Effect of Heat Treatment on Repetitively Scanned SLM NiTi Shape Memory Alloy

Abstract

1. Introduction

2. Experimental Procedure

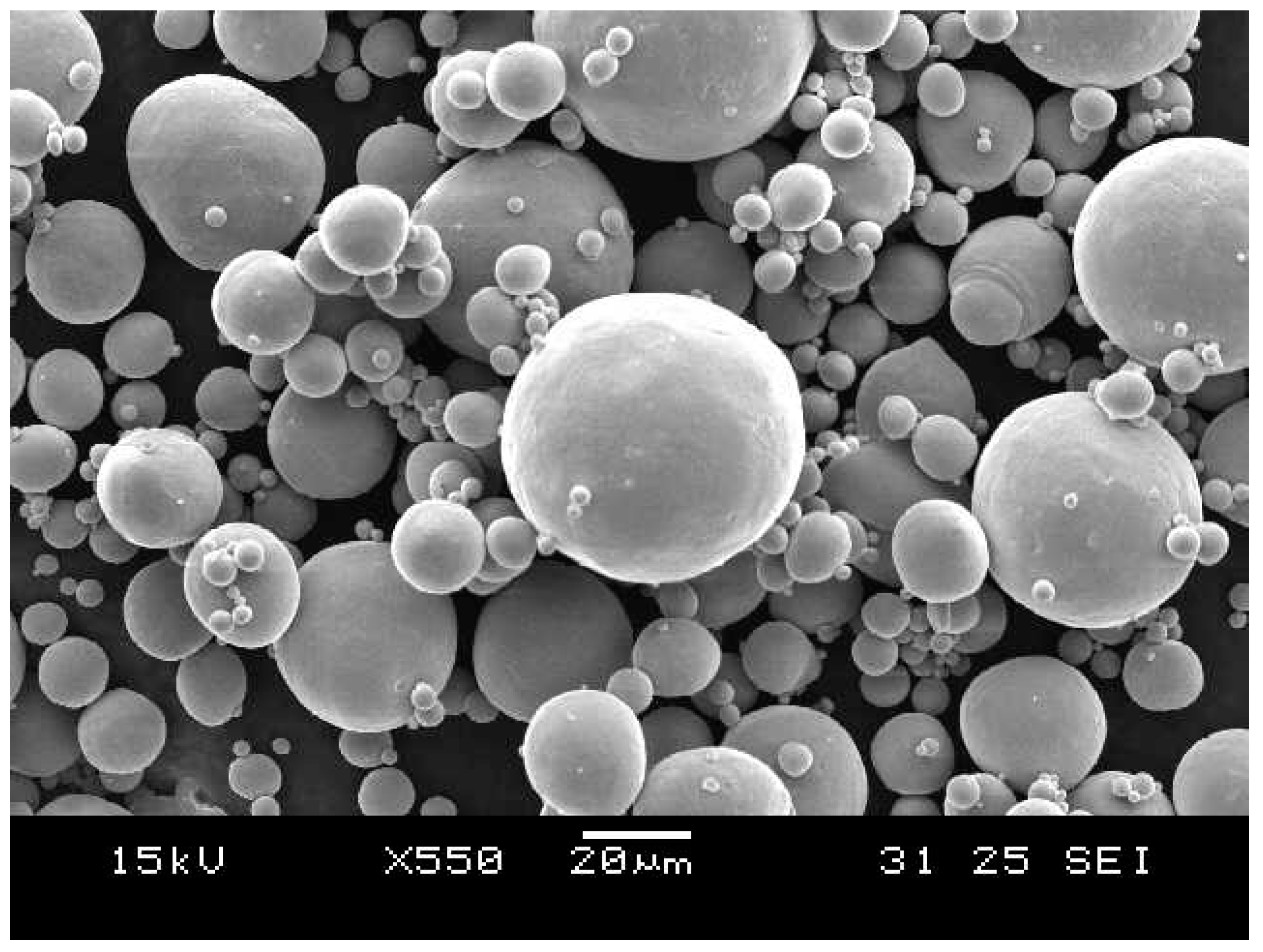

2.1. Material

2.2. Material Processing

2.3. Material Characterisation

3. Results

3.1. Shape Memory Responses

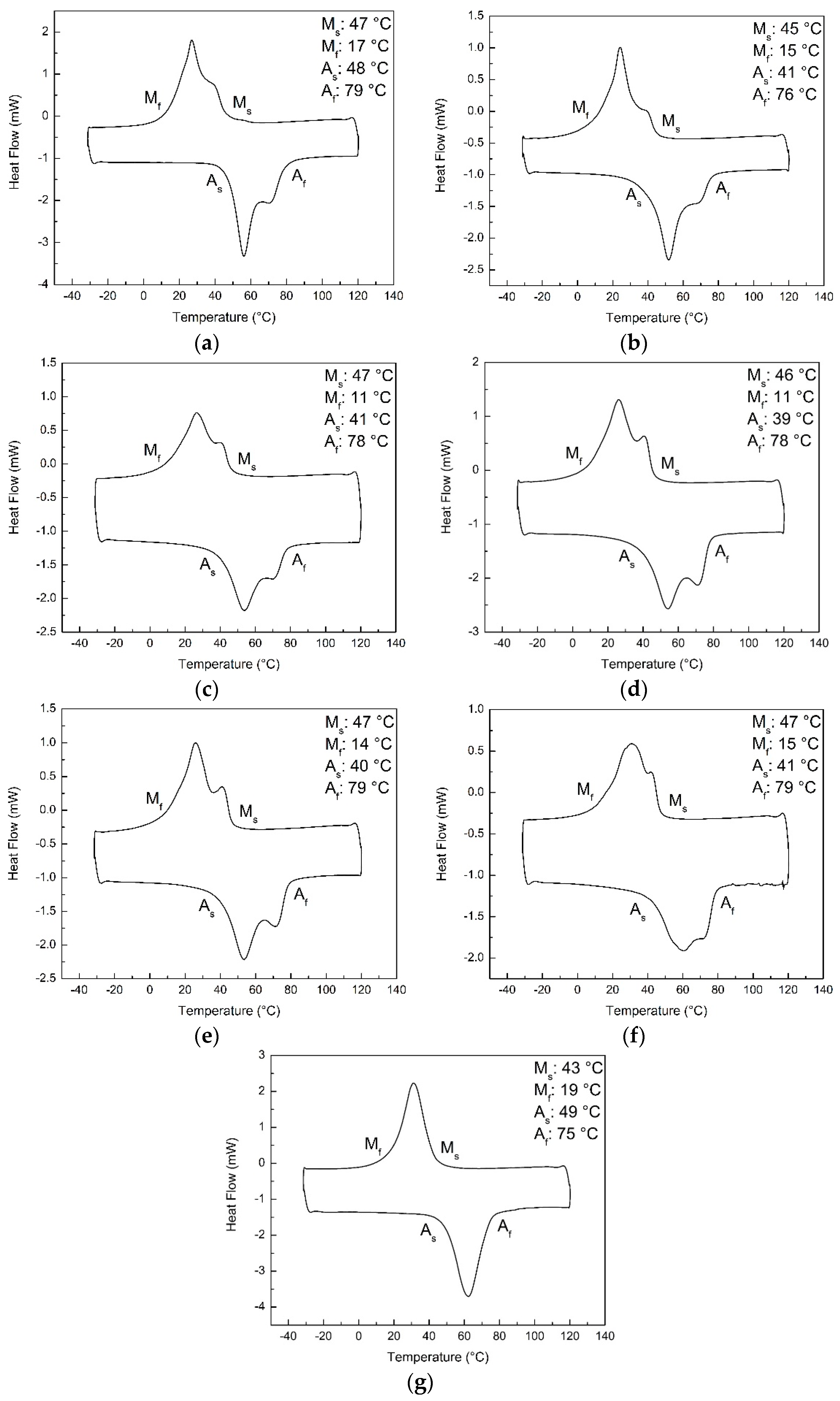

3.2. Phase Transformation Characteristics

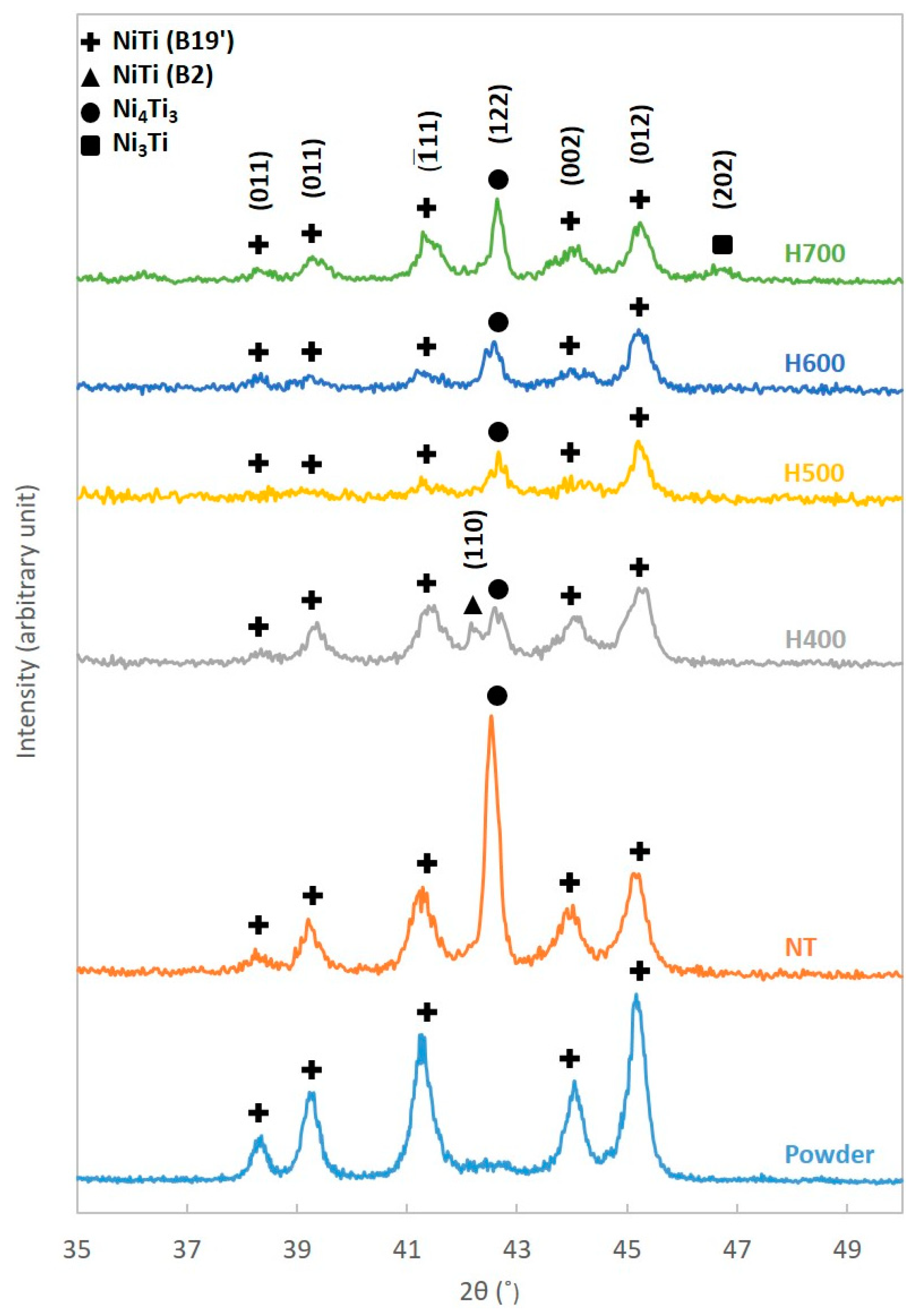

3.3. Phase Analysis

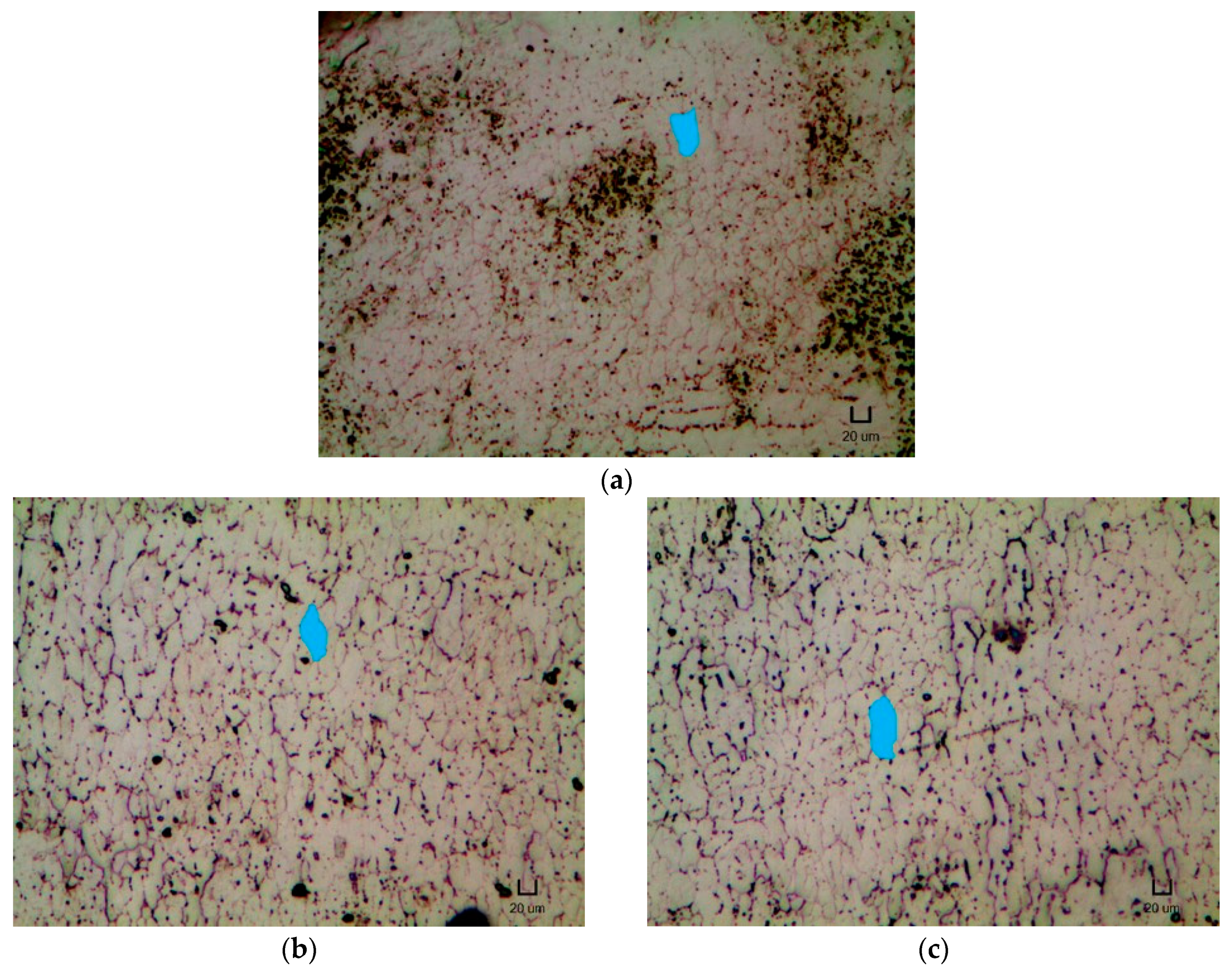

3.4. Grain Size Measurement

4. Discussion

4.1. Analysis of Phase Transformation Characteristics

