Experimental Parametric Model for Adhesion Wear Measurements in the Dry Turning of an AA2024 Alloy

Abstract

1. Introduction

- Build of Primary BUL. A layer of near-pure aluminium, with a very low quantity of copper, is adhered due to the thermomechanical conditions. Under high pressure and temperature, the matrix is softened and welded to the cutting tool rake face by pressure.

- Build of BUE. It is produced by the mechanical adhesion of the workpiece alloy close to the cutting edge.

- Build of secondary BUL. A mechanical extrusion of the workpiece material over the rake face takes place. The BUE and secondary BUL usually grow to a critical size. Once it is reached they are detached—at least partially—from the cutting tool, taking with them cutting tool particles, thereby damaging the tool.

2. Materials and Methods

3. Results

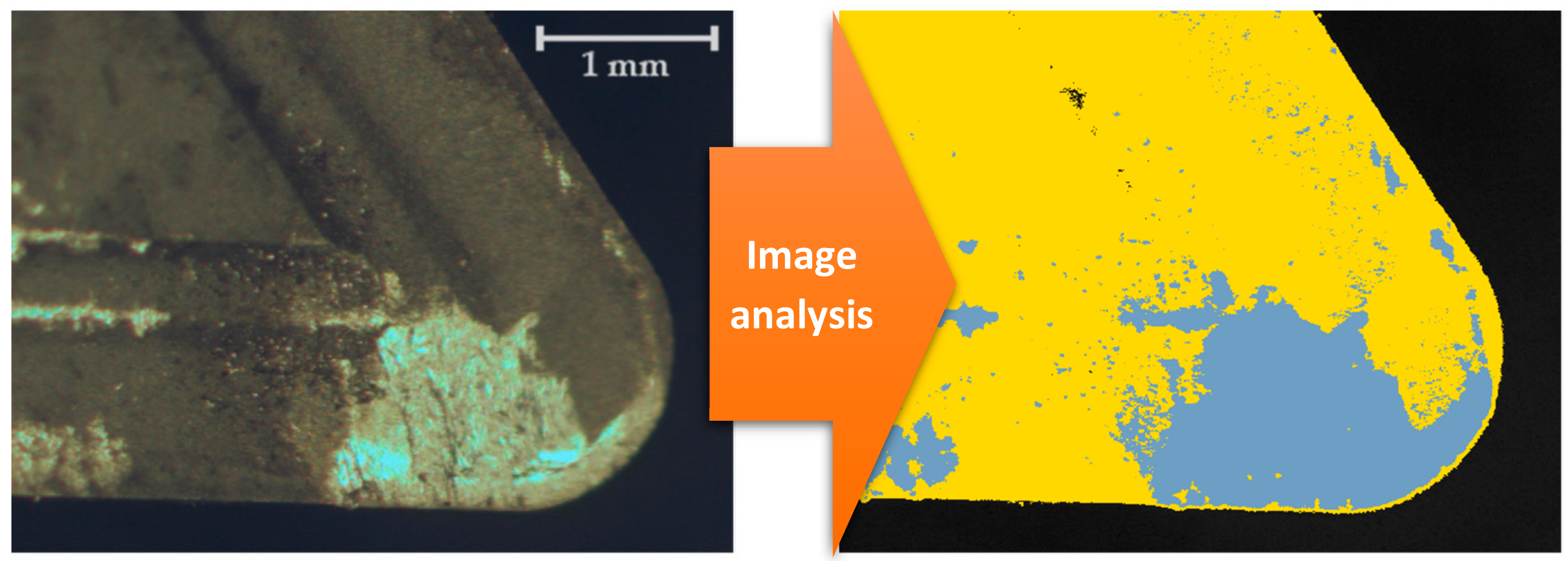

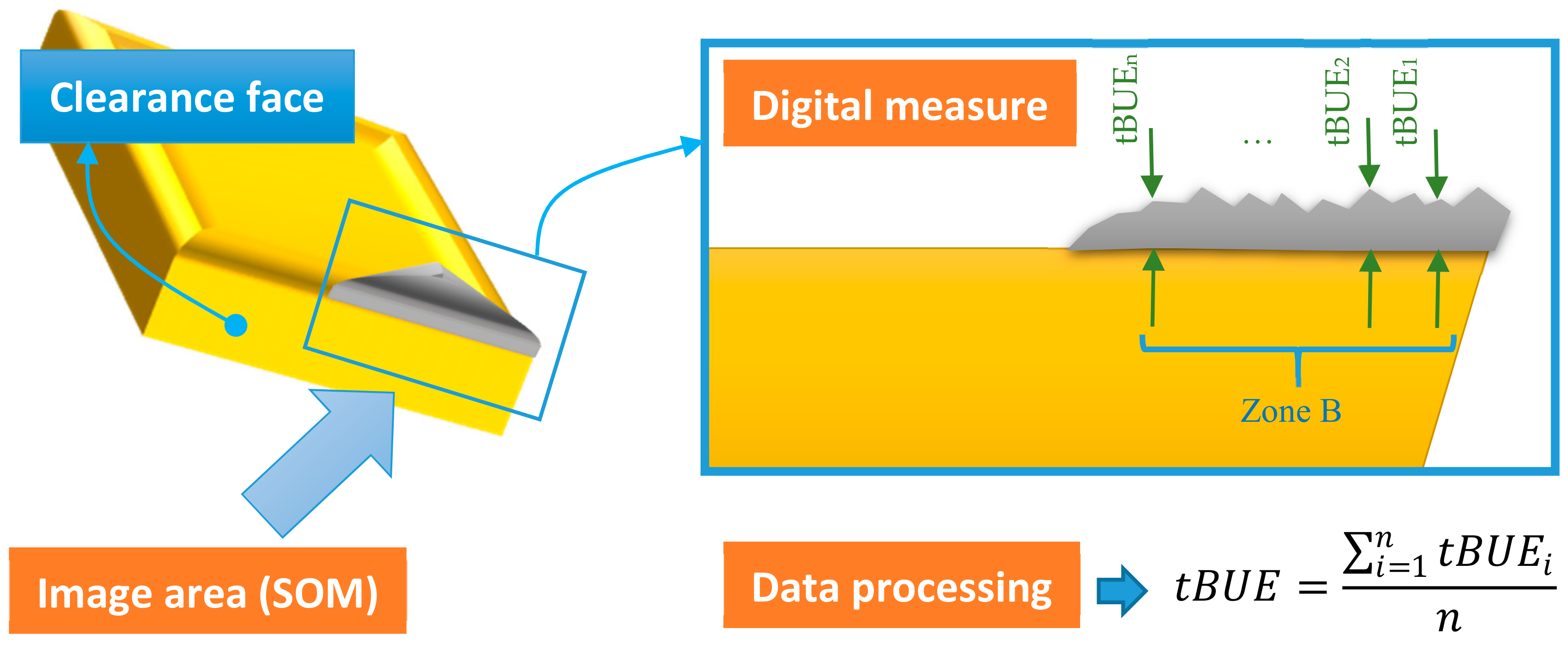

