Production of Lightweight Alkali Activated Mortars Using Mineral Wools

Abstract

1. Introduction

2. Experiment Plan

2.1. Materials and Mix Design

2.2. Casting and Curing

2.3. Tests Procedures

2.3.1. Mini-Slump Flow Test

2.3.2. Density Measurement

2.3.3. Ultrasonic Pulse Velocity

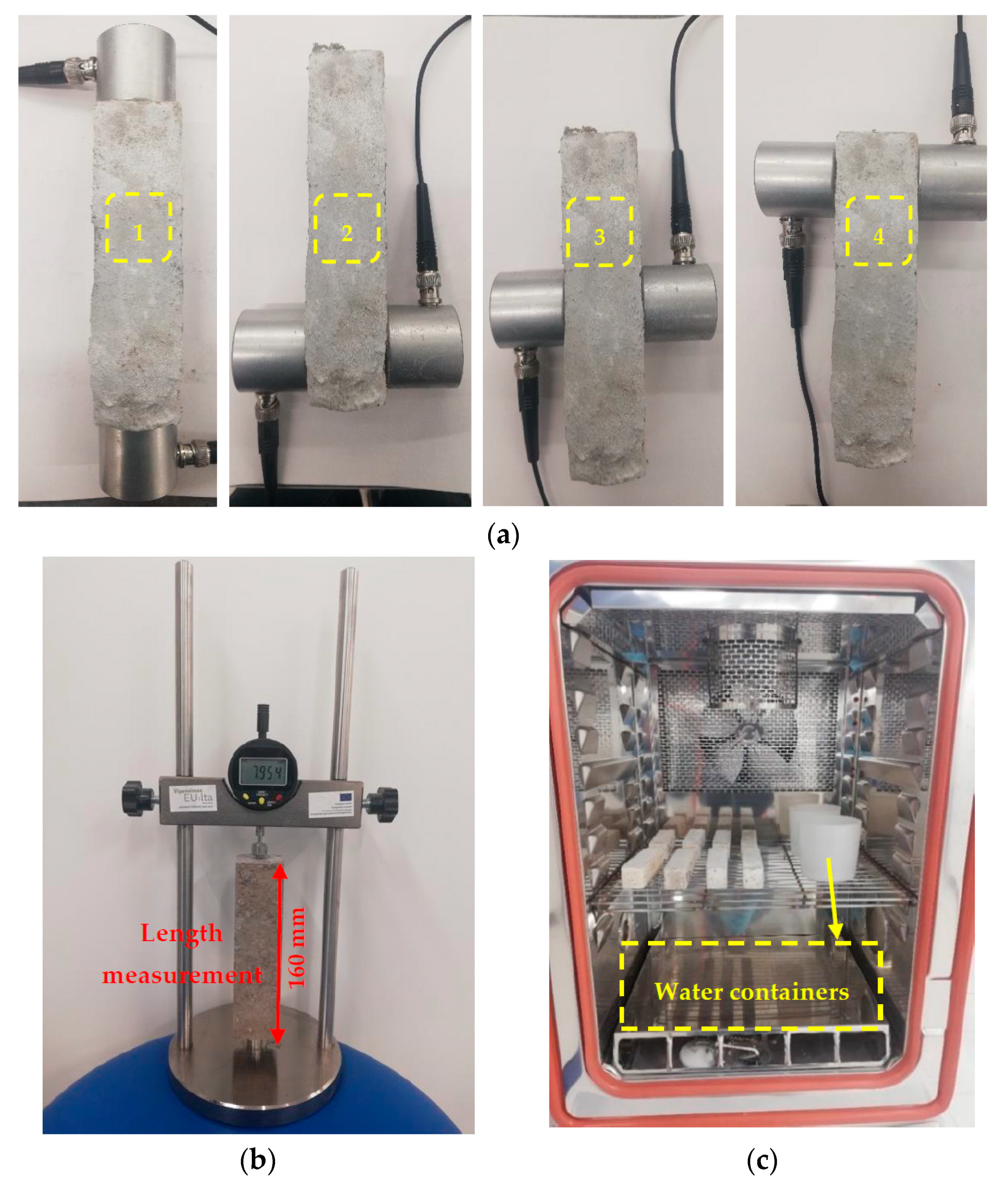

2.3.4. Compressive Strength

2.3.5. Flexural Strength

2.3.6. Drying Shrinkage

2.3.7. Efflorescence Assessment

2.3.8. Water Absorption and Permeable Porosity

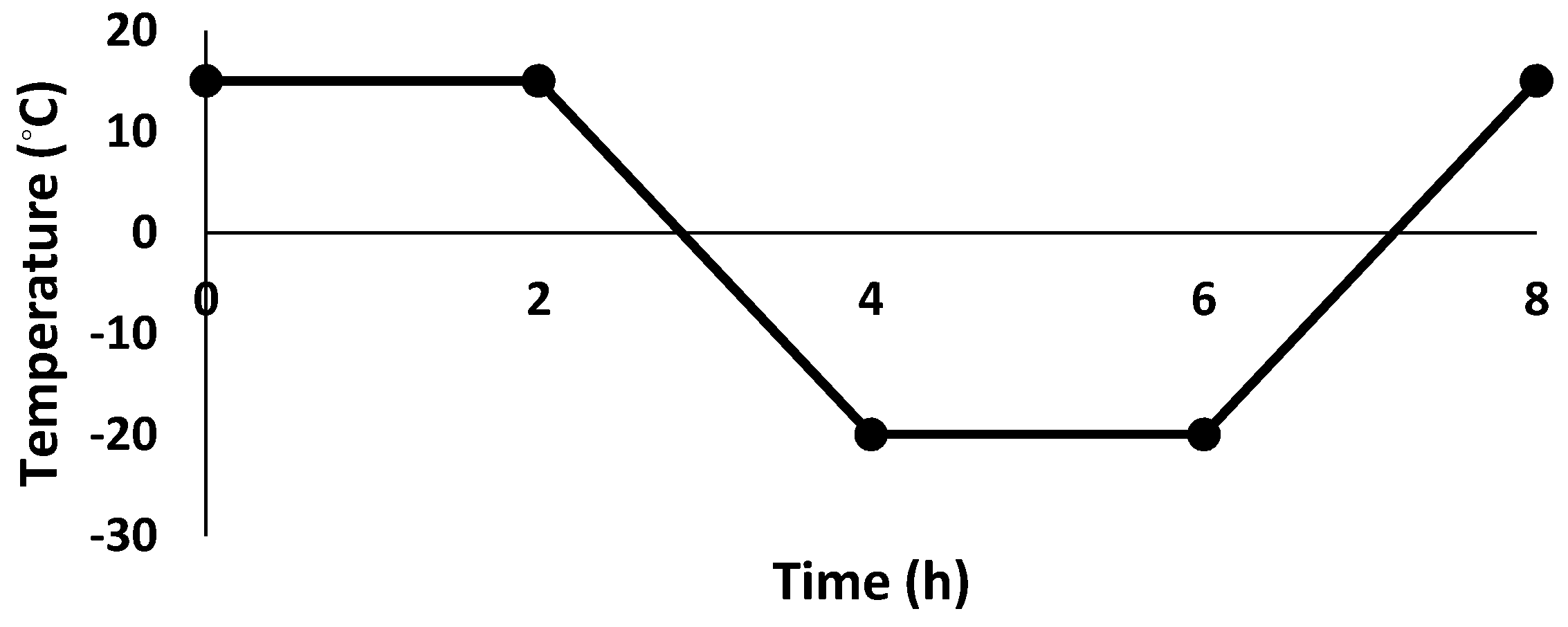

2.3.9. Freeze and Thaw Resistance

2.3.10. Carbonation Test

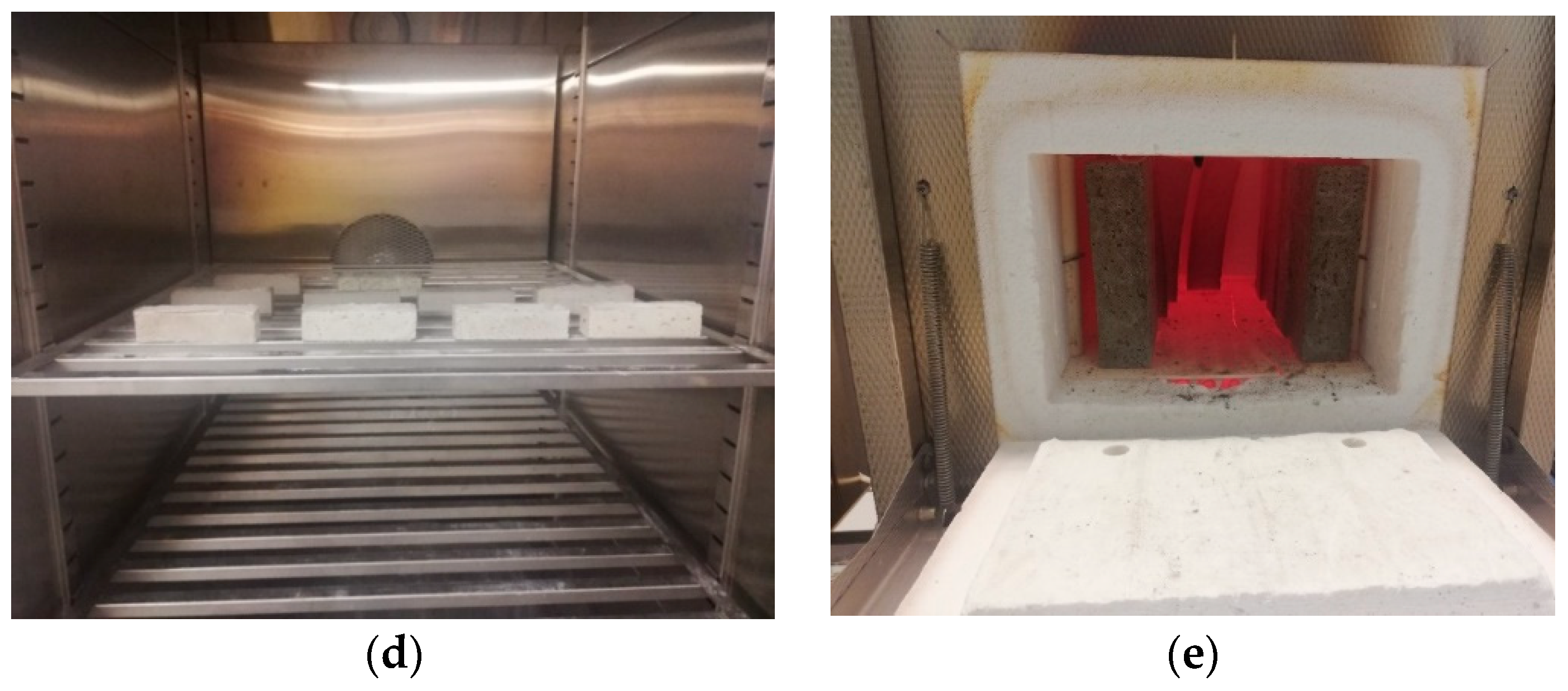

2.3.11. High-Temperature Test

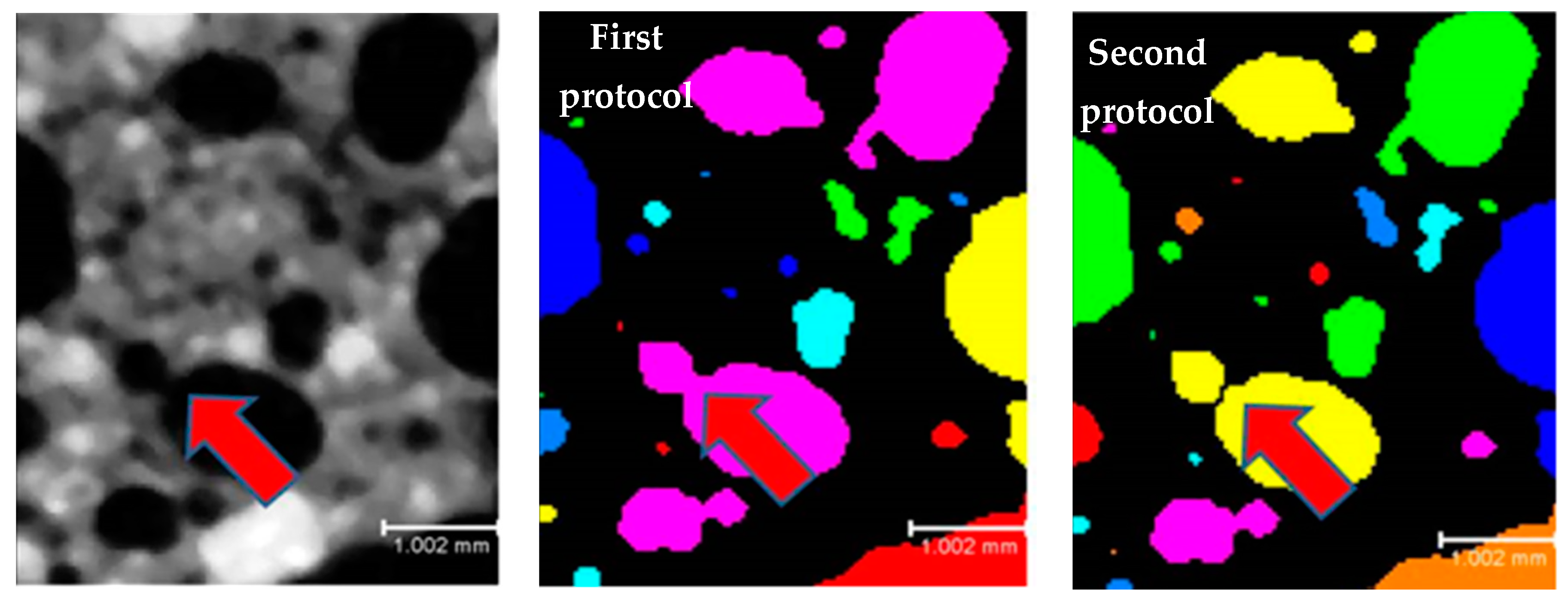

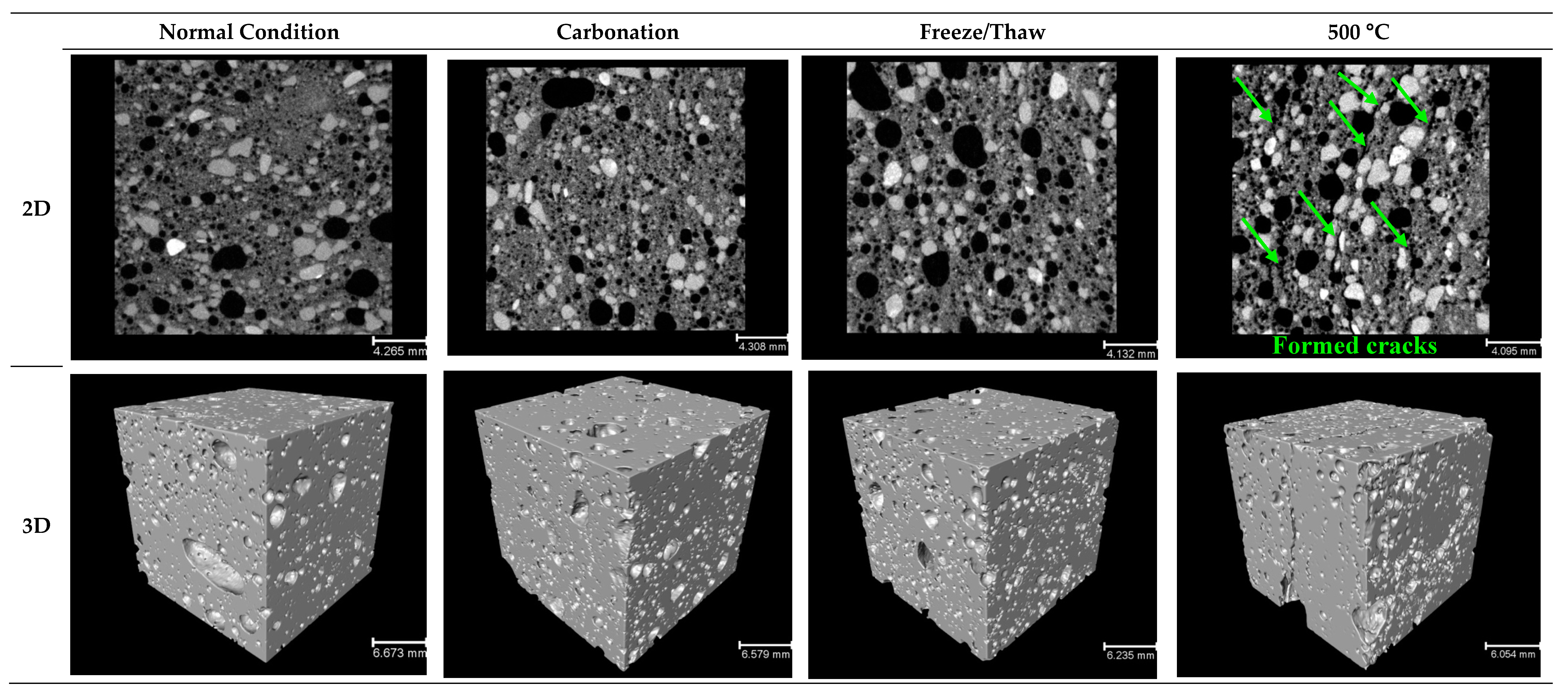

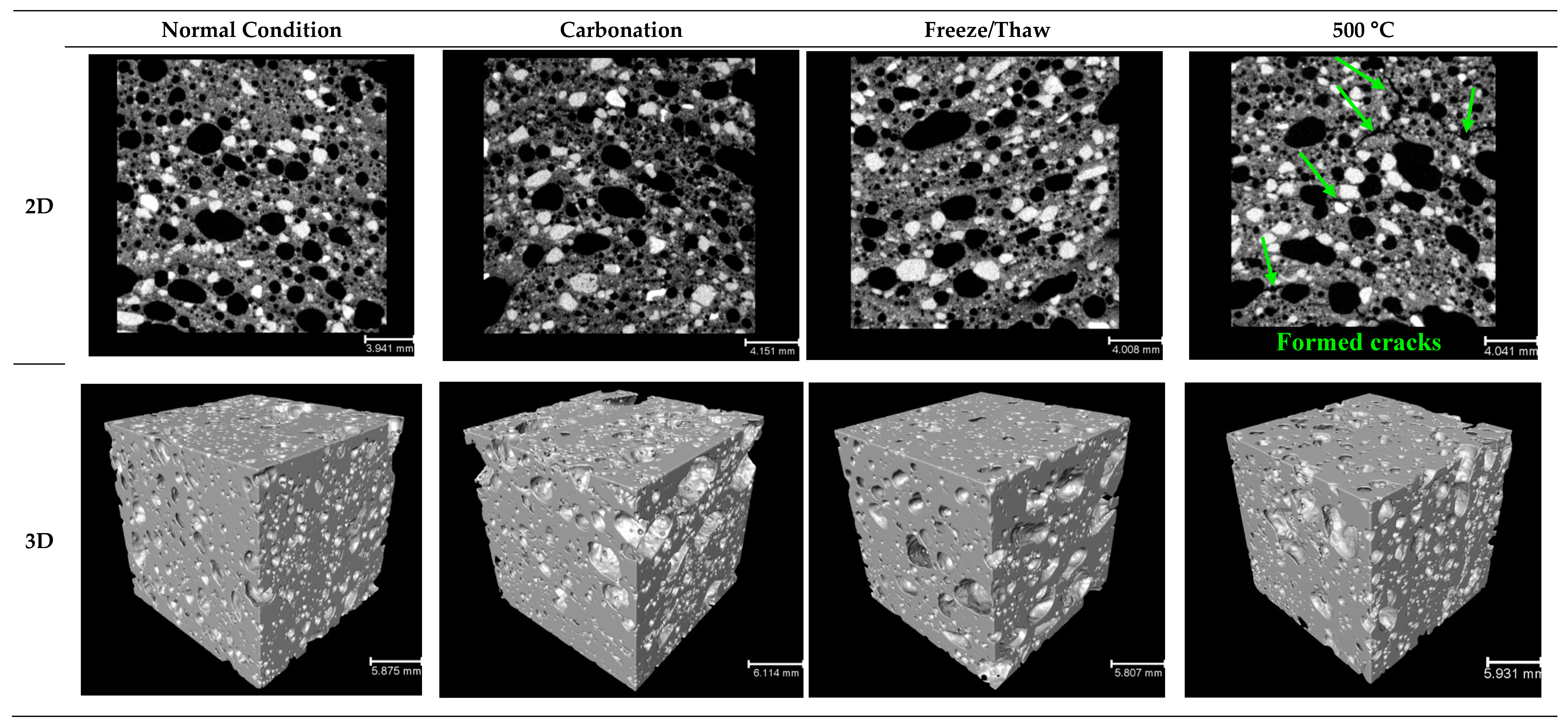

2.3.12. X-Ray Micro-Computed Tomography Technique

3. Results and Discussion

3.1. Mini-Flow Slump Test

3.2. Hardened State Properties

