Effect of Tow Size and Interface Interaction on Interfacial Shear Strength Determined by Iosipescu (V-Notch) Testing in Epoxy Resin

Abstract

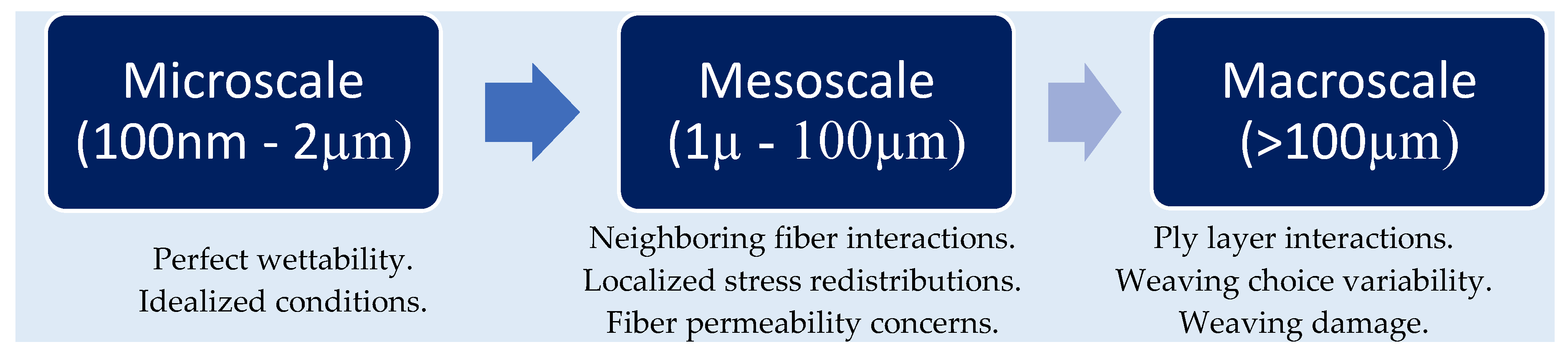

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Electro-Grafting Procedure

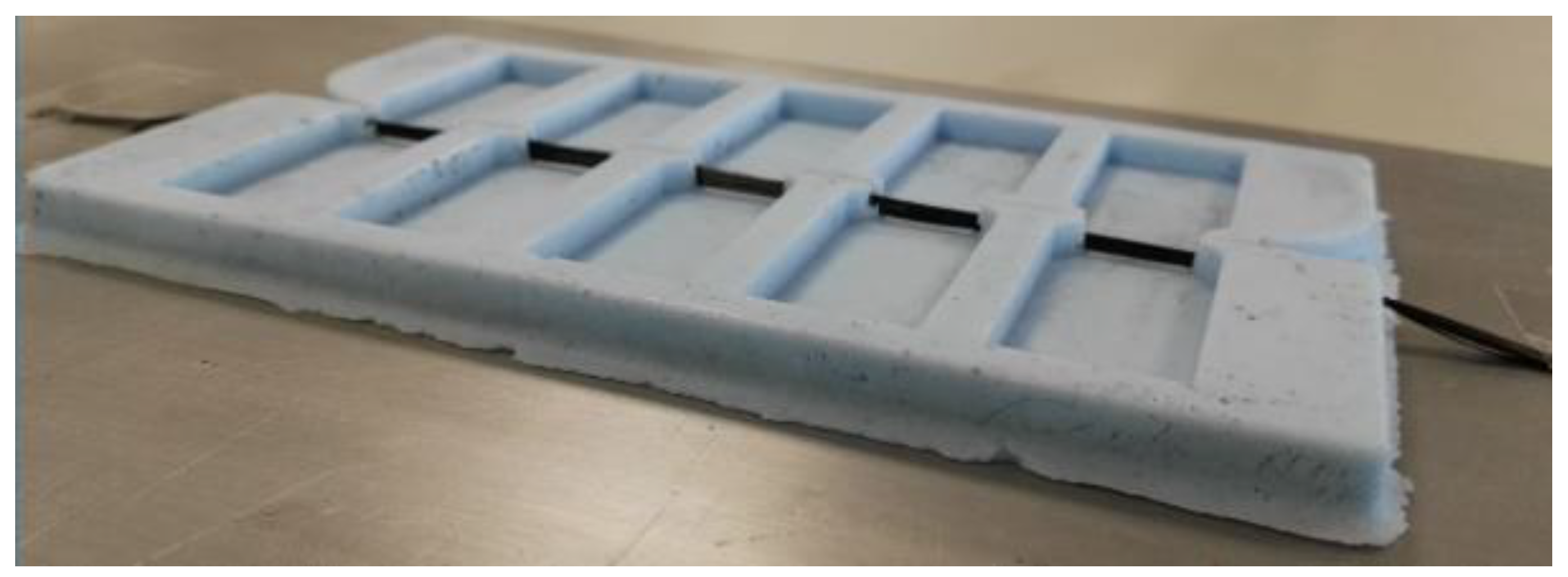

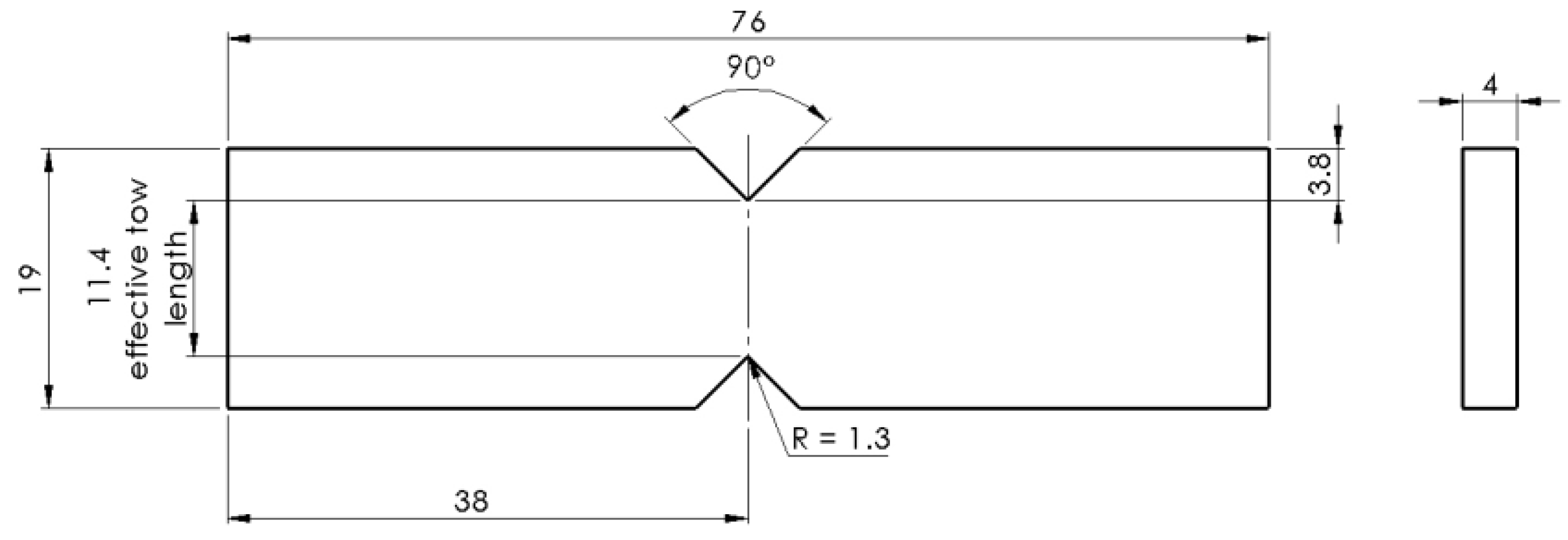

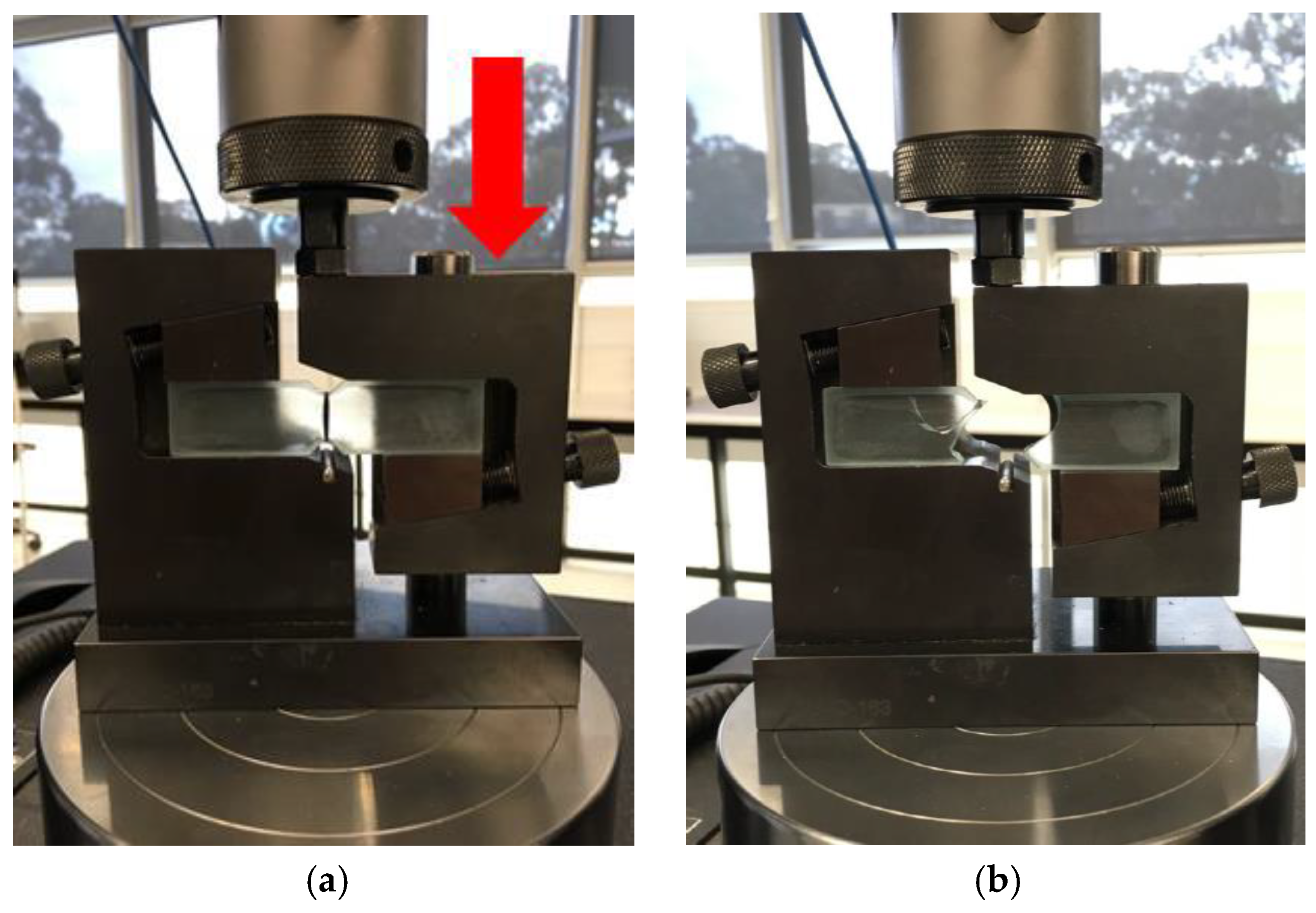

2.2. Iosipescu Testing

2.3. Single Fiber Fragment Testing (SFFT)

