Plasma Electrolytic Oxidation of Magnesium Alloy AZ31B in Electrolyte Containing Al2O3 Sol as Additives

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

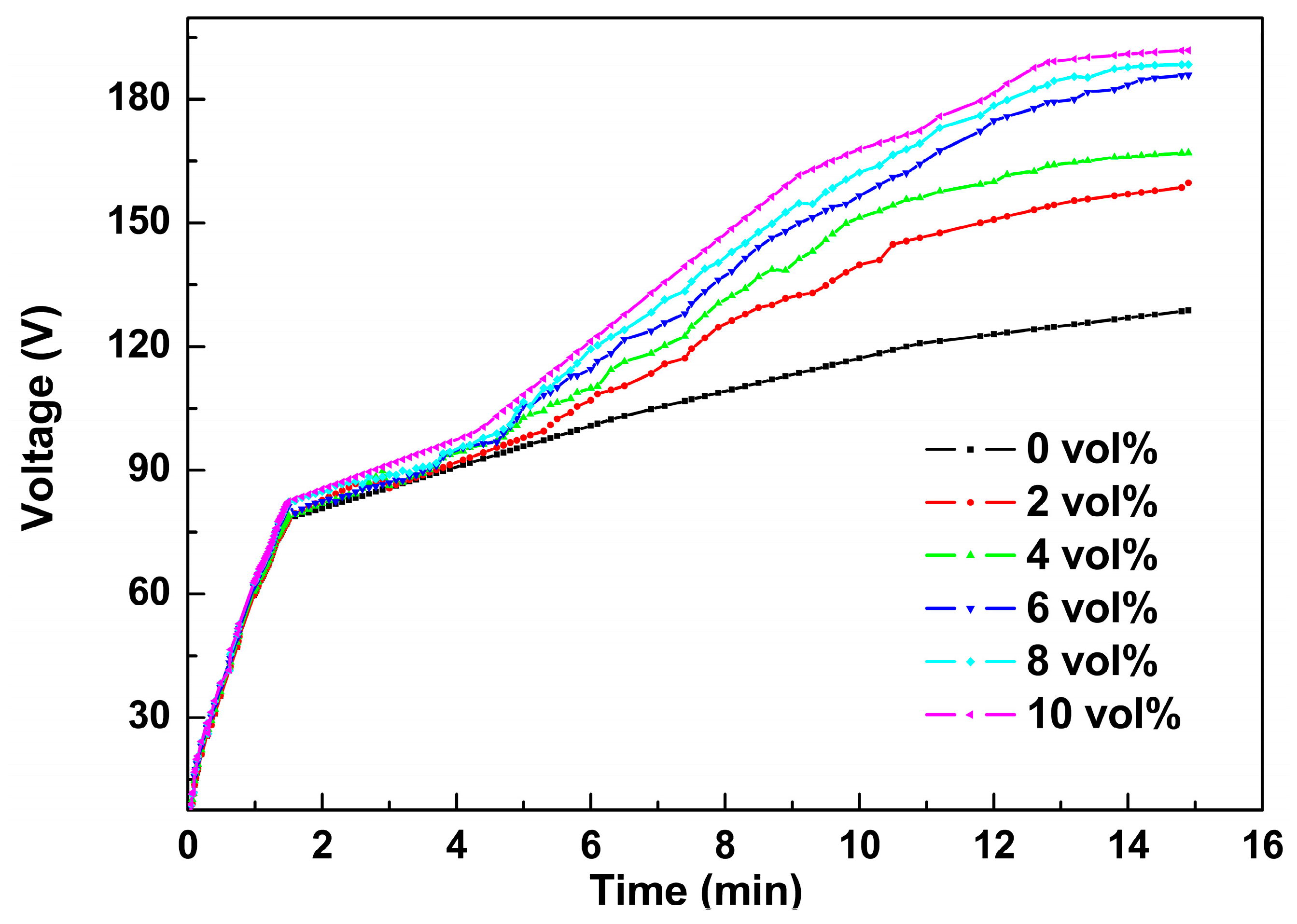

