390/ma12111821

Chicago/Turabian StyleChen, Yanmin, Weiwei Xing, Ling Wang, and Lingxia Chen. 2019. "Experimental and Electrochemical Research of an Efficient Corrosion and Scale Inhibitor" Materials 12, no. 11: 1821. https://doi.org/10.3390/ma12111821

APA StyleChen, Y., Xing, W., Wang, L., & Chen, L. (2019). Experimental and Electrochemical Research of an Efficient Corrosion and Scale Inhibitor. Materials, 12(11), 1821. https://doi.org/10.3390/ma12111821