Online Structural-Health Monitoring of Glass Fiber-Reinforced Thermoplastics Using Different Carbon Allotropes in the Interphase

Abstract

1. Introduction

2. Experimental

2.1. Materials and Processing

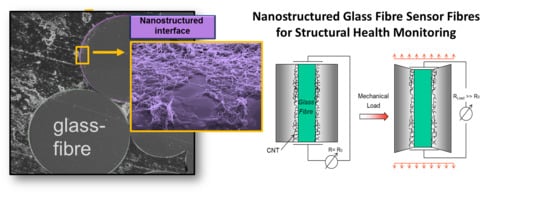

Glass Fiber Spinning and Interface Modification

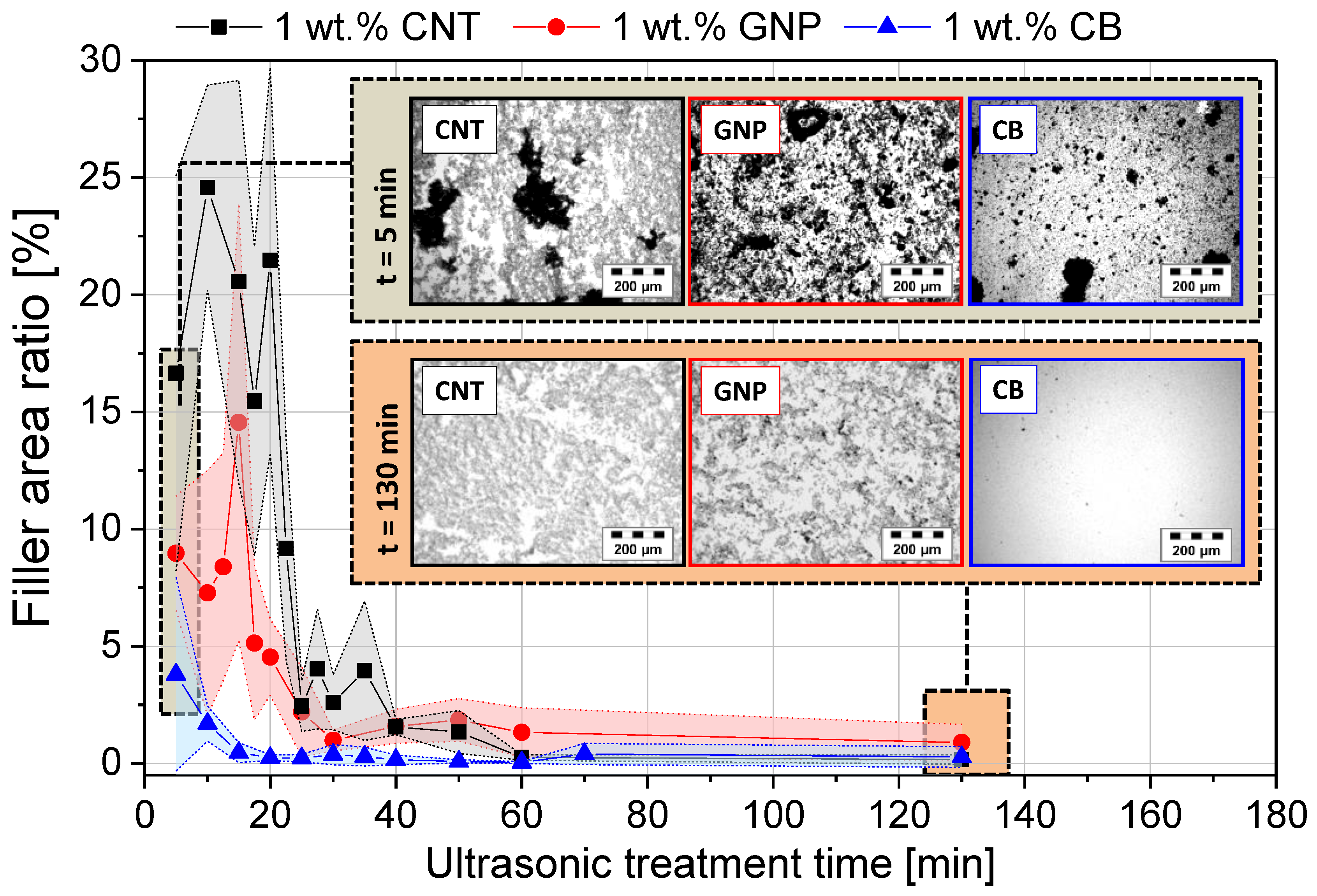

2.2. Filler Dispersion Characterization

2.3. Filler Dispersion Characterization

