Simulation Study of Helium Effect on the Microstructure of Nanocrystalline Body-Centered Cubic Iron

Abstract

1. Introduction

2. Simulation Method

3. Results

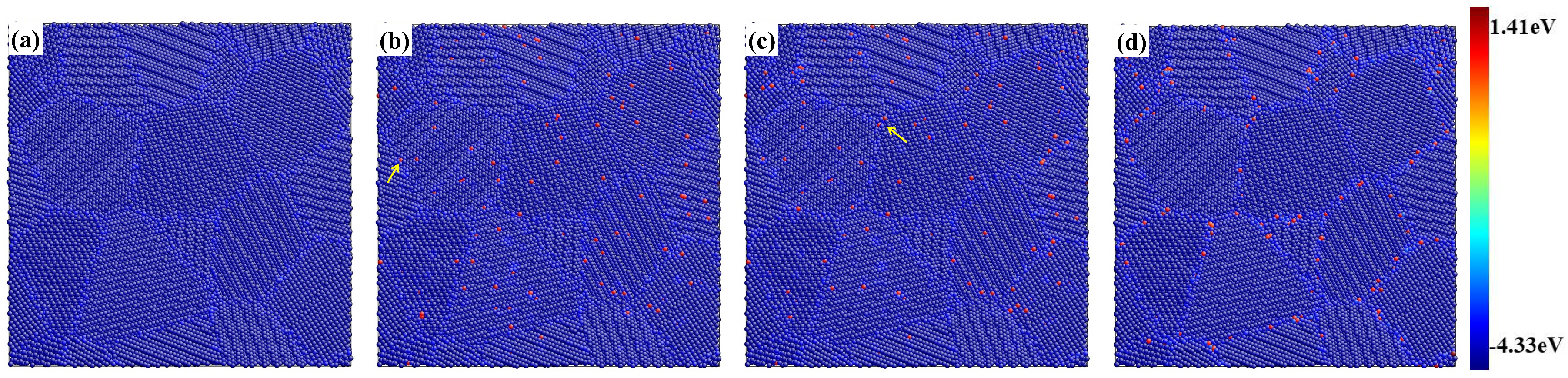

3.1. He Effects on Microstructure of Nanocrystalline BCC-Fe after Energy Minimization

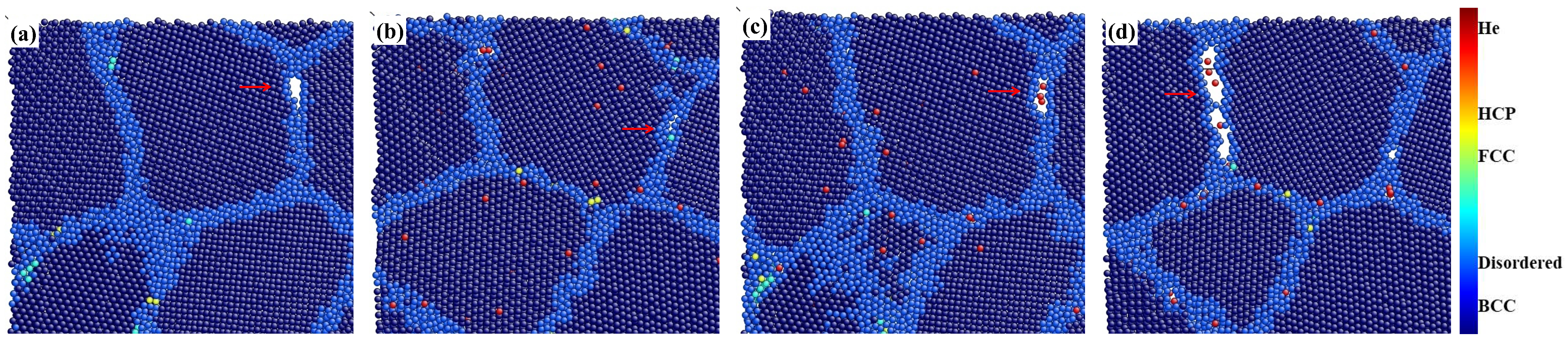

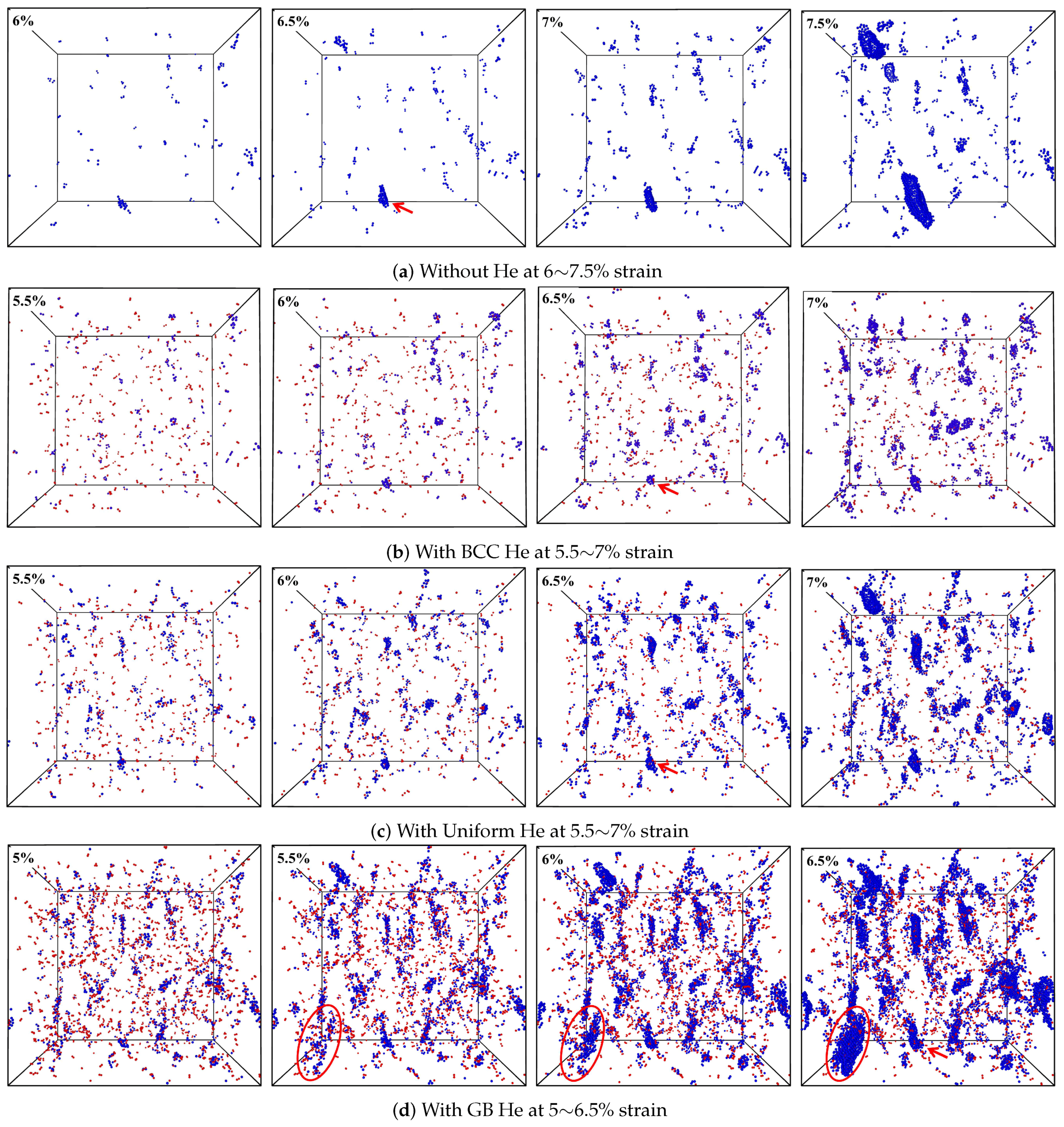

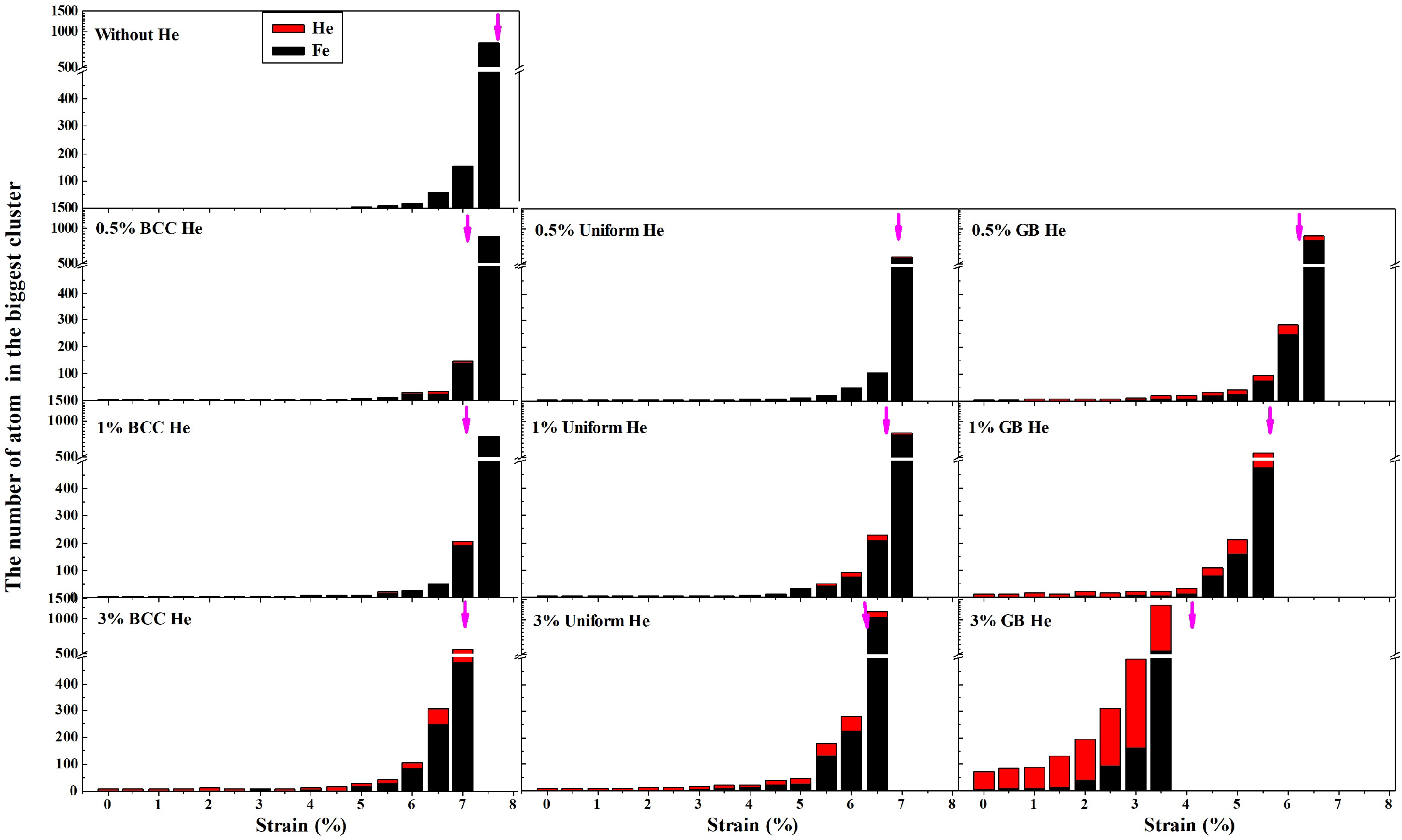

3.2. He Effect on the Generation and Growth of Cracks in Nanocrystalline BCC-Fe during Loading

