3.1. Microstructure

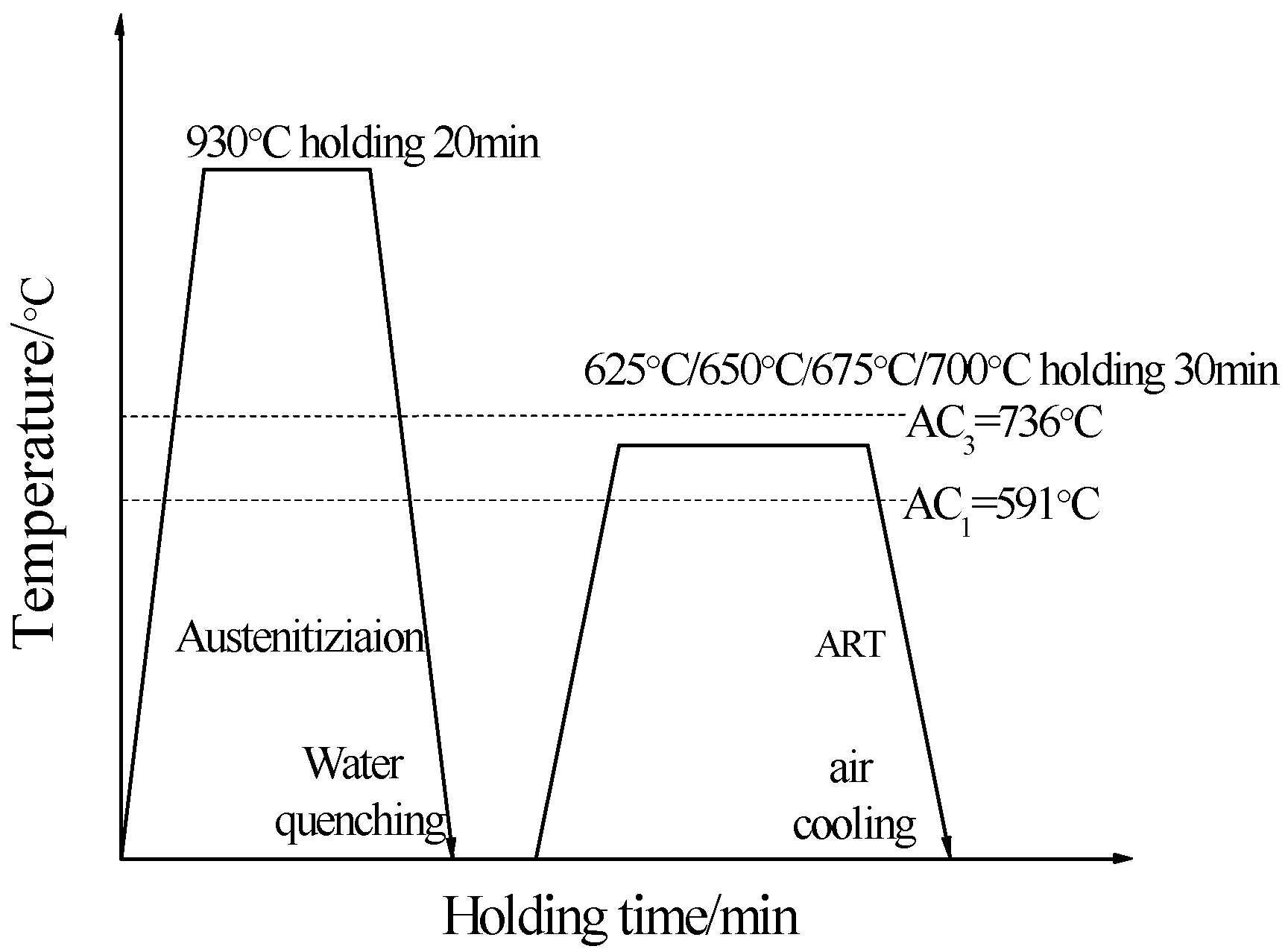

Figure 2 depicts an SEM image of studied steel after the reverse-phase transformation annealing at 625, 650, 675 and 700 °C.

Figure 2a shows the SEM image of studied steel after austenitizing water quenching at 930 °C with 20 min. It could be found that the microstructure after quenching is complete lath martensite. It can be seen that there are small amounts of dark black martensite lath bundles and a small amount of carbides in the bundle. Meanwhile, no austenite microstructure is discovered. From

Figure 2b, we can conclude that after quenching and annealing at 625 °C, the lath martensite still exists. When reverse-phase transformation annealing occurs in the two-phase region, the quenched martensite lath is broken to form the annealed martensite (ultra-fine grained ferrite), and a small quantity of carbides are precipitated on the ferrite grain boundary while no carbides are found in the lath martensite bundle. Meanwhile, the volume fraction of austenite after annealing at 625 °C is 5.09% and the percent of the content is relatively low. This is because that annealing at 625 °C, it will generate a large number of carbide precipitation and the precipitation is not completely dissolved, however, the austenite volume fraction still maintains at 5.09%. Most nucleation regions of austenite are dissolved in ferritic crystal and carbide, however, a large amount of carbides in

Figure 2b are concentrated on ferritic grain boundary and a small amount of carbides are dissolved in ferritic crystal to form a small amount of austenite [

14]. As the annealing temperature raises to 650 °C, the lath martensite is almost completely broken to form ultra-fine grained ferrite, as shown in

