Effects of Heating Mode and Temperature on the Microstructures, Electrical and Optical Properties of Molybdenum Thin Films

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

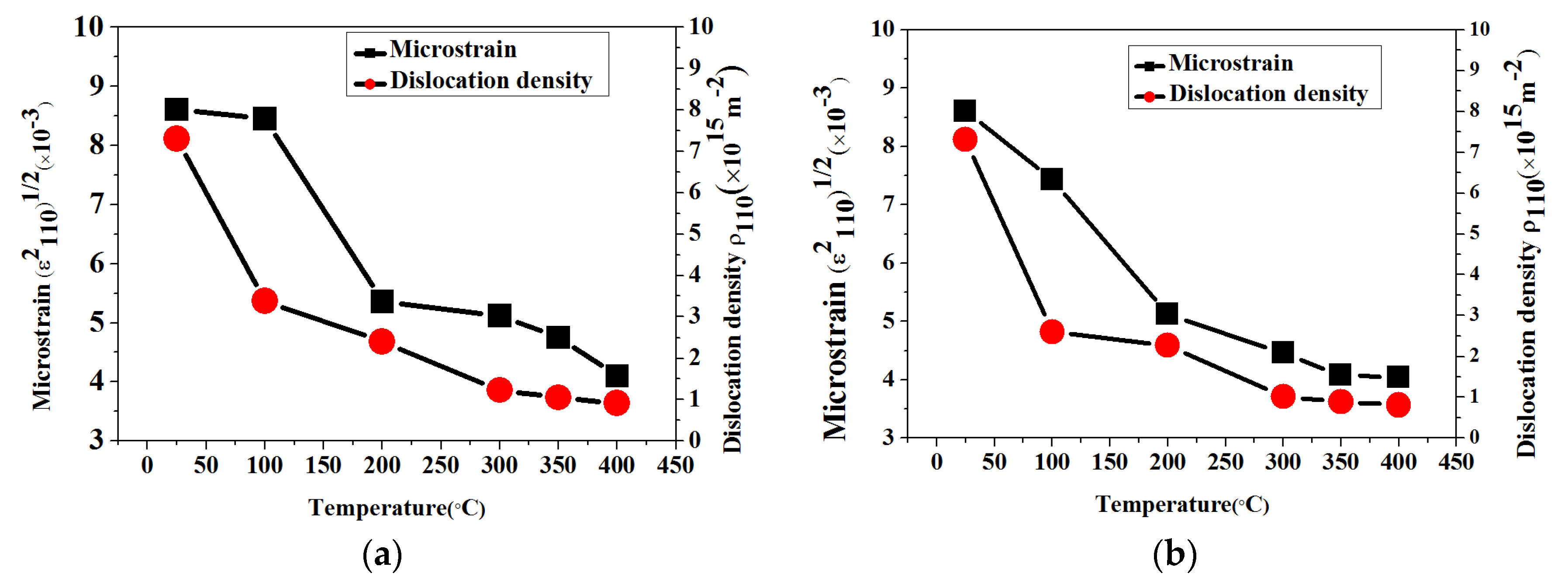

3.1. The Effects of Heating Mode and Temperature on Crystal Structures of Films

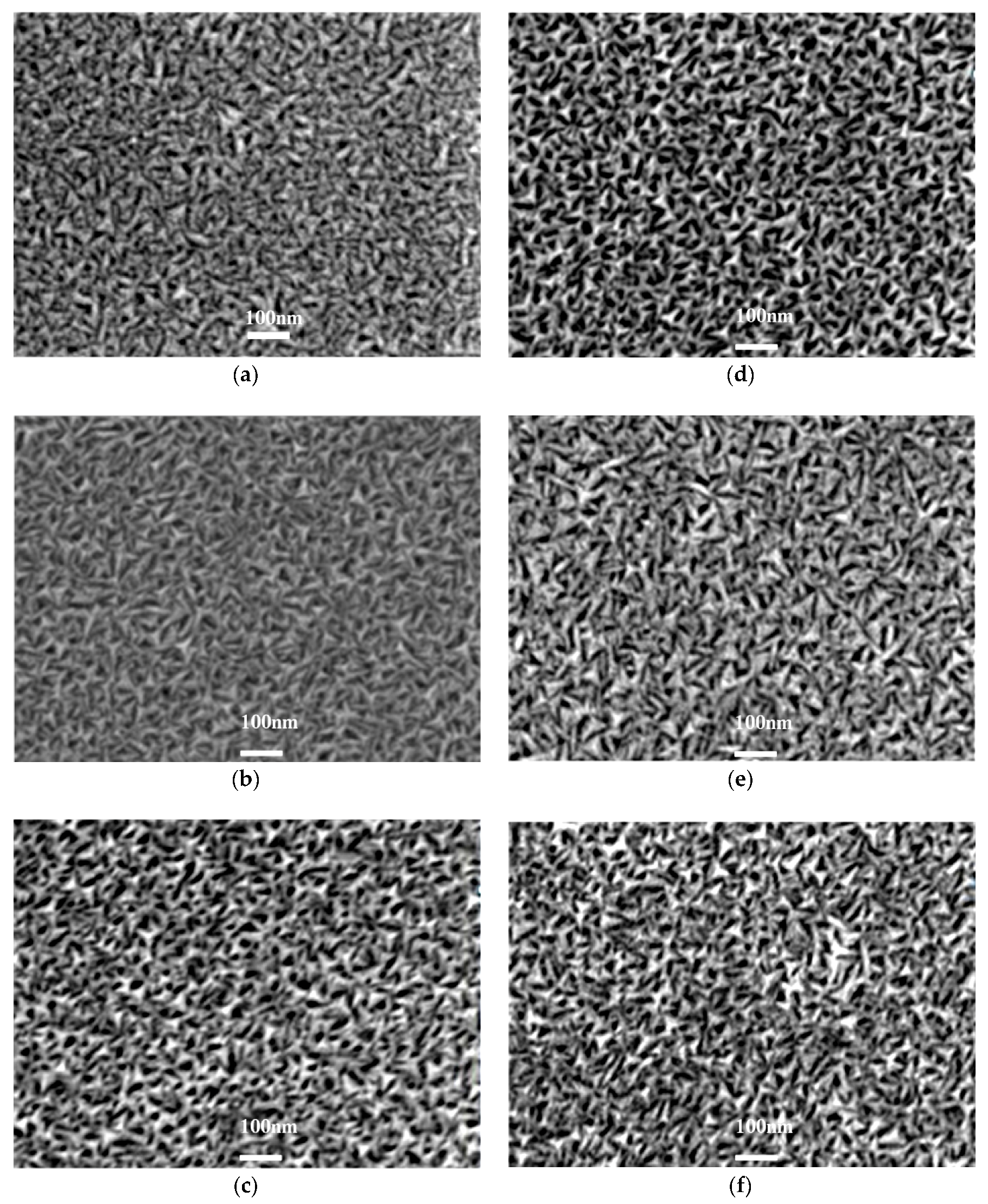

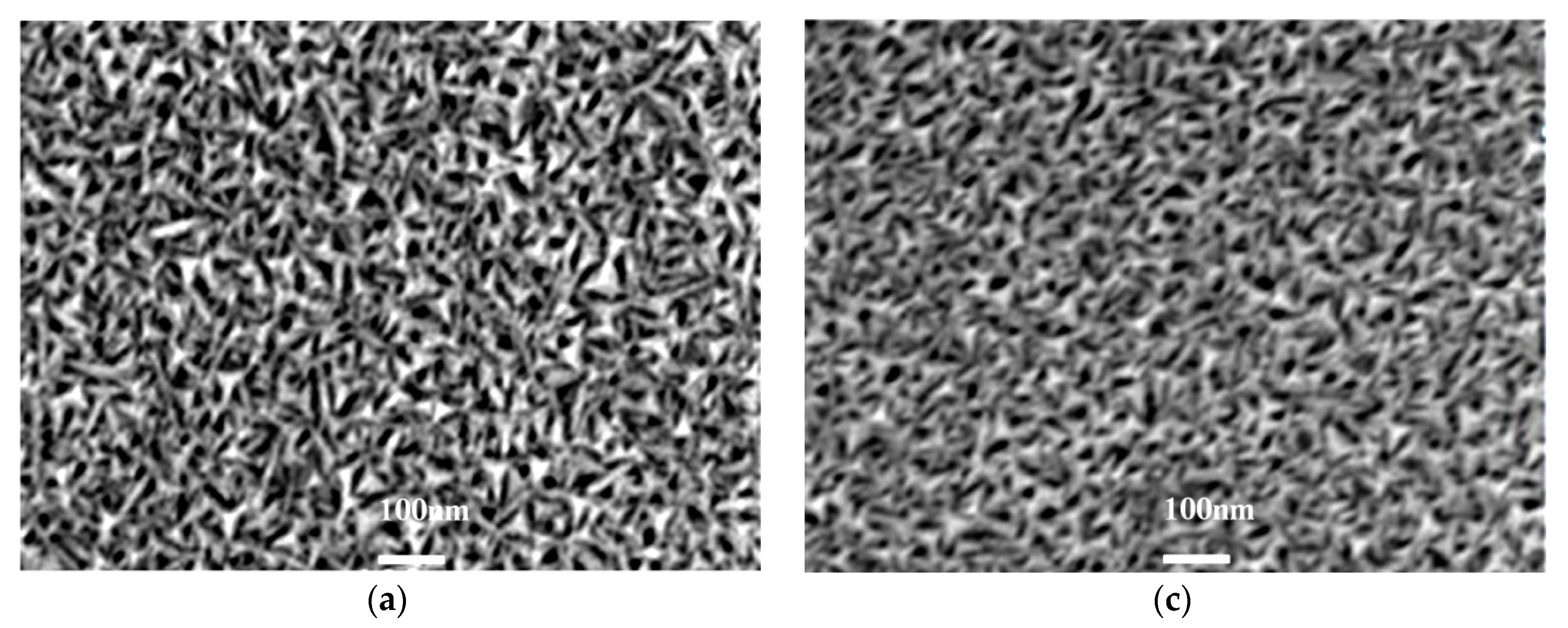

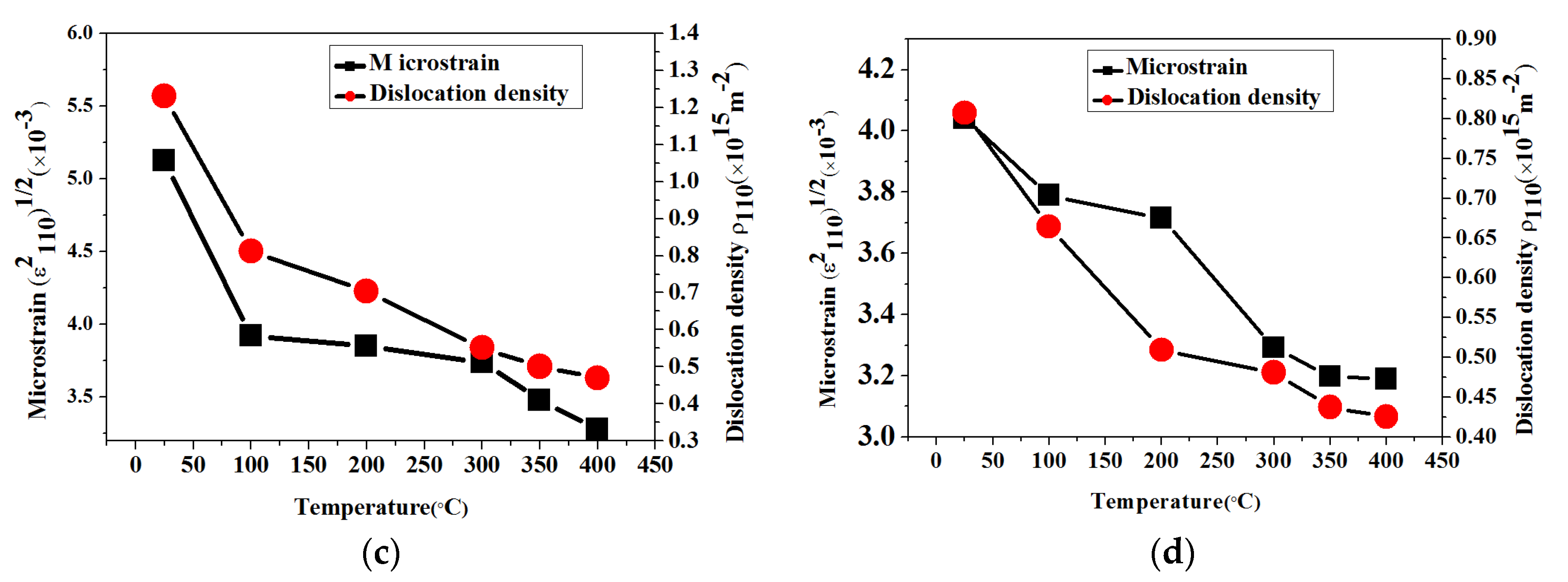

