Thermochromic and Femtosecond-Laser-Induced Damage Performance of Tungsten-Doped Vanadium Dioxide Films Prepared Using an Alloy Target

Abstract

:1. Introduction

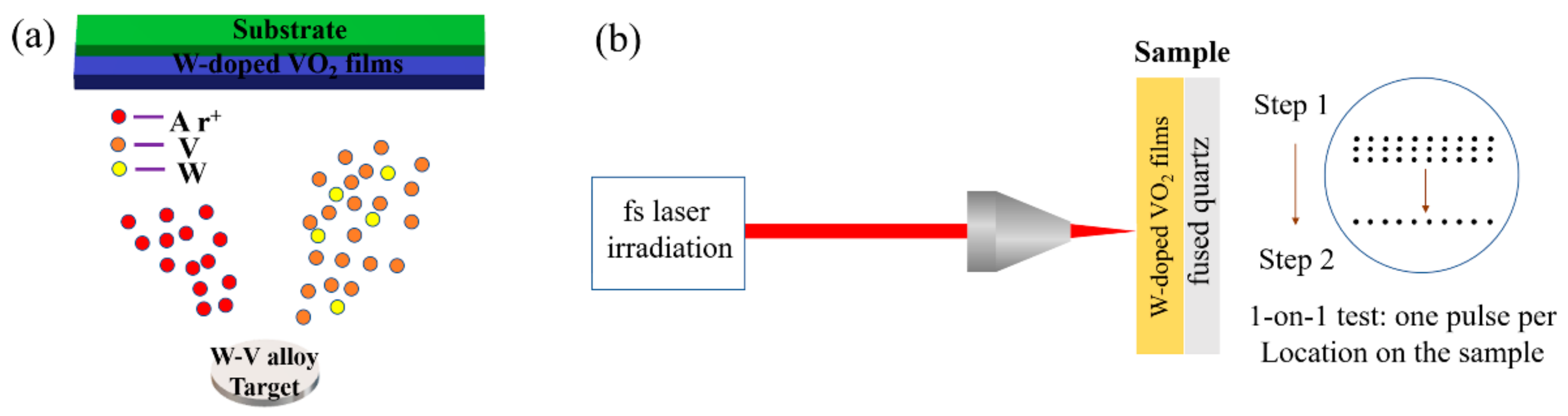

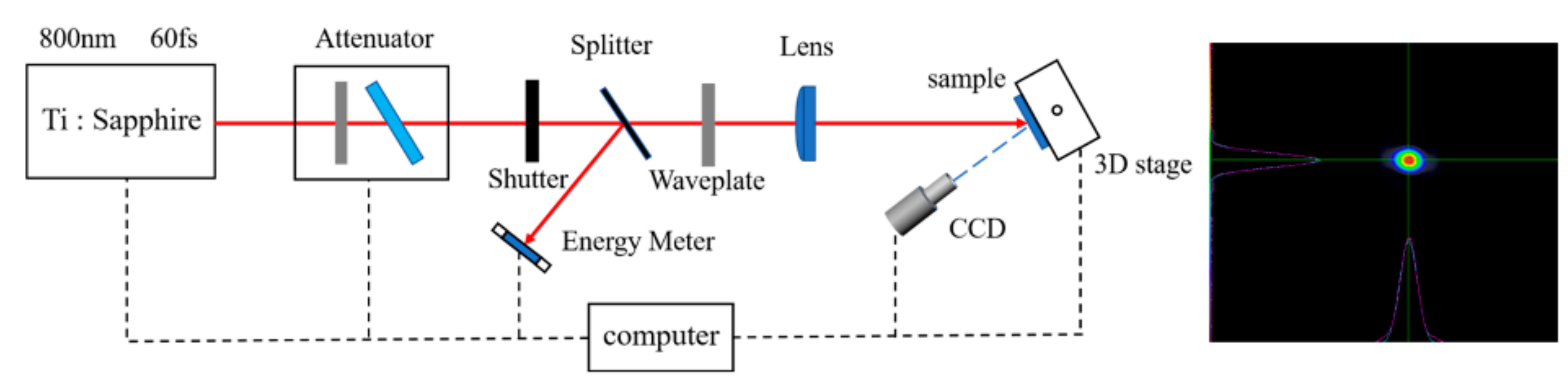

2. Experimental Methods

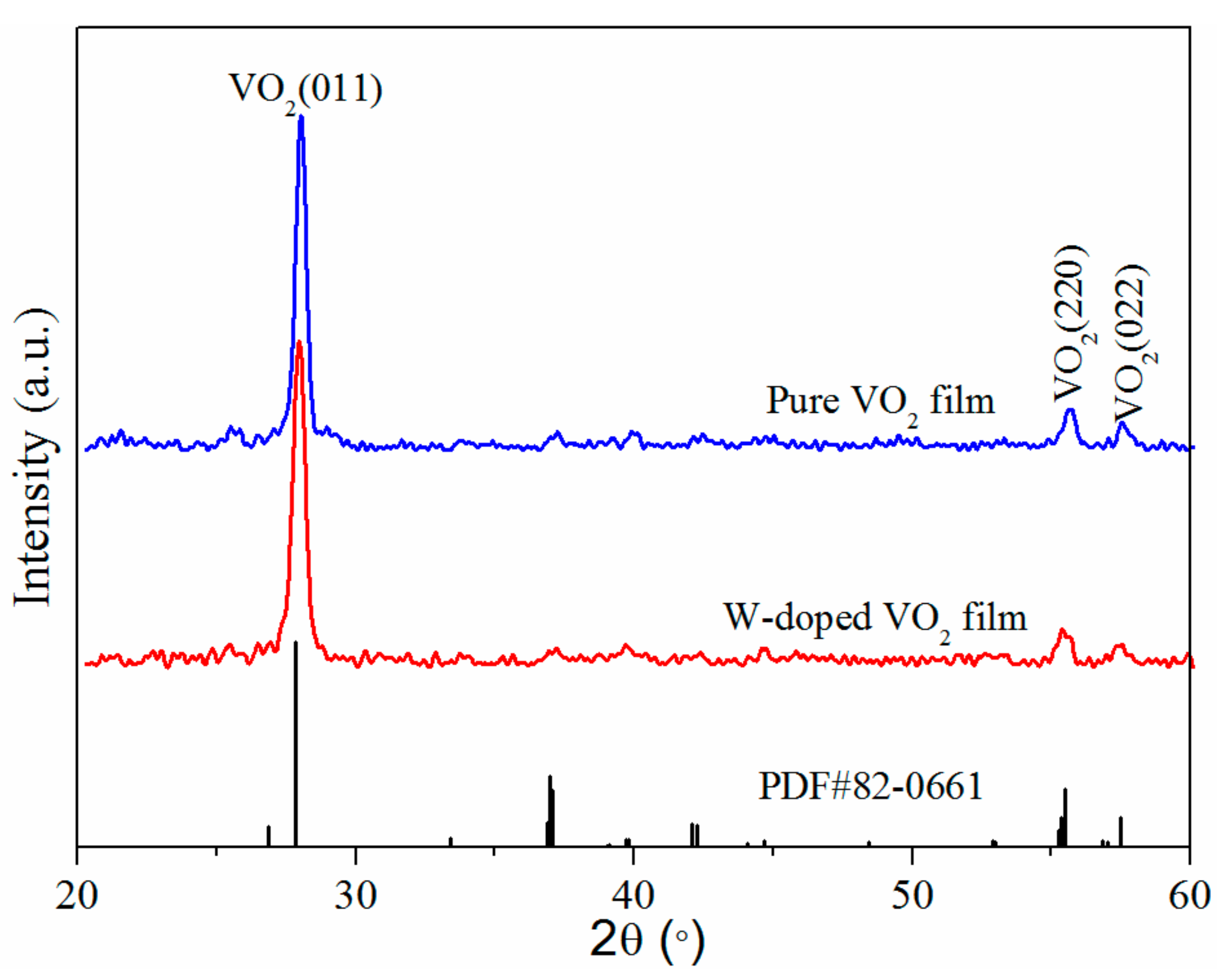

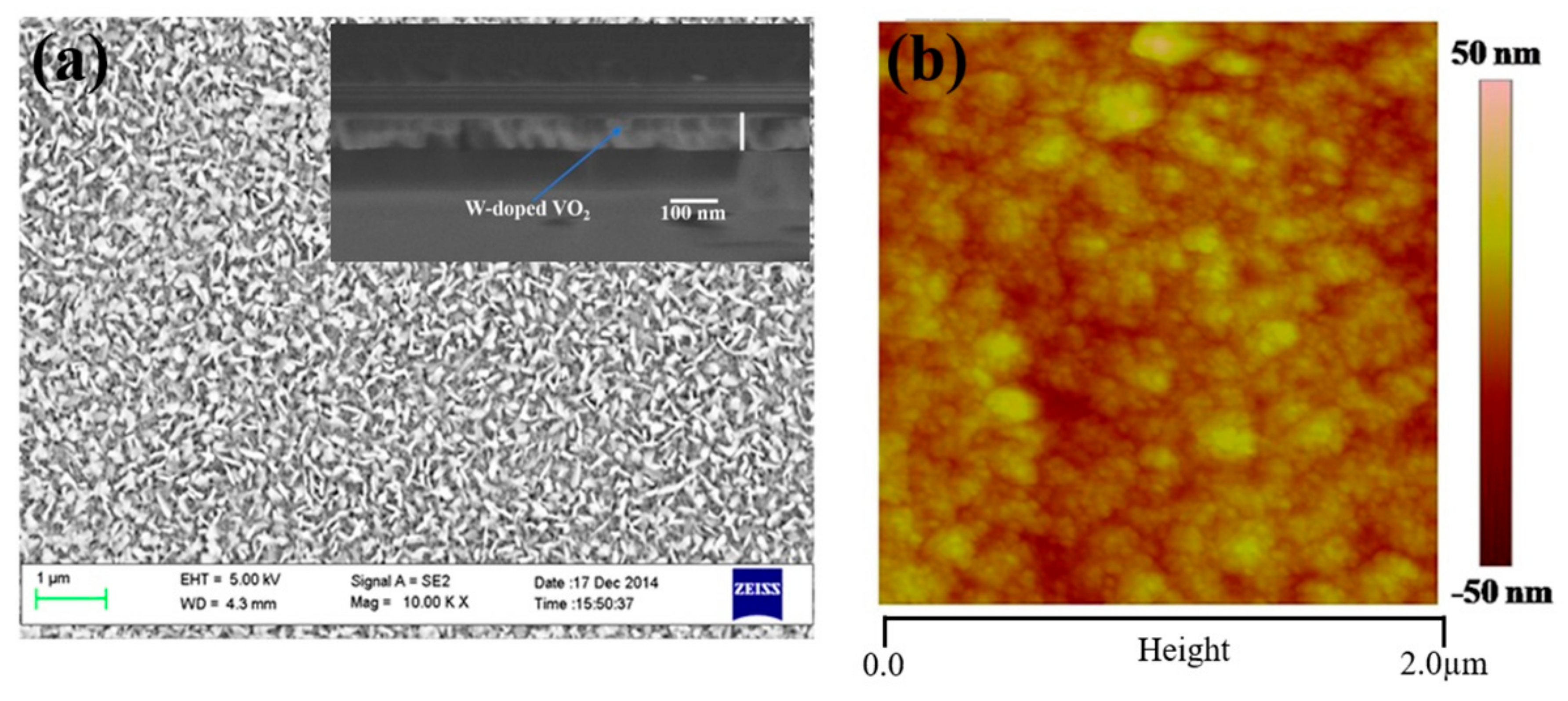

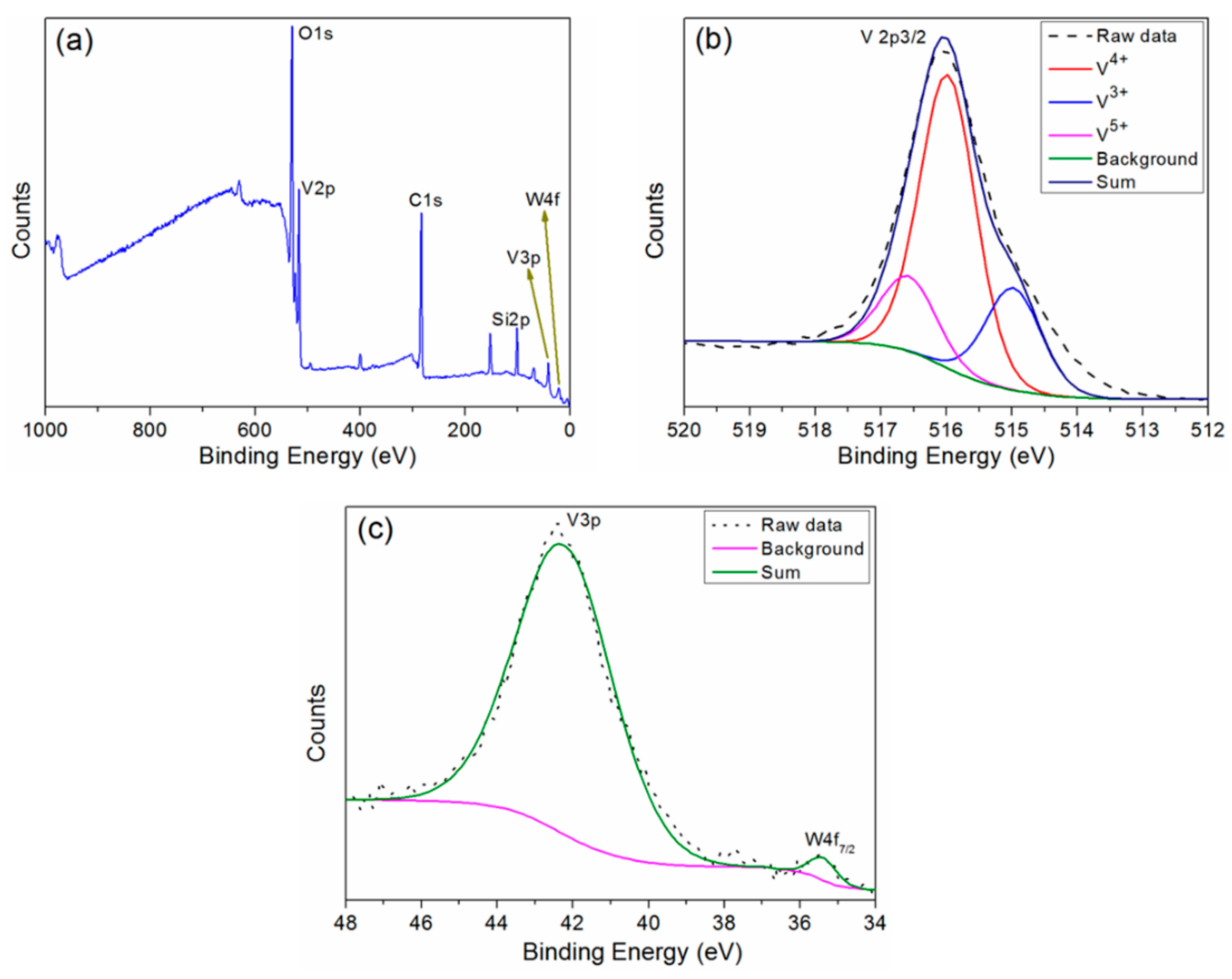

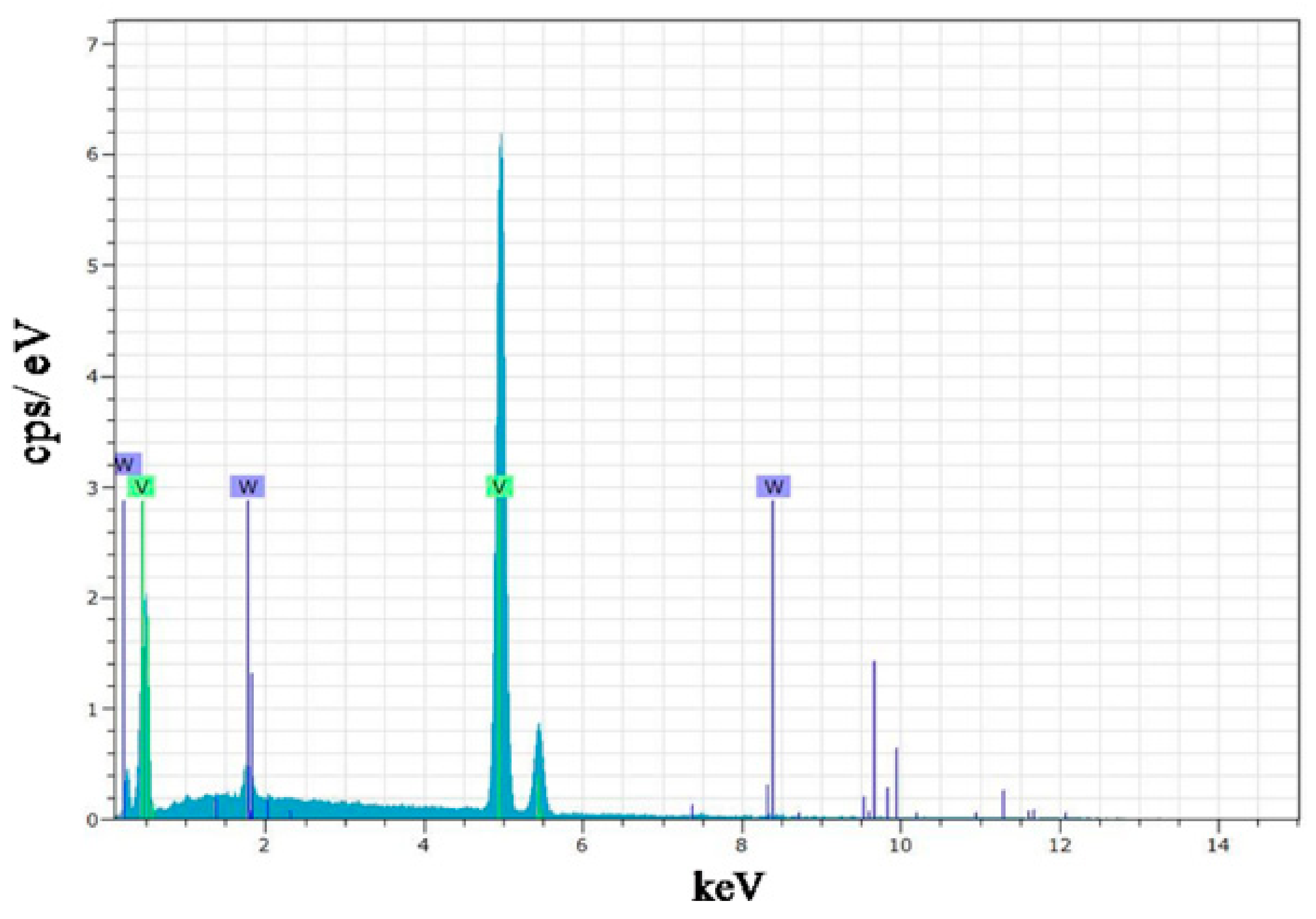

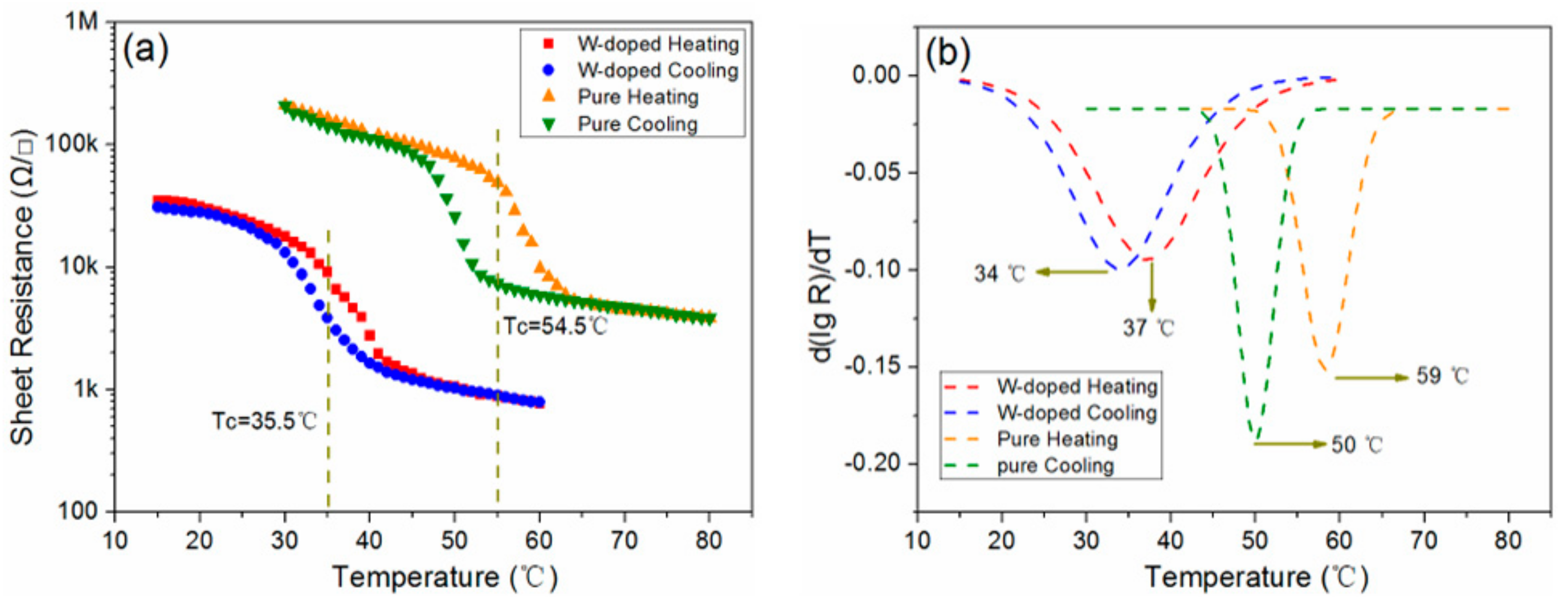