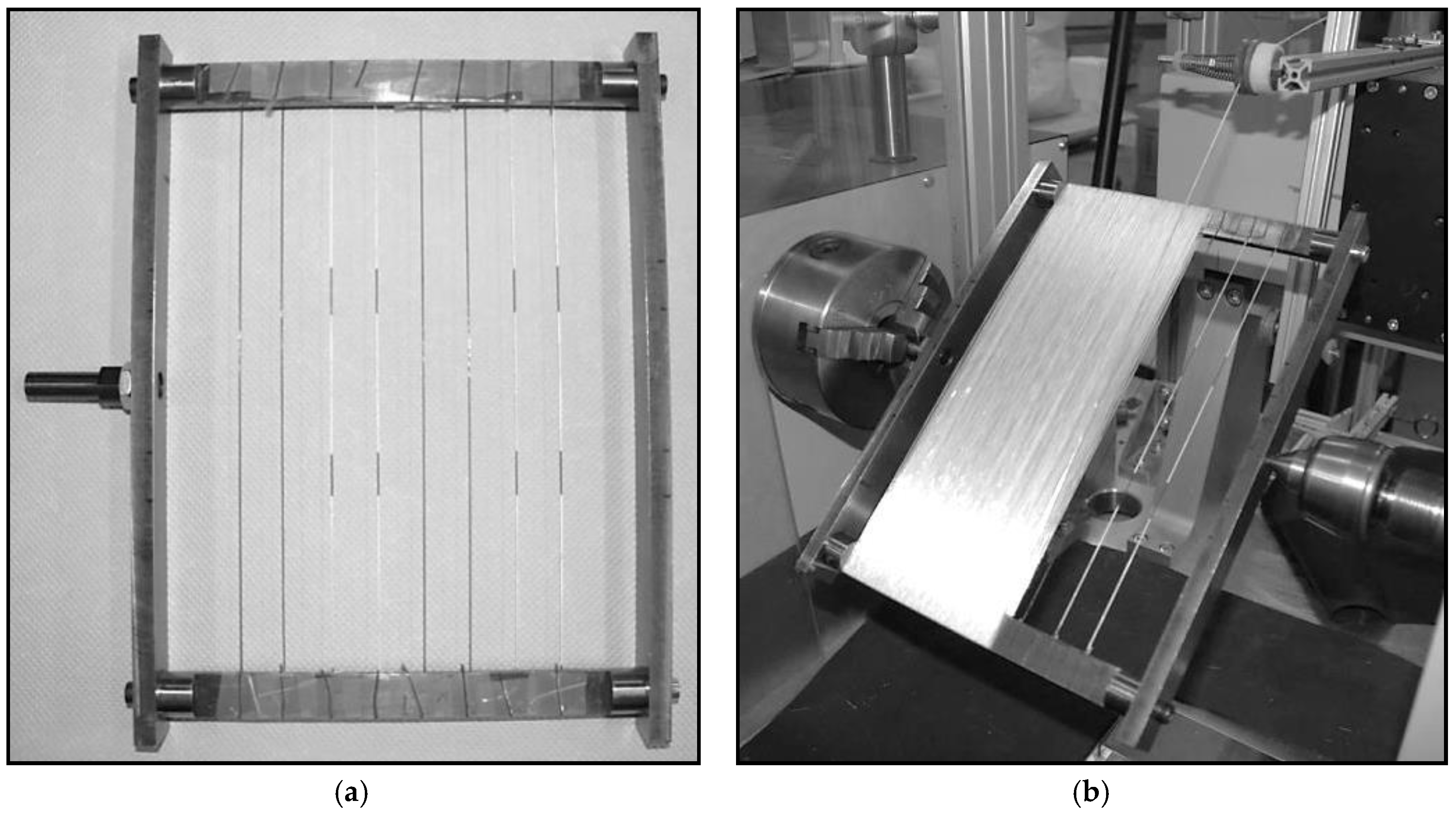

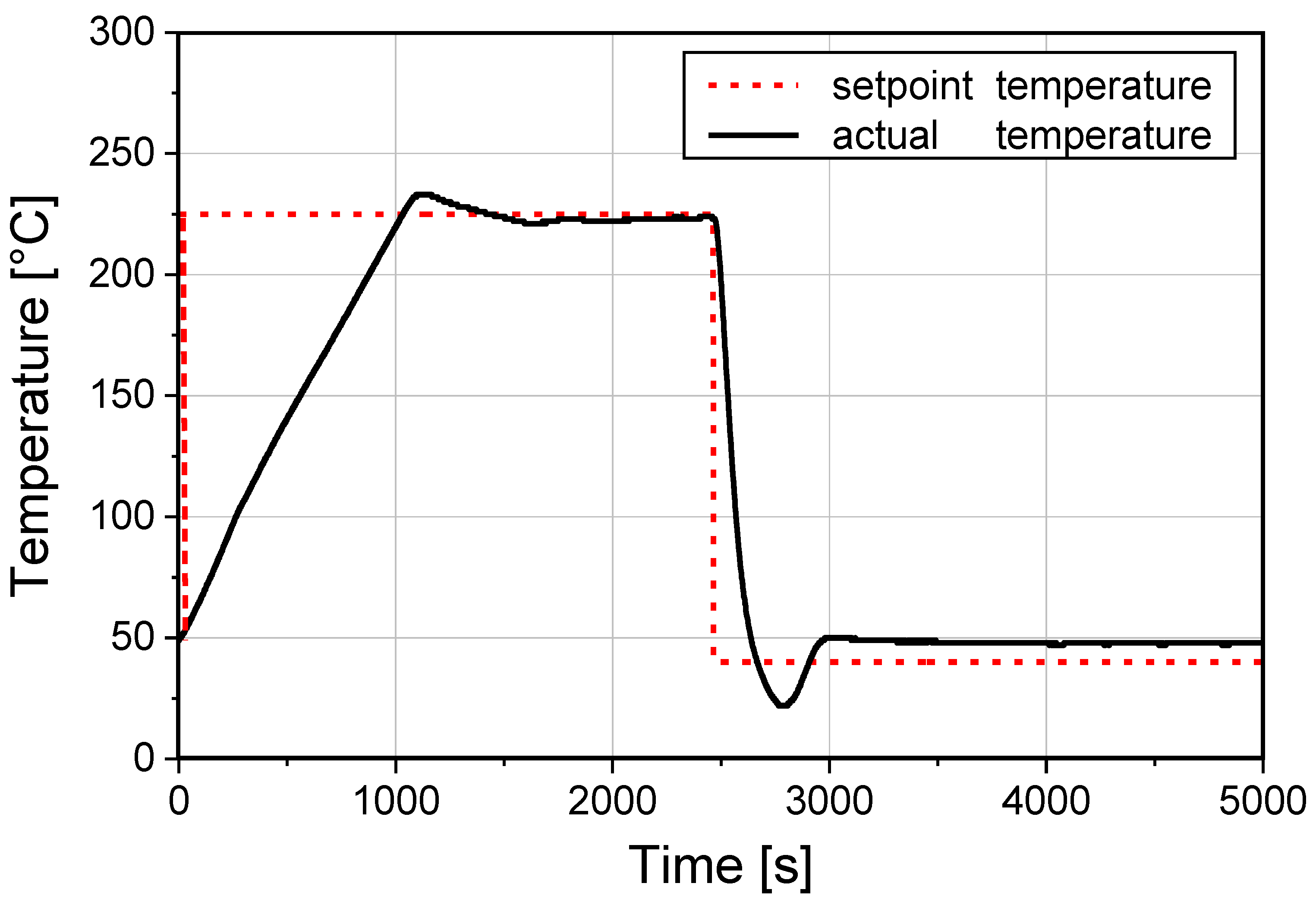

2.4. GF-Composite Preparation

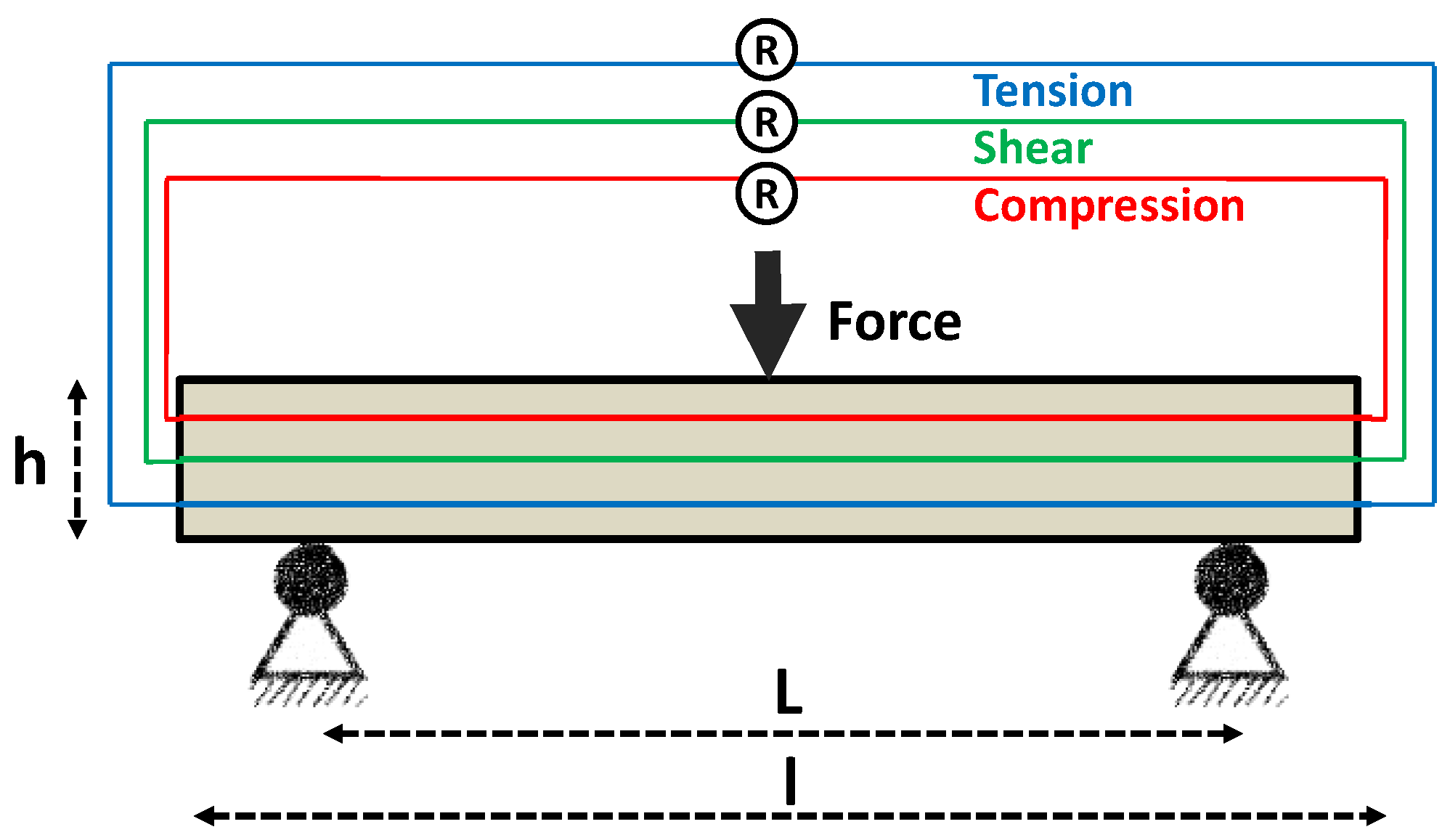