4. Discussion and Analysis

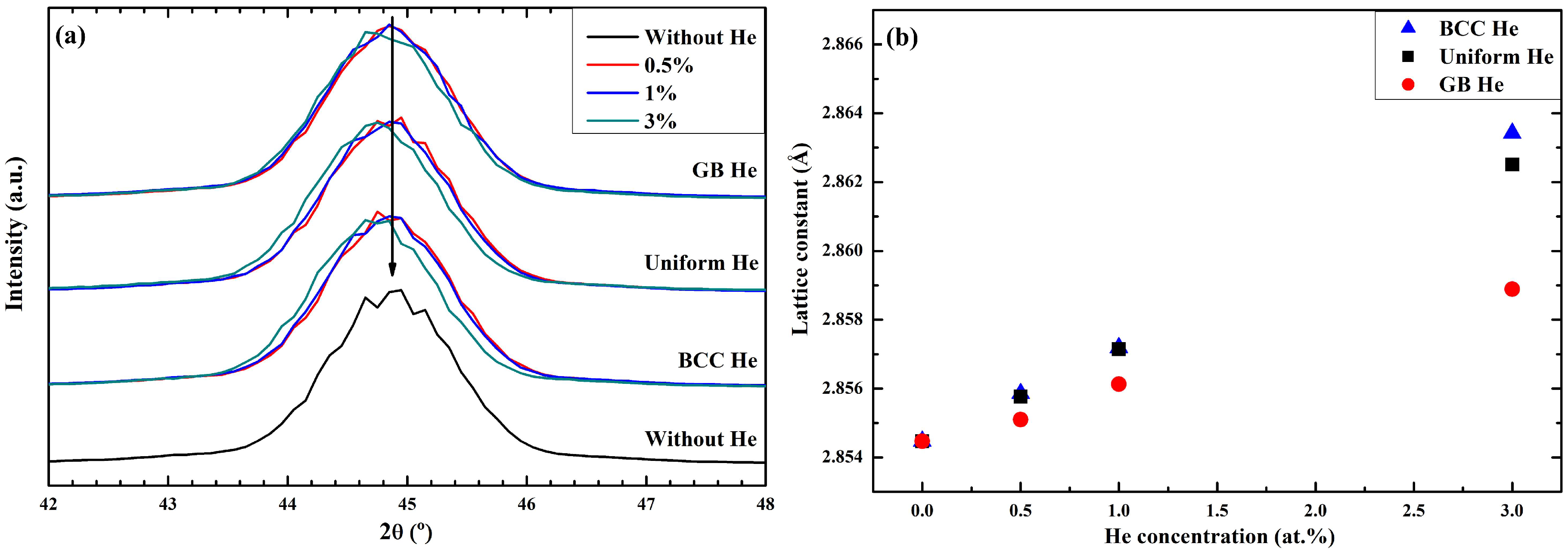

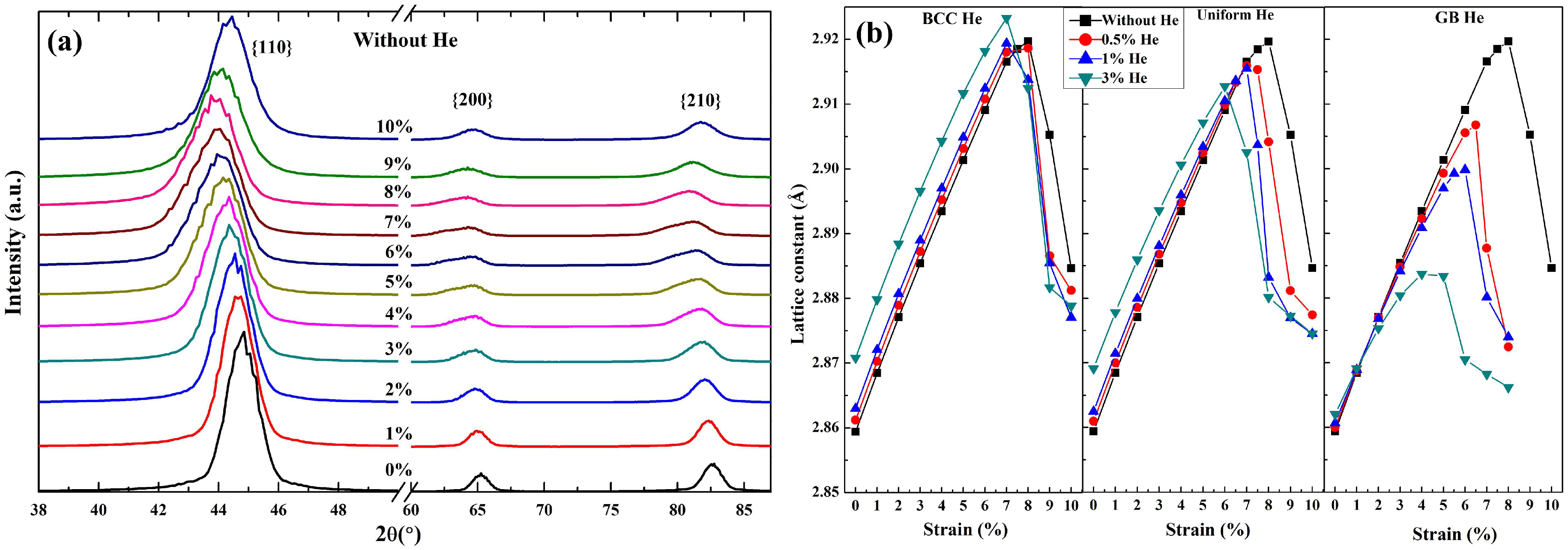

4.1. The Simulated XRD Patterns of Nanocrystalline Model during Loading

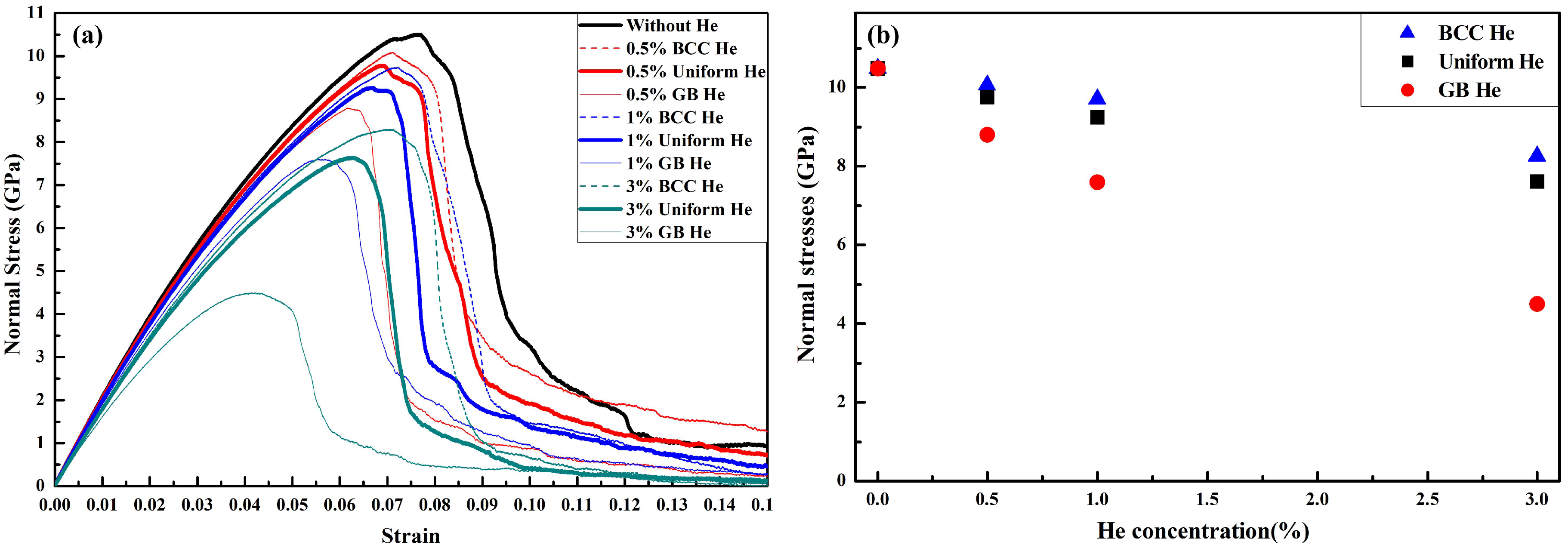

- BCC He. It is not difficult to understand that the number of BCC Fe atom per unit volume is reduced in grain interior region due to the BCC He is doped into the nanocrystalline models. Suppose that the lattice is a bunch of springs, which can be broken because of the existence of substitution He. The length of this bunch of springs may need to extend more to balance the given tensile stress if some of the springs are broken before loading. So the maximum lattice constant of model with the concentration of BCC He at 0.5% or 1% is changed slightly comparing that of the model without He. It is also observed that the maximum lattice constant is lower in the model without He than in the model with 3% BCC He (Figure 10), although the tensile strength of the former is stronger than that of the latter (Figure 6b). It is implied that the expansion of lattice constant is unsaturated when the ultimate strength of GB is reached in the model without He. Then the maximum lattice constant during loading is determined by the number of BCC Fe atom per unit volume if there is only BCC He in the model. The maximum of tensile stress in the models with BCC He is reduced because the GB strength is weakened by He or He clusters, which trapped by GB region during energy minimization (see Figure 2) or deformation of the models.

- GB He. The maximum lattice constant of the models with GB He and the ultimate strength of GB decrease with the increasing concentration of GB He, because the ultimate strength of GB is weakened by GB He and the expansion lattice constant is limited correspondingly. Thus, it is deduced in Figure 10b that the failure of mechanical property is caused due to the ultimate strength GB is reached. It implied that the expansion of lattice constant is governed by the strength of GB while the GB He is introduced in the nanocrystalline models.

