Mechanical and Corrosion Properties of Mg-Based Alloys with Gd Addition

Abstract

1. Introduction

2. Materials and Methods

2.1. Structure Testing and Phase Analysis

2.2. Mechanical Tests

2.3. Electrochemical and Immersion Tests

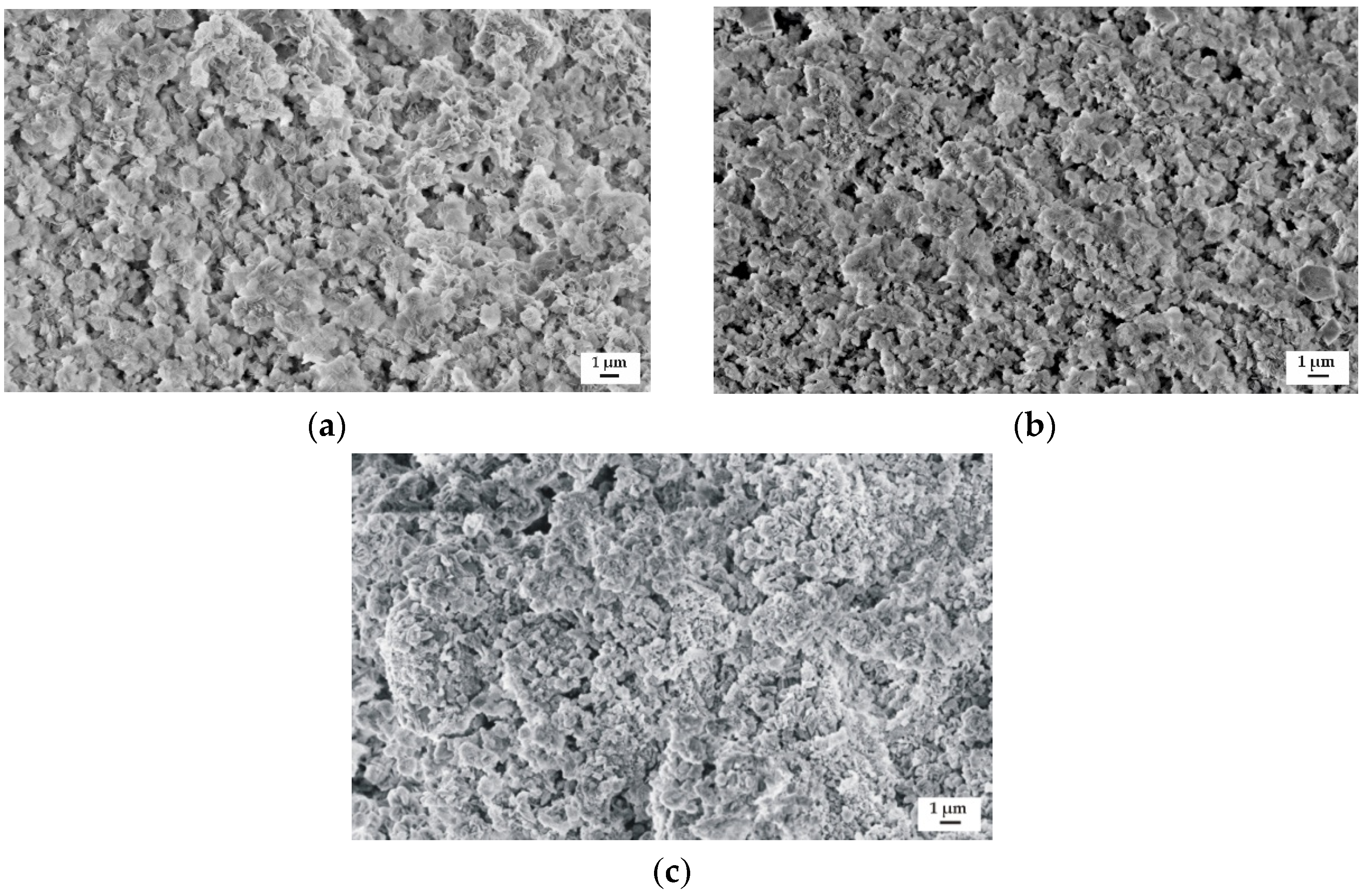

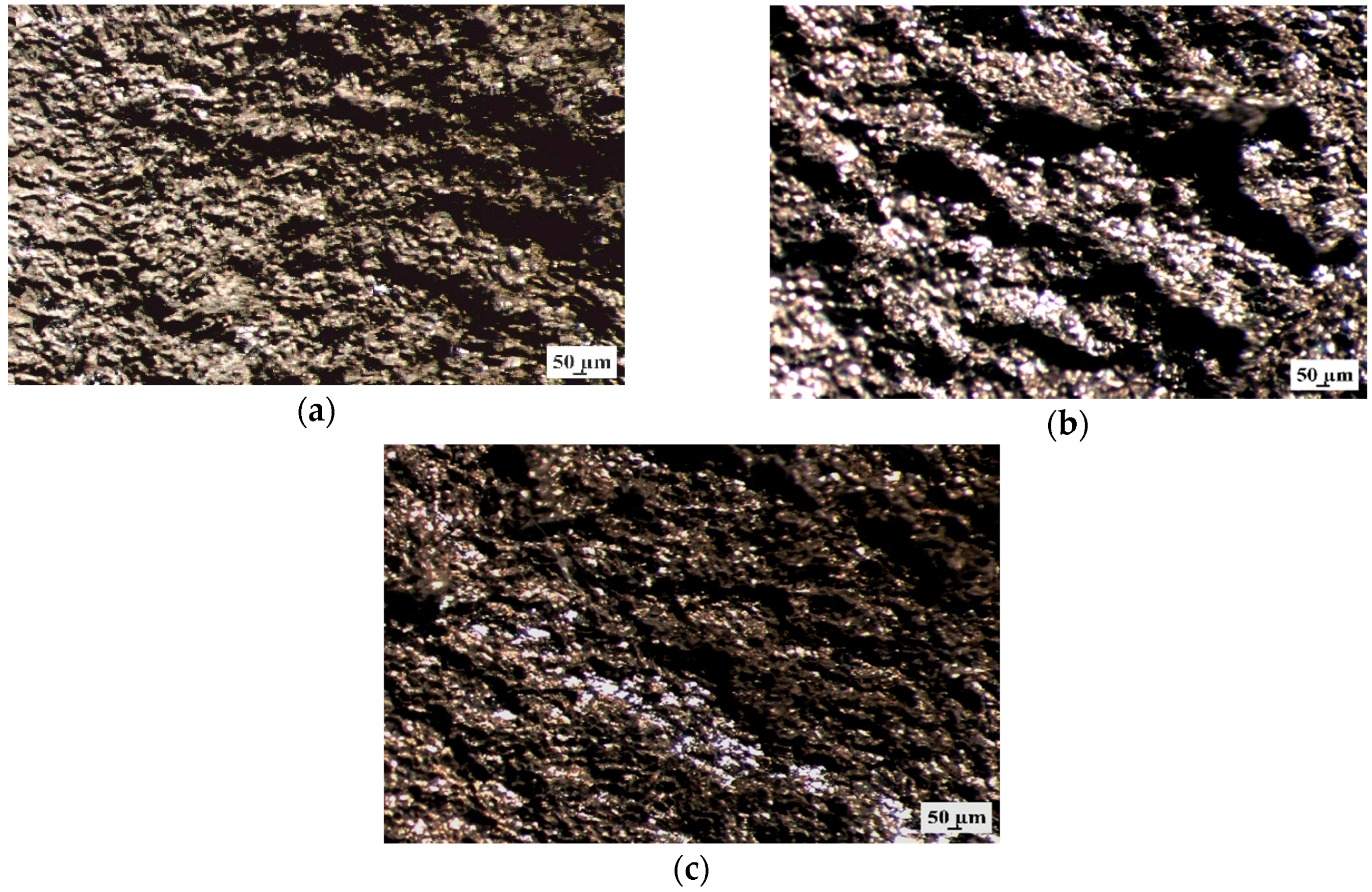

3. Results and Discussion

4. Conclusions

- In the present study the mechanical and corrosion properties of a new designed MgCa5-xZn1Gdx (x = 1, 2, and 3 wt. %) alloys were presented.