3.2. The Effects of Heating Modes and Temperature on the Morphologies of Mo Thin Films

3.3. The Effects of Heating Mode and Temperature on Electrical Properties

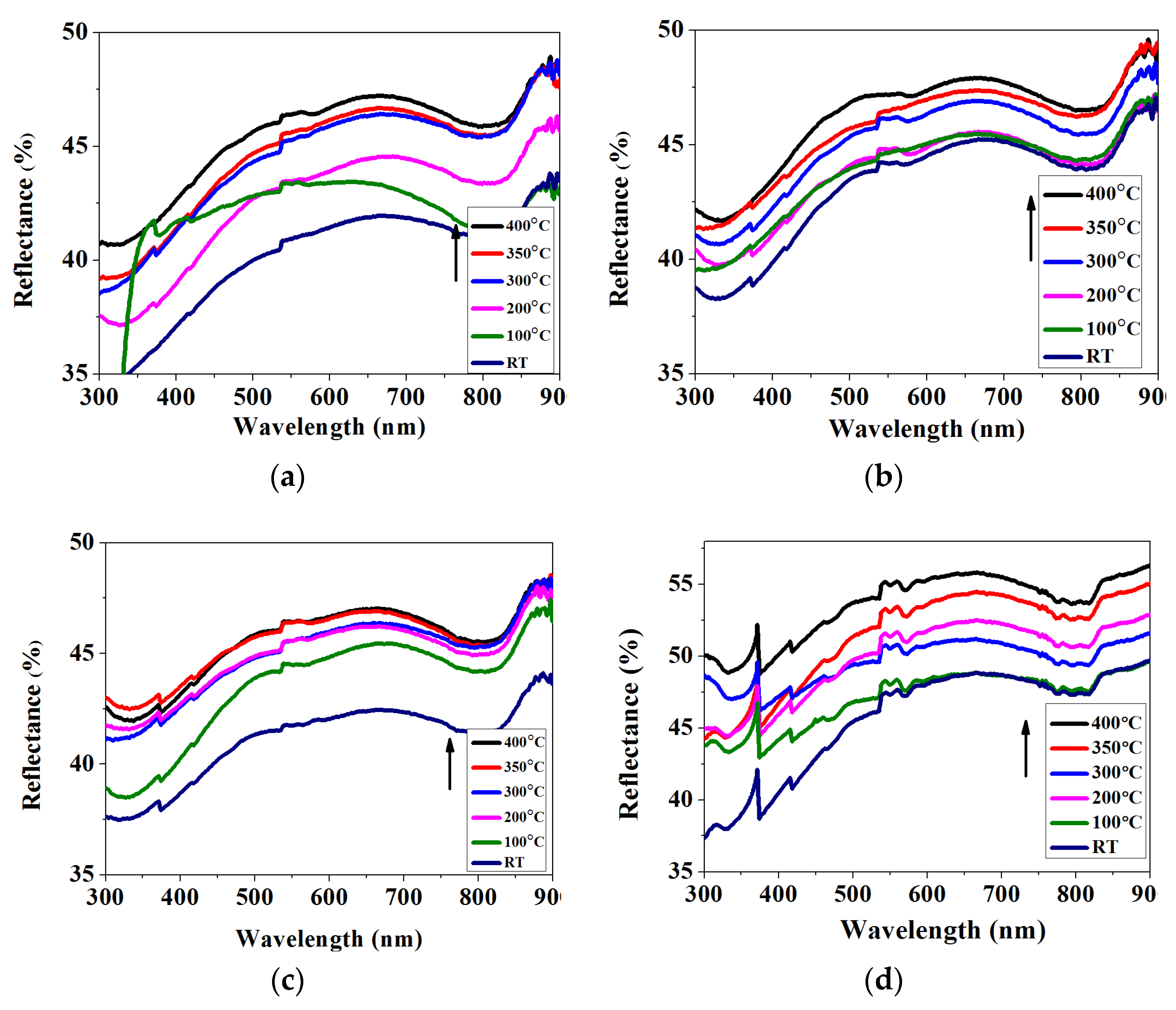

3.4. The Effects of Heating Modes and Temperature on Optical Properties of Mo Thin Films

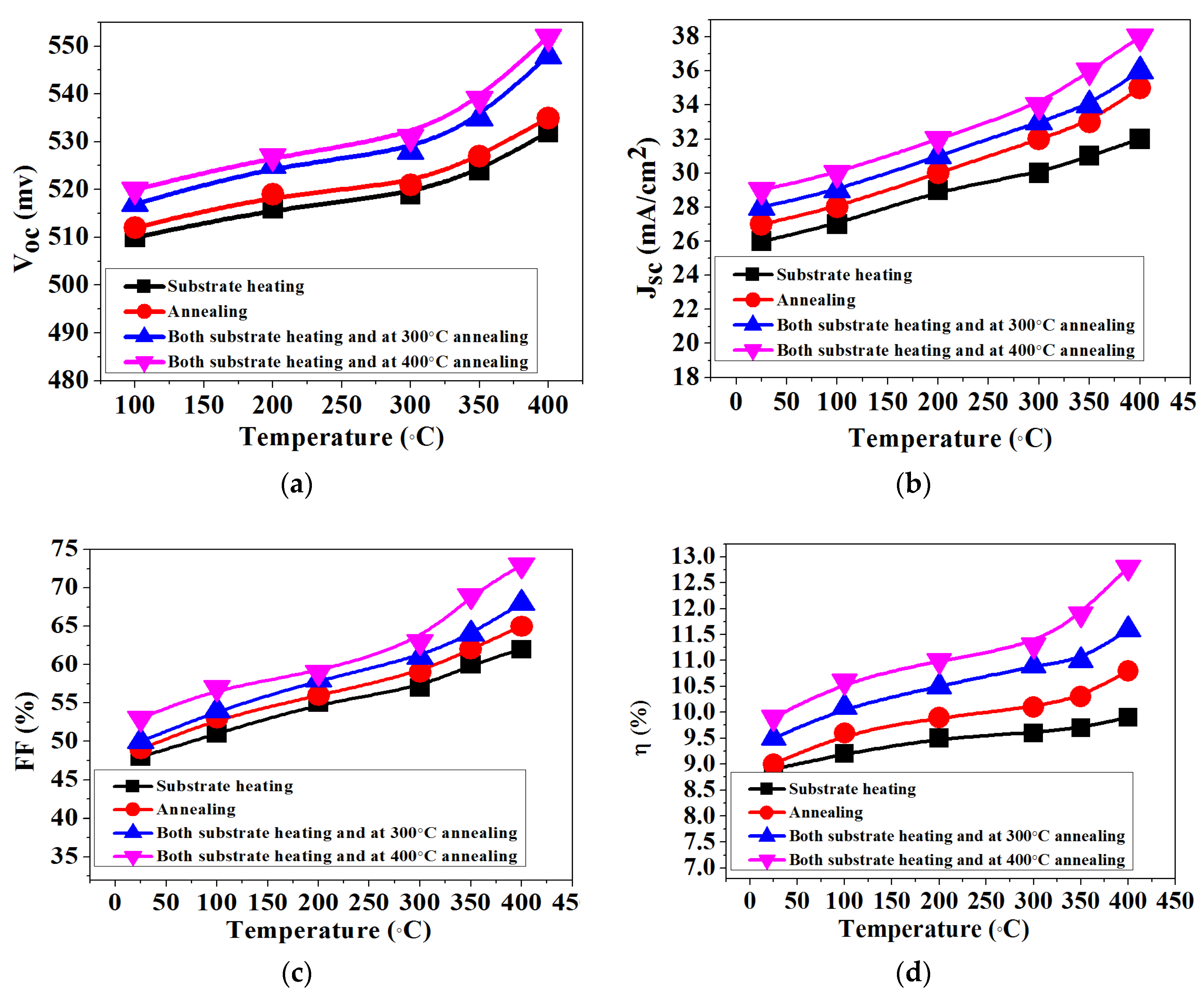

3.5. The Effects of Heating Modes and Temperature on CIGS Solar Cell