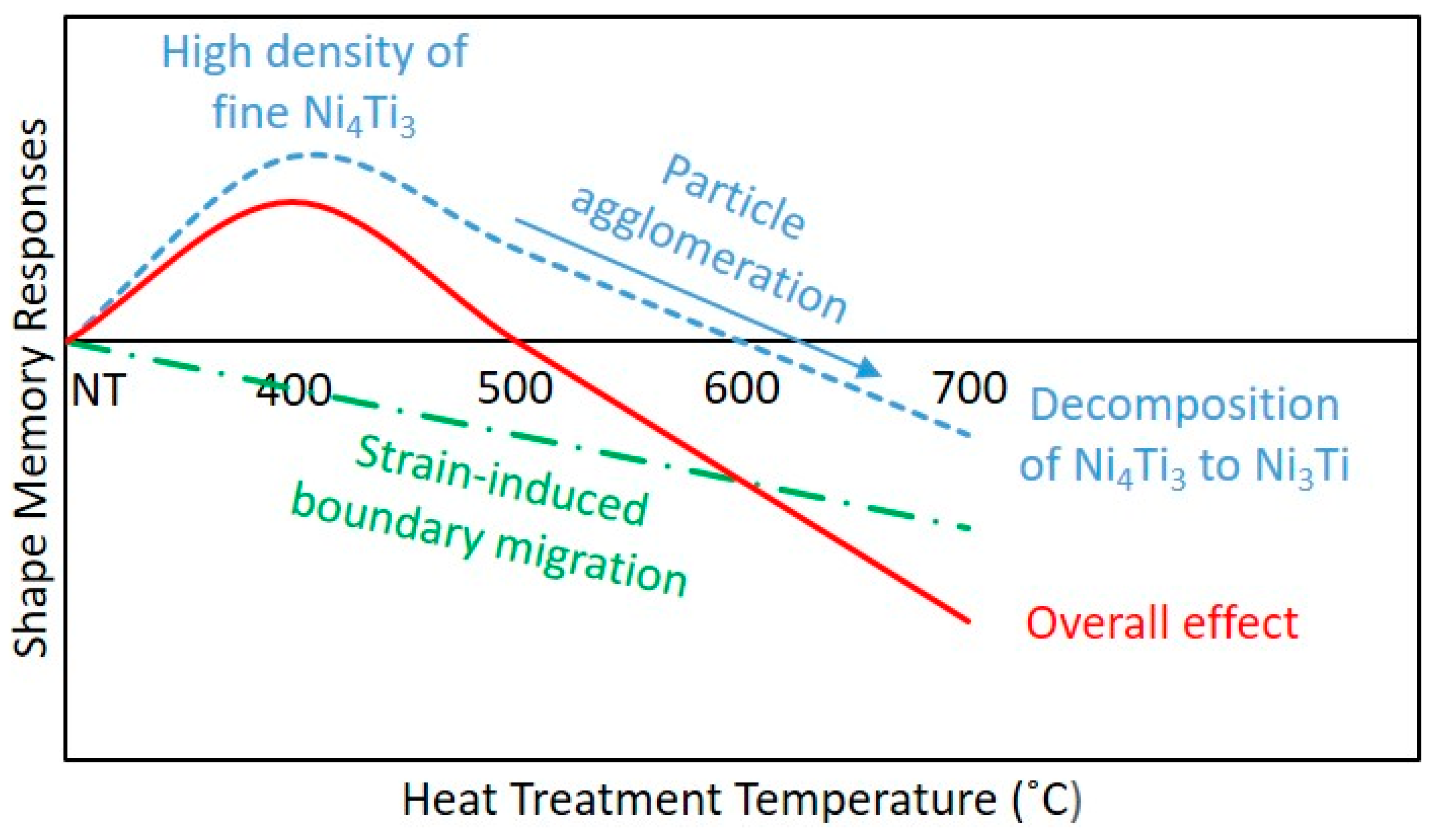

4.2. Analysis of Shape Memory Responses

4.2.1. Formation and Effects of Ni4Ti3 Precipitates

4.2.2. Formation and Effects of Grain Boundary Migration

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Meier, H.; Haberland, C.; Frenzel, J. Structural and functional properties of NiTi shape memory alloys produced by Selective Laser Melting. In Proceedings of the 5th International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 28 September–1 October 2011; pp. 291–296. [Google Scholar]

