Optimization of Coconut Fiber in Coconut Shell Concrete and Its Mechanical and Bond Properties

Abstract

:1. Introduction

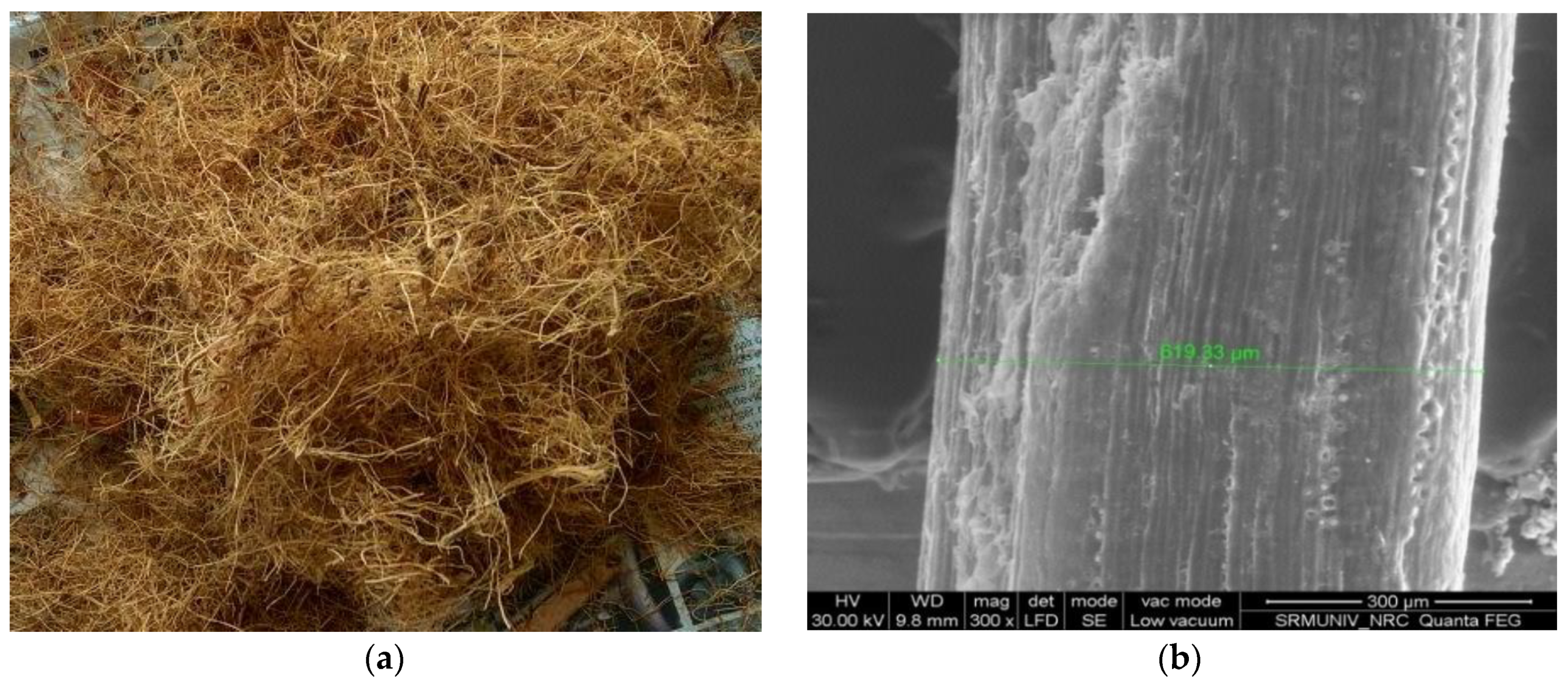

2. Materials Used