3.1. Plasma Electrolytic Oxidation Process

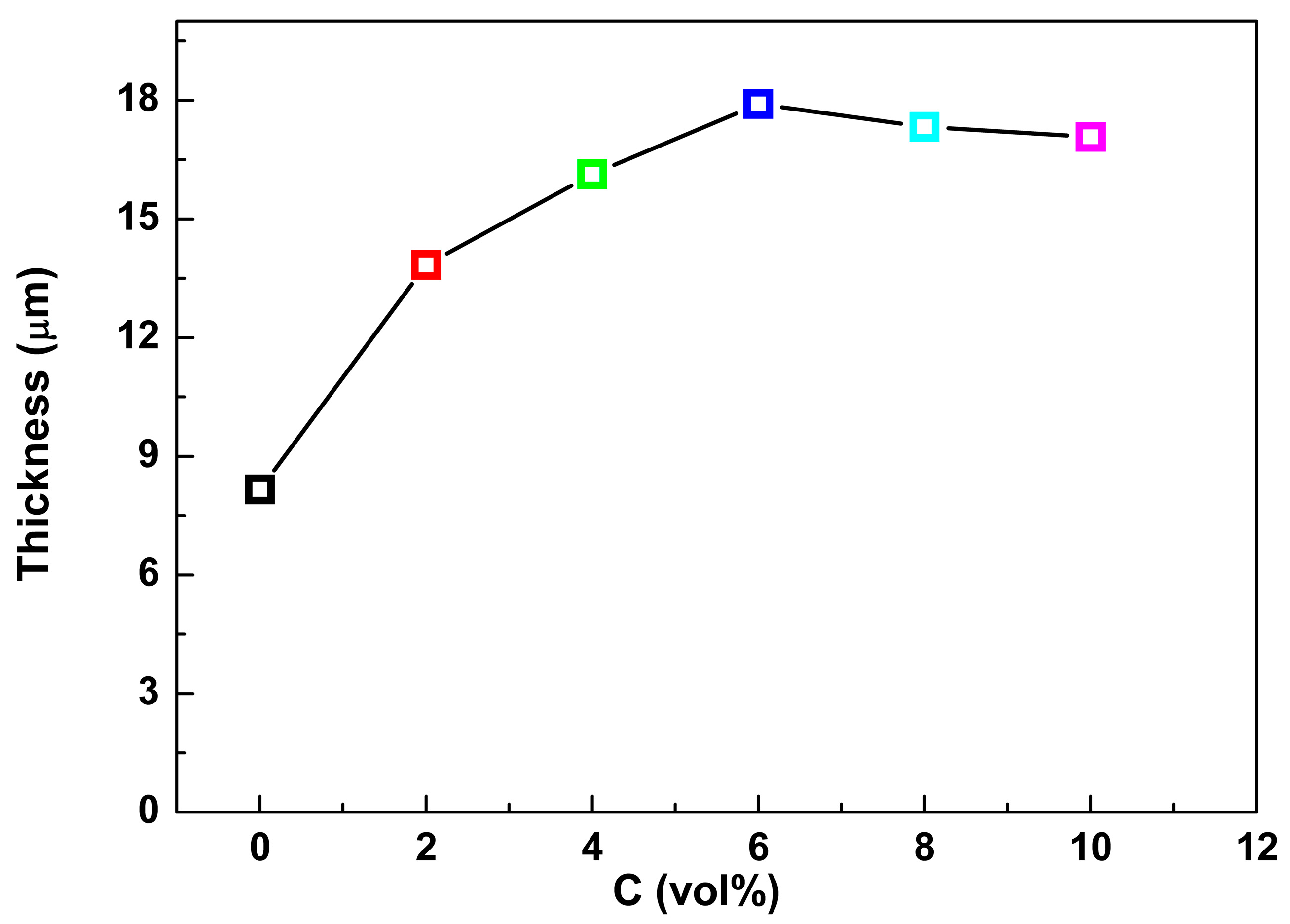

3.2. Coating Thickness of PEO Coatings

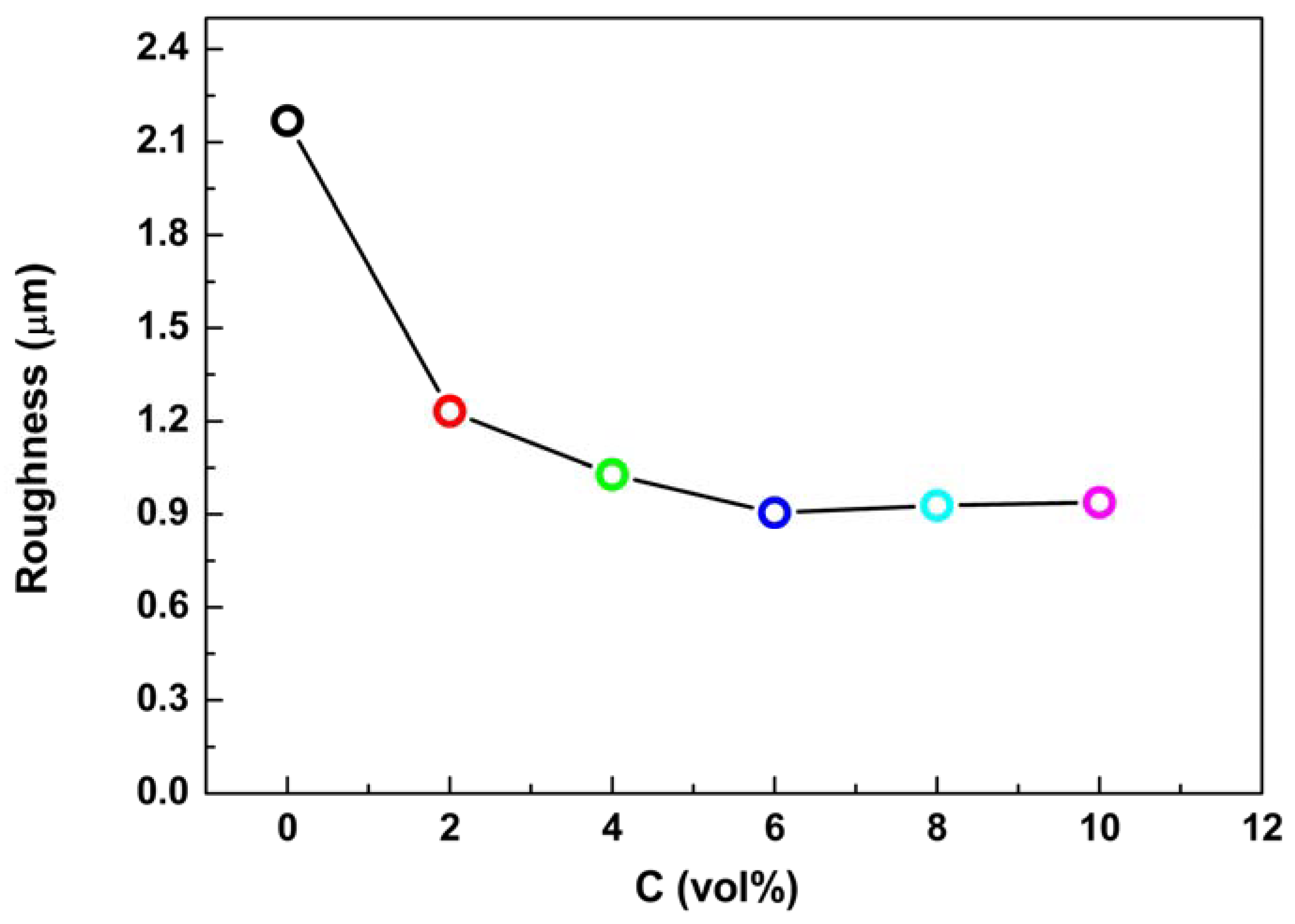