2.5. Electro-Mechanical Response during 3-Point Bending Test

3. Results and Discussion

3.1. Filler Dispersion Preparation

3.2. Electrical Properties

3.3. Interphase Modification

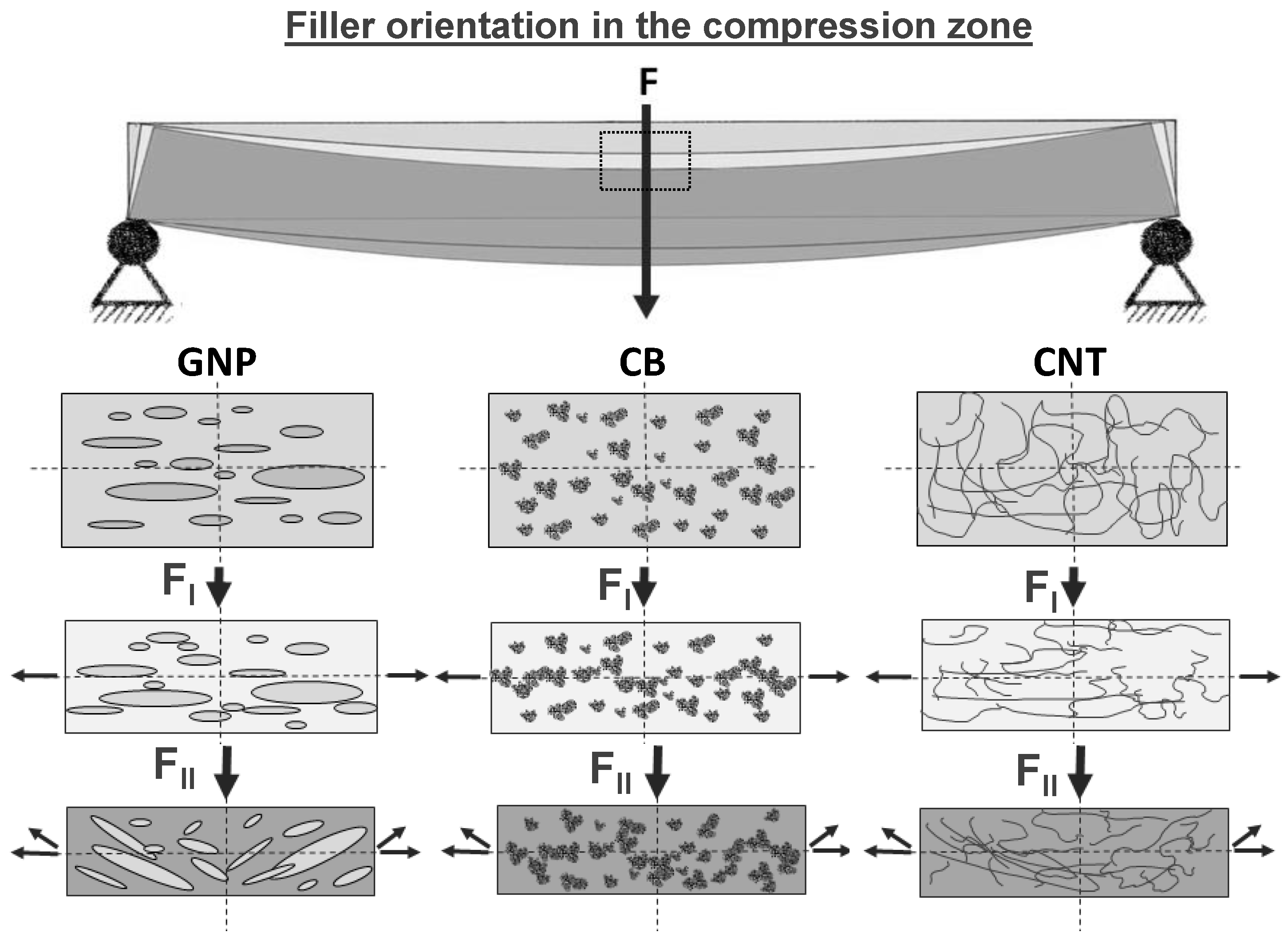