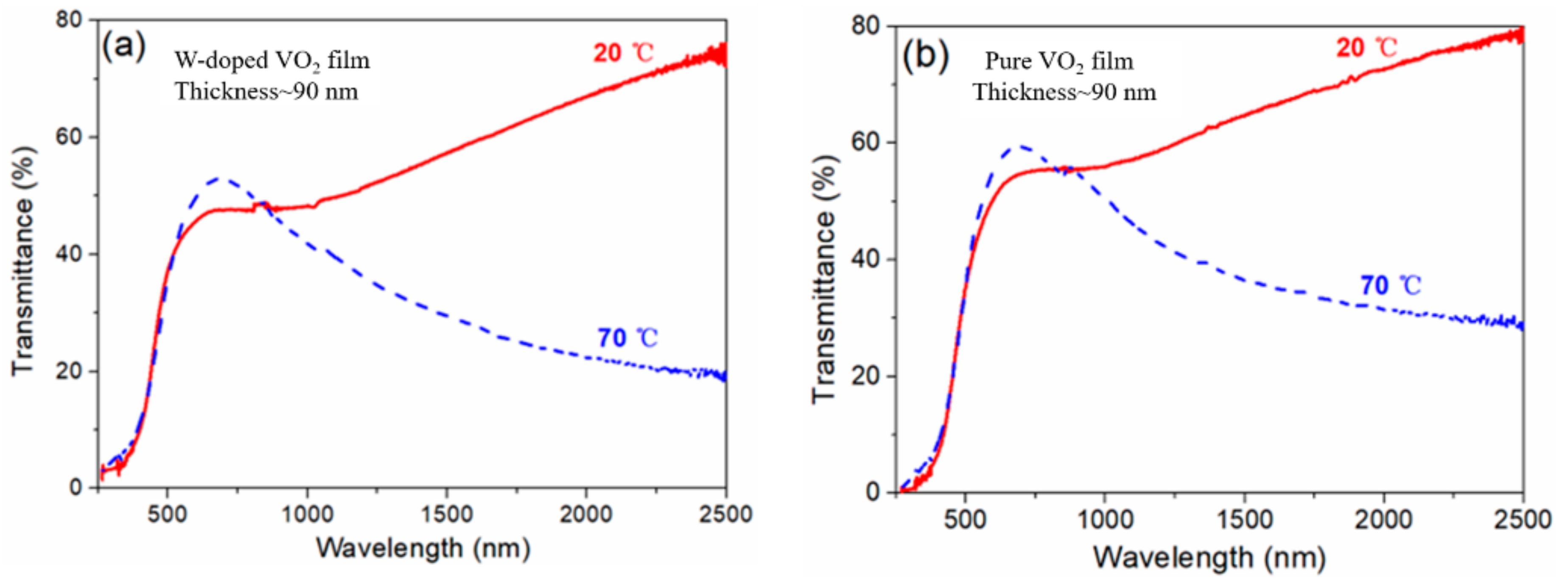

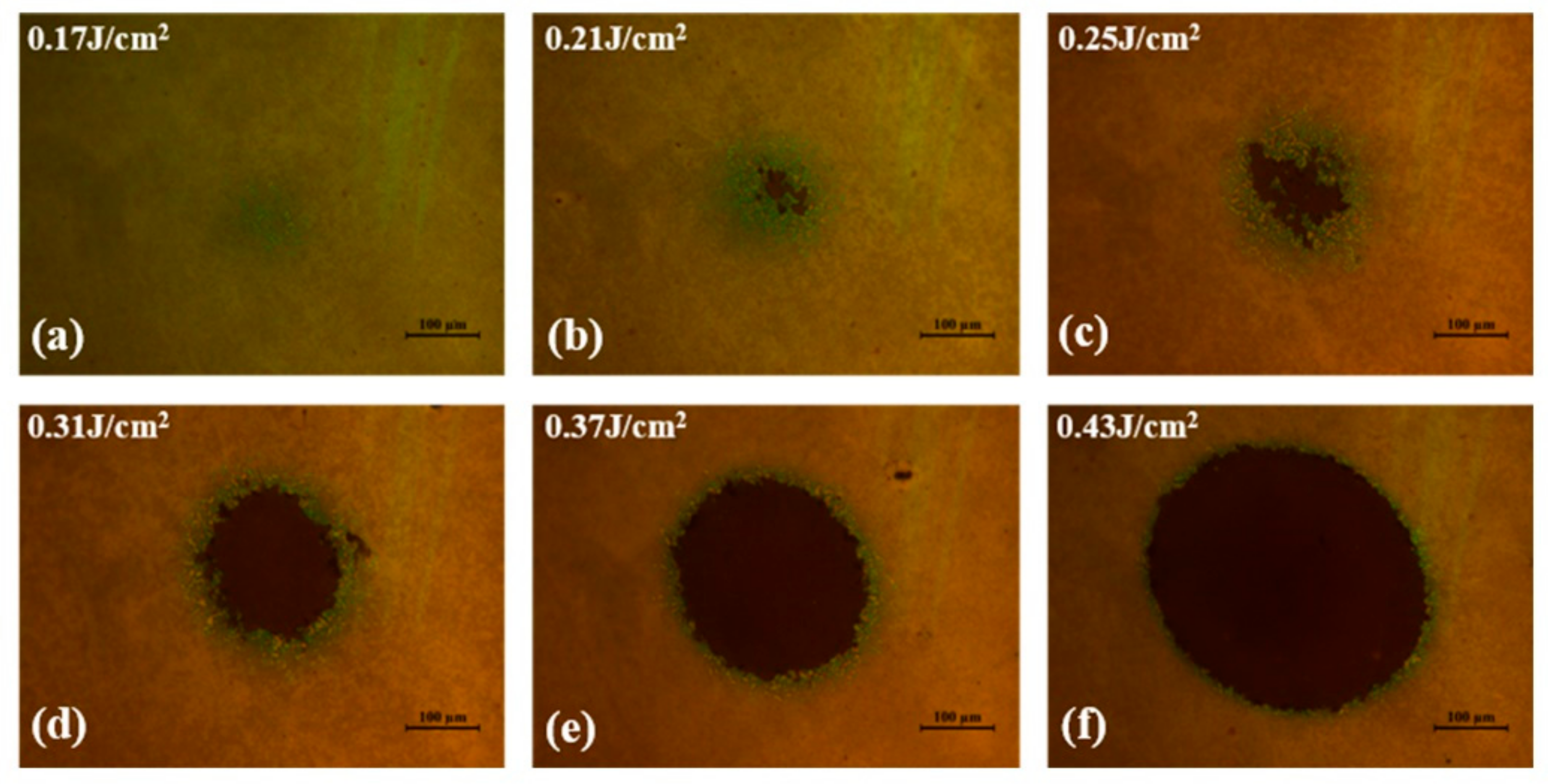

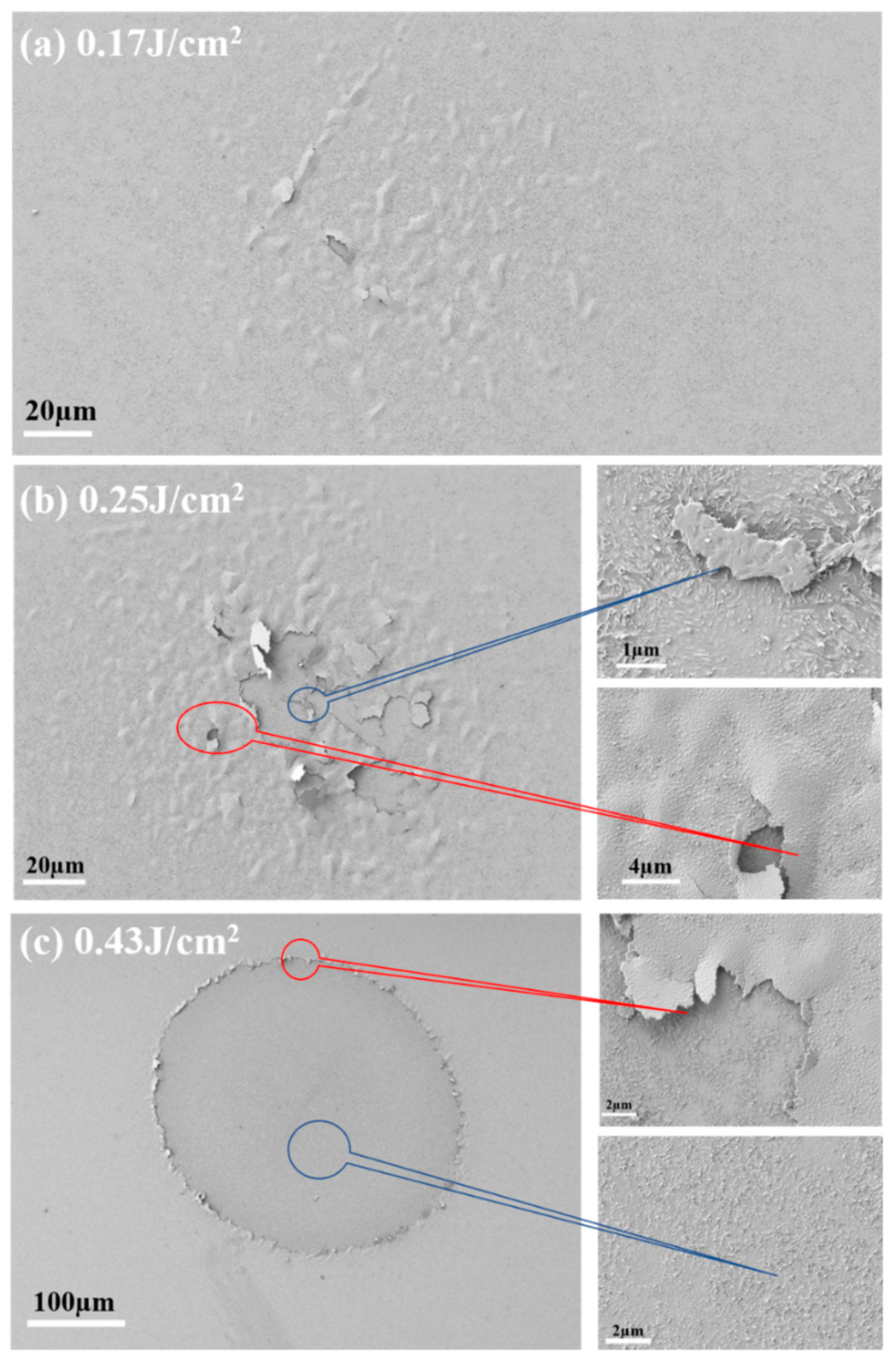

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lu, Y.; Feng, Y.S.; Ling, Y.S.; Qiao, Y. The mechanism of laser disturbing infrared detector and its intelligent protection. Proc. SPIE 2013, 8904, 89040T. [Google Scholar]

- Huang, Z.L.; Chen, S.H.; Lv, C.H.; Huang, Y.; Lai, J.J. Infrared characteristics of VO2 thin films for smart window and laser protection. Appl. Phys. Lett. 2012, 101, 191905. [Google Scholar] [CrossRef]