3. Experimental Procedure

4. Results and Discussion

4.1. Properties of Fresh and Hardened Concrete Without Fibers

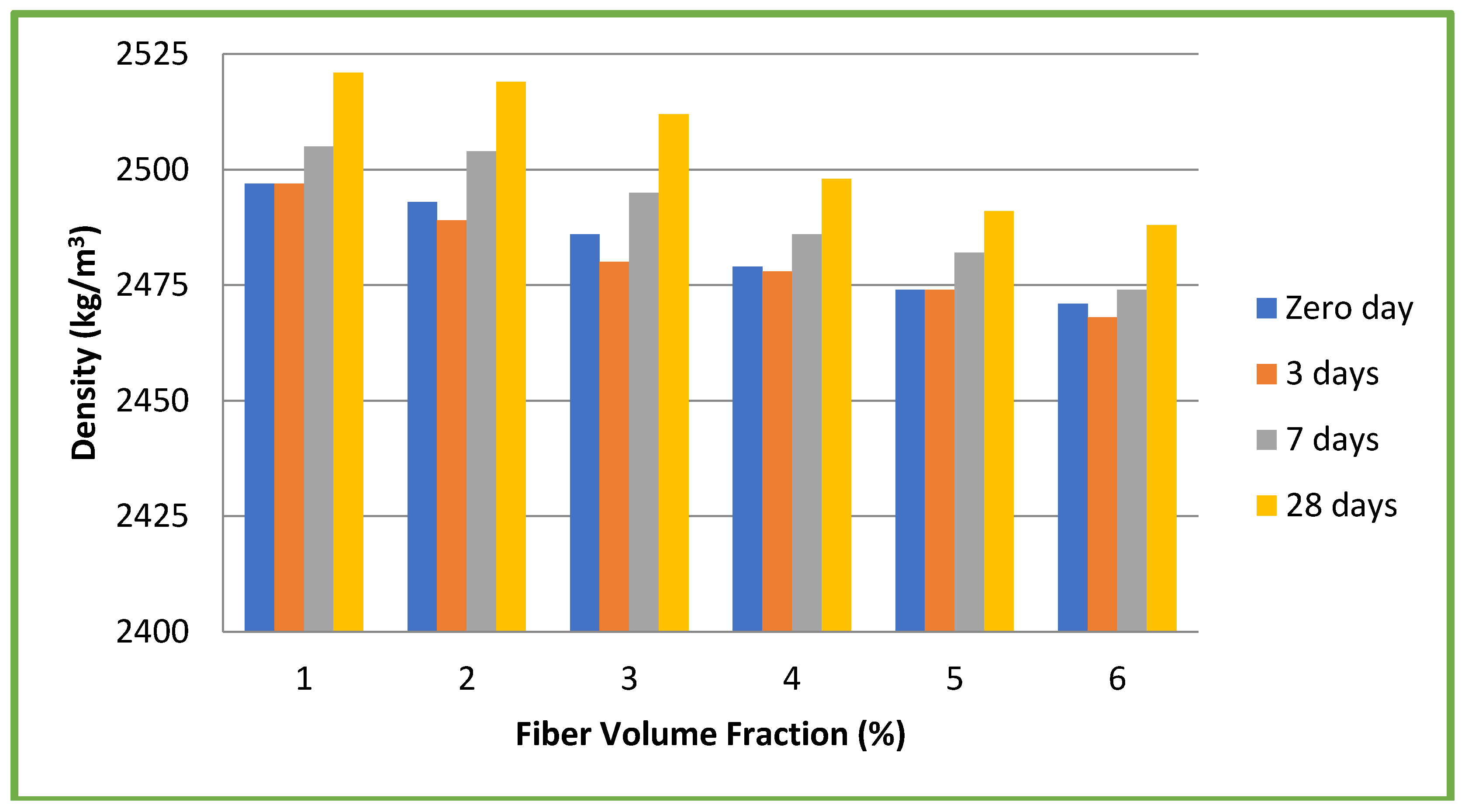

4.2. Properties of Fresh and Hardened CC and CSC with Fibers

