Mechanical and Microstructural Characterization of an AZ91–Activated Carbon Syntactic Foam

Abstract

1. Introduction

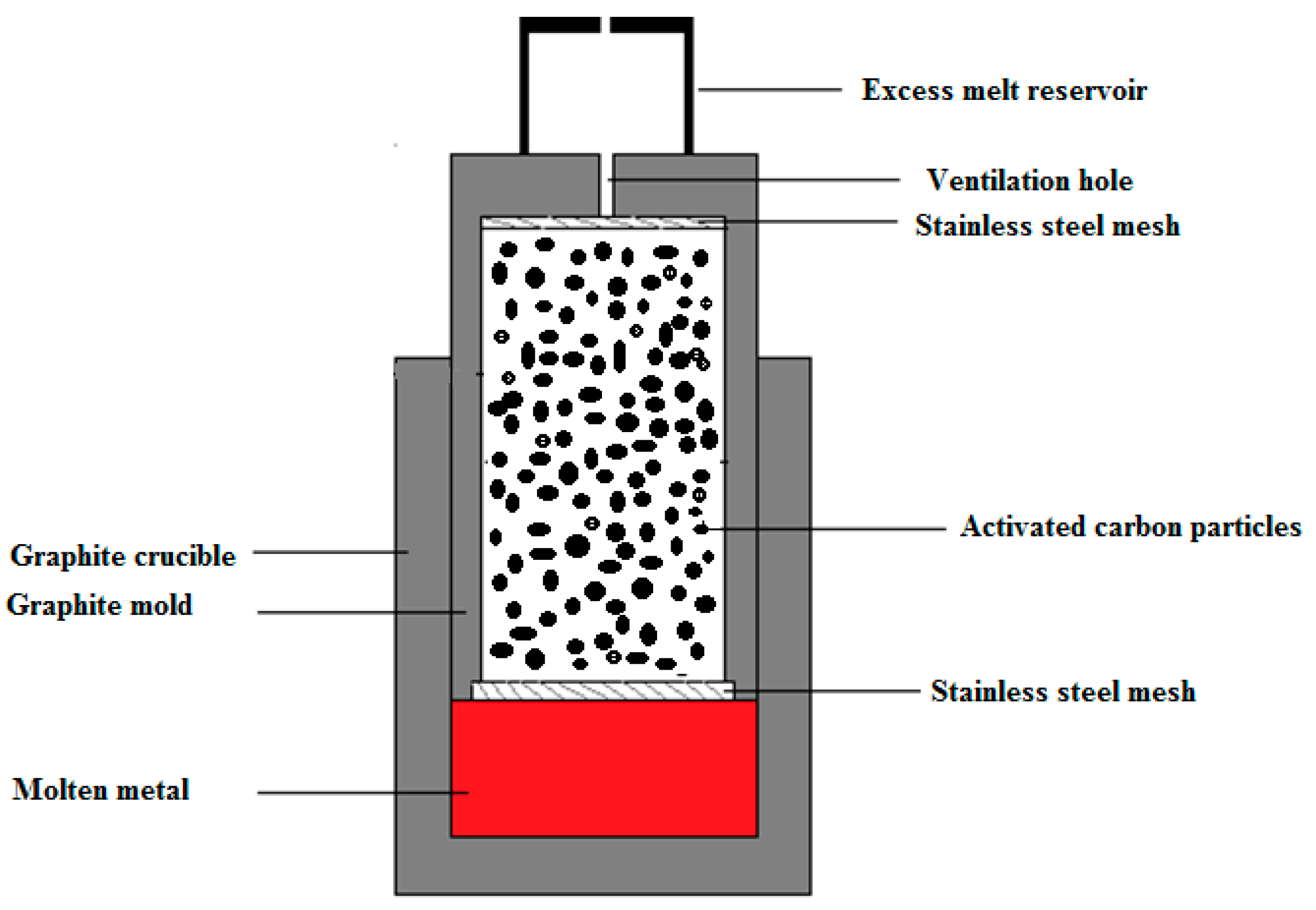

2. Materials and Methods

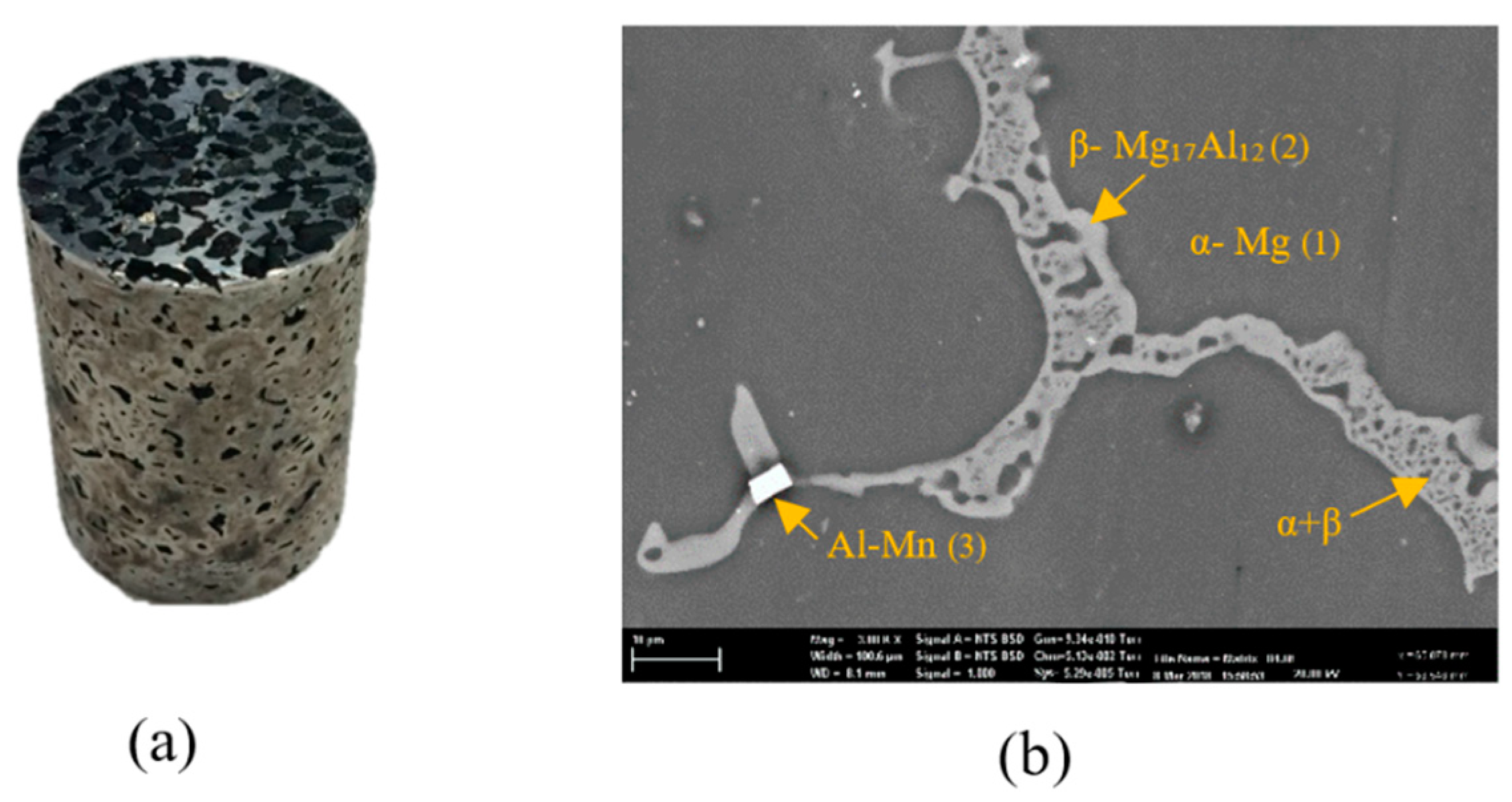

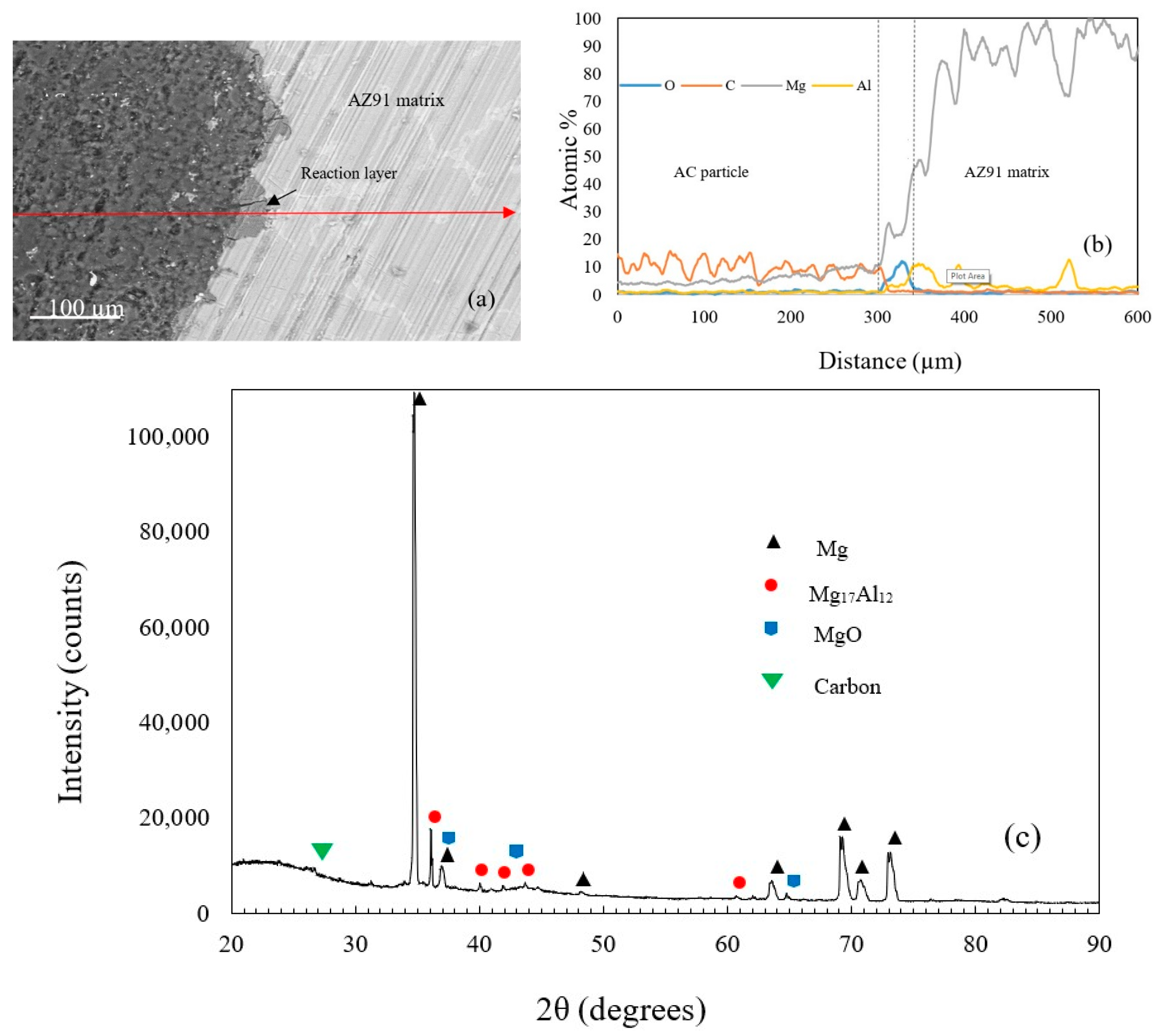

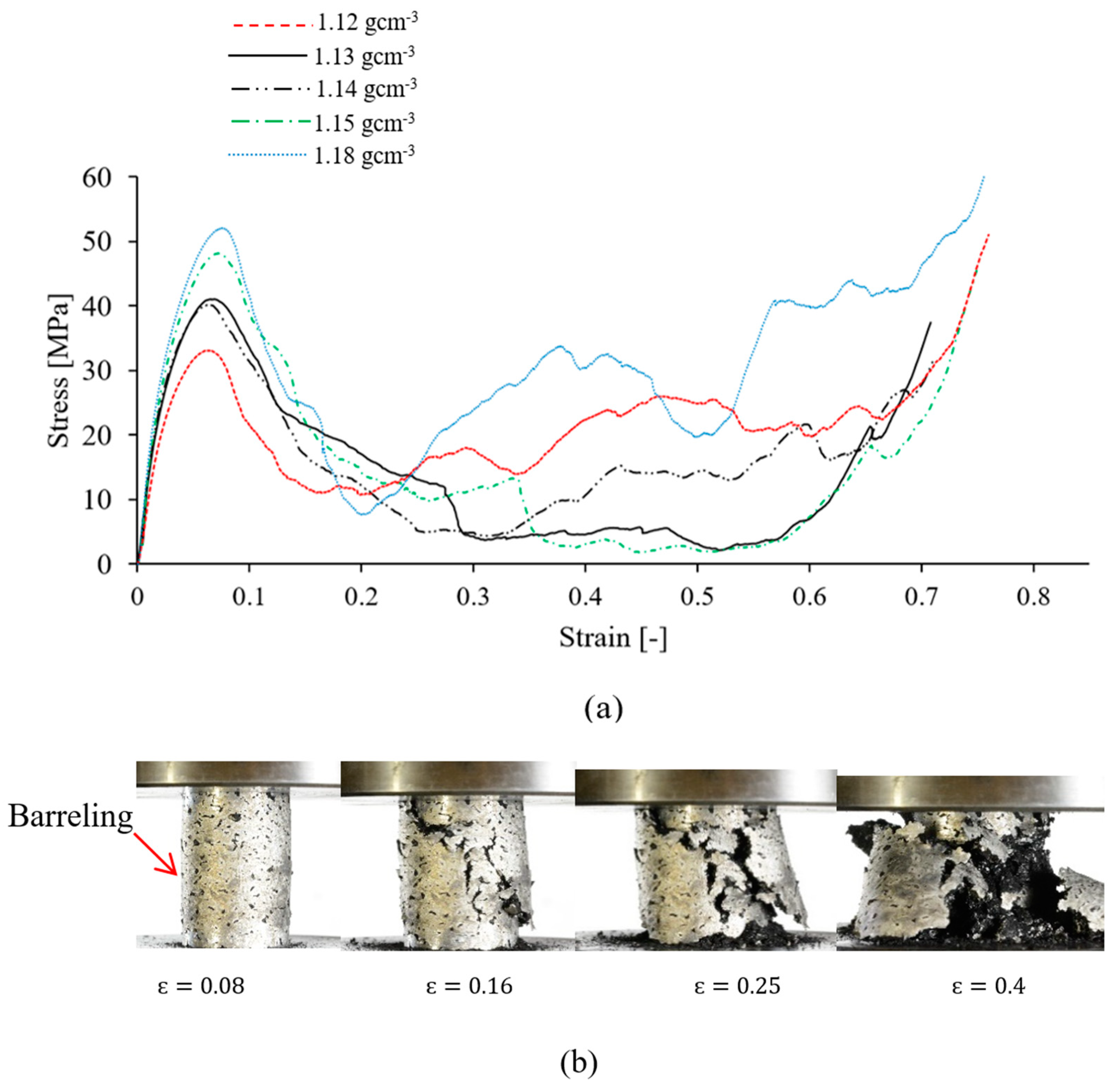

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gibson, L.J.; Ashby, M.F. Cellular Solids Structure and