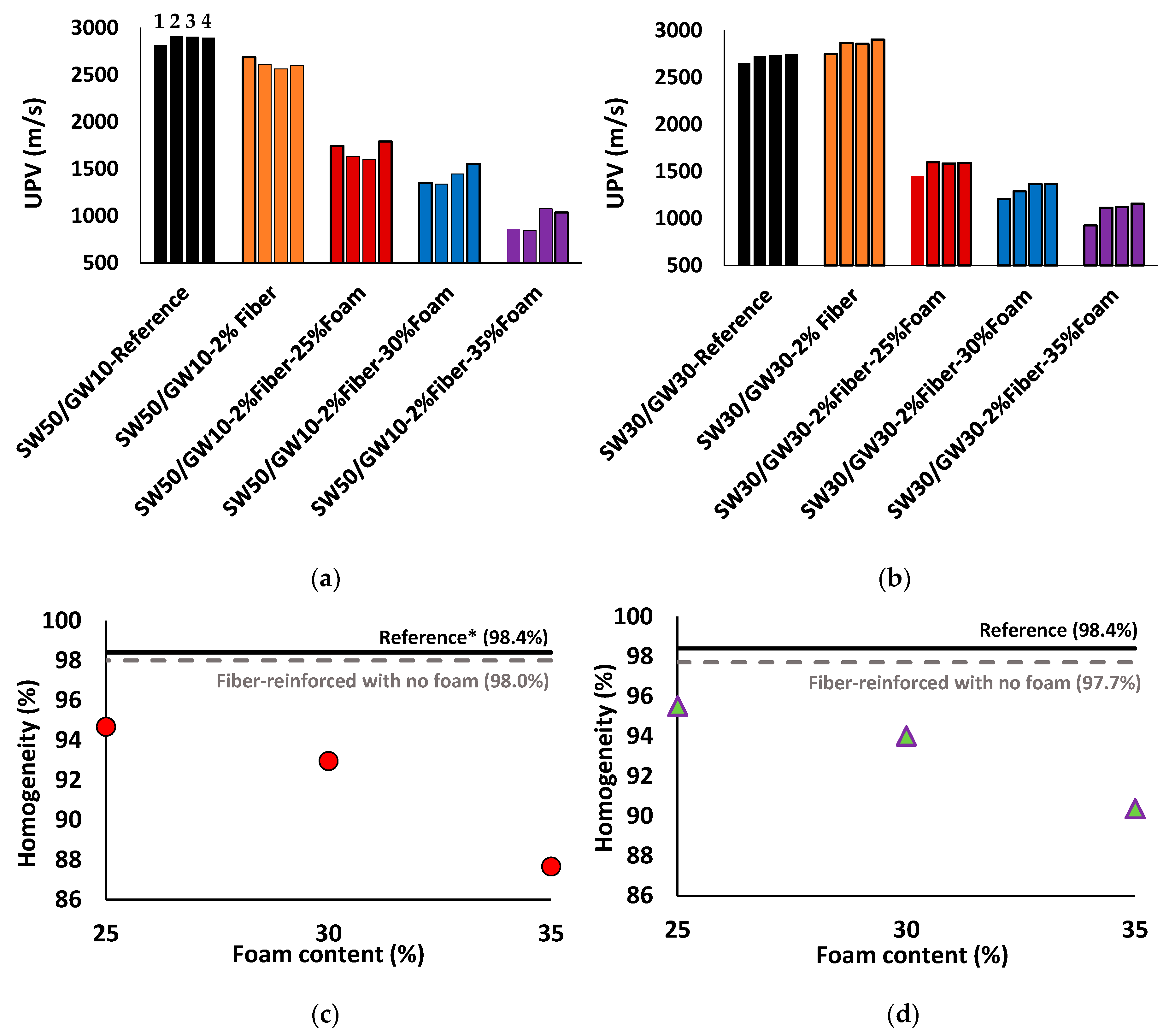

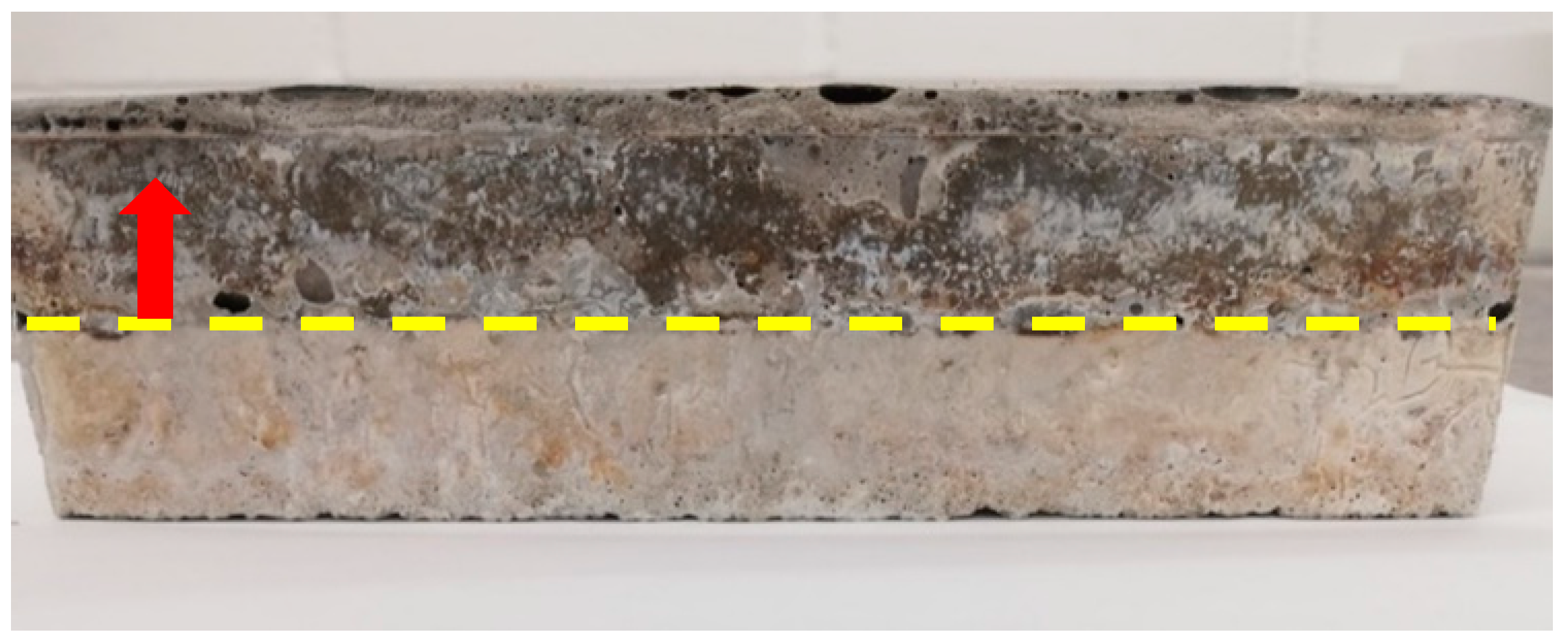

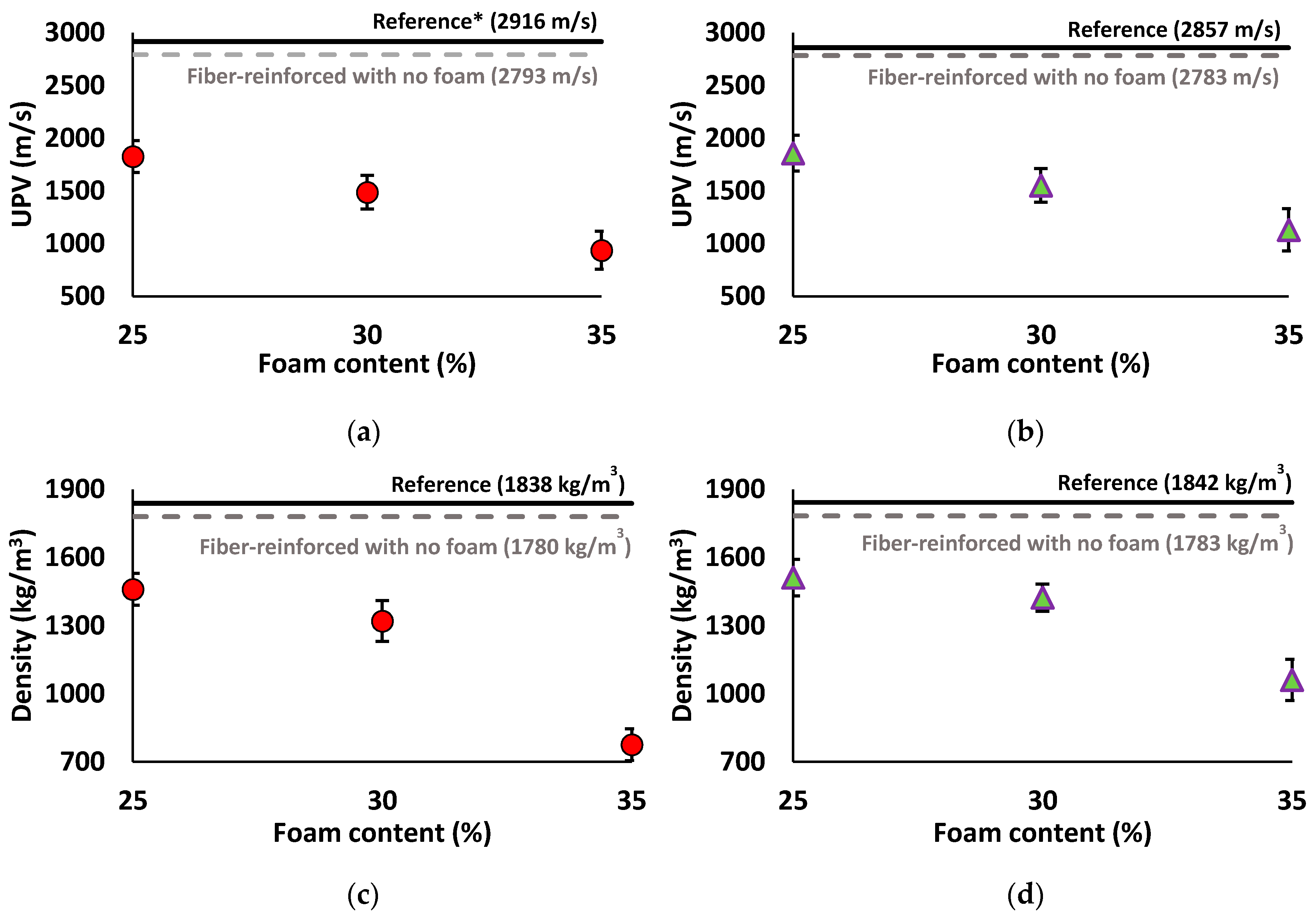

3.2.1. UPV and Density

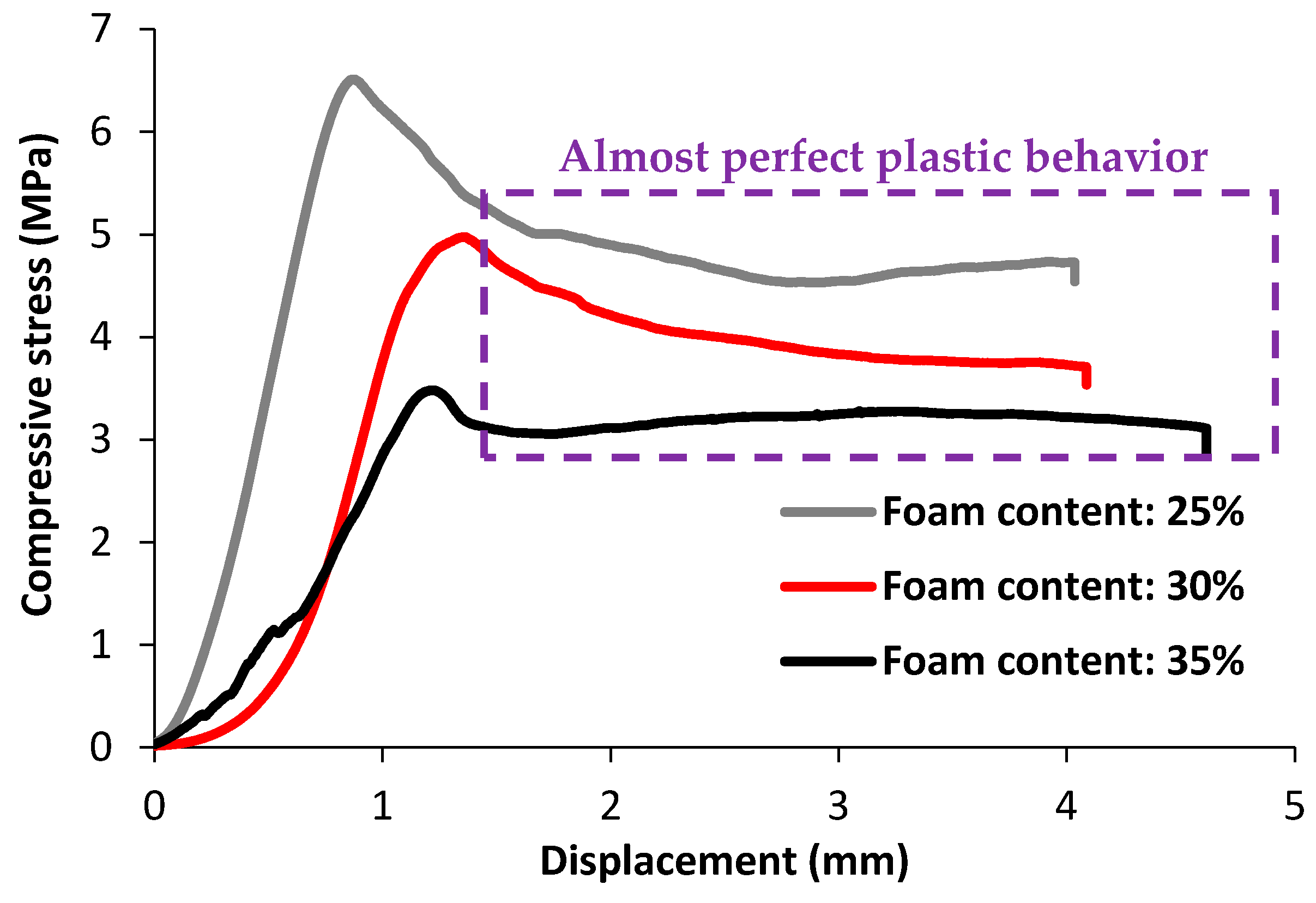

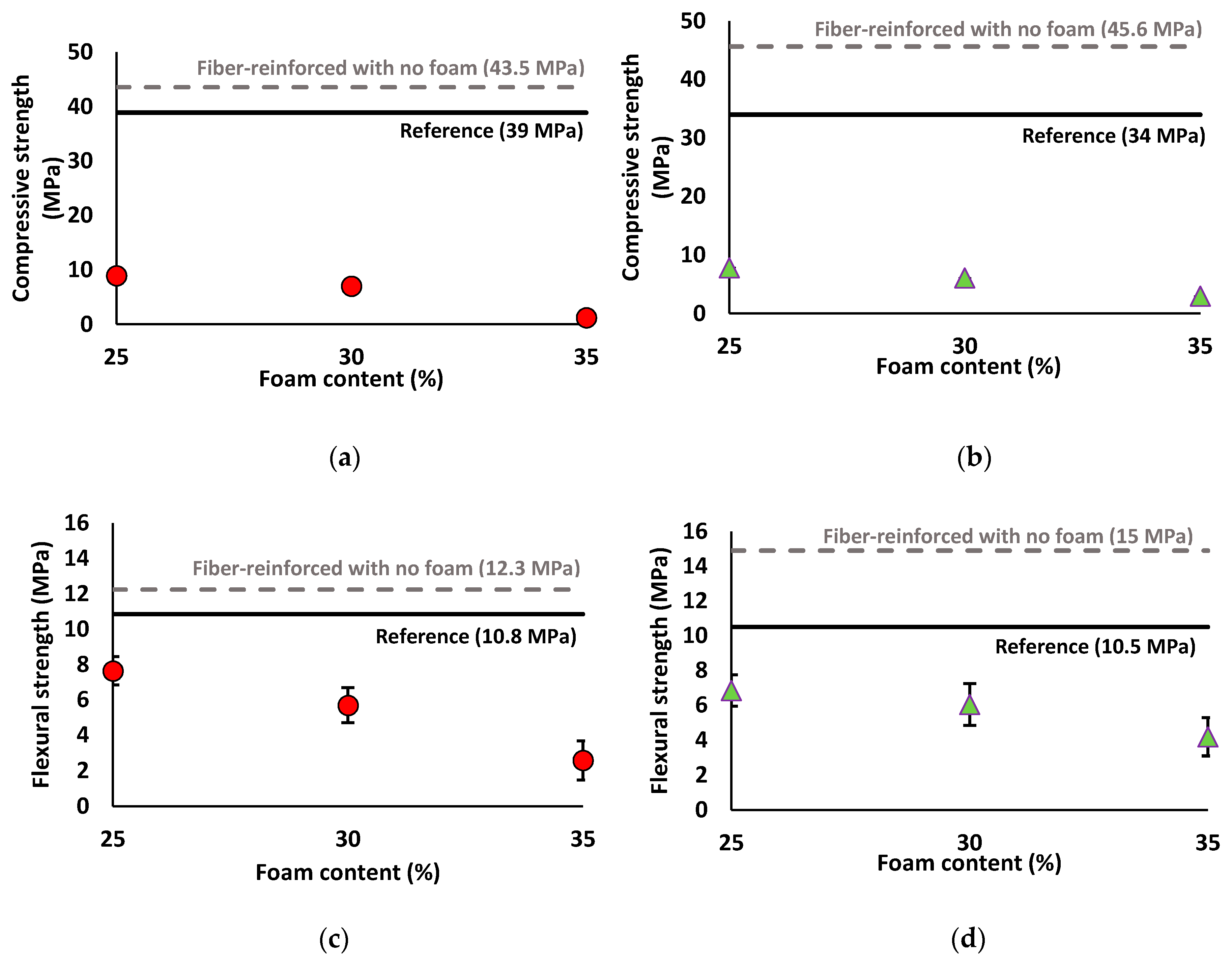

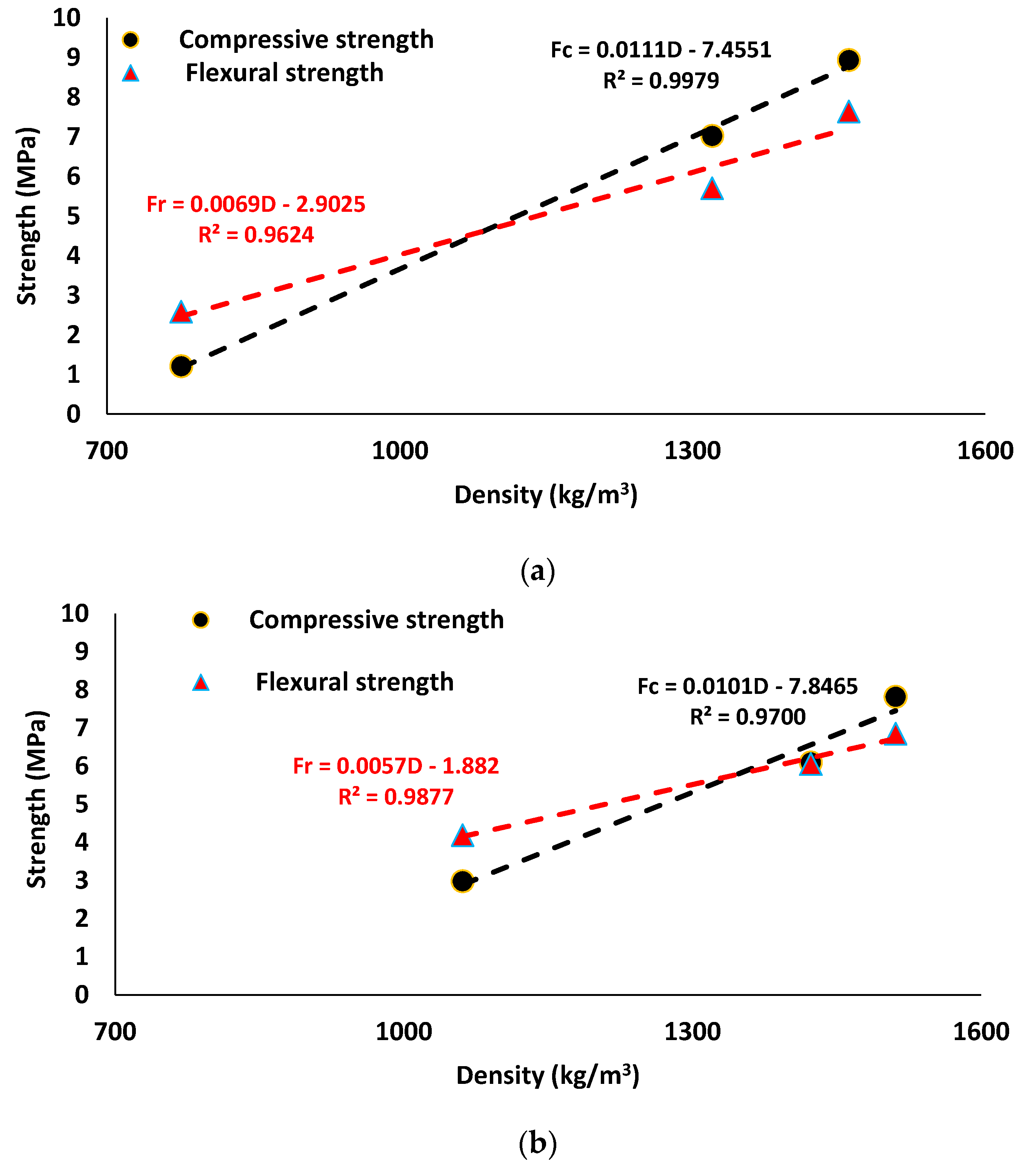

3.2.2. Strength Assessment

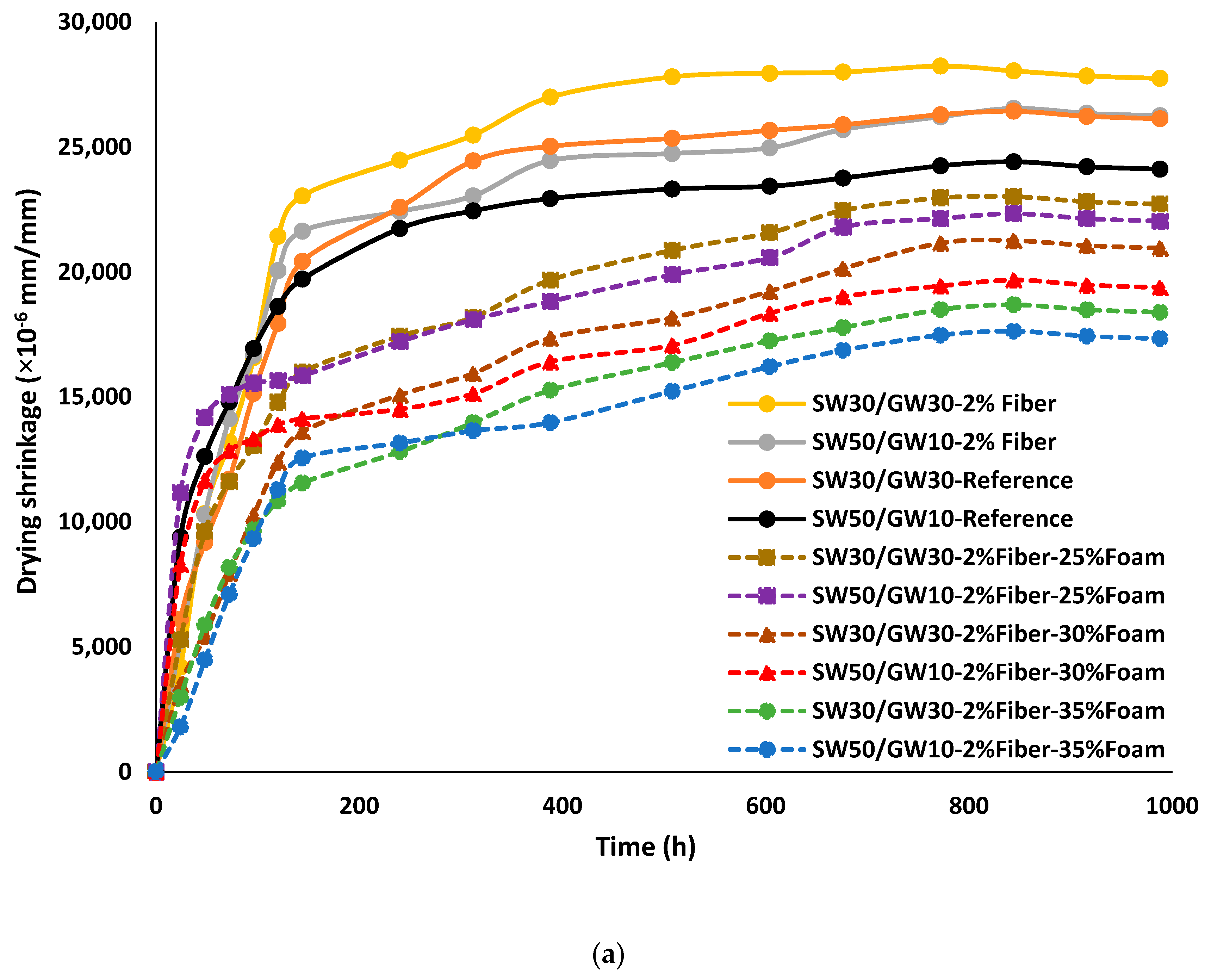

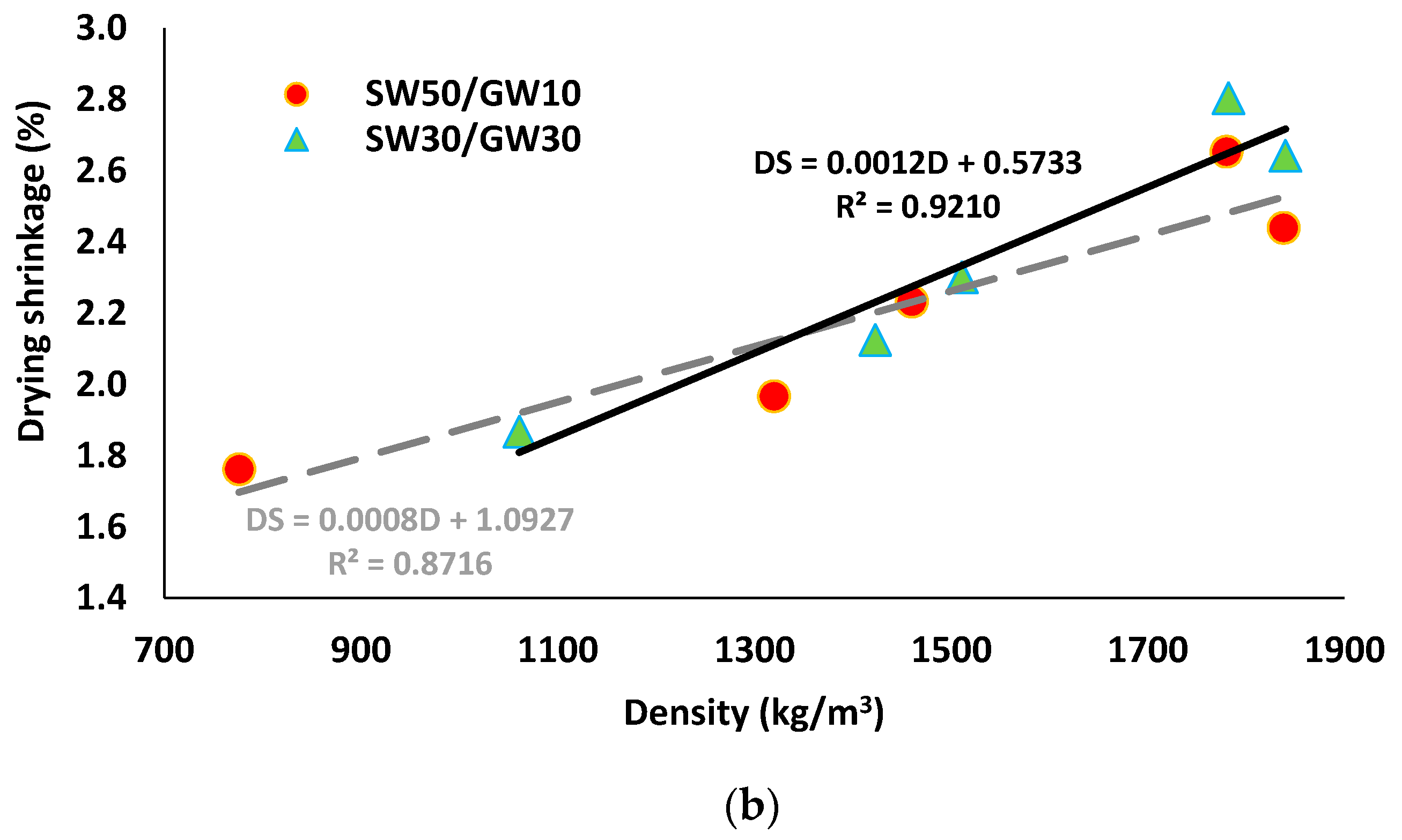

3.2.3. Drying Shrinkage

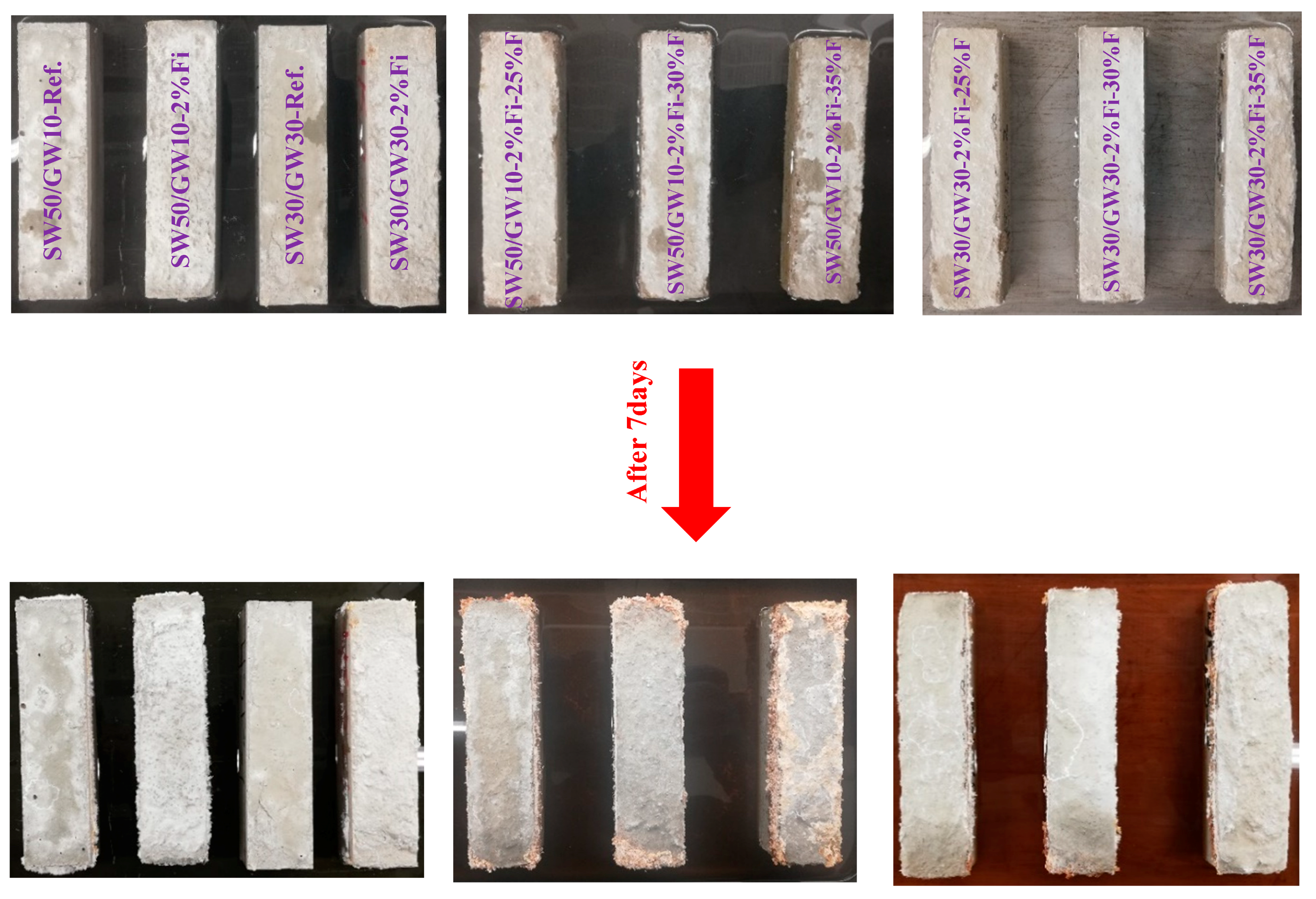

3.2.4. Efflorescence Assessment

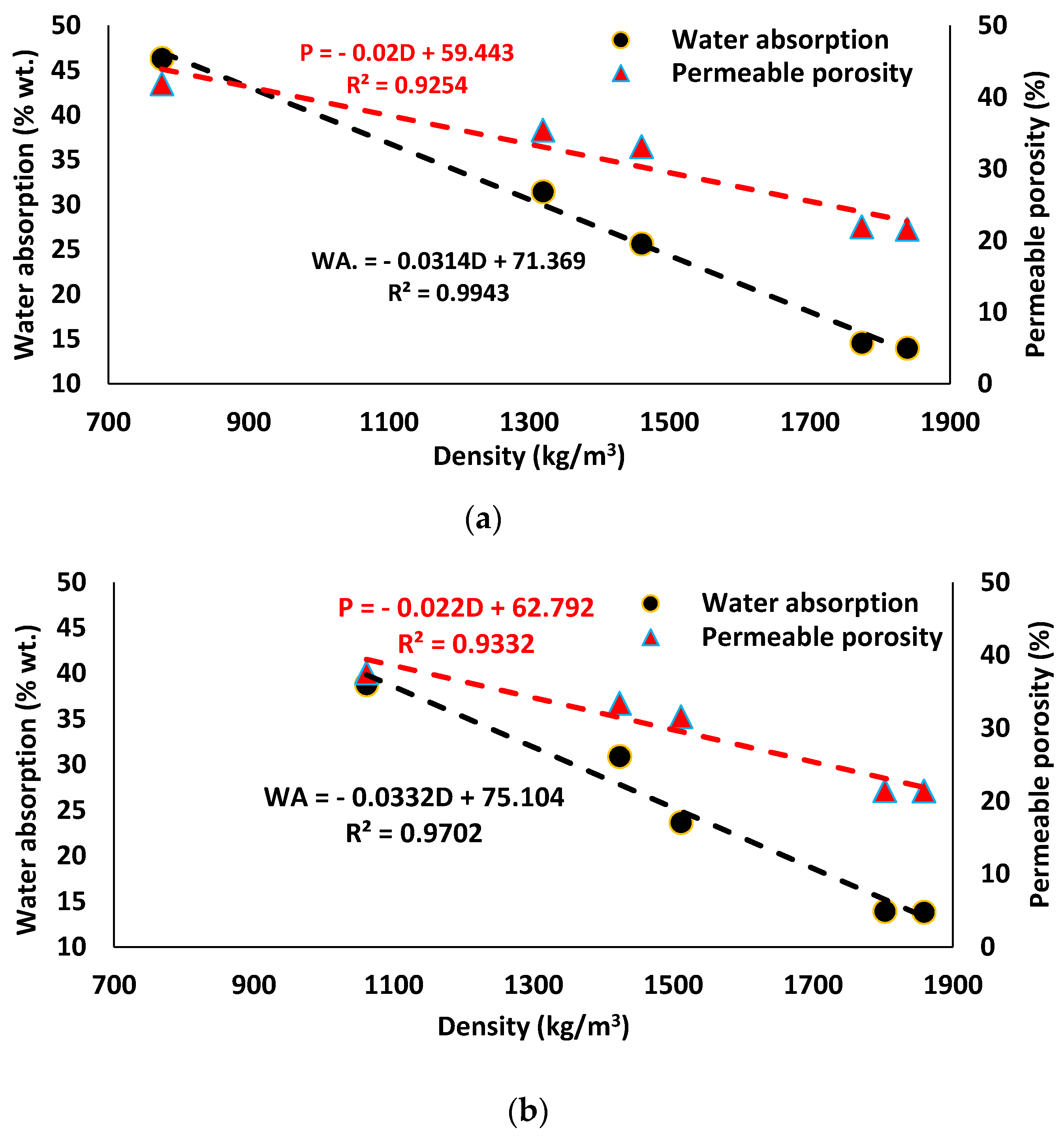

3.2.5. Water Absorption and Permeable Porosity

3.3. Effects of Harsh Conditions on Hardened Properties

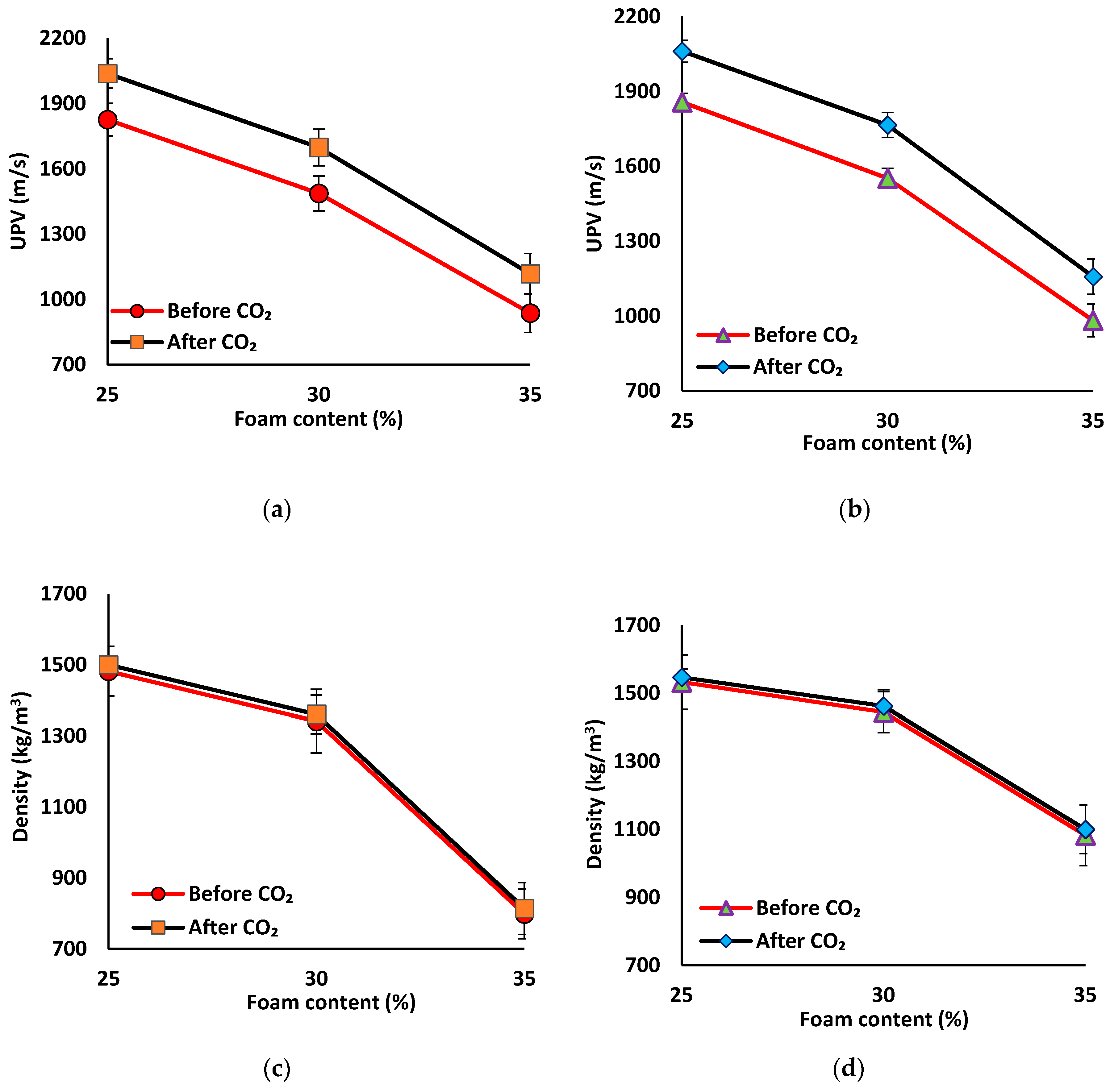

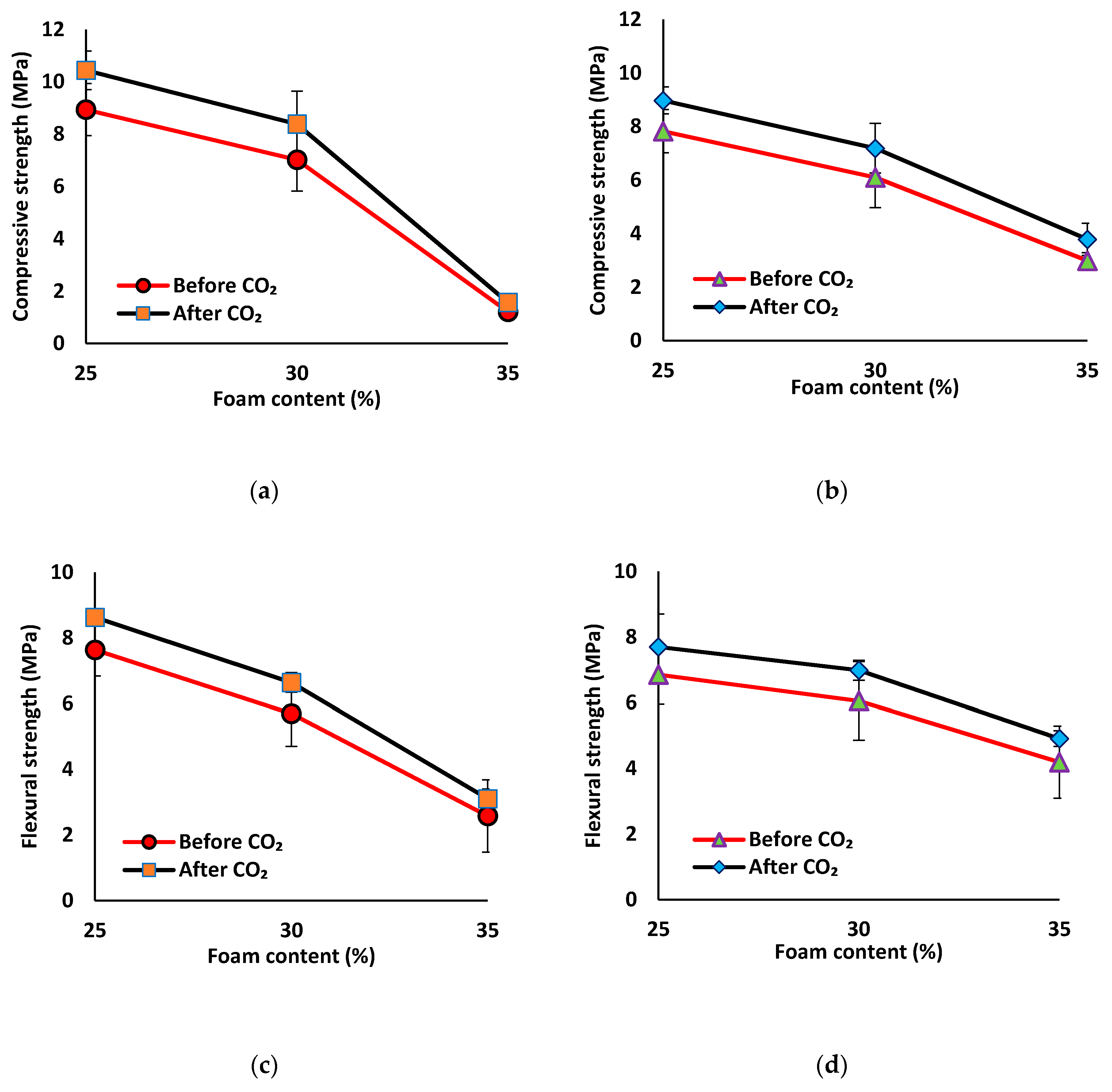

3.3.1. Carbonation Resistance

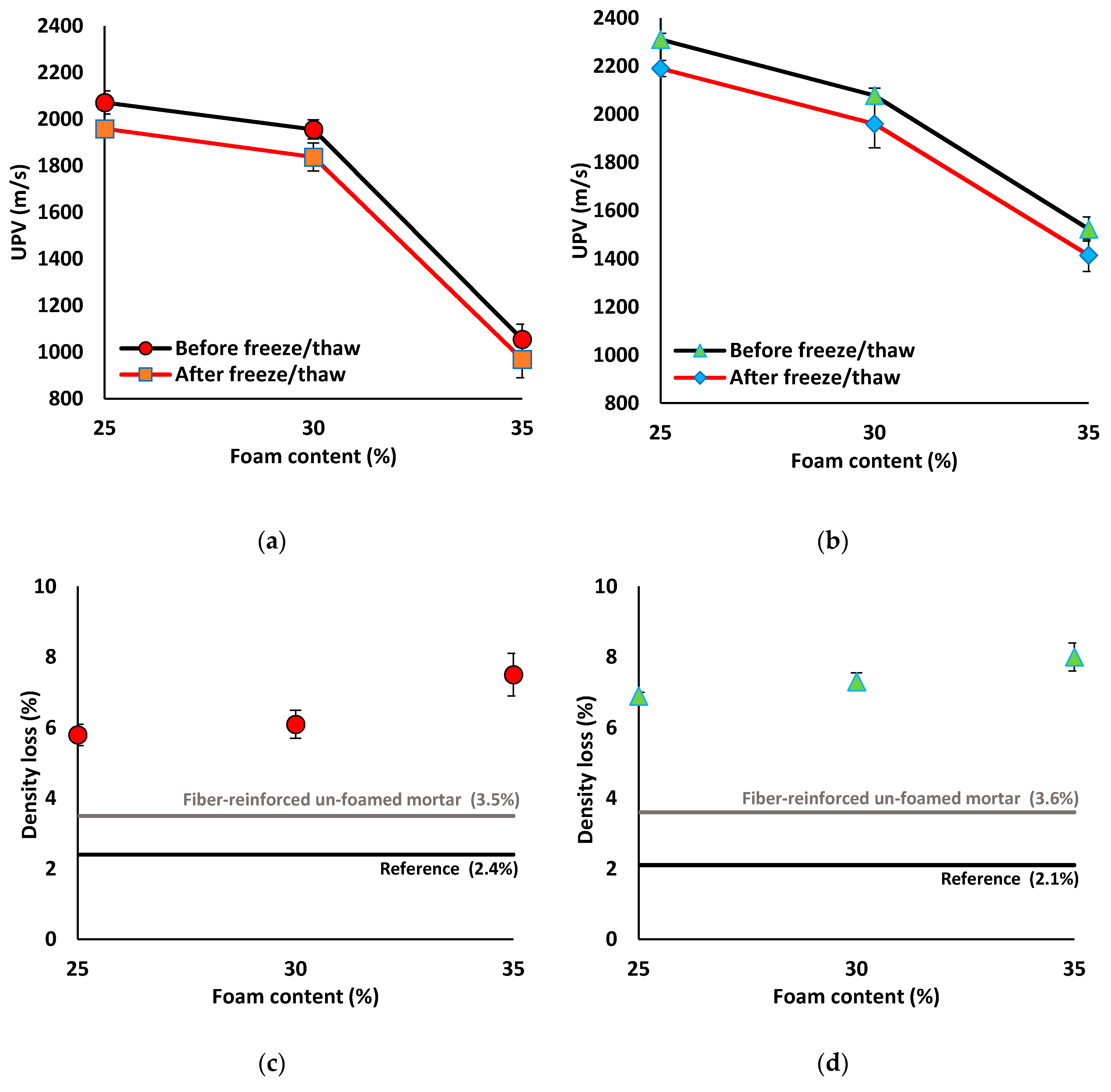

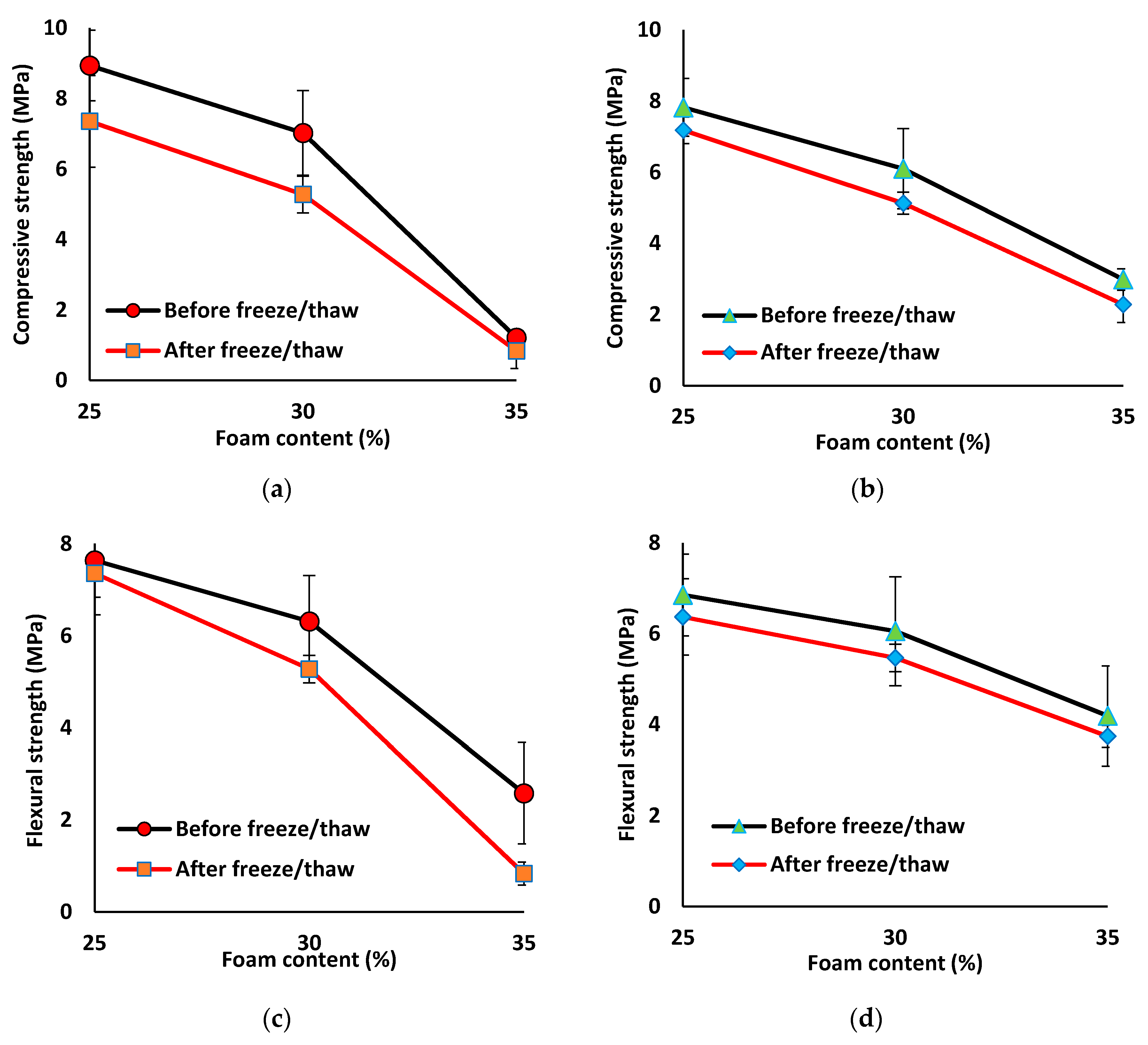

3.3.2. Freeze and Thaw Resistance

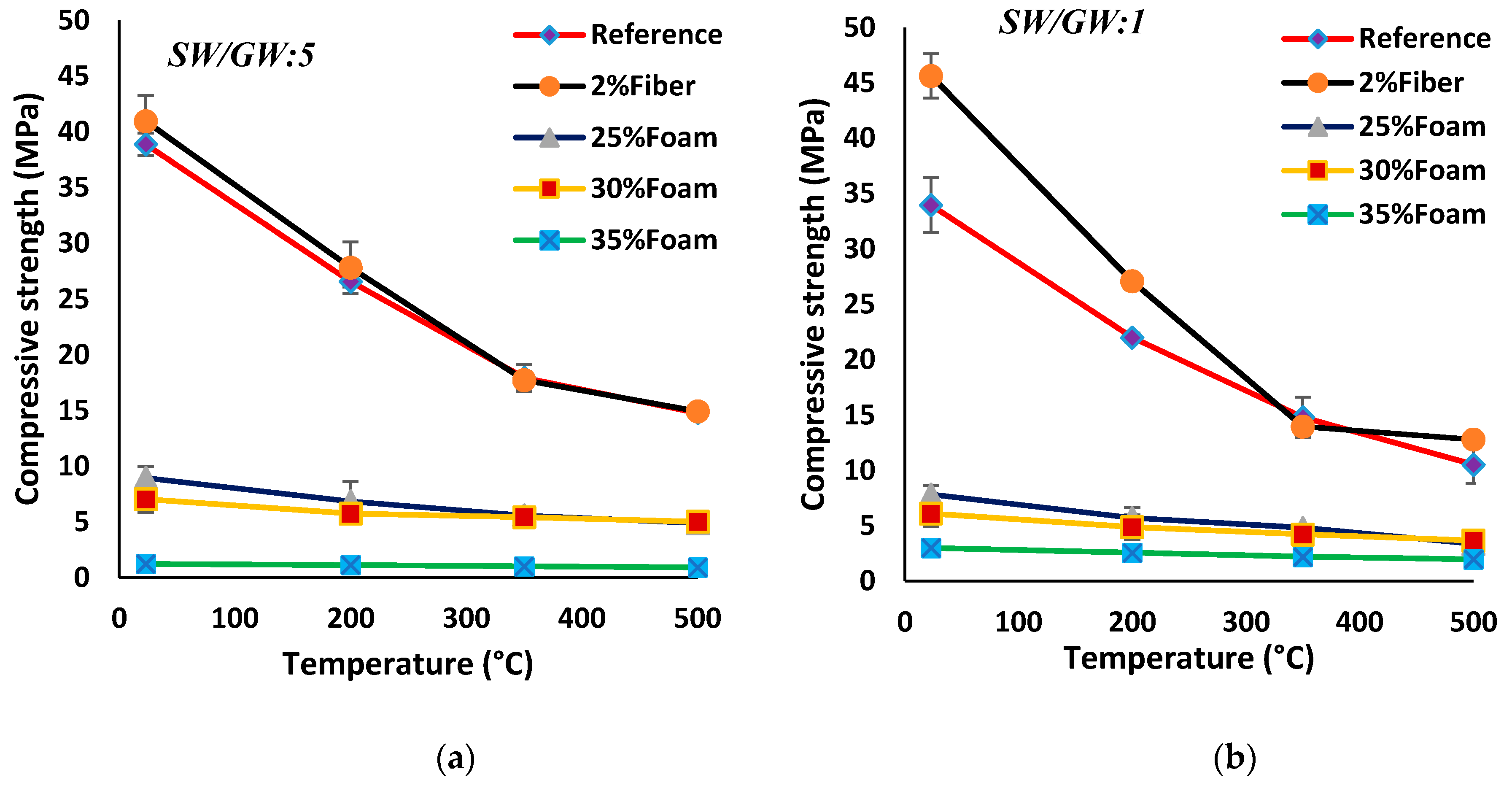

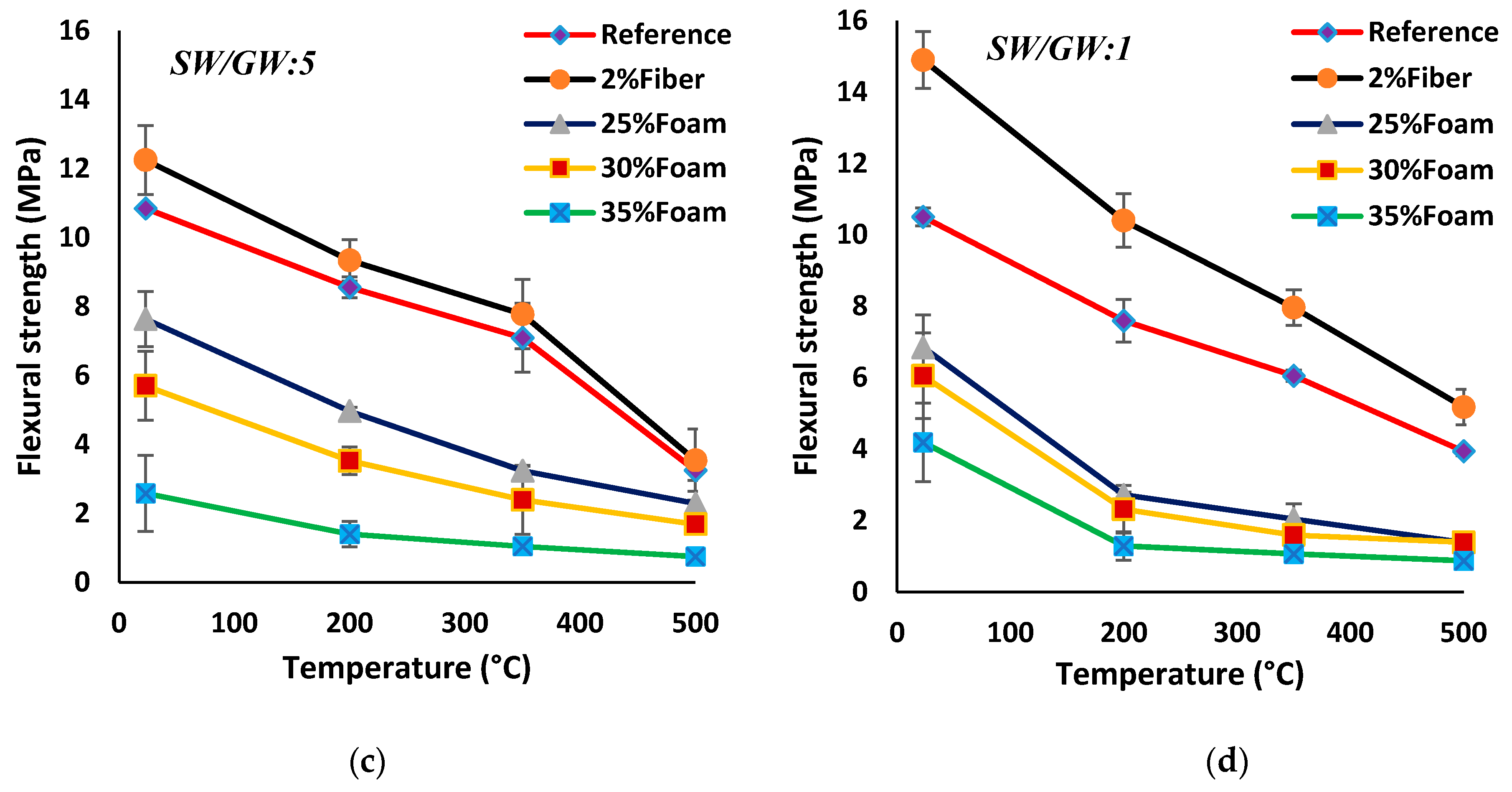