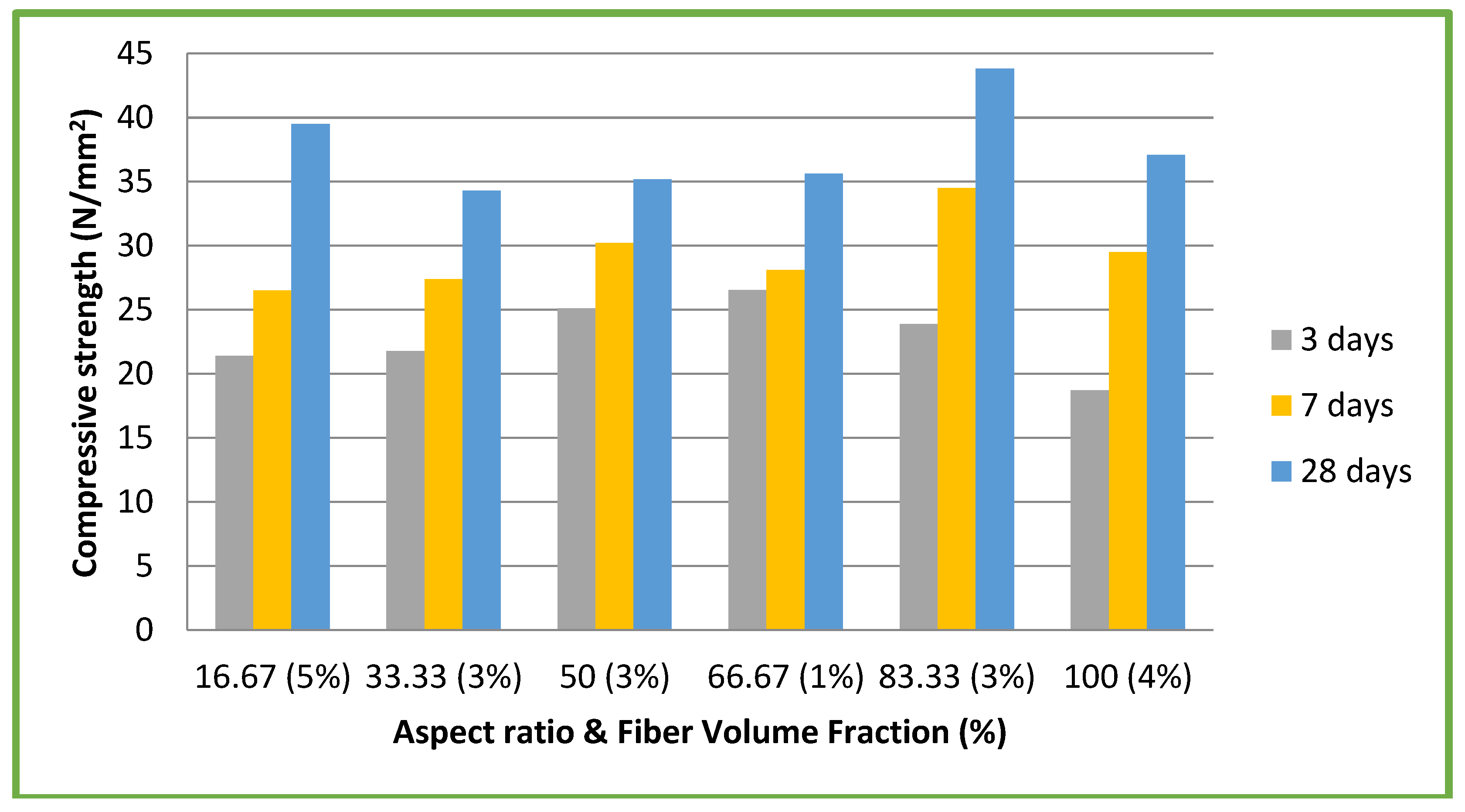

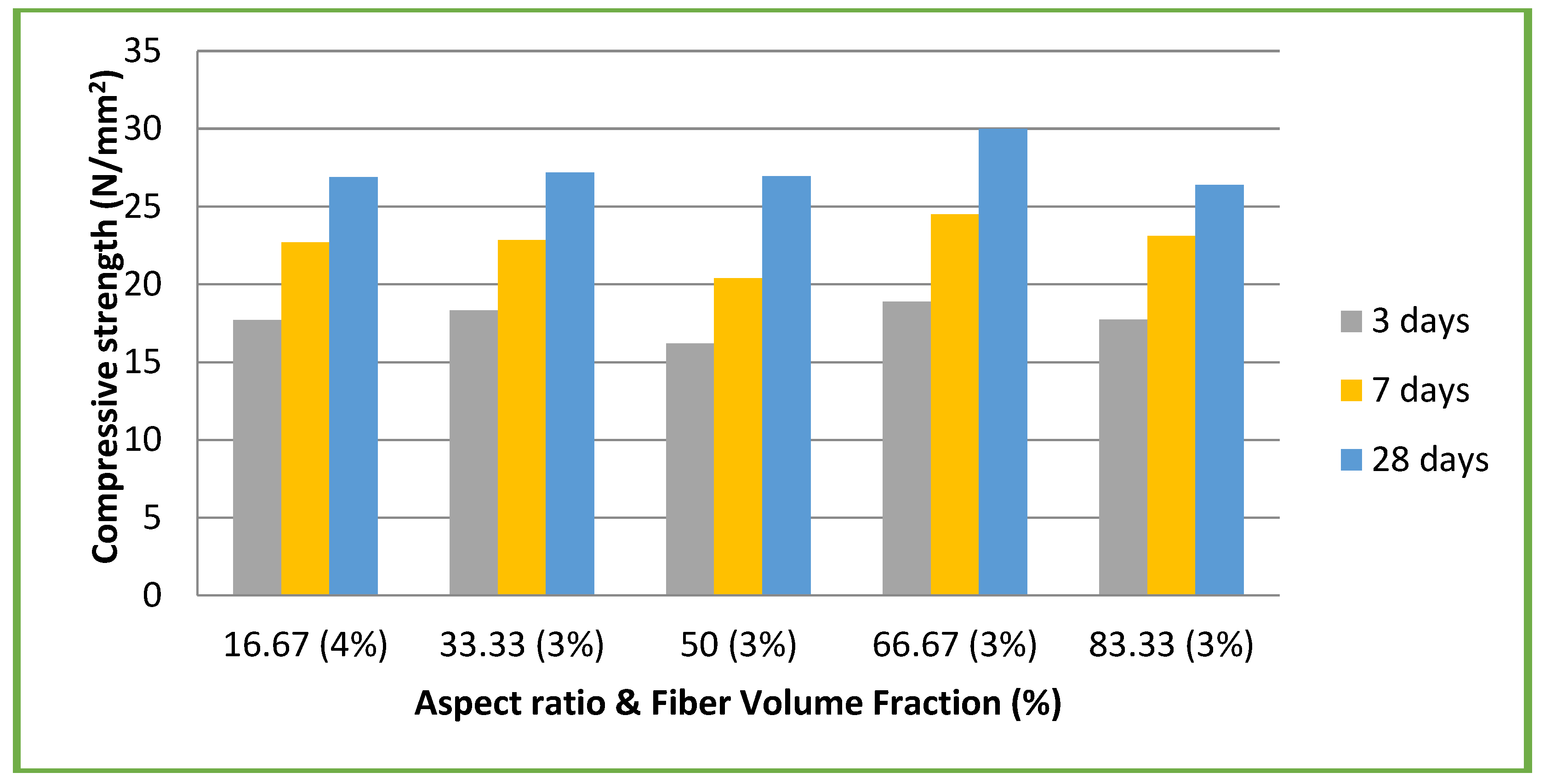

4.3. Optimization of Coconut Fibers in CC and CSC Mixes

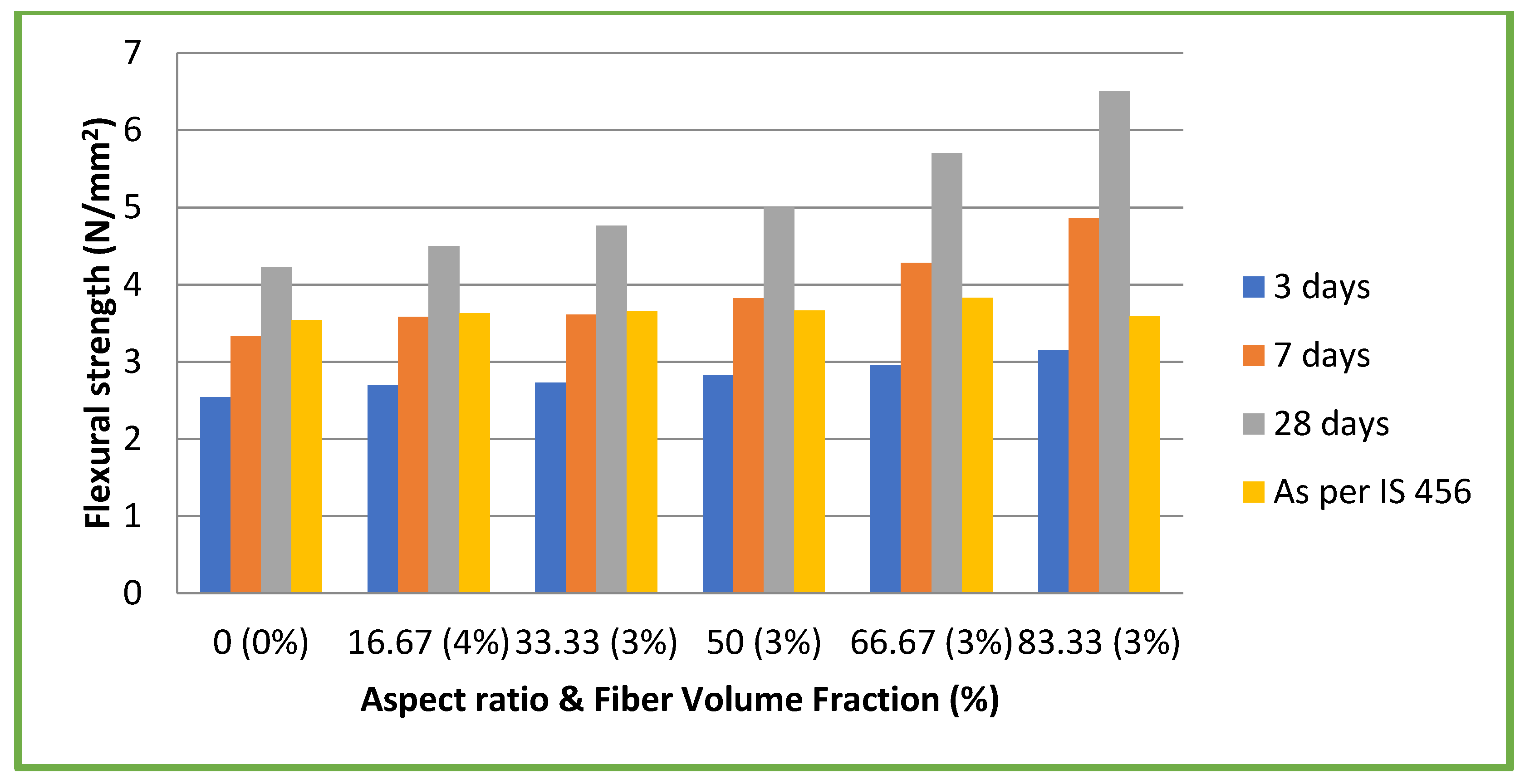