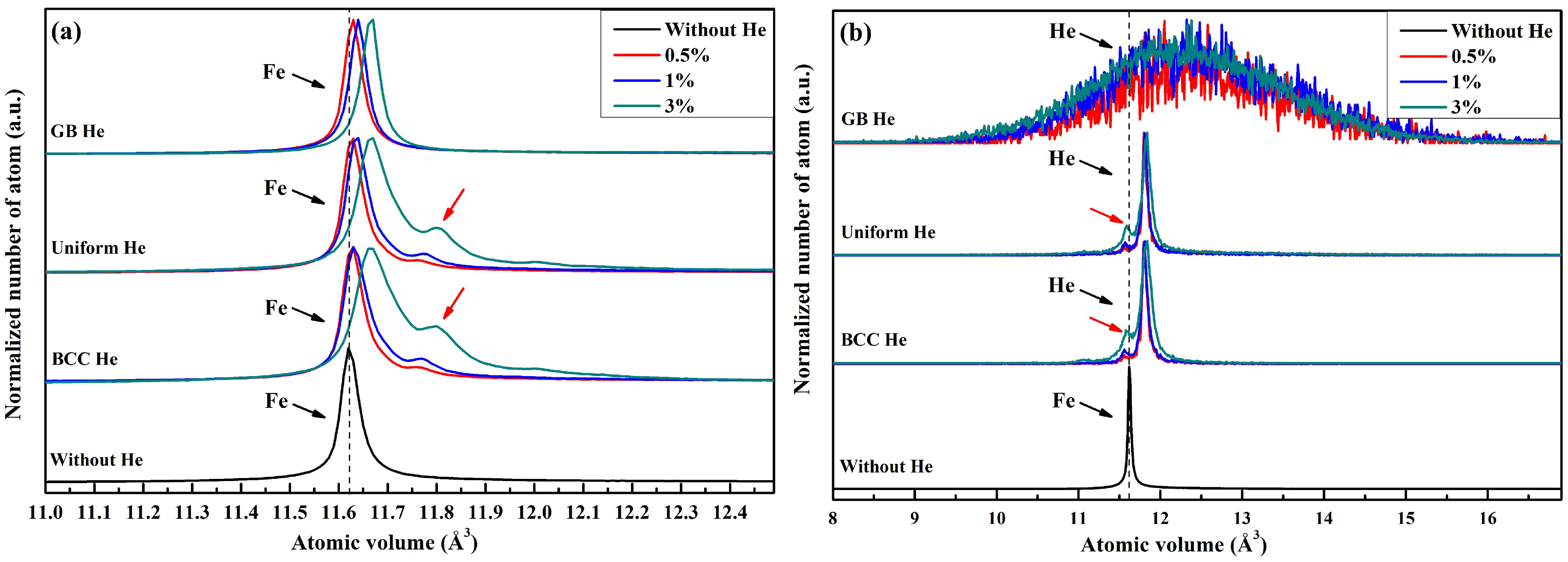

4.2. The Volume Expansion of Nanocrystalline Model during Loading

5. Conclusions

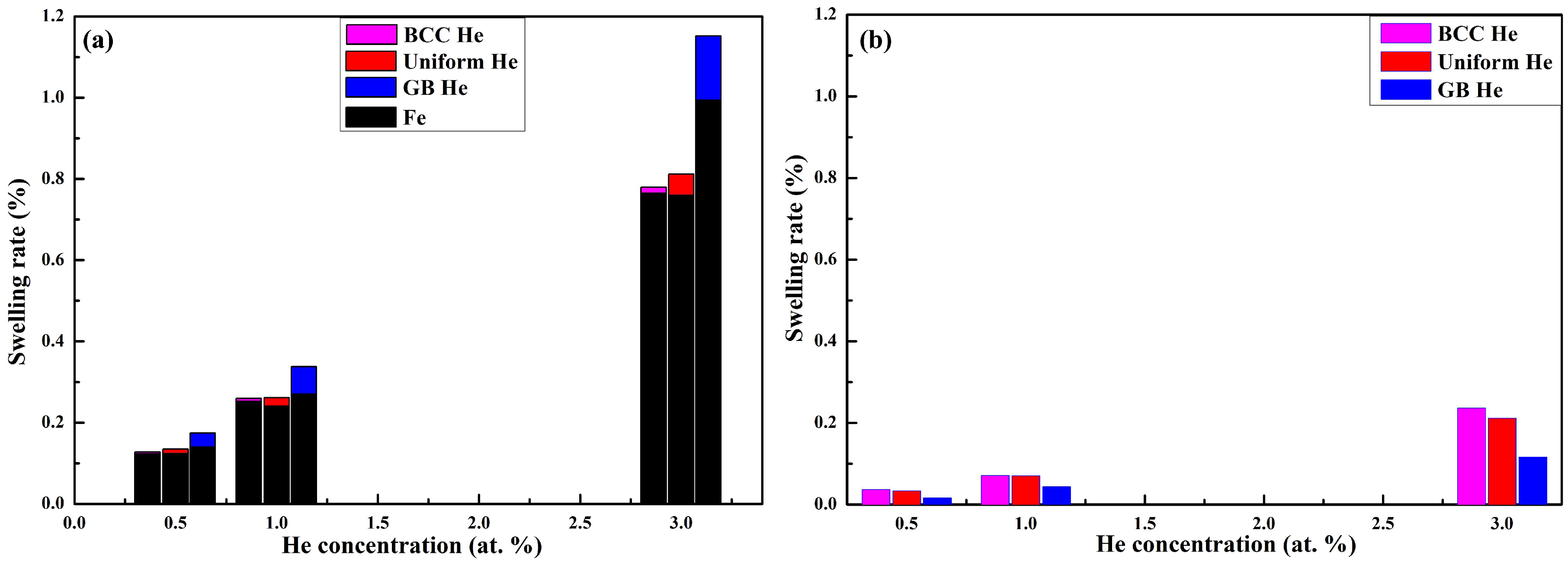

- The swelling of the model with He is contributed by doped He, disordered Fe and BCC Fe; the He distributed uniformly in nanocrystalline structure causes more expansion of lattice constant than that distributed at grain boundary (GB) structure; the total swelling rate induced by uniform He is lower than that induced by GB He.