3.3.3. High-Temperature Resistance

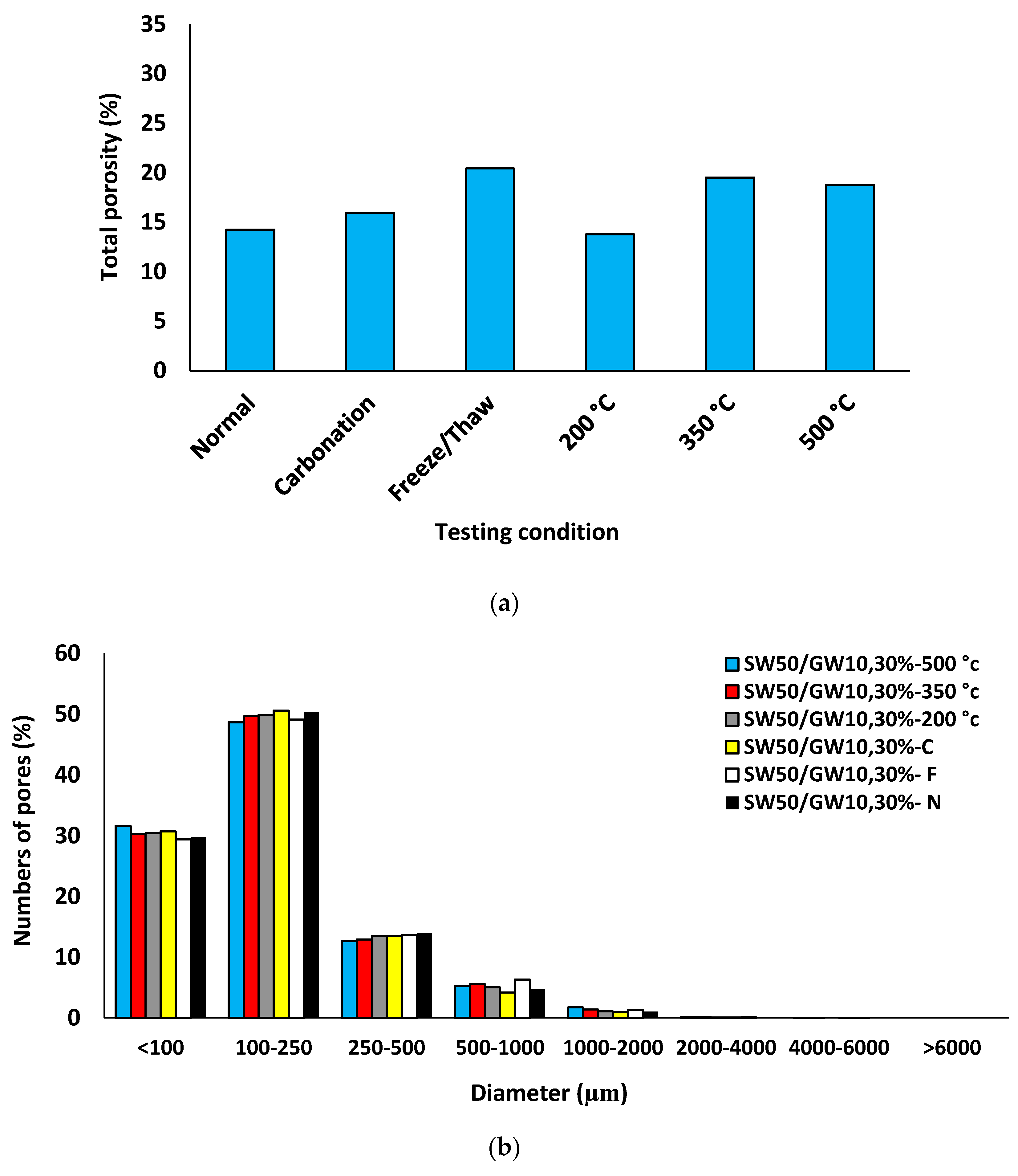

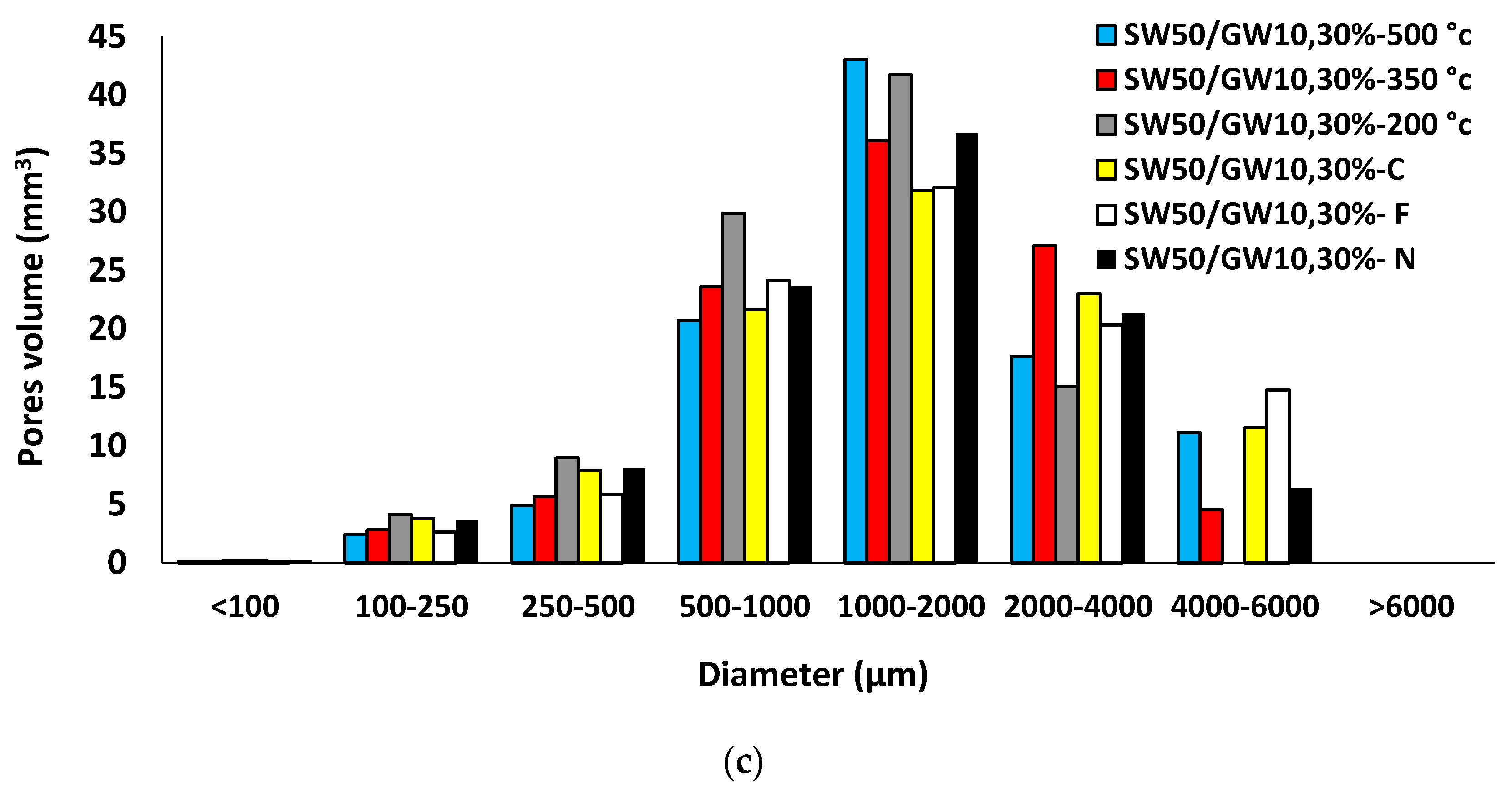

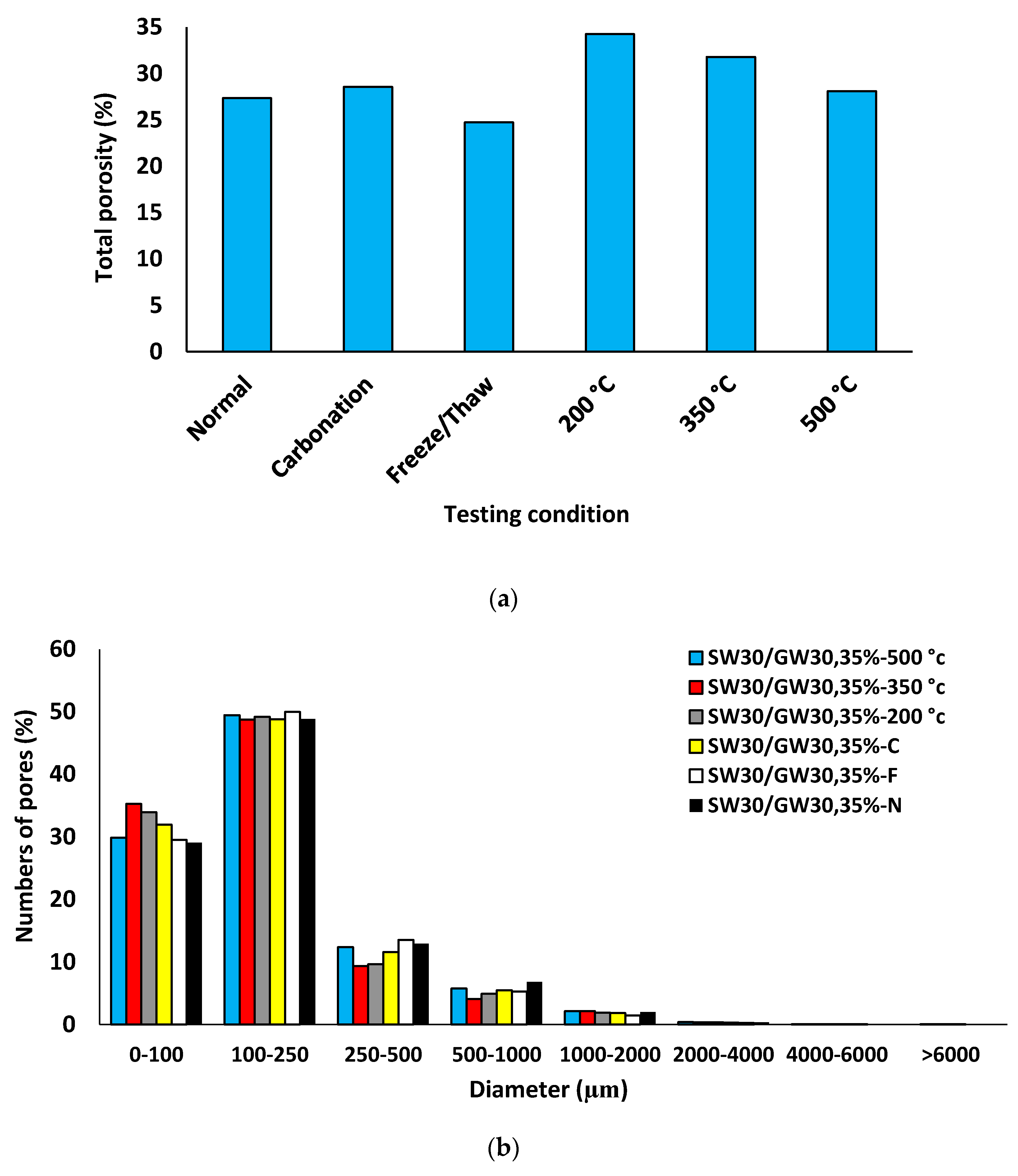

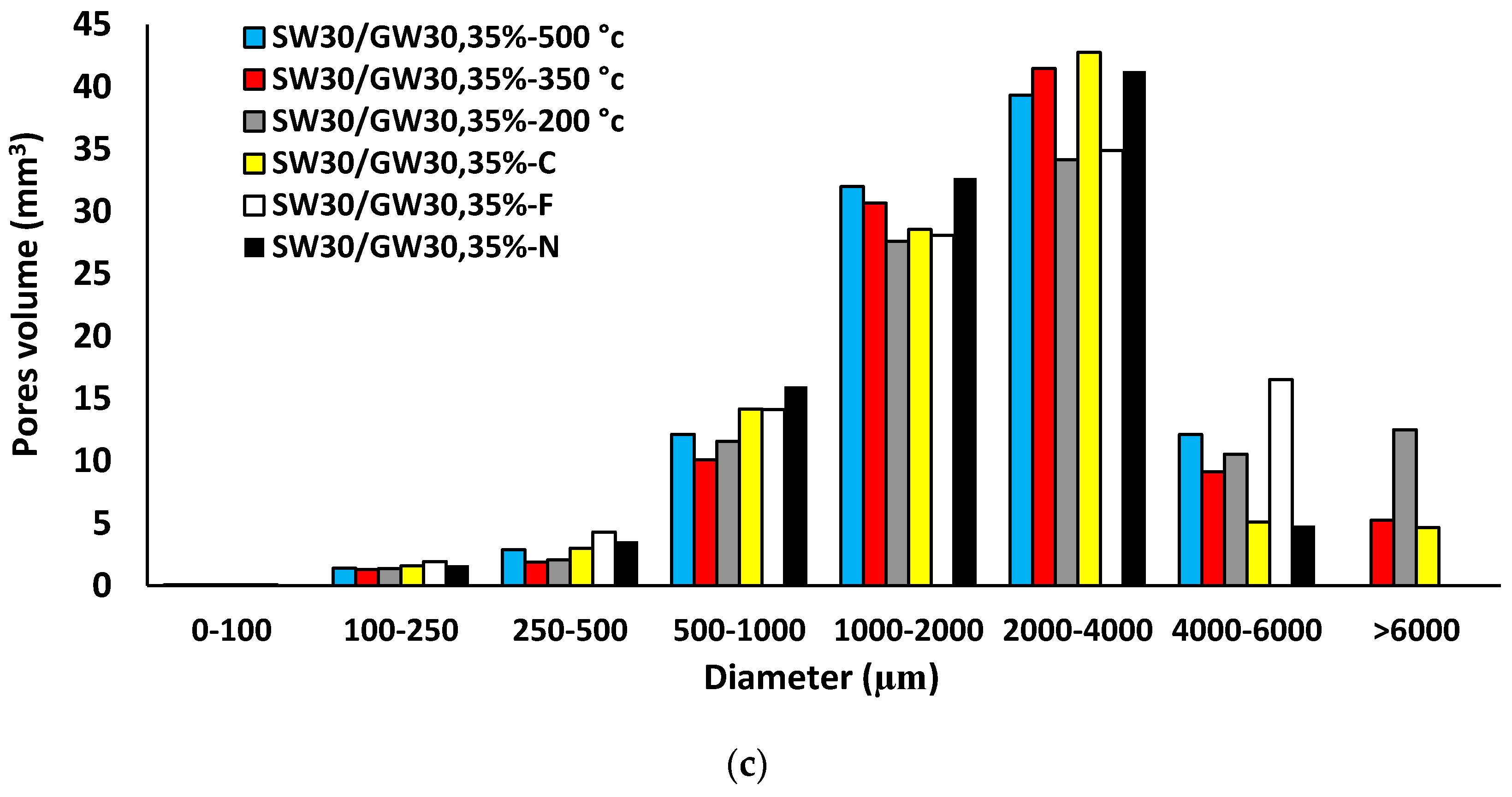

3.4. Assessment of Porous Structure

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Mixture | Density (kg/m3) | UPV (m/s) | Compressive Strength (MPa) | Flexural Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | Before | After | |

| SW50/GW10-Reference | 1860 | 1867 | 2916 | 2998 | 39.0 | 41.0 | 10.8 | 12.0 |

| SW50/GW10-2% Fiber | 1794 | 1803 | 2793 | 2890 | 43.5 | 46.6 | 12.3 | 13.7 |

| SW30/GW30-Reference | 1880 | 1887 | 2857 | 2920 | 34.0 | 37.0 | 10.5 | 11.6 |

| SW30/GW30-2% Fiber | 1824 | 1832 | 2783 | 2870 | 45.6 | 50.3 | 15.0 | 16.6 |

| Mixture | UPV (m/s) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | |

| SW50/GW10-Reference | 2870 | 2814 | 39.0 | 36.7 | 10.8 | 10.1 |