4.4. Flexural Strength

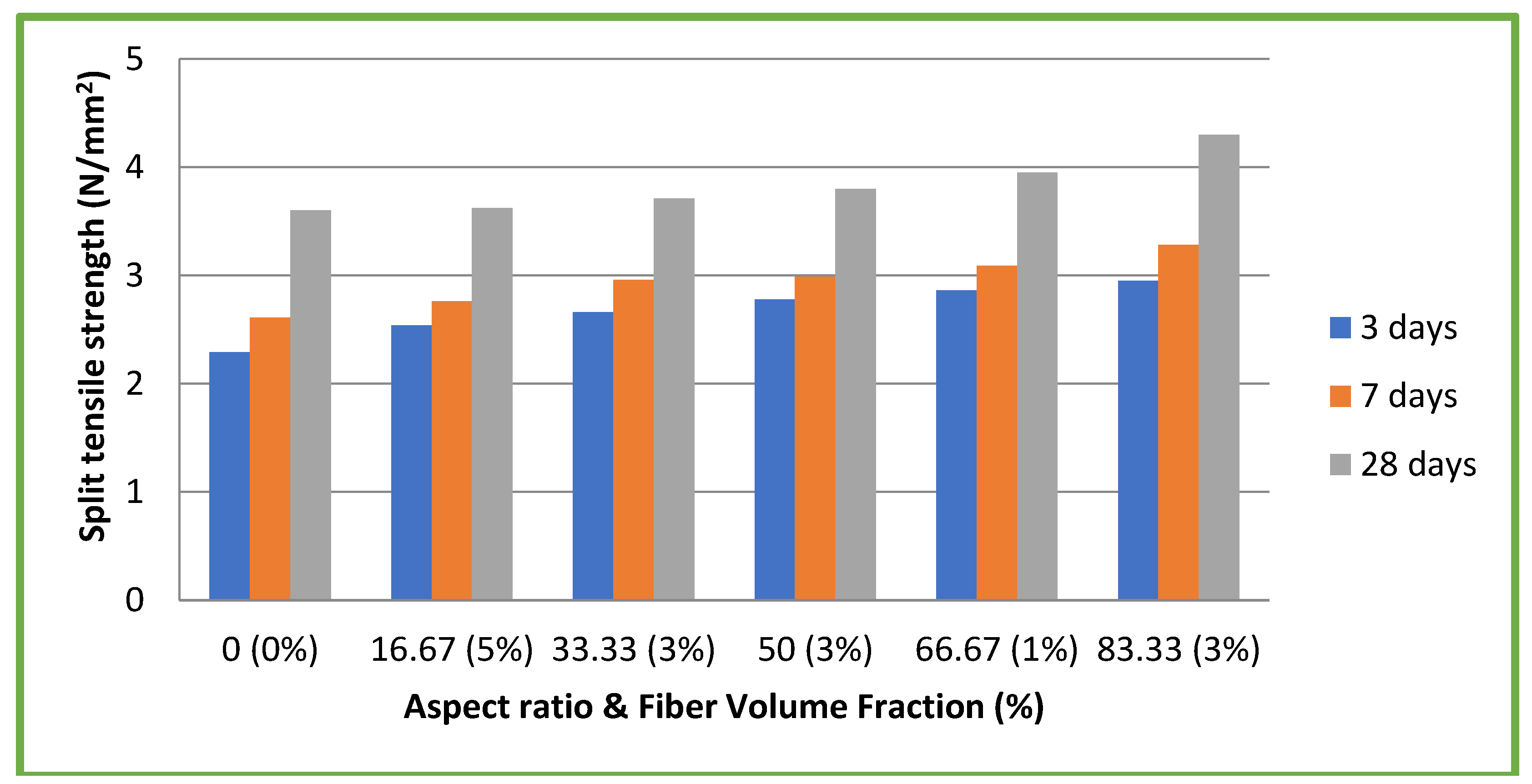

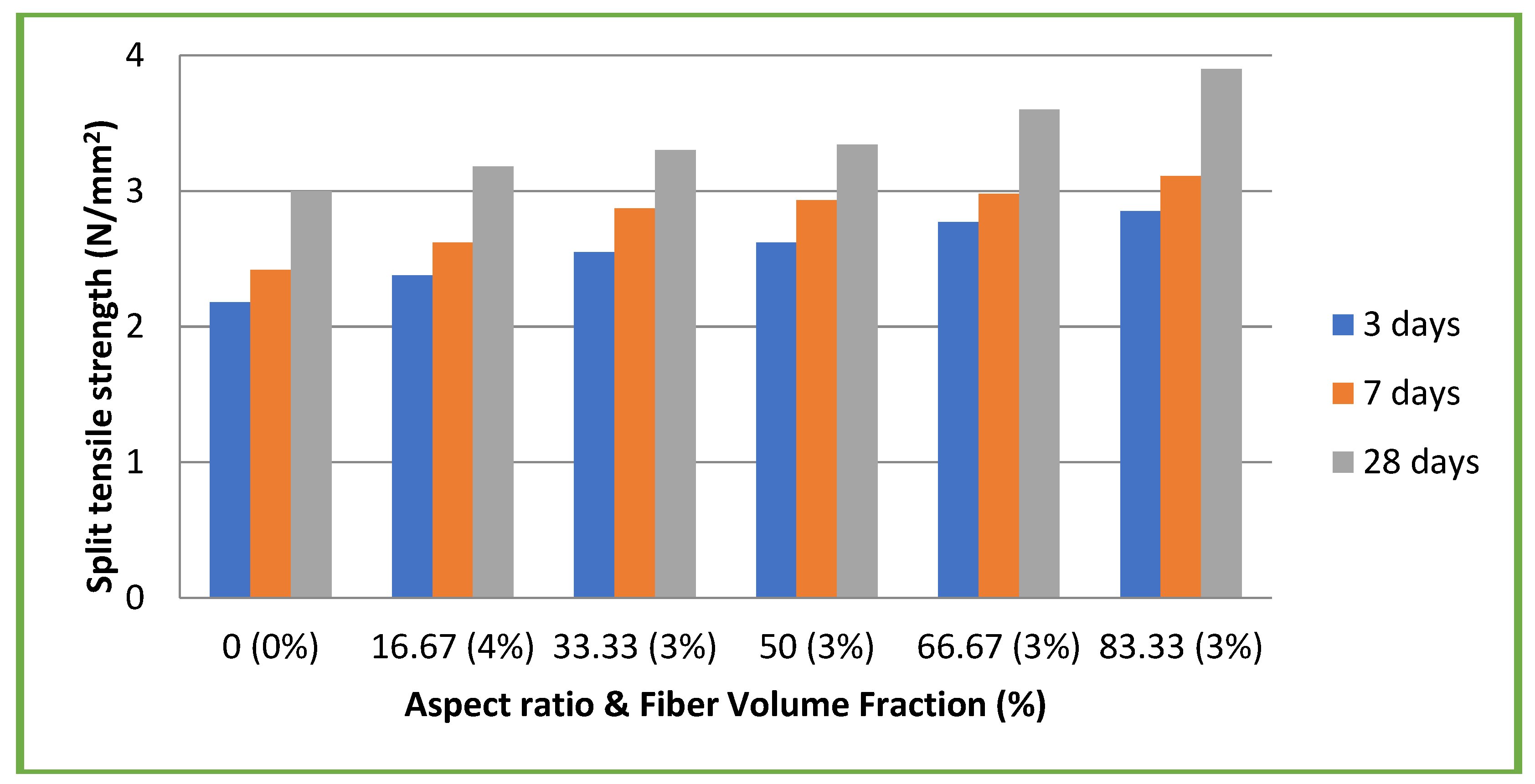

4.5. Split Tensile Strength

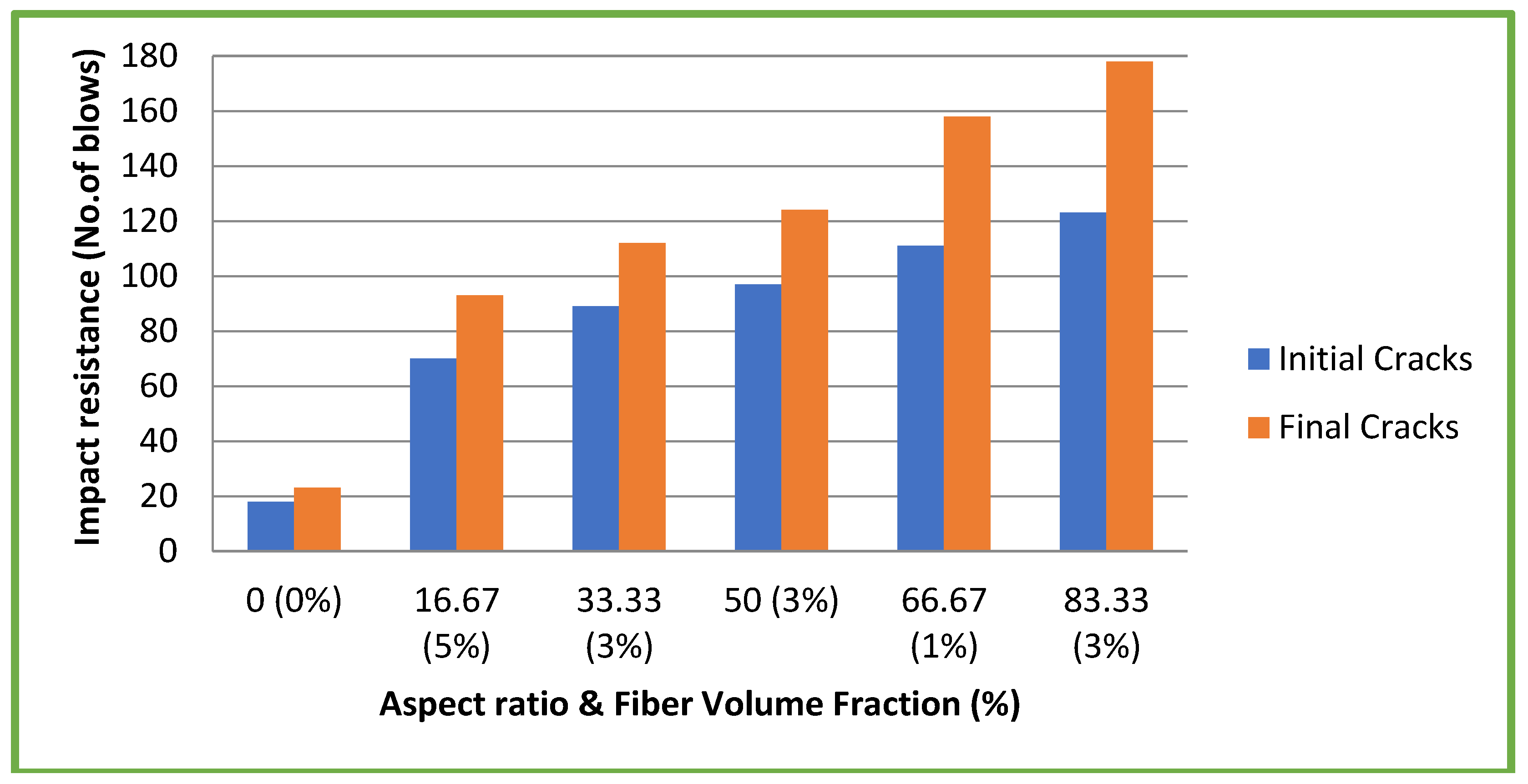