3.3. Coating Roughness of PEO Coatings

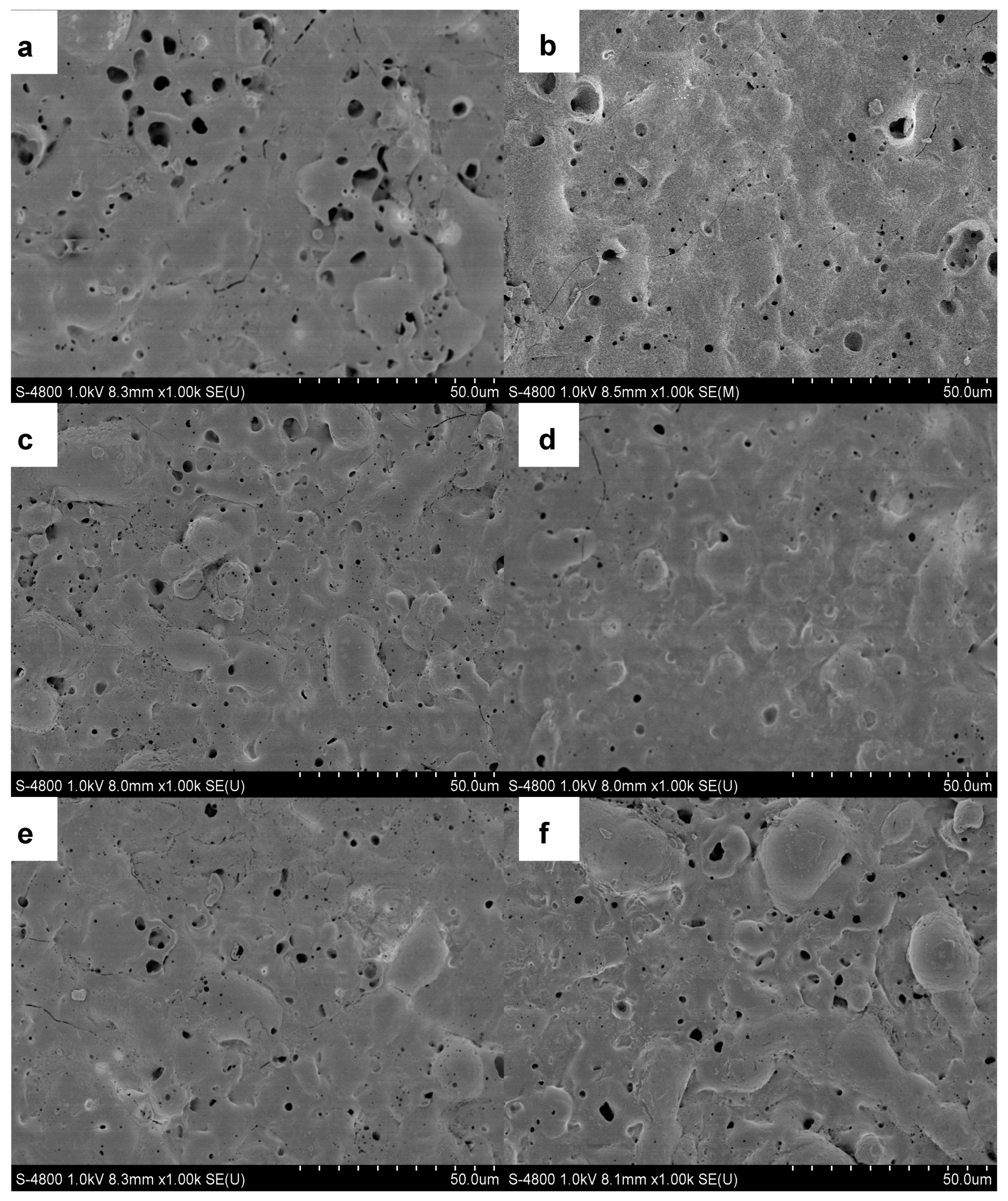

3.4. Morphological Characteristics of PEO Coatings

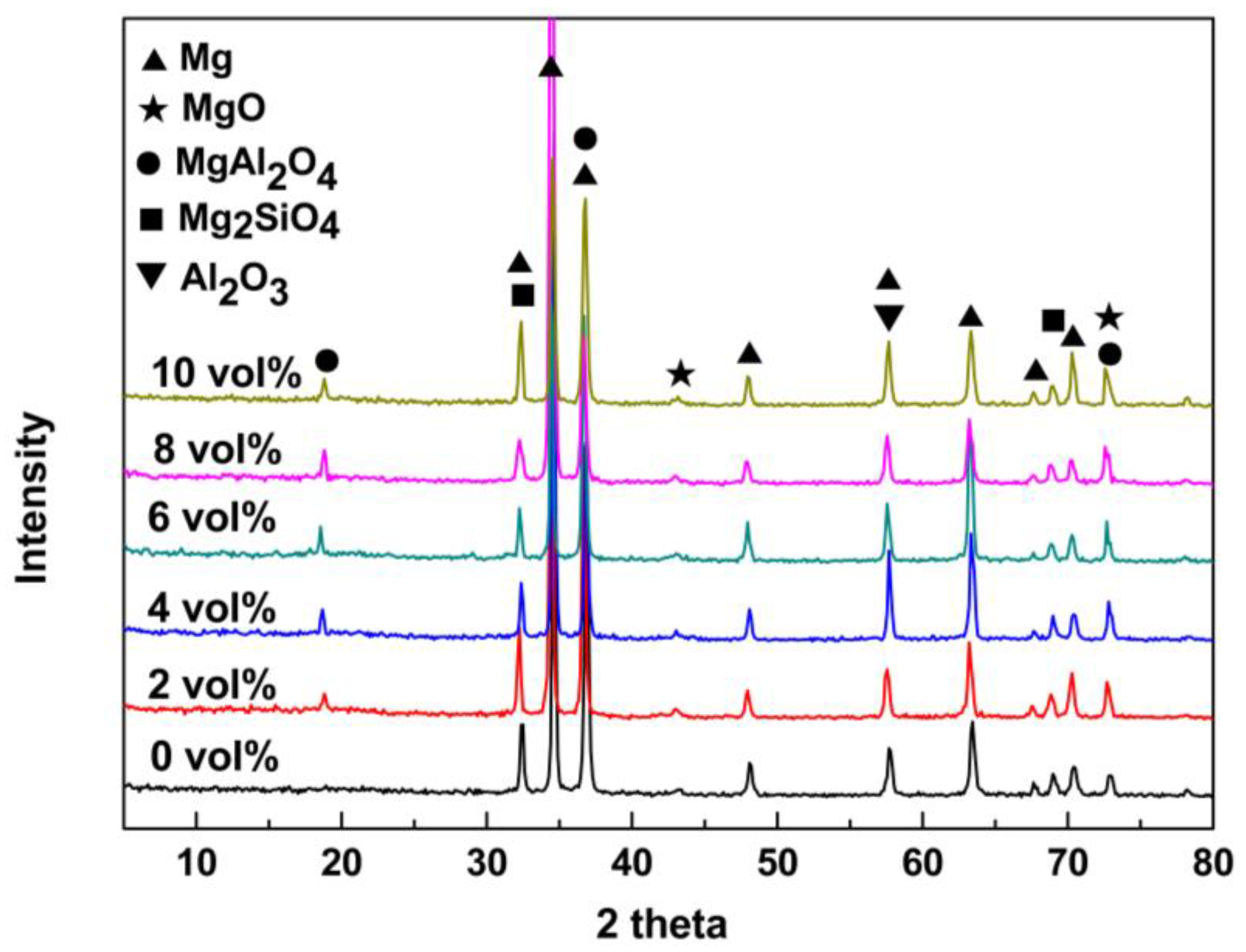

3.5. Phase Analysis of PEO Coatings