| SW50/GW10-2% Fiber | 2776 | 2703 | 40.6 | 43.5 | 12.3 | 11.4 |

| SW30/GW30-Reference | 3100 | 3036 | 34.0 | 32.0 | 10.5 | 10.0 |

| SW30/GW30-2% Fiber | 2980 | 2896 | 45.6 | 42.7 | 15.0 | 14.1 |

References

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Geopolymer foam concrete: An emerging material for sustainable construction. Constr. Mater. 2014, 56, 113–127. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Van Deventer, J.S. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Stengel, T.; Heinz, D.; Reger, J. Life cycle assessment of geopolymer concrete–what is the environmental benefit. In Proceedings of the 24th Biennial Conference of the Concrete Institute of Australia, Sydney, Australia, 13–15 July 2009. [Google Scholar]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Sanjayan, J.G.; Nazari, A.; Chen, L.; Nguyen, G.H. Physical and mechanical properties of lightweight aerated geopolymer. Constr. Mater. 2015, 79, 236–244. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. Comparison of alkali and silica sources in one-part alkali-activated blast furnace slag mortar. J. Clean. Prod. 2018, 187, 171–179. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Provis, J.L.; Van Deventer, J.S. The effect of silica availability on the mechanism of geopolymerisation. Cem. Concr. Res. 2011, 41, 210–216. [Google Scholar] [CrossRef]

- Yliniemi, J.; Kinnunen, P.; Karinkanta, P.; Illikainen, M. Utilization of Mineral wools as an alkali-activated material precursor. Materials 2016, 9, 312. [Google Scholar] [CrossRef]

- Kinnunen, P.; Yliniemi, J.; Talling, B.; Illikainen, M. Rockwool waste in fly ash geopolymer composites. J. Mater. Cycles Waste Manag. 2017, 19, 1220–1227. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Zhang, Z.; Wang, H.; Mastali, M. Comparative study on the drying shrinkage and mechanical properties of