Properties; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Nihad, D. Metal Foams: Fundamentals and Applications; DEStec-Publications Inc.: Lancaster, PA, USA, 2013. [Google Scholar]

- Sharma, M.; Modi, O.P.; Kumar, P. Experimental modelling of copper foams processed through powder metallurgy route using a compressible space holder material. J. Porous Mater. 2017, 24, 1581–1593. [Google Scholar] [CrossRef]

- Papantoniou, I.G.; Markopoulos, A.P.; Pantelis, D.I.; Manolakos, D.E. Application of Aluminium Flakes in Fabrication of Open-Cell Aluminium Foams by Space Holder Method. Materials 2018, 11, 1420. [Google Scholar] [CrossRef] [PubMed]

- Linul, E.; Movahedi, N.; Marsavina, L. On the Lateral Compressive Behavior of Empty and Ex-Situ Aluminum Foam-Filled Tubes at High Temperature. Materials 2018, 11, 554. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Dai, S.; Li, C.; Li, W.; Ren, Y. Effects of Pore Size on Fatigue Deformation Mechanism of Open-Cell Copper Foam at Low Stress Amplitude. Materials 2018, 11, 1639. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Ren, Z.; Xu, Y.; Pang, S.; Zhao, X.; Zhao, Y. Biodegradable Magnesium Alloys Developed as Bone Repair Materials: A Review. Scanning 2018, 9216314. [Google Scholar] [CrossRef] [PubMed]