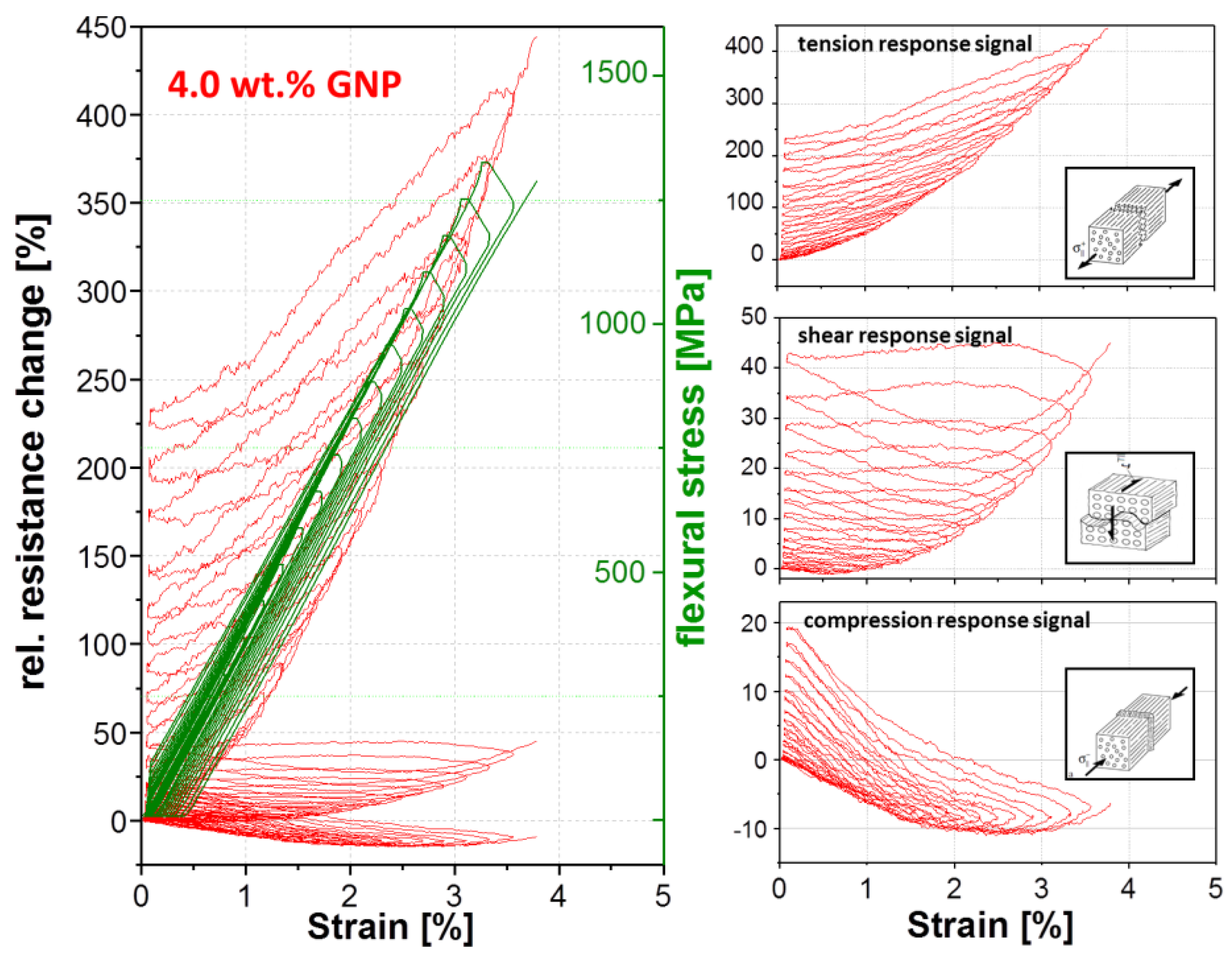

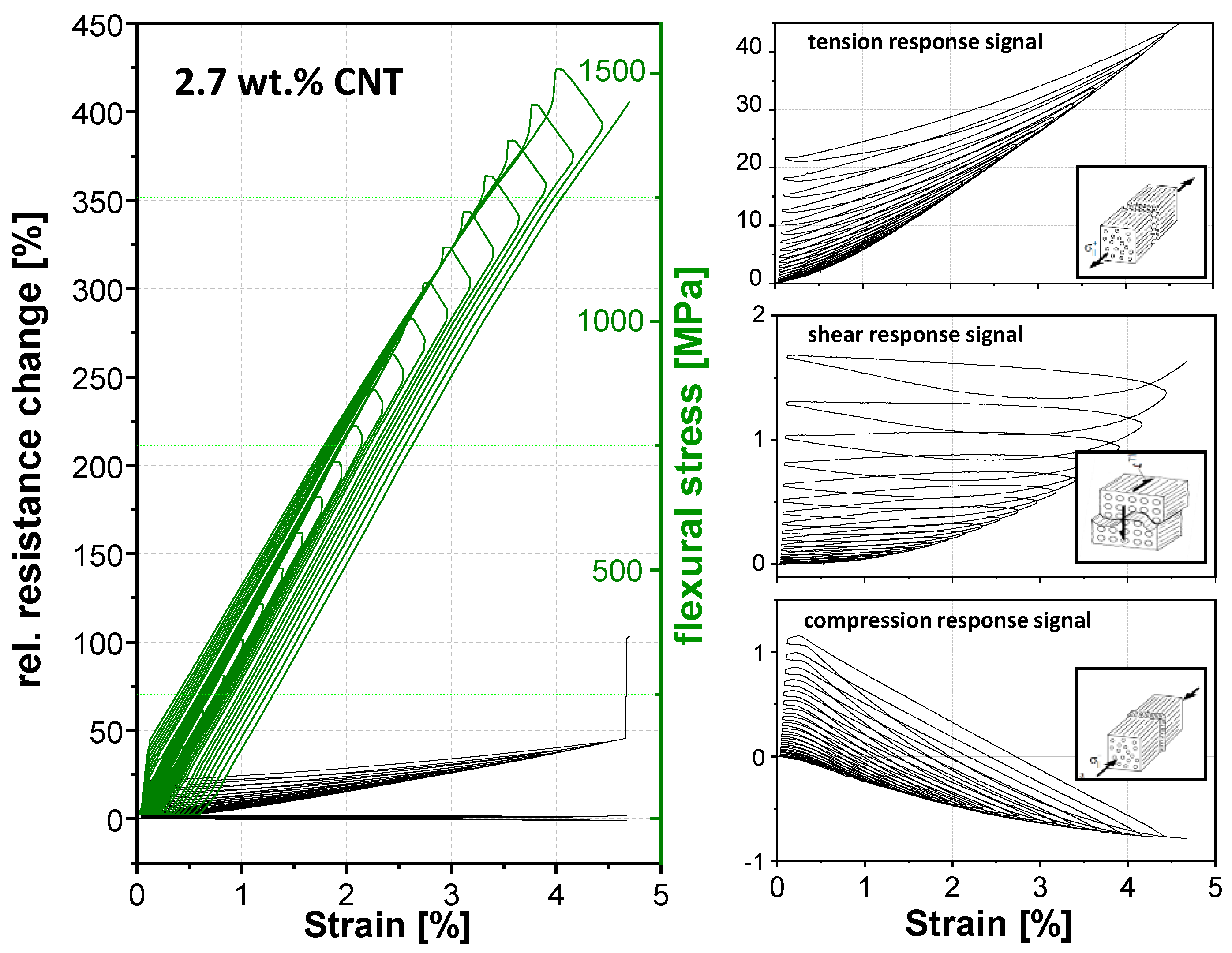

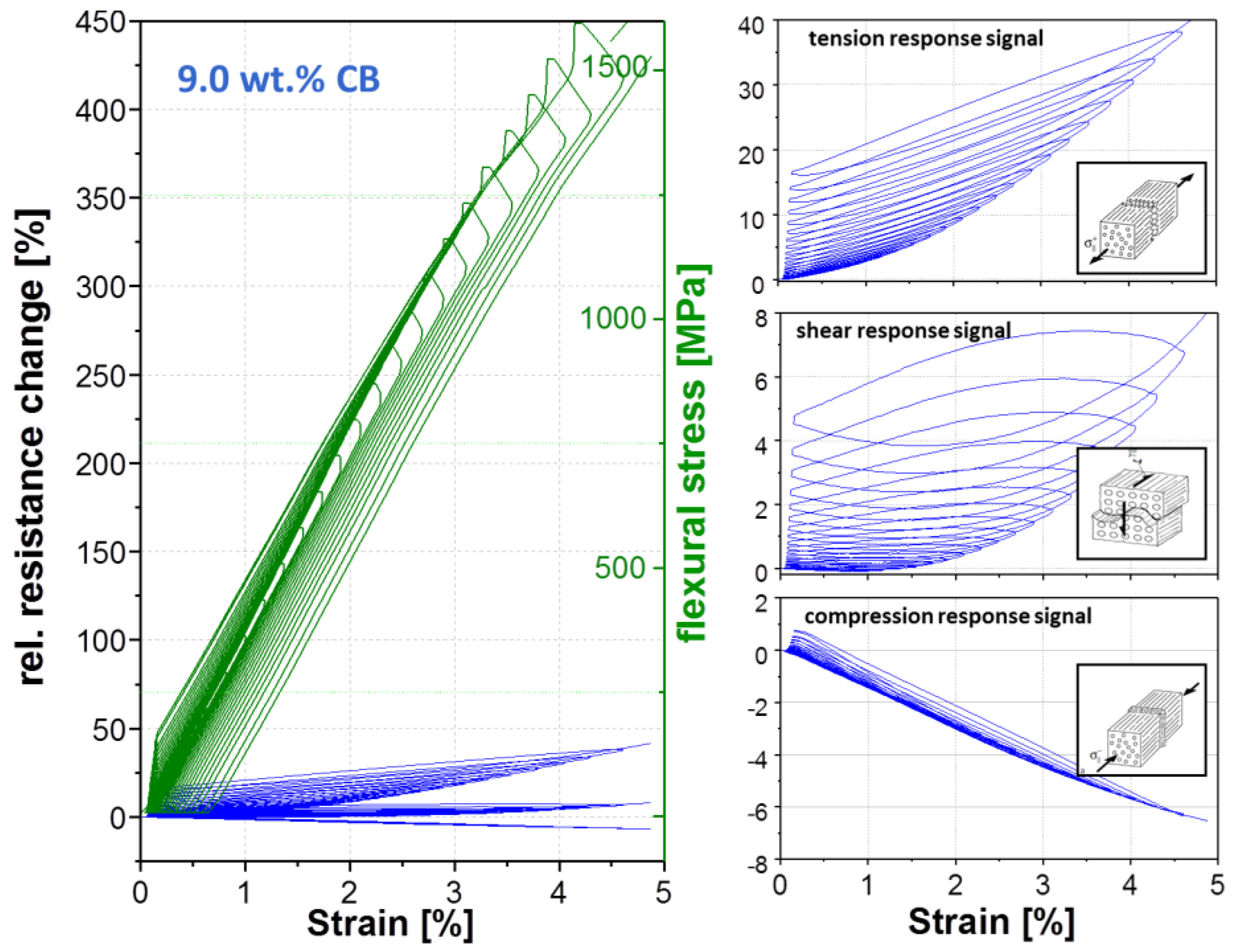

3.4. Electro-Mechanical Response Behaviour

4. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Allwood, G.; Wild, G.; Hinckley, S. Optical Fiber Sensors in Physical Intrusion Detection Systems: A Review. IEEE Sens. J. 2016, 16, 5497–5509. [Google Scholar] [CrossRef]

