Field Validation of a Magnetic Sensor to Monitor Borehole Deviation during Tunnel Excavation

Abstract

1. Introduction

2. Working Principle of Magnetic Sensor

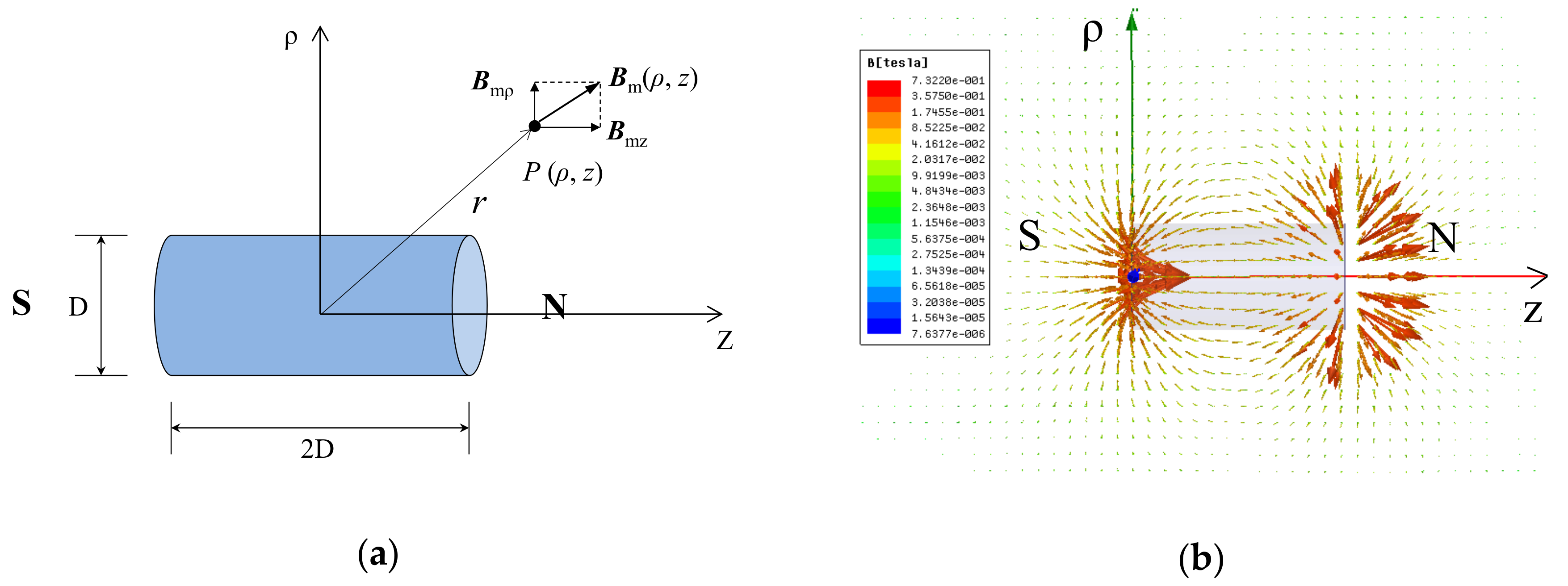

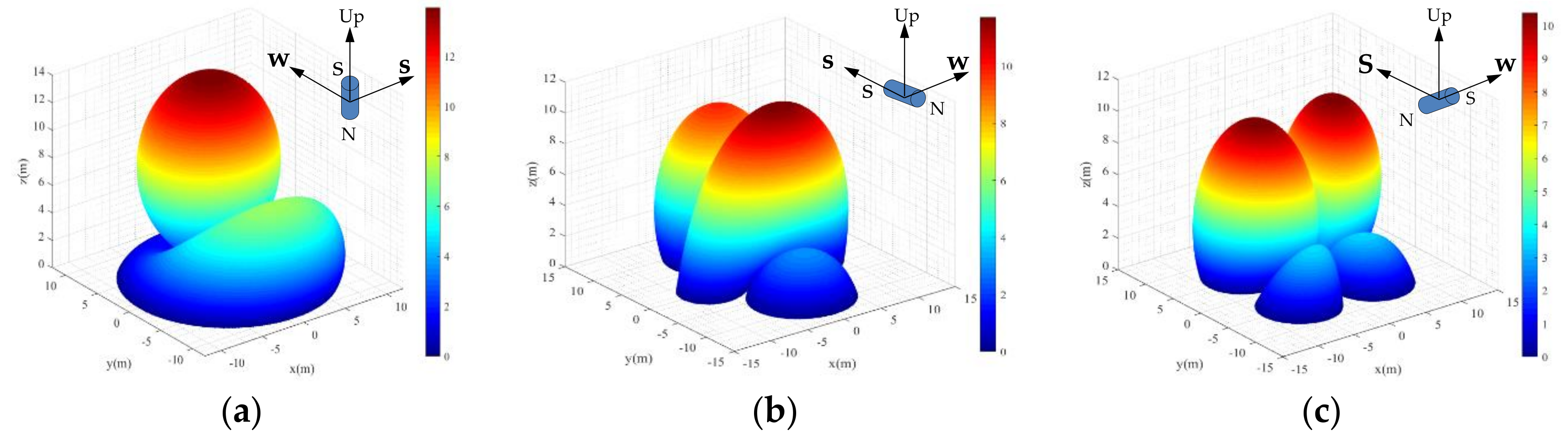