Figure 2c. The strip austenite is shown up in the lath beam of lath martensite, and the austenite volume fraction austenite is 10.39%. However, with the increase of the annealing temperature, the carbides do not dissolve completely and, instead, a small amount of them are distributed in the ferrite crystal. As the annealing temperature goes up to 675 °C, the austenite lath becomes wider and the same strip bundle of austenite is combined to form bulk austenite, and the volume fraction is increased into 22.34%, as illustrated in

Figure 2d. At the same time, the components of the microstructure are ultra-fine grained ferrite, bulk and strip austenite and not completely broken lath martensite. As the annealing temperature raises up to 700 °C, martensite rapidly transforms into austenite, because such temperature is close to the austenite single-phase region temperature. It is believed that the higher annealing temperature, the bigger the austenite volume fraction. With the increment of the temperature, the diffusion rate of C and Mn elements is increased so that the average C and Mn content in austenite decreases [

11,

15]. Under this situation, the stability of austenite decreases significantly and the volume fraction of austenite reduces from 22.34% to 9.32%. Finally, martensite is formed during the cooling process [

11]. The final microstructure at 700 °C incorporates ultra-fine grained ferrite, lath martensite and a small amount of austenites, as shown in

Figure 2e.

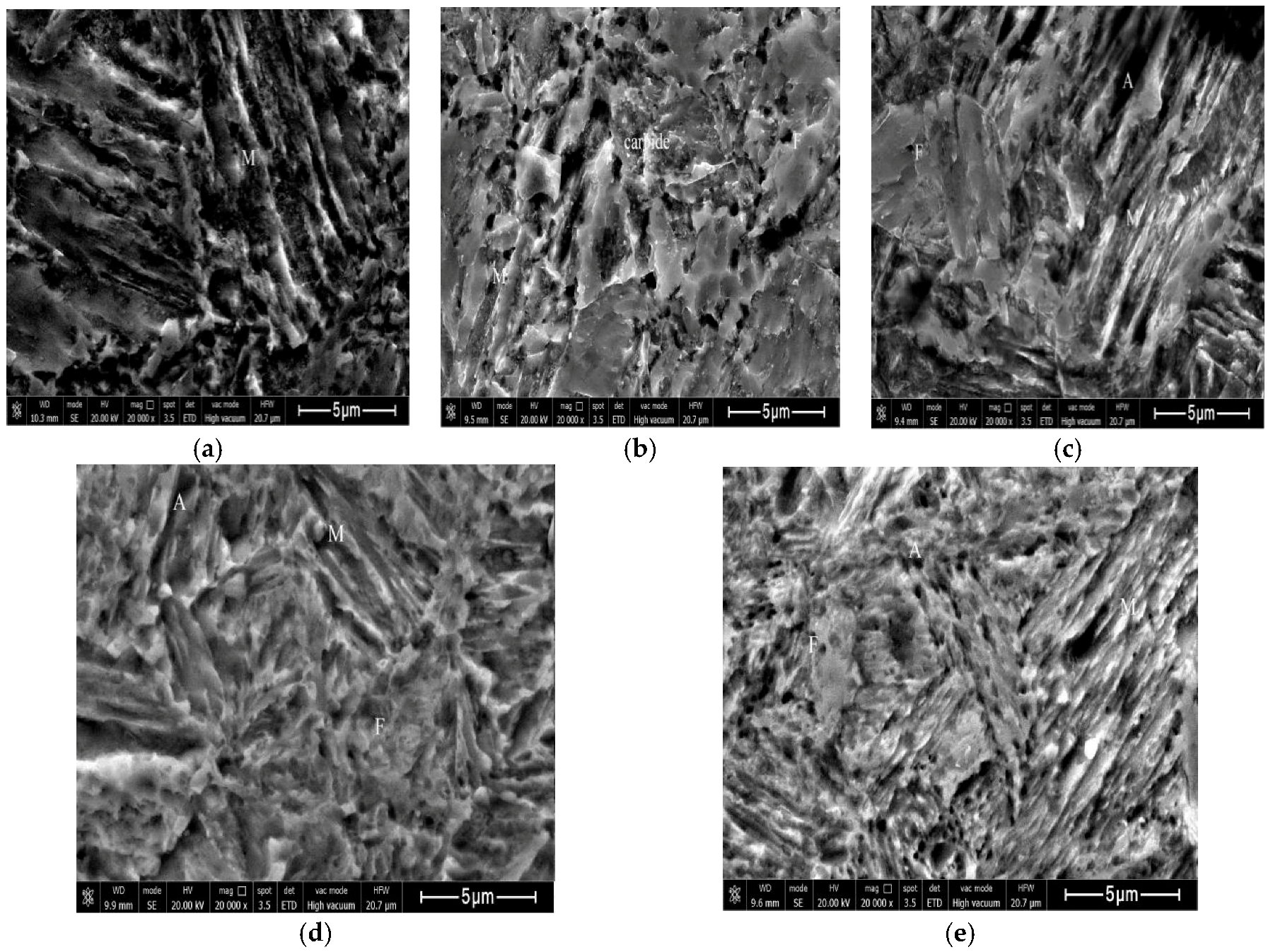

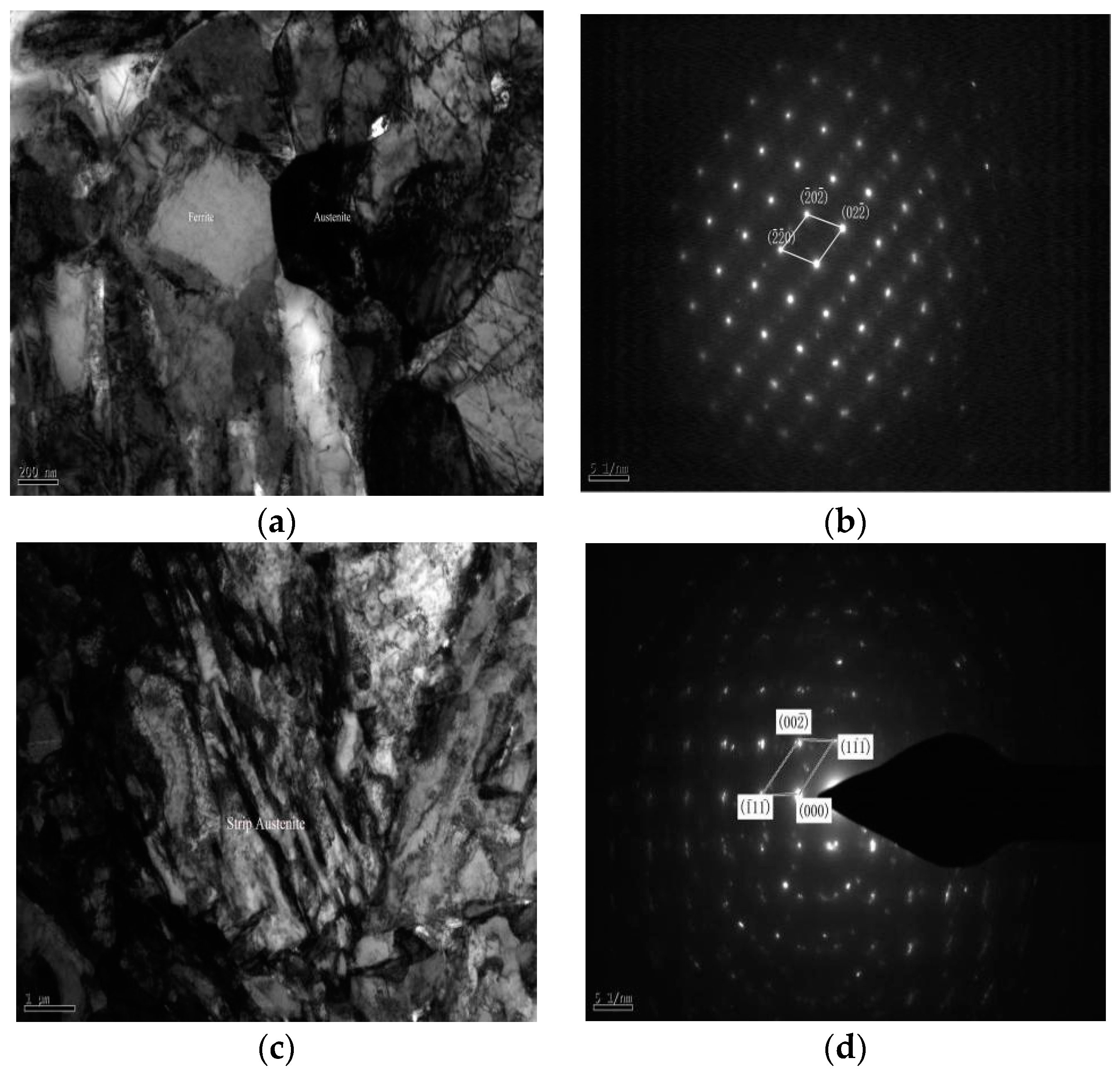

Figure 3 depicts the TEM image of studied steel after the reverse annealing at different temperatures of 650, 675 and 700 °C with austenitizing water quenching at 930 °C.