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kohara, N.; Nishiwaki, S.; Hashimoto, Y.; Negami, T.; Wada, T. Electrical properties of the Cu(In,Ga)Se2/MoSe2/Mo structure. Sol. Energy Mater. Sol. Cells 2001, 67, 209–215. [Google Scholar] [CrossRef]

- Orgassa, K.; Schock, H.W.; Werner, J.H. Alternative back contactmaterials for thin film Cu(In,Ga)Se2 solar cells. Thin Solid Films 2003, 431, 387–391. [Google Scholar] [CrossRef]

- Yoon, J.H.; Kim, W.M.; Park, J.K.; Baik, Y.J.; Seong, T.Y.; Jeong, J.H. Control of the preferred orientations of Cu(In,Ga)Se2 films and the photovoltaic conversion efficiency using a surface-functionalized molybdenum back contact. Prog. Photovolt. Res. Appl. 2014, 22, 69–76. [Google Scholar] [CrossRef]

- Lepetit, T.; Mangin, D.; Gautron, E. Impact of DC-power during Mo back contact sputtering on the alkali distribution in Cu(In,Ga)Se2-based thin film solar cells. Thin Solid Film 2015, 582, 304–307. [Google Scholar] [CrossRef]

- Lin, Y.C.; Hong, D.H.; Hsieh, Y.T.; Wang, L.C.; Hsu, H.R. Role of Mo: Na layer on the formation of MoSe2 phase in Cu(In,Ga)Se2 thin film solar cells. Sol. Energy Mater. Sol. Cells 2016, 155, 226–233. [Google Scholar] [CrossRef]

- Koike, J.; Chino, K.; Aihara, N.; Aihara, H. Cu2SnS3 thin-film solar cells from electroplated precursors. J. Appl. Phys. 2012, 51, 1753–1756. [Google Scholar] [CrossRef]