- Elahinia, M.H.; Hashemi, M.; Tabesh, M.; Bhaduri, S.B. Manufacturing and processing of NiTi implants: A review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Kruth, J.-P.; Schrooten, J.; Luyten, J.; Van Humbeeck, J. Effect of SLM parameters on transformation temperatures of shape memory nickel titanium parts. Adv. Eng. Mater. 2014, 16, 1140–1146. [Google Scholar] [CrossRef]

- Kumar, P.K.; Lagoudas, D.C. Introduction to shape memory alloys. In Shape Memory Alloys: Modeling and Engineering Applications; Lagoudas, D.C., Ed.; Springer Science: Berlin, Germany, 2008; pp. 1–51. [Google Scholar]

- Humbeeck, J.V. Shape memory alloys. In Smart Materials; Schwartz, M., Ed.; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Wang, L.; Xie, L.; Zhang, L.-C.; Chen, L.; Ding, Z.; Lv, Y.; Zhang, W.; Lu, W.; Zhang, D. Microstructure evolution and superelasticity of layer-like NiTiNb porous metal prepared by eutectic reaction. Acta Mater. 2018, 143, 214–226. [Google Scholar] [CrossRef]

- Wang, L.; Wang, C.; Zhang, L.-C.; Chen, L.; Lu, W.; Zhang, D. Phase transformation and deformation behavior of NiTi-Nb eutectic joined NiTi wires. Sci. Rep. 2016, 6, 23905. [Google Scholar] [CrossRef] [PubMed]