Figure 3a indicates the TEM image after water quenching for 20 min at 930 °C, and we find that lath martensite microstructure is the completely thick after the water quenching, with average lath width up to 0.5 μm. There are many dislocations in the martensite lath bundle along with some dislocations slide along the dislocation lines to form multi-slip and cross-slip to form dislocation entanglement which increases the dislocation density. After quenching at a high temperature, the stacking fault energy of studied steel is relatively high, and the stacking fault is not easy to carry out. The deformation is mainly caused by dislocations, and new dislocations are formed as shown in

Figure 3a. The new dislocation resistance is small. It is necessary to form multiple slips, high stacking fault energy, easy dynamic recrystallization, and easy to slippage.

Figure 3b shows that the ultra-fine-grained ferrite after annealing at 650 °C. The average lath width is 0.19 μm while the average lath width of the unbroken martensite is 0.23 μm. There exists a large amount of carbides and acres of dislocations between the ferrite and martensite laths. The ultra-fine-grained ferrite formed after annealing is in the martensite with relatively high dislocation density. Nevertheless, after the annealing, the dislocation density of retained martensite is relatively low. It is mainly because that ultra-fine-grained ferrite is formed during reverse-phase transformation annealing and the dislocation density in martensite is low during quenching and reverse-phase transformation annealing. However, the volume expansion caused by the subsequent cooling of martensitic transformation process leads to boundaries of the ultra-fine grained ferrite and forms dislocation lines which are concentrated on the lath martensite [

16,

17].