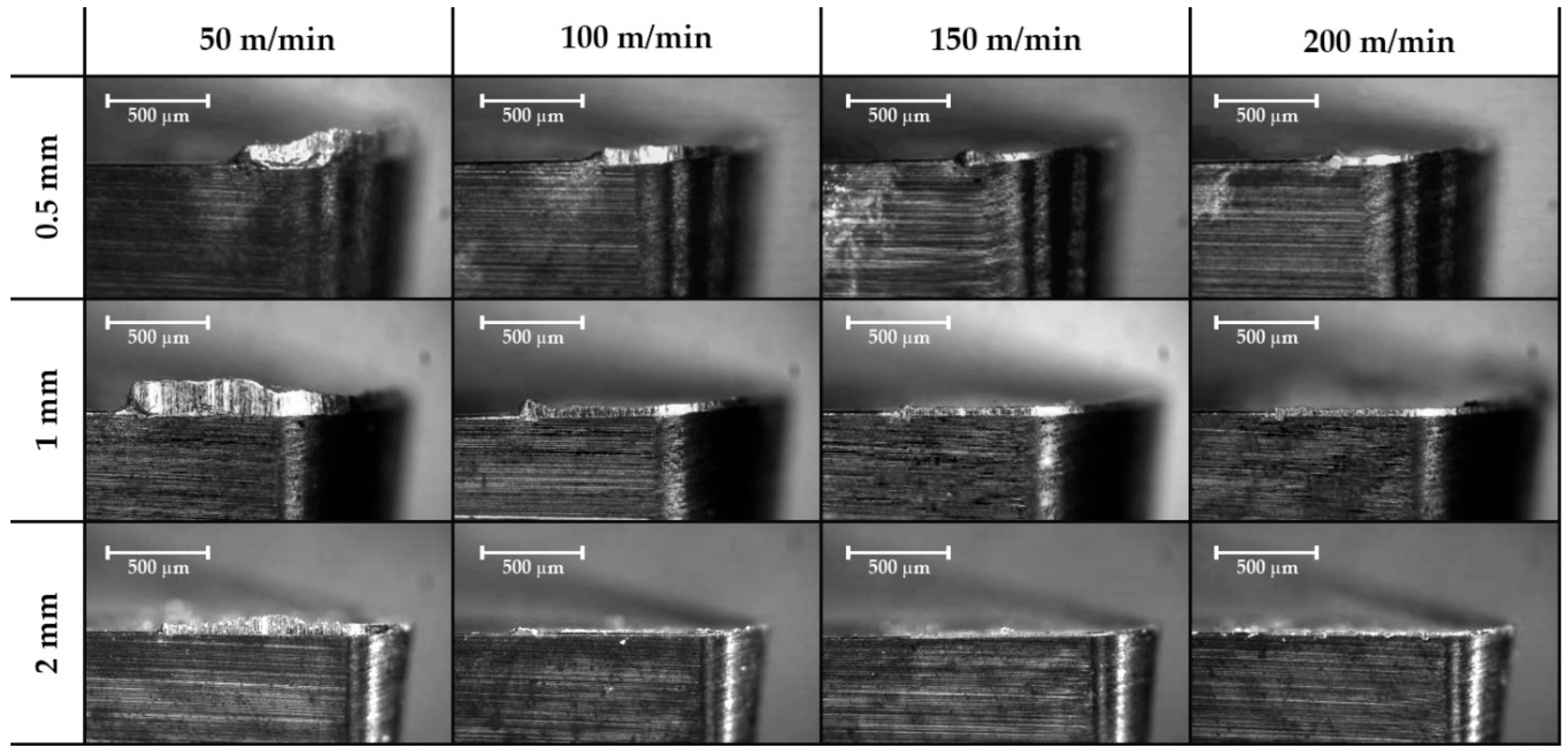

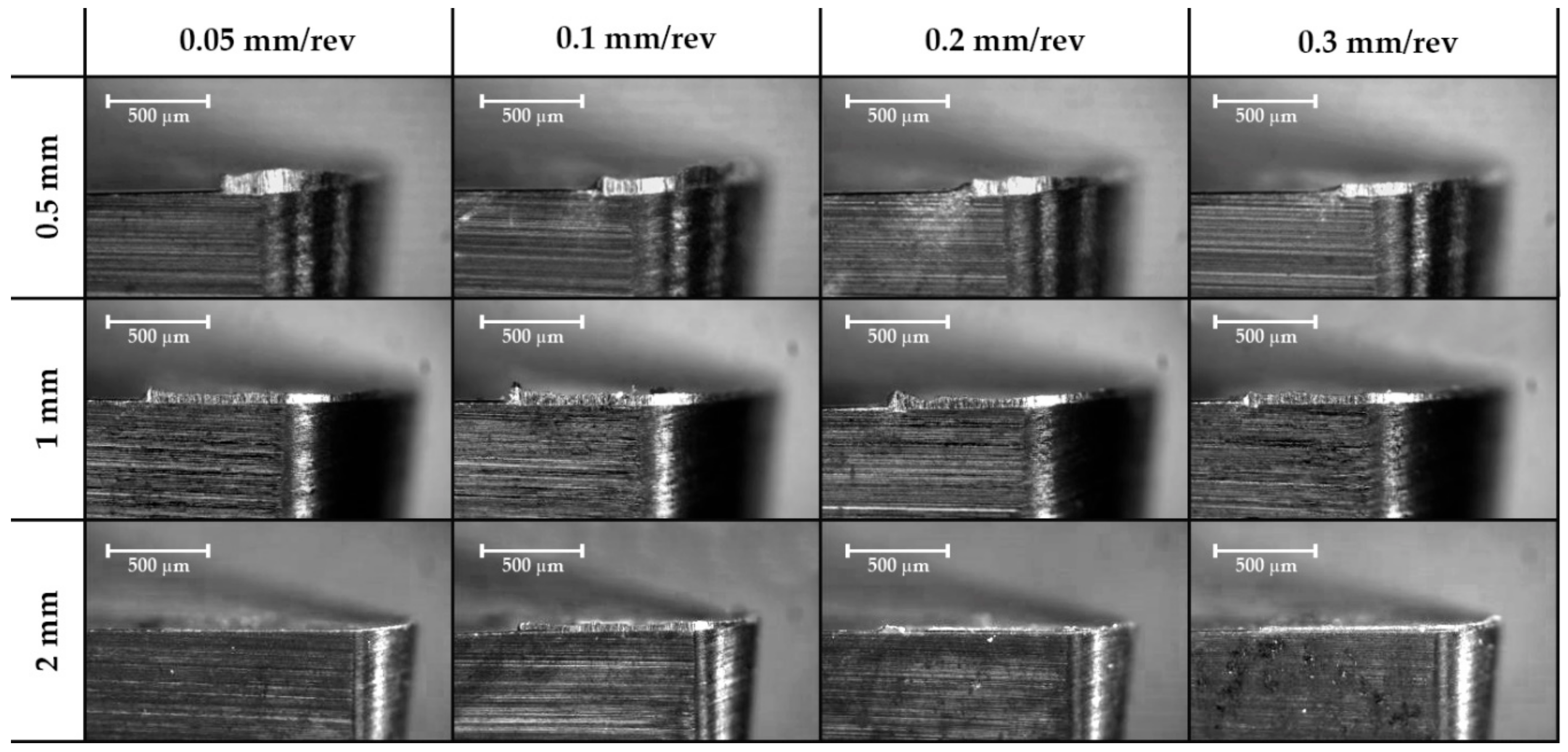

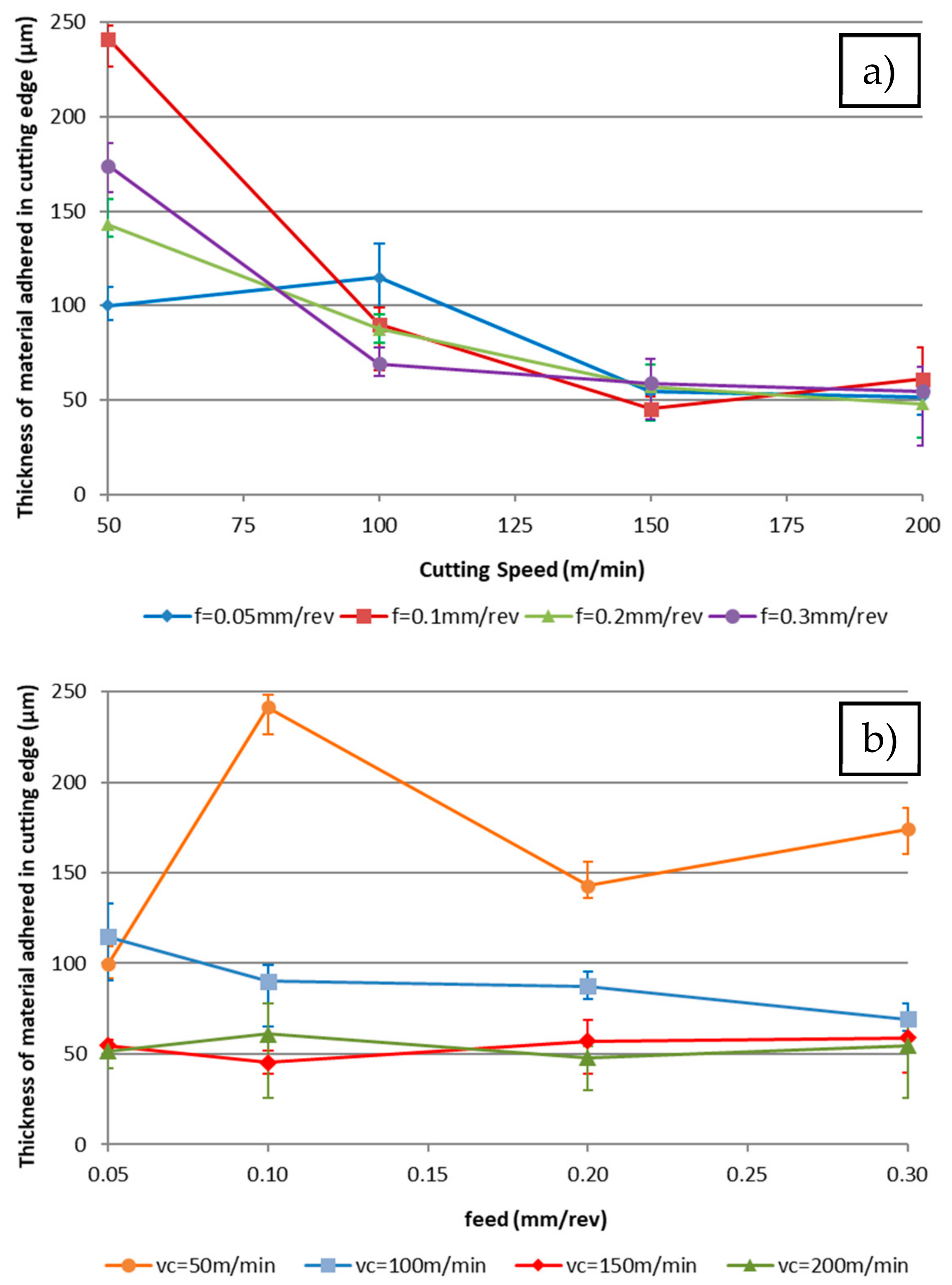

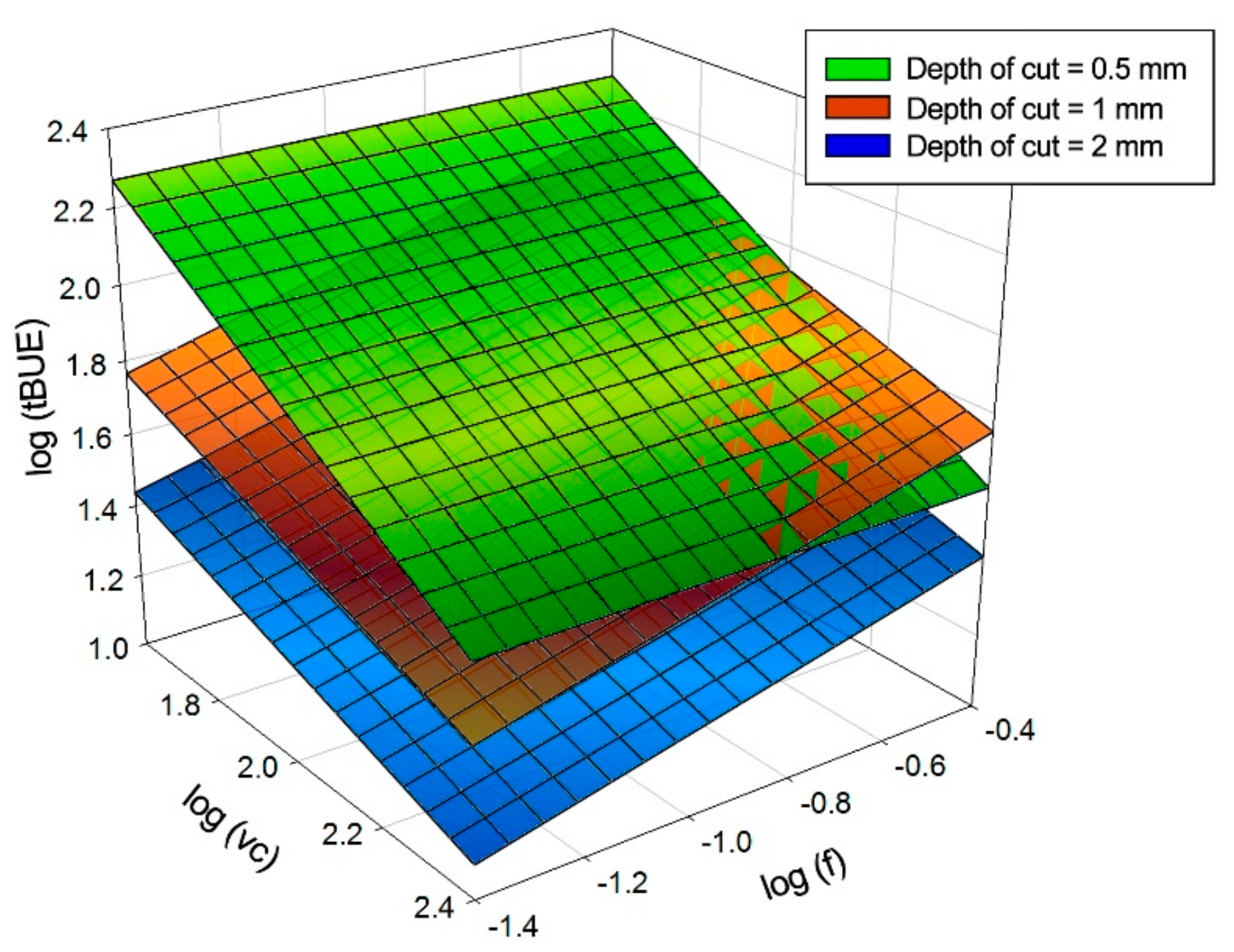

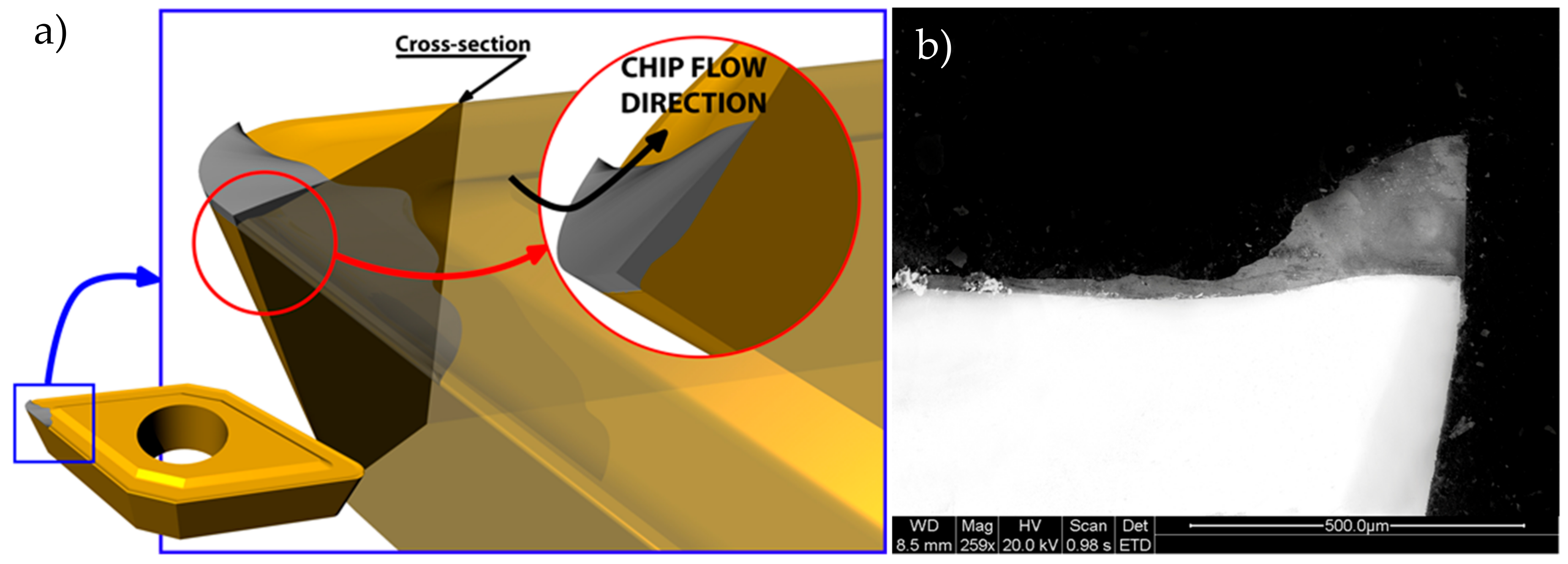

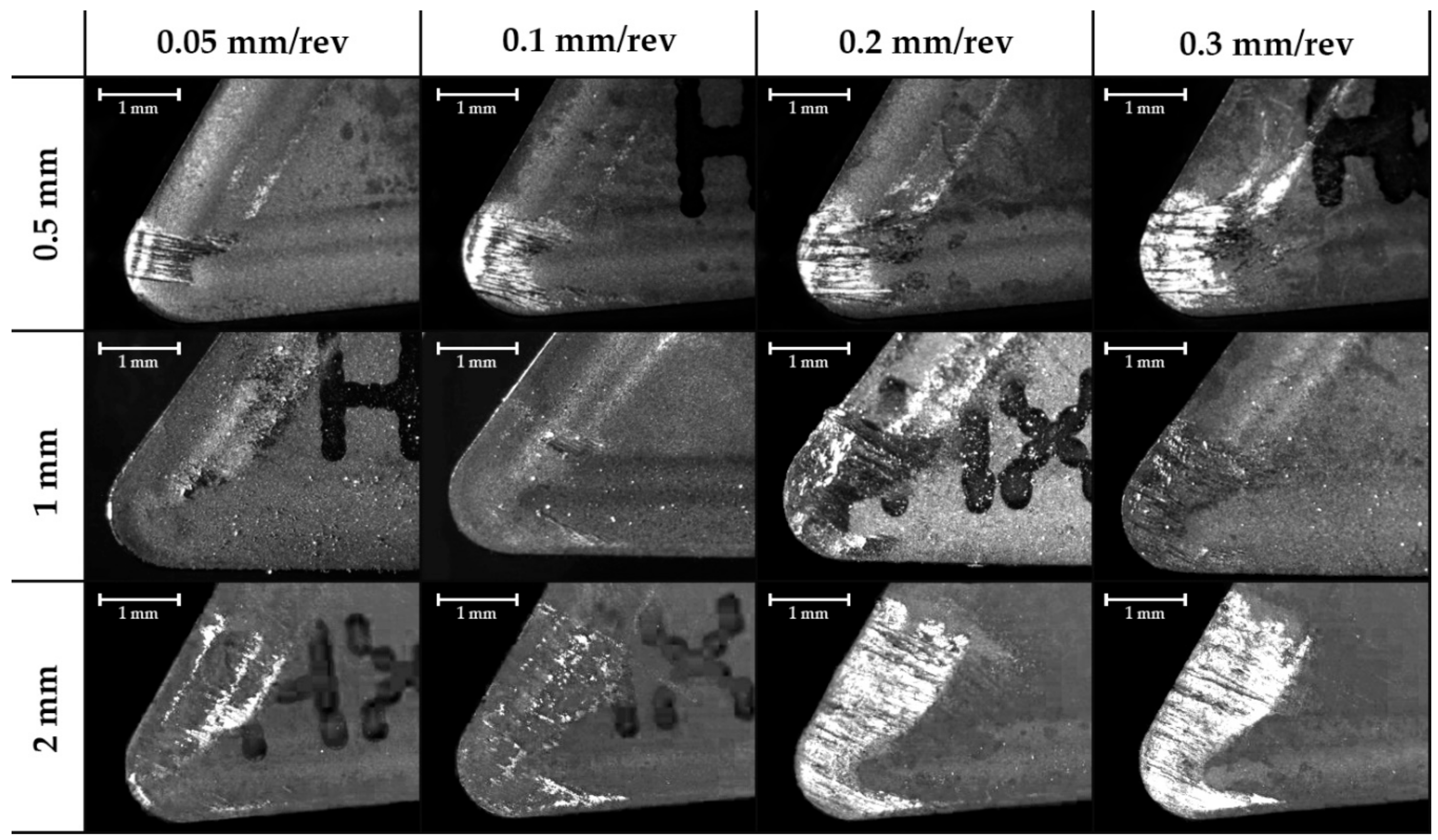

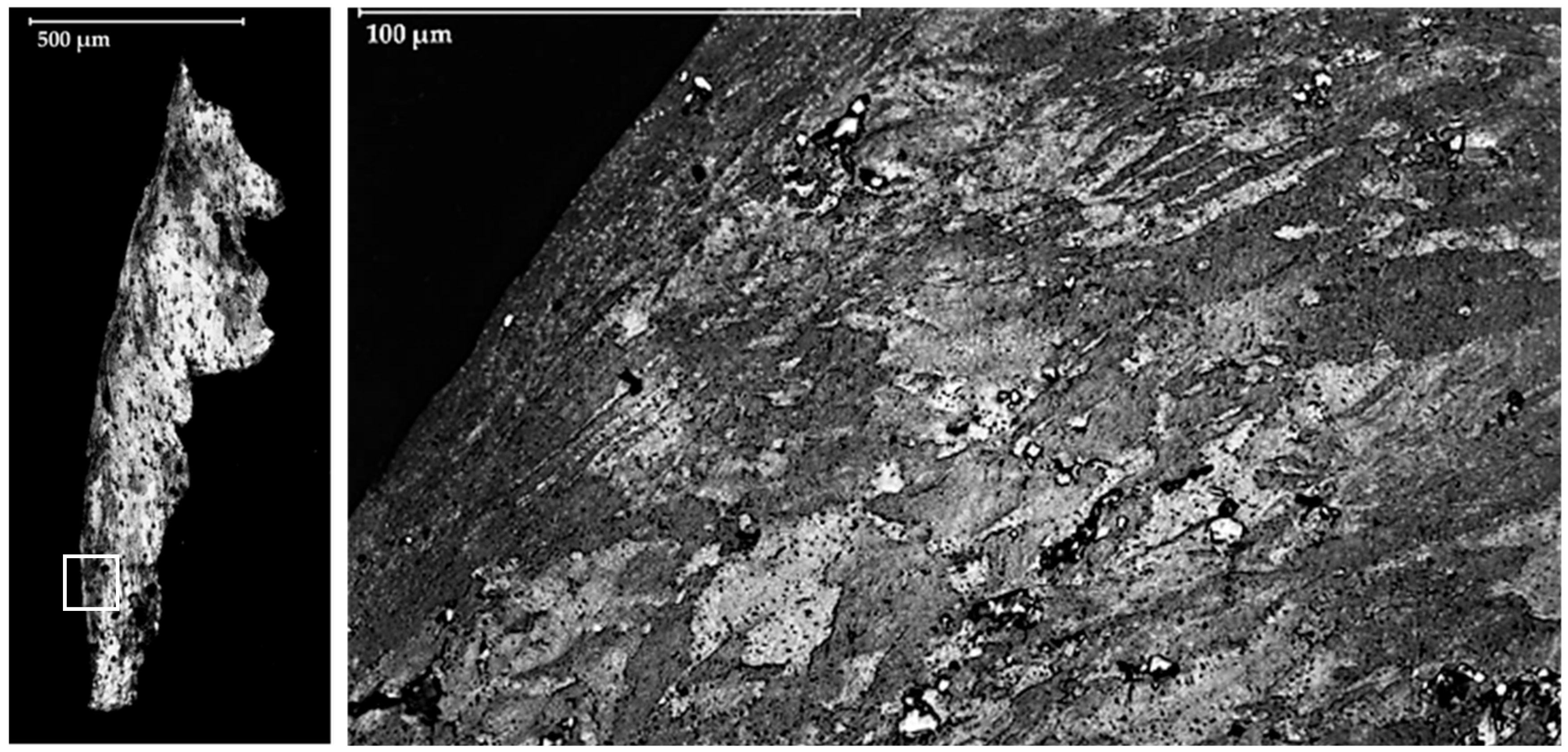

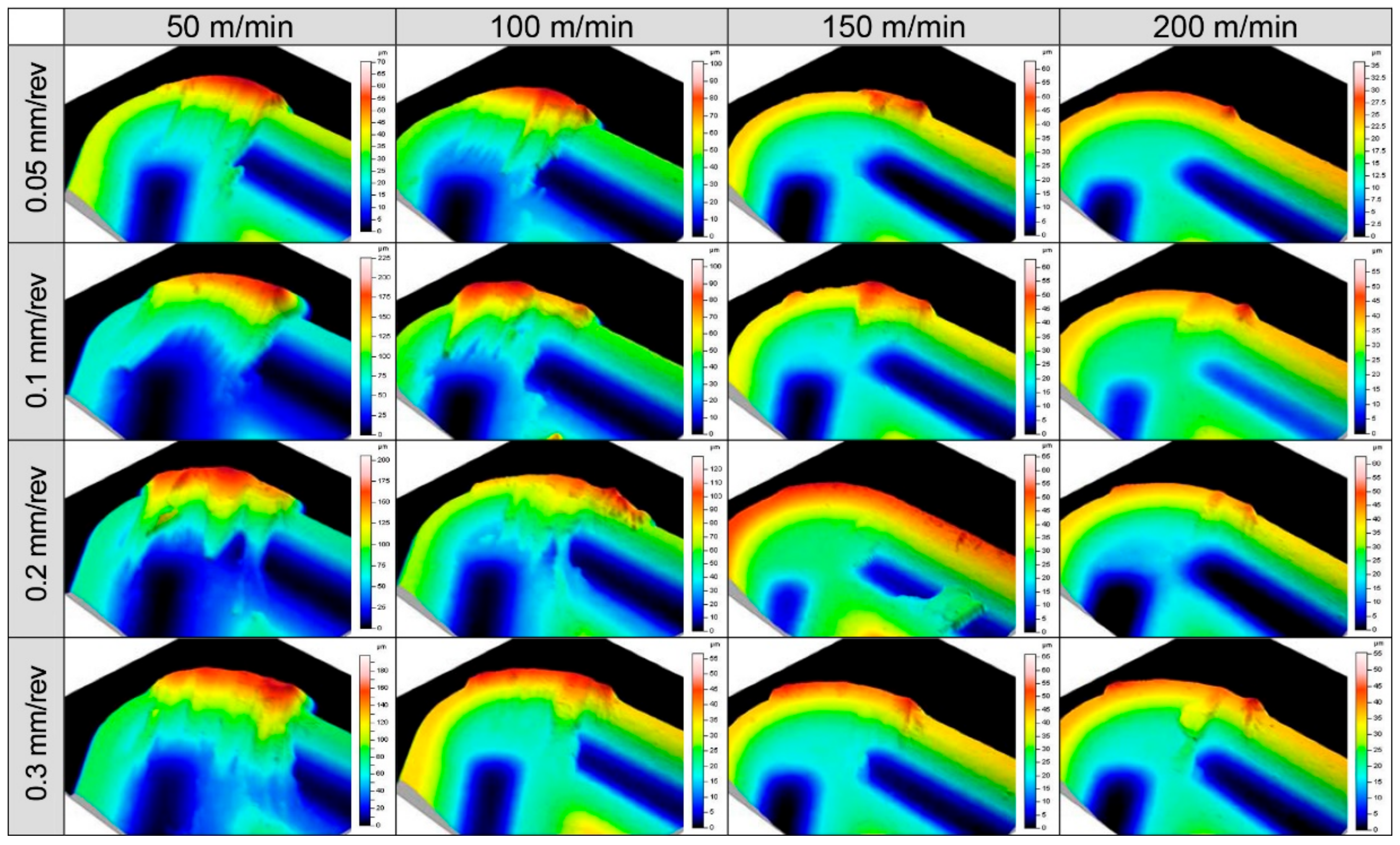

3.1. Evaluation of the Thickness of the Adhered Material onto the Cutting Edge

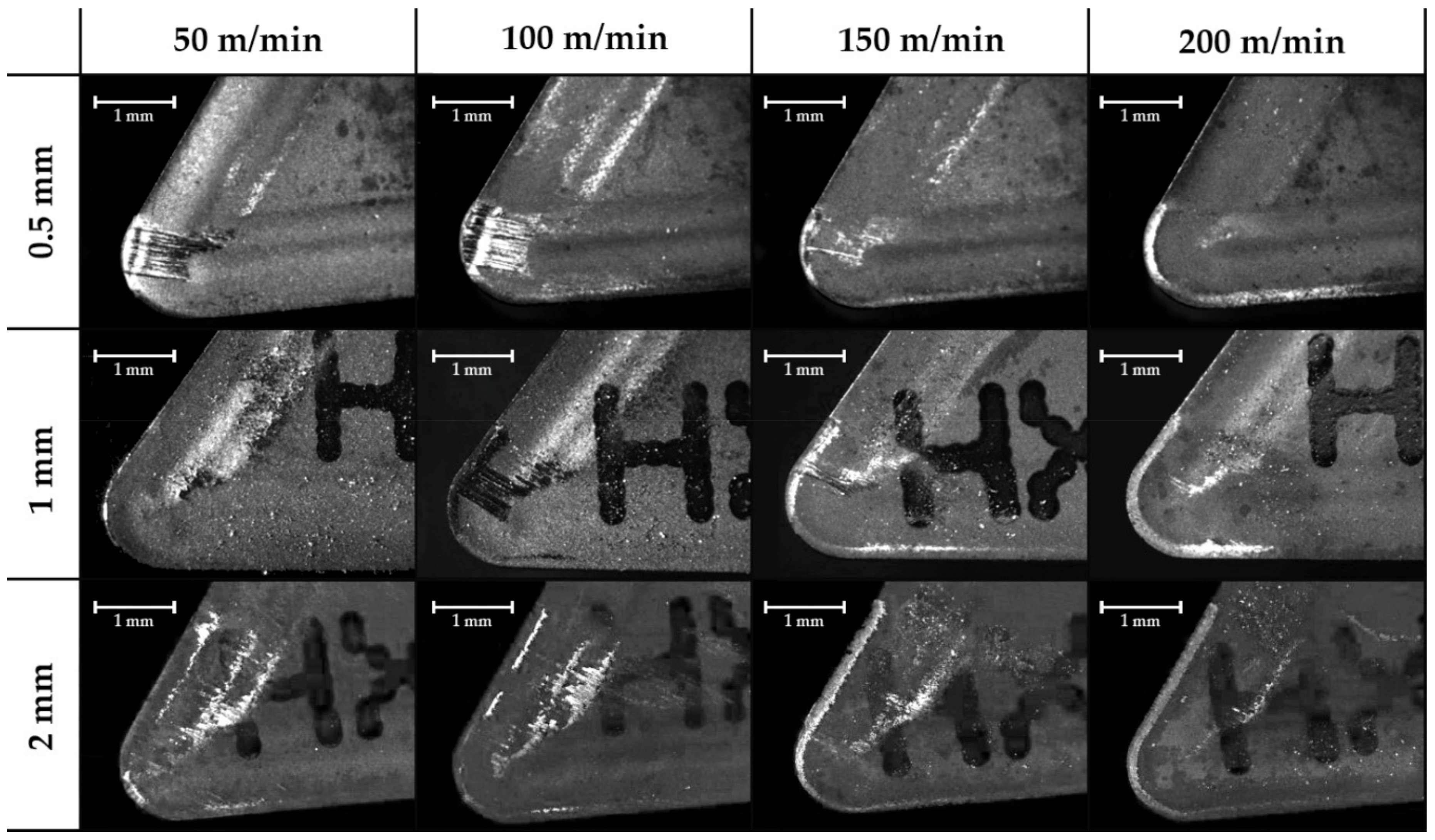

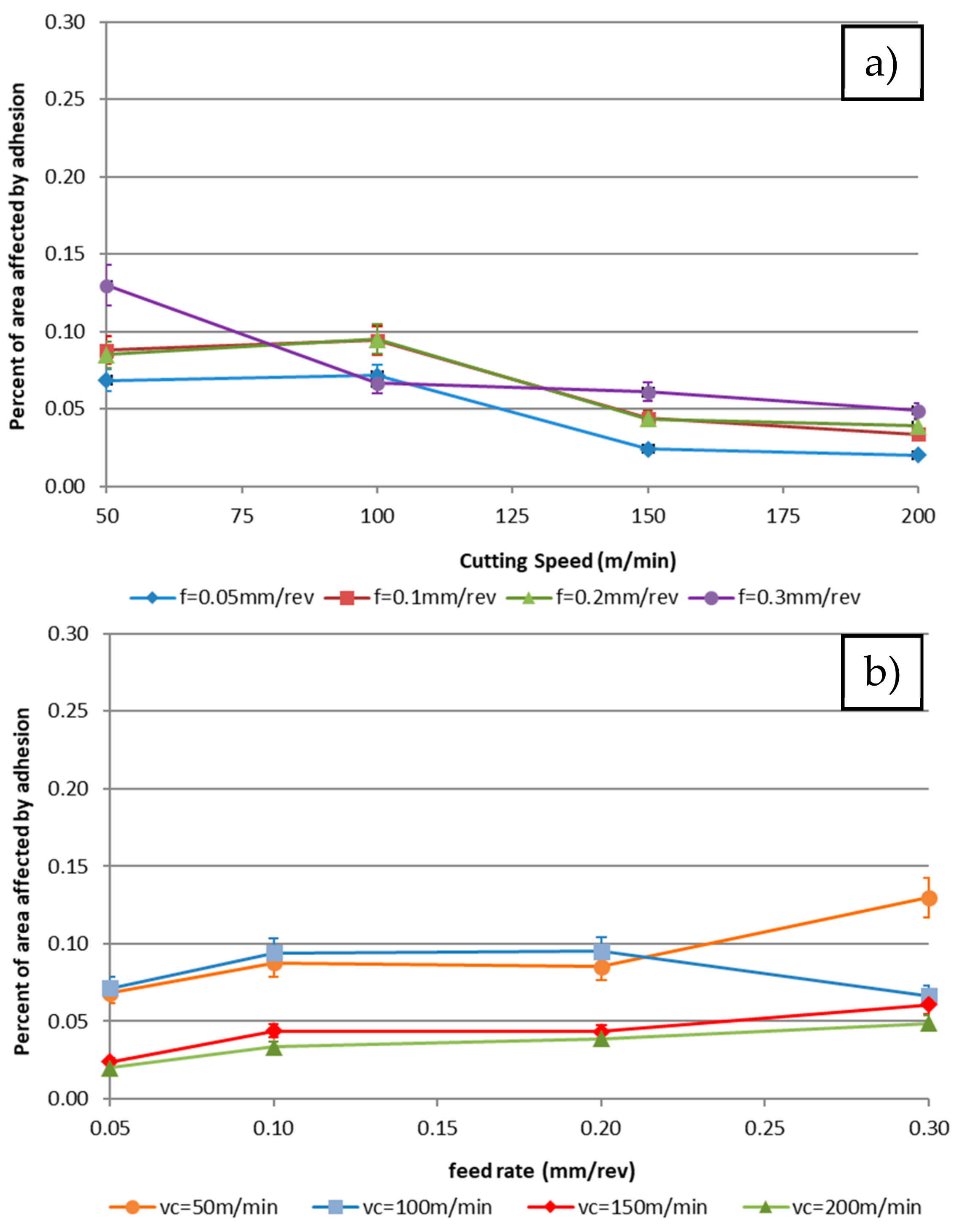

3.2. Evaluation of the Area Affected by Adhesion

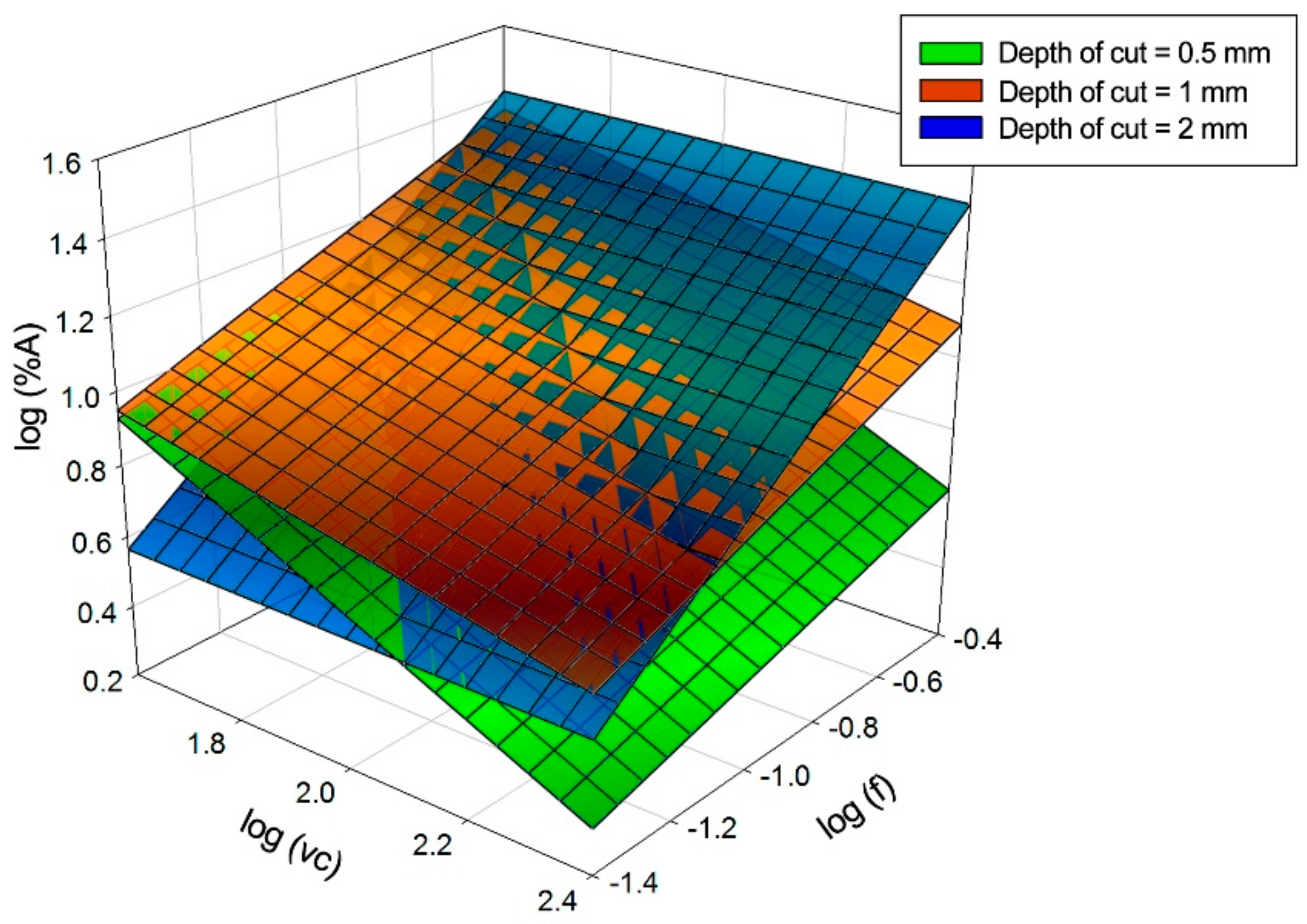

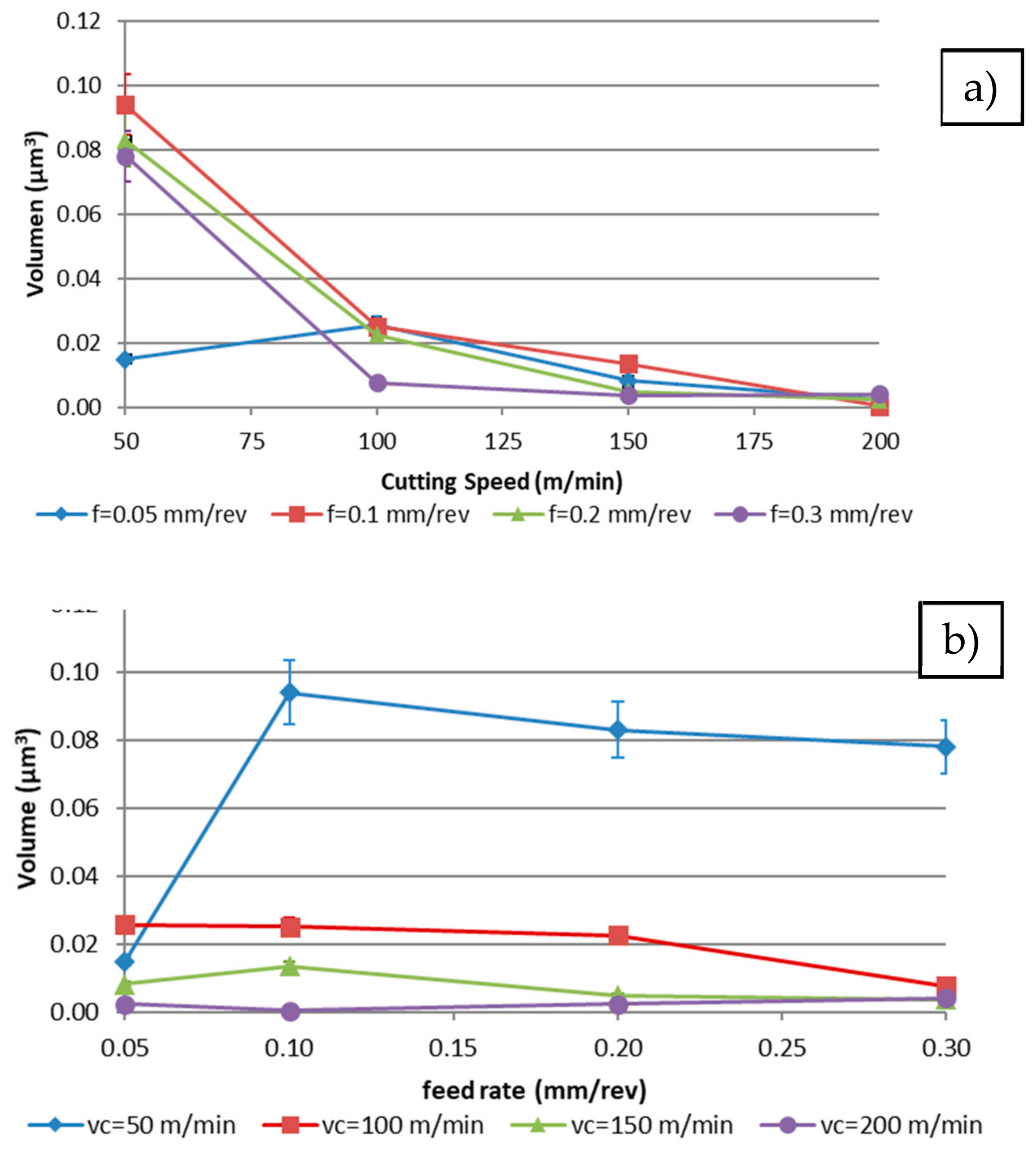

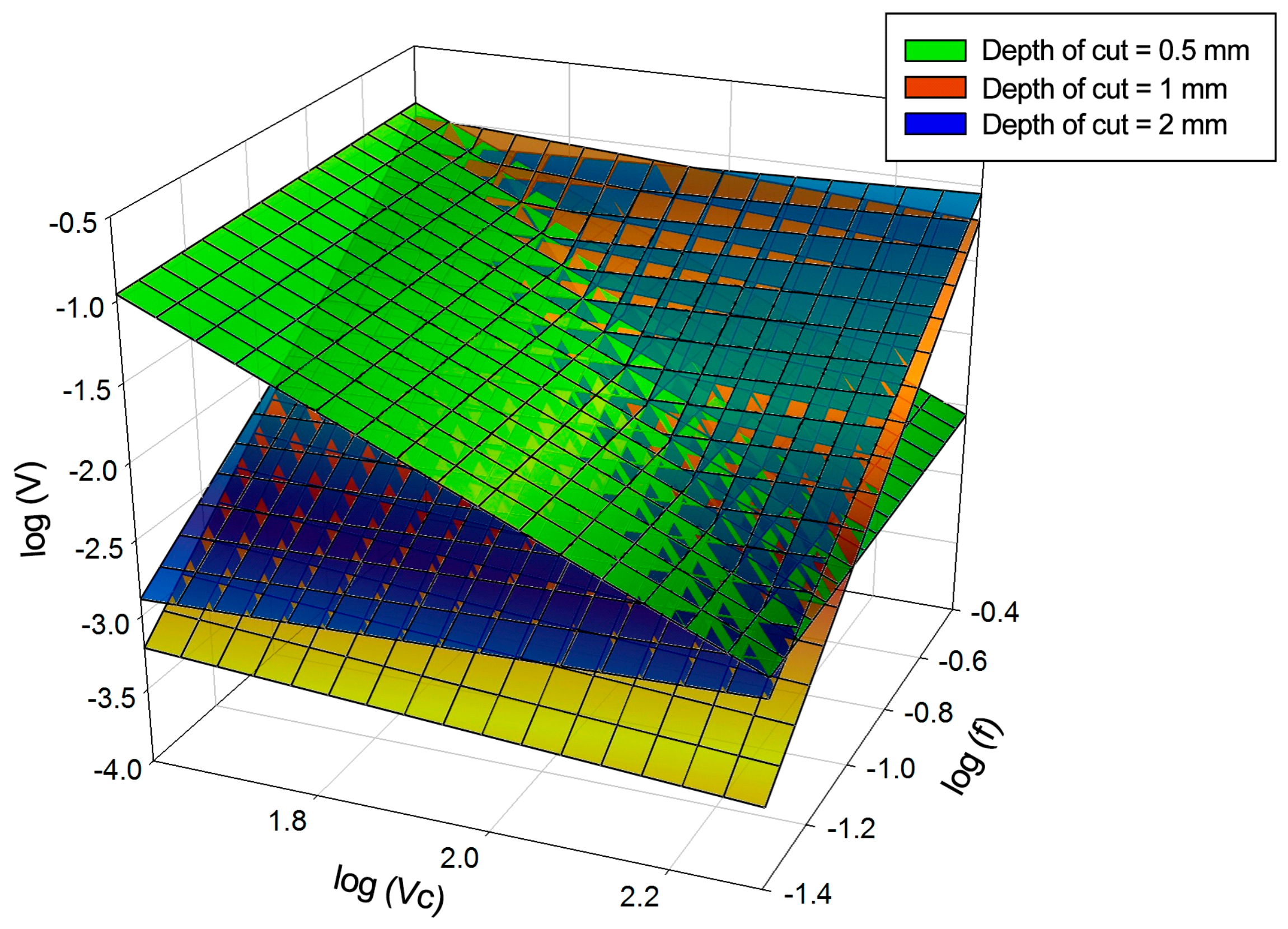

3.3. Volume of the Material Adhered of the Cutting Tool

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Merchant, M.E.; Krabacher, E.J. Radioactive tracers for rapid measurement of cutting tool life. J. Appl. Phys. 1951, 22, 1507–1508. [Google Scholar] [CrossRef]