- Shariat, B.S.; Liu, Y.; Rio, G. Pseudoelastic behaviour of perforated NiTi shape memory plates under tension. Intermetallics 2014, 50, 59–64. [Google Scholar] [CrossRef]

- Meier, H.; Haberland, C.; Frenzel, J.; Zarnetta, R. Selective Laser Melting of NiTi shape memory components. In Proceedings of the Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 6–10 October 2009; pp. 233–238. [Google Scholar]

- Hartl, D.J.; Lagoundas, D.C. Thermomechanical characterization of shape memory alloy materials. In Shape Memory Alloys: Modeling and Engineering Applications; Lagoundas, D.C., Ed.; Springer Science: Berlin, Germany, 2008; pp. 53–119. [Google Scholar]

- Haberland, C.; Elahinia, M.; Walker, J.M.; Meier, H.; Frenzel, J. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater. Struct. 2014, 23, 104002. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Shahedin, A.M.; Dawood, S.D.S.; Ariffin, A.K. An investigation on the optimum machinability of NiTi based shape memory alloy. Mater. Manuf. Process. 2017, 32, 1497–1504. [Google Scholar] [CrossRef]

- Kaya, E.; Kaya, İ. A review on machining of NiTi shape memory alloys: The process and post process perspective. Int. J. Adv. Manuf. Technol. 2018, 1–43. [Google Scholar] [CrossRef]

- Leist, S.K.; Zhou, J. Current status of 4D printing technology and the potential of light-reactive smart materials as 4D printable materials. Virtual Phys. Prototyp. 2016, 11, 249–262. [Google Scholar] [CrossRef]

- Yang, C.; Wang, B.; Li, D.; Tian, X. Modelling and characterisation for the responsive performance of CF/PLA and CF/PEEK smart materials fabricated by 4D printing. Virtual Phys. Prototyp. 2017, 12, 69–76. [Google Scholar] [CrossRef]

- Teoh, J.E.M.; An, J.; Chua, C.K.; Lv, M.; Krishnasamy, V.; Liu, Y. Hierarchically self-morphing structure through 4D printing. Virtual Phys. Prototyp. 2017, 12, 61–68. [Google Scholar] [CrossRef]

- An, J.; Chua, C.K.; Mironov, V. A perspective on 4D bioprinting. Int. J. Bioprint. 2016, 2, 3–5. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Yadroitsev, I.; Smurov, I. Direct Selective Laser Melting of nitinol powder. Phys. Procedia 2012, 39, 447–454. [Google Scholar] [CrossRef]

- Shishkovsky, I.V.; Yadroitsev, I.A.; Smurov, I.Y. Manufacturing three-dimensional nickel titanium articles using layer-by-layer laser-melting technology. Tech. Phys. Lett. 2013, 39, 1081–1084. [Google Scholar] [CrossRef]

- Bormann, T.; Schumacher, R.; Muller, B.; Mertmann, M.; Wild, M.d. Tailoring Selective Laser Melting process parameters for NiTi implants. J. Mater. Eng. Perform. 2012, 21, 2519–2524. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, J.; Coddet, C. Microstructure and transformation behavior of in-situ shape memory alloys by Selective Laser Melting Ti-Ni mixed powder. J. Mater. Sci. Technol. 2013, 29, 863–867. [Google Scholar] [CrossRef]

- Clare, A.T.; Chalker, P.R.; Davies, S.; Sutcliffe, C.J.; Tsopanos, S. Selective Laser Melting of high aspect ratio 3D nickel-titanium structures two way trained for MEMS applications. Int. J. Mech. Mater. Des. 2008, 4, 181–187. [Google Scholar] [CrossRef]

- Habijan, T.; Haberland, C.; Meier, H.; Frenzel, J.; Wittsiepe, J.; Wuwer, C.; Greulich, C.; Schildhauer, T.A.; Köller, M. The biocompatibility of dense and porous nickel–titanium produced by Selective Laser Melting. Mater. Sci. Eng. C 2013, 33, 419–426. [Google Scholar] [CrossRef] [PubMed]

- Dadbakhsh, S.; Speirs, M.; Kruth, J.-P.; Van Humbeeck, J. Influence of SLM on shape memory and compression behaviour of NiTi scaffolds. CIRP Ann. Manuf. Technol. 2015, 64, 209–212. [Google Scholar] [CrossRef]

- Bormann, T.; Müller, B.; Schinhammer, M.; Kessler, A.; Thalmann, P.; Wild, M.d. Microstructure of selective laser melted nickel–titanium. Mater. Charact. 2014, 94, 189–202. [Google Scholar] [CrossRef]

- Speirs, M.; Wang, X.; Baelen, S.V.; Ahadi, A.; Dadbakhsh, S.; Kruth, J.-P.; Humbeeck, J.V. On the transformation behavior of NiTi shape-memory alloy produced by SLM. Shape Mem. Superelast. 2016, 2, 310–316. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Vrancken, B.; Kruth, J.-P.; Luyten, J.; Van Humbeeck, J. Texture and anisotropy in Selective Laser Melting of NiTi alloy. Mater. Sci. Eng. A 2016, 650, 225–232. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Ong, C.; Liu, Y.; Chua, C.K.; Leong, K.F.; Yang, S.F. Selective Laser Melting of nickel titanium shape memory alloy. In Proceedings of the 2nd International Conference on Progress in Additive Manufacturing, Nanyang Executive Centre, Nanyang Technological University, Singapore, 16–19 May 2016; pp. 451–456. [Google Scholar]