2.1. Magnetic Field Produced by a Cylinder Magnet

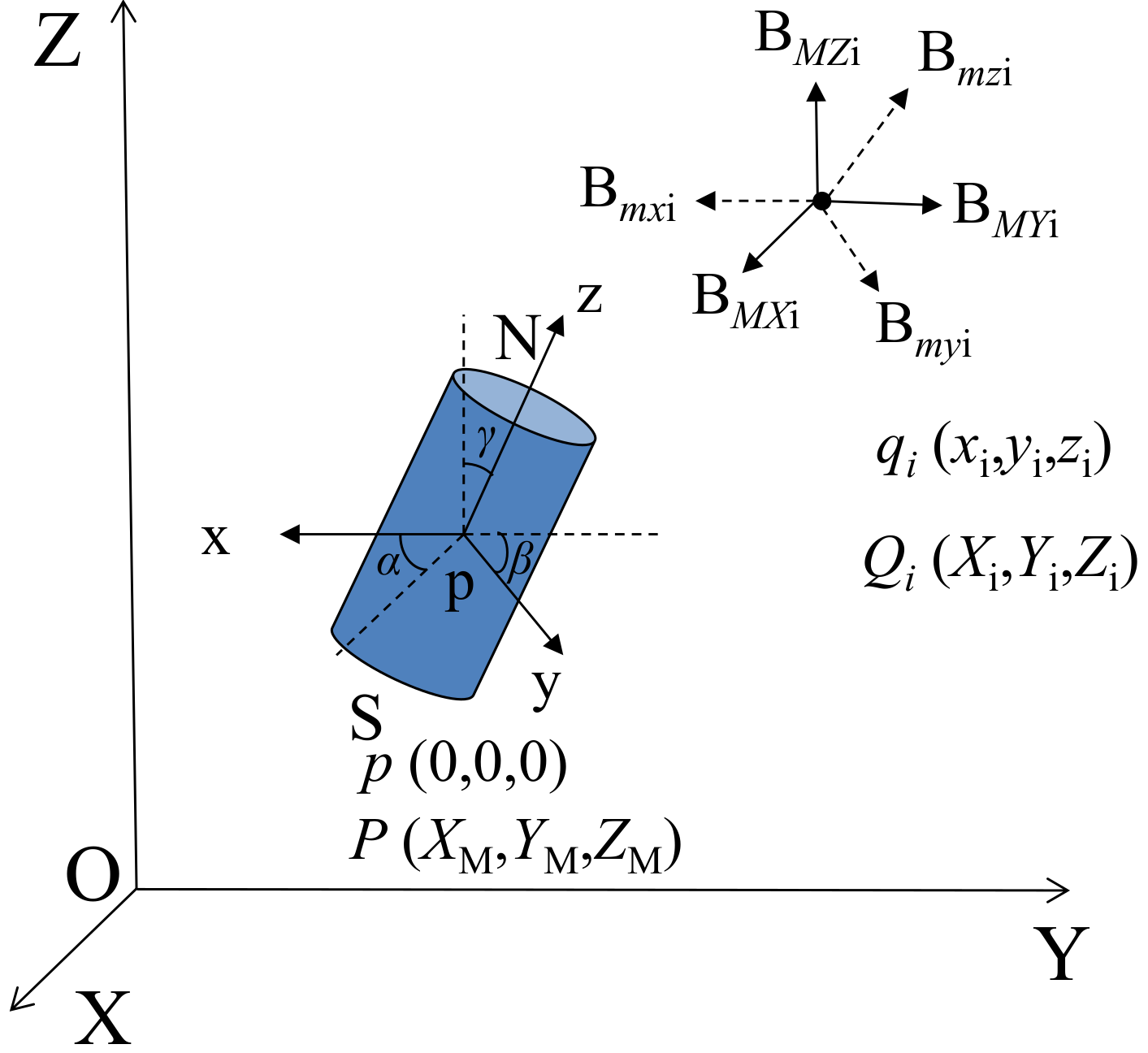

2.2. Determination of the Geomagnetic Field and the Total Magnetic Field in Global Coordinate System

2.3. Localization Algorithm

3. Field Validation Tests

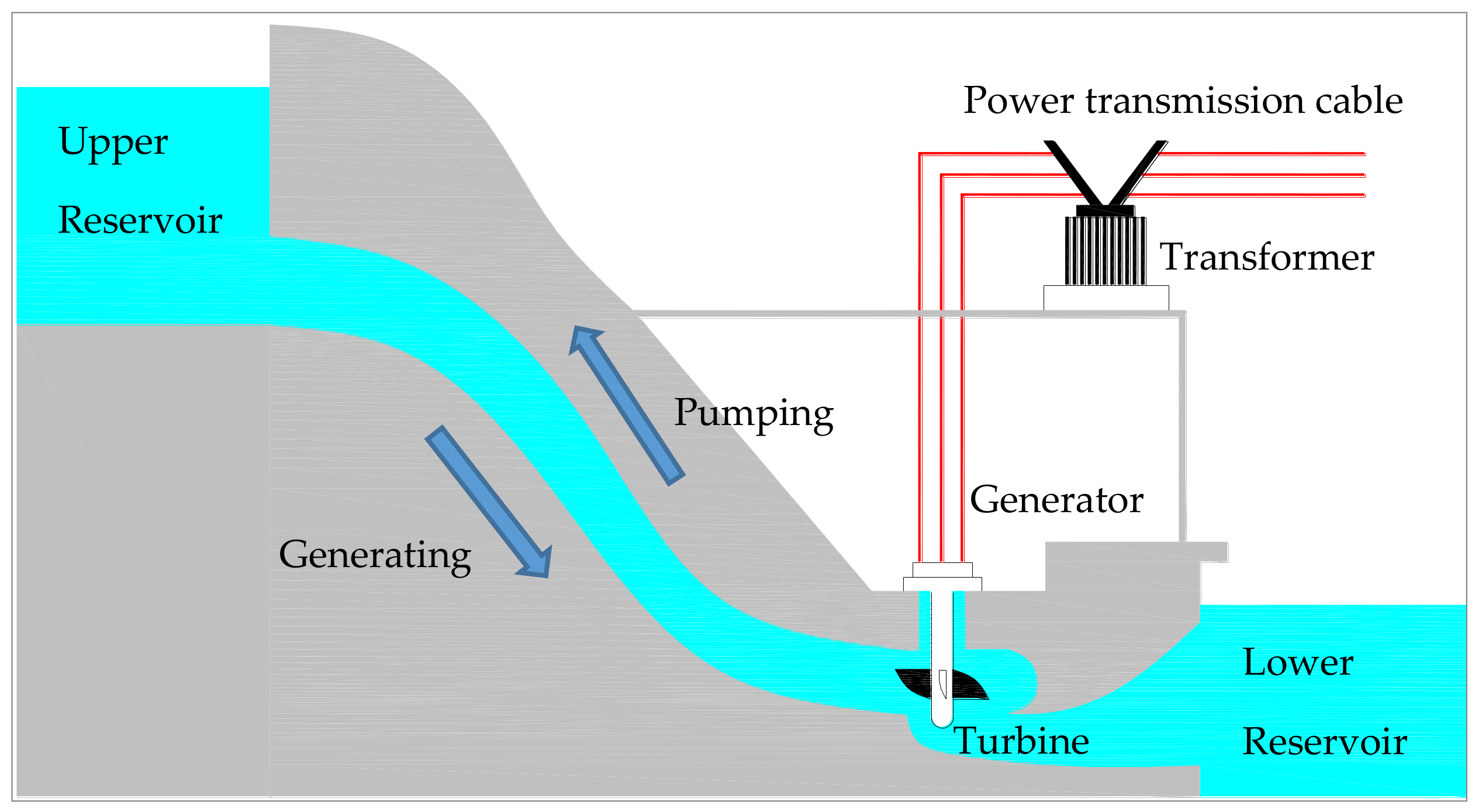