- The tensile strength of nanocrystalline BCC-Fe is reduced after the introduction of He; the strain–stress curve shows He concentration and distribution dependence; the crack generation and growth are observed in the GB region during loading.

- The tensile strength is affected by the strength of GB which is mainly weakened by He distributed at GB region; the change of lattice constant and the atomic volume during loading should contribute to understand the degradation of mechanical property in the nanocrystalline models.

- The mechanical property of nanocrystalline BCC-Fe under an irradiation environment would be improved by enhancing the GB strength or reducing He concentration in GB region.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| BBC | Body-centered cubic |

| XRD | X-ray Diffraction |

| GB | Grain boundary |

| ACNA | Adaptive common neighbor analysis |

References

- Olander, D.R. Fundamental Aspects of Nuclear Reactor Fuel Elements; U.S. Department of Commerce: Washington, DC, USA, 1976. [CrossRef]

- Kramer, D.; Brager, H.R.; Rhodes, C.G.; Pard, A.G. Helium embrittlement in type 304 stainless steel. J. Nucl. Mater. 1968, 25, 121–131. [Google Scholar] [CrossRef]

- Fu, C.-C.; Willaime, F. Ab initio study of helium in α-Fe: Dissolution, migration, and clustering with vacancies. Phys. Rev. B 2005, 72, 064117. [Google Scholar] [CrossRef]

- Han, W.-Z.; Ding, M.-S.; Shan, Z.-W. Cracking behavior of helium-irradiated small-volume copper. Scr. Mater. 2008, 147, 1359–6462. [Google Scholar] [CrossRef]

- Zhang, L.; Shu, X.; Jin, S.; Zhang, Y.; Lu, G.H. First-principles study of He effects in a bcc Fe grain boundary: site preference, segregation and theoretical tensile strength. J. Phys. Condens. Matter 2010, 22, 375401. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Fu, C.-C.; Hayward, E.; Lu, G.-H. Properties of He clustering in α-Fe grain boundaries. J. Nucl. Mater. 2015, 459, 247–258. [Google Scholar] [CrossRef]

- Suzudo, T.; Yamaguchi, M.; Tsuru, T. Atomistic modeling of He embrittlement at grain boundaries of α-Fe: A common feature over different grain boundaries. Model. Simul. Mater. Sci. Eng. 2013, 21, 085013. [Google Scholar] [CrossRef]

- Singh, B.N. Effect of grain size on void formation during high-energy electron irradiation of austenitic stainless steel. Philos. Mag. 1974, 29, 25–42. [Google Scholar] [CrossRef]

- Chen, D.; Wang, J.; Chen, T.; Shao, L. Defect annihilation at grain boundaries in alpha-Fe. Sci. Rep. 2013, 2, 1450. [Google Scholar] [CrossRef]

- Bai, X.M.; Voter, A.F.; Hoagland, R.G.; Nastasi, M.; Uberuaga, B.P. Efficient annealing of radiation damage near grain boundaries via interstitial emission. Science 2010, 327, 1631–1634. [Google Scholar] [CrossRef]

- Yu, K.Y.; Liu, Y.; Sun, C.; Wang, H.; Shao, L.; Fu, E.G.; Zhang, X. Radiation damage in helium ion irradiated nanocrystalline Fe. J. Nucl. Mater. 2012, 425, 140–146. [Google Scholar] [CrossRef]

- Cheng, G.M.; Xu, W.Z.; Wang, Y.Q.; Misra, A.; Zhu, Y.T. Grain size effect on radiation tolerance of nanocrystalline Mo. Scr. Mater. 2016, 123, 90–94. [Google Scholar] [CrossRef]

- Odette, G.R.; Alinger, M.J.; Wirth, B.D. Recent Developments in Irradiation-Resistant Steels. Annu. Rev. Mater. Res. 2008, 38, 471–503. [Google Scholar] [CrossRef]

- Edmondson, P.D.; Parish, C.M.; Zhang, Y.; Hallén, A.; Miller, M.K. Helium entrapment in a nanostructured ferritic alloy. Scr. Mater. 2011, 65, 731–734. [Google Scholar] [CrossRef]

- Tschopp, M.A.; Gao, F.; Solanki, K.N. He-V cluster nucleation and growth in α-Fe grain boundaries. Acta Mater. 2017, 124, 544–555. [Google Scholar] [CrossRef]