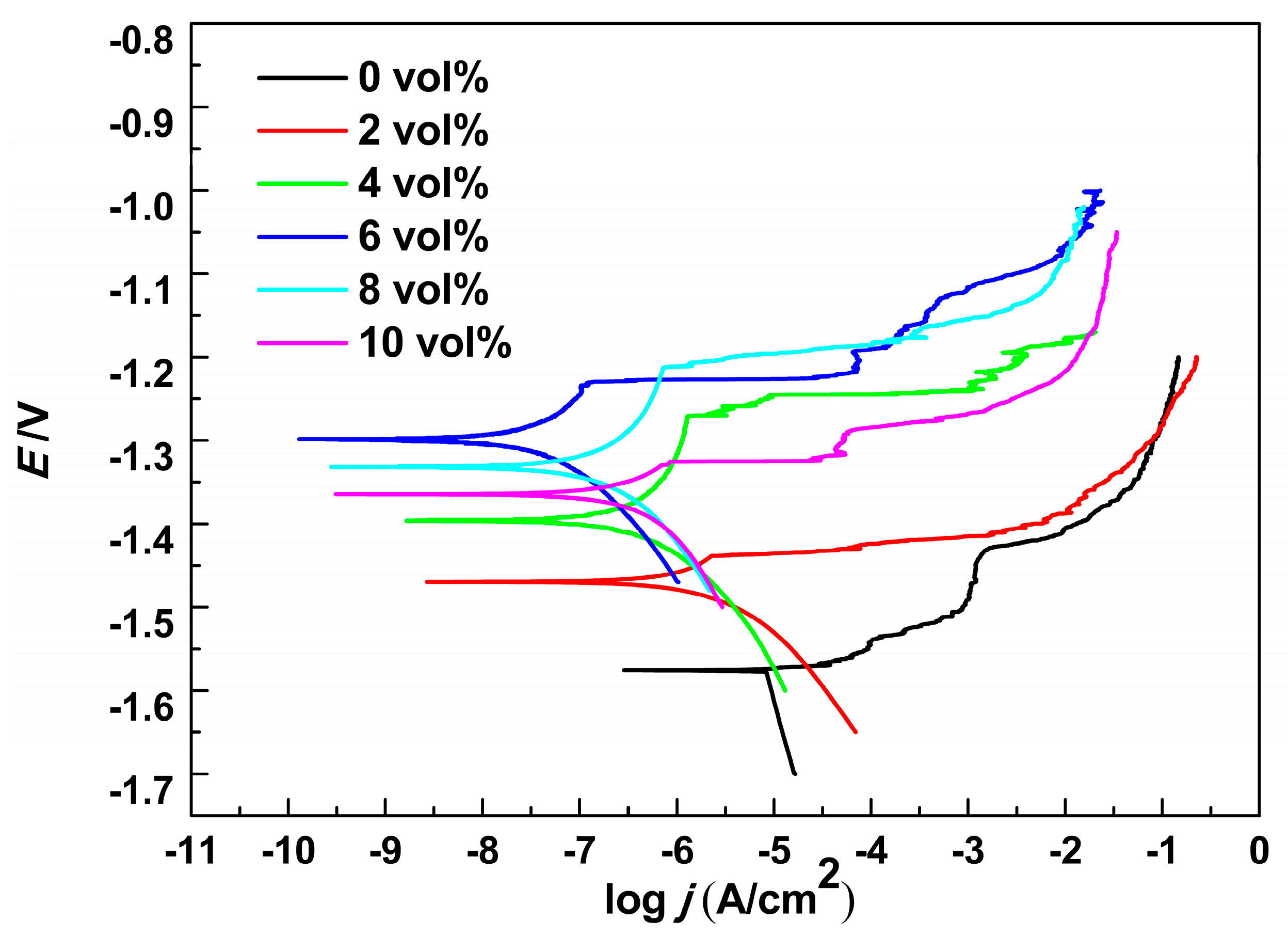

3.6. Corrosion Behavior of PEO Coatings

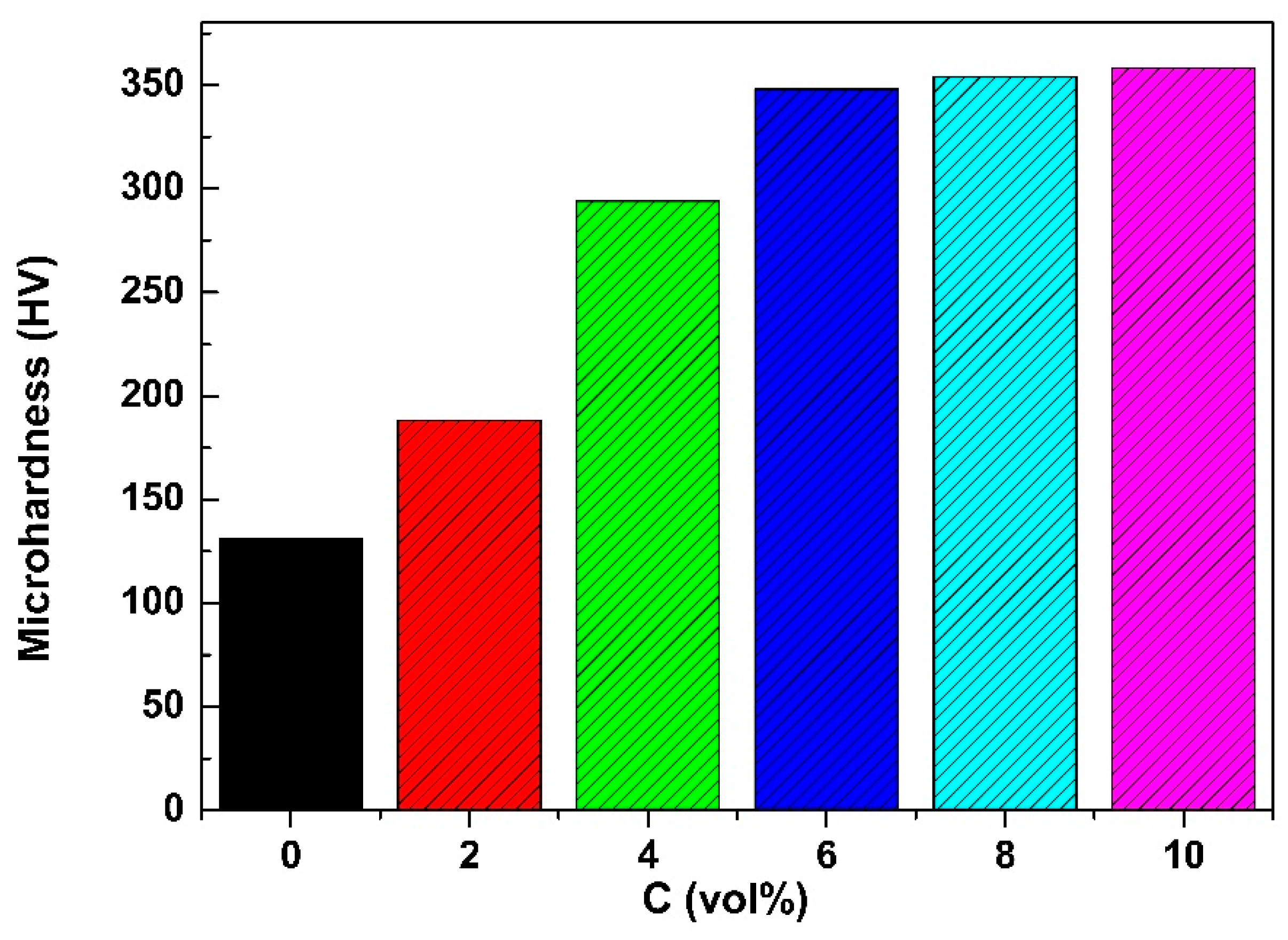

3.7. Microhardness of PEO Coatings

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gray, X.; Luan, B. Protective coatings on magnesium and its alloys—A critical review. J. Alloys Compd. 2002, 336, 88–113. [Google Scholar] [CrossRef]