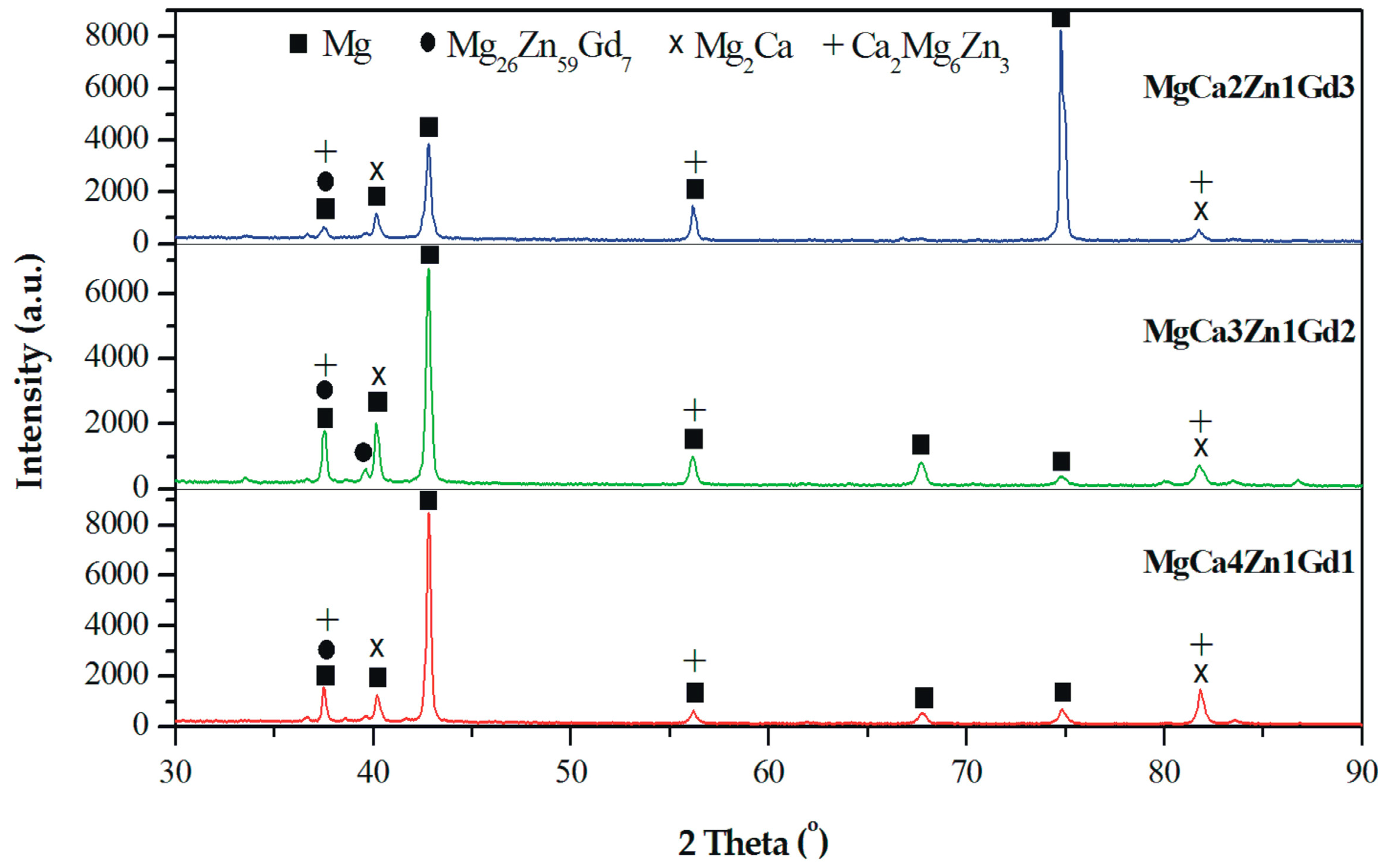

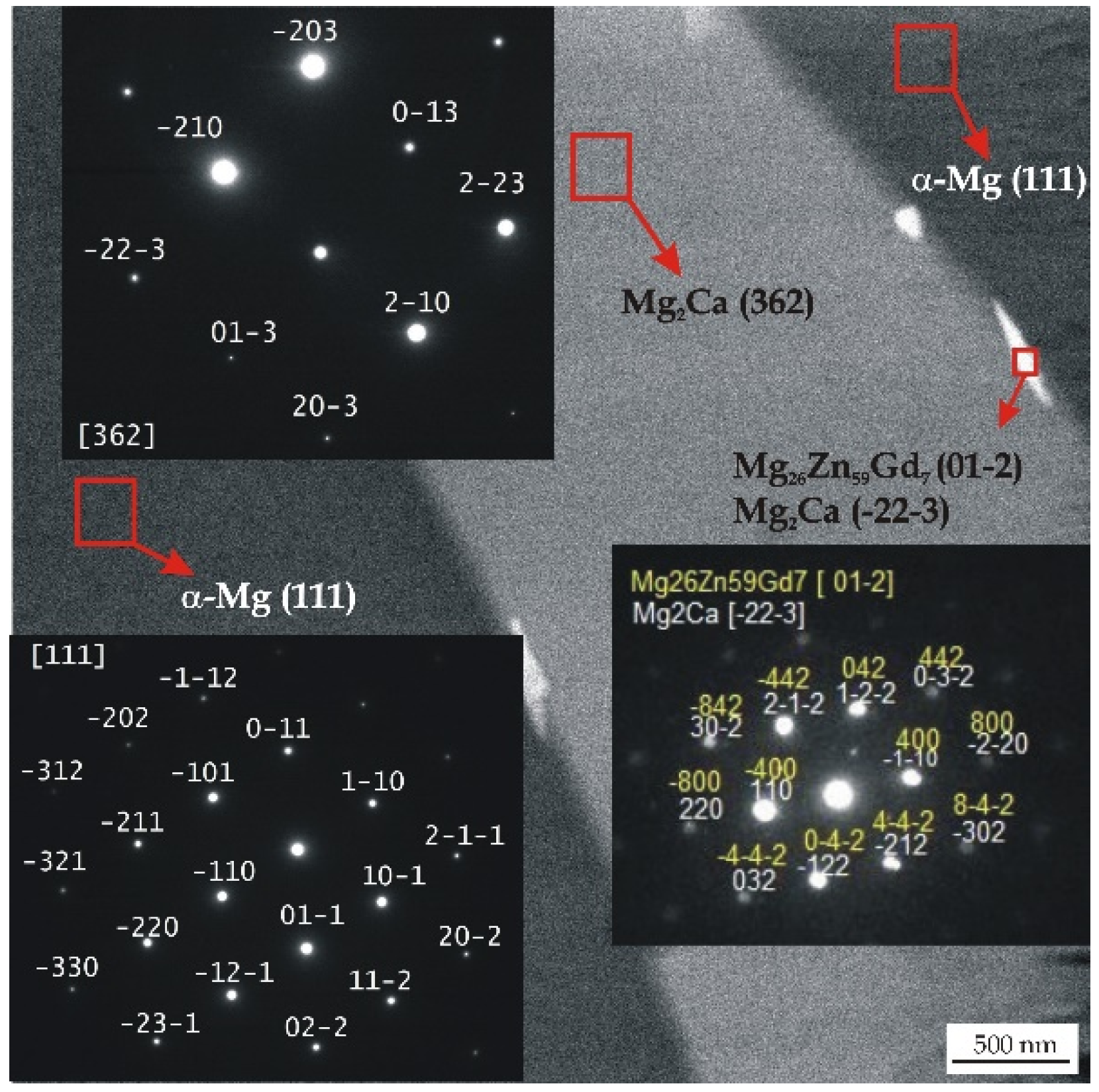

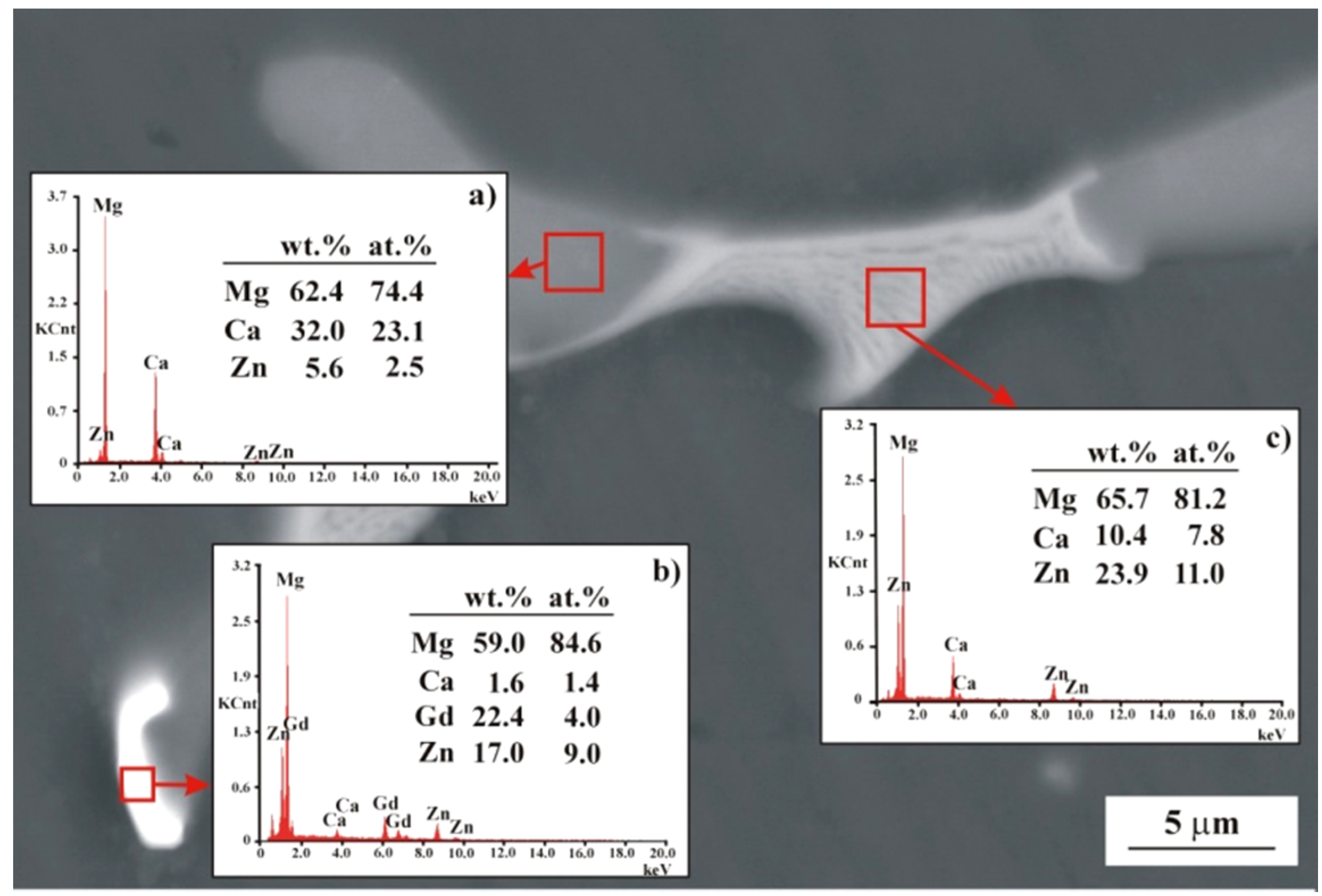

- The increase of Gd content in Mg alloys had an effect on the microstructure changes. A small reduction of eutectic volume by a low volume of Mg2Ca and Ca2Mg6Zn3 secondary phases could be observed.