- Zhou, G.; Sim, L.M. Damage detection and assessment in fibre-reinforced composite structures with embedded fibre optic sensors-review. Smart Mater. Struct. 2002, 11, 925. [Google Scholar] [CrossRef]

- López-Higuera, J.M.; Rodriguez-Cobo, L.; Quintela Incera, A.; Cobo, A. Fiber Optic Sensors in Structural Health Monitoring. J. Lightwave Technol. 2011, 29, 587–608. [Google Scholar] [CrossRef]

- Walter, S.E.G. Entwicklung Piezoelektrisch Wirksamer Sensorfasern Auf Basis Von Polyvinylidenfluorid; Shaker Verlag: Herzogenrath, Germany, 2012. [Google Scholar]

- Häntzsche, E.; Onggar, T.; Nocke, A.; Hund, R.D.; Cherif, C. Multi-Layered Sensor Yarns for In Situ Monitoring of Textile Reinforced Composites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 042012. [Google Scholar] [CrossRef]

- Cherif, C.; Häntzsche, E.; Mueller, R.; Nocke, A.; Hübner, M.; Hasan, M. Carbon fibre sensors embedded in glass fibre-based composites for windmill blades. Smart Text. Their Appl. 2016, 329–352. [Google Scholar] [CrossRef]

- Gibson, R.F. A review of recent research on mechanics of multifunctional composite materials and structures. Compos. Struct. 2010, 92, 2793–2810. [Google Scholar] [CrossRef]

- Schueler, R.; Joshi, S.P.; Schulte, K. Damage detection in CFRP by electrical conductivity mapping. Compos. Sci. Technol. 2001, 61, 921–930. [Google Scholar] [CrossRef]

- Schubel, P.J.; Crossley, R.J.; Boateng, E.K.G.; Hutchinson, J.R. Review of structural health and cure monitoring techniques for large wind turbine blades. Renew. Energy 2013, 51, 113–123. [Google Scholar] [CrossRef]

- Pukánszky, B. Interfaces and interphases in multicomponent materials: Past, present, future. Eur. Polym. J. 2005, 41, 645–662. [Google Scholar] [CrossRef]

- Zhuang, R.C.; Burghardt, T.; Mäder, E. Study on interfacial adhesion strength of single glass fibre/polypropylene model composites by altering the nature of the surface of sized glass fibres. Compos. Sci. Technol. 2010, 70, 1523–1529. [Google Scholar] [CrossRef]

- Ishida, H. A review of recent progress in the studies of molecular and microstructure of coupling agents and their functions in composites, coatings and adhesive joints. Polym. Compos. 1984, 5, 101–123. [Google Scholar] [CrossRef]

- Kim, J.-K.; Mai, Y.-W. High strength, high fracture toughness fibre composites with interface control—A review. Compos. Sci. Technol. 1991, 41, 333–378. [Google Scholar] [CrossRef]

- Wiegand, N.; Mäder, E. Multifunctional Interphases: Percolation Behavior, Interphase Modification, and Electro-Mechanical Response of Carbon Nanotubes in Glass Fiber Polypropylene Composites. Adv. Eng. Mater. 2016, 18, 376–384. [Google Scholar] [CrossRef]

- Wiegand, N.; Mäder, E. Multifunctional interphases for sensing applications in glass fiber polypropylene composites. In Proceedings of the CAMX, Orlando, FL, USA, 13–16 October 2014. [Google Scholar]

- Zhang, J.; Zhuang, R.; Liu, J.; Scheffler, C.; Mäder, E.; Heinrich, G.; Gao, S. A Single Glass Fiber with Ultrathin Layer of Carbon Nanotube Networks Beneficial to In-Situ Monitoring of Polymer Properties in Composite Interphases. Soft Mater. 2014, 12, S115–S120. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, J.; Zhuang, R.; Mäder, E.; Heinrich, G.; Gao, S. Single MWNT-Glass Fiber as Strain Sensor and Switch. Adv. Mater. 2011, 23, 3392–3397. [Google Scholar] [CrossRef] [PubMed]

- Rausch, J.; Mäder, E. Carbon nanotube coated glass fibres for interphase health monitoring in textile composites. Mater. Technol. 2011, 26, 153–158. [Google Scholar] [CrossRef]

- Rausch, J.; Mäder, E. Health monitoring in continuous glass fibre reinforced thermoplastics: Tailored sensitivity and cyclic loading of CNT-based interphase sensors. Compos. Sci. Technol. 2010, 70, 2023–2030. [Google Scholar] [CrossRef]

- Rausch, J.; Mäder, E. Health monitoring in continuous glass fibre reinforced thermoplastics: Manufacturing and application of interphase sensors based on carbon nanotubes. Compos. Sci. Technol. 2010, 70, 1589–1596. [Google Scholar] [CrossRef]

- Hill, J.W.; Petrucci, R.H. General Chemistry, 3rd ed.; Prentice Hall: Bergen County, NJ, USA, 2002. [Google Scholar]

