Infrared Brazed Joints of Ti50Ni50 Shape Memory Alloy and Ti-15-3 Alloy Using Two Ag-Based Fillers

Abstract

:1. Introduction

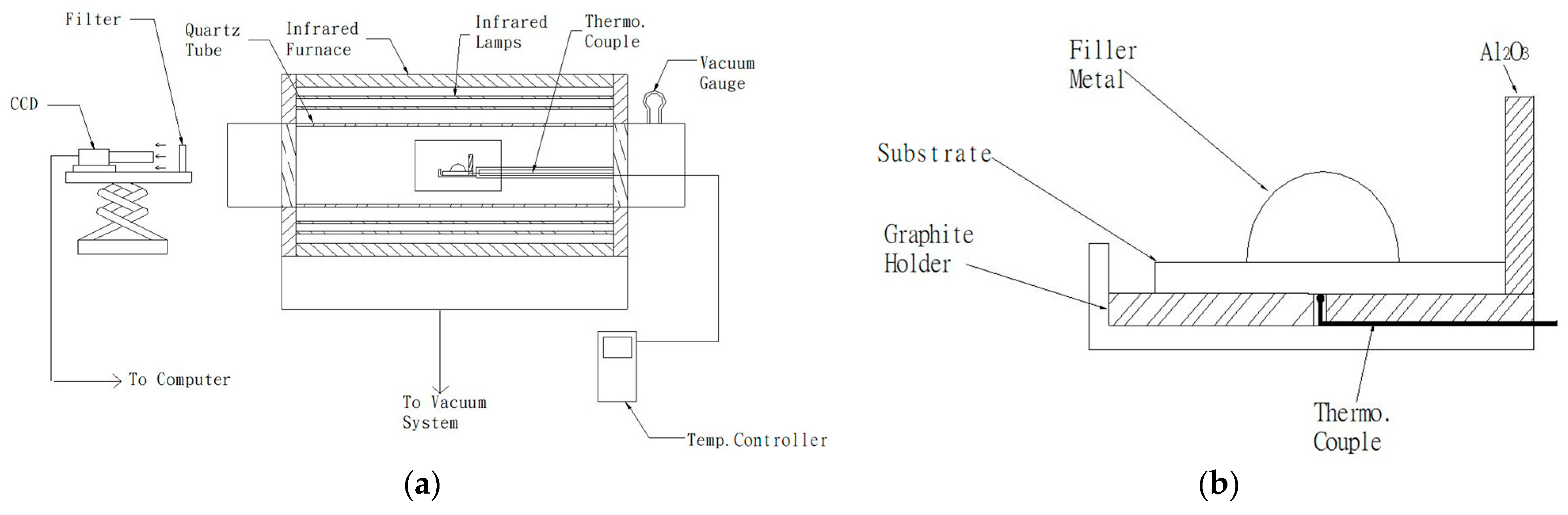