- Ernst, H.; Martellotti, M. The formation of the Build-Up Edge. ASME Mech. Eng. 1938, 57, 487–498. [Google Scholar]

- Bailey, J.A. Friction in metal machining-mechanical aspects. Wear 1975, 31, 243–275. [Google Scholar] [CrossRef]

- Komanduri, R. Machining and grinding: A historical review of the classical papers. Appl. Mech. Rev. 1993, 46. [Google Scholar] [CrossRef]

- Da Silva, R.B.; Machado, Á.R.; Ezugwu, E.O.; Bonney, J.; Sales, W.F. Tool life and wear mechanisms in high speed machining of Ti-6Al-4V alloy with PCD tools under various coolant pressures. J. Mater. Process. Technol. 2013, 213, 1459–1464. [Google Scholar] [CrossRef]

- Nouari, M.; List, G.; Girot, F.; Coupard, D. Experimental analysis and optimisation of tool wear in dry machining of aluminium alloys. Wear 2003, 255, 1359–1368. [Google Scholar] [CrossRef]

- Santos, M.; Machado, A.; Sales, W.; Barrozo, M.; Ezugwu, E. Machining of aluminum alloys: A review. Int. J. Adv. Manuf. Technol. 2013, 86, 3067–3080. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental friendly cutting fluids and cooling techniques in machining: A review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Mia, M.; Gupta, M.K.; Singh, G.; Królczyk, G.; Pimenov, D.Y. An approach to cleaner production for machining hardened steel using different cooling-lubrication conditions. J. Clean. Prod. 2018, 187, 1069–1081. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Nieslony, P.; Wojciechowski, S.; Legutko, S. Parametric and nonparametric description of the surface topography in the dry and MQCL cutting conditions. Measurement 2018, 121, 225–239. [Google Scholar] [CrossRef]