- Malladi, L.; Mahapatro, A.; Gomes, A.S. Fabrication of magnesium-based metallic scaffolds for bone tissue engineering. Mater. Technol. 2017, 33, 173–182. [Google Scholar] [CrossRef]

- Huang, W.Z.; Luo, H.J.; Mu, Y.L.; Lin, H.; Du, H. Low-frequency damping behavior of closed-cell Mg alloy foams reinforced with SiC particles. Int. J. Miner. Metall. Mater. 2017, 24, 701–707. [Google Scholar] [CrossRef]

- Gupta, N.; Rohatgi, P.K. Metal Matrix Syntactic Foams, Processing, Microstructure, Properties and Applications; DEStech Publication Inc.: Pennsylvania, PA, USA, 2015. [Google Scholar]

- Taherishargh, M.; Katona, B.; Fiedler, T.; Orbulov, I.N. Fatigue properties of expanded perlite/aluminum syntactic foams. J. Compos. Mater. 2016, 51, 773–781. [Google Scholar] [CrossRef]

- Zou, L.C.; Zhang, Q.; Su, H.; Sun, D.L.; Wu, G.H.; Jiang, L.T. Compression deformation behaviour of aluminium matrix syntactic foams under quasi static loading: In situ SEM compressive tests. Mater. Res. Innov. 2014, 18. [Google Scholar] [CrossRef]

- Sun, Y.; Lyu, Y.; Jiang, A.; Zhao, J. Fabrication and characterization of aluminum matrix fly ash cenosphere composites using different stir casting routes. J. Mater. Res. 2014, 29, 260–266. [Google Scholar] [CrossRef]

- Anbuchezhiyan, G.; Mohan, B.; Sathianarayanan, D.; Muthuramalingam, T. Synthesis and characterization of hollow glass microspheres reinforced magnesium alloy matrix syntactic foam. J. Alloys Compd. 2017, 719, 125–132. [Google Scholar] [CrossRef]

- Nguyen, Q.B.; Sharon Nai, M.L.; Nguyen, A.S.; Seetharaman, S.; Wai Leong, E.W.; Gupta, M. Synthesis and properties of light weight magnesium–cenosphere composite. Mater. Sci. Technol. 2016, 32, 923–929. [Google Scholar] [CrossRef]

- Manakari, V.; Parande, G.; Gupta, M. Effects of Hollow Fly-Ash Particles on the Properties of Magnesium Matrix Syntactic Foams: A Review. Mater. Perform. Charact. 2016, 5, 116–131. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Kamieniak, J. The Role of Ni-P Coating Structure on Fly Ash Cenospheres in the Formation of Magnesium Matrix Composites. Metall. Mater. Trans. A 2017, 48, 5649–5657. [Google Scholar] [CrossRef]

- Witte, F.; Feyerabend, F.; Maier, P.; Fischer, J.; Stormer, M.; Blawert, C.; Dietzel, W.; Hort, N. Biodegradable magnesium-hydroxyapatite metal matrix composites. Biomaterials 2007, 28, 2163–2174. [Google Scholar] [CrossRef] [PubMed]

- Gupta, M.; Handjaja, C.; Manakari, V.; Parande, G. Corrosion behaviour of Magnesium/glass microballoon syntactic foams targeting engineering and biomedical applications. J. Mater. Sci. Eng. 2018, 7, 33. [Google Scholar] [CrossRef]

- Chen, H.L.; Fetzer, R.S. The Mg–C phase equilibria and their thermodynamic basis. Int. J. Mater. Res. 2012, 103, 1294–1301. [Google Scholar] [CrossRef]

- Ferri, J.M.; Molina, J.M.; Louis, E. Fabrication of Mg foams for biomedical applications by means of a replica method based upon spherical carbon particles. Biomed. Phys. Eng. Express 2015, 1, 045002. [Google Scholar] [CrossRef]

- Paraskeva, P.; Kalderis, D.; Diamadopoulos, E. Production of activated carbon from agricultural by-products. J. Chem. Technol. Biotechnol. 2008, 83, 581–592. [Google Scholar] [CrossRef]

- Al-Sahlani, K.; Taherishargh, M.; Kisi, E.; Fiedler, T. Controlled Shrinkage of Expanded Glass Particles in Metal Syntactic Foams. Materials 2017, 10, 1073. [Google Scholar] [CrossRef]