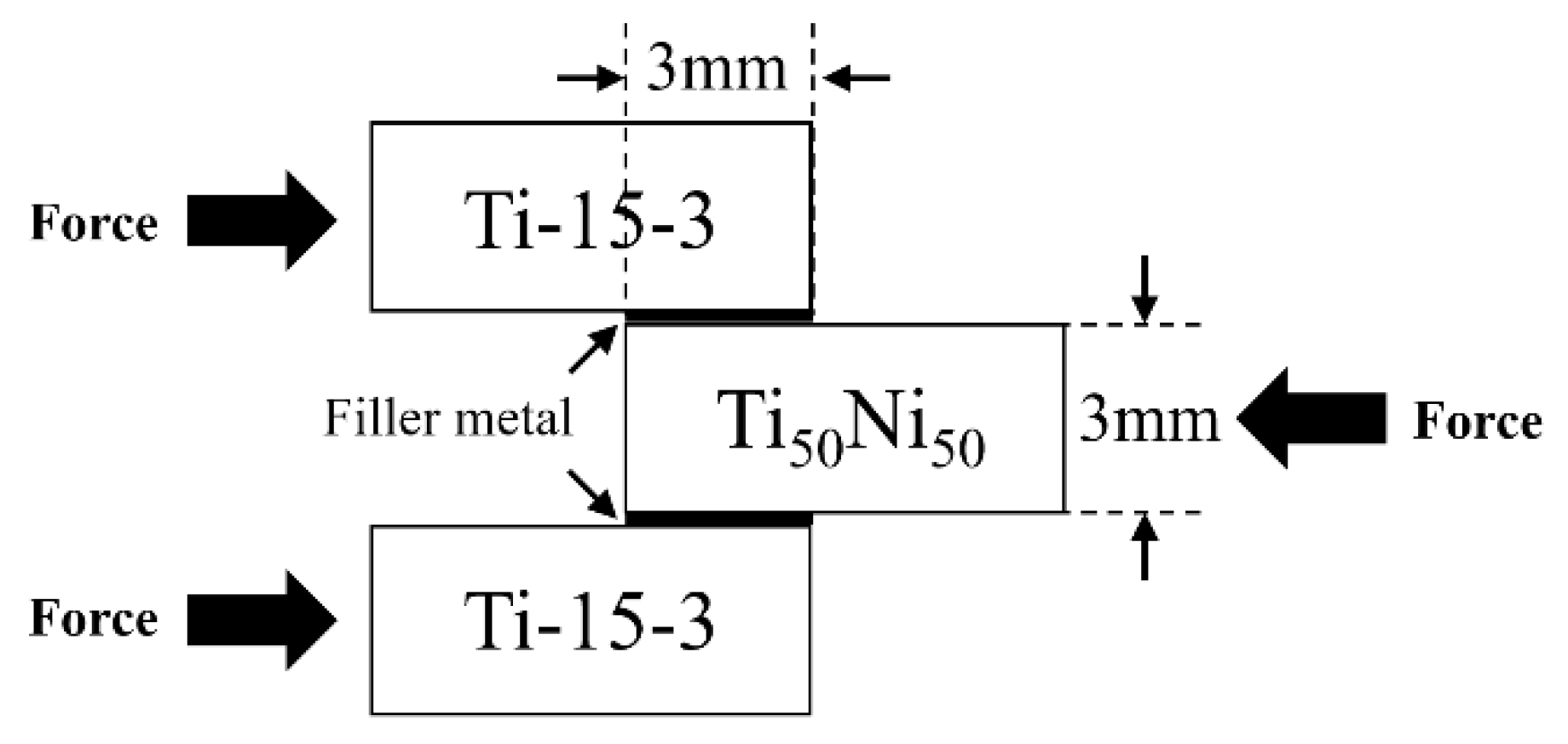

2. Materials and Methods

3. Results and Discussion

3.1. Dynamic Wetting Angle Test

3.2. Microstructures of Brazed Joints