- Chen, X.; Birbilis, N.; Abbott, T. Review of corrosion-resistant conversion coatings for magnesium and its alloys. Corrosion 2011, 67, 035005. [Google Scholar] [CrossRef]

- Song, G.; Shi, Z. Anodization and corrosion of magnesium (Mg) alloys. In Corrosion Prevention of Magnesium Alloys; Song, G., Ed.; Woodhead Pubilishing Limited: Oxford, UK, 2013; Volume 9, pp. 232–281. [Google Scholar]

- Elsentriecy, H.H.; Azumi, K.; Konno, H. Improvement in stannate chemical conversion coatings on AZ91 D magnesium alloy using the potentiostatic technique. Electrochim. Acta 2007, 53, 1006–1012. [Google Scholar] [CrossRef]

- Song, Y.; Shan, D.; Han, E. Corrosion behaviors of electroless plating Ni–P coatings deposited on magnesium alloys in artificial sweat solution. Electrochim. Acta 2007, 53, 2009–2015. [Google Scholar] [CrossRef]

- Song, G.; Shi, Z. Corrosion mechanism and evaluation of anodized magnesium alloys. Corros. Sci. 2014, 85, 126–140. [Google Scholar] [CrossRef]

- Baloch, A.; Kannan, M.B. Electropolymerisation of aniline on AZ91 magnesium alloy: The effect of coating electrolyte corrosiveness. Metals 2017, 7, 533. [Google Scholar] [CrossRef]

- Verdier, S.; Boinet, M.; Maximovitch, S.; Dalard, F. Formation, structure and compostion of anodic films on AM60 magnesium alloy obtained by DC plasma anodizing. Corros. Sci. 2005, 47, 1429–1444. [Google Scholar] [CrossRef]

- Zhang, R. Film formation in the second step of micro-arc oxidation on magnesium alloy. Corros. Sci. 2010, 52, 1285–1290. [Google Scholar] [CrossRef]

- Salman, S.; Okido, M. Anodization of magnesium (Mg) alloys to improve corrosion resistance. In Corrosion Prevention of Magnesium Alloys; Song, G., Ed.; Woodhead Pubilishing Limited: Oxford, UK, 2013; Volume 8, pp. 197–231. [Google Scholar]

- Rama Krishna, L.; Sundararajan, G. Aqueous corrosion behavior of micro arc oxidation (MAO)-coated magnesium alloys: A critical review. JOM 2014, 6, 1045–1060. [Google Scholar] [CrossRef]

- Li, Z.; Yuan, Y.; Jing, X. Comparison of plasma electrolytic oxidation coatings on Mg-Li alloy formed in molybdate/silicate and aluminates/silicate composite electrolytes. Mater. Corros. 2014, 65, 493–501. [Google Scholar] [CrossRef]

- Yagi, S.; Kuwabara, K.; Fukuta, Y.; Kubota, K.; Matsubara, E. Formation of self-repairing anodized film on ACM522 magnesium alloy by plasma electrolytic oxidaition. Corros. Sci. 2013, 73, 188–195. [Google Scholar] [CrossRef]

- Wu, X.; Su, P.; Jiang, Z.; Meng, S. Influences of current density on tribological characteristics of ceramic coatings on ZK60 Mg alloy by plasma electrolytic oxidation. ACS Appl. Mater. Interfaces 2010, 3, 808–812. [Google Scholar] [CrossRef] [PubMed]

- Veys-Renaux, D.; Barchiche, C.; Rocca, E. Corrosion behavior of AZ91 Mg alloy anodized by low-energy micro-arc oxidation: Effect of aluminates and silicates. Surf. Coat. Technol. 2014, 251, 232–238. [Google Scholar] [CrossRef]

- Birss, V.; Xia, S.; Yue, R.; Rateick, G. Characterization of oxide films formed on Mg-based WE43 alloy using AC/DC anodizaition in silicate solution. J. Electrochem. Soc. 2004, 151, B1–B10. [Google Scholar] [CrossRef]

- Arrabal, R.; Matykina, E.; Hashimoto, T.; Skeldon, P.; Thompson, G. Characterization of AC PEO coatings on magnesium alloys. Surf. Coat. Technol. 2009, 203, 2207–2220. [Google Scholar] [CrossRef]

- Hwang, D.; Kim, Y.; Park, D.; Yoo, B.; Shin, D. Corrosion resistance of oxide layers formed on AZ91 Mg alloy in KMnO4 electrolyte by plasma electrolytic oxidation. Electrochim. Acta 2009, 54, 5479–5485. [Google Scholar] [CrossRef]

- Guo, H.; An, M.; Huo, H.; Xu, S.; Wu, L. Microstructure characteristic of ceramic coatings fabricated on magnesium alloys by micro-arc oxidation in alkaline silicate solutions. Appl. Surf. Sci. 2006, 252, 7911–7916. [Google Scholar] [CrossRef]