3. Results

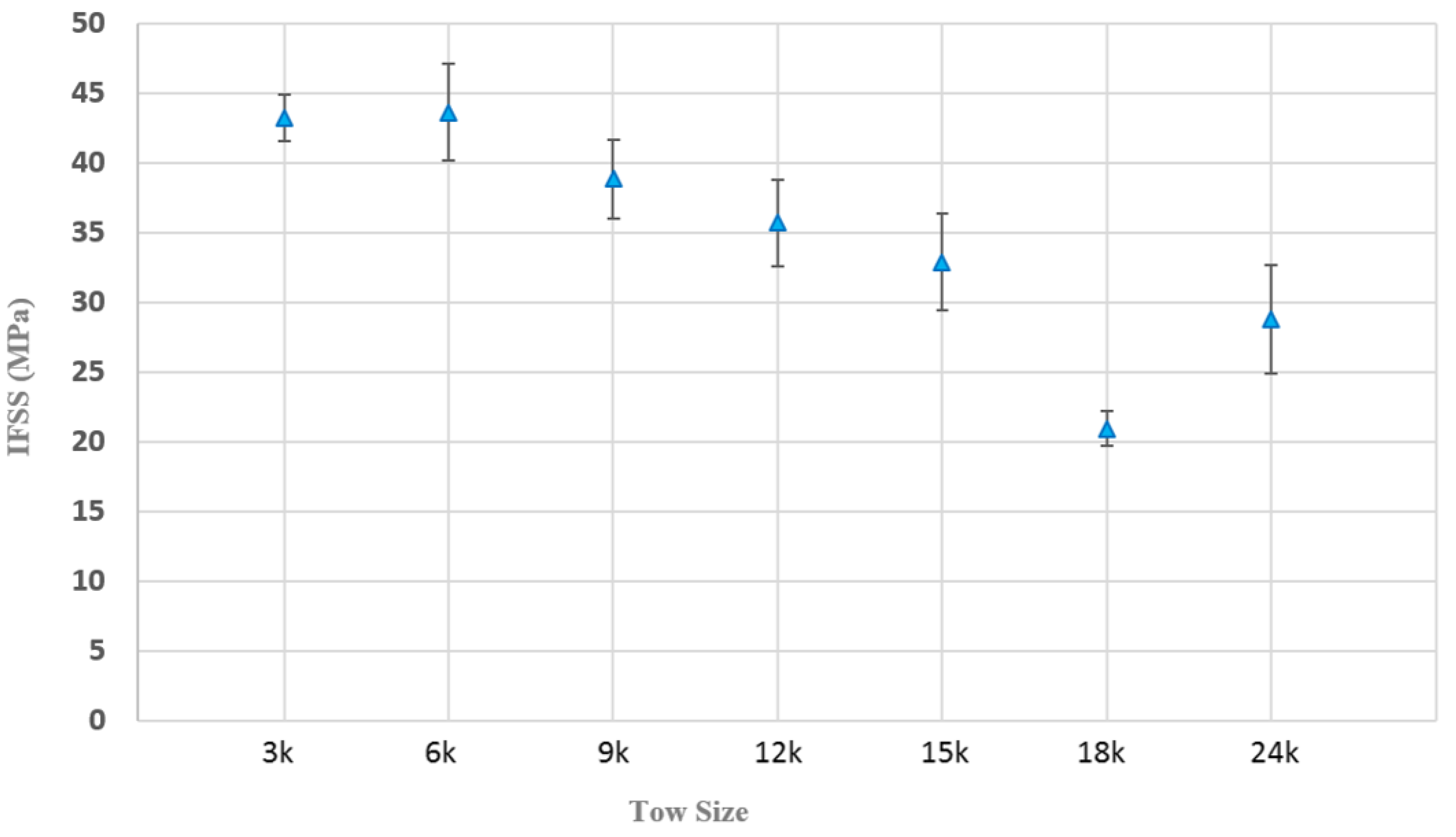

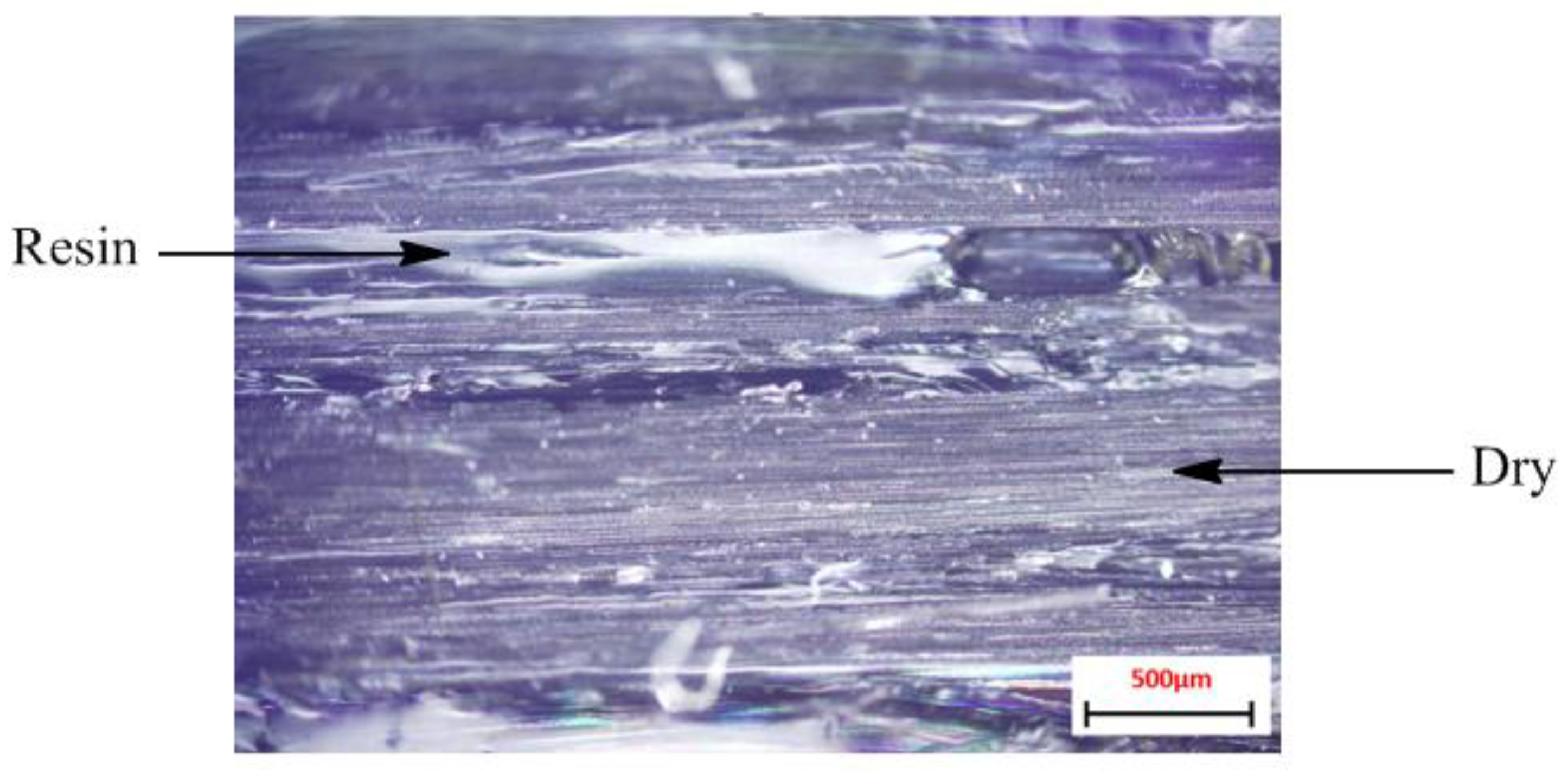

3.1. Fiber Tow Sensitivity of the V-Notch Shear Test

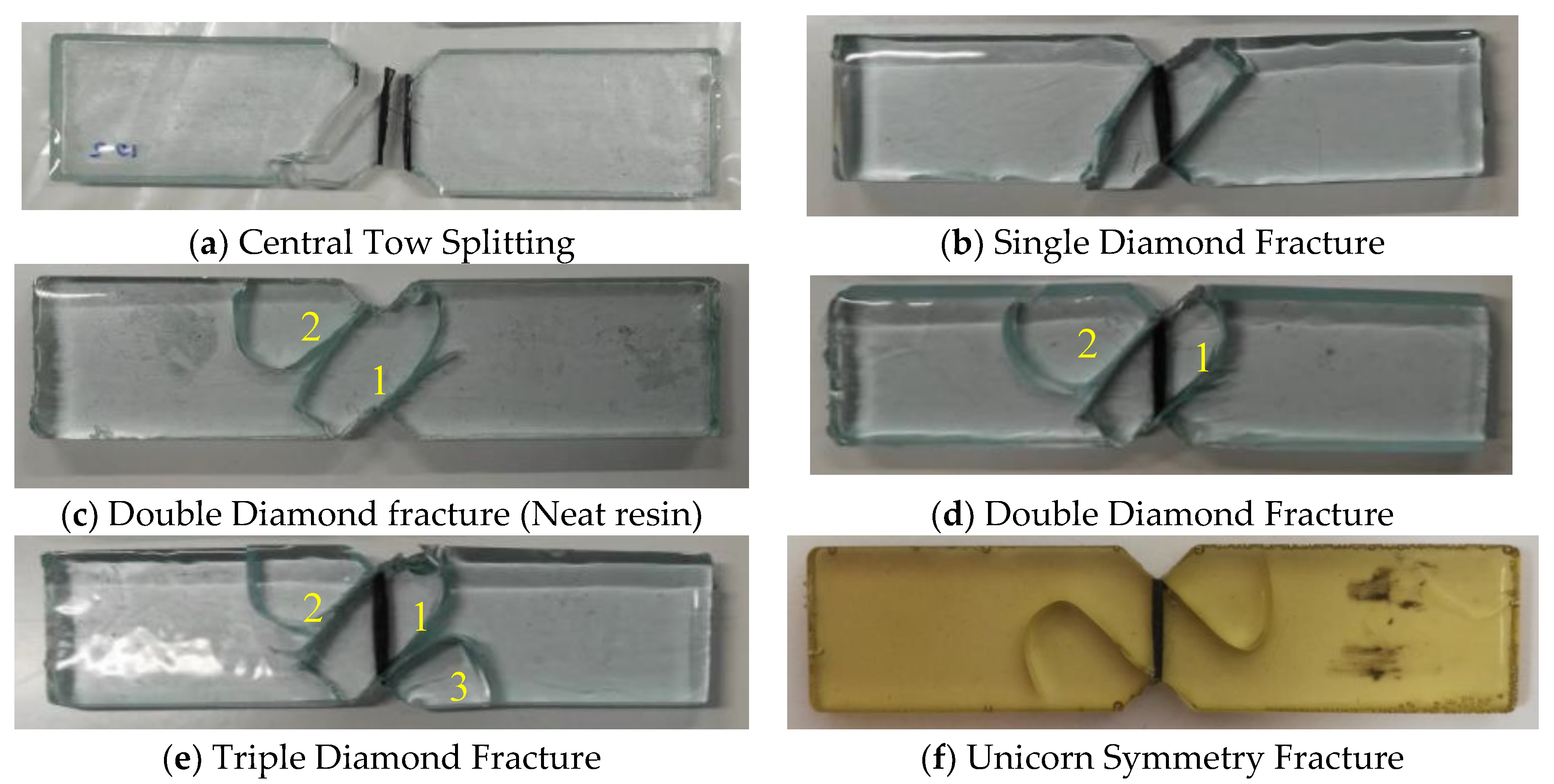

3.2. Fracture Pattern Analysis

- Central Tow Splitting: This mode of failure is characterized by a very low fracture load and poor interfacial adhesion. While it is an acceptable mode of failure in accordance with ASTM D5379, researchers are encouraged to conduct post analysis of fracture sites to conclude failure was indeed related to interface delamination and not poor fiber wetting which is a more likely cause. (Failure load—Low).

- Single Diamond Fracture: This is the most commonly observed fracture pattern in single tow Iosipescu testing. It is characterized by a 45 degree “diamond” breakage that runs parallel to the V-notch walls and may fracture fibers close to the notch root. (Failure load—moderate).

- Double diamond fracture (neat resin): All neat resin samples were observed to fracture identically in this fracture pattern. Aesthetically comparable to the “single diamond fracture” shape, however also ejects a secondary section (2) off the coupon upon fracture. (Failure load—moderate to high).

- Double diamond fracture (tow): The same fracture pattern as observed by the neat resin specimens, though with a tow embedded. Failure load was observed to always be larger than that of the single diamond fracture pattern. (Failure load—moderate to high).

- Triple diamond fracture: A further variant of the diamond fracture pattern however characterized by the breakage of three distinct sections; the central diamond (1) and two adjacent nubs (2 and 3). This mode of failure is observed to provide the best interfacial properties. (Failure load—extremely high).