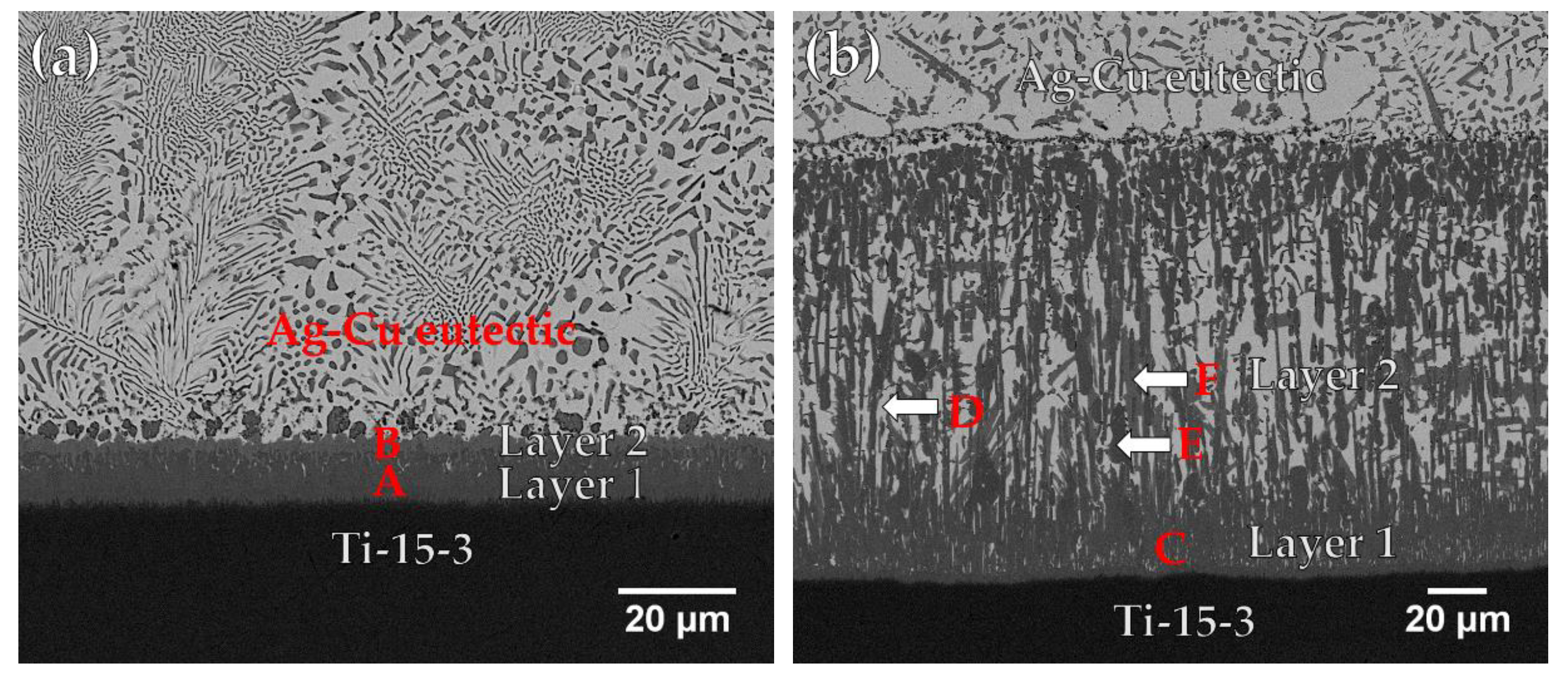

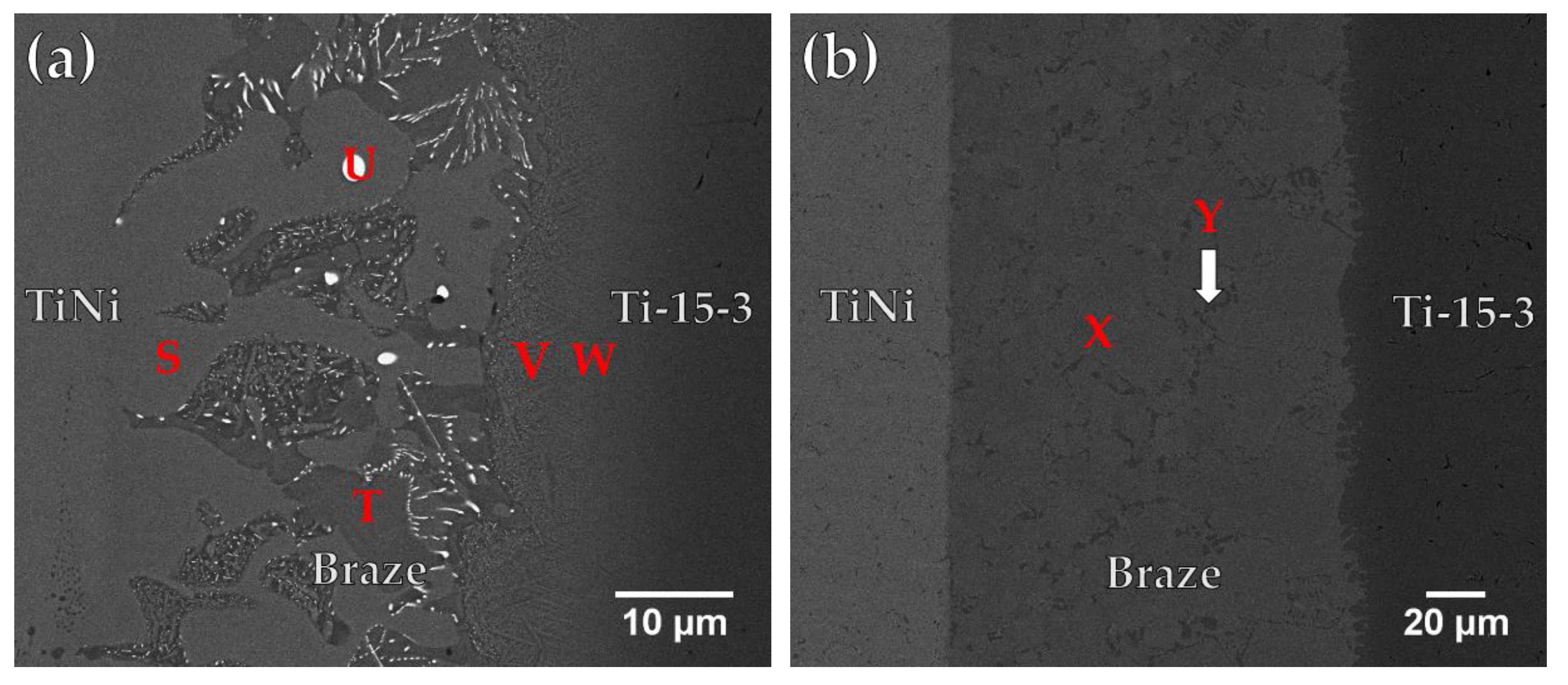

3.2.1. Ti-15-3/BAg-8/Ti50Ni50 Joints

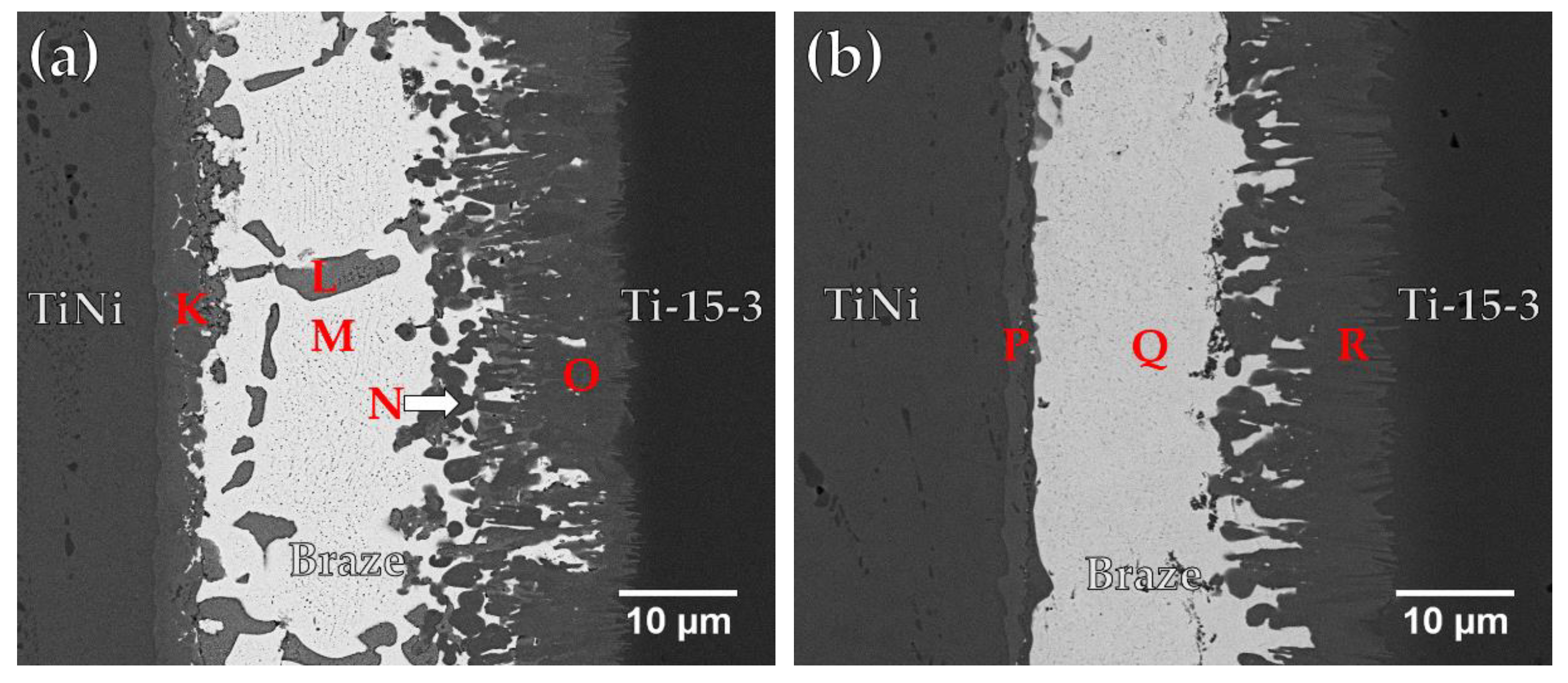