- ISO. ISO 13314—Mechanical Testing of Metals—Ductility Testing—Compression Test for Porous and Cellular Metals; ISO: Geneva, Switzerland, 2011. [Google Scholar]

- Wen, C.E.; Yamada, Y.; Shimojima, K.; Chino, Y.; Hosokawa, H.; Mabuchi, M. Compressibility of porous magnesium foam: Dependency on porosity and pore size. Mater. Lett. 2004, 5, 357–360. [Google Scholar] [CrossRef]

- Newsome, D.B.; Schultz, B.F.; Ferguson, J.B.; Rohatgi, P.K. Synthesis and Quasi-Static Compressive Properties of Mg-AZ91D-Al2O3 Syntactic Foams. Materials 2015, 8, 6085–6095. [Google Scholar] [CrossRef] [PubMed]

- Anantharaman, H.; Shunmugasamy, V.C.; Strbik, O.M.; Gupta, N.; Cho, K. Dynamic properties of silicon carbide hollow particle filled magnesium alloy (AZ91D) matrix syntactic foams. Int. J. Impact Eng. 2015, 82, 14–24. [Google Scholar] [CrossRef]

- Uematsu, Y.; Tokaji, K.; Fujiwara, K.; Tozaki, Y.; Shibata, H. Fatigue behaviour of cast magnesium alloy AZ91 microstructurally modified by friction stir processing. Fatigue Fract. Eng. Mater. Struct. 2009, 32, 541–551. [Google Scholar] [CrossRef]

- Urben, P.G.; Nobel, A. Bretherick’s Handbook of Reactive Chemical Hazards, 6th ed.; Butterworth-Heineman: Oxford, UK, 1999. [Google Scholar]

- Liu, J.A.; Yu, S.R.; Huang, Z.Q.; Ma, G.; Liu, Y. Microstructure and compressive property of in situ Mg2Si reinforced Mg-microballoon composites. J. Alloys Compd. 2012, 537, 12–18. [Google Scholar] [CrossRef]

| Sample No | SF Density (gcm−3) | FAZ91 (%) | FAC (%) | Fv (%) |

|---|---|---|---|---|

| MSF1 | 1.12 | 36.01 | 58.75 | 5.24 |

| MSF2 | 1.13 | 36.51 | 58.75 | 4.74 |

| MSF3 | 1.14 | 36.92 | 58.75 | 4.33 |

| MSF4 | 1.15 | 37.32 | 58.75 | 3.93 |

| MSF5 | 1.18 | 39.38 | 58.75 | 1.87 |

| Sample Density (gcm−3) | Quasi-Elastic Gradient (MPa) | Peak Stress (MPa) | Plateau Stress (MPa) | Energy Absorption (MJ/m3) |

|---|---|---|---|---|

| 1.12 | 1467.8 | 32.45 | 16.01 | 9.53 |

| 1.13 | 1663.34 | 40.90 | 8.25 | 7.61 |

| 1.14 | 1890.00 | 39.30 | 7.03 | 7.85 |

| 1.15 | 1889.96 | 48.00 | 9.52 | 8.30 |

| 1.18 | 2667.82 | 51.43 | 22.74 | 13.49 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Movahedi, N.; Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Mechanical and Microstructural Characterization of an AZ91–Activated Carbon Syntactic Foam. Materials 2019, 12, 3. https://doi.org/10.3390/ma12010003

Movahedi N, Taherishargh M, Belova IV, Murch GE, Fiedler T. Mechanical and Microstructural Characterization of an AZ91–Activated Carbon Syntactic Foam. Materials. 2019; 12(1):3. https://doi.org/10.3390/ma12010003

Chicago/Turabian StyleMovahedi, Nima, Mehdi Taherishargh, Irina V. Belova, Graeme E. Murch, and Thomas Fiedler. 2019. "Mechanical and Microstructural Characterization of an AZ91–Activated Carbon Syntactic Foam" Materials 12, no. 1: 3. https://doi.org/10.3390/ma12010003

APA StyleMovahedi, N., Taherishargh, M., Belova, I. V., Murch, G. E., & Fiedler, T. (2019). Mechanical and Microstructural Characterization of an AZ91–Activated Carbon Syntactic Foam. Materials, 12(1), 3. https://doi.org/10.3390/ma12010003