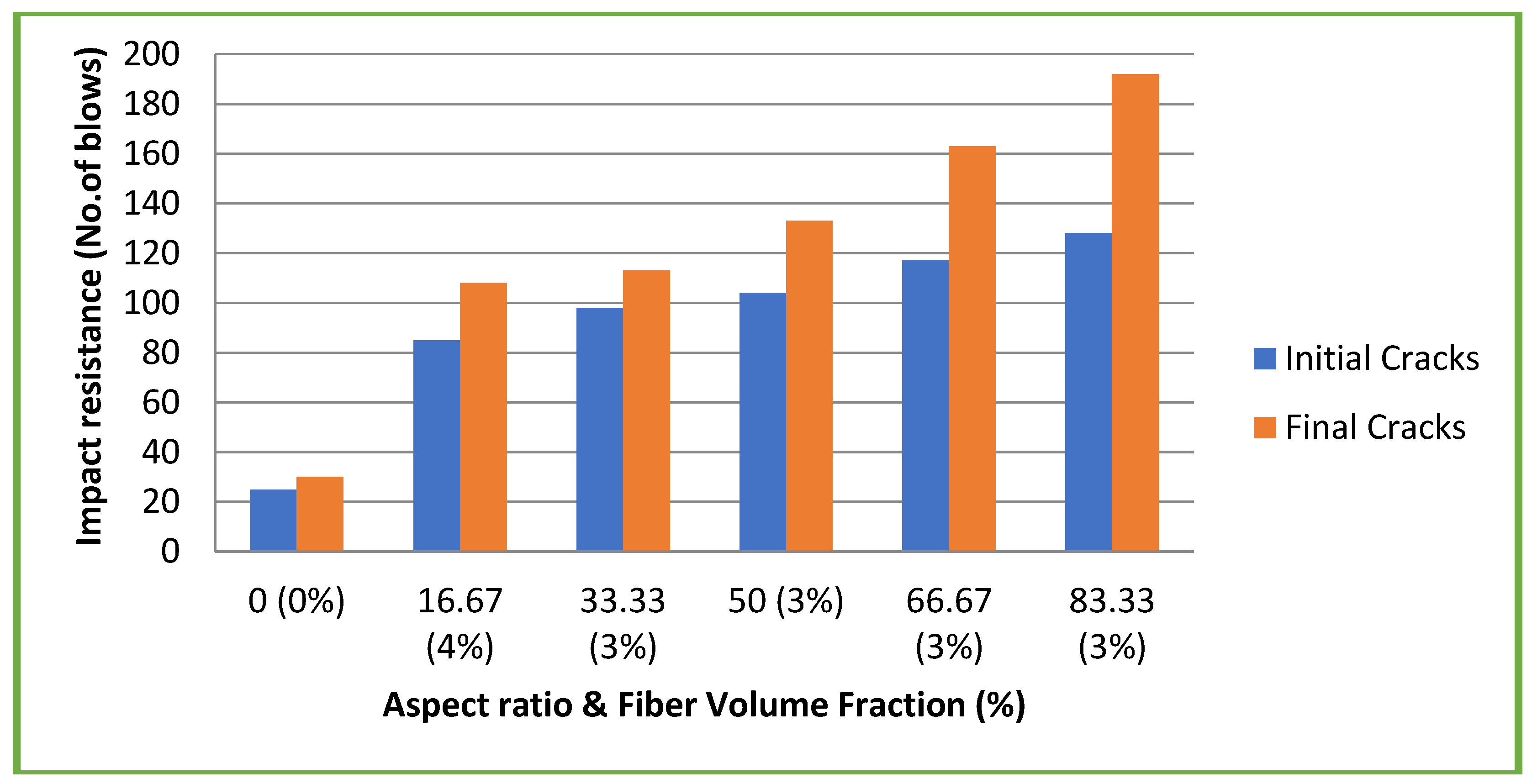

4.6. Impact Resistance

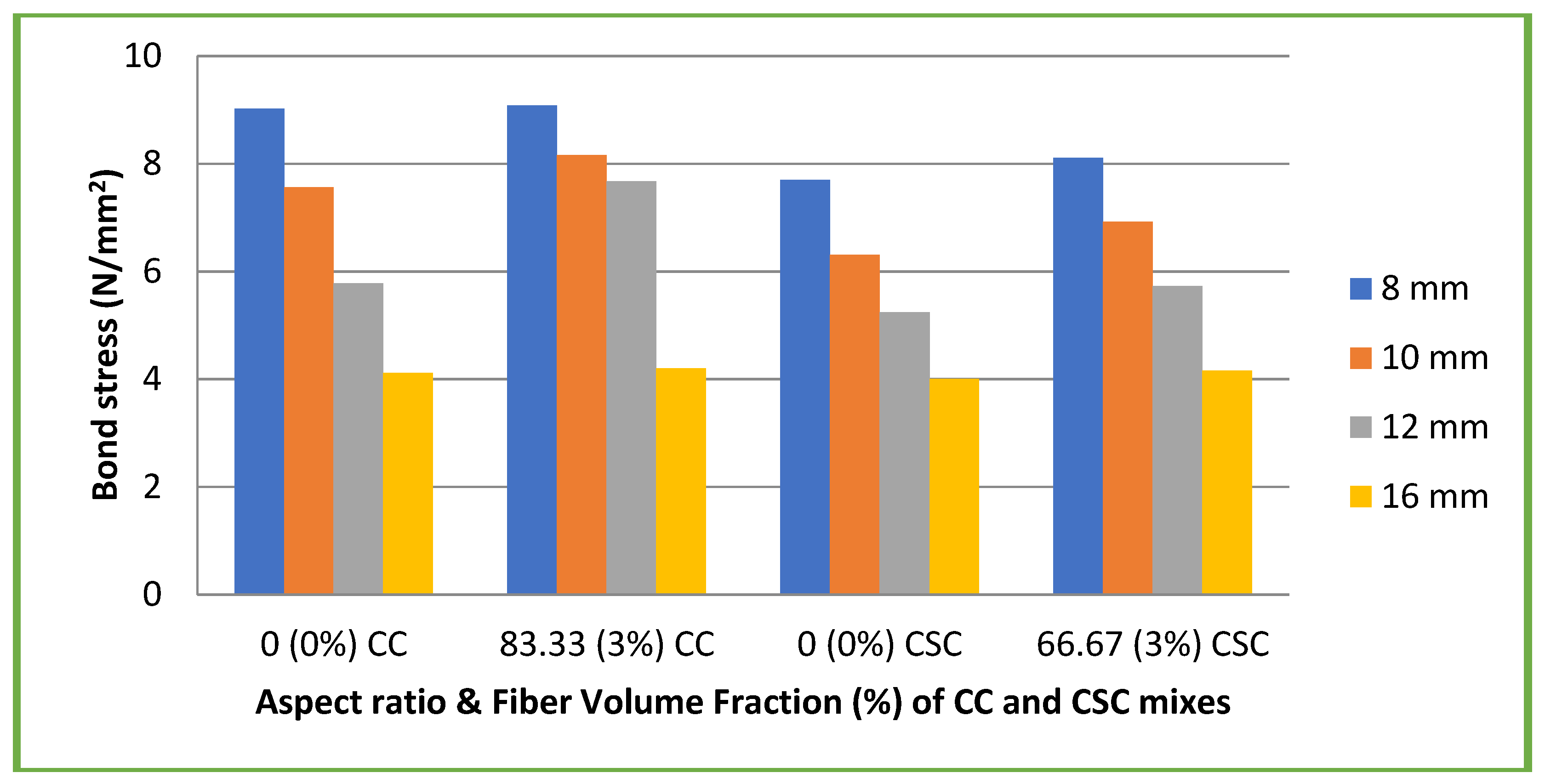

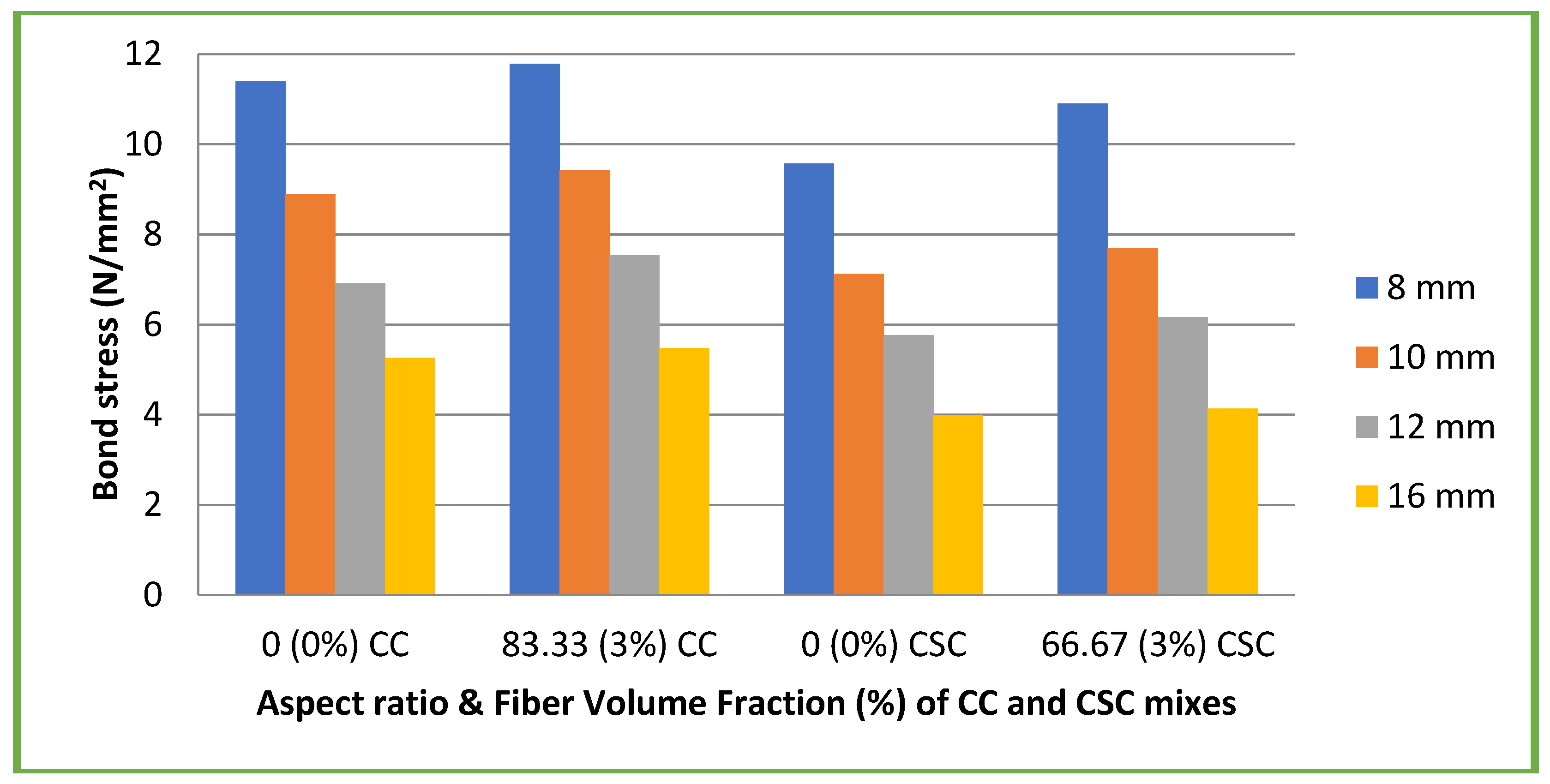

4.7. Bond Properties

4.8. Post-Cracking Behaviour

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shetty, M.S. Concrete Technology Theory and Practice; S Chand & Company Ltd.: New Delhi, India, 2006. [Google Scholar]