- Polvorosa, R.; Suárez, A.; López de Lacalle, L.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of alloy 718 and waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Sartori, S.; Moro, L.; Ghiotti, L.; Bruschi, S. On the tool wear mechanisms in dry and cryogenic turning Additive Manufactured titanium alloys. Tribol. Int. 2017, 105, 264–273. [Google Scholar] [CrossRef]

- Mia, M. Multi-response optimization of end milling parameters under through-tool cryogenic cooling condition. Measurement 2017, 111, 134–145. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Newman, S.T. Environmentally conscious machining of difficult-to-machine materials with regard to cutting fluids. Int. J. Mach. Tools Manuf. 2012, 57, 83–101. [Google Scholar] [CrossRef]

- Goindi, G.; Sarkar, P. Dry machining: A step towards sustainable machining-challenges and future directions. J. Clean. Prod. 2017, 165, 1557–1571. [Google Scholar] [CrossRef]

- Krolczyk, G.; Nieslony, P.; Maruda, R.; Wojciechowski, S. Dry cutting effect in turning of a duplex stainless steel as a key factor in clean production. J. Clean. Prod. 2017, 142, 3343–3354. [Google Scholar] [CrossRef]

- Salguero, J.; Vazquez-Martinez, J.M.; Del Sol, I.; Batista, M. Application of Pin-On-Disc techniques for the study of tribological interferences in the dry machining of A92024-T3 (Al-Cu) alloys. Materials 2018, 11, 1236. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Parra, A.; Alvarez-Alcon, M.; Salguero, J.; Batista, M.; Marcos, M. Analysis of the evolution of the Built-Up Edge and Built-Up Layer formation mechanisms in the dry turning of aeronautical aluminium alloys. Wear 2013, 302, 1209–1218. [Google Scholar] [CrossRef]

- Carrilero, M.S.; Bienvenido, R.; Sánchez, J.M.; Álvarez, M.; González, A.; Marcos, M. A SEM and EDS insight into the BUL and BUE differences in the turning processes of AA2024 Al–Cu alloy. Int. J. Mach. Tools Manuf. 2002, 42, 215–220. [Google Scholar] [CrossRef]

- Trent, E.M.; Wright, P.K. Metal Cutting; Butterworth-Heinemann: Oxford, UK, 2000; ISBN 978-0-7506-7069-2. [Google Scholar]

- Klocke, F.; Eisenblätter, G.; Krieg, T. Machining: Wear of Tools. In Encyclopedia of Materials: Science and Technology; Elsevier Ltd.: New York, NY, USA, 2001; pp. 4708–4711. ISBN 978-0-08-043152-9. [Google Scholar]

- Krolczyk, G.; Gajek, M.; Legutko, S. Predicting the tool life in the dry machining of duplex stainless steel. Maint. Reliab. 2013, 15, 62–65. [Google Scholar]

- Krolczyk, G.; Legutko, S.; Gajek, Y.S. Predicting the surface roughness in the dry machining of duplex stainless steel (DSS). Metalurgija 2013, 52, 259–262. [Google Scholar]

- Fernández-Valdivielso, A.; Lopez de Lacalle, L.; Urbikain, G.; Rodriguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. J. Mech. Eng. Sci. 2016, 230, 3725–3742. [Google Scholar] [CrossRef]