- Beebe, M.R.; Klopf, J.M.; Wang, Y.; Kittiwatanakul, S.; Lu, J.; Wolf, S.A.; Lukaszew, R.A. Time-resolved lightinduced insulator-metal transition in niobium dioxide and vanadium dioxide thin films. Opt. Mater. Express 2017, 7, 213–223. [Google Scholar] [CrossRef]

- Song, S.C.; Ma, X.L.; Pu, M.B.; Li, X.; Guo, Y.H.; Gao, P.; Luo, X.G. Tailoring active color rendering and multiband photodetection in a vanadium-dioxide-based metamaterial absorber. Photonics Res. 2018, 6, 492–497. [Google Scholar] [CrossRef]

- Dietrich, M.K.; Kuhl, F.; Polity, A.; Klar, P.J. Optimizing thermochromic VO2 by co-doping with W and Sr for smart window applications. Appl. Phys. Lett. 2017, 110, 141907. [Google Scholar] [CrossRef]

- Currie, M.; Mastro, M.A.; Wheeler, V.D. Characterizing the tunable refractive index of vanadium dioxide. Opt. Mater. Express 2017, 7, 1697–1707. [Google Scholar] [CrossRef]

- Lysenko, S.; Rúa, A.; Vikhnin, V.; Fernández, F.; Liu, H. Insulator-to-metal phase transition and recovery processes in VO2 thin films after femtosecond laser excitation. Phys. Rev. B 2007, 76, 035104. [Google Scholar] [CrossRef]

- Chen, L.; Ye, H.; Liu, Y.M.; Wu, D.; Ma, R.; Yu, Z.Y. Numerical investigations of an optical switch based on a silicon stripe waveguide embedded with vanadium dioxide layers. Photonics Res. 2017, 5, 335–339. [Google Scholar] [CrossRef]

- Madida, I.G.; Simo, A.; Sone, B.; Maity, A.; Kana, J.B.; Gibaud, A.; Merad, G.; Thema, F.T.; Maaza, M. Submicronic VO2-PVP composites coatings for smart windows applications and solar heat management. Sol. Energy 2014, 107, 758–769. [Google Scholar] [CrossRef]

- Cavalleri, A.; Dekorsy, T.; Chong, H.H.W.; Kieffer, J.C.; Schoenlein, R.W. Evidence for a structurally driven insulator-to-metal transition in VO2: A view from the ultrafast timescale. Phys. Rev. B 2004, 70, 161102. [Google Scholar] [CrossRef]