- Larisa, U.; Solbon, L.; Sergei, B. fiber-reinforced concrete with mineral fibers and nanosilica. Procedia Eng. 2017, 195, 147–154. [Google Scholar] [CrossRef]

- Lee, J.H. Influence of concrete strength combined with fiber content in the residual flexural strengths of fiber reinforced concrete. Compos. Struct. 2017, 168, 216–225. [Google Scholar] [CrossRef]

- Pikus, G.A. Steel fiber concrete mixture work ability. Procedia Eng. 2016, 150, 2119–2123. [Google Scholar] [CrossRef]

- Ganesan, N.; Abraham, R.; Deepa Raj, S. Durability characteristics of steel fibre reinforced geopolymer concrete. Constr. Build. Mater. 2015, 93, 471–476. [Google Scholar] [CrossRef]

- Dey, V.; Bonakdar, A.; Mobasher, B. Low-velocity flexural impact response of fiber-reinforced aerated concrete. Cem. Concr. Compos. 2014, 49, 100–110. [Google Scholar] [CrossRef]

- Ali, M.; Li, X.; Chouw, N. Experimental investigations on bond strength between coconut fibre and concrete. Mater. Des. 2013, 44, 596–605. [Google Scholar] [CrossRef]

- Blanco, A.; Pujadas, P.; Fuente, A.D.L.; Cavalaro, S.H.P.; Aguado, A. Influence of the type of fiber on the structural response and design of FRC slabs. J. Struct. Eng. 2016, 142, 04016054. [Google Scholar] [CrossRef]

- Pujadas, P.; Blanco, A.; Cavalaro, S.; Aguado, A. Plastic fibres as the only reinforcement for flat suspended slabs: experimental investigation and numerical simulation. Constr. Build. Mater. 2014, 57, 92–104. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Kumar, P.S.; Lakshmipathy, M. Mechanical and bond properties of coconut shell concrete. Constr. Build. Mater. 2011, 25, 92–98. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Annadurai, R.; Kumar, P.S. Study on reinforced lightweight coconut shell concrete beam behavior under flexure. Mater. Des. 2013, 46, 157–167. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Ramasubramani, R.; Annadurai, R.; Prakash Chandar, S. Study on reinforced lightweight coconut shell concrete beam behavior under torsion. Mater. Des. 2014, 57, 374–382. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Annadurai, R.; Kumar, P.S. A study on some durability properties of coconut shell aggregate concrete. Mater. Struct. 2015, 48, 1253–1264. [Google Scholar] [CrossRef]

- Jayaprithika, A.; Sekar, S.K. Stress-strain characteristics and flexural behaviour of reinforced eco-friendly coconut shell concrete. Constr. Build. Mater. 2016, 117, 244–250. [Google Scholar] [CrossRef]

- Olanipekun, E.A.; Olusola, K.O.; Ata, O. A comparative study of concrete properties using coconut shell and palm kernel shell as coarse aggregates. Build. Environ. 2006, 41, 297–301. [Google Scholar] [CrossRef]

- Yerramala, A.; Ramachandrudu, C. Properties of concrete with coconut shells as aggregate replacement. Int. J. Eng. Invent. 2012, 1, 21–31. [Google Scholar]

- Gunasekaran, K.; Annadurai, R.; Chandar, S.P.; Anandh, S. Study for the relevance of coconut shell aggregate concrete non-pressure pipe. Ain Shams Eng. J. 2017, 8, 523–530. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Pennarasi, G.; Soumya, S.; Richards, N.J. Study for the relevance of coconut shell aggregate concrete flooring tiles. Int. J. Civil Eng. Technol. 2017, 8, 370–379. [Google Scholar]

- Bureau of Indian Standards. Specification for 53 Grade Ordinary Portland Cement; IS 12269: 1987; Bureau of Indian Standards: New Delhi, India, 1987.

- Bureau of Indian Standards. Specification for Coarse and Fine Aggregate from Natural Sources for Concrete; IS 383: 1970; Bureau of Indian Standards: New Delhi, India, 1970.

- Bureau of Indian Standards. Indian Standard Specification for Methods of Tests for Strength of Concrete; IS 516: 1959; Bureau of Indian Standards: New Delhi, India, 1959.

- American Society for Testing and Materials International. Standard Test Method for Flexural Strength of Concrete; ASTM C78-84; American Society for Testing and Materials International: West Conshohocken, PA, USA, 1984. [Google Scholar]

- American Society for Testings and Materials International. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM C496-90; American Society for Testings and Materials International: West Conshohocken, PA, USA, 1990. [Google Scholar]

- Bureau of Indian Standards. Indian Standard Methods of Testing Bond in Reinforced Concrete; IS: 2770-(Part I)-1967; UDC 666.982: 620.172.21; Bureau of Indian Standards: New Delhi, India, 1967.

- Bureau of Indian Standards. Indian Standard Plain and Reinforced Concrete—Code of Practice; IS 456: 2000; BIS 2000; Bureau of Indian Standards: New Delhi, India, 2000.

- Gunasekaran, K.; Prakash Chandar, S.; Annadurai, R.; Satyanarayanan, K.S. Augmentation of mechanical and bond strength of coconut shell concrete using quarry dust. Eur. J. Environ. Civil Eng. 2016, 21, 629–640. [Google Scholar] [CrossRef]

- Swamy, R.N.; Jojagha, A.H. Impact resistance of steel fiberreinforced lightweight concrete. Int. J. Cem. Compos. Lightweight Concr. 1982, 4, 209–220. [Google Scholar] [CrossRef]

- Structural use of concrete Part 1. In Code of Practice for Design and Construction; BS 8110; British Standard Institution: London, UK, 1997.