- Unicorn Symmetry Fracture: While not a part of this study, a theoretically perfect fracture was observed during in-house testing. Representative of the von-mises stress contour plots, this fracture was an extremely unique occurrence presenting an experimentally ideal failure with respect to theoretical stress mapping. (Failure load—moderate).

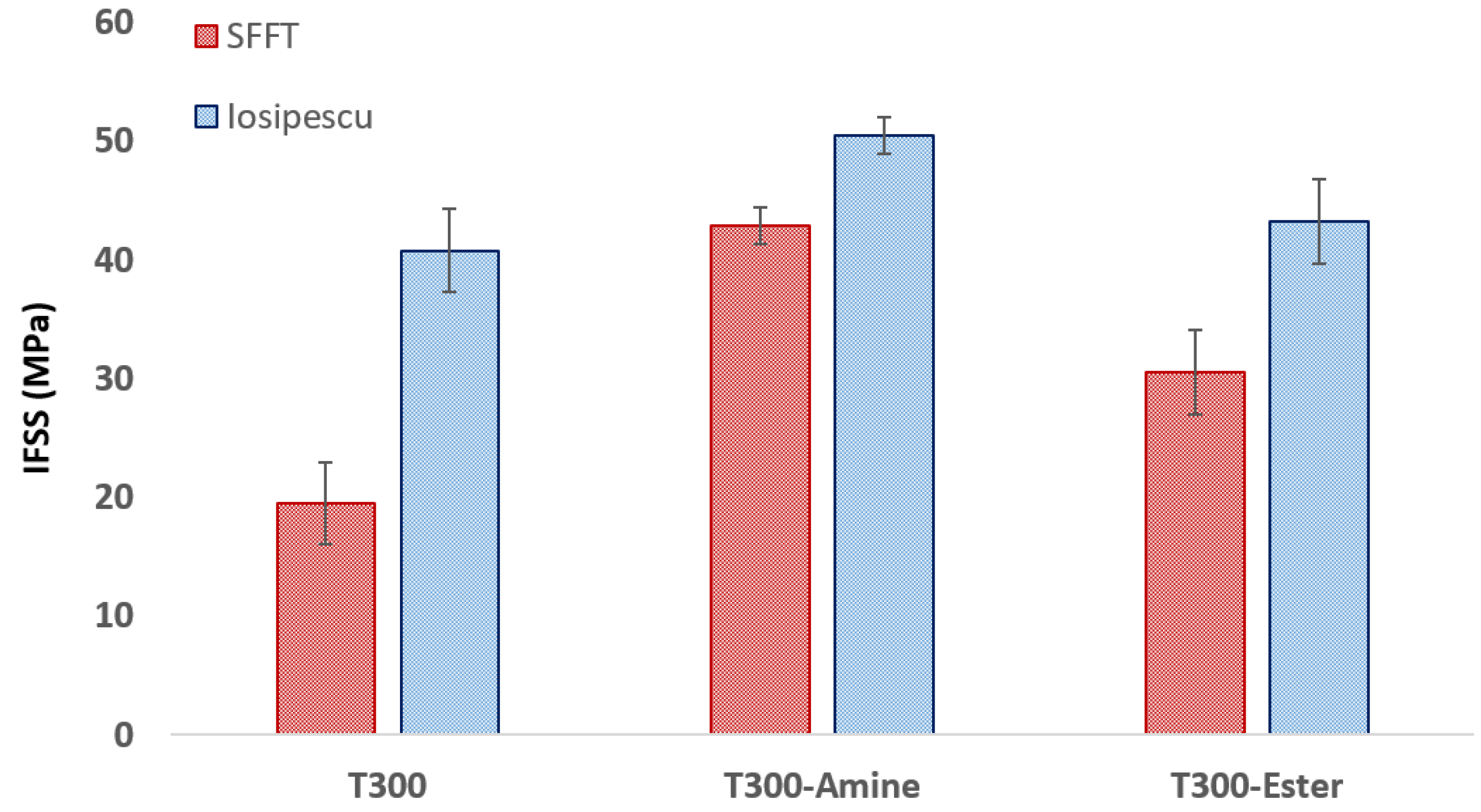

3.3. Interface Chemistry Sensitivity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Herrera-Franco, P.J.; Drzal, L.T. Comparison of methods for the measurement of fibre/matrix adhesion in composites. Composites 1992, 23, 2–27. [Google Scholar] [CrossRef]

- Madhukar, M.S.; Drzal, L.T. Fiber-matrix adhesion and its effect on composite mechanical properties: II. Longitudinal (0°) and transverse (90°) tensile and flexure behavior of graphite/epoxy composites. J. Compos. Mater. 1991, 25, 958–991. [Google Scholar] [CrossRef]

- Madhukar, M.S.; Drzal, L.T. Fiber-matrix adhesion and its effect on composite mechanical properties: I. Inplane and interlaminar shear behavior of graphite/epoxy composites. J. Compos. Mater. 1991, 25, 932–957. [Google Scholar] [CrossRef]