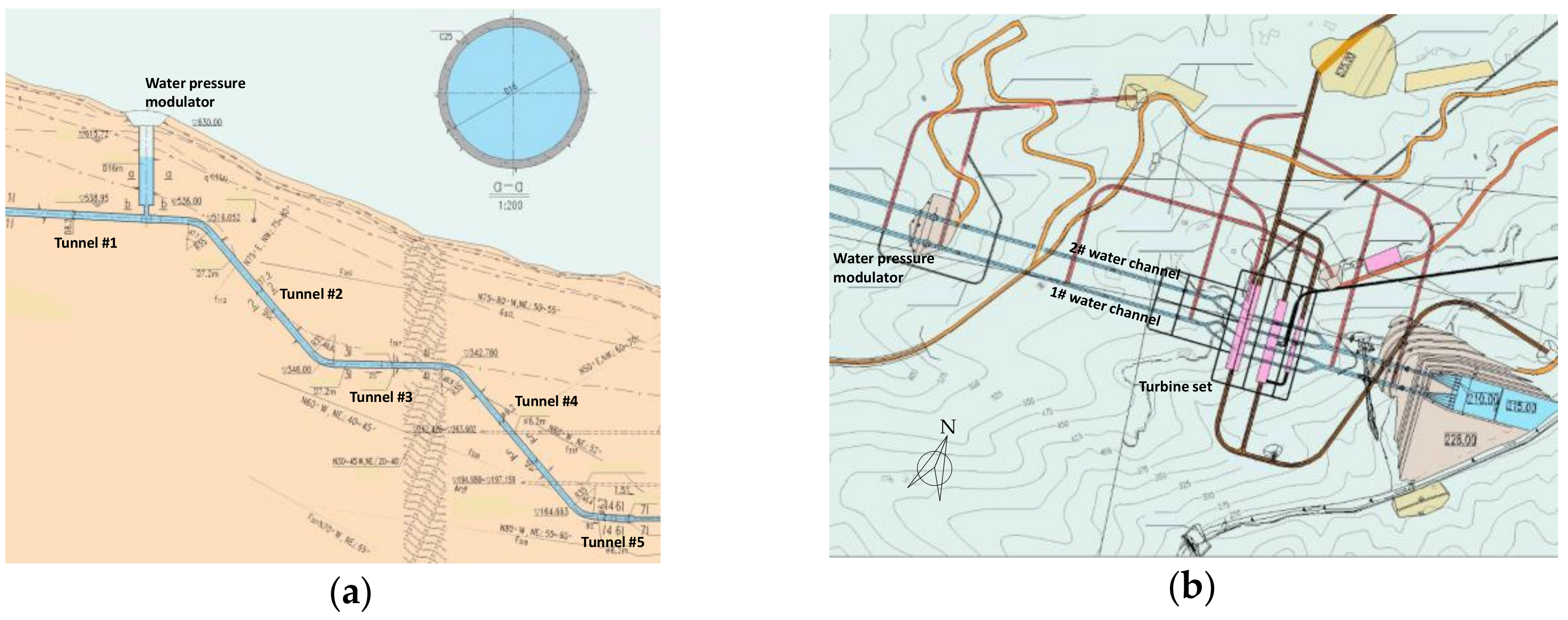

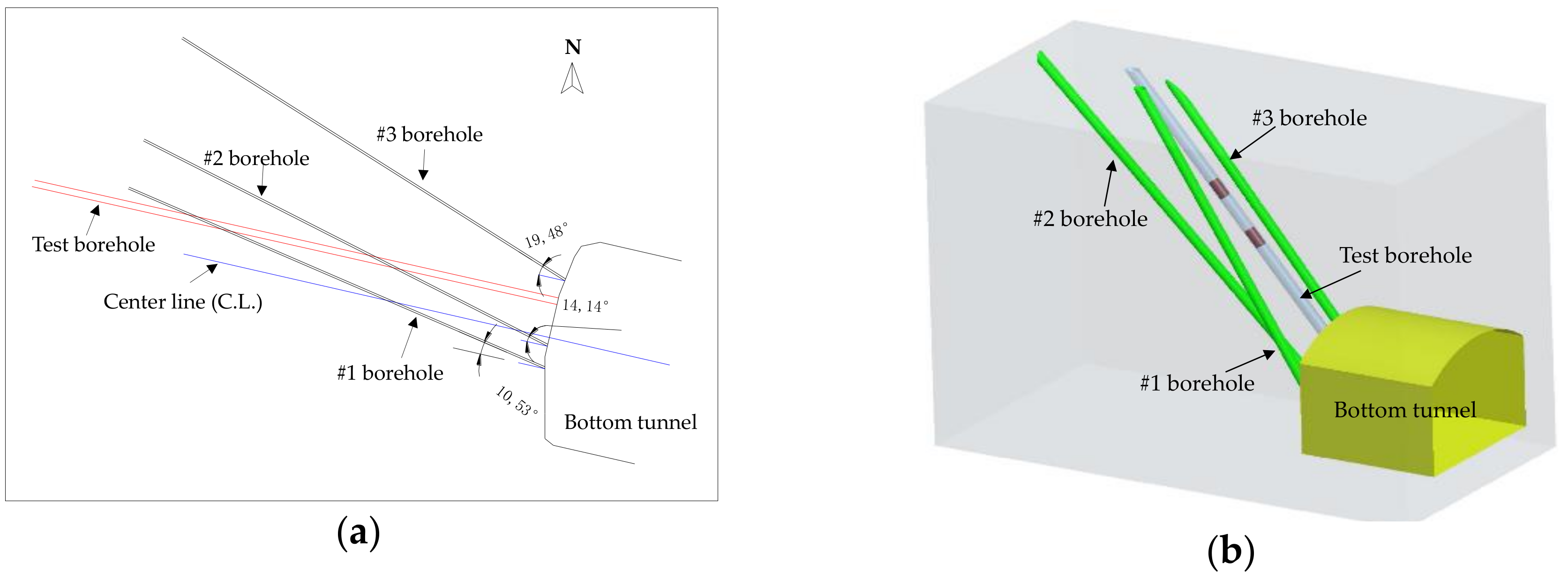

3.1. Jinzhai Pumped-Storage Hydroelectricity Station

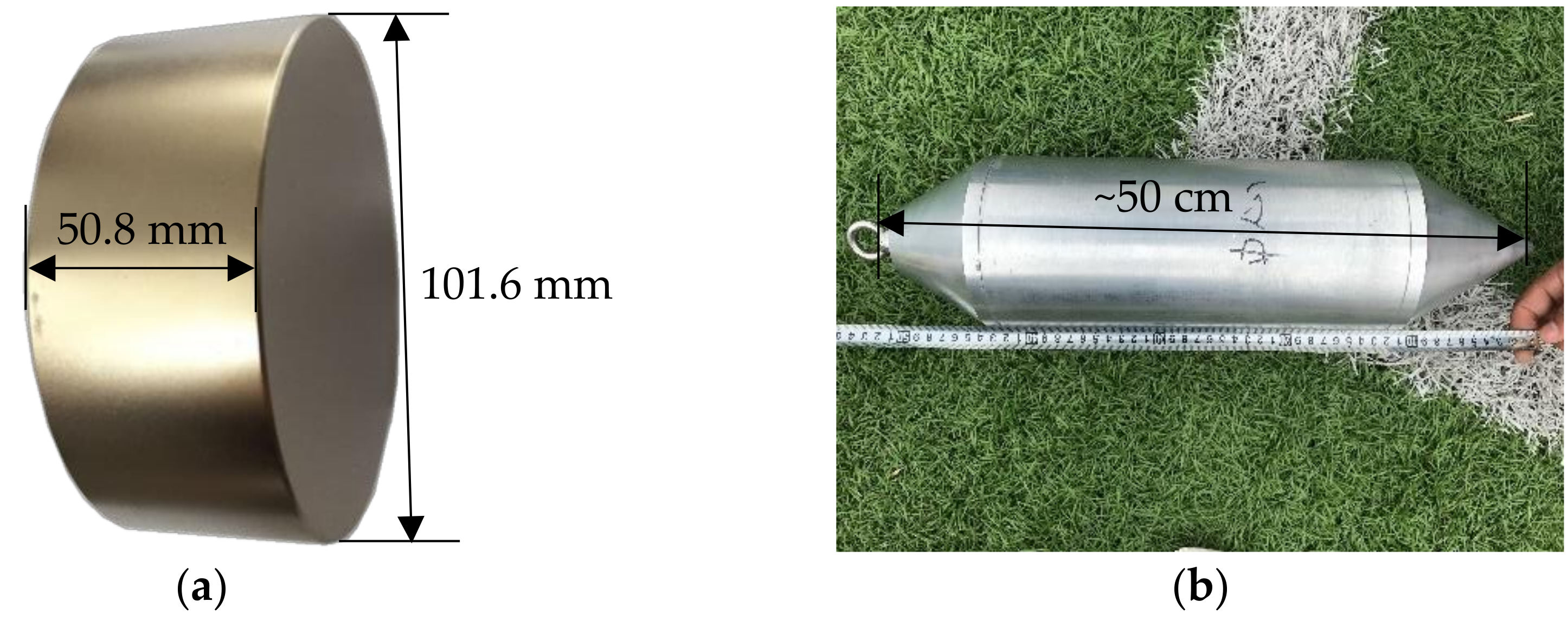

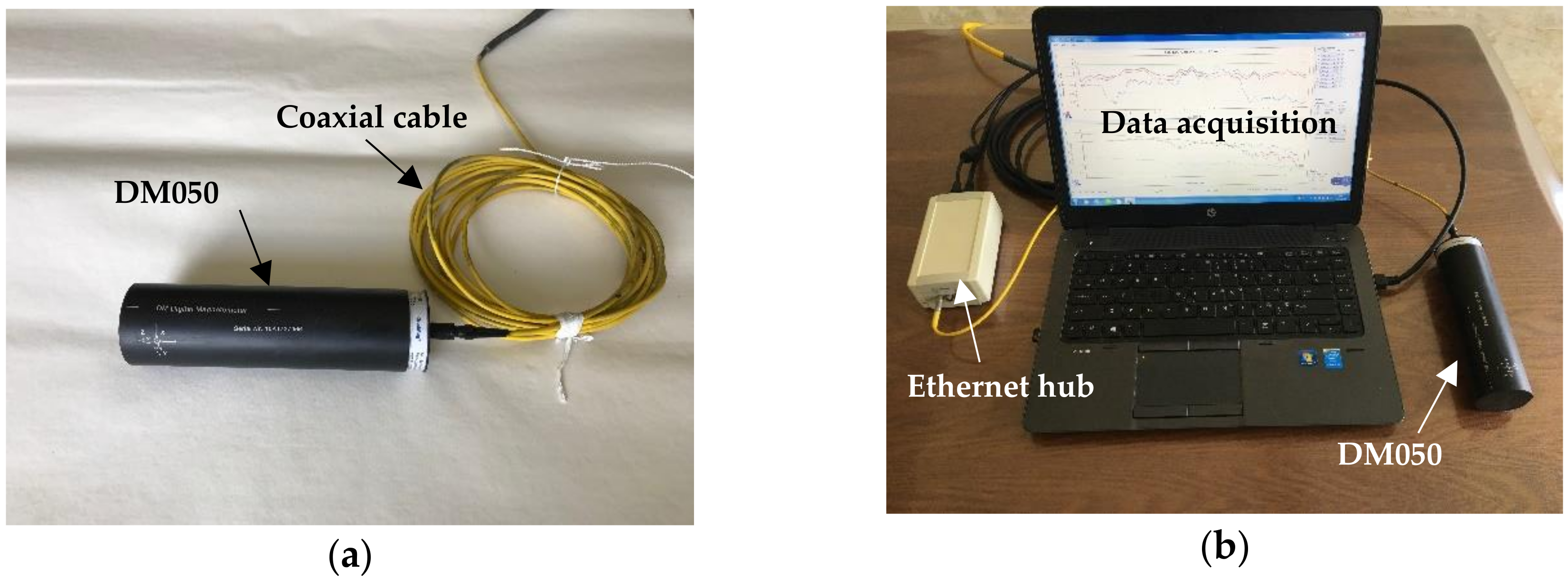

3.2. Fabrication of Magnetic Sensor