- Sinsermsuksakul, P.; Hartman, K.; Kim, S.B.; Heo, J.; Sun, L.; Park, H.H.; Chakraborty, R.; Buonassisi, T.; Gordon, R.G. Enhancing the efficiency of SnS solar cells via band-offset engineering with a zinc oxysulfide buffer layer. Appl. Phys. Lett. 2013, 102, 2072–2077. [Google Scholar] [CrossRef]

- Wang, K.C.; Hsu, H.R.; Chen, H.S. Study of surface sulfurization of Cu2ZnSn(S,Se)4 thin film solar cell by sequential H2Se-selenization/H2S-sulfurization. Sol. Energy Mater. Sol. Cells 2017, 163, 31–37. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wang, L.C.; Liu, K.T.; Syu, Y.R.; Hsu, H.R. A comparative investigation of secondary phases and MoSe2 in Cu2ZnSnSe4 solar cells: Effect of Zn/Sn ratio. J. Alloys Compd. 2018, 743, 249–257. [Google Scholar] [CrossRef]

- Zhou, D.; Zhu, H.; Liang, X. Sputtered molybdenum thin films and the application in CIGS solar cells. Appl. Surf. Sci. 2016, 362, 202–209. [Google Scholar] [CrossRef]

- Huang, P.C.; Sung, C.C.; Chen, J.H.; Huang, C.H.; Hsu, C.Y. The optimization of a Mo bilayer and its application in Cu(In, Ga)Se2 solar cells. Appl. Surf. Sci. 2017, 425, 24–31. [Google Scholar] [CrossRef]

- Huang, Y.; Gao, S.; Tang, Y.; Ao, J.; Yuan, W.; Lu, L. The multi-functional stack design of a molybdenum back contact prepared by pulsed DC magnetron sputtering. Thin Solid Films 2016, 616, 820–827. [Google Scholar] [CrossRef]

- Akçay, N.; Akın, N.; Cömert, B.; Özçelik, S. Temperature effects on the structural, optical, electrical and morphological properties of the RF-sputtered Mo thin films. J. Mater. Sci. Mater. Electron. 2017, 28, 399–406. [Google Scholar] [CrossRef]

- Zoppi, G.; Beattie, N.S.; Major, J.D.; Miles, R.W.; Forbes, I. Electrical, morphological and structural properties of RF magnetron sputtered Mo thin films for application in thin film photovoltaic solar cells. J. Mater. Sci. 2011, 46, 4913–4921. [Google Scholar] [CrossRef]

- Gabor, A.M.; Tuttle, J.R.; Bode, M.H.; Franz, A.; Tennant, A.L.; Contreras, M.A.; Noufi, R.; Jensen, D.G.; Hermann, A.M. Bandgap engineering in Cu(In,Ga)Se2 thin films grown from (In,Ga)2Se3 precursors. Sol. Energy Mater. Sol. Cells 1996, 41–42, 247–260. [Google Scholar] [CrossRef]

- Patterson, A.L. The Scherrer formula for X-ray particle size determination. Phys. Rev. 1939, 56, 978–982. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag. 1956, 1, 34–36. [Google Scholar] [CrossRef]

- Pethe, S.A.; Takahashi, E.; Kaul, A.; Dhere, N.G. Effect of sputtering process parameters on film properties of molybdenum back contact. Sol. Energy Mater. Sol. Cells 2012, 100, 1–5. [Google Scholar] [CrossRef]

- Phuan, Y.W.; Chong, M.N.; Zhu, T.; Yong, S.T.; Chan, E.S. Effects of annealing temperature on the physicochemical, optical and photoelectrochemical properties of nanostructured hematite thin films prepared via electrodeposition method. Mater. Res. Bull. 2015, 69, 71–77. [Google Scholar] [CrossRef]

- Jubault, M.; Ribeaucourt, L.; Chassaing, E.; Renou, G.; Lincot, D.; Donsanti, F. Optimization of molybdenum thin films for electrodeposited CIGS solar cells. Sol. Energy Mater. Sol. Cells 2011, 95, 26–31. [Google Scholar] [CrossRef]

- Vergara, L.; Olivares, J.; Iborra, E.; Clement, M.; Sanz-Hervás, A.; Sangrador, J. Effect of rapid thermal annealing on the crystal quality and the piezoelectric response of polycrystalline AlN films. Thin Solid Films 2006, 515, 1814–1818. [Google Scholar] [CrossRef]

- Robbemond, A.; Thijsse, B.J. Ion-beam assisted deposition of thin molybdenum films studied by molecular dynamics simulation. Nucl. Instr. Meth. Phys. Res. B 1997, 127, 273–277. [Google Scholar] [CrossRef]