Figure 3c demonstrates the TEM image after annealing at 675 °C. The composition of microstructure is mainly ultra-fine grained ferrite, lath martensite and austenite with different forms. The average lath width of martensite increases into 0.29 μm and plentiful of carbides are dissolved on the martensite lath bundle boundary. The dissolution of carbides provides energy for the austenite nucleation so that the austenite appears in a lath-like shape at the martensite lath bundle boundary [

14]. As the annealing temperature increases, the dislocation lines in the ferrite grain boundaries and martensite laths almost disappear. With the annealing temperature rises to 700 °C, the lath-like microstructure of alternating light and dark martensite laths are clearly visible, as revealed in

Figure 3d. The average lath width of martensite serves as 0.32 μm, and a small amount of lath martensite ruptures to form ultra-fine grained ferrite. Only a handful of austenite microstructure exists and carbide precipitation is less. As the annealing temperature increases, the dislocation lines and dislocation density decrease so that C and Mn cannot diffuse more into the austenite. Due to the inability of C, Mn elements to diffuse more into austenite which the stability is too weak to reserve to room temperature.

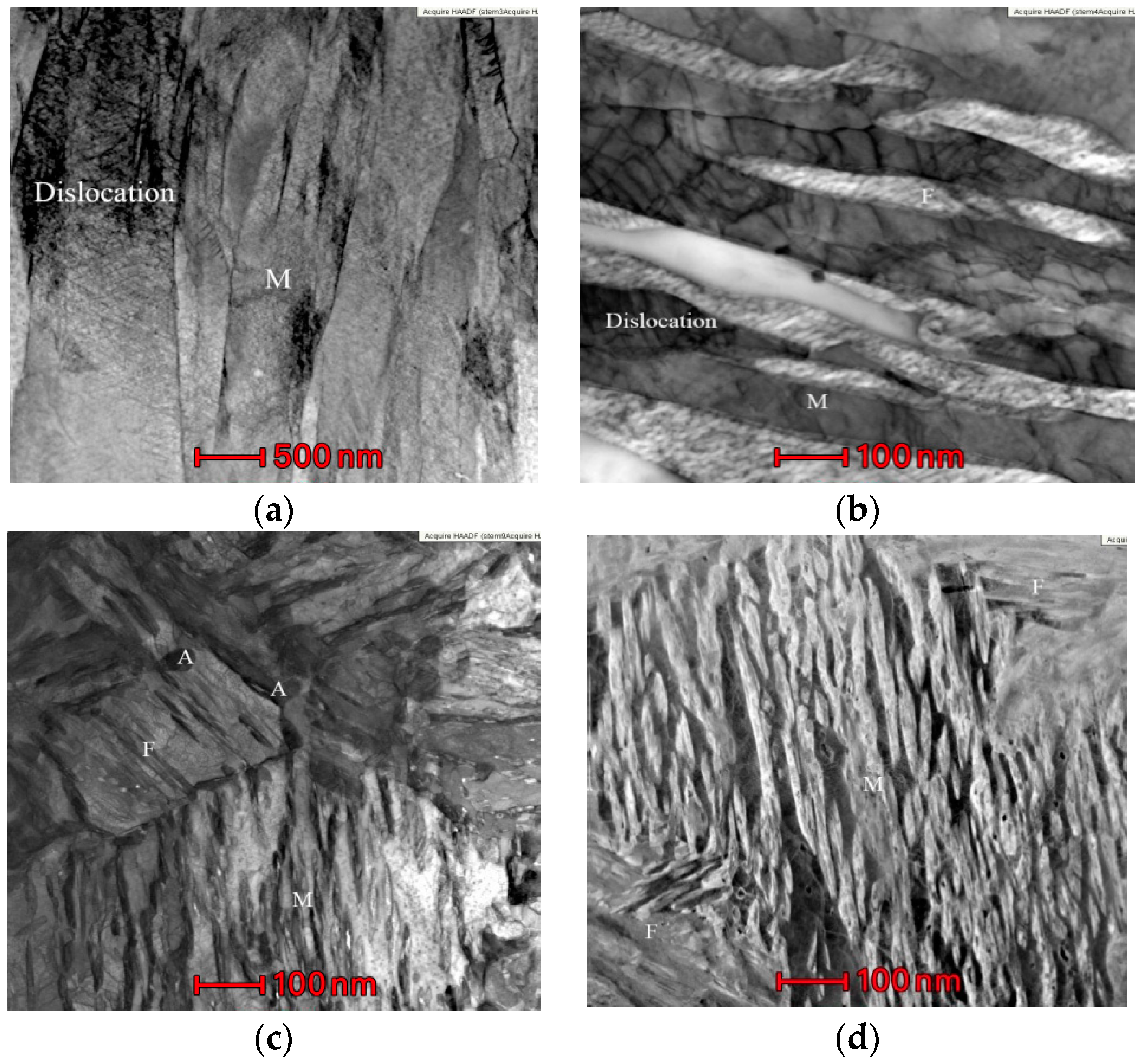

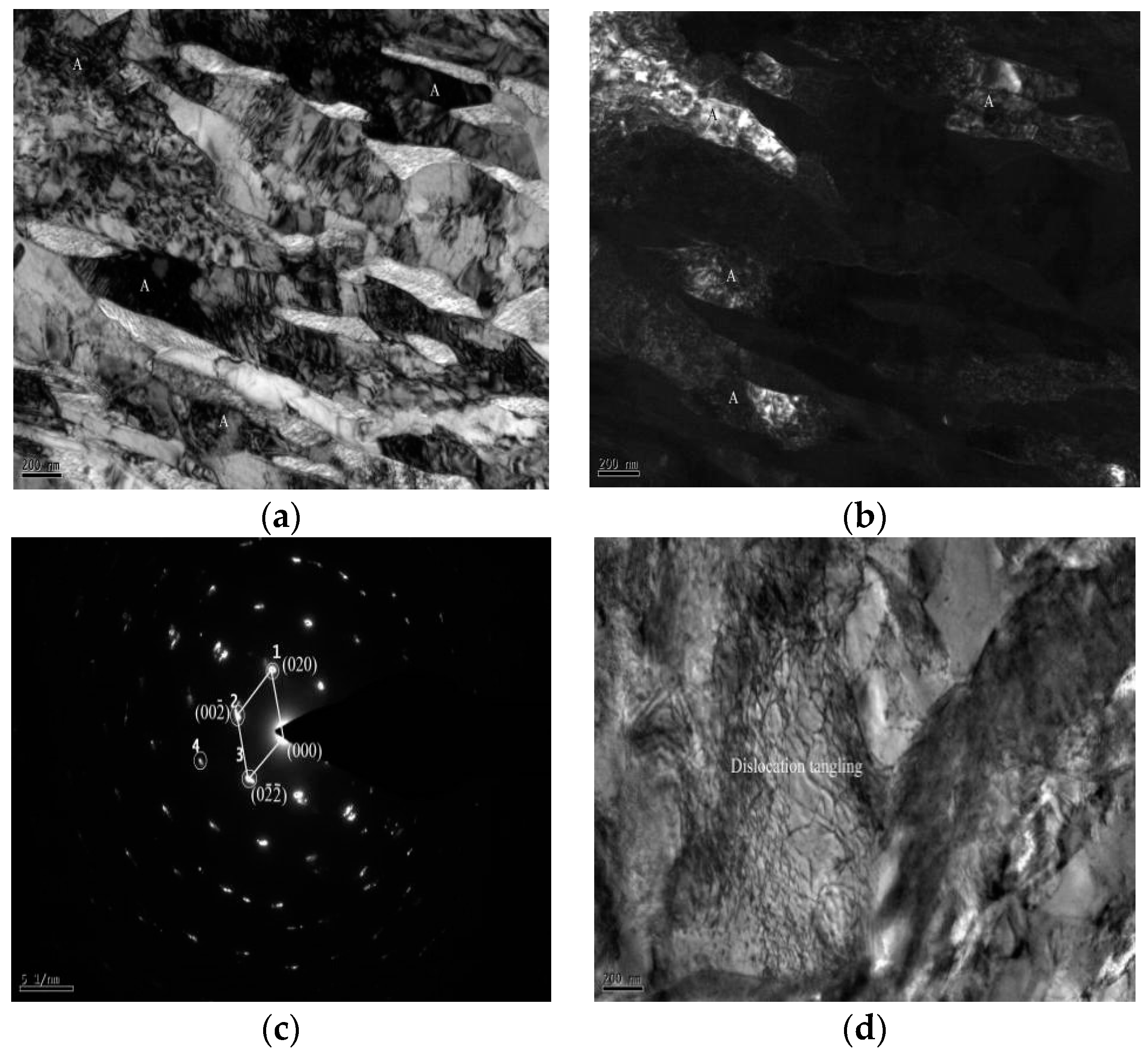

Figure 4a,b are the TEM image of austenite after annealing of the studied steel at 650 °C.