- Yang, L.; Gao, F.; Kurtz, R.J.; Zu, X.T. Atomistic simulations of helium clustering and grain boundary reconstruction in alpha-iron. Acta Mater. 2015, 82, 275–286. [Google Scholar] [CrossRef]

- Terentyev, D.; He, X. Effect of Cr precipitates and He bubbles on the strength of <110> tilt grain boundaries in BCC Fe: An atomistic study. Comput. Mater. Sci. 2011, 50, 925–933. [Google Scholar] [CrossRef]

- Godon, A.; Creus, J.; Cohendoz, S.; Conforto, E.; Feaugas, X.; Girault, P.; Savall, C. Effects of grain orientation on the Hall–Petch relationship in electrodeposited nickel with nanocrystalline grains. Scr. Mater. 2010, 62, 403–406. [Google Scholar] [CrossRef]

- Gunkelmann, N.; Bringa, E.M.; Kang, K.; Ackland, G.J.; Ruestes, C.J. Polycrystalline iron under compression: Plasticity and phase transitions. Phys. Rev. B 2012, 86, 144111. [Google Scholar] [CrossRef]

- Hahn, E.N.; Meyers, M.A. Grain-size dependent mechanical behavior of nanocrystalline metals. Mater. Sci. Eng. A 2015, 646, 101–134. [Google Scholar] [CrossRef]

- Finney, J.L. A procedure for the construction of Voronoi polyhedr. J. Comput. Phys. 1979, 32, 137–143. [Google Scholar] [CrossRef]

- Available online: http://lammps.sandia.gov/index.html (accessed on 17 November 2016).

- Mendelev, M.I.; Han, S.; Srolovitz, D.J.; Ackland, G.J.; Sun, D.Y.; Asta, M. Development of new interatomic potentials appropriate for crystalline and liquid iron. Philos. Mag. 2003, 83, 3977–3994. [Google Scholar] [CrossRef]

- Fu, C.-C.; Willaime, F. Interaction between helium and self-defects in α-iron from first principles. J. Nucl. Mater. 2007, 367, 244–250. [Google Scholar] [CrossRef]

- Morishita, K.; Sugano, R.; Wirth, B.D.; Diaz de la Rubia, T. Thermal stability of helium-vacancy clusters in iron. Nucl. Instrum. Meth. B 2003, 202, 76–81. [Google Scholar] [CrossRef]

- Aziz, R.A.; Janzen, A.R.; Moldover, M.R. Ab initio calculations for helium: A standard for transport property measurements. Phys. Rev. Lett. 1995, 74, 1586–1589. [Google Scholar] [CrossRef] [PubMed]

- Gao, F.; Deng, H.; Heinisch, H.L.; Kurtz, R.J. A new Fe-He interatomic potential based on ab initio calculations in α-Fe. J. Nucl. Mater. 2011, 418, 115–120. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Zhao, X.; Lu, C.; Tieu, A.K.; Zhan, L.; Pei, L.; Huang, M. Deformation mechanisms and slip-twin interactions in nanotwinned body-centered cubic iron by molecular dynamics simulations. Comput. Mater. Sci. 2018, 147, 34–48. [Google Scholar] [CrossRef]

- Kiener, D.; Hosemann, P.; Maloy, S.A.; Minor, A.M. In situ nanocompression testing of irradiated copper. Nat. Mater. 2011, 10, 142–149. [Google Scholar] [CrossRef]

- Jeon, J.B.; Lee, B.-J.; Chang, Y.W. Molecular dynamics simulation study of the effect of grain size on the deformation behavior of nanocrystalline body-centered cubic iron. Scr. Mater. 2011, 64, 494–497. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, C.; Wang, W. Simulation Study of Helium Effect on the Microstructure of Nanocrystalline Body-Centered Cubic Iron. Materials 2019, 12, 91. https://doi.org/10.3390/ma12010091

Xu C, Wang W. Simulation Study of Helium Effect on the Microstructure of Nanocrystalline Body-Centered Cubic Iron. Materials. 2019; 12(1):91. https://doi.org/10.3390/ma12010091

Chicago/Turabian StyleXu, Chunping, and Wenjun Wang. 2019. "Simulation Study of Helium Effect on the Microstructure of Nanocrystalline Body-Centered Cubic Iron" Materials 12, no. 1: 91. https://doi.org/10.3390/ma12010091

APA StyleXu, C., & Wang, W. (2019). Simulation Study of Helium Effect on the Microstructure of Nanocrystalline Body-Centered Cubic Iron. Materials, 12(1), 91. https://doi.org/10.3390/ma12010091