- Scofield, J.H.; Duda, A.; Albin, D.; Ballard, B.L.; Predecki, P.K. Sputtered molybdenum bilayer back contact for copper indium diselenide-based polycrystalline thin-film solar cells. Thin Solid Films 1995, 260, 26–31. [Google Scholar] [CrossRef]

- Khatri, H.; Marsillac, S. The effect of deposition parameters on radiofrequency sputtered molybdenum thin films. J. Phys. Condens. Matter 2008, 20, 192–201. [Google Scholar] [CrossRef]

- Malhotra, S.G.; Rek, Z.U.; Yalisove, S.M.; Bilello, J.C. Strain gradients and normal stresses in textured Mo thin films. J. Vac. Sci. Technol. A Vac. Surf. Films 1997, 15, 345–352. [Google Scholar] [CrossRef]

- Chelvanathan, P.; Zakaria, Z.; Yusoff, Y. Annealing effect in structural and electrical properties of sputtered Mo thin film. Appl. Surf. Sci. 2015, 334, 129–137. [Google Scholar] [CrossRef]

- Brown, R.A. Electrical resistivity of dislocations in metals. J. Phys. F Met. Phys. 2001, 7, 1477–1488. [Google Scholar] [CrossRef]

- Rafaja, D.; Köstenbauer, H.; Mühle, U. Effect of the deposition process and substrate temperature on the microstructure defects and electrical conductivity of molybdenum thin films. Thin Solid Films 2013, 528, 42–48. [Google Scholar] [CrossRef]

- Ungár, T.; Dragomir, I.; Révész, Á.; Borbély, A. The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice. J. Appl. Crystallogr. 1999, 32, 992–1002. [Google Scholar] [CrossRef]

- Wilkens, M. The determination of density and distribution of dislocations in deformed single crystals from broadened X-ray diffraction profiles. Phys. Status Solidi A 1970, 2, 359–370. [Google Scholar] [CrossRef]

- Watts, B.R. The contribution of the long-range strain field of dislocations in metals to their electrical resistivity. J. Phys. F Met. Phys. 1988, 18, 1183–1195. [Google Scholar] [CrossRef]

- Yoon, J.H.; Cho, S.; Kim, W.M. Optical analysis of the microstructure of a Mo back contact for Cu(In,Ga)Se2 solar cells and its effects on Mo film properties and Na diffusivity. Sol. Energy Mater. Sol. Cells 2011, 95, 2959–2964. [Google Scholar] [CrossRef]

- Poncelet, O.; Kotipalli, R.; Vermang, B.; Macleod, A.; Francis, L.A.; Flandre, D. Optimisation of rear reflectance in ultra-thin CIGS solar cells towards >20% efficiency. Sol. Energy 2017, 146, 443–452. [Google Scholar] [CrossRef]

- Xu, Y.J.; Cai, Q.W.; Yang, X.X.; Zuo, Y.Z.; Song, H.; Liu, Z.M.; Hang, Y.P. Preparation of novel SiO2 protected Ag thin films with high reflectivity by magnetron sputtering for solar front reflectors. Sol. Energy Mater. Sol. Cells 2012, 316–321. [Google Scholar] [CrossRef]

| Sample Identification | Substrate Temperature (°C) | Post Annealing Temperature (°C) | Lattice Parameter (Å) | Grain Size (nm) | Intensity of (110) Peak | Strain (%) | Adhesion (Pass/Fail) |