Figure 4c illustrates the austenite diffraction spot. Austenite mainly appears in ferrite grain boundaries and martensite lath bundles in the form of bulk. During the reverse-phase transformation annealing, the enrichment of C and Mn elements contribute increment into austenite stability [

17].

Figure 4d shows the TEM image of dislocation entanglements after annealing at 650 °C. Admittedly, the studied steel after annealing at 650 °C does not completely eliminate dislocations and there exists more dislocation lines in the ultra-fine grained ferrite. These dislocation lines slip to form dislocation entanglements and the dislocation density is tremendously large.

Figure 5 reveals the austenitic TEM images of different forms after annealing at 675 °C. The lath-like austenite with the same orientation combines to form bulk austenite and there are stacking faults and austenite twins in bulk austenite as illustrated in

Figure 5a.

Figure 5b demonstrates the bulk austenite diffraction spot.

Figure 5c,d illustrate the lath-like austenite morphology and diffraction spots, separately. The austenite volume fraction is relatively high when the annealing at the temperature of 675 °C. Since the nucleation and growth of austenite involves the migration of interfacial boundaries to the ferrite phase and the diffusion of interstitial C atoms and substituted Mn atoms between the ferrite and austenite phases gap type. [

14,

16,

17]. The diffusion coefficient of C atom and replacement Mn atom in ferrite is greater than in austenite. As a result, as the annealing temperature increases, the alloying elements can diffuse rapidly which will lead to the final alloying elements being continuously diffused and enriched from ferrite to austenite [

18].