- Rausch, J.; Zhuang, R.C.; Maeder, E. Systematically varied interfaces of continuously reinforced glass fibre/polypropylene. Express Polym. Lett. 2010, 4, 576–588. [Google Scholar] [CrossRef]

- Mäder, E.; Rausch, J.; Schmidt, N. Commingled yarns—Processing aspects and tailored surfaces of polypropylene/glass composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 612–623. [Google Scholar] [CrossRef]

- Krause, B.; Mende, M.; Pötschke, P.; Petzold, G. Dispersability and particle size distribution of CNTs in an aqueous surfactant dispersion as a function of ultrasonic treatment time. Carbon 2010, 48, 2746–2754. [Google Scholar] [CrossRef]

- Nanocyl. NC7000 Series—Product Datasheet—Thin Multi-Wall Carbon Nanotubes; Nanocyl: Sambreville, Belgium, 2010. [Google Scholar]

- Müller, M.; Hilarius, K.; Liebscher, M.; Lellinger, D.; Alig, I.; Pötschke, P. Effect of Graphite Nanoplate Morphology on the Dispersion and Physical Properties of Polycarbonate Based Composites. Materials 2017, 10, 545. [Google Scholar] [CrossRef] [PubMed]

- Graphit-Kropfmühl. Datasheet—Multilayer Graphene EXG 98 300; Graphit-Kropfmühl: Hauzenberg, Germany, 2013. [Google Scholar]

- Orion Engineered Carbons. Datasheet—Printex XE2B; Orion Engineered Carbons: Senningerberg, Luxembourg, 2010. [Google Scholar]

- ISO 18553:2002-03; Method for the Assessment of the Degree of Pigment or Carbon Black Dispersion in Polyolefin Pipes, Fittings and Compounds; International Organization for Standardization (ISO): Geneva, Switzerland, 2002.

- ASTM-D257; Standard Test Methods for DC Resistance or Conductance of Insulating Materials; American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2014.

- Wiegand, N.; Mäder, E. Commingled Yarn Spinning for Thermoplastic/Glass Fiber Composites. Fibers 2017, 5, 26. [Google Scholar] [CrossRef]

- DIN EN 2563:1997-03; Aerospace Series—Carbon Fibre Reinforced Plastics—Unidirectional Laminates; Determination of Apparent Interlaminar Shear Strength; German Institute for Standardization: Berlin, Germany, 1997.

| Material as Named by the Producer/Producer | Morphology | Average Particle Size d50 [µm] | Thickness/Diameter | Electrical Conductivity [S∙cm−1] | Specific Surface [m2∙g−1] | Bulk Density [kg∙m−3] |

|---|---|---|---|---|---|---|

| Nanocyl™ NC7000 (CNT) Nanocyl S.A. | fiber | >675 [24] | Ø 9.5 nm [25] | 15 [26] *2 | 250–300 [25] | 66 [24] |

| EXG 98 300 (GNP) Graphit Kropfmühl | lamellar | 305 *3 | - | 3 [26] *2 | >300 [27] | 1 *1 |

| Printex XE2B (CB) Orion Engineered Carbons | spherical | 60 *3 | Ø 30–35 nm [28] | 20 [26] *2 | 1000 [28] | 100–400 [28] |

| Sample | Strain [%] Compression | Strain [%] Shear | Strain [%] Tension |

|---|---|---|---|

| CNT (2.7 wt. %) | 0.07 ± 0.03 | 0.63 ± 0.1 | 0.07 ± 0.002 |

| GNP (4 wt. %) | 0.03 ± 0.02 | 0.48 ± 0.2 | 0.14 ± 0.06 |

| CB (9 wt. %) | 0.07 ± 0.02 | 0.17 ± 0.01 | 0.05 ± 0.01 |

| Sample | Gauge Factor Compression | Gauge Factor Shear | Gauge Factor Tension |

|---|---|---|---|

| CNT (2.7 wt. %) | −40 ± 1 | 20 ± 1 | 120 ± 2 |

| GNP (4 wt. %) | −130 ± 2 | 120 ± 11 | 900 ± 18 |

| CB (9 wt. %) | −130 ± 1 | 20 ± 1 | 290 ± 4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Müller, M.T.; Pötzsch, H.F.; Gohs, U.; Heinrich, G. Online Structural-Health Monitoring of Glass Fiber-Reinforced Thermoplastics Using Different Carbon Allotropes in the Interphase. Materials 2018, 11, 1075. https://doi.org/10.3390/ma11071075

Müller MT, Pötzsch HF, Gohs U, Heinrich G. Online Structural-Health Monitoring of Glass Fiber-Reinforced Thermoplastics Using Different Carbon Allotropes in the Interphase. Materials. 2018; 11(7):1075. https://doi.org/10.3390/ma11071075

Chicago/Turabian StyleMüller, Michael Thomas, Hendrik Florian Pötzsch, Uwe Gohs, and Gert Heinrich. 2018. "Online Structural-Health Monitoring of Glass Fiber-Reinforced Thermoplastics Using Different Carbon Allotropes in the Interphase" Materials 11, no. 7: 1075. https://doi.org/10.3390/ma11071075

APA StyleMüller, M. T., Pötzsch, H. F., Gohs, U., & Heinrich, G. (2018). Online Structural-Health Monitoring of Glass Fiber-Reinforced Thermoplastics Using Different Carbon Allotropes in the Interphase. Materials, 11(7), 1075. https://doi.org/10.3390/ma11071075