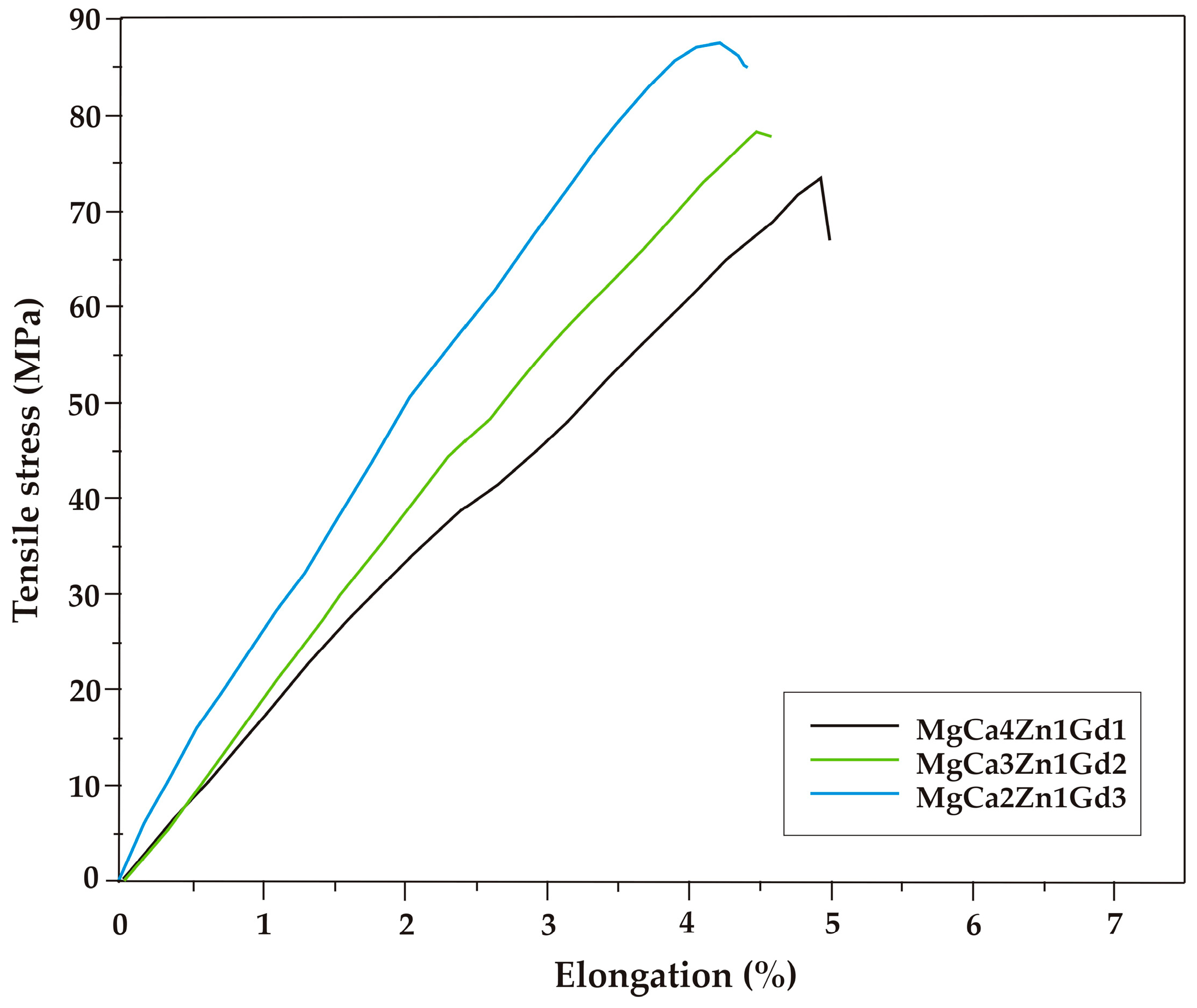

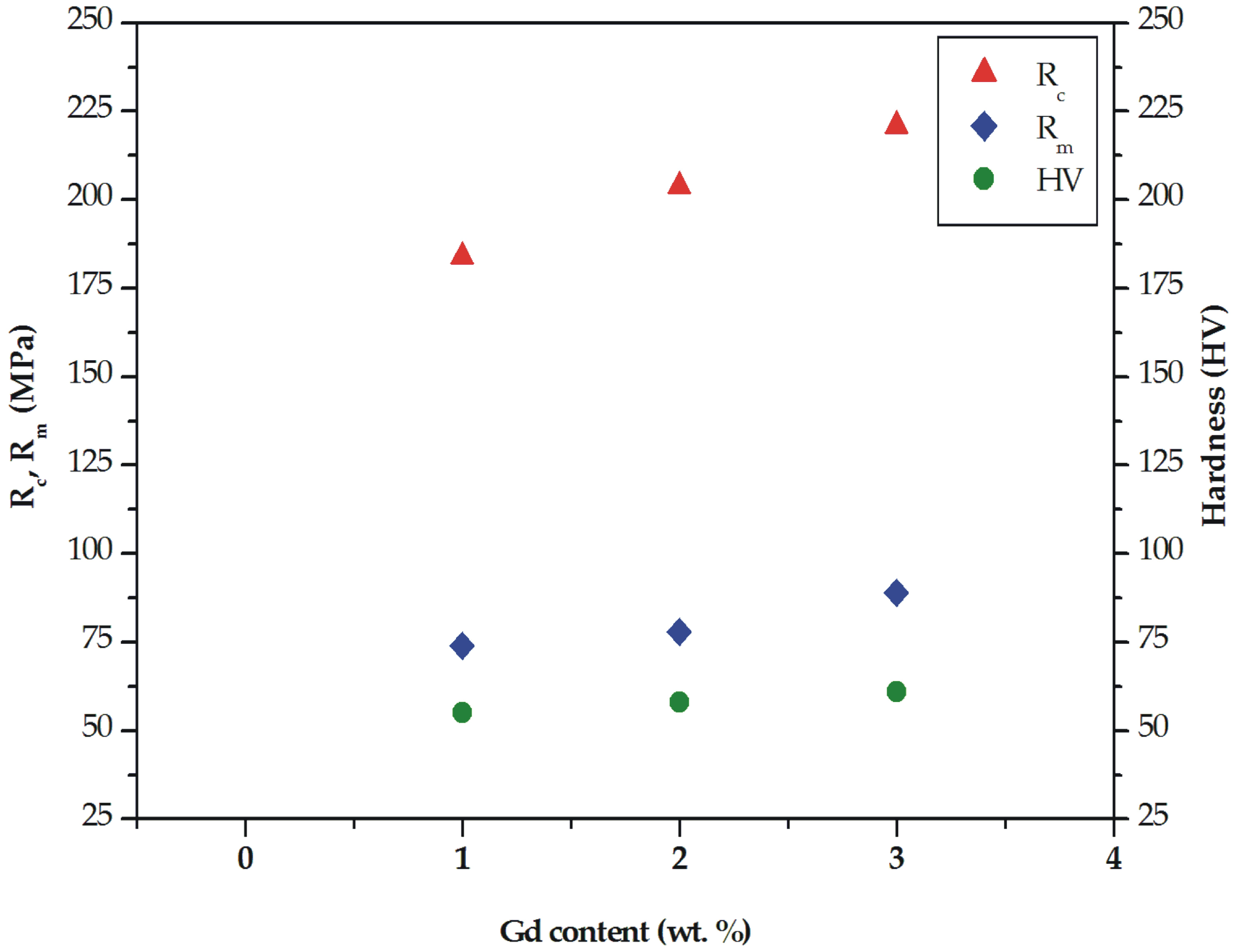

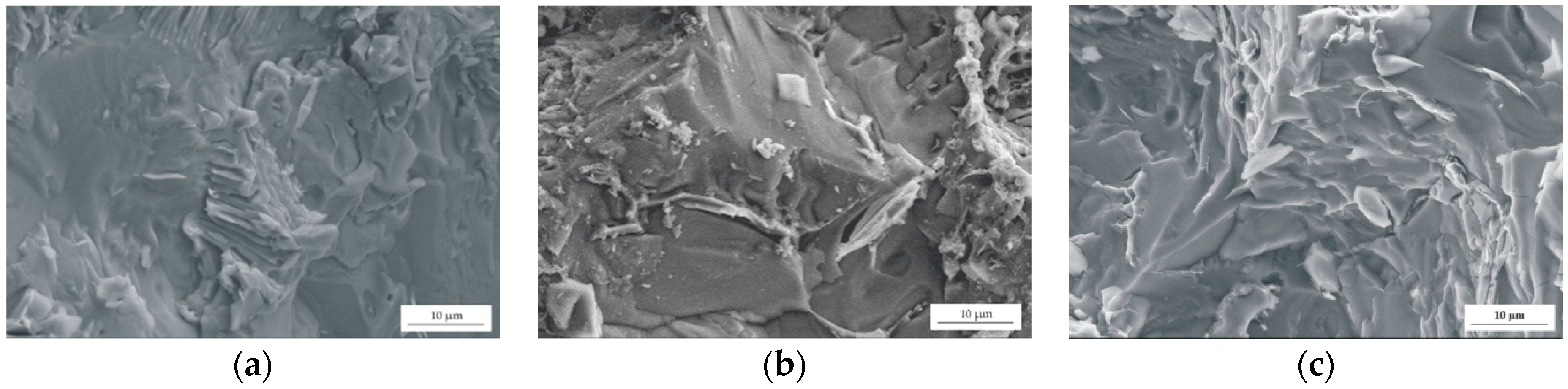

- The addition of Gd in the studied alloys resulted in the improvement of ultimate tensile strength (Rm for the alloys with 1, 2, and 3 wt. % Gd were 74, 78, and 89 MPa, respectively) and a decrease of the elongation (from 4.8% to 4.2%).

- The increase of Gd content also improved the compressive properties (for example, the compressive strength, Rc, were 184, 204, and 221 MPa for the MgCa4Zn1Gd1, MgCa3Zn1Gd2, and MgCa2Zn1Gd3 alloys, consequently).

- The Vickers hardness increased from 55 to 61 HV1 for the alloys with 1–3 wt. % Gd.