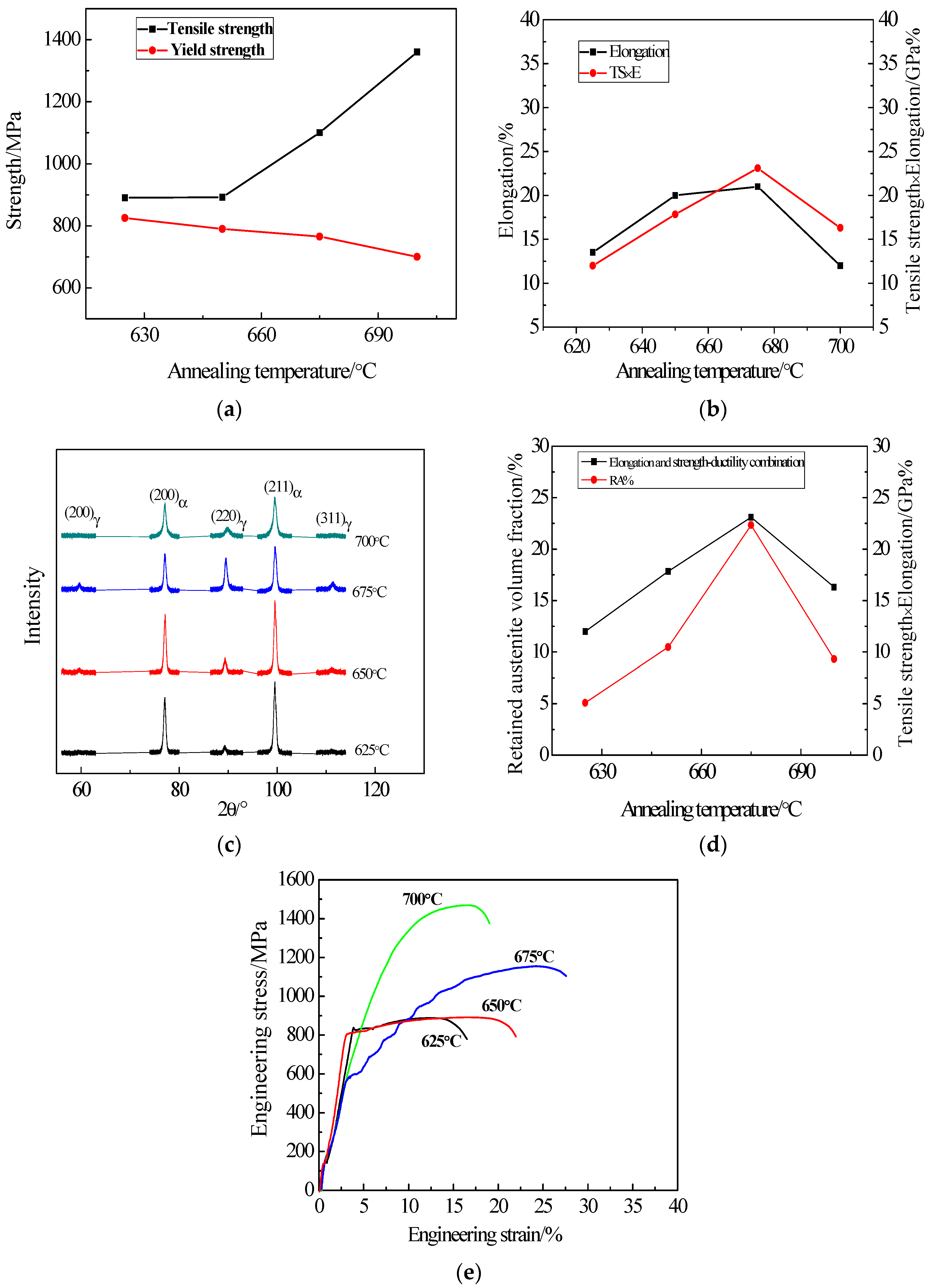

3.2. Mechanical Properties

The variation of mechanical properties of studied steel with annealing temperature is illustrated in

Figure 6. The variation of tensile strength and yield strength are indicated in

Figure 6a. As the annealing temperature increases, the tensile strength increases continuously, obtaining 1360 MPa at 700 °C while the yield strength decreases constantly, gaining 825 MPa at 625 °C. The elongation and strength-ductility combination are shown in

Figure 6b. The elongation and the strength-ductility combination increase first, which gradually decrease with the annealing temperature increases, and the maximum value is obtained at 675 °C (22% and 23.1 GPa %, respectively).

Figure 6c is X-ray diffraction patterns at different annealing temperatures, showing that the retained austenite peaks are the highest and the cumulative strength is the highest after annealing at 675%.

Figure 6d indicates the variation of annealing temperature on the retained austenite volume fraction and the strength-ductility combination, which both increase first and then decrease with the increase of temperature. With the retained austenite volume fraction reaches 22.34%, and the strength-ductility combination gets to 23.1 GPa % at the maximum.

Figure 6e is an engineering stress-strain curve with different annealing temperatures. After annealing with ART, the tensile strength is 1360 MPa; the lowest is 890 MPa, the engineering strain is 22% and the lowest is 12%.

With the increase of the temperature, the tensile strength increases. However, this phenomenon is not conspicuous when the temperature anneals from 625 to 650 °C. As depicted in

Figure 6, with the annealing temperature accesses to 675 °C, the austenite volume fraction reaches its maximum at 22.34%. The TRIP effect is enhanced when the stability of austenite stays in the room temperature and the tensile deformation is improved. The dislocation entanglement exists at 675 °C, as shown in

Figure 5c. During the slip process, dislocation interacts with each other and the process generates dislocation entanglements and plugging, which prevents the further movement and enhances the tensile strength of experimental steel.