- Fukuda, H.; Matsumoto, Y. Effects of Na2SiO3 on anodization of Mg-Al-Zn alloy in 3M KOH solution. Corros. Sci. 2004, 46, 2135–2142. [Google Scholar] [CrossRef]

- Hsiao, H.; Tsung, H.; Tsai, W. Anodization of AZ91D magnesium alloy in silicate-containing electrolytes. Surf. Coat. Technol. 2005, 199, 127–134. [Google Scholar] [CrossRef]

- Wu, H.; Cheng, Y.; Li, L.; Chen, Z.; Wang, H.; Zhang, Z. The anodization of ZK60 magnesium alloy in alkaline solution containing silicate and the corrosion properties of the anodized films. Appl. Surf. Sci. 2007, 253, 9387–9394. [Google Scholar] [CrossRef]

- Lu, J.; He, X.; Li, H.; Song, R. Microstructure and corrosion resistance of PEO coatings formed on KBM10 Mg alloy pretreated with Nd(NO3)3. Materials 2018, 11, 1062. [Google Scholar] [CrossRef] [PubMed]

- Mandelli, A.; Bestetti, M.; Da Forno, A.; Lecis, N.; Trasatti, S.; Trueba, M. A composite coating for corrosion protection of AM60B magnesium alloy. Surf. Coat. Technol. 2011, 205, 4459–4465. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Y.; Miao, C.; Tu, X.; Yu, J.; Li, J. Effect of Tungsten Carbide Particles on the Characteristics of PEO Coatings Formed on AZ31B Magnesium Alloy in Alkaline Electrolyte. Int. J. Electrochem. Sci. 2018, 13, 7923–7929. [Google Scholar] [CrossRef]

- Mashtalyar, D.; Gnedenkov, S.; Sinebryukhov, S.; Imshinetskiy, I.; Puz, A. Plasma electrolytic oxidation of the magnesium alloy MA8 in electrolytes containing TiN nanoparticles. J. Mater. Sci. Technol. 2017, 33, 461–468. [Google Scholar] [CrossRef]

- Lu, X.; Blawert, C.; Kainer, K.; Zheludkevich, M. Investigation of the formation mechanisms of plasma electrolytic oxidation coatings on Mg alloy AM50 using particles. Electrochim. Acta 2016, 196, 680–691. [Google Scholar] [CrossRef]

- Lu, X.; Blawert, C.; Huang, Y.; Ovri, H.; Zheludkevich, M.; Kainer, K. Plasma electrolytic oxidation coatings on Mg alloy with addition of SiO2 particles. Electrochim. Acta 2016, 187, 20–33. [Google Scholar] [CrossRef]

- Lou, B.; Lin, Y.; Tseng, C.; Lu, Y.; Duh, J.; Lee, J. Plasma electrolytic oxidation coatings on AZ31 magnesium alloys with Si3N4 nanoparticle additives. Surf. Coat. Technol. 2017, 332, 358–367. [Google Scholar] [CrossRef]

- Lee, K.; Shin, K.; Namgung, S.; Yoo, B.; Shin, D. Electrochemical response of ZrO2-incorporated oxide layer on AZ91 Mg alloy processed by plasma electrolytic oxidation. Surf. Coat. Technol. 2011, 205, 3779–3784. [Google Scholar] [CrossRef]

- Guo, J.; Wang, L.; Wang, S.; Liang, J.; Xue, Q.; Yan, F. Preparation and performance of a novel multifunctional plasma electrolytic oxidation composite coating formed on magnesium alloy. J. Mater. Sci. 2009, 44, 1998–2002. [Google Scholar] [CrossRef]

- White, L.; Koo, Y.; Yun, Y.; Sankar, J. TiO2 deposition on AZ31 magnesium alloy using plasma electrolytic oxidation. J. Nanomater. 2013, 2013, 319437. [Google Scholar] [CrossRef]

- Zhang, D.; Gou, Y.; Liu, Y.; Guo, X. A composite anodizing coating containing superfine Al2O3 particles on AZ31 magnesium alloy. Surf. Coat. Technol. 2013, 236, 52–57. [Google Scholar] [CrossRef]

- Arrabal, R.; Matykina, E.; Skeldon, P. Incorporation of zirconia particles into coatings formed on magnesium by plasma electrolytic oxidation. J. Mater. Sci. 2008, 43, 1532–1538. [Google Scholar] [CrossRef]

- Li, X.; Luan, B.L. Discovery of Al2O3 particles incorporation mechanism in plasma electrolytic oxidation of AM60B magnesium alloy. Mater. Lett. 2012, 86, 88–91. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, D.; Yu, J.; Di, S. Effects of Al2O3 nano-additive on performance of micro-arc oxidation coatings formed on AZ91D Mg alloy. J. Mater. Sci. Technol. 2014, 30, 984–990. [Google Scholar] [CrossRef]

- Li, Q.; Chen, B.; Xu, S.; Gao, H.; Zhang, L.; Liu, C. Structure and electrochemical behavior of sol-gel ZrO2 ceramic film on chemically pre-treated AZ91D magnesium alloy. J. Alloys Compd. 2009, 478, 544–549. [Google Scholar] [CrossRef]

- Zhong, X.; Li, Q.; Hu, J.; Lu, Y. Characterization and corrosion studies of ceria thin film based on fluorinated AZ91D magnesium alloy. Corros. Sci. 2008, 50, 2304–2309. [Google Scholar] [CrossRef]