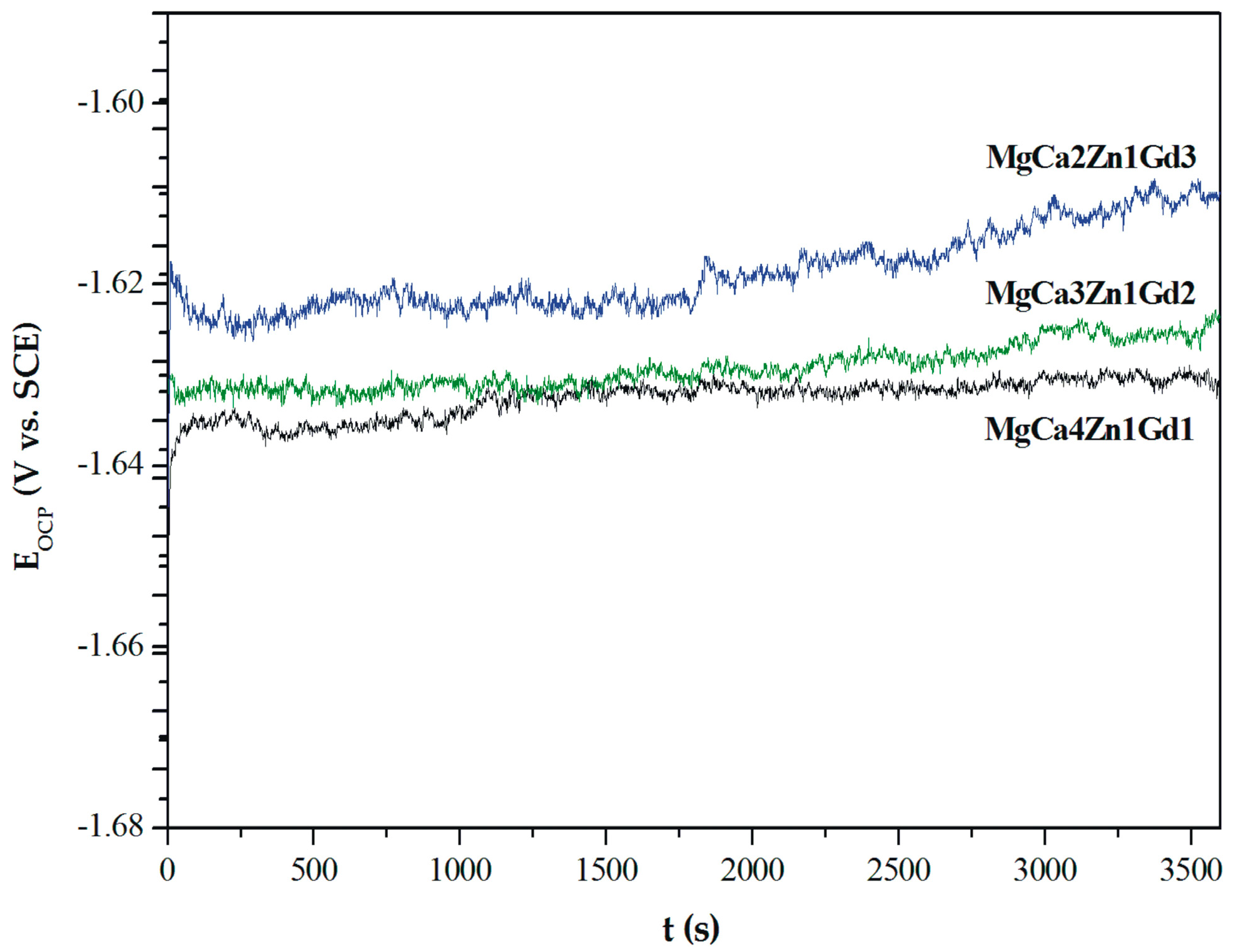

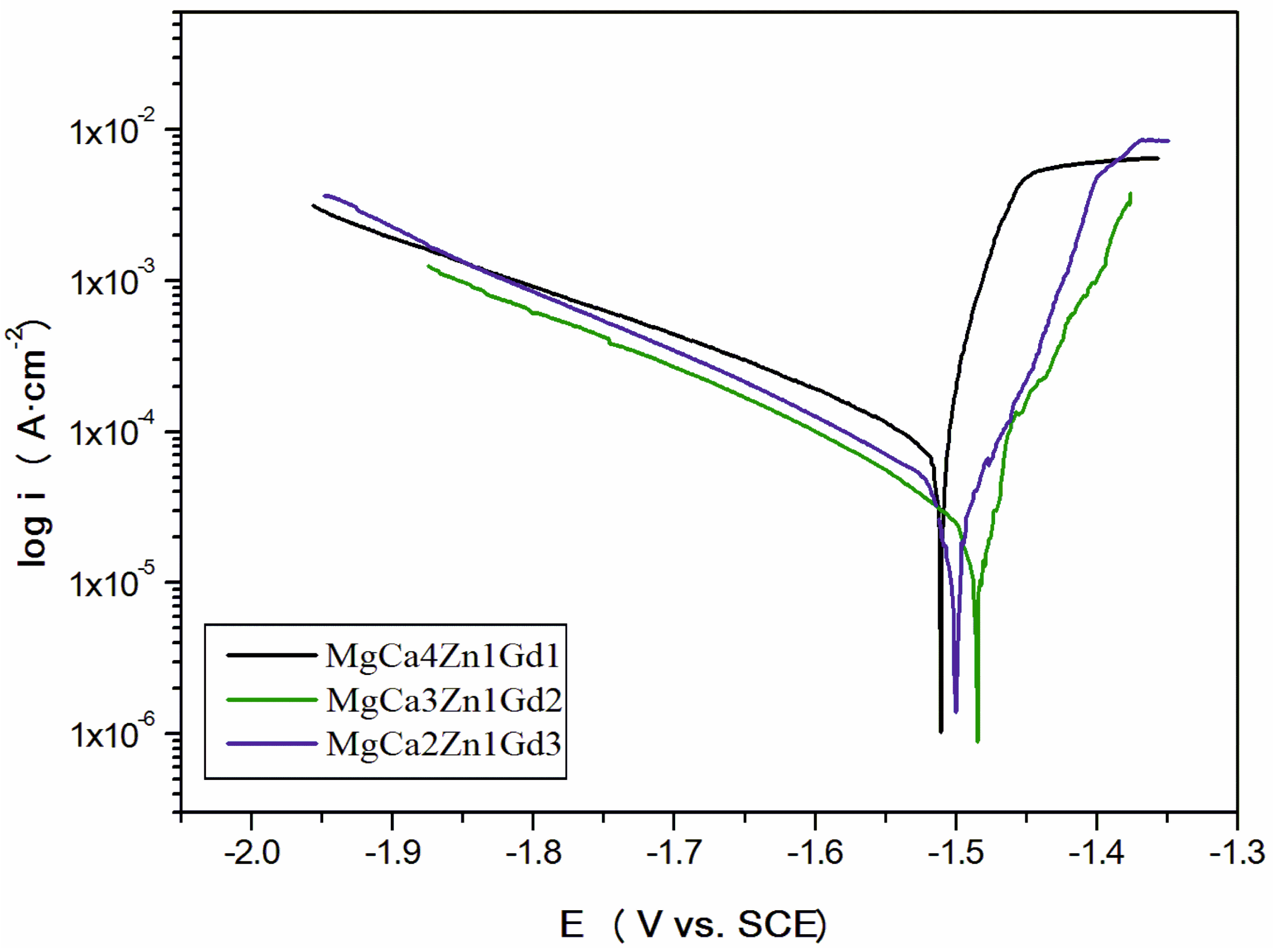

- The results of electrochemical corrosion tests showed that the studied alloys were characterized by good corrosion resistance. The corrosion potential (Ecorr) of the alloys shifted towards positive values in comparison to the EOCP potential.