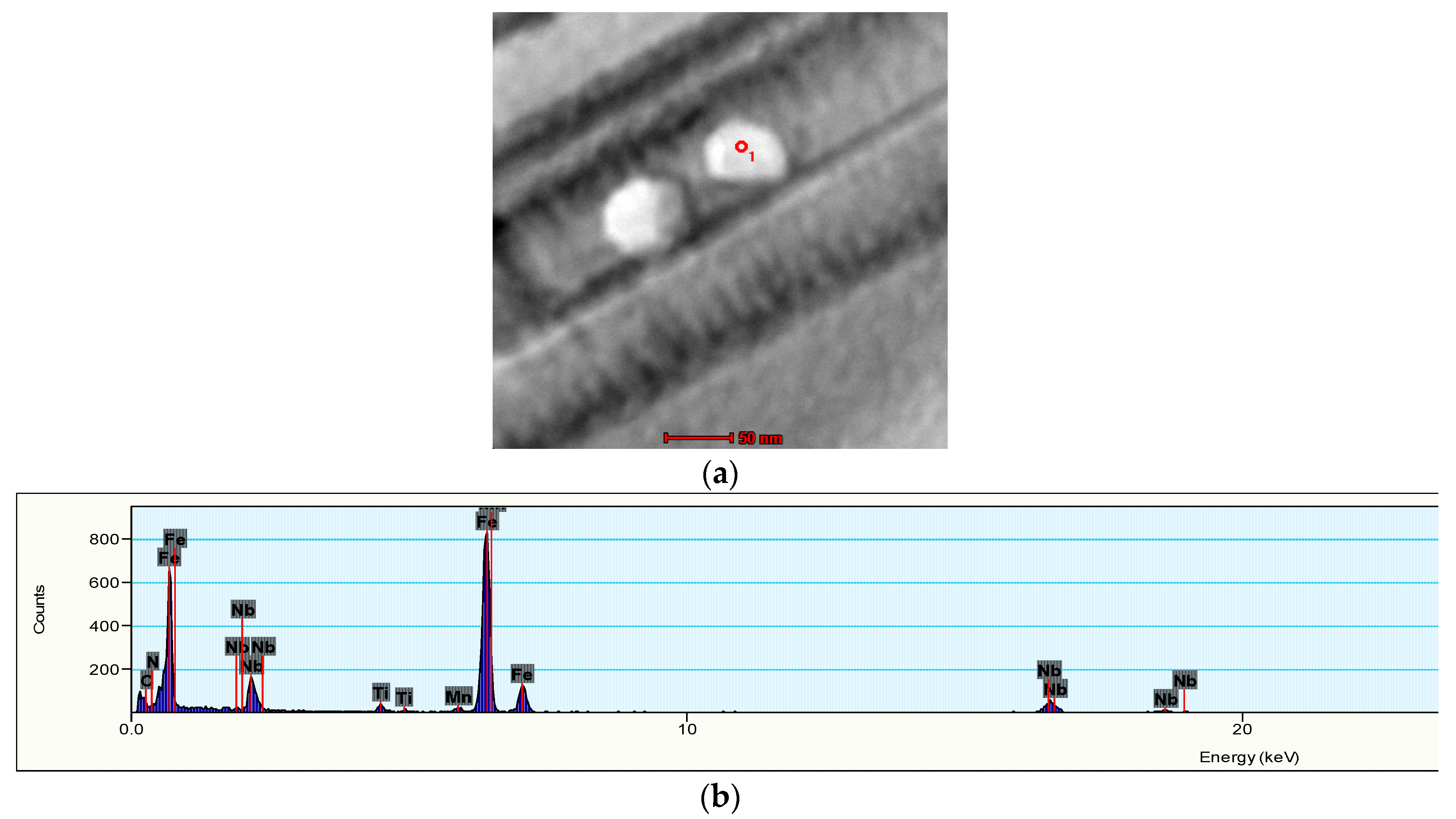

Figure 7a,b illustrates the TEM morphology and energy spectrum of Nb and Ti precipitates. From those two figures, we can conclude that from 200 to 300 nm, precipitates are dispersed in the ferrite matrix. Under this circumstance, the dislocation movement is retrained and the tensile strength is improved. At the same time, with the temperature increases to 700 °C, martensite rapidly transforms into austenite because this temperature is close to the temperature of austenite single-phase region. However, the component of C and Mn in austenite decreases to a low level, and this causes the stability of austenite to reduce into a lower stage. Finally, during the cooling process, almost the whole martensite is completely formed. Considering the analysis and demonstrations above, we find that the tensile strength reaches the peak at 700 °C.

As the annealing temperature increases, the grain constantly grows and the microstructure becomes more uniform. Due to the recrystallization of crystal grains, even the dislocations are rearranged, the dislocation density reduces and the dislocation entanglement decreases during tensile deformation, which lowers the yield strength [

19]. With the increase of annealing temperature, the average grain size of ferrite at 650 °C acts as 0.22 μm and 0.30 μm at 675 °C, respectively. Calculating by the Hall–Petch formula, we could conclude that with the increment of the average size of grain, the yield strength of the material decreases [

20]. At 700 °C, although the austenite volume fraction decreases, the formed ultra-fine-grained ferrite provides better elongation and spontaneously stimulates the yield strength to decrease.

From

Figure 6d, we find that with the annealing temperature increases, the variational trends of austenite volume fraction and the strength-ductility combination are similar. All of the austenite volume fraction, elongation and strength-ductility combination increase first and then decrease. When the annealing temperature increases from 625 to 675 °C, the ultra-fine-grained ferrite and austenite formed by reversing phase annealing, which provides better elongation. Nevertheless, the austenite volume fraction is only 5.09%. With the annealing at 625 °C while the strength-ductility combination represents relatively low. When the annealing temperature increasing, the austenite volume fraction rises to 10.48% at 650 °C and reaches to its peaked of 22.34% at 675 °C. It is also well known that with the increment of austenite volume fraction, the TRIP effect facilitates the martensitic transformation more easily. After the martensitic transformation, the partial strength is naturally improved whereas it is difficult to continue deformation. Because the deformation transforms to the parts where the martensite seldom happens, the formation of necking is delayed and the concentration at the crack tip is loosened. When this phenomenon occurs, the formation of microcracks is prevented so that the elongation is increased [

15,

21,

22]. The Nb and Ti carbides from 200 to 300 nm precipitates at 675 °C and they interact with dislocations as a second phase particle. This will hinder the continuing slip of dislocations and increase the strengthening of material. With the precipitated spacing reaches to a certain critical value, dislocations will bypass the precipitated phase particles and maximum strengthening effect will be generated [

23]. At 700 °C, the austenitic stability gradually deteriorated due to the decrease of C and Mn components. Therefore, the elongation as well as the strength-ductility combination at 700 °C can be significantly reduced. So, it is effectively to increase the strength-ductility combination of studied steel by enhancing the volume fraction of austenite [

24].