geopolymer foam concrete incorporating different dosages of fiber, sand and foam agents. In High Tech Concrete: Where Technology and Engineering Meet; Springer: New York, NY, USA, 2018; pp. 42–48. [Google Scholar]

- Mastali, M.; Kinnunen, P.; Karhu, M.; Abdollahnejad, Z.; Korat, L.; Ducman, V.; Alzaza, A.; Illikainen, M. Impacts of Casting Scales and Harsh Conditions on the Thermal, Acoustic, and Mechanical Properties of Indoor Acoustic Panels Made with Fiber-Reinforced Alkali-Activated Slag Foam Concretes. Materials 2019, 12, 825. [Google Scholar]

- Amran, Y.M.; Farzadnia, N.; Ali, A.A. Properties and applications of foamed concrete; a review. Constr. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Nambiar, E.K.; Ranjani, G.I.S. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Pacheco-Torgal, F.; Felix, T.; Tahri, W.; Aguiar, J.B. Mix design, properties and cost analysis of fly ash-based geopolymer foam. Constr. Mater. 2015, 80, 18–30. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Miraldo, S.; Pacheco-Torgal, F.; Aguiar, J.B. Cost-efficient one-part alkali-activated mortars with low global warming potential for floor heating systems applications. Eur. J. Environ. Civil Eng. 2017, 21, 412–429. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Mendis, P. Enhancing the strength of pre-made foams for foam concrete applications. Cem. Concr. Compos. 2018, 87, 164–171. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Mendis, P.; Sanjayan, J. Regulating the chemical foaming reaction to control the porosity of geopolymer foams. Mater. Des. 2017, 120, 255–265. [Google Scholar] [CrossRef]

- Van Deventer, J.S.J.; Provis, J.L.; Duxson, P.; Brice, D.G. Chemical Research and Climate Change as Drivers in the Commercial Adoption of Alkali Activated Materials. Waste Biomass Valorization 2010, 1, 145–155. [Google Scholar] [CrossRef]