| Physical and Mechanical Properties | Crushed Stone Aggregate | Coconut Shell | River Sand |

|---|---|---|---|

| Maximum size (mm) | 12.50 | 12.50 | 4.75 |

| Water absorption (%) | 0.25 | 23.50 | - |

| Specific gravity | 2.67 | 1.15 | 2.61 |

| Fineness Modulus | 6.76 | 6.55 | 3.72 |

| Bulk density (kg/m3) | 1620 | 655 | 1695 |

| Crushing value (%) | 18.44 | 2.62 | - |

| Impact value (%) | 15.70 | 4.72 | - |

| Sl. No | Test Parameter | Number of Specimens | Age during Testing |

|---|---|---|---|

| 1 | For compressive strength test—optimization | For CC—31 mixes; 9 cubes in each mix; total of 279 cubes. For CSC—25 mixes; 9 cubes in each mix; total of 225 cubes. | 3 days, 7 days and 28 days 3 days, 7 days and 28 days |

| 2 | Flexural strength test | For CC—6 mixes; 9 beams in each mix; total of 54 beams. For CSC—6 mixes; 9 beams in each mix; total of 54 beams. | 3 days, 7 days and 28 days 3 days, 7 days and 28 days |

| 3 | Split tensile test | For CC—6 mixes; 9 cylinders in each mix; total of 54 cylinders. For CSC—6 mixes; 9 cylinders in each mix; total of 54 cylinders. | 3 days, 7 days and 28 days 3 days, 7 days and 28 days |

| 4 | Impact strength test | For CC—6 mixes; 9 specimens in each mix; total of 54 specimens. For CSC—6 mixes; 9 specimens in each mix; total of 54 specimens. | 3 days, 7 days and 28 days 3 days, 7 days and 28 days |

| 5 | Bond strength test | For CC—4 mixes; 48 specimens in total. For CSC—4 mixes; 48 specimens in total. | 28 days 28 days |

| Aspect Ratio | % of Fiber | Compressive Strength, N/mm2 | ||

|---|---|---|---|---|

| 3 Day Strength | 7 Day Strength | 28 Day Strength | ||

| 16.67 | 1 | 16.80 | 22.20 | 31.40 |

| 2 | 17.30 | 23.00 | 32.70 | |

| 3 | 18.90 | 24.80 | 34.60 | |

| 4 | 21.00 | 26.30 | 37.00 | |

| 5 | 21.40 | 26.50 | 39.50 | |

| 6 | 20.90 | 26.00 | 37.50 | |

| 33.33 | 1 | 19.86 | 25.70 | 32.50 |

| 2 | 20.53 | 26.66 | 33.73 | |

| 3 | 21.76 | 27.40 | 34.30 | |

| 4 | 18.23 | 21.90 | 29.20 | |

| 5 | 17.60 | 20.70 | 25.80 | |

| 50 | 1 | 20.61 | 22.89 | 29.90 |

| 2 | 23.45 | 27.33 | 32.13 | |

| 3 | 25.12 | 30.20 | 35.17 | |

| 4 | 21.01 | 27.78 | 33.98 | |

| 5 | 16.30 | 25.81 | 29.52 | |

| 66.67 | 1 | 26.53 | 28.10 | 35.63 |

| 2 | 21.57 | 24.97 | 33.46 | |

| 3 | 19.33 | 23.37 | 33.16 | |

| 4 | 16.71 | 19.23 | 32.01 | |

| 5 | 14.60 | 16.63 | 27.93 | |

| 83.33 | 1 | 17.87 | 23.70 | 30.10 |

| 2 | 21.30 | 27.03 | 36.97 | |

| 3 | 23.90 | 34.50 | 43.80 | |

| 4 | 15.36 | 23.03 | 32.03 | |

| 5 | 14.90 | 21.90 | 28.41 | |

| 100 | 1 | 16.90 | 23.10 | 31.20 |

| 2 | 17.40 | 26.10 | 33.10 | |

| 3 | 17.63 | 27.90 | 34.90 | |

| 4 | 18.70 | 29.50 | 37.10 | |

| 5 | 15.61 | 24.00 | 32.50 | |

| Aspect Ratio | % of Fiber | Compressive Strength, N/mm2 | ||

|---|---|---|---|---|

| 3 Day Strength | 7 Day Strength | 28 Day Strength | ||

| 16.67 | 1 | 16.20 | 20.00 | 26.00 |

| 2 | 16.30 | 21.30 | 26.20 | |

| 3 | 16.50 | 21.90 | 26.50 | |

| 4 | 17.70 | 22.70 | 26.90 | |

| 5 | 15.90 | 20.70 | 24.40 | |

| 33.33 | 1 | 16.80 | 18.10 | 21.30 |

| 2 | 17.00 | 19.76 | 23.60 | |

| 3 | 18.33 | 22.84 | 27.20 | |

| 4 | 17.76 | 21.83 | 25.30 | |

| 5 | 17.66 | 19.13 | 23.50 | |

| 50 | 1 | 13.70 | 18.60 | 26.00 |

| 2 | 15.60 | 19.20 | 26.30 | |

| 3 | 16.20 | 20.40 | 26.95 | |

| 4 | 12.90 | 18.40 | 25.91 | |

| 5 | 11.40 | 18.30 | 24.00 | |

| 66.67 | 1 | 15.20 | 19.90 | 25.87 |

| 2 | 16.80 | 21.89 | 27.80 | |

| 3 | 18.90 | 24.49 | 30.01 | |

| 4 | 16.20 | 22.14 | 26.78 | |

| 5 | 15.90 | 21.09 | 25.10 | |

| 83.33 | 1 | 17.00 | 22.90 | 25.20 |

| 2 | 17.10 | 22.98 | 26.00 | |

| 3 | 17.73 | 23.11 | 26.40 | |

| 4 | 16.61 | 21.19 | 24.90 | |

| 5 | 16.31 | 20.03 | 24.85 | |

| Aspect Ratio & Fiber Volume Fraction (%) & Mix Type | Theoretical Bond Strength, N/mm2 | |||

|---|---|---|---|---|

| IS 456: 2000 | BS 8110 | |||

| Plain Bar | Deformed Bar | Plain Bar | Deformed Bar | |

| 0 (0%) CC | 1.40 | 2.24 | 1.53 | 2.74 |

| 83.33 (3%) CC | 1.85 | 3.30 | ||

| 0 (0%) CSC | 1.41 | 2.52 | ||

| 66.67 (3%) CSC | 1.53 | 2.74 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sekar, A.; Kandasamy, G. Optimization of Coconut Fiber in Coconut Shell Concrete and Its Mechanical and Bond Properties. Materials 2018, 11, 1726. https://doi.org/10.3390/ma11091726

Sekar A, Kandasamy G. Optimization of Coconut Fiber in Coconut Shell Concrete and Its Mechanical and Bond Properties. Materials. 2018; 11(9):1726. https://doi.org/10.3390/ma11091726

Chicago/Turabian StyleSekar, Anandh, and Gunasekaran Kandasamy. 2018. "Optimization of Coconut Fiber in Coconut Shell Concrete and Its Mechanical and Bond Properties" Materials 11, no. 9: 1726. https://doi.org/10.3390/ma11091726

APA StyleSekar, A., & Kandasamy, G. (2018). Optimization of Coconut Fiber in Coconut Shell Concrete and Its Mechanical and Bond Properties. Materials, 11(9), 1726. https://doi.org/10.3390/ma11091726