- Százdi, L.; Gulyás, J.; Pukánszky, B. Surface characterization of electrochemically oxidized carbon fibers: Surface properties and interfacial adhesion. Compos. Interfaces 2002, 9, 219–232. [Google Scholar] [CrossRef]

- Liu, J.; Tian, Y.; Chen, Y.; Liang, J.; Zhang, L.; Fong, H. A surface treatment technique of electrochemical oxidation to simultaneously improve the interfacial bonding strength and the tensile strength of pan-based carbon fibers. Mater. Chem. Phys. 2010, 122, 548–555. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A. Tensile and thermomechanical properties of short carbon fiber reinforced polyamide 6 composites. Compos. Part B Eng. 2013, 51, 270–275. [Google Scholar] [CrossRef]

- Gulyás, J.; Földes, E.; Lázár, A.; Pukánszky, B. Electrochemical oxidation of carbon fibres: Surface chemistry and adhesion. Compos. Part A Appl. Sci. Manuf. 2001, 32, 353–360. [Google Scholar] [CrossRef]

- Gnädinger, F.; Middendorf, P.; Fox, B. Interfacial shear strength studies of experimental carbon fibres, novel thermosetting polyurethane and epoxy matrices and bespoke sizing agents. Compos. Sci. Technol. 2016, 133, 104–110. [Google Scholar] [CrossRef]

- Dilsiz, N.; Wightman, J.P. Effect of acid–base properties of unsized and sized carbon fibers on fiber/epoxy matrix adhesion. Colloids Surf. A Physicochem. Eng. Asp. 2000, 164, 325–336. [Google Scholar] [CrossRef]

- Dai, Z.; Shi, F.; Zhang, B.; Li, M.; Zhang, Z. Effect of sizing on carbon fiber surface properties and fibers/epoxy interfacial adhesion. Appl. Surf. Sci. 2011, 257, 6980–6985. [Google Scholar] [CrossRef]

- Stojcevski, F.; Hilditch, T.; Henderson, L.C. A modern account of iosipescu testing. Compos. Part A Appl. Sci. Manuf. 2018, 107, 545–554. [Google Scholar] [CrossRef]

- Searles, K.; Odegard, G.; Kumosa, M. The effect of eccentric loads on the macroscopic strain and stress distributions in woven fabric composite iosipescu specimens. J. Compos. Mater. 2002, 36, 571–588. [Google Scholar] [CrossRef]

- Bru, T.; Olsson, R.; Gutkin, R.; Vyas, G.M. Use of the iosipescu test for the identification of shear damage evolution laws of an orthotropic composite. Compos. Struct. 2017, 174, 319–328. [Google Scholar] [CrossRef]

- Arcan, M. The iosipescu shear test as applied to composite materials. Exp. Mech. 1984, 24, 66–67. [Google Scholar] [CrossRef]

- Adams, D.F.; Walrath, D.E. Current status of the iosipescu shear test method. J. Compos. Mater. 1987, 21, 494–507. [Google Scholar] [CrossRef]

- Feih, S.; Wonsyld, K.; Minzari, D.; Westermann, P.; Lilholt, H. Testing Procedure for the Single Fiber Fragmentation Test; Forskningscenter Risø: Brussels, Belgium, 2004. [Google Scholar]

- Hurwitz, F.; Behrendt, D.R. Application of Iosipescu Specimen Geometry to Determination of Shear Strength in Unidirectional Composites; NASA Langley Research Center: Hampton, VA, USA, 1984. [Google Scholar]

- Krishnan, A.; Xu, L.R. A short-beam shear fracture approach to measure the mode ii fracture toughness of materials with preferred interfaces. Int. J. Fract. 2011, 169, 15–25. [Google Scholar] [CrossRef]

- Melin, L.; Neumeister, J.; Pettersson, K.; Johansson, H.; Asp, L. Evaluation of four composite shear test methods by digital speckle strain mapping and fractographic analysis. J. Compos. Technol. Res. 2000, 22, 161–172. [Google Scholar]

- Deng, S.; Qi, B.; Hou, M.; Ye, L.; Magniez, K. Assessment of interfacial bonding between polymer threads and epoxy resin by transverse fibre bundle (TFB) tests. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1698–1707. [Google Scholar] [CrossRef]

- Toray. T300 data sheet. In CFA-001; Toray: Santa Ana, CA, USA, 2018. [Google Scholar]

- Servinis, L.; Beggs, K.M.; Scheffler, C.; Wöfel, E.; Randall, J.D.; Gengenbach, T.R.; Demir, B.; Walsh, T.R.; Doeven, E.H.; Francis, P.S.; et al. Electrochemical surface modification of carbon fibres by grafting of amine, carboxylic and lipophilic amide groups. Carbon 2017, 118, 393–403. [Google Scholar] [CrossRef]

- Standard Test Method for Shear Properties of Composite Materials by the v-Notched Beam Method. Available online: https://www.astm.org/Standards/D5379 (accessed on 10 April 2018).