- Chang, S.J.; Park, J.B.; Lee, G.; Kim, H.J.; Lee, J.B.; Bae, T.S.; Han, Y.K.; Park, T.J.; Huh, Y.S.; Hong, W.K. In situ probing of doping-and stress-mediated phase transitions in a single-crystalline VO2 nanobeam by spatially resolved Raman spectroscopy. Nanoscale 2014, 6, 8068–8074. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Li, W.; Fan, M.; Zhang, F.; Zhang, J.; Liu, X.; Zhang, H.; Huang, C.; Li, H. Preparation of Wand Mo doped VO2(M) by ethanol reduction of peroxovanadium complexes and their phase transition and optical switching properties. J. Alloys Compd. 2012, 544, 30–36. [Google Scholar] [CrossRef]

- Ji, C.H.; Wu, Z.M.; Feng, H.Q.; Wang, J.; Huang, Z.H.; Zhou, H.X.; Yao, W.; Gou, J.; Jiang, Y.D. Optimization of metal-to-insulator phase transition properties in polycrystalline VO2 films for terahertz modulation applications by doping. J. Mater. Chem. C 2018, 6, 1722–1730. [Google Scholar] [CrossRef]

- Ji, H.N.; Liu, D.Q.; Cheng, H.F.; Zhang, C.Y. Inkjet printing of vanadium dioxide nanoparticles for smart windows. J. Mater. Chem. C 2018, 6, 2424–2429. [Google Scholar] [CrossRef]

- Shi, R.; Wang, J.W.; Cai, X.B.; Zhang, L.F.; Chen, P.C.; Liu, S.Y.; Zhang, L.; Ouyang, W.K.; Wang, N.; Cheng, C. Axial Modulation of Metal−Insulator Phase Transition of VO2 Nanowires by Graded Doping Engineering for Optically Readable Thermometers. J. Phys. Chem. C 2017, 121, 24877–24885. [Google Scholar] [CrossRef]

- Wu, S.W.; Tian, S.Q.; Liu, B.S.; Tao, H.Z.; Zhao, X.J.; Palgrave, R.G.; Sankar, G.; Parkin, I.P. Facile synthesis of mesoporous VO2 nanocrystals by a cotton-template method and their enhanced thermochromic properties. Sol. Energy Mater. Sol. Cells 2018, 176, 427–434. [Google Scholar] [CrossRef]

- Vlček, J.; Kolenatý, D.; Houška, J.; Kozák, T.; Čerstvý, R. Controlled reactive HiPIMS-effective technique for low-temperature (300 °C) synthesis of VO2 films with semiconductor-to-metal transition. J. Phys. D Appl. Phys. 2017, 50, 38LT01. [Google Scholar] [CrossRef]

- Zhang, D.P.; Zhu, M.D.; Liu, Y.; Yang, K.; Liang, G.X.; Zheng, Z.H.; Cai, X.M.; Fan, P. High performance VO2 thin films growth by DC magnetron sputtering at low temperature for smart energy efficient window application. J. Alloys Compd. 2016, 659, 198–202. [Google Scholar] [CrossRef]

- Paone, A.; Sanjines, R.; Jeanneret, P.; Whitlow, H.J.; Guibert, E.; Guibert, G.; Bussy, F.; Scartezzini, J.L.; Schüler, A. Influence of doping in thermochromic V1−xWxO2 and V1−xAlxO2 thin films: Twice improved doping efficiency in V1−xWxO2. J. Alloys Compd. 2015, 621, 206–211. [Google Scholar] [CrossRef]

- Jin, P.; Tanemura, S. Relationship between Transition Temperature and x in V1−xWxO2 Films Deposited by Dual-Target Magnetron. Jpn. J. Appl. Phys. 1995, 34, 2459–2460. [Google Scholar] [CrossRef]

- Li, W.J.; Ji, S.D.; Li, Y.M.; Huang, A.; Luo, H.J.; Jin, P. Synthesis of VO2 nanoparticles by a hydrothermal-assisted homogeneous precipitation approach for thermochromic applications. RSC Adv. 2014, 4, 13026–13033. [Google Scholar] [CrossRef]

- Liang, S.; Shi, Q.W.; Zhu, H.F.; Peng, B.; Huang, W.X. One-Step Hydrothermal Synthesis of W-Doped VO2(M) Nanorods with a Tunable Phase-Transition Temperature for Infrared Smart Windows. ACS Omega 2016, 1, 1139–1148. [Google Scholar] [CrossRef]

- Mao, Z.P.; Wang, W.; Liu, Y.; Zhang, L.P.; Xu, H.; Zhong, Y. Infrared stealth property based on semiconductor (M)-to-metallic (R) phase transition characteristics of W-doped VO2 thin films coated on cotton fabrics. Thin Solid Films 2014, 558, 208–214. [Google Scholar] [CrossRef]

- Zhu, M.D.; Qi, H.J.; Wang, B.; Wang, H.; Zhang, D.P.; Lv, W.Z. Enhanced visible transmittance and reduced transition temperature for VO2 thin films modulated by index-tunable SiO2 anti-reflection coatings. RSC Adv. 2018, 8, 28953–28959. [Google Scholar] [CrossRef]

- Brassard, D.; Fourmanux, S.; Jean-Jacques, M.; Kieffer, J.C.; Khakania, M.A. Grain size effect on the semiconductor-metal phase transition characteristics of magnetron-sputtered thin films. Appl. Phys. Lett. 2005, 87, 051910. [Google Scholar] [CrossRef]

- Houska, J.; Kolenaty, D.; Vlcek, J.; Cerstvy, R. Properties of thermochromic VO2 films prepared by HiPIMS onto unbiased amorphous glass substrates at a low temperature of 300 °C. Thin Solid Films 2018, 660, 463–470. [Google Scholar] [CrossRef]

- Huang, Z.L.; Chen, C.H.; Lv, C.H.; Chen, S.H. Tungsten-doped vanadium dioxide thin films on borosilicate glass for smart window application. J. Alloys Compd. 2013, 564, 158–161. [Google Scholar] [CrossRef]