3.3. Measurement of Magnetic Field Intensity

3.4. Test Setup and Layout of Measurement Points

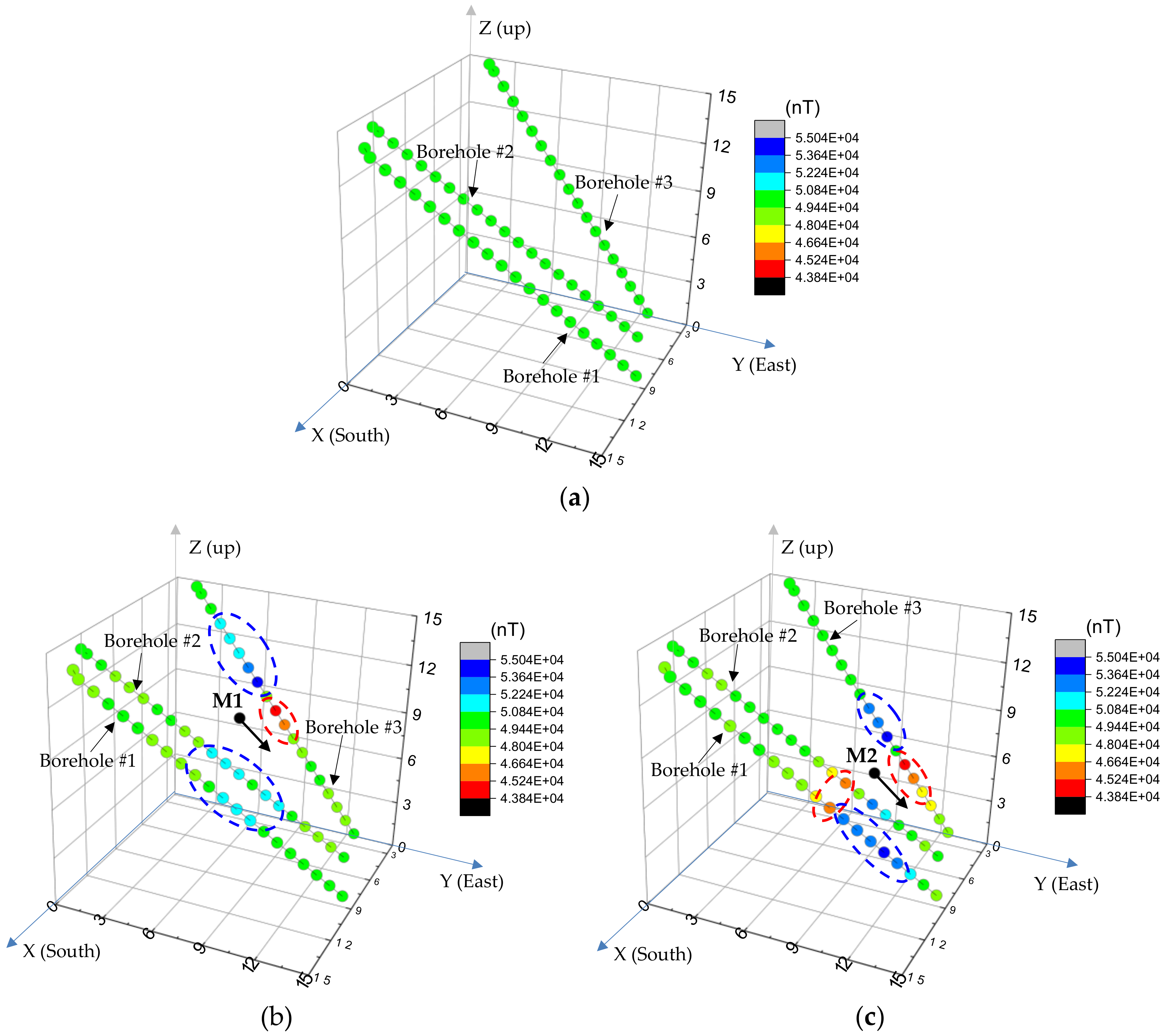

3.5. Test Results and Discussion

4. Effective Monitoring Range of Magnetic Sensor

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rehan, J.; Irfan, J.; Zhao, J.; Ming, L.; Jiang, Q.; Rizwan, J. Development trend of Chinese hydroelectric generation technology of hydro power plant (HPP). Int. J. Eng. Works 2014, 1, 1–5. [Google Scholar]

- Jia, J. A technical review of hydro-project development in China. Engineering 2016, 2, 302–312. [Google Scholar] [CrossRef]

- Zhang, S.; Andrews-Speed, P.; Perera, P. The evolving policy regime for pumped storage hydroelectricity in China: A key support for low-carbon energy. Appl. Energy 2015, 150, 15–24. [Google Scholar] [CrossRef]

- Levine, J.G. Pumped Hydroelectric Energy Storage and Spatial Diversity of Wind Resources as Methods of Improving Utilization of Renewable Energy Sources. Master’s Thesis, Michigan Technological University, Houghton, MI, USA, 27 November 2007. [Google Scholar]