- Lamikiz, A.; Lopez de Lacalle, L.; Sanchez, J.; Bravo, U. Calculation of the specific cutting coefficients and geometrical aspects in sculptured surface machining. Mach. Sci. Technol. 2005, 9, 411–436. [Google Scholar] [CrossRef]

- Calleja, A.; Bo, P.; Gonzalez, H.; Barton, H.; Lopez de Lacalle, L. Highly accurate 5-axis flank CNC machining with conical tools. Int. J. Adv. Manuf. Technol. 2018, 97, 1605–1615. [Google Scholar] [CrossRef]

- Trujillo, F.; Sevilla, L.; Marcos, M. Experimental parametric model for indirect adhesion wear measurement in the dry turning of UNS A97075 (Al-Zn) alloy. Materials 2017, 10, 152. [Google Scholar] [CrossRef] [PubMed]

- Batista, M.; Salguero, J.; Gómez, A.; Carrilero, M.S.; Álvarez, M.; Marcos Bárcena, M. Identification, analysis and evolution of the mechanisms of wear for secondary adhesion for dry turning processes of Al-Cu alloys. Adv. Mater. Res. 2010, 107, 141–146. [Google Scholar] [CrossRef]

- Salguero, J.; Batista Ponce, M.; Sánchez-Carrilero, M.; Álvarez, M.; Marcos-Bárcena, M. Sustainable manufacturing in aerospace industry—Analysis of the viability of intermediate stages elimination in sheet processing. Adv. Mater. Res. 2010, 107, 9–14. [Google Scholar] [CrossRef]

- Salguero, J.; Carrilero, M.S.; Batista, M.; Álvarez, M.; Marcos, M. Analysis of the influence of thermal treatment on the dry turning of Al-Cu alloys. In Proceedings of the Third Manufacturing Engineering Society International Conference: Mesic-09, Alcoy, Spain, 17–19 June 2009. [Google Scholar]

- Bleither, F.; Reiter, M. Wear reduction on cutting inserts by additional internal cooling of the cutting edge. Procedia Eng. 2018, 21, 518–524. [Google Scholar] [CrossRef]

- Maine, J.; Batista, M.; García-Jurado, D.; Shaw, L.; Marcos, M. FVM based methodology for evaluating adhesion wear of cutting tools. Procedia CIRP 2013, 8, 552–557. [Google Scholar] [CrossRef]

- Gontard, L.; Batista, M.; Salguero, J.; Calvino, J. Three-dimensional chemical mapping using non-destructive SEM and photogrammetry. Sci. Rep. 2018, 8, 11000. [Google Scholar] [CrossRef] [PubMed]

- Castejon, M.; Alegre, E.; Barreiro, J.; Hernandez, L. On-line tool wear monitoring using geometric descriptors from digital images. Int. J. Mach. Tools Manuf. 2007, 47, 1847–1853. [Google Scholar] [CrossRef]

- Shahabi, H.; Ratnam, M. In-cycle detection of Built-Up Edge (BUE) from 2-D images of cutting tools using machine vision. Int. J. Adv. Manuf. Technol. 2010, 46, 1179–1189. [Google Scholar] [CrossRef]

- Sen, B.; Mandal, U.; Mondal, S. Advancement of an intelligent system based on ANFIS for predicting machining performance parameters of Inconel 690—A perspective of metaheuristic approach. Measurement 2017, 109, 9–17. [Google Scholar] [CrossRef]

- Dan, L.; Mathew, J. Tool wear and failure monitoring techniques for turning—A review. Int. J. Mach. Tools Manuf. 1990, 30, 579–598. [Google Scholar] [CrossRef]

- Cook, N.H. Tool wear sensors. Wear 1980, 62, 49–57. [Google Scholar] [CrossRef]

- Rivero, A.; Lacalle, L.; Penalva, M. Tool wear detection in dry high-speed milling based upon the analysis of machine internal signals. Mechatronics 2008, 18, 627–633. [Google Scholar] [CrossRef]

- Lauro, C.; Brandao, L.; Baldo, D.; Reis, R.; Davim, J. Monitoring and processing signal applied in machining processes—A review. Measurement 2014, 58, 73–86. [Google Scholar] [CrossRef]

- Haddag, B.; Atlati, S.; Nouari, M.; Moufki, A. Dry machining aeronautical aluminum alloy AA2024-T351: Analysis of cutting forces, chip segmentation and Built-Up Edge formation. Metals 2016, 6, 197. [Google Scholar] [CrossRef]

- Melkote, S.N.; Liu, R.; Fernandez-Zelaia, P.; Marusich, T. A physically based constitutive model for simulation of segmented chip formation in orthogonal cutting of commercially pure titanium. CIRP Ann.-Manuf. Technol. 2015, 64, 65–68. [Google Scholar] [CrossRef]

- Davim, J.P. Modern Mechanical Engineering; Springer-Verlag: Berlin/Heidelberg, Germany, 2014; ISBN 978-3-642-45176-8. [Google Scholar]

- Batista, M.; Salguero, J.; Gómez-Parra, A.; Alvarez, M.; Marcos, M. Image based analysis evaluation of the elements of secondary image based analysis evaluation of the elements of secondary. Adv. Mater. Res. 2012, 498, 133–138. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). 1832:2012 Indexable Inserts for Cutting Tools—Designation; ISO: Genève, Switzerland, 2012. [Google Scholar]

- International Organization for Standardization (ISO). 3685:1993 Tool-Life Testing with Single-point Turning Tools; ISO: Genève, Switzerland, 1993. [Google Scholar]

- Rubio, E.; Camacho, A.; Sanchez-Sola, J.; Marcos, M. Chip arrangement in the dry cutting of aluminium alloys. J. Achievements Mater. Manuf. Eng. 2006, 16, 164–170. [Google Scholar]

- Davis, J.R. ASM Handbook Volume 16: Machining, 9th ed.; ASM International: Metals Park, OH, USA, 1989; ISBN 978-0-87170-022-3. [Google Scholar]

- Carrilero, M.; Marcos, M.; Sanchez, V. Feed, cutting speed and cutting forces as machinability parameters of Al-Cu alloy. J. Mech. Behav. Mater. 1996, 7, 167–178. [Google Scholar] [CrossRef]

- Carrilero, M.; Marcos, M. On the machinability of aluminium and aluminium alloys. J. Mech. Behav. Mater. 1996, 7, 179–193. [Google Scholar] [CrossRef]

- Sebastian, M.; Sanchez-Sola, J.; Carrilero, M.; Gonzalez, J.; Alvarez, M.; Marcos, M. Parametric model for predicting surface finish of machined UNS A92024 alloy bars. J. Manuf. Sci. Prod. 2011, 4, 181–188. [Google Scholar] [CrossRef]

- Agustina, B.; Rubio, E.; Villeta, M.; Sebastián, A.M. Analysis of the surface roughness obtained during the dry turning of UNS A97050-T7 aluminium alloys. In Proceedings of the Third Manufacturing Engineering Society International Conference: Mesic-09, Alcoy, Spain, 17–19 June 2009. [Google Scholar]

- Atlati, S.; Haddag, B.; Nouari, M.; Moufki, A. Effect of the local friction and contact nature on the Built-Up Edge formation processin machining ductile metals. Tribol. Int. 2015, 90, 217–227. [Google Scholar] [CrossRef]

| Cutting Speed (vc) (m/min) | 50 | 100 | 150 | 200 |

| Feed (f) (mm/rev) | 0.05 | 0.1 | 0.2 | 0.3 |

| Depth of cut (ap) (mm) | 0.5 | 1 | 2 | - |

| Time of cut (t) (s) | 10 | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Batista Ponce, M.; Del Sol Illana, I.; Fernandez-Vidal, S.R.; Salguero Gomez, J. Experimental Parametric Model for Adhesion Wear Measurements in the Dry Turning of an AA2024 Alloy. Materials 2018, 11, 1598. https://doi.org/10.3390/ma11091598

Batista Ponce M, Del Sol Illana I, Fernandez-Vidal SR, Salguero Gomez J. Experimental Parametric Model for Adhesion Wear Measurements in the Dry Turning of an AA2024 Alloy. Materials. 2018; 11(9):1598. https://doi.org/10.3390/ma11091598

Chicago/Turabian StyleBatista Ponce, Moises, Irene Del Sol Illana, Severo Raul Fernandez-Vidal, and Jorge Salguero Gomez. 2018. "Experimental Parametric Model for Adhesion Wear Measurements in the Dry Turning of an AA2024 Alloy" Materials 11, no. 9: 1598. https://doi.org/10.3390/ma11091598

APA StyleBatista Ponce, M., Del Sol Illana, I., Fernandez-Vidal, S. R., & Salguero Gomez, J. (2018). Experimental Parametric Model for Adhesion Wear Measurements in the Dry Turning of an AA2024 Alloy. Materials, 11(9), 1598. https://doi.org/10.3390/ma11091598