- Lin, T.G.; Wang, L.P.; Wang, X.F.; Zhang, Y.F.; Yu, Y.H. Influence of bias voltage on microstructure and phase transition properties of VO2 thin film synthesized by HiPIMS. Surf. Coat. Technol. 2016, 305, 110–115. [Google Scholar] [CrossRef]

- Silversmit, G.; Depla, D.; Poelman, H.; Marin, G.B.; Gryse, R.D. Determination of the V2p XPS binding energies for different vanadium oxidation states (V5+ to V0+). J. Electron Spectrosc. 2004, 135, 167–175. [Google Scholar] [CrossRef]

- Zhu, M.D.; Qi, H.J.; Li, C.; Wang, B.; Wang, H.; Guan, T.R.; Zhang, D.P. VO2 thin films with low phase transition temperature grown on ZnO/glass by applying substrate DC bias at low temperature of 250 °C. Appl. Surf. Sci. 2018, 453, 23–30. [Google Scholar] [CrossRef]

- Wu, Y.F.; Fan, L.L.; Huang, W.F.; Chen, S.M.; Chen, S.; Chen, F.H.; Zou, C.W.; Wu, Z.Y. Depressed transition temperature of WxV1-xO2: Mechanistic insights from the X-ray absorption fine structure (XAFS) spectroscopy. Phys. Chem. Chem. Phys. 2014, 16, 17705–17714. [Google Scholar] [CrossRef] [PubMed]

- Pan, M.; Zhong, H.M.; Wang, S.W.; Liu, J.; Li, Z.F.; Chen, X.S.; Lu, W. Properties of VO2 thin film prepared with precursor VO (acac) (2). J. Cryst. Growth 2004, 265, 121–126. [Google Scholar] [CrossRef]

- Ye, J.W.; Zhou, L.; Liu, F.J.; Qi, J.; Gong, W.T.; Lin, Y.; Ning, G.L. Properties of thermochromic tungsten-doped vanadium dioxide by thermal reduction and annealing. J. Alloys Compd. 2010, 504, 503–507. [Google Scholar] [CrossRef]

- Zhu, M.D.; Qi, H.J.; Wang, B.; Wang, H.; Guan, T.R.; Zhang, D.P. Thermochromism of vanadium dioxide films controlled by the thickness of ZnO buffer layer under low substrate temperature. J. Alloys Compd. 2018, 740, 844–851. [Google Scholar] [CrossRef]

- Piccirillo, C.; Binions, R.; Parkin, I.P. Synthesis and characterisation of W-doped VO2 by Aerosol Assisted Chemical Vapour Deposition. Thin Solid Films 2008, 516, 1992–1997. [Google Scholar] [CrossRef]

- Manning, T.D.; Parkin, I.P.; Pemble, M.E.; Sheel, D.; Dimitra, V. Intelligent Window Coatings: Atmospheric Pressure Chemical Vapor Deposition of Tungsten-Doped Vanadium Dioxide. Chem. Mater. 2004, 16, 744–749. [Google Scholar] [CrossRef]

- Natoli, J.Y.; Gallais, L.; Akhouayri, H.; Amra, C. Laser-induced damage of materials in bulk, thin-film, and liquid forms. Appl. Opt. 2002, 41, 3156–3166. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.M. Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt. Lett. 1982, 7, 196–198. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Qi, H.J.; Zhao, J.L.; Wang, B.; Shao, J.D. Transition from isolated submicrometer pits to integral ablation of HfO2 and SiO2 films under subpicosecond irradiation. Opt. Commun. 2017, 387, 214–222. [Google Scholar] [CrossRef]

- Yuan, L. Comparison of femtosecond and nanosecond laser-induced damage in HfO2 single-layer film and HfO2-SiO2 high reflector. J. Opt. Soc. Am. B 2007, 24, 538–543. [Google Scholar] [CrossRef]

- Laurence, T.A.; Negres, R.A.; Ly, S.; Shen, N.; Carr, C.W.; Alessi, D.A.; Rigatti, A.; Bude, J.D. Role of defects in laser-induced modifications of silica coatings and fused silica using picosecond pulses at 1053 nm: II. Scaling laws and the density of precursors. Opt. Express 2017, 25, 15381–15401. [Google Scholar] [CrossRef] [PubMed]

- Gallais, L.; Capoulade, J.; Natoli, J.Y.; Commandré, M. Investigation of nanodefect properties in optical coatings by coupling measured and simulated laser damage statistics. J. Appl. Phys. 2008, 104, 053120. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, M.-D.; Shan, C.; Li, C.; Wang, H.; Qi, H.-J.; Zhang, D.-P.; Lv, W.Z. Thermochromic and Femtosecond-Laser-Induced Damage Performance of Tungsten-Doped Vanadium Dioxide Films Prepared Using an Alloy Target. Materials 2018, 11, 1724. https://doi.org/10.3390/ma11091724

Zhu M-D, Shan C, Li C, Wang H, Qi H-J, Zhang D-P, Lv WZ. Thermochromic and Femtosecond-Laser-Induced Damage Performance of Tungsten-Doped Vanadium Dioxide Films Prepared Using an Alloy Target. Materials. 2018; 11(9):1724. https://doi.org/10.3390/ma11091724

Chicago/Turabian StyleZhu, Mao-Dong, Chong Shan, Cheng Li, Hu Wang, Hong-Ji Qi, Dong-Ping Zhang, and Wei Zhong Lv. 2018. "Thermochromic and Femtosecond-Laser-Induced Damage Performance of Tungsten-Doped Vanadium Dioxide Films Prepared Using an Alloy Target" Materials 11, no. 9: 1724. https://doi.org/10.3390/ma11091724

APA StyleZhu, M.-D., Shan, C., Li, C., Wang, H., Qi, H.-J., Zhang, D.-P., & Lv, W. Z. (2018). Thermochromic and Femtosecond-Laser-Induced Damage Performance of Tungsten-Doped Vanadium Dioxide Films Prepared Using an Alloy Target. Materials, 11(9), 1724. https://doi.org/10.3390/ma11091724