|---|---|---|---|---|---|---|---|

| A-0 | RT | --- | 3.1592 | 11.7 | 904 | 0.3813 | Pass |

| A-1 | 100 | --- | 3.1581 | 17.2 | 1210 | 0.3495 | Pass |

| A-2 | 200 | --- | 3.1570 | 20.4 | 1224 | 0.3178 | Pass |

| A-3 | 300 | --- | 3.1562 | 28.5 | 3403 | 0.2860 | Pass |

| A-4 | 350 | --- | 3.1553 | 30.9 | 3706 | 0.2542 | Pass |

| A-5 | 400 | --- | 3.1544 | 33.1 | 4569 | 0.2224 | Pass |

| B-0 | --- | RT | 3.1592 | 11.7 | 904 | 0.3813 | Pass |

| B-1 | --- | 100 | 3.1554 | 19.6 | 1332 | 0.2542 | Pass |

| B-2 | --- | 200 | 3.1531 | 21.0 | 1456 | 0.1907 | Pass |

| B-3 | --- | 300 | 3.1522 | 31.3 | 3608 | 0.1589 | Pass |

| B-4 | --- | 350 | 3.1483 | 33.6 | 4735 | 0.0318 | Pass |

| B-5 | --- | 400 | 3.1441 | 35.2 | 5062 | −0.105 | Pass |

| C-1 | 100 | 300 | 3.1531 | 35.1 | 3623 | 0.1907 | Pass |

| C-2 | 200 | 300 | 3.1524 | 37.7 | 6501 | 0.1589 | Pass |

| C-3 | 300 | 300 | 3.1512 | 42.6 | 6806 | 0.1271 | Pass |

| C-4 | 350 | 300 | 3.1472 | 44.7 | 8215 | 0.0000 | Pass |

| C-5 | 400 | 300 | 3.1434 | 46.1 | 8502 | −0.127 | Pass |

| D-1 | 100 | 400 | 3.1482 | 38.8 | 5831 | 0.0318 | Pass |

| D-2 | 200 | 400 | 3.1451 | 44.3 | 6012 | −0.064 | Pass |

| D-3 | 300 | 400 | 3.1447 | 45.6 | 8326 | −0.075 | Pass |

| D-4 | 350 | 400 | 3.1446 | 47.8 | 8893 | −0.076 | Pass |

| D-5 | 400 | 400 | 3.1430 | 48.5 | 9229 | −0.127 | Pass |

| Sample Identification | Grain Size (nm) | Resistivity (×10−5 Ω·cm) | Hall Mobility (cm2/Vs) | Carrier Concentration (1022 cm−3) | RMS Roughness (nm) |

|---|---|---|---|---|---|

| A-0 | 11.7 | 3.50 | 7.95 | 10.87 | 2.36 |

| A-1 | 17.2 | 3.28 | 8.21 | 11.28 | 3.03 |

| A-2 | 20.4 | 3.03 | 8.88 | 12.01 | 3.62 |

| A-3 | 28.5 | 2.86 | 9.00 | 12.86 | 3.95 |

| A-4 | 30.9 | 2.62 | 9.16 | 13.24 | 4.02 |

| A-5 | 33.1 | 2.50 | 9.31 | 13.56 | 4.35 |

| B-0 | 11.7 | 3.50 | 8.32 | 12.69 | 2.36 |

| B-1 | 19.6 | 3.15 | 8.65 | 12.01 | 3.38 |

| B-2 | 21.0 | 3.00 | 8.96 | 12.63 | 3.83 |

| B-3 | 31.3 | 2.58 | 9.20 | 13.41 | 4.26 |

| B-4 | 33.6 | 2.45 | 9.66 | 13.80 | 4.53 |

| B-5 | 35.2 | 2.32 | 9.98 | 13.96 | 4.31 |

| C-1 | 35.1 | 2.35 | 10.22 | 14.03 | 4.30 |

| C-2 | 37.7 | 2.01 | 11.12 | 14.85 | 4.85 |

| C-3 | 42.6 | 1.86 | 11.35 | 15.32 | 5.26 |

| C-4 | 44.7 | 1.66 | 11.98 | 16.02 | 5.48 |

| C-5 | 46.1 | 1.52 | 12.36 | 17.29 | 5.60 |

| D-1 | 38.8 | 1.99 | 10.54 | 15.02 | 4.90 |

| D-2 | 44.3 | 1.72 | 11.36 | 15.58 | 5.46 |

| D-3 | 45.6 | 1.58 | 12.65 | 16.95 | 5.52 |

| D-4 | 47.8 | 1.49 | 12.88 | 17.78 | 6.01 |

| D-5 | 48.5 | 1.36 | 13.62 | 17.82 | 6.24 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Xie, J.; Mao, A.; Wang, A.; Chen, Y.; Liang, T.; Ma, D. Effects of Heating Mode and Temperature on the Microstructures, Electrical and Optical Properties of Molybdenum Thin Films. Materials 2018, 11, 1634. https://doi.org/10.3390/ma11091634

Zhao H, Xie J, Mao A, Wang A, Chen Y, Liang T, Ma D. Effects of Heating Mode and Temperature on the Microstructures, Electrical and Optical Properties of Molybdenum Thin Films. Materials. 2018; 11(9):1634. https://doi.org/10.3390/ma11091634

Chicago/Turabian StyleZhao, Haili, Jingpei Xie, Aixia Mao, Aiqin Wang, Yanfang Chen, Tingting Liang, and Douqin Ma. 2018. "Effects of Heating Mode and Temperature on the Microstructures, Electrical and Optical Properties of Molybdenum Thin Films" Materials 11, no. 9: 1634. https://doi.org/10.3390/ma11091634

APA StyleZhao, H., Xie, J., Mao, A., Wang, A., Chen, Y., Liang, T., & Ma, D. (2018). Effects of Heating Mode and Temperature on the Microstructures, Electrical and Optical Properties of Molybdenum Thin Films. Materials, 11(9), 1634. https://doi.org/10.3390/ma11091634