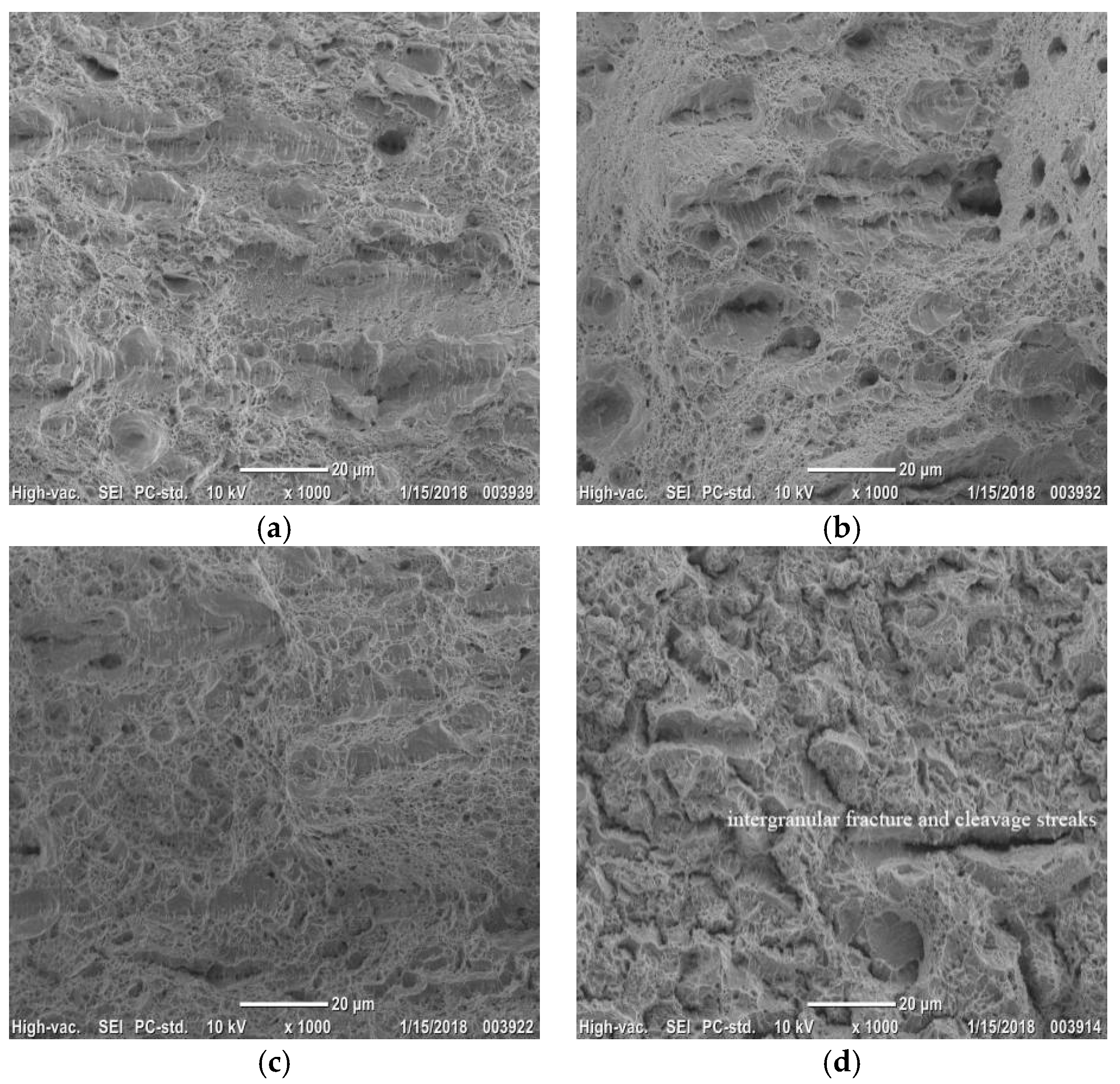

Figure 8a,b are tensile fracture morphology after reverse-phase transformation annealing at 625 and 650 °C, respectively. There are smaller dimples at the fractures of steel annealing at 625 °C and 650 °C and some brittle intergranular fractures appear in the fracture morphology.

Figure 8c shows the fracture after annealing at 675 °C. The smaller dimples mainly belong to ductile fracture at 675 °C. In addition, at 700 °C, the dimples almost completely disappear; the fracture are mainly based on brittle intergranular fractures and are also cleavage streaks. By observing the fracture morphology and mechanical properties, we find that with the increment of temperature, the increment of tensile strength is not significant from 625 to 650 °C. After the reverse transformation annealing, the plasticity of the steel is low, and the type of fracture in the surface is intergranular fracture. As the temperature raises to 650 °C, the elongation becomes poor. The austenite volume fraction peaks at 675 °C, and we can see that more dimples in the fracture, the elongation reaches its peak at 675 °C. At 700 °C, the tensile strength reaches its peak with the lowest elongation. The exhibition of fracture intergranular fracture and cleavage streaks are illustrated in

Figure 8d.