- Yang, C.J. Pumped hydroelectric storage. In Storing Energy: With Special Reference to Renewable Energy Sources, 1st ed.; Letcher, T.M., Ed.; Elsevier Science Publishing Co., Inc.: New York, NY, USA, 2016. [Google Scholar]

- Zheng, Y.L.; Zhang, Q.B.; Zhao, J. Challenges and opportunities of using tunnel boring machine in minining. Tunn. Undergr. Space Technol. 2016, 57, 287–299. [Google Scholar] [CrossRef]

- Hong, K. Typical underwater tunnels in the Mainland of China and related tunneling technologies. Engineering 2017, 3, 871–879. [Google Scholar] [CrossRef]

- Aneziris, O.N.; Papazoglou, I.A.; Kallianiotis, D. Occupational risk of tunneling construction. Saf. Sci. 2010, 48, 964–972. [Google Scholar] [CrossRef]

- Cardu, M.; Seccatore, J. Quantifying the difficulty of tunneling by drilling and blasting. Tunn. Undergr. Space Technol. 2016, 60, 178–182. [Google Scholar] [CrossRef]

- Brown, E.T.; Green, S.J.; Sinha, K.P. The influence of rock anisotropy on hole deviation in rotary drilling—A review. Int. J. Rock Mech. Min. Sci. Geomech. 1981, 18, 387–401. [Google Scholar] [CrossRef]

- Bulant, P.; Eisner, L.; Psencik, I.; Calvez, J.L. Importance of borehole deviation surveys for monitoring of hydraulic fracturing treatments. Geophys. Prospect. 2007, 55, 891–899. [Google Scholar] [CrossRef]

- Lukawski, M.Z.; Anderson, B.J.; Augustine, G.; Capuano, L.E., Jr.; Beckers, K.F.; Livesay, B.; Tester, J.W. Cost analysis of oil, gas and geothermal well drilling. J. Petroleum Sci. Eng. 2014, 118, 1–14. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, F.; Li, Z.; Chen, G.; Tang, Y. Bridge scour monitoring using smart rocks based on magnetic field interference. Smart Mater. Struct. 2018, 27, 085012. [Google Scholar] [CrossRef]

- Derby, N.; Olbert, S. Cylinder magnets and ideal solenoids. Am. J. Phys. 2010, 78, 229–235. [Google Scholar] [CrossRef]

- Boggs, P.T.; Tolle, J.W. A strategy for global convergence in a sequential quadratic programming algorithm. SIAM J. Numer. Anal. 1989, 26, 600–623. [Google Scholar] [CrossRef]

| Sensor Location | Estimated Coordinate | Measured Coordinate | RSS Error (m) | ||||

|---|---|---|---|---|---|---|---|

| XE (m) | YE (m) | ZE (m) | XM (m) | YM (m) | ZM (m) | ||

| M1 (10 m) | 8.104 | 7.769 | 9.704 | 7.995 | 7.298 | 9.783 | 0.490 |

| M2 (6 m) | 7.651 | 10.299 | 6.409 | 7.809 | 9.853 | 6.712 | 0.561 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, F.; Yang, J.; Li, H.-N.; Liu, F.; Wang, N.; Jia, P.; Chen, Y. Field Validation of a Magnetic Sensor to Monitor Borehole Deviation during Tunnel Excavation. Materials 2018, 11, 1511. https://doi.org/10.3390/ma11091511

Tang F, Yang J, Li H-N, Liu F, Wang N, Jia P, Chen Y. Field Validation of a Magnetic Sensor to Monitor Borehole Deviation during Tunnel Excavation. Materials. 2018; 11(9):1511. https://doi.org/10.3390/ma11091511

Chicago/Turabian StyleTang, Fujian, Jianzhou Yang, Hong-Nan Li, Fuqiang Liu, Ningbo Wang, Peng Jia, and Yizheng Chen. 2018. "Field Validation of a Magnetic Sensor to Monitor Borehole Deviation during Tunnel Excavation" Materials 11, no. 9: 1511. https://doi.org/10.3390/ma11091511

APA StyleTang, F., Yang, J., Li, H.-N., Liu, F., Wang, N., Jia, P., & Chen, Y. (2018). Field Validation of a Magnetic Sensor to Monitor Borehole Deviation during Tunnel Excavation. Materials, 11(9), 1511. https://doi.org/10.3390/ma11091511