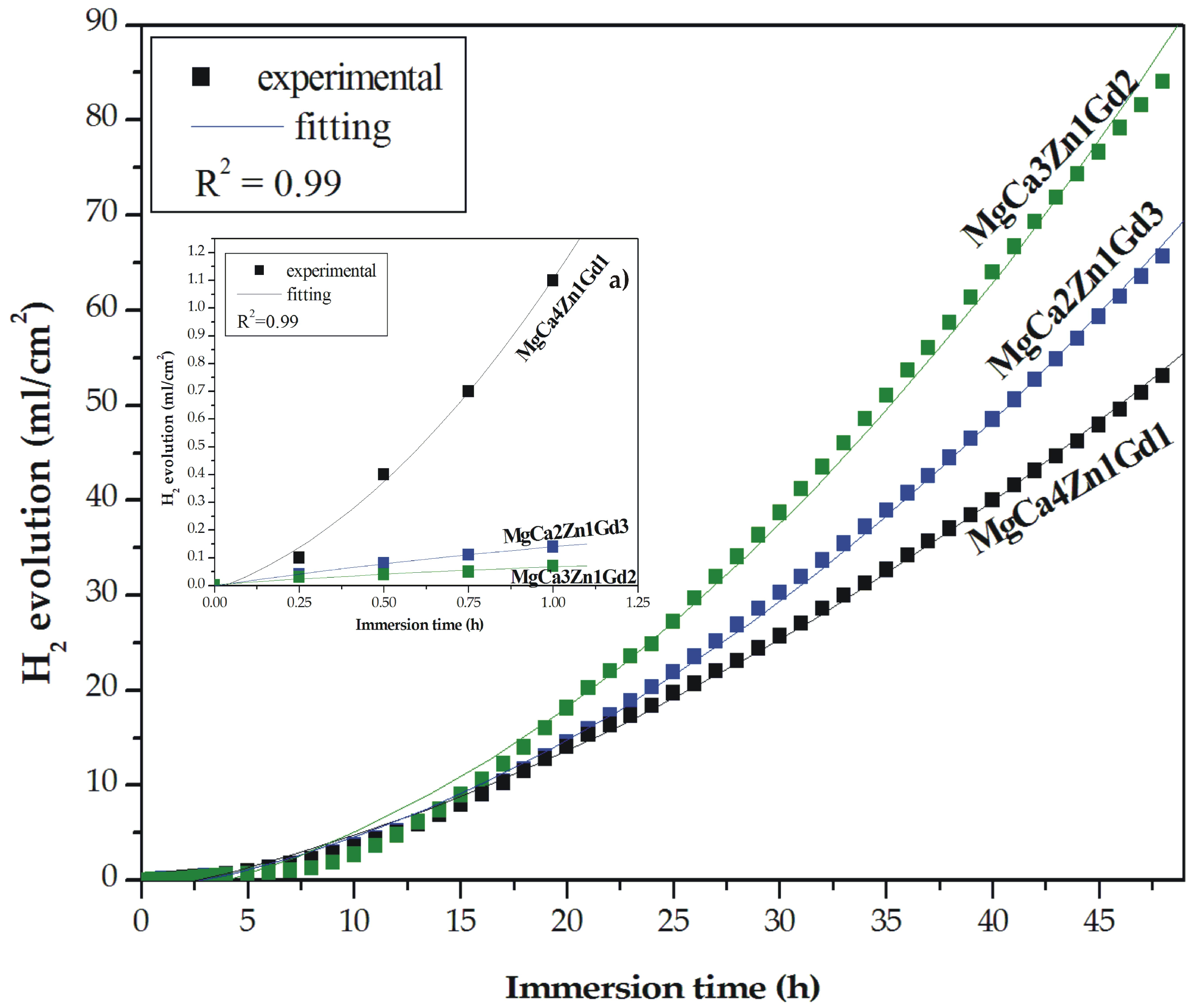

- The electrochemical corrosion rates corresponded with the corrosion rates measured in an aggressive environment during 8 h with immersion tests. The high corrosion resistance estimated by the evolved H2 volume after 1 and 8 h of immersion was indicated for the alloy with 2 wt. % Gd. The vcorr were 0.10 and 1.14 mm·y−1 for 1 and 8 h, respectively. The corrosion rates changed with time and after 48 h of immersion, the lowest vcorr equaled 5.97 mm·y−1 was noticed for the MgCa4Zn1Gd1 alloy.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, E.; Yin, D.; Xu, L.; Yang, L.; Yang, K. Microstructure, mechanical and corrosion properties and biocompatibility of Mg-Zn-Mn alloys for biomedical application. Mater. Sci. Eng. C 2009, 29, 987–993. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, B.; Wang, Y.; Geng, L.; Jiao, X. Preparation and characterization of a new biomedical Mg–Zn–Ca alloy. Mater. Des. 2012, 34, 58–64. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, Z.; Smith, C.; Sankar, J. Recent advances on the development of magnesium alloys for biodegradable implants. Acta Biomater. 2014, 10, 4561–4573. [Google Scholar] [CrossRef]

- Nowosielski, R.; Bajorek, A.; Babilas, R. Corrosion behavior of bioresorbable Ca-Mg-Zn bulk metallic glasses. J. Non-Cryst. Solids 2016, 447, 126–133. [Google Scholar] [CrossRef]

- Xin, Y.; Hu, T.; Chu, P.K. In vitro studies of biomedical magnesium alloys in a simulated physiological environment: A review. Acta Biomater. 2011, 7, 1452–1459. [Google Scholar] [CrossRef]

- Nassif, N.; Ghayad, I. Corrosion protection and surface treatment of magnesium alloys used for orthopedic applications. Adv. Mater. Sci. Eng. 2013, 2013, 1–10. [Google Scholar] [CrossRef]

- Li, H.F.; Xie, X.H.; Zhao, K.; Wang, Y.B.; Zheng, Y.F.; Wang, W.H.; Qin, L. In vitro and in vivo studies on biodegradable CaMgZnSrYb high-entropy bulk metallic glass. Acta Biomater. 2013, 9, 8561–8573. [Google Scholar] [CrossRef]

- Wang, Y.B.; Xie, X.H.; Li, H.F.; Wang, X.L.; Zhao, M.Z.; Zhang, E.W.; Bai, Y.J.; Zheng, Y.F.; Qin, L. Biodegradable CaMgZn bulk metallic glass for potential skeletal application. Acta Biomater. 2011, 7, 3196–3208. [Google Scholar] [CrossRef] [PubMed]

- Mareci, D.; Bolat, G.; Izquierdo, J.; Crimu, C.; Munteanu, C.; Antoniac, I.; Souto, R.M. Electrochemical characteristics of bioresorbable binary MgCa alloys in Ringer’s solution: Revealing the impact of local pH distributions during in-vitro dissolution. Mater. Sci. Eng. C 2016, 60, 402–410. [Google Scholar] [CrossRef]

- Gu, X.N.; Zhou, W.R.; Zheng, Y.F.; Cheng, Y.; Wei, S.C.; Zhong, S.P.; Xi, T.F.; Chen, L.J. Corrosion fatigue behaviors of two biomedical Mg alloys - AZ91D and WE43 - in simulated body fluid. Acta Biomater. 2010, 6, 4605–4613. [Google Scholar] [CrossRef] [PubMed]