- Feil, F.; Furbeth, W.; Schutze, M. Nanoparticle based inorganic coatings for corrosion protection of magnesium alloys. Surf. Eng. 2008, 24, 198–203. [Google Scholar] [CrossRef]

- Zhong, X.; Li, Q.; Chen, B.; Wang, J.; Hu, J.; Hu, W. Effect of sintering temperature on corrosion properties of sol-gel based Al2O3 coatings on pre-treated AZ91D magnesium alloy. Corros. Sci. 2009, 51, 2950–2958. [Google Scholar] [CrossRef]

- Wang, Z.; Zeng, R. Comparison in characterization of composite and sol-gel coating on AZ31 magnesium alloy. Trans. Nonferrous Met. Soc. China 2010, 20, s665–s669. [Google Scholar] [CrossRef]

- Zhu, L.; Li, Y.; Li, W. Influence of silica sol particles behavior on the magnesium anodizing process with different anions addition. Surf. Coat. Technol. 2008, 202, 5853–5857. [Google Scholar] [CrossRef]

- Tang, M.; Liu, H.; Li, W.; Zhu, L. Effect of zirconia sol in electrolyte on the characteristics of microarc oxidation coating on AZ91D magnesium. Mater. Lett. 2011, 65, 413–415. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, G.; Dong, G.; Zhang, L.; Zhang, M. Corrosion resistance of anodized AZ31 Mg alloy in borate solution containing titania sol. J. Alloys Compd. 2008, 463, 458–461. [Google Scholar]

- Li, Z.; Jing, X.; Yuan, Y.; Zhang, M. Composite coatings on a Mg-Li alloy prepared by combined plasma electrolytic oxidation an sol-gel techniques. Corros. Sci. 2012, 63, 358–366. [Google Scholar] [CrossRef]

- Guo, X.; An, M.; Yang, P.; Su, C. Effects of benzotriazole on anodized film formed on AZ31B magnesium alloy in environmental-friendly electrolyte. J. Alloys Compd. 2009, 482, 487–497. [Google Scholar] [CrossRef]

- Zhu, F.; Wang, J.; Li, S.; Zhang, J. Preparation and characterization of anodic films on AZ31B Mg alloy formed in the silicate electrolyte with ethylene glycol oligomers as additives. Appl. Surf. Sci. 2012, 258, 8985–8990. [Google Scholar] [CrossRef]

- Tu, X.; Chen, L.; Wu, J. Effect of glucose on properties of anodizing film on AZ31B magnesium alloy. Chin. J. Nonferrous Met. 2013, 23, 727–734. [Google Scholar]

- Yoo, B.; Shin, K.; Hwang, D.; Lee, D.; Shin, D. Effect of surface roughness on leakage current and corrosion resistance of oxide layer on AZ91 Mg alloy prepared by plasma electrolytic oxidation. Appl. Surf. Sci. 2010, 256, 6667–6672. [Google Scholar] [CrossRef]

- Kamil, M.; Kaseem, M.; Lee, Y.; Ko, Y. Microstructure characteristics of oxide layer formed by plasma electrolytic oxidation: Nanocrystalline and amorphous structure. J. Alloys Compd. 2017, 707, 167–171. [Google Scholar] [CrossRef]

| Samples | Ecorr (V) | jcorr (A/cm2) | βa (V/Decade) | βc (V/Decade) | Rp (Ω·cm2) |

|---|---|---|---|---|---|

| 0 vol% | −1.58 | 8.52 × 10−6 | 0.031 | 0.406 | 1570 |

| 2 vol% | −1.47 | 2.53 × 10−6 | 0.022 | 0.104 | 3121 |

| 4 vol% | −1.40 | 5.61 × 10−7 | 0.313 | 0.134 | 72,720 |

| 6 vol% | −1.30 | 5.18 × 10−8 | 0.156 | 0.135 | 607,446 |

| 8 vol% | −1.33 | 3.29 × 10−7 | 0.271 | 0.198 | 151,195 |

| 10 vol% | −1.37 | 4.77 × 10−7 | 0.118 | 0.177 | 64,534 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, X.; Miao, C.; Zhang, Y.; Xu, Y.; Li, J. Plasma Electrolytic Oxidation of Magnesium Alloy AZ31B in Electrolyte Containing Al2O3 Sol as Additives. Materials 2018, 11, 1618. https://doi.org/10.3390/ma11091618

Tu X, Miao C, Zhang Y, Xu Y, Li J. Plasma Electrolytic Oxidation of Magnesium Alloy AZ31B in Electrolyte Containing Al2O3 Sol as Additives. Materials. 2018; 11(9):1618. https://doi.org/10.3390/ma11091618

Chicago/Turabian StyleTu, Xiaohua, Chengping Miao, Yang Zhang, Yaling Xu, and Jiayou Li. 2018. "Plasma Electrolytic Oxidation of Magnesium Alloy AZ31B in Electrolyte Containing Al2O3 Sol as Additives" Materials 11, no. 9: 1618. https://doi.org/10.3390/ma11091618

APA StyleTu, X., Miao, C., Zhang, Y., Xu, Y., & Li, J. (2018). Plasma Electrolytic Oxidation of Magnesium Alloy AZ31B in Electrolyte Containing Al2O3 Sol as Additives. Materials, 11(9), 1618. https://doi.org/10.3390/ma11091618