- Toray. Types of Carbon Fiber; Toray: Santa Ana, CA, USA, 2018. [Google Scholar]

- Eyckens, D.J.; Stojcevski, F.; Hendlmeier, A.; Arnold, C.L.; Randall, J.D.; Perus, M.D.; Servinis, L.; Gengenbach, T.R.; Demir, B.; Walsh, T.R.; et al. An efficient high-throughput grafting procedure for enhancing carbon fiber-to-matrix interactions in composites. Chem. Eng. J. 2018, 353, 373–380. [Google Scholar] [CrossRef]

- Servinis, L.; Beggs, K.M.; Gengenbach, T.R.; Doeven, E.H.; Francis, P.S.; Fox, B.L.; Pringle, J.M.; Pozo-Gonzalo, C.; Walsh, T.R.; Henderson, L.C. Tailoring the fibre-to-matrix interface using click chemistry on carbon fibre surfaces. J. Mater. Chem. A 2017, 5, 11204–11213. [Google Scholar] [CrossRef]

- Eyckens, D.J.; Servinis, L.; Scheffler, C.; Wolfel, E.; Demir, B.; Walsh, T.R.; Henderson, L.C. Synergistic interfacial effects of ionic liquids as sizing agents and surface modified carbon fibers. J. Mater. Chem. A. 2018, 6, 4504–4514. [Google Scholar] [CrossRef]

- Drzal, L.T.; Madhukar, M. Fibre-matrix adhesion and its relationship to composite mechanical properties. J. Mater. Sci. 1993, 28, 569–610. [Google Scholar] [CrossRef]

- Piggott, M.R. Why interface testing by single-fibre methods can be misleading. Compos. Sci. Technol. 1997, 57, 965–974. [Google Scholar] [CrossRef]

- Madhukar, M.S.; Drzal, L.T. Fiber-matrix adhesion and its effect on composite mechanical properties. III. Longitudinal (0°) compressive properties of graphite/epoxy composites. J. Compos. Mater. 1992, 26, 310–333. [Google Scholar] [CrossRef]

| Property | T300 | T300-Amine | T300-Ester |

|---|---|---|---|

| Elongation (%) | 1.7 [0.3] | 1.7 [0.3] | 1.7 [0.2] |

| Break Tension (GPa) | 3.7 [0.6] | 3.2 [0.6] | 3.5 [0.6] |

| Modulus (GPa) | 239.4 [16.2] | 206.4 [7.4] | 227.8 [6.6] |

| Specification | 3 k | 6 k | # 9 k | 12 k | 15 k | 18 k | 24 k |

|---|---|---|---|---|---|---|---|

| IFSS | 43.21 | 43.61 | 38.81 | 35.70 * | 32.85 * | 20.92 * | 24.40 * |

| (SD) | (3.37) | (6.93) | (5.70) | (6.20) | (6.94) | (2.47) | (2.40) |

| PF | 0 | 0 | 0 | 1 | 0 | 2 | 2 |

| Specification | T300 | T300-Amine | T300-Ester | |||

|---|---|---|---|---|---|---|

| SFFT | IOS | SFFT | IOS | SFFT | IOS | |

| IFSS (MPa) | 19.46 | 40.80 | 42.85 | 50.45 | 30.51 | 43.26 |

| St. Dev | 0.48 | 1.55 | 6.1 | 3.55 | 2.5 | 3.46 |

| Increase (MPa) a | - | 21.4 | - | 7.6 | - | 12.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stojceveski, F.; Hendlmeier, A.; Randall, J.D.; Arnold, C.L.; Stanfield, M.K.; Eyckens, D.J.; Alexander, R.; Henderson, L.C. Effect of Tow Size and Interface Interaction on Interfacial Shear Strength Determined by Iosipescu (V-Notch) Testing in Epoxy Resin. Materials 2018, 11, 1786. https://doi.org/10.3390/ma11091786

Stojceveski F, Hendlmeier A, Randall JD, Arnold CL, Stanfield MK, Eyckens DJ, Alexander R, Henderson LC. Effect of Tow Size and Interface Interaction on Interfacial Shear Strength Determined by Iosipescu (V-Notch) Testing in Epoxy Resin. Materials. 2018; 11(9):1786. https://doi.org/10.3390/ma11091786

Chicago/Turabian StyleStojceveski, Filip, Andreas Hendlmeier, James D. Randall, Chantelle L. Arnold, Melissa K. Stanfield, Daniel J. Eyckens, Richard Alexander, and Luke C. Henderson. 2018. "Effect of Tow Size and Interface Interaction on Interfacial Shear Strength Determined by Iosipescu (V-Notch) Testing in Epoxy Resin" Materials 11, no. 9: 1786. https://doi.org/10.3390/ma11091786

APA StyleStojceveski, F., Hendlmeier, A., Randall, J. D., Arnold, C. L., Stanfield, M. K., Eyckens, D. J., Alexander, R., & Henderson, L. C. (2018). Effect of Tow Size and Interface Interaction on Interfacial Shear Strength Determined by Iosipescu (V-Notch) Testing in Epoxy Resin. Materials, 11(9), 1786. https://doi.org/10.3390/ma11091786