- He, S.M.; Peng, L.M.; Zeng, X.Q.; Ding, W.J.; Zhu, Y.P. Comparison of the microstructure and mechanical properties of a ZK60 alloy with and without 1.3 wt.% gadolinium addition. Mater. Sci. Eng. A 2006, 433, 175–181. [Google Scholar] [CrossRef]

- Vlcek, M.; Cizek, J.; Lukac, F.; Hruska, P.; Smola, B.; Stulikova, I.; Kudrnova, H.; Minarik, P.; Kmjec, T.; Vlasak, T. Hydrogen absorption in Mg-Gd alloy. Int. J. Hydrog. Energ. 2017, 42, 22598–22604. [Google Scholar] [CrossRef]

- Srinivasan, A.; Huang, Y.; Mendis, C.L.; Blawert, C.; Kainer, K.U.; Hort, N. Investigations on microstructures, mechanical and corrosion properties of Mg–Gd–Zn alloys. Mater. Sci. Eng. A 2014, 595, 224–234. [Google Scholar] [CrossRef]

- Shi, L.; Huang, Y.; Yang, L.; Feyerabend, F.; Mendis, C.; Willumeit, R.; Kainer, K.U.; Hort, N. Mechanical properties and corrosion behavior of Mg-Gd-Ca-Zr alloys for medical applications. J. Mech. Behav. Biomed. Mater. 2015, 47, 38–48. [Google Scholar] [CrossRef]

- Zheng, K.Y.; Dong, J.; Zeng, X.Q.; Ding, W.J. Effect of thermo-mechanical treatment on the microstructure and mechanical properties of a Mg–6Gd–2Nd–0.5Zr alloy. Mater. Sci. Eng. A 2007, 454–455, 314–321. [Google Scholar] [CrossRef]

- Agarwal, S.; Curtin, J.; Duffy, B.; Jaiswal, S. Biodegradable magnesium alloys for orthopaedic applications: A review on corrosion, biocompatibility and surface modifications. Mater. Sci. Eng. C 2016, 68, 948–963. [Google Scholar] [CrossRef]

- Zheng, Y.F.; Gu, X.N.; Witte, F. Biodegradable metals. Mater. Sci. Eng. R 2014, 77, 1–34. [Google Scholar] [CrossRef]

- Srinivasan, A.; Blawert, C.; Huang, Y.; Mendis, C.L.; Kainer, K.U.; Hort, N. Corrosion behavior of Mg-Gd-Zn based alloys in aqueous NaCl solution. J. Magnes. Alloy. 2014, 2, 245–256. [Google Scholar] [CrossRef]

- Atrens, A.; Song, G.L.; Liu, M.; Shi, Z.; Cao, F.; Dargusch, M.S. Review of recent developments in the field of magnesium corrosion. Adv. Eng. Mater. 2015, 17, 400–453. [Google Scholar] [CrossRef]

- Song, G.; Atrens, A. Understanding magnesium corrosion mechanism: A framework for improved alloy performance. Adv. Eng. Mater. 2003, 5, 837–858. [Google Scholar] [CrossRef]

- Song, G.; Atrens, A. Corrosion mechanisms of magnesium alloys. Adv. Eng. Mater. 1999, 1, 11–33. [Google Scholar] [CrossRef]

- Shi, Z.; Liu, M.; Atrens, A. Measurement of the corrosion rate of magnesium alloys using Tafel extrapolation. Corros. Sci. 2010, 52, 579–588. [Google Scholar] [CrossRef]

- Cao, F.; Shi, Z.; Hofstetter, J.; Uggowitzer, P.J.; Song, G.; Liu, M.; Atrens, A. Corrosion of ultra-high-purity Mg in 3.5 % NaCl solution saturated with Mg(OH)2. Corros. Sci. 2013, 75, 78–99. [Google Scholar] [CrossRef]

- Atrens, A.; Johnston, S.; Shi, Z.; Dargusch, M.S. Viewpoint—Understanding Mg corrosion in the body for biodegradable medical implants. Scripta Mater. 2018, 154, 92–100. [Google Scholar] [CrossRef]

- Liu, M.; Uggowitzer, P.J.; Nagasekhar, A.V.; Schmutz, P.; Easton, M.; Song, G.; Atrens, A. Calculated phase diagrams and the corrosion of die-cast Mg-Al alloys. Corros. Sci. 2009, 51, 602–619. [Google Scholar] [CrossRef]

- Atrens, A.; Song, G.L.; Cao, F.; Shi, Z.; Bowen, P.K. Advances in Mg corrosion and research suggestions. J. Magnes. Alloy. 2013, 1, 177–200. [Google Scholar] [CrossRef]

- Zainal Abidin, N.I.; Atrens, A.D.; Martin, D.; Atrens, A. Corrosion of high purity Mg, Mg2Zn0.2Mn, ZE41 and AZ91 in Hank’s solution at 37 °C. Corros. Sci. 2011, 53, 3542–3556. [Google Scholar] [CrossRef]

- Zainal Abidin, N.I.; Rolfe, B.; Owen, H.; Malisano, J.; Martin, D.; Hofstetter, J.; Uggowitzer, P.J.; Atrens, A. The in vivo and in vitro corrosion of high-purity magnesium and magnesium alloys WZ21 and AZ91. Corros. Sci. 2013, 75, 354–366. [Google Scholar] [CrossRef]

- Liu, M.; Zanna, S.; Ardelean, H.; Frateur, I.; Schmutz, P.; Song, G.; Atrens, A.; Marcus, P. A first quantitative XPS study of the surface films formed, by exposure to water, on Mg and on the Mg-Al intermetallics: Al3Mg2 and Mg17Al12. Corros. Sci. 2009, 51, 1115–1127. [Google Scholar] [CrossRef]

- Chaojie, C.; Cheng, L.; Tong, L.; Cai, Z.; Zhang, H. The effect of Gd and Zn additions on microstructures and mechanical properties of Mg-4Sm-3Nd-Zr alloy. J. Alloy. Compd. 2017, 706, 526–537. [Google Scholar] [CrossRef]

- Liu, P.; Jiang, H.; Cai, Z.; Kang, Q.; Zhang, Y. The effect of Y, Ce and Gd on texture, recrystallization and mechanical property of Mg–Zn alloys. J. Magnes. Alloy. 2016, 4, 188–196. [Google Scholar] [CrossRef]

- Zhang, X.; Dai, J.; Yang, H.; Liu, S.; He, X.; Wang, Z. Influence of Gd and Ca on microstructure, mechanical and corrosion properties of Mg-Gd-Zn(-Ca) alloys. Mater. Technol. 2017, 32, 399–408. [Google Scholar] [CrossRef]

- Hantzsche, K.; Bohlen, J.; Wendt, J.; Kainer, K.U.; Yia, S.B.; Letzig, D. Effect of rare earth additions on microstructure and texture development of magnesium alloy sheets. Scripta Mater. 2010, 63, 725–730. [Google Scholar] [CrossRef]

- Gao, L.; Chen, R.S.; Han, E.H. Effects of rare-earth elements Gd and Y on the solid solution strengthening of Mg alloys. J. Alloy. Compd. 2009, 481, 379–384. [Google Scholar] [CrossRef]

- Zhang, X.; Ba, Z.; Wang, Z.; He, X.; Shen, C.; Wang, Q. Influence of silver addition on microstructure and corrosion behavior of Mg-Nd-Zn-Zr alloys for biomedical application. Mater. Lett. 2013, 100, 188–191. [Google Scholar] [CrossRef]