- Nambiar, E.K.; Ramamurthy, K. Air-void characterisation of foam concrete. Cem. Concr. Res. 2007, 37, 221–230. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Kashani, A. Sustainable one-part geopolymer foams with glass fines versus sand as aggregates. Constr. Mater. 2018, 171, 223–231. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete. Cem. Concr. Compos. 2015, 62, 97–105. [Google Scholar] [CrossRef]

- Abdullah, M.M.A.B.; Hussin, K.; Bnhussain, M.; Ismail, K.N.; Yahya, Z.; Razak, R.A. Fly Ash-based Geopolymer Lightweight Concrete Using Foaming Agent. Int. J. Mol. Sci. 2012, 13, 7186–7198. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Zhang, Z.; Zhang, Y.; Li, D. Preparation and characterization of ultra-lightweight foamed geopolymer (UFG) based on fly ash-metakaolin blends. Constr. Mater. 2018, 168, 771–779. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, R.; Gong, L.; Li, Y.; Cao, W.; Cheng, X. Development of porous fly ash-based geopolymer with low thermal conductivity. Mater. Des. 2015, 65, 529–533. [Google Scholar] [CrossRef]

- Hlaváček, P.; Smilauer, V.; Škvára, F.; Kopecký, L.; Šulc, R. Inorganic foams made from alkali-activated fly ash: Mechanical, chemical and physical properties. J. Eur. Ceram. Soc. 2015, 35, 703–709. [Google Scholar] [CrossRef]

- Zuda, L.; Drchalová, J.; Rovnaník, P.; Bayer, P.; Keršner, Z.; Černý, R. Alkali-activated aluminosilicate composite with heat-resistant lightweight aggregates exposed to high temperatures: Mechanical and water transport properties. Cem. Concr. Compos. 2010, 32, 157–163. [Google Scholar] [CrossRef]

- Bai, C.; Colombo, P. High-porosity geopolymer membrane supports by peroxide route with the addition of egg white as surfactant. Ceram. Int. 2017, 43, 2267–2273. [Google Scholar] [CrossRef]

- Skvara, F.; Sulc, R.; Zdenek, T.; Petr, S.; Vit, S.; Zuzana, Z.C. Preparation and properties of fly ash-based geopolymer foams. Ceram. Silikaty 2014, 58, 188–197. [Google Scholar]

- Liu, Z.; Shao, N.-N.; Qin, J.-F.; Kong, F.-L.; Wang, C.-X.; Wang, D.-M. Strength and thermal behavior of low weight foam geopolymer using circulating fluidized bed combustion fly ash. J. Central South Univ. 2015, 22, 3633–3640. [Google Scholar] [CrossRef]

- McCarthy, A.; Jones, R. Preliminary views on the potential of foamed concrete as a structural material. Mag. Concr. Res. 2005, 57, 21–31. [Google Scholar]

- Jones, M.; McCarthy, A.; Jones, R. Utilising unprocessed low-lime coal fly ash in foamed concrete. Fuel 2005, 84, 1398–1409. [Google Scholar] [CrossRef]

- Chica, L.; Alzate, A. Cellular concrete review: New trends for application in construction. Constr. Mater. 2019, 200, 637–647. [Google Scholar] [CrossRef]

- Kheradmand, M.; Mastali, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. Experimental and numerical investigations on the flexural performance of geopolymers reinforced with short hybrid polymeric fibres. Compos. Part B Eng. 2017, 126, 108–118. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.; Abdollahnejad, Z.; Illikainen, M. Characterization and optimization of hardened properties of self-consolidating concrete incorporating recycled steel, industrial steel, polypropylene and hybrid fibers. Compos. Part B Eng. 2018, 151, 186–200. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Dai, J.-G. Tensile behavior and microstructure of hybrid fiber ambient cured one-part engineered geopolymer composites. Constr. Mater. 2018, 184, 419–431. [Google Scholar] [CrossRef]

- Alzaza, A. Development of Inorganic Binder Foam from Rock/Glass Wool and Metakaolin. Master´s Thesis, Univesity of Oulu, Oulu, Finland, 2019. [Google Scholar]

- NORMENSAND Characteristics. Available online: https://www.normensand.de/en/products/cen-standard-sand-en-196-1/ (accessed on 13 April 2019).

- EABASSOC Foaming Agent. Available online: https://www.eabassoc.co.uk/Foamed-Concrete-Foaming-Agent.php (accessed on 16 April 2019).

- Mastali, M.; Alzaza, A.; Mohammad Shaad, K.; Kinnunen, P.; Abdollahnejad, Z.; Woof, B.; Illikainen, M. Using carbonated BOF slag aggregates in alkali-activated concretes. Materials 2019, 12, 1288. [Google Scholar] [CrossRef] [PubMed]

- Standard Test Method for Hydraulic Cement Mortar; ASTM C 1437; ASTM International: West Conshohocken, PA, USA, 2006.

- Standard test method for pulse velocity through concrete; ASTM C 597; ASTM International: West Conshohocken, PA, USA, 2009.

- Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure); ASTM C 349; ASTM International: West Conshohocken, PA, USA, 2014.

- Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM C78; ASTM International: West Conshohocken, PA, USA, 2010.

- Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete; ASTM C157/C157M-17; ASTM International: West Conshohocken, PA, USA, 2017.

- Standard Test Method for Density, Absorption, and Voids in Hardened Concrete; ASTM C642; ASTM International: West Conshohocken, PA, USA, 2006.

- Adesanya, E.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Properties and durability of alkali-activated ladle hose. Mater. Struct. 2017, 50, 255. [Google Scholar] [CrossRef]

- Kang, S.-H.; Hong, S.-G.; Moon, J. The effect of superabsorbent polymer on various scale of pore structure in ultra-high performance concrete. Constr. Mater. 2018, 172, 29–40. [Google Scholar] [CrossRef]

- Korat, L.; Ducman, V.; Legat, A.; Mirtič, B. Characterisation of the pore-forming process in lightweight aggregate based on silica sludge by means of X-ray micro-tomography (micro-CT) and mercury intrusion porosimetry (MIP). Ceram. Int. 2013, 39, 6997–7005. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Mendis, P.; Kashani, A.; Van Deventer, J.S. Alkali activated slag foams: The effect of the alkali reaction on foam characteristics. J. Clean. Prod. 2017, 147, 330–339. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Luukkonen, T.; Kinnunen, P.; Illikainen, M. Fiber-reinforced one-part alkali-activated slag/ceramic binders. Ceram. Int. 2018, 44, 8963–8976. [Google Scholar] [CrossRef]

- Mastali, M.; Kinnunen, P.; Isomoisio, H.; Karhu, M.; Illikainen, M. Mechanical and acoustic properties of fiber-reinforced alkali-activated slag foam concretes containing lightweight structural aggregates. Constr. Mater. 2018, 187, 371–381. [Google Scholar] [CrossRef]

- Korat, L.; Ducman, V. The influence of the stabilizing agent SDS on porosity development in alkali-activated fly-ash based foams. Cem. Concr. Compos. 2017, 80, 168–174. [Google Scholar] [CrossRef]

- Ducman, V.; Korat, L. Characterization of geopolymer fly-ash based foams obtained with the addition of Al powder or H2O2 as foaming agents. Mater. Charact. 2016, 113, 207–213. [Google Scholar] [CrossRef]

- Şahin, M.; Erdoğan, S.T.; Bayer, O. Production of lightweight aerated alkali-activated slag pastes using hydrogen peroxide. Constr. Mater. 2018, 181, 106–118. [Google Scholar] [CrossRef]

- Narayanan, N.; Ramamurthy, K. Structure and properties of aerated concrete: A review. Cem. Concr. Compos. 2000, 22, 321–329. [Google Scholar] [CrossRef]

- Zollo, R.F. Fiber-reinforced concrete: An overview after 30 years of development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Zollo, R.F.; Hays, C.D. Engineering material properties of a fiber reinforced cellular concrete. ACI Mater. J. 1998, 95, 631–635. [Google Scholar]

- Bing, C.; Zhen, W.; Ning, L. Experimental research on properties of high-strength foamed concrete. J. Mater. Civil Eng. 2011, 24, 113–118. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Bui, H.H.; Ngo, T.D.; Nguyen, G.D. Experimental and numerical investigation of the influence of air-voids on compressed concrete. Mater. Des. 2017, 130, 103–119. [Google Scholar] [CrossRef]

- Yang, Q.; Zhu, P.; Wu, X.; Huang, S. Properties of concrete with a new type of saponin air-entraining agent. Cem. Concr. Res. 2000, 30, 1313–1317. [Google Scholar] [CrossRef]

- Mastali, M.; Kinnunen, P.; Dalvand, A.; Firouz, R.M.; Illikainen, M. Drying shrinkage in alkali-activated binders—A critical review. Constr. Mater. 2018, 190, 533–550. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Mastali, M.; Dalvand, A. Comparative Study on the Effects of Recycled Glass–Fiber on Drying Shrinkage Rate and Mechanical Properties of the Self-Compacting Mortar and Fly Ash–Slag Geopolymer Mortar. J. Mater. Civ. Eng. 2017, 29, 4017076. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Shrinkage Behavior of Foam Concrete. J. Mater. Civ. Eng. 2009, 21, 631–636. [Google Scholar] [CrossRef]

- Tada, S.; Nakano, S. Microstructural Approach to Moist Cellular Concrete; Elsevier: Amsterdam, The Netherlands, 1983; pp. 71–89. [Google Scholar]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Fly ash-based geopolymers: The relationship between composition, pore structure and efflorescence. Cem. Concr. Res. 2004, 64, 30–41. [Google Scholar] [CrossRef]

- Yang, K.-H.; Lo, C.-W.; Huang, J.-S. Production and properties of foamed reservoir sludge inorganic polymers. Cem. Concr. Compos. 2013, 38, 50–56. [Google Scholar] [CrossRef]

- Nambiar, E.K.; Ramamurthy, K. Sorption characteristics of foam concrete. Cem. Concr. Res. 2007, 37, 1341–1347. [Google Scholar] [CrossRef]

- Petlitckaia, S.; Poulesquen, A. Design of lightweight metakaolin based geopolymer foamed with hydrogen peroxide. Ceram. Int. 2019, 45, 1322–1330. [Google Scholar] [CrossRef]

- Masi, G.; Rickard, W.D.; Vickers, L.; Bignozzi, M.C.; Van Riessen, A. A comparison between different foaming methods for the synthesis of light weight geopolymers. Ceram. Int. 2014, 40, 13891–13902. [Google Scholar] [CrossRef]

- Fu, Y.; Cai, L.; Yonggen, W. Freeze–thaw cycle test and damage mechanics models of alkali-activated slag concrete. Constr. Mater. 2011, 25, 3144–3148. [Google Scholar] [CrossRef]

- Qu, X.; Zhao, X. Previous and present investigations on the components, microstructure and main properties of autoclaved aerated concrete—A review. Constr. Mater. 2017, 135, 505–516. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, H. The Pore Characteristics of Geopolymer Foam Concrete and Their Impact on the Compressive Strength and Modulus. Front. Mater. 2016, 3, 402. [Google Scholar] [CrossRef]

- Aldridge, D. Introduction to foamed concrete: What, why, how? In Use of Foamed Concrete in Construction. In Proceedings of the International Conference held at the University of Dundee, Scotland, UK, 5–7 July 2005. [Google Scholar]

- Vilches, J.; Ramezani, M.; Neitzert, T. Experimental investigation of the fire resistance of ultra lightweight foam concrete. Int. J. Adv. Eng. Appl. 2012, 1, 15–22. [Google Scholar]

| Material | Element/Oxides (%, w/w) | Density (g/cm3) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | Na2O | K2O | MgO | P2O5 | TiO2 | SO3 | Cl | ||

| SW | 17.40 | 40.40 | 15.80 | 9.20 | 1.40 | 0.40 | 12.60 | 0.10 | 0.80 | - | - | 2.90 |

| GW | 7.10 | 62.40 | 1.80 | 0.60 | 16.80 | 0.90 | 2.20 | - | - | 0.90 | 0.10 | 2.50 |

| MK | 0.10 | 51.78 | 38.27 | 1.86 | 0.17 | 2.27 | 1.13 | 0.11 | 0.09 | 0.10 | - | 2.60 |

| Fiber Type | Length/ Diameter (mm/mm) | Elastic Modulus (GPa) | Tensile Strength (MPa) | Elongation at Break (%) | Density (g/cm3) |

|---|---|---|---|---|---|

| PP | 833 | 9.6 | 910 | <12 | 0.91 |

| Mixture | NaOH Concentration | PP Fiber Content | Foam Content | ||||||

|---|---|---|---|---|---|---|---|---|---|

| SW50/GW10-Reference | 50 | 10 | 40 | 0.88 | 2.5 | 10 M | 1 | 0 | 0 |

| SW50/GW10-2% Fiber | 2 | 0 | |||||||

| SW50/GW10-2% Fiber-25% Foam | 25 | ||||||||

| SW50/GW10-2% Fiber-30% Foam | 30 | ||||||||

| SW50/GW10-2% Fiber-35% Foam | 35 | ||||||||

| SW30/GW30-Reference | 30 | 30 | 40 | 0 | 0 | ||||

| SW30/GW30-2% Fiber | 2 | 0 | |||||||

| SW30/GW30-2% Fiber-25% Foam | 25 | ||||||||

| SW30/GW30-2% Fiber-30% Foam | 30 | ||||||||

| SW30/GW30-2% Fiber-35% Foam | 35 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alzaza, A.; Mastali, M.; Kinnunen, P.; Korat, L.; Abdollahnejad, Z.; Ducman, V.; Illikainen, M. Production of Lightweight Alkali Activated Mortars Using Mineral Wools. Materials 2019, 12, 1695. https://doi.org/10.3390/ma12101695

Alzaza A, Mastali M, Kinnunen P, Korat L, Abdollahnejad Z, Ducman V, Illikainen M. Production of Lightweight Alkali Activated Mortars Using Mineral Wools. Materials. 2019; 12(10):1695. https://doi.org/10.3390/ma12101695

Chicago/Turabian StyleAlzaza, Ahmad, Mohammad Mastali, Paivo Kinnunen, Lidija Korat, Zahra Abdollahnejad, Vilma Ducman, and Mirja Illikainen. 2019. "Production of Lightweight Alkali Activated Mortars Using Mineral Wools" Materials 12, no. 10: 1695. https://doi.org/10.3390/ma12101695

APA StyleAlzaza, A., Mastali, M., Kinnunen, P., Korat, L., Abdollahnejad, Z., Ducman, V., & Illikainen, M. (2019). Production of Lightweight Alkali Activated Mortars Using Mineral Wools. Materials, 12(10), 1695. https://doi.org/10.3390/ma12101695