3.2.2. Ti-15-3/Ticusil®/Ti50Ni50 Joints

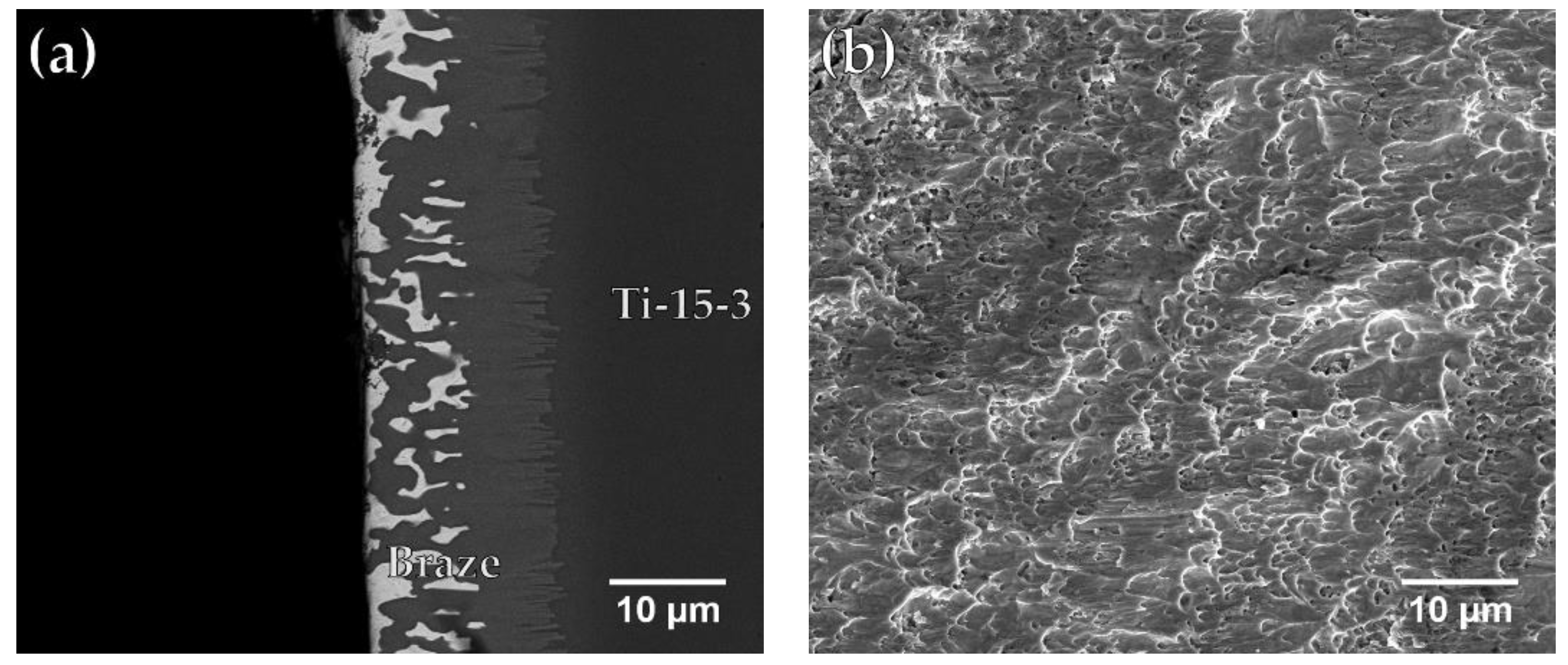

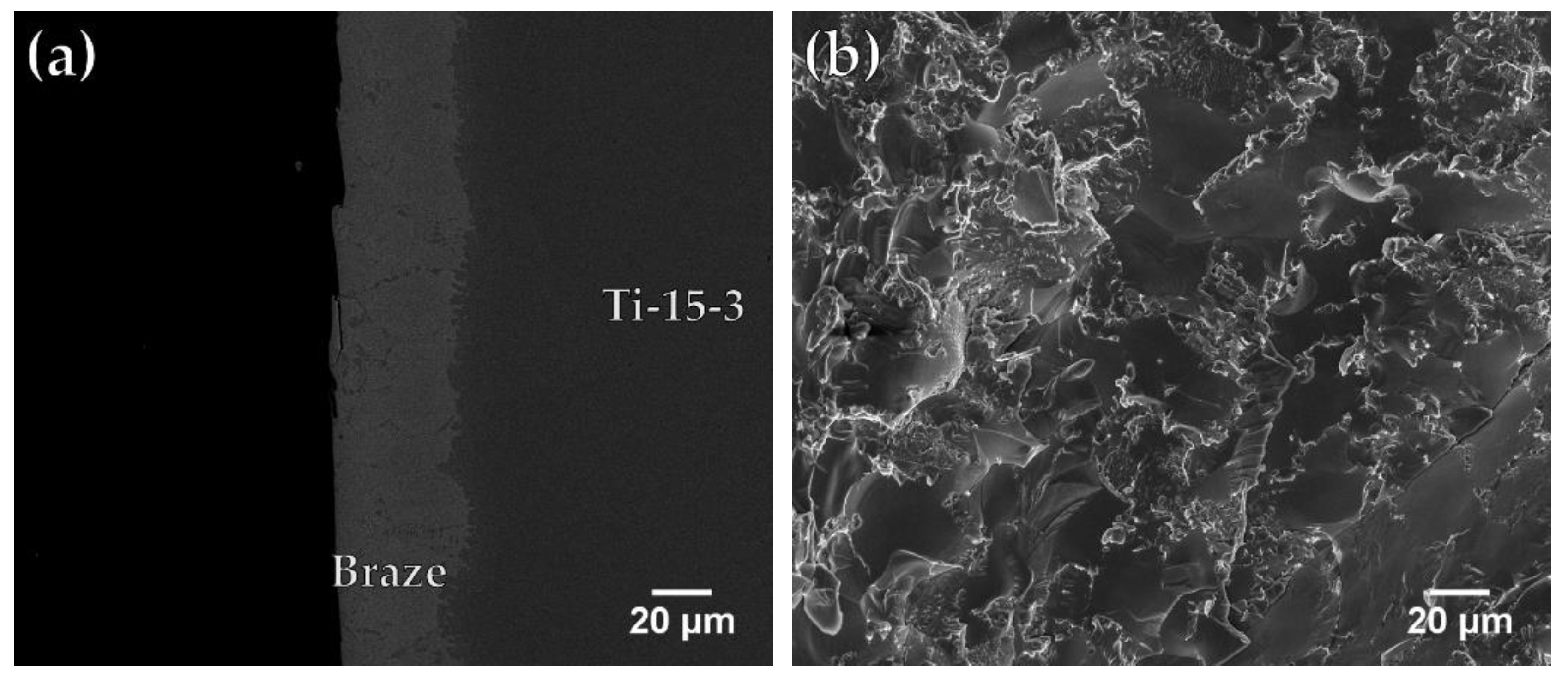

3.3. Shear Strengths of Brazed Joints

4. Conclusions

- BAg-8 and Ticusil® brazing foils wet the Ti-15-3 substrate. The wettability of Ag-Cu eutectic is greatly ameliorated by alloying with 4.5 wt.% Ti.