- Khoo, Z.X.; Lim, Y.L.; Liu, Y.; Chua, C.K. Effect of hatch distance on Selective Laser Melting of nickel titanium shape memory alloy. In Proceedings of the 2nd International Conference in Sports Science & Technology, Nanyang Executive Centre, Nanyang Technological University, Singapore, 12–13 December 2016; pp. 98–101. [Google Scholar]

- Saedi, S.; Turabi, A.S.; Andani, M.T.; Haberland, C.; Karaca, H.; Elahinia, M. The influence of heat treatment on the thermomechanical response of Ni-rich NiTi alloys manufactured by selective laser melting. J. Alloys Compd. 2016, 677, 204–210. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Liu, Y.; Low, Z.H.; An, J.; Chua, C.K.; Leong, K.F. Fabrication of SLM NiTi shape memory alloy via repetitive laser scanning. Shape Mem. Superelast. 2018, 4, 112–120. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Teoh, J.E.M.; Liu, Y.; Chua, C.K.; Yang, S.; An, J.; Leong, K.F.; Yeong, W.Y. 3D printing of smart materials: A review on recent progresses in 4D printing. Virtual Phys. Prototyp. 2015, 10, 103–122. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Liu, Y.; An, J.; Chua, C.K.; Shen, Y.F.; Kuo, C.N. A review of Selective Laser Melted NiTi shape memory alloy. Materials 2018, 11, 519. [Google Scholar] [CrossRef] [PubMed]

- Sing, S.L.; Wang, S.; Agarwala, S.; Wiria, F.E.; Ha, T.M.H.; Yeong, W.Y. Fabrication of titanium based biphasic scaffold using Selective Laser Melting and collagen immersion. Int. J. Bioprint. 2017, 3, 65–71. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Yin, H.; He, Y.; Moumni, Z.; Sun, Q. Effects of grain size on tensile fatigue life of nanostructured NiTi shape memory alloy. Int. J. Fatigue 2016, 88, 166–177. [Google Scholar] [CrossRef]

- Miyazaki, S.; Ohmi, Y.; Otsuka, K.; Suzuki, Y. Characteristics of deformation and transformation pseudoelasticity in Ti-Ni alloy. J. Phys. Colloq. 1982, 43, C4-255. [Google Scholar] [CrossRef]

- Ataei, M.; Zarei-Hanzaki, A.; Shamsolhodaei, A. Shape memory response and mechanical properties of warm deformed NiTi intermetallic alloy. Mater. Sci. Eng. A 2017, 680, 291–296. [Google Scholar] [CrossRef]

- Morgan, N.B.; Friend, C. A review of shape memory stability in NiTi alloys. In Proceedings of the Fifth European Symposium on Martensitic Transformations and Shape Memory Alloys, Como, Italy, 4–8 September 2000; pp. 325–332. [Google Scholar]

- Marattukalam, J.J.; Balla, V.K.; Das, M.; Bontha, S.; Kalpathy, S.K. Effect of heat treatment on microstructure, corrosion, and shape memory characteristics of laser deposited NiTi alloy. J. Alloys Compd. 2018, 744, 337–346. [Google Scholar] [CrossRef]

- Miyazaki, S.; Kim, H.Y. Basic characteristics of titanium-nickel (Ti-Ni)-based and titanium-niobium (Ti-Nb)-based alloys. In Shape Memory and Superelastic Alloys—Technologies and Applications; Yamauchi, K., Ohkata, I., Tsuchiya, K., Miyazaki, S., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2011; pp. 15–42. [Google Scholar]

- Sartorius. Manual of Weighing Applications Part 1: Density. 1999. Available online: http://instrumentationandcontrol.net/sartorious-2016-manual-of-weighing-applications-density/ (accessed on 26 December 2018).

- Spierings, A.B.; Schneider, M. Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyp. J. 2011, 17, 380–386. [Google Scholar] [CrossRef]

- Zhang, L.C.; Shen, Z.Q.; Xu, J. Glass formation in a (Ti,Zr,Hf)-(Cu,Ni,Ag)-Al high-order alloy system by mechanical alloying. J. Mater. Res. 2003, 18, 2141–2149. [Google Scholar] [CrossRef]

- Yang, H.W.; Wen, J.; Quan, M.X.; Wang, J.Q. Evaluation of the volume fraction of nanocrystals devitrified in Al-based amorphous alloys. J. Non-Cryst. Solids 2009, 355, 235–238. [Google Scholar] [CrossRef]

- Gloriant, T.; Gich, M.; Surinach, S.; Baro, M.D.; Greer, A.L. Evaluation of the volume fraction crystallised during devitrification of Al-based amorphous alloys. J. Metastab. Nanocryst. Mater. 2000, 8, 365–370. [Google Scholar]

- ASTM E112–13 Standard Test Methods for Determining Average Grain Size; American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- Gall, K.; Tyber, J.; Wilkesanders, G.; Robertson, S.W.; Ritchie, R.O.; Maier, H.J. Effect of microstructure on the fatigue of hot-rolled and cold-drawn NiTi shape memory alloys. Mater. Sci. Eng. A 2008, 486, 389–403. [Google Scholar] [CrossRef]