- Wen, Q.; Deng, K.; Shi, J.; Zhang, B.; Liang, W. Effect of Ca addition on the microstructure and tensile properties of Mg–4.0Zn–2.0Gd alloys. Mater. Sci. Eng. A 2014, 609, 1–6. [Google Scholar] [CrossRef]

- Liu, S.J.; Yang, G.Y.; Luo, S.F.; Jie, W.Q. Microstructure and mechanical properties of sand mold cast Mg–4.58Zn–2.6Gd–0.18Zr magnesium alloy after different heat treatments. J. Alloy. Compd. 2015, 644, 846–853. [Google Scholar] [CrossRef]

- Yang, G.; Luo, S.; Liu, S.; Xiao, L.; Jie, W. Microstructural evolution, phase constitution and mechanical properties of directionally solidified Mg-5.5Zn-xGd (x = 0.8, 2.0, and 4.0) alloys. J. Alloy. Compd. 2017, 725, 145–154. [Google Scholar] [CrossRef]

- Fei, S.H.I.; Wang, C.Q.; Zhang, Z.M. Microstructures, corrosion and mechanical properties of as-cast Mg-Zn-Y-(Gd) alloys. Trans. Nonferrous Met. Soc. China 2015, 25, 2172–2180. [Google Scholar] [CrossRef]

- Liu, M.; Qiu, D.; Zhao, M.C.; Song, G.; Atrens, A. The effect of crystallographic orientation on the active corrosion of pure magnesium. Scripta Mater. 2008, 58, 421–424. [Google Scholar] [CrossRef]

- Myrissa, A.; Agha, N.A.; Lu, Y.; Martinelli, E.; Eichler, J.; Szakács, G.; Kleinhans, K.; Willumeit-Römer, R.; Schäfer, U.; Weinberg, A.M. In vitro and in vivo comparison of binary Mg alloys and pure Mg. Mater. Sci. Eng. C 2016, 61, 865–874. [Google Scholar] [CrossRef]

- ISO. Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature; ISO 6892−1:2016; ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Static Compression Test of Metallic Materials; PN-H-04320:1957; Polish Committee for Standardization: Warsaw, Poland, 1957. (In Polish)

- Hiraga, K.; Ohsuna, T.; Yasuda, K.; Sugiyama, K. The structures of hexagonal phases in Mg-Zn-RE (RE = Sm and Gd) alloys. Z. Krist. 1998, 213, 537–543. [Google Scholar] [CrossRef]

- Li, Y.; Qin, F.; Liu, C.; Wu, Z. A review: Effect of friction stir welding on microstructure and mechanical properties of magnesium alloys. Metals 2017, 7, 524. [Google Scholar] [CrossRef]

- Min, Y.; Debao, L.; Runfang, Z.; Minfang, C. Microstructure and properties of Mg-3Zn-0.2Ca alloy for biomedical application. Rare Met. Mater. Eng. 2018, 47, 93–98. [Google Scholar] [CrossRef]

- Zainal Abidin, N.I.; Martin, D.; Atrens, A. Corrosion of high purity Mg, AZ91, ZE41, and Mg2Zn0.2Mn in Hank’s solution at room temperature. Corros. Sci. 2011, 53, 862–872. [Google Scholar] [CrossRef]

- Song, G.L.; Atrens, A.; StJohn, D. An hydrogen evolution method for the estimation of the corrosion rate of magnesium alloys. Mag. Technol. 2001, 255–262. [Google Scholar]

- Hort, N.; Huang, Y.; Fechner, D.; Störmer, M.; Blawert, C.; Witte, F.; Vogt, C.; Drücker, H.; Willumeit, R.; Kainer, K.U.; et al. Magnesium alloys as implant materials – Principles of property design for Mg-RE alloys. Acta Biomater. 2010, 6, 1714–1725. [Google Scholar] [CrossRef]

- Zeng, R.C.; Dietzel, W.; Witte, F.; Hort, N.; Blawert, C. Progress and challenge for magnesium alloys as biomaterials. Adv. Eng. Mater. 2008, 10, B3–B14. [Google Scholar] [CrossRef]

| Alloy | Tensile Yield Strength, YTS, MPa | Ultimate Tensile Strength, Rm, MPa | Maximum Elongation, At, % |

|---|---|---|---|

| MgCa4Zn1Gd1 | 40 ± 1.7 | 74 | 4.8 |

| MgCa3Zn1Gd2 | 42 ± 2.4 | 78 | 4.4 |

| MgCa2Zn1Gd3 | 48 ± 2.9 | 89 | 4.2 |

| Alloy | Compressive Yield Strength, YCS, MPa | Compressive Strength, Rc, MPa | Compressive Strain, % |

|---|---|---|---|

| MgCa4Zn1Gd1 | 120 ± 4.6 | 184 | 7.0 ± 1.1 |

| MgCa3Zn1Gd2 | 130 ± 3.9 | 204 | 8.5 ± 0.9 |

| MgCa2Zn1Gd3 | 135 ± 5.1 | 221 | 9.0 ± 1.3 |

| Alloy | Corrosion Potential, Ecorr, V | Polarization Resistance, Rp, Ω·cm2 | Corrosion Current Density, icorr, μA·cm−2 | Corrosion Rate, vcorr, mm·y−1 |

|---|---|---|---|---|

| MgCa4Zn1Gd1 | −1.51 ± 0.03 | 110 ± 2 | 170 ± 7 | 1.86 ± 0.02 |

| MgCa3Zn1Gd2 | −1.48 ± 0.03 | 532 ± 10 | 51 ± 2 | 0.62 ± 0.02 |

| MgCa2Zn1Gd3 | −1.50 ± 0.03 | 480 ± 9 | 98 ± 4 | 1.48 ± 0.02 |

| Alloy | Corrosion Rate, vcorr, mm·y−1 (after 1 h) | Corrosion Rate, vcorr, mm·y−1 (after 8 h) | Corrosion Rate, vcorr, mm·y−1 (after 48 h) |

|---|---|---|---|

| MgCa4Zn1Gd1 | 0.16 ± 0.03 | 2.66 ± 0.02 | 5.97 ± 0.02 |

| MgCa3Zn1Gd2 | 0.10 ± 0.03 | 1.14 ± 0.02 | 8.22 ± 0.02 |

| MgCa2Zn1Gd3 | 0.11 ± 0.03 | 1.67 ± 0.02 | 6.63 ± 0.02 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kania, A.; Nowosielski, R.; Gawlas-Mucha, A.; Babilas, R. Mechanical and Corrosion Properties of Mg-Based Alloys with Gd Addition. Materials 2019, 12, 1775. https://doi.org/10.3390/ma12111775

Kania A, Nowosielski R, Gawlas-Mucha A, Babilas R. Mechanical and Corrosion Properties of Mg-Based Alloys with Gd Addition. Materials. 2019; 12(11):1775. https://doi.org/10.3390/ma12111775

Chicago/Turabian StyleKania, Aneta, Ryszard Nowosielski, Agnieszka Gawlas-Mucha, and Rafał Babilas. 2019. "Mechanical and Corrosion Properties of Mg-Based Alloys with Gd Addition" Materials 12, no. 11: 1775. https://doi.org/10.3390/ma12111775

APA StyleKania, A., Nowosielski, R., Gawlas-Mucha, A., & Babilas, R. (2019). Mechanical and Corrosion Properties of Mg-Based Alloys with Gd Addition. Materials, 12(11), 1775. https://doi.org/10.3390/ma12111775