- A Ti-15-3/BAg-8/Ti50Ni50 joint brazed at 800 °C for 300 s consists of Cu2Ti intermetallics in the Ag-rich matrix, and only the Ag-rich matrix remains in a joint infrared brazed at 850 °C for 300 s. An interfacial Cu(Ti,V) reaction layer next to Ti-15-3 and interfacial (CuxNi1−x)2Ti phase next to the Ti50Ni50 are attributed to the reactive wetting of both substrates.

- A Ti-15-3/Ticusil®/Ti50Ni50 joint brazed at 900 °C for 300 s consists of CuNiTi and CuTi2. A CuTi2 interfacial layer is next to the Ti-15-3 substrate. For the sample, brazing at 950 °C causes all Ag-rich melt to overflow out of the specimen, leaving the Ti2Ni matrix and Ti-rich particles in the joint.

- The best joint strengths using BAg-8 foil and Ticusil® are 197 and 230 MPa, respectively. For the BAg-8 joint, cracks propagate at the location between the interfacial Cu(Ti,V) and the Ag-rich phase. In a Ticusil® brazed joint, cracks are initiated and propagate along the central Ti2Ni intermetallic compound in the brazed zone.

- The dissimilar infrared brazed joints show moderate average shear strengths of between 172 and 230 MPa. It is a much faster process than that of the traditional furnace brazing, and very limited distortion of the joint is observed. It shows potential for future application in industry.

Author Contributions

Funding

Conflicts of Interest

References

- Otsuka, K.; Ren, X. Physical metallurgy of TiNi-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Fili, P.; Lausmaa, J.; Musialek, J.; Mazanec, K. Structure and surface of TiNi human implants. Biomaterials 2001, 22, 2131–2138. [Google Scholar] [CrossRef]

- Firstov, G.S.; Vitchev, R.G.; Kumar, H.; Blanpain, B.; Van Humbeeck, J. Surface oxidation of NiTi shape memory alloy. Biomaterials 2002, 23, 4863–4871. [Google Scholar] [CrossRef]

- Chen, M.C.; Wu, S.K. Surface analyses and biocompatibility study of 500 °C oxidized Ni50Ti50 and Ni40Ti50Cu10 shape memory alloys. Surf. Coat. Technol. 2009, 203, 1715–1721. [Google Scholar] [CrossRef]

- Rocher, P.; El Medawar, L.; Hornez, J.C.; Traisnel, M.; Breme, J.; Hildebrand, H.F. Biocorrosion and cytocompatibility assessment of NiTi shape memory alloys. Scripta Mater. 2004, 50, 255–260. [Google Scholar] [CrossRef]

- Yoneyama, T.; Miyazaki, S. Shape Memory Alloys for Biomedical Applications; Woodhead Publishing: Cambridge, UK, 2008. [Google Scholar]

- Lecce, L.; Concilio, A. Shape Memory Alloy Engineering: For Aerospace, Structural and Biomedical Applications; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Wang, L.; Zhang, L.C. Development and Application of Biomedical Titanium Alloys; Bentham Science Publishers: Sharjah, UAE, 2018. [Google Scholar]

- Welsch, G.; Boyer, R.; Collings, E.W. Materials Properties Handbook: Titanium Alloys; ASM International: Materials Park, OH, USA, 1993. [Google Scholar]

- Oliveira, J.P.; Miranda, R.M.; Braz Fernandes, F.M. Welding and joining of NiTi shape memory alloys: A review. Prog. Mater. Sci. 2017, 88, 412–466. [Google Scholar] [CrossRef]

- Olson, D.L.; Siewert, T.A.; Liu, S.; Edwards, G.R. ASM Handbook Volume 6: Welding, Brazing, and Soldering; ASM International: Materials Park, OH, USA, 1993. [Google Scholar]

- Li, H.M.; Sun, D.Q.; Cai, X.L.; Dong, P.; Wang, W.Q. Laser welding of TiNi shape memory alloy and stainless steel using Ni interlayer. Mater. Des. 2012, 39, 285–293. [Google Scholar] [CrossRef]

- Qiu, X.M.; Li, M.G.; Sun, D.Q.; Liu, W.H. Study on brazing of TiNi shape memory alloy with stainless steels. J. Mater. Process. Technol. 2006, 176, 8–12. [Google Scholar] [CrossRef]

- van der Eijk, C.; Sallom, Z.K.; Akselsen, O.M. Microwave brazing of NiTi shape memory alloy with Ag-Ti and Ag-Cu-Ti alloys. Scr. Mater. 2008, 58, 779–781. [Google Scholar] [CrossRef]