- Sadiq, H.; Wong, M.B.; Al-Mahaidi, R.; Zhao, X.L. The effects of heat treatment on the recovery stresses of shape memory alloys. Smart Mater. Struct. 2010, 19, 035021. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Lee, Y.L.D.; An, J.; Chua, C.K.; Liu, Y. Annealing of Selective Laser Melted NiTi shape memory alloy. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing, Nanyang Executive Centre, Nanyang Technological University, Singapore, 14–17 May 2018; pp. 445–450. [Google Scholar]

- Frenzel, J.; George, E.P.; Dlouhy, A.; Somsen, C.; Wagner, M.F.-X.; Eggeler, G. Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2010, 58, 3444–3458. [Google Scholar] [CrossRef]

- Bhagyaraj, J.; Ramaiah, K.V.; Saikrishna, C.N.; Bhaumik, S.K.; Gouthama. Behaviour and effect of Ti2Ni phase during processing of NiTi shape memory alloy wire from cast ingot. J. Alloys Compd. 2013, 581, 344–351. [Google Scholar] [CrossRef]

- Liu, Y.; Humbeeck, J.V.; Stalmans, R.; Delaey, L. Some aspects of the properties of NiTi shape memory alloy. J. Alloys Compd. 1997, 247, 115–121. [Google Scholar] [CrossRef]

- Ortega, A.M.; Tyber, J.; Frick, C.P.; Gall, K.; Maier, H.J. Cast NiTi shape-memory alloys. Adv. Eng. Mater. 2005, 7, 492–507. [Google Scholar] [CrossRef]

- Losertová, M.; Štencek, M.; Matýsek, D.; Štefek, O.; Drápala, J. Microstructure evolution of heat treated NiTi alloys. Mater. Sci. Eng. Conf. Ser. 2017, 266, 012008. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Miranda, R.M.; Fernandes, F.M.B. Welding and joining of NiTi shape memory alloys: A review. Prog. Mater. Sci. 2017, 88, 412–466. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Xu, L.; Wang, R. The effect of annealing and cold-drawing on the super-elasticity of the Ni-Ti shape memory alloy wire. Mod. Appl. Sci. 2010, 4, 109–115. [Google Scholar] [CrossRef]

- Firstov, G.S.; Vitchev, R.G.; Kumar, H.; Blanpain, B.; Humbeeck, J.V. Surface oxidation of NiTi shape memory alloy. Biomaterials 2002, 23, 4863–4871. [Google Scholar] [CrossRef]

- Saburi, T.; Tatsumi, T.; Nenno, S. Effects of heat treatment on mechanical behavior of Ti-Ni alloys. J. Phys. Colloq. 1982, 43, C4-261. [Google Scholar] [CrossRef]

- Nishida, M.; Wayman, C.M.; Honma, T. Precipitation processes in near-equiatomic TiNi shape memory alloys. Metall. Trans. A 1986, 17A, 1505–1515. [Google Scholar] [CrossRef]

- Gall, K.; Sehitoglu, H.; Chumlyakov, Y.I.; Kireeva, I.V.; Maier, H.J. The influence of aging on critical transformation stress levels and martensite start temperatures in NiTi: Part 1—Aged microstructure and micro-mechanical modeling. J. Eng. Mater. Technol. 1999, 121, 19–27. [Google Scholar] [CrossRef]

- Yan, X.J.; Yang, D.Z.; Liu, X.P. Influence of heat treatment on the fatigue life of a laser-welded NiTi alloy wire. Mater. Charact. 2007, 58, 262–266. [Google Scholar] [CrossRef]

- Groover, M.P. Heat treatment of metals. In Principles of Modern Manufacturing; John Wiley & Sons (Asia) Pte Ltd.: Singapore, 2011; pp. 646–657. [Google Scholar]

- Chan, C.W.; Man, H.C.; Yue, T.M. Effect of postweld heat treatment on the microstructure and cyclic deformation behavior of laser-welded NiTi-shape memory wires. Metall. Mater. Trans. A 2012, 43, 1956–1965. [Google Scholar] [CrossRef]

- Filip, P.; Mazanec, K. On precipitation kinetics in TiNi shape memory alloys. Scr. Mater. 2001, 45, 701–707. [Google Scholar] [CrossRef]

- Avner, S.H. Annealing and hot working. In Introduction to Physical Metallurgy; McGraw-Hill Book Company: New York, NY, USA, 1974; pp. 129–146. [Google Scholar]

- Bellier, S.P.; Doherty, R.D. The structure of deformed aluminium and its recrystallization—Investigations with transmission kossel diffraction. Acta Metall. 1977, 25, 521–538. [Google Scholar] [CrossRef]

- Beck, P.A.; Sperry, P.R. Strain induced grain boundary migration in high purity aluminum. J. Appl. Phys. 1950, 21, 150–152. [Google Scholar] [CrossRef]

- Groover, M.P. Mechanical properties of materials. In Principles of Modern Manufacturing; John Wiley & Sons (Asia) Pte Ltd.: Singapore, 2011; pp. 40–66. [Google Scholar]

- Prithiv, T.S.; Bhuyan, P.; Pradhan, S.K.; Sarma, V.S.; Mandal, S. A critical evaluation on efficacy of recrystallization vs. strain induced boundary migration in achieving grain boundary engineered microstructure in a Ni-base superalloy. Acta Mater. 2018, 146, 187–201. [Google Scholar] [CrossRef]