- Mirshekari, G.R.; Saatchi, A.; Kermanpur, A.; Sadrnezhaad, S.K. Laser welding of NiTi shape memory alloy: Comparison of the similar and dissimilar joints to AISI 304 stainless steel. Opt. Laser Technol. 2013, 54, 151–158. [Google Scholar] [CrossRef]

- Lee, S.J.; Wu, S.K.; Lin, R.Y. Infrared joining of TiAl intermetallics using Ti-15Cu-15Ni foil—i. The microstructure morphologies of joint interfaces. Acta Mater. 1998, 46, 1283–1295. [Google Scholar] [CrossRef]

- Shiue, R.K.; Wu, S.K.; Chen, S.Y. Infrared brazing of TiAl intermetallic using Bag-8 braze alloy. Acta Mater. 2003, 51, 1991–2004. [Google Scholar] [CrossRef]

- Shiue, R.K.; Wu, S.K.; Chan, C.H. The interfacial reactions of infrared brazing Cu and Ti with two silver-based braze alloys. J. Alloys Compd. 2004, 372, 148–157. [Google Scholar] [CrossRef]

- Shiue, R.K.; Wu, S.K.; Shiue, J.Y. Infrared brazing of Ti-6Al-4V and 17-4 PH stainless steel with (Ni)/Cr barrier layer(s). Mater. Sci. Eng. A 2008, 488, 186–194. [Google Scholar] [CrossRef]

- Shiue, R.K.; Chen, C.P.; Wu, S.K. Infrared brazing of Ti50Ni50 shape memory alloy and 316L stainless steel with two sliver-based fillers. Metall. Mater. Trans. A 2015, 46, 2364–2371. [Google Scholar] [CrossRef]

- Shiue, R.-K.; Wu, S.-K.; Yang, S.-H.; Liu, C.-K. Infrared dissimilar joining of Ti50Ni50 and 316L stainless steel with copper barrier layer in between two silver-based fillers. Metals 2017, 7, 276. [Google Scholar] [CrossRef]

- Shiue, R.H.; Wu, S.K. Infrared brazing of Ti50Ni50 shape memory alloy using two Ag-Cu-Ti active braze alloys. Intermetallics 2006, 14, 630–638. [Google Scholar] [CrossRef]

- Shiue, R.K.; Wu, S.K.; Chan, C.H. Infrared brazing Cu and Ti using a 95Ag-5Al braze alloy. Metall. Mater. Trans. A 2004, 35, 3177–3186. [Google Scholar] [CrossRef]

- Sandpaper-Wikipedia. Available online: https://en.wikipedia.org/wiki/Sandpaper (accessed on 4 May 2019).

- ASM International. ASM Handbook; ASM International: Materials Park, OH, USA, 1992; Volume 3. [Google Scholar]

- Shiue, R.H.; Wu, S.K. Infrared brazing Ti50Ni50 and Ti-6Al-4V using the Bag-8 braze alloy. Mater. Trans. JIM 2005, 46, 2057–2066. [Google Scholar] [CrossRef]

- Gupta, K.P. Phase Diagrams of Ternary Nickel Alloys: Ternary Systems Containing Co-Ni-X, Mn-Ni-X, Mo-Ni-X, Nb-Ni-X, Ni-Ta-X, Ni-Ti-X and Ni-V-X; Indian Institute of Metals: Kolkata, India, 1990. [Google Scholar]

| Filler Foil | Substrate | Brazing Period | Brazing Temperature | |||

|---|---|---|---|---|---|---|

| 800 °C | 850 °C | 900 °C | 950 °C | |||

| BAg-8 | Ti-15-3 | 300 s | W | W | ||

| Ticusil® | Ti-15-3 | 300 s | W | W | ||

| BAg-8 | Ti50Ni50, Ti-15-3 | 300 s | S/M | S/M | ||

| Ticusil® | Ti50Ni50, Ti-15-3 | 300 s | S/M | S/M | ||

| at % | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Ag | 1.8 | 1.3 | 2.2 | 86.8 | 2.6 | 1.5 |

| Al | 1.1 | 0.2 | 1.7 | - | 0.1 | - |

| Cr | 1.8 | - | 0.9 | - | 2.6 | 0.4 |

| Cu | 47.1 | 78.8 | 43.0 | 13.1 | 53.3 | 78.2 |

| Sn | 0.3 | - | 0.6 | - | 0.3 | 0.1 |

| Ti | 41.9 | 18.9 | 43.6 | 0.2 | 32.6 | 19.9 |

| V | 5.9 | 0.7 | 7.9 | - | 8.5 | - |

| phase | Cu(Ti,V) | Cu4Ti | Cu(Ti,V) | Ag-rich | Cu4(Ti,V)3 | Cu4Ti |

| at % | G | H | I | J |

|---|---|---|---|---|

| Ag | 2.9 | 3.9 | 2.1 | 4.9 |

| Al | 0.1 | 1.2 | 3.7 | 2.3 |

| Cr | 4.0 | 0.5 | 3.2 | 0.5 |

| Cu | 17.4 | 45.3 | 15.2 | 43.5 |

| Sn | 1.6 | 0.2 | 1.3 | 0.2 |

| Ti | 56.6 | 43.1 | 58.9 | 44.3 |

| V | 17.4 | 5.9 | 15.6 | 4.3 |

| phase | Ti-Cu-V | CuTi | Ti-Cu-V | CuTi |

| at % | K | L | M | N | O | P | Q | R |

|---|---|---|---|---|---|---|---|---|

| Ag | 0.8 | 2.0 | 87.5 | 1.9 | 2.1 | 1.2 | 87.2 | 3.5 |

| Al | 0.3 | 7.7 | 0.1 | 1.2 | 1.3 | 0.6 | - | 1.5 |

| Cr | 0.2 | - | 1.8 | 1.0 | 1.4 | - | 1.3 | 1.1 |

| Cu | 58.1 | 65.2 | 8.4 | 37.5 | 43.9 | 51.6 | 10.1 | 46.1 |

| Ni | 10.6 | 0.8 | 1.3 | 0.6 | - | 15.6 | 0.9 | - |

| Sn | - | 0.3 | - | 1.8 | 0.9 | 0.1 | - | 0.2 |

| Ti | 29.8 | 23.3 | 0.4 | 46.0 | 41.1 | 30.4 | 0.5 | 43.0 |

| V | 0.1 | 0.6 | 0.6 | 10.0 | 9.2 | 0.5 | - | 4.7 |

| phase | (CuxNi1−x)2Ti | Cu2Ti | Ag-rich | Cu(Ti,V) | Cu(Ti,V) | (CuxNi1−x)2Ti | Ag-rich | Cu(Ti,V) |

| at % | S | T | U | V | W | X | Y |

|---|---|---|---|---|---|---|---|

| Ag | 1.4 | 3.0 | 90.3 | 5.1 | 3.0 | - | 0.4 |

| Al | 2.1 | 1.1 | 0.6 | 3.1 | 3.2 | 2.0 | 2.3 |

| Cr | 1.4 | 0.4 | - | 0.3 | 2.5 | 0.5 | 3.0 |

| Cu | 26.8 | 27.1 | 2.6 | 19.4 | 15.3 | 0.1 | 1.3 |

| Ni | 16.9 | 5.5 | 1.9 | 6.3 | 4.7 | 30.5 | 10.2 |

| Sn | 0.2 | 0.4 | 0.2 | 1.0 | 1.3 | 0.6 | 1.4 |

| Ti | 47.4 | 61.3 | 4.5 | 56.2 | 57.2 | 63.1 | 64.9 |

| V | 3.7 | 1.2 | - | 8.6 | 12.7 | 3.1 | 26.5 |

| phase | CuNiTi | CuTi2 | Ag-rich | CuTi2 | CuTi2 | Ti2Ni | Ti-rich |

| Filler Foil | Brazing Temperature | Brazing Period | Shear Strength |

|---|---|---|---|

| BAg-8 | 800 °C | 300 s | 172 ± 32 MPa |

| 850 °C | 300 s | 197 ± 35 MPa | |

| Ticusil® | 900 °C | 300 s | 220 ± 5 MPa |

| 950 °C | 300 s | 230 ± 44 MPa |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.; Shiue, R.-K.; Wu, S.-K.; Yang, T.-E. Infrared Brazed Joints of Ti50Ni50 Shape Memory Alloy and Ti-15-3 Alloy Using Two Ag-Based Fillers. Materials 2019, 12, 1603. https://doi.org/10.3390/ma12101603

Lin C, Shiue R-K, Wu S-K, Yang T-E. Infrared Brazed Joints of Ti50Ni50 Shape Memory Alloy and Ti-15-3 Alloy Using Two Ag-Based Fillers. Materials. 2019; 12(10):1603. https://doi.org/10.3390/ma12101603

Chicago/Turabian StyleLin, Chieh, Ren-Kae Shiue, Shyi-Kaan Wu, and Tsung-En Yang. 2019. "Infrared Brazed Joints of Ti50Ni50 Shape Memory Alloy and Ti-15-3 Alloy Using Two Ag-Based Fillers" Materials 12, no. 10: 1603. https://doi.org/10.3390/ma12101603

APA StyleLin, C., Shiue, R.-K., Wu, S.-K., & Yang, T.-E. (2019). Infrared Brazed Joints of Ti50Ni50 Shape Memory Alloy and Ti-15-3 Alloy Using Two Ag-Based Fillers. Materials, 12(10), 1603. https://doi.org/10.3390/ma12101603