- Delville, R.; Malard, B.; Pilch, J.; Sittner, P.; Schryvers, D. Microstructure changes during non-conventional heat treatment of thin Ni–Ti wires by pulsed electric current studied by transmission electron microscopy. Acta Mater. 2010, 58, 4503–4515. [Google Scholar] [CrossRef]

| Scanned Section | Atomic Percentage of Ni (%) | Atomic Percentage of Ti (%) |

|---|---|---|

| 1 | 51.07 | 48.93 |

| 2 | 48.99 | 51.01 |

| 3 | 51.19 | 48.81 |

| 4 | 48.30 | 51.70 |

| 5 | 49.74 | 50.26 |

| 6 | 51.24 | 48.76 |

| Average | 50.09 | 49.91 |

| Strains/Samples | NT | H400 | H500 | H600 | H700 |

|---|---|---|---|---|---|

| Residual Strain (%) | 5.14 ± 0.11 | 4.99 ± 0.01 | 4.96 ± 0.09 | 5.01 ± 0.07 | 4.96 ± 0.02 |

| Transformation Strain (%) | 3.37 ± 0.19 | 3.59 ± 0.17 | 3.36 ± 0.28 | 3.18 ± 0.21 | 3.08 ± 0.30 |

| Shape Recovery = (%) | 0.66 ± 0.04 | 0.72 ± 0.04 | 0.68 ± 0.05 | 0.63 ± 0.04 | 0.62 ± 0.06 |

| Samples/Transformation Temperatures | Ms (°C) | Mf (°C) | As (°C) | Af (°C) | (Af − As) (°C) |

|---|---|---|---|---|---|

| NiTi Powder | 47 ± 0.0 | 17 ± 0.0 | 48 ± 0.7 | 79 ± 0.0 | 31 ± 0.7 |

| NT Samples | 45 ± 0.0 | 15 ± 0.8 | 40 ± 1.1 | 76 ± 0.0 | 36 ± 1.1 |

| H400 Samples | 47 ± 0.5 | 12 ± 2.9 | 40 ± 1.3 | 78 ± 0.7 | 38 ± 0.8 |

| H500 Samples | 47 ± 0.5 | 11 ± 2.2 | 41 ± 1.2 | 79 ± 0.5 | 38 ± 0.9 |

| H600 Samples | 47 ± 0.0 | 14 ± 1.1 | 40 ± 1.2 | 79 ± 0.0 | 39 ± 1.2 |

| H700 Samples | 48 ± 0.5 | 15 ± 1.1 | 41 ± 1.1 | 79 ± 0.4 | 38 ± 1.2 |

| Samples/Phases | Martensitic Phase (%) | Austenitic Phase (%) | Ni4Ti3 (%) | Ni3Ti (%) |

|---|---|---|---|---|

| NiTi Powder | 100.0 | - | - | - |

| NT Sample | 64.4 | - | 35.6 | - |

| H400 Sample | 89.4 | 2.4 | 8.2 | - |

| H500 Sample | 72.3 | - | 27.7 | - |

| H600 Sample | 77.8 | - | 22.2 | - |

| H700 Sample | 74.0 | - | 19.0 | 7.0 |

| Parameters/Samples | NT | H400 | H500 | H600 | H700 |

|---|---|---|---|---|---|

| ASTM Grain Size Number | 3.35 ± 0.07 | 2.97 ± 0.07 | 2.37 ± 0.14 | 2.05 ± 0.18 | 1.74 ± 0.12 |

| Average Grain Area (μm2) | 12,830 ± 698 | 16,634 ± 897 | 25,296 ± 2632 | 31,696 ± 4007 | 39,173 ± 3396 |

| Positive Impacts | Negative Impacts |

|---|---|

| Precipitation of a high density of fine Ni4Ti3 precipitates at a lower heat treatment temperature of 400 °C | Initiation of particle agglomeration and formation of dislocations with increasing heat treatment temperature from 500 to 700 °C |

| Improvements in the transformation strain (from 3.37 ± 0.19 to 3.59 ± 0.17) and shape recovery percentage (from 0.66 ± 0.04 to 0.72 ± 0.04) of repetitively scanned NiTi samples | Occurrence of strain-induced boundary migration with the implementation of heat treatment and with rising heat treatment temperature from 400 to 700 °C |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khoo, Z.X.; An, J.; Chua, C.K.; Shen, Y.F.; Kuo, C.N.; Liu, Y. Effect of Heat Treatment on Repetitively Scanned SLM NiTi Shape Memory Alloy. Materials 2019, 12, 77. https://doi.org/10.3390/ma12010077

Khoo ZX, An J, Chua CK, Shen YF, Kuo CN, Liu Y. Effect of Heat Treatment on Repetitively Scanned SLM NiTi Shape Memory Alloy. Materials. 2019; 12(1):77. https://doi.org/10.3390/ma12010077

Chicago/Turabian StyleKhoo, Zhong Xun, Jia An, Chee Kai Chua, Yu Fang Shen, Che Nan Kuo, and Yong Liu. 2019. "Effect of Heat Treatment on Repetitively Scanned SLM NiTi Shape Memory Alloy" Materials 12, no. 1: 77. https://doi.org/10.3390/ma12010077

APA StyleKhoo, Z. X., An, J., Chua, C. K., Shen, Y. F., Kuo, C. N., & Liu, Y. (2019). Effect of Heat Treatment on Repetitively Scanned SLM NiTi Shape Memory Alloy. Materials, 12(1), 77. https